A B2B Buyer’s Guide to Welded Wire Mesh Sizes: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for welded wire mesh sizes

In an increasingly interconnected global market, navigating the complexities of sourcing welded wire mesh sizes can be a daunting task for B2B buyers, especially those operating across diverse regions like Africa, South America, the Middle East, and Europe. With varying specifications, applications, and regulatory standards, understanding the nuances of welded wire mesh is essential for making informed purchasing decisions that align with specific project requirements. This guide delves into the extensive range of welded wire mesh sizes, exploring their types, applications, and the critical factors involved in supplier vetting.

From construction projects requiring robust reinforcement to agricultural applications demanding durability and flexibility, the applications of welded wire mesh are vast. This comprehensive resource will equip you with the knowledge to assess the strength and suitability of different mesh gauges and sizes, optimizing your procurement process. Additionally, it will offer insights into cost considerations, helping you identify the most cost-effective solutions without compromising on quality.

By empowering international B2B buyers with actionable insights and practical information, this guide aims to enhance your sourcing strategy, ensuring you can confidently navigate the global market for welded wire mesh sizes. Whether you’re based in Saudi Arabia, Vietnam, or elsewhere, understanding these elements is crucial for achieving successful project outcomes.

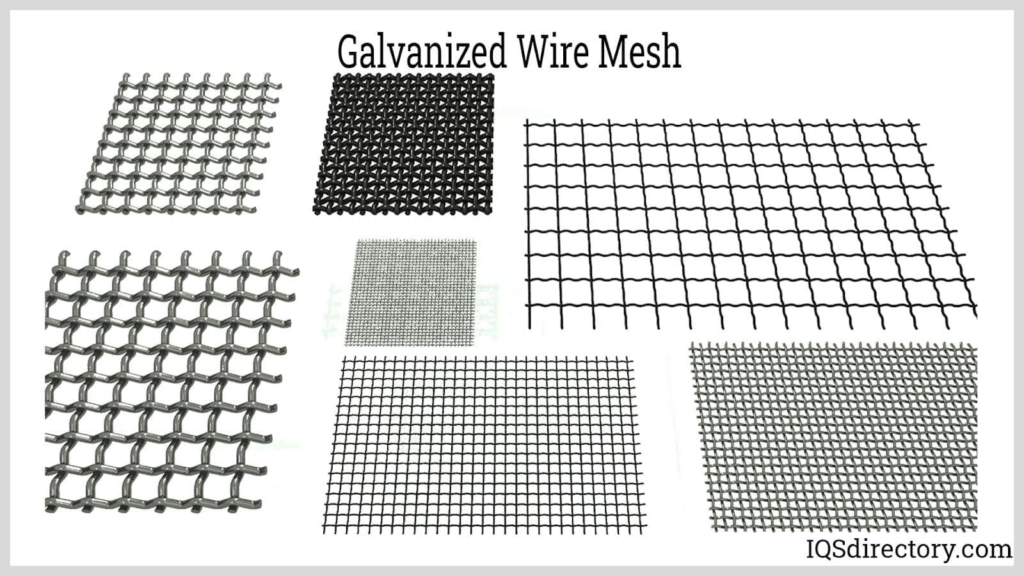

Understanding welded wire mesh sizes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Welded Wire | Available in various gauges, sizes, and spacings; typically galvanized for rust resistance. | Construction, fencing, and reinforcement. | Pros: Versatile and durable. Cons: May require custom sizes for specific applications. |

| Heavy-Duty Wire Mesh | Thicker wire gauge (lower numbers) for enhanced strength; often used in demanding environments. | Industrial and commercial construction, heavy equipment support. | Pros: High load-bearing capacity. Cons: Higher cost and weight. |

| Light-Duty Wire Mesh | Thinner wire gauge for lighter applications; easier to manipulate and install. | Residential fencing, garden supports, and decorative uses. | Pros: Cost-effective and easy to work with. Cons: Limited load-bearing capability. |

| Reinforcement Mesh | Specifically designed for concrete reinforcement; typically comes in larger sheets. | Foundations, slabs, and structural applications. | Pros: Enhances structural integrity. Cons: Requires precise installation for effectiveness. |

| Architectural Wire Mesh | Aesthetic designs and patterns; available in various materials (stainless steel, aluminum). | Architectural applications, facades, and decorative elements. | Pros: Enhances visual appeal. Cons: More expensive and may require custom fabrication. |

What Are the Key Characteristics of Standard Welded Wire Mesh?

Standard welded wire mesh is a versatile product available in various gauges and sizes, typically galvanized to prevent rust. It is widely used in construction for concrete reinforcement, fencing, and other structural applications. B2B buyers should consider the specific gauge and spacing required for their projects, as these factors significantly impact strength and durability. While standard sizes are often readily available, custom orders can accommodate unique project specifications.

How Does Heavy-Duty Wire Mesh Stand Out in Industrial Applications?

Heavy-duty wire mesh is characterized by its thicker wire gauge, providing enhanced strength and durability. It is ideal for industrial and commercial applications where high load-bearing capacity is essential, such as supporting heavy equipment or reinforcing concrete structures. Buyers should evaluate the specific load requirements and consider the associated costs, as heavy-duty options tend to be more expensive. Additionally, the weight of the material may influence transportation and installation logistics.

When Should Light-Duty Wire Mesh Be Considered?

Light-duty wire mesh features thinner wire gauges, making it suitable for lighter applications such as residential fencing, garden supports, and decorative installations. Its ease of manipulation and lower cost make it an attractive option for projects that do not require high strength. Buyers should assess the intended use and ensure that the selected mesh meets the necessary structural requirements, as its load-bearing capacity is limited compared to heavier alternatives.

Why Is Reinforcement Mesh Critical in Concrete Applications?

Reinforcement mesh is specifically designed for use in concrete applications, providing essential support to enhance structural integrity. Typically available in larger sheets, this type of mesh is crucial for foundations, slabs, and other structural elements. B2B buyers should prioritize precise measurements and installation techniques, as the effectiveness of reinforcement mesh hinges on proper placement within the concrete. Considerations regarding the mesh’s gauge and spacing are also vital to achieving the desired strength.

What Are the Advantages of Using Architectural Wire Mesh?

Architectural wire mesh combines functionality with aesthetic appeal, making it popular for architectural applications such as facades and decorative elements. Available in various materials, including stainless steel and aluminum, it can be tailored to fit specific design needs. Buyers should weigh the benefits of visual enhancement against the higher costs associated with custom fabrication. Additionally, the choice of material can influence durability and maintenance requirements, making it essential to align selections with project goals.

Key Industrial Applications of welded wire mesh sizes

| Industry/Sector | Specific Application of welded wire mesh sizes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Infrastructure | Reinforcement for concrete slabs and foundations | Enhances structural integrity, reduces cracking risk | Compliance with local building codes, material strength, and load specifications |

| Agriculture & Farming | Animal enclosures and fencing | Provides secure environments for livestock, reducing loss | Corrosion resistance, gauge selection based on animal type, and durability against weather conditions |

| Mining & Quarrying | Support structures and safety barriers | Increases safety for workers, prevents collapses | Weight capacity, mesh size selection for specific applications, and local sourcing options |

| Landscaping & Architecture | Decorative fencing and garden trellises | Aesthetic appeal while providing functionality | Custom sizes and finishes, resistance to corrosion, and design flexibility |

| Security & Safety | High-security fencing and barriers | Deters unauthorized access, enhances property security | Gauge strength, mesh size for visibility and deterrence, and installation requirements |

How is welded wire mesh used in construction and infrastructure projects?

Welded wire mesh is primarily used as reinforcement in concrete slabs and foundations, offering significant enhancements to structural integrity. By distributing loads evenly, it minimizes the risk of cracking and structural failures, which is crucial in regions prone to seismic activity or heavy rainfall, such as parts of South America and the Middle East. Buyers in this sector need to consider local building codes and standards, as well as the specific load-bearing requirements for their projects, ensuring that the chosen mesh size and gauge meet these demands.

What applications does welded wire mesh have in agriculture and farming?

In agriculture, welded wire mesh serves as a robust solution for animal enclosures and fencing. It creates secure environments that protect livestock from predators and prevent escapes, thereby reducing financial losses for farmers. When sourcing welded wire mesh for agricultural use, buyers should prioritize corrosion resistance and select the appropriate gauge based on the type of animals being contained, ensuring durability against harsh weather conditions common in various regions, including Africa and South America.

Illustrative image related to welded wire mesh sizes

How is welded wire mesh utilized in the mining and quarrying industries?

In the mining sector, welded wire mesh is essential for creating support structures and safety barriers, enhancing workplace safety by preventing collapses and providing secure access points. The choice of mesh size and gauge is critical, as it must withstand significant stress and weight. International buyers should focus on sourcing from suppliers who understand local regulations and safety standards, ensuring that the mesh can handle the specific environmental conditions found in mining operations.

What role does welded wire mesh play in landscaping and architecture?

Welded wire mesh is increasingly used in landscaping and architectural designs for decorative fencing and garden trellises. It provides both aesthetic appeal and functional support for climbing plants, adding value to residential and commercial properties. Buyers should consider custom sizes and finishes to align with their design visions, as well as the mesh’s resistance to corrosion, especially in humid or coastal areas, ensuring longevity and minimal maintenance.

How is welded wire mesh applied in security and safety solutions?

In the realm of security, welded wire mesh is a fundamental component in high-security fencing and barriers. It deters unauthorized access and enhances the overall safety of properties, making it a preferred choice for businesses and residential areas alike. When sourcing welded wire mesh for security applications, buyers need to evaluate the gauge strength, mesh size for visibility, and installation requirements to ensure optimal protection against potential threats, particularly in regions with higher crime rates.

3 Common User Pain Points for ‘welded wire mesh sizes’ & Their Solutions

Scenario 1: Navigating Confusion Over Wire Gauge and Size Specifications

The Problem: B2B buyers often face confusion regarding the wire gauge and size specifications when ordering welded wire mesh. For instance, a construction company in Saudi Arabia may require a specific gauge for a structural project but finds discrepancies in the measurements listed by different suppliers. This inconsistency can lead to ordering the wrong materials, resulting in project delays, increased costs, and potential safety risks.

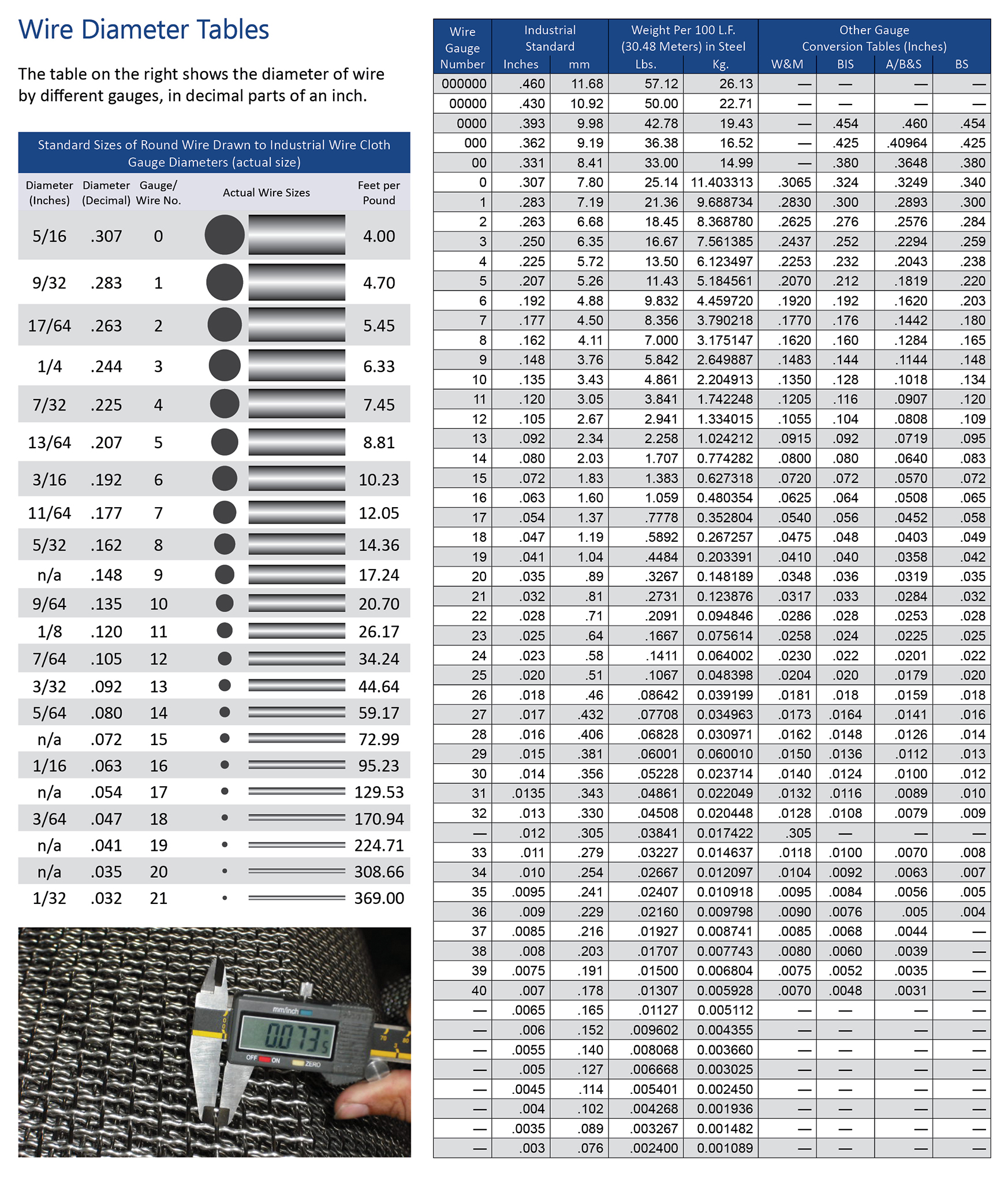

The Solution: To mitigate this issue, buyers should establish a standardized specification guide based on industry standards, such as the American Wire Gauge (AWG) system, alongside metric measurements. When sourcing welded wire mesh, it is crucial to cross-reference specifications from multiple suppliers to ensure uniformity. Buyers can also request samples or detailed product data sheets that outline gauge thickness, mesh size, and wire diameter, which can help clarify any ambiguities. Additionally, leveraging technology like digital catalogs or product configurators can streamline the selection process, ensuring that the exact specifications are met for each project.

Illustrative image related to welded wire mesh sizes

Scenario 2: Overcoming Sizing Limitations for Custom Projects

The Problem: International buyers frequently encounter limitations with standard sizes of welded wire mesh, particularly for custom projects. A landscaping company in South America, for example, may require specific dimensions for a unique garden installation but struggles to find suppliers that offer mesh in the desired sizes without incurring exorbitant custom fees. This lack of flexibility can stifle creativity and lead to project delays.

The Solution: To overcome sizing limitations, buyers should work closely with manufacturers who offer custom fabrication services. Establishing a relationship with a supplier that understands the regional market and can accommodate unique requests will be invaluable. Buyers can also consider bulk ordering or collaborating with other businesses to meet minimum order quantities, which could reduce costs for custom sizes. Additionally, utilizing local suppliers who have the capability to cut and weld mesh on-site can expedite the process and offer more tailored solutions.

Scenario 3: Ensuring Cost-Effectiveness Without Compromising Quality

The Problem: Cost constraints are a common challenge for B2B buyers procuring welded wire mesh, especially in regions like Africa and the Middle East where budget limitations are prevalent. A construction firm may opt for lower-quality mesh to save costs, unaware that this decision could compromise the structural integrity of their projects, leading to long-term expenses due to repairs or replacements.

The Solution: To ensure cost-effectiveness while maintaining quality, buyers should conduct a thorough cost-benefit analysis before making purchasing decisions. This involves evaluating the long-term performance and durability of different welded wire mesh options, factoring in the total lifecycle costs rather than just the initial purchase price. Collaborating with suppliers who offer competitive pricing models or volume discounts can also help. Furthermore, buyers should seek out warranties or guarantees on their purchases, ensuring they are covered against defects and performance issues. Regularly reviewing supplier performance and product quality can lead to better purchasing decisions in the future, ultimately balancing cost and quality effectively.

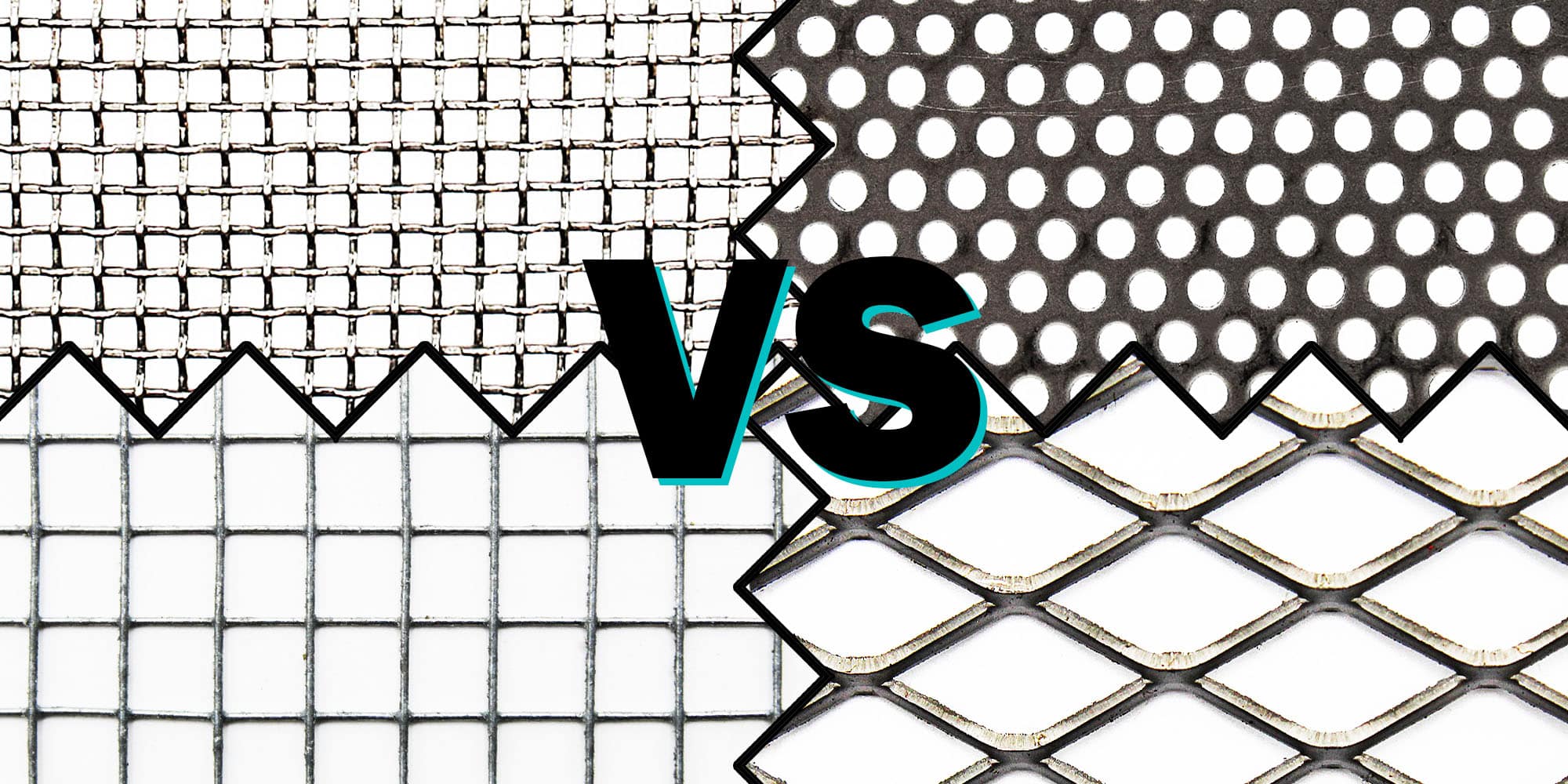

Illustrative image related to welded wire mesh sizes

Strategic Material Selection Guide for welded wire mesh sizes

What Are the Key Properties of Common Materials Used in Welded Wire Mesh?

When selecting welded wire mesh for various applications, understanding the properties of the materials used is crucial. Here, we analyze four common materials: carbon steel, stainless steel, galvanized steel, and aluminum. Each material offers distinct advantages and disadvantages that can significantly impact performance, cost, and suitability for specific applications.

How Does Carbon Steel Perform in Welded Wire Mesh Applications?

Carbon steel is one of the most widely used materials for welded wire mesh due to its strength and versatility. It typically offers high tensile strength, making it suitable for heavy-duty applications such as construction reinforcement and fencing. However, carbon steel is susceptible to rust and corrosion when exposed to moisture, which can limit its lifespan in outdoor or humid environments.

Pros:

– High tensile strength and durability.

– Cost-effective for large-scale projects.

Cons:

– Prone to corrosion without protective coatings.

– Limited temperature resistance compared to other metals.

For international buyers, particularly in regions like Africa and the Middle East, understanding local environmental conditions is essential. Areas with high humidity or saltwater exposure may require additional protective measures, such as coatings or selecting alternative materials.

Illustrative image related to welded wire mesh sizes

What Advantages Does Stainless Steel Offer for Welded Wire Mesh?

Stainless steel is renowned for its corrosion resistance and aesthetic appeal, making it a popular choice for applications requiring longevity and visual quality, such as architectural designs and food processing environments. It maintains its strength in high-temperature applications, making it suitable for industrial uses.

Pros:

– Excellent corrosion resistance and durability.

– High-temperature tolerance.

Cons:

– Higher cost compared to carbon steel.

– More complex manufacturing processes can lead to longer lead times.

International buyers should consider compliance with standards like ASTM for food safety and construction. Stainless steel is particularly favored in Europe and North America due to stringent regulations regarding material safety.

Why Is Galvanized Steel a Preferred Choice for Welded Wire Mesh?

Galvanized steel combines the strength of carbon steel with a protective zinc coating, which enhances its corrosion resistance. This makes it ideal for outdoor applications such as fencing, agricultural uses, and construction projects exposed to the elements.

Pros:

– Cost-effective solution with enhanced corrosion resistance.

– Suitable for various environmental conditions.

Cons:

– Zinc coating can wear off over time, especially in harsh conditions.

– Limited aesthetic appeal compared to stainless steel.

For buyers in South America and Africa, galvanized steel often meets local standards for construction and agricultural applications, providing a balance between cost and performance.

How Does Aluminum Compare as a Material for Welded Wire Mesh?

Aluminum is lightweight and resistant to corrosion, making it an excellent choice for applications where weight is a concern, such as in transportation and aerospace. It is also easy to handle and can be cut to size without specialized tools.

Pros:

– Lightweight and easy to work with.

– Excellent corrosion resistance.

Cons:

– Lower tensile strength compared to steel options.

– Higher cost for comparable strength applications.

Illustrative image related to welded wire mesh sizes

Aluminum is increasingly popular in Europe and the Middle East, where lightweight materials are preferred for reducing transportation costs and improving efficiency. Buyers should verify compliance with regional standards regarding structural integrity.

Summary Table of Material Selection for Welded Wire Mesh

| Material | Typical Use Case for welded wire mesh sizes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Construction reinforcement, fencing | High tensile strength | Prone to corrosion | Low |

| Stainless Steel | Food processing, architectural applications | Excellent corrosion resistance | Higher cost | High |

| Galvanized Steel | Agricultural fencing, outdoor construction | Cost-effective with corrosion resistance | Zinc coating can wear off | Medium |

| Aluminum | Transportation, aerospace applications | Lightweight and easy to work with | Lower tensile strength | High |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for welded wire mesh, enabling informed decisions based on specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for welded wire mesh sizes

What Are the Key Stages in the Manufacturing Process of Welded Wire Mesh Sizes?

The manufacturing process of welded wire mesh involves several critical stages, each designed to ensure that the final product meets the necessary specifications for various applications.

Material Preparation: Selecting the Right Steel Wire

The first step in manufacturing welded wire mesh is the selection and preparation of steel wire. This wire is typically made from low carbon steel and can be galvanized to enhance corrosion resistance. The wire is drawn to specified diameters, with common gauges ranging from 10 to 16. A consistent quality of raw material is crucial, as it directly affects the strength and durability of the mesh.

Forming: Shaping the Mesh

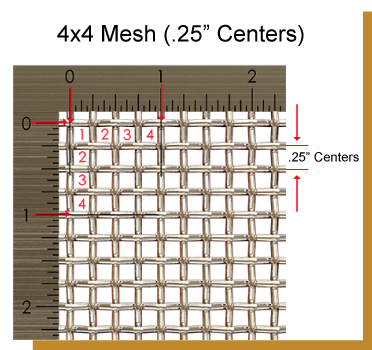

Once the wire is prepared, it is cut to the desired lengths. The wires are then arranged in a grid pattern, either manually or through automated machinery, to form the mesh. This process may involve either a two-dimensional or three-dimensional approach, depending on the product’s intended use. High-speed welding machines apply intense heat to join the wires at their intersections, creating a robust structure. The spacing between the wires can vary, typically ranging from 2 inches to 6 inches, based on application requirements.

Illustrative image related to welded wire mesh sizes

Assembly: Ensuring Structural Integrity

After welding, the mesh undergoes a thorough assembly process. This includes trimming excess wire and inspecting each sheet or roll for defects. At this stage, manufacturers often employ automated systems to ensure consistency in size and quality. The assembled mesh is then rolled or cut into sheets, ready for packaging.

Finishing: Enhancing Performance and Aesthetics

The final stage involves finishing processes such as galvanization or coating. Galvanization involves dipping the mesh in molten zinc to create a protective layer that prevents rust and enhances durability. Other finishes may include PVC coating for additional weather resistance. This finishing process not only improves the product’s lifespan but can also enhance its aesthetic appeal, making it suitable for architectural applications.

How Is Quality Assurance Implemented in Welded Wire Mesh Production?

Quality assurance is paramount in the production of welded wire mesh. Manufacturers adhere to various international and industry-specific standards to ensure that their products meet customer expectations.

What International Standards Govern Welded Wire Mesh Production?

ISO 9001 is one of the key international standards that governs quality management systems across industries, including manufacturing. Compliance with ISO 9001 ensures that manufacturers consistently provide products that meet customer and regulatory requirements. Additionally, CE marking is essential for products sold in the European market, indicating conformity with health, safety, and environmental protection standards.

Illustrative image related to welded wire mesh sizes

What Are the Checkpoints in the Quality Control Process?

Quality control (QC) checkpoints are critical at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials for compliance with specifications. Wire diameter, tensile strength, and surface finish are assessed to ensure quality standards are met before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor the quality of welding and assembly. Automated systems often include sensors that detect inconsistencies in wire placement or weld integrity.

-

Final Quality Control (FQC): After the mesh is finished, a comprehensive inspection is performed. This includes checking for dimensional accuracy, weld strength, and surface finish. Random sampling methods are often employed to ensure that a representative batch is tested.

Which Common Testing Methods Are Used?

Several testing methods are utilized to validate the quality of welded wire mesh:

-

Tensile Testing: Measures the strength of the wire and its ability to withstand pulling forces.

-

Weld Integrity Testing: Ensures that the welded joints meet specified strength criteria.

-

Corrosion Resistance Testing: Involves exposing the mesh to corrosive environments to evaluate the effectiveness of galvanization or coating.

-

Dimensional Testing: Confirms that the mesh dimensions conform to specified tolerances.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are some actionable steps:

What Audits and Reports Should Buyers Request?

Buyers should request copies of quality management system certifications, such as ISO 9001, and inquire about internal audit reports. A transparent supplier will have no issue sharing these documents, demonstrating their commitment to quality.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing practices. This is particularly valuable for buyers unfamiliar with local standards or practices. Third-party inspections can include pre-shipment inspections, where the quality and compliance of the products are verified before shipping.

What Are the Quality Control Nuances for International Buyers?

International buyers must be aware of regional standards and regulations that may differ from their home countries. For instance, products exported to Europe must meet CE marking requirements, while buyers in the Middle East may have specific local standards to consider. Understanding these nuances ensures compliance and helps avoid costly mistakes.

In summary, the manufacturing processes and quality assurance measures in the production of welded wire mesh are critical for ensuring product reliability and performance. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ultimately leading to successful project outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘welded wire mesh sizes’

In the competitive landscape of B2B procurement, sourcing welded wire mesh sizes requires a strategic approach to ensure quality, compliance, and cost-effectiveness. This guide provides a practical checklist for international buyers seeking to procure welded wire mesh tailored to their specific needs.

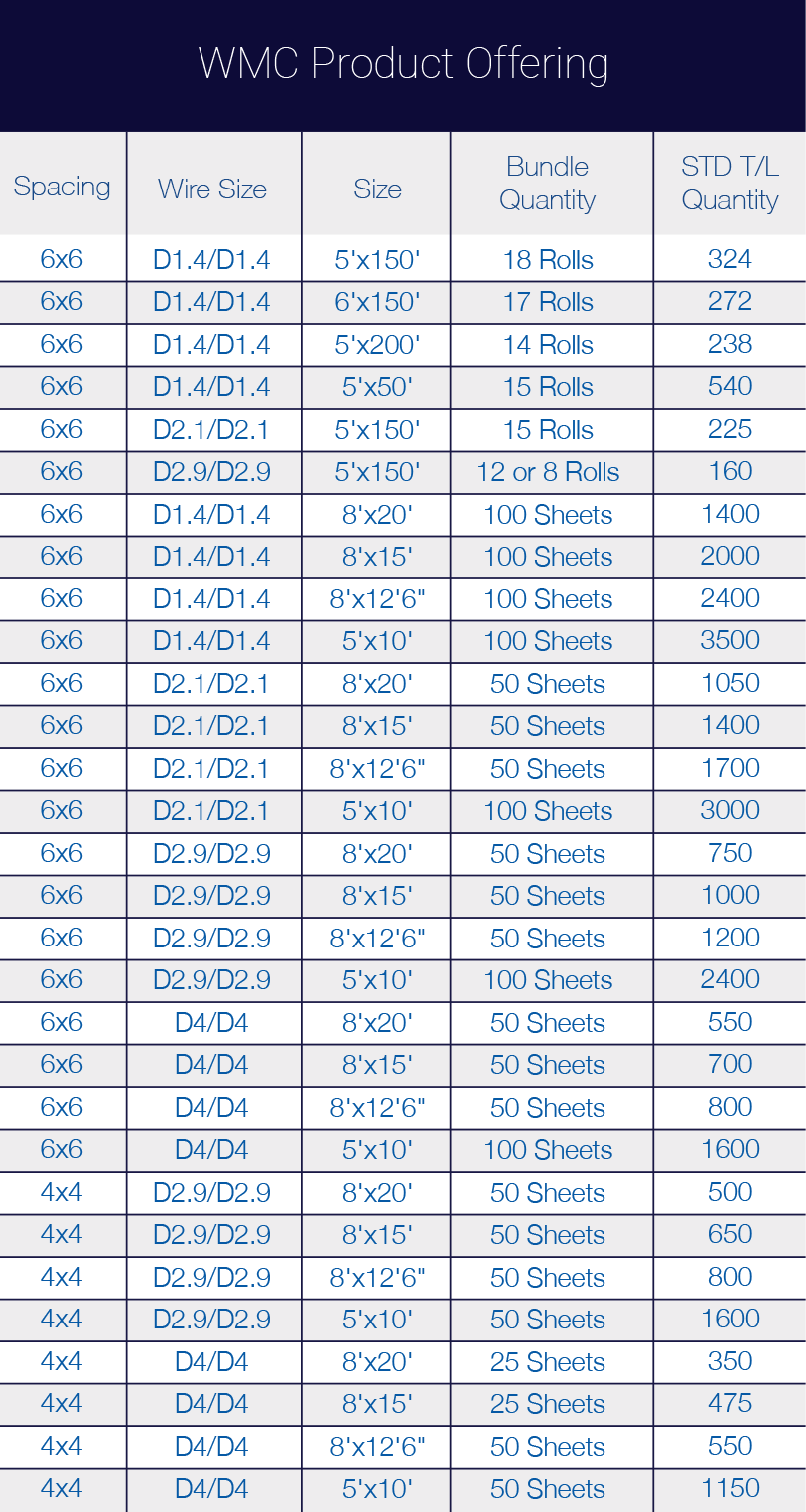

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for successful procurement. Consider factors such as mesh size, wire gauge, and material type. For instance, different projects may require varying mesh sizes (e.g., 2×2, 4×4) and wire gauges (e.g., 10 gauge, 12 gauge) depending on the intended application—be it construction reinforcement or agricultural use.

Step 2: Research Industry Standards and Regulations

Understanding the relevant industry standards and regulations is critical, especially when sourcing internationally. Familiarize yourself with standards such as ASTM (American Society for Testing and Materials) or ISO certifications that apply to welded wire mesh. Compliance with these standards ensures that the products meet safety and quality benchmarks necessary for your projects.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to conduct a thorough evaluation of potential suppliers. Look for suppliers with established reputations in the industry and request company profiles, case studies, and references. Pay particular attention to suppliers who have experience in your region or industry, as they are more likely to understand local market dynamics and requirements.

Step 4: Request Samples for Quality Assessment

Always request samples of the welded wire mesh before finalizing your order. Assessing samples allows you to evaluate the quality, thickness, and durability of the mesh firsthand. Check for uniformity in welds and ensure that the wire gauge meets your specifications. This step is vital to avoid costly mistakes later in the procurement process.

Step 5: Review Pricing and Payment Terms

Pricing can vary significantly based on gauge, size, and supplier. Obtain detailed quotes from multiple suppliers, ensuring that you understand what is included in the price (e.g., shipping, taxes). Additionally, clarify payment terms—consider options such as letters of credit or partial payments to manage cash flow effectively.

Step 6: Verify Certifications and Compliance

Ensure that the suppliers you are considering have the necessary certifications and compliance documentation. This includes certifications for material quality and safety standards. Suppliers should provide evidence of compliance with local and international regulations, ensuring that the welded wire mesh you receive is safe and reliable for your intended use.

Step 7: Establish Clear Communication Channels

Effective communication is key to a successful procurement process. Establish clear communication channels with your selected supplier to address any questions or concerns promptly. Make sure to clarify timelines for delivery, potential lead times, and any after-sales support available. This proactive approach can help mitigate misunderstandings and ensure a smoother transaction.

Illustrative image related to welded wire mesh sizes

By following this checklist, B2B buyers can navigate the complexities of sourcing welded wire mesh sizes efficiently, ultimately leading to successful procurement outcomes that meet project requirements.

Comprehensive Cost and Pricing Analysis for welded wire mesh sizes Sourcing

What Are the Key Cost Components in Sourcing Welded Wire Mesh Sizes?

When sourcing welded wire mesh, understanding the cost structure is crucial for B2B buyers. The main cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The type of wire used (e.g., galvanized, stainless steel) significantly impacts the base cost. Thicker wires (lower gauges) cost more due to higher material requirements. Buyers should consider the specific requirements of their project when selecting wire types to optimize material costs.

-

Labor: Labor costs can vary based on the manufacturing location. Regions with lower labor costs can offer competitive pricing, but buyers should also factor in potential quality differences.

-

Manufacturing Overhead: This includes all costs related to production facilities, utilities, and indirect labor. Efficient manufacturing processes can reduce overhead, impacting overall pricing.

-

Tooling: Custom tooling may be necessary for specialized mesh sizes or patterns, adding to upfront costs. Buyers should assess the need for customization versus standard sizes to manage tooling expenses effectively.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes can increase costs but is vital for maintaining standards, especially in structural applications. Certifications (e.g., ISO, ASTM) may also incur additional costs but can enhance product value.

-

Logistics: Transportation and handling costs can vary based on the geographic location of suppliers and buyers. Incoterms will influence who bears these costs, impacting the final price.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market conditions and competition.

How Do Price Influencers Impact Welded Wire Mesh Sourcing?

Several factors influence the pricing of welded wire mesh, including volume, specifications, materials, quality certifications, supplier reliability, and Incoterms.

-

Volume/MOQ: Bulk orders often result in lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) to benefit from discounts.

-

Specifications/Customization: Custom specifications can lead to higher costs. Standard sizes typically have more competitive pricing. Buyers should evaluate the necessity of custom features against their budget.

-

Materials: The choice of materials affects not only the initial price but also the long-term cost of ownership due to durability and maintenance needs. For instance, galvanized wire mesh may have a higher upfront cost but offers better longevity.

-

Quality/Certifications: Higher-quality products with relevant certifications may command premium prices. However, investing in quality can lead to reduced maintenance costs and longer service life.

-

Supplier Factors: The supplier’s reputation, reliability, and service level can influence pricing. Established suppliers may offer better warranties and customer service, which can justify higher prices.

-

Incoterms: Understanding Incoterms is essential for determining responsibility for shipping costs and risks. This can significantly affect the total cost of ownership.

What Tips Can Buyers Use to Optimize Cost-Efficiency in Welded Wire Mesh Sourcing?

International B2B buyers, especially from Africa, South America, the Middle East, and Europe, should consider several strategies for cost-effective sourcing of welded wire mesh.

-

Negotiate Terms: Leverage relationships with suppliers to negotiate better pricing, payment terms, and shipping arrangements. Establishing long-term partnerships can lead to volume discounts.

-

Evaluate Total Cost of Ownership (TCO): Beyond the purchase price, consider factors such as maintenance, durability, and potential downtime. Investing in higher-quality mesh may result in lower TCO over time.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations, tariffs, and import duties can significantly affect pricing. Buyers should factor these elements into their budgeting and sourcing strategies.

-

Research Local Suppliers: Local suppliers may offer competitive pricing due to lower shipping costs and shorter lead times. Investigating regional options can reveal cost-saving opportunities.

-

Stay Informed on Market Trends: Keeping abreast of market conditions, including raw material prices and supply chain dynamics, can help buyers make informed purchasing decisions.

Disclaimer on Pricing

Prices for welded wire mesh can vary widely based on the aforementioned factors. It is advisable for buyers to conduct thorough market research and request multiple quotes to ensure they receive competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing welded wire mesh sizes With Other Solutions

Exploring Alternatives to Welded Wire Mesh Sizes for Industrial Applications

In the construction and industrial sectors, selecting the right materials is crucial for ensuring durability, safety, and cost-effectiveness. While welded wire mesh is a popular choice for reinforcement and fencing, it’s important to consider alternative solutions that may better meet specific project requirements. This section evaluates welded wire mesh against two viable alternatives: Expanded Metal Mesh and Woven Wire Mesh.

| Comparison Aspect | Welded Wire Mesh Sizes | Expanded Metal Mesh | Woven Wire Mesh |

|---|---|---|---|

| Performance | High tensile strength, ideal for concrete reinforcement. | Rigid and resistant to bending; good for safety barriers. | Flexible and can conform to various shapes; suitable for filtration. |

| Cost | Generally affordable, but prices vary by gauge and size. | Typically more expensive due to manufacturing process. | Cost-effective, especially for larger rolls or sheets. |

| Ease of Implementation | Requires minimal tools; easy to cut and install. | More challenging to cut and shape; may require specialized tools. | Generally easy to install; can be cut to size with standard tools. |

| Maintenance | Low maintenance; galvanized options resist rust. | Low maintenance; durable against wear and tear. | May require regular inspections; susceptible to rust unless coated. |

| Best Use Case | Ideal for concrete reinforcement and construction applications. | Best for safety applications, such as fencing and barriers. | Suitable for applications requiring filtration or aesthetic designs. |

What Are the Advantages and Disadvantages of Expanded Metal Mesh?

Expanded Metal Mesh is created by cutting and stretching a sheet of metal, resulting in a rigid, lightweight product with a diamond pattern. This design offers excellent strength and rigidity, making it suitable for safety applications, such as security fencing and protective barriers. The primary advantage is its ability to resist bending and deformation under pressure. However, it can be more expensive than welded wire mesh and requires specialized tools for cutting and installation, which may increase labor costs.

How Does Woven Wire Mesh Compare in Practical Applications?

Woven Wire Mesh consists of wire strands woven together, creating a flexible and versatile material. It is commonly used for filtration, screening, and architectural applications. The flexibility of woven wire allows it to conform to various shapes and be used in diverse environments, from industrial filtration to decorative elements in buildings. While it is generally cost-effective, woven wire mesh can be less durable than welded wire mesh for heavy-duty applications, and it may require regular maintenance to prevent rusting, especially in outdoor settings.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting between welded wire mesh sizes and alternative solutions like expanded metal mesh or woven wire mesh, B2B buyers should carefully assess their specific project needs. Consider the performance requirements, budget constraints, and the intended use case. Welded wire mesh is ideal for structural reinforcement, while expanded metal mesh excels in safety applications. Woven wire mesh offers flexibility for filtration and aesthetics. Ultimately, the right choice will depend on a combination of these factors, ensuring that the selected material aligns with project goals and operational efficiency.

Essential Technical Properties and Trade Terminology for welded wire mesh sizes

What Are the Essential Technical Properties of Welded Wire Mesh Sizes?

When selecting welded wire mesh, understanding the technical specifications is crucial for ensuring the material meets the requirements of your project. Here are some key properties to consider:

-

Material Grade

– Welded wire mesh is commonly made from carbon steel, stainless steel, or galvanized steel. The material grade determines the strength, corrosion resistance, and suitability for specific applications. For instance, galvanized steel is ideal for outdoor applications due to its protective zinc coating, which prevents rusting. -

Wire Gauge

– The wire gauge, measured in American Wire Gauge (AWG) or by diameter in millimeters, indicates the thickness of the wire used in the mesh. Thicker wires (lower gauge numbers) provide higher tensile strength and load-bearing capacity, making them suitable for heavy-duty applications. Understanding gauge specifications helps buyers select the right mesh for their specific structural or non-structural needs. -

Mesh Size and Spacing

– Mesh size refers to the dimensions of the openings in the wire mesh, typically expressed in inches or millimeters (e.g., 2×2 inches). Spacing indicates how far apart the wires are, affecting the overall strength and application of the mesh. Smaller openings are suitable for applications requiring higher security or containment, while larger openings may be used for drainage or landscaping purposes. -

Tolerance

– Tolerance refers to the acceptable variation in dimensions for wire diameter and mesh size. Tight tolerances ensure that the welded wire mesh will perform as expected in structural applications, where deviations can lead to failures. B2B buyers should inquire about tolerances to ensure compliance with industry standards and project specifications. -

Unit Weight

– The unit weight of welded wire mesh is critical for logistical planning, as it affects shipping costs and handling procedures. Understanding the weight per square foot or per roll helps buyers calculate material requirements and transportation needs efficiently. -

Coating and Finish

– The type of coating applied to welded wire mesh, such as galvanization or PVC coating, influences its resistance to corrosion and wear. For projects exposed to harsh environments, selecting the appropriate coating can extend the lifespan of the mesh and reduce maintenance costs.

What Are Common Trade Terms Used in Welded Wire Mesh Sourcing?

Navigating the procurement of welded wire mesh requires familiarity with industry jargon. Here are some essential terms:

Illustrative image related to welded wire mesh sizes

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces components or products that are marketed by another company under its brand name. In the context of welded wire mesh, understanding OEM relationships can be beneficial for buyers seeking specific product certifications or quality assurances. -

MOQ (Minimum Order Quantity)

– MOQ is the minimum number of units a supplier is willing to sell in a single order. This term is crucial for B2B buyers to understand, as it affects inventory levels and purchasing strategies. Knowing the MOQ can help buyers negotiate better terms or plan for bulk purchases. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers asking for price quotes on specific products or services. For welded wire mesh, submitting an RFQ can facilitate competitive pricing and help buyers identify the best suppliers based on cost and specifications. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping and delivery. Understanding these terms is essential for B2B buyers, especially when sourcing materials from international suppliers, as they determine who bears the risk and costs associated with transportation. -

Lead Time

– Lead time refers to the amount of time it takes from placing an order to receiving the goods. This metric is vital for project planning and inventory management. Buyers should always inquire about lead times to ensure timely delivery of welded wire mesh for their projects.

By grasping these essential properties and trade terms, B2B buyers can make informed decisions that align with their project needs and procurement strategies.

Navigating Market Dynamics and Sourcing Trends in the welded wire mesh sizes Sector

What Are the Current Market Dynamics and Key Trends in the Welded Wire Mesh Sizes Sector?

The global welded wire mesh market is witnessing significant growth, driven by increasing demand across various sectors such as construction, agriculture, and security. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, look for reliable sourcing solutions, understanding market dynamics becomes crucial. Emerging trends include the integration of technology in sourcing processes, such as e-procurement platforms that enhance transparency and efficiency. Additionally, advancements in production techniques are enabling manufacturers to offer a broader range of sizes and specifications, catering to diverse project requirements.

One of the notable market dynamics is the increasing emphasis on customization. Buyers are seeking specific mesh sizes and gauges to meet particular structural and aesthetic needs. For instance, in regions like Saudi Arabia and Vietnam, where construction projects are booming, there is a heightened focus on welded wire mesh that supports high load-bearing capacities and durability. Furthermore, the trend towards modular construction is influencing sourcing strategies, as companies look for mesh solutions that can be easily integrated into prefabricated structures.

How Are Sustainability and Ethical Sourcing Affecting the Welded Wire Mesh Sizes Sector?

Sustainability is becoming an essential consideration in the welded wire mesh industry, with buyers increasingly demanding environmentally friendly products. The environmental impact of wire mesh production, particularly in terms of energy consumption and waste generation, is prompting manufacturers to adopt greener practices. For B2B buyers, understanding the sustainability credentials of suppliers is critical. Many manufacturers are now obtaining certifications that demonstrate their commitment to eco-friendly practices, such as using recycled materials or employing energy-efficient production methods.

Illustrative image related to welded wire mesh sizes

Ethical sourcing also plays a significant role in the decision-making process for international buyers. Ensuring that supply chains are transparent and socially responsible is vital for maintaining brand integrity. This includes evaluating suppliers based on their labor practices, material sourcing, and adherence to environmental regulations. Buyers are increasingly looking for suppliers who can provide evidence of their ethical standards, such as certifications from recognized bodies. As the demand for sustainable and ethically sourced products continues to rise, welded wire mesh manufacturers that prioritize these principles will likely gain a competitive edge in the market.

How Has the Welded Wire Mesh Sizes Sector Evolved Over Time?

The evolution of the welded wire mesh sector can be traced back to its origins in the early 20th century when it was primarily used for agricultural fencing and basic construction applications. Over the decades, technological advancements have significantly transformed the industry. The introduction of automated welding processes allowed for more precise and consistent production of various mesh sizes and gauges, enhancing the material’s overall strength and durability.

As construction methods evolved, so did the applications of welded wire mesh. It became integral to concrete reinforcement and structural applications, leading to increased demand across various sectors. Today, welded wire mesh is not only a staple in construction but also finds applications in landscaping, security, and architectural design. The shift towards modular and sustainable construction practices is likely to further influence the development of new mesh sizes and specifications, ensuring that the sector continues to adapt to the changing needs of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of welded wire mesh sizes

-

How do I determine the appropriate welded wire mesh size for my project?

To select the right welded wire mesh size, consider the specific application and load requirements. Evaluate the wire gauge, which indicates the thickness and strength of the mesh; lower gauges represent thicker wires suitable for heavy-duty use, while higher gauges are better for lighter applications. Additionally, examine the mesh spacing (e.g., 2×2, 4×4) to ensure it meets your project’s structural and aesthetic needs. It may also be beneficial to consult with a supplier who can provide samples and technical specifications tailored to your project. -

What is the best wire gauge for welded wire mesh applications?

The best wire gauge for welded wire mesh depends on the intended use. For construction and reinforcement, thicker wires (lower gauge numbers, such as 4 or 6 gauge) offer greater strength and durability, making them ideal for concrete applications. Conversely, for lighter applications like garden fencing or decorative projects, thinner wires (higher gauge numbers, such as 10 or 12 gauge) may suffice. Always assess the specific environmental conditions and load requirements before making a decision. -

How can I ensure the quality of welded wire mesh when sourcing internationally?

To ensure quality when sourcing welded wire mesh internationally, start by vetting suppliers thoroughly. Look for manufacturers with industry certifications, such as ISO, and request samples to assess the mesh’s strength and durability. Additionally, consider supplier reviews and references from previous clients. Establishing clear communication regarding specifications, quality control processes, and compliance with international standards will help mitigate risks associated with international trade. -

What are the minimum order quantities (MOQ) for welded wire mesh?

Minimum order quantities for welded wire mesh can vary widely among suppliers and depend on factors such as the type of mesh and production capabilities. Generally, MOQs can range from a few hundred square feet for standard sizes to several tons for custom orders. It is advisable to discuss your specific requirements with potential suppliers to determine their MOQs and negotiate terms that suit your purchasing needs. -

What payment terms should I expect when purchasing welded wire mesh from international suppliers?

Payment terms for international purchases of welded wire mesh typically include options like advance payment, letters of credit, or net payment terms (e.g., 30 or 60 days). Suppliers may require a deposit before production, with the balance due upon shipment or delivery. It is essential to clarify payment terms upfront and ensure they align with your financial practices to avoid any misunderstandings during the transaction. -

What logistics considerations should I be aware of when importing welded wire mesh?

When importing welded wire mesh, consider logistics aspects such as shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder familiar with your destination country’s import regulations. Be aware of potential tariffs and duties that may apply to your shipment, and ensure all documentation is accurate to prevent delays. Discuss with your supplier about packaging and handling to avoid damage during transit. -

Can I customize the size and specifications of welded wire mesh?

Yes, many suppliers offer customization options for welded wire mesh sizes, gauges, and configurations to meet specific project requirements. Customization may include different mesh sizes, wire thicknesses, and even coatings for corrosion resistance. When discussing your needs with a supplier, provide detailed specifications and quantities to receive accurate quotes and lead times for production. -

What are the common applications for welded wire mesh in different industries?

Welded wire mesh is utilized across various industries for applications such as construction reinforcement, fencing, agricultural uses, and industrial screens. In construction, it is commonly used for concrete reinforcement, while in agriculture, it serves for animal enclosures and crop protection. Additionally, it can be found in landscaping, safety barriers, and security fencing. Understanding these applications can help you select the appropriate mesh type for your specific industry needs.

Top 4 Welded Wire Mesh Sizes Manufacturers & Suppliers List

1. MCSW USA – Wire Mesh Gauges

Domain: mcswusa.com

Registered: 2016 (9 years)

Introduction: Wire mesh gauges refer to the thickness of the wire used in the mesh, measured in American Wire Gauge or by diameter in inches or millimeters. Common wire mesh gauges and their diameters include: 6 gauge: 0.192 inches (4.88 mm), 8 gauge: 0.128 inches (3.25 mm), 10 gauge: 0.102 inches (2.59 mm), 12 gauge: 0.080 inches (2.03 mm), 14 gauge: 0.064 inches (1.63 mm), 16 gauge: 0.050 inches (1.27 mm), 18…

2. McNichols – Metal Sheets and Coils

Domain: mcnichols.com

Registered: 1996 (29 years)

Introduction: This company, McNichols – Metal Sheets and Coils, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Darby Wire Mesh – Stainless Steel Welded Wire Mesh

Domain: catalog.darbywiremesh.com

Registered: 2007 (18 years)

Introduction: Stainless Steel Welded Wire Mesh available in T-304 and T-316 stainless steel. Opening sizes range from 0.937″ to 0.203″. Common wire diameters include 0.063″, 0.080″, 0.105″, 0.120″, 0.135″, and 0.148″. Popular widths are 36″, 48″, and 60″. Applications include animal caging, agricultural use, food processing, and residential projects. Corrosion resistant and available in roll form or custom manu…

4. Online Metals – 1×1 Mesh Stainless Steel Welded Wire Mesh

Domain: onlinemetals.com

Registered: 1997 (28 years)

Introduction: {“Product Name”: “1×1 Mesh .063\” Wire Diameter Stainless Steel Welded Wire Mesh 304″, “Part Number”: “mp-00002860”, “Wire Diameter”: “0.063\””, “Mesh Size”: “1×1”, “Opening Size”: “0.937\””, “Open Area”: “0.878\””, “Shipping Information”: {“Ships”: “rolled unless specified at checkout”, “Lead Time to Ship”: “3 Business Days”, “Shipping From”: “US-PA, Morrisville”}, “Available Sizes”: [{“Size”: “1…

Strategic Sourcing Conclusion and Outlook for welded wire mesh sizes

As international demand for welded wire mesh continues to grow, understanding the diverse sizes and specifications available is crucial for B2B buyers. The various gauges, from 4/4 to 10/10, offer distinct strengths suitable for a wide range of applications, including construction reinforcement, fencing, and agricultural use. Buyers should prioritize sourcing from reputable suppliers who can provide detailed specifications and customization options to meet project requirements effectively.

Strategic sourcing plays a pivotal role in optimizing supply chain efficiency and cost management. By carefully evaluating suppliers based on quality, delivery times, and compliance with international standards, businesses can enhance their competitive edge in global markets. Furthermore, leveraging local suppliers in regions like Africa, South America, the Middle East, and Europe can facilitate smoother logistics and reduce lead times.

Looking ahead, the welded wire mesh market is poised for innovation, with emerging technologies aimed at improving production efficiency and sustainability. B2B buyers are encouraged to stay informed about these advancements and consider partnerships that align with their long-term goals. Engage with suppliers now to secure the best options for your upcoming projects and ensure that your sourcing strategy aligns with market trends and demands.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to welded wire mesh sizes

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.