A B2B Buyer’s Guide to Valve Pvc Pipe: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for valve pvc pipe

Navigating the complexities of sourcing valve PVC pipe can be a daunting task for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. With a myriad of options available, understanding the specific types, applications, and technical specifications of PVC valves is essential for making informed purchasing decisions. This guide aims to streamline your procurement process by providing a comprehensive overview of the various types of valve PVC pipe, including ball, check, and butterfly valves, along with their respective industrial applications.

In addition to detailing the functional aspects of these products, this guide will also address critical considerations such as supplier vetting, pricing strategies, and quality standards. By equipping buyers with insights into the nuances of valve PVC pipe, we empower them to make strategic decisions that align with their operational needs and budget constraints. Whether you’re sourcing for a large-scale industrial project or a localized application, understanding the global market for valve PVC pipe will enhance your purchasing power and operational efficiency. Prepare to delve into a resource that transforms the way you approach your sourcing challenges, ensuring you find the right solutions for your unique business requirements.

Understanding valve pvc pipe Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PVC Ball Valves | Offers on/off control, available in various sizes | Water supply, chemical processing | Pros: Durable, easy to install; Cons: Limited to lower pressure applications. |

| PVC Check Valves | Prevents backflow, operates automatically | Wastewater management, irrigation systems | Pros: Protects systems from contamination; Cons: Can be sensitive to flow rates. |

| PVC Butterfly Valves | Compact design, suitable for throttling flow | HVAC systems, water treatment facilities | Pros: Lightweight, low torque requirements; Cons: Not ideal for high-pressure applications. |

| PVC Gate Valves | Provides straight-line flow, used for isolation | Oil and gas, fire protection systems | Pros: Minimal pressure drop; Cons: Slower operation compared to other valve types. |

| PVC Diaphragm Valves | Uses a flexible diaphragm for flow control | Pharmaceutical, food processing | Pros: Excellent sealing capabilities; Cons: More expensive than other valve types. |

What are the Key Characteristics of PVC Ball Valves?

PVC ball valves are widely recognized for their simple operation and reliable performance. They feature a spherical disc that controls flow, making them ideal for on/off applications. Available in various sizes, they are commonly used in water supply systems and chemical processing industries. When purchasing, consider the maximum pressure ratings and compatibility with the fluids being handled, as these factors can influence the valve’s longevity and performance.

How Do PVC Check Valves Function in Industrial Applications?

PVC check valves are designed to prevent backflow in piping systems, ensuring that liquids flow in one direction. They automatically operate based on fluid dynamics, making them essential for wastewater management and irrigation systems. Buyers should assess the valve’s flow rate sensitivity and installation requirements, as these can affect the overall efficiency of the system.

What Makes PVC Butterfly Valves Suitable for Throttling Flow?

PVC butterfly valves are characterized by their compact design and ability to control flow rates. They are particularly useful in HVAC systems and water treatment facilities where space is limited. Buyers should consider the torque requirements and whether the valve will be subjected to high pressures, as these factors can impact operational efficiency and maintenance needs.

Why Choose PVC Gate Valves for Isolation Purposes?

PVC gate valves are primarily used for isolating flow in pipelines, allowing for maintenance without disrupting the entire system. They provide a straight-line flow with minimal resistance, making them suitable for applications in oil and gas industries, as well as fire protection systems. When selecting gate valves, consider the speed of operation and whether the application may require frequent valve adjustments.

What are the Advantages of PVC Diaphragm Valves in Sensitive Applications?

PVC diaphragm valves utilize a flexible diaphragm to control flow, providing excellent sealing capabilities. They are particularly advantageous in pharmaceutical and food processing industries where contamination must be minimized. Buyers should evaluate the cost versus the benefits of enhanced sealing and performance, as diaphragm valves tend to be more expensive than traditional valve types but offer superior reliability in sensitive applications.

Key Industrial Applications of valve pvc pipe

| Industry/Sector | Specific Application of valve pvc pipe | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Treatment | Flow control in water purification systems | Enhanced efficiency in managing water flow and quality | Ensure chemical resistance and compatibility with local standards |

| Agriculture | Irrigation systems for crop management | Improved water delivery and resource conservation | Evaluate pressure ratings and adaptability to local climates |

| Chemical Processing | Control of corrosive liquid transfers | Reduced maintenance costs due to corrosion resistance | Confirm compatibility with specific chemicals handled |

| HVAC Systems | Air conditioning and ventilation applications | Increased energy efficiency and reduced operational costs | Check for temperature ratings and installation flexibility |

| Construction | Plumbing systems in residential and commercial buildings | Cost-effective and lightweight solutions for piping | Assess local building codes and installation requirements |

How is Valve PVC Pipe Used in Water Treatment Systems?

In water treatment facilities, valve PVC pipes are crucial for flow control in purification processes. These systems require reliable components that can withstand various chemical exposures while maintaining water quality. PVC’s corrosion resistance ensures longevity, reducing the need for frequent replacements and minimizing downtime. International buyers should focus on sourcing pipes that meet local regulations and standards for water quality to ensure compliance.

What Role Does Valve PVC Pipe Play in Agriculture?

In agriculture, valve PVC pipes are extensively used in irrigation systems to optimize water delivery to crops. Their lightweight nature allows for easy installation and flexibility in design, accommodating various field layouts. The use of PVC helps in conserving water resources and improving crop yields. Buyers in regions like Africa and South America should consider local climate conditions and pressure ratings to ensure the system’s effectiveness and durability.

How is Valve PVC Pipe Beneficial in Chemical Processing?

Chemical processing industries rely on valve PVC pipes for the safe transfer of corrosive liquids. The material’s inherent resistance to chemicals significantly reduces maintenance costs and enhances operational safety. When sourcing, international buyers must ensure that the selected PVC valves are compatible with the specific chemicals they will handle, as well as adhere to safety regulations in their respective regions.

How Does Valve PVC Pipe Improve HVAC Systems?

In HVAC systems, valve PVC pipes are integral for managing air conditioning and ventilation. They facilitate the efficient flow of air and can significantly enhance energy efficiency in buildings. The lightweight nature of PVC also simplifies installation, which is a key consideration for contractors. Buyers should evaluate the temperature ratings and installation requirements to ensure optimal performance in varying climates across Europe and the Middle East.

What is the Importance of Valve PVC Pipe in Construction?

In the construction sector, valve PVC pipes are widely utilized for plumbing in both residential and commercial buildings. Their cost-effectiveness and ease of installation make them a preferred choice among contractors. Buyers should be aware of local building codes and installation requirements, as these can vary significantly across regions, impacting the overall project timeline and compliance.

3 Common User Pain Points for ‘valve pvc pipe’ & Their Solutions

Scenario 1: The Challenge of Corrosion Resistance in Harsh Environments

The Problem: B2B buyers often face significant challenges when sourcing valves for applications in corrosive environments, such as chemical processing or wastewater management. Traditional metal valves can quickly corrode, leading to costly repairs, unplanned downtime, and compromised safety. Buyers may find themselves in a situation where they need to balance performance, durability, and cost, all while ensuring that the valves can withstand specific chemicals and environmental conditions.

The Solution: To address this problem, it is essential for buyers to prioritize sourcing PVC valves that are specifically designed for corrosive environments. PVC offers excellent chemical resistance and is lightweight, making it easier to handle and install. When specifying valves, buyers should look for products that meet ASTM D1784 standards, which ensures they are suitable for industrial applications. Additionally, incorporating true union ball valves can enhance maintenance flexibility. These valves allow for easy disassembly without damaging the piping, facilitating routine inspections and cleaning to prolong the lifespan of the system. Working closely with suppliers who understand the unique requirements of specific industries will also help in selecting the right valve for the application.

Scenario 2: Compatibility Issues with Existing Systems

The Problem: Many B2B buyers encounter compatibility issues when integrating new PVC valves into existing piping systems. Mismatched sizes, connection types, or materials can lead to leaks, inefficiencies, and even system failures. This is particularly common in facilities that have older infrastructure or a mix of different materials, such as metal and PVC. Buyers need to ensure that any new components can seamlessly fit into their existing systems without extensive modifications.

The Solution: To overcome compatibility issues, buyers should conduct a thorough assessment of their current piping system before making a purchase. This includes measuring the diameter of existing pipes and understanding the connection types (e.g., threaded or slip-joint). When selecting PVC valves, it is critical to choose those that offer various connection options and sizes. Suppliers often provide detailed specifications and sizing charts, which can aid buyers in selecting compatible products. Additionally, considering valves with adjustable or flexible connection systems can provide greater adaptability and ease of installation. Engaging with knowledgeable suppliers who can assist in identifying the right fit will ultimately save time and reduce the risk of costly errors.

Scenario 3: Ensuring Reliability Under Pressure

The Problem: In industries where pressure control is vital, such as water treatment or manufacturing, buyers are often concerned about the reliability of PVC valves under varying pressure conditions. They may worry that lower-quality valves could fail under high pressure, leading to operational disruptions and safety hazards. This concern can be particularly acute in regions with fluctuating environmental conditions or where systems must handle sudden surges in pressure.

Illustrative image related to valve pvc pipe

The Solution: Buyers can mitigate these risks by selecting PVC valves that are specifically rated for high pressure and temperature applications. It’s essential to review the maximum pressure ratings (PSI) provided by manufacturers and choose valves that exceed the expected operational pressure. Additionally, opting for products that feature reinforced designs—like those with thicker walls or additional support structures—can enhance durability. Buyers should also consider integrating pressure relief valves into their systems to prevent over-pressurization. Regular maintenance checks and pressure testing can further ensure that the valves continue to perform reliably over time. Collaborating with suppliers who provide detailed performance data and support can greatly aid in making informed decisions that enhance system reliability.

Strategic Material Selection Guide for valve pvc pipe

What Are the Key Properties of PVC in Valve Applications?

Polyvinyl Chloride (PVC) is a widely used material for valve pipes due to its favorable properties. PVC exhibits excellent corrosion resistance, making it suitable for a variety of liquids, including acids and alkalis. It has a maximum operating temperature of around 140°F (60°C) and can handle pressures up to 150 PSI, depending on the specific valve design. This makes PVC valves ideal for non-potable water applications, irrigation systems, and certain industrial uses.

What Are the Advantages and Disadvantages of Using PVC Valves?

The primary advantages of PVC valves include their lightweight nature, ease of installation, and cost-effectiveness. They are significantly less expensive than metal alternatives, making them a popular choice for budget-sensitive projects. However, PVC can become brittle over time when exposed to UV light, which may limit its outdoor applications unless properly protected. Additionally, while PVC is suitable for many chemicals, it may not be compatible with certain solvents and oils, which could lead to premature failure.

How Do Other Materials Compare to PVC for Valve Applications?

CPVC (Chlorinated Polyvinyl Chloride)

CPVC is similar to PVC but offers higher temperature resistance, with a maximum operating temperature of around 200°F (93°C). This makes it suitable for hot water applications and some industrial processes. CPVC also has good chemical resistance but is generally more expensive than PVC. International buyers should note that CPVC is compliant with ASTM standards, making it a reliable choice for many applications.

ABS (Acrylonitrile Butadiene Styrene)

ABS is another plastic material used in valve applications. It offers excellent impact resistance and can handle a range of temperatures, but it is less chemically resistant than PVC and CPVC. ABS is often used in drainage systems and venting applications. Its lower cost makes it appealing, but it is not suitable for high-temperature or high-pressure applications.

Metal Valves (Brass, Stainless Steel)

Metal valves, such as those made from brass or stainless steel, are known for their durability and high-pressure capabilities. They can withstand higher temperatures and pressures compared to PVC and are suitable for a broader range of applications, including potable water systems. However, they are significantly more expensive and may require more complex installation processes. Additionally, metal valves can corrode over time, especially in harsh environments, which could lead to increased maintenance costs.

What Should International Buyers Consider When Selecting Valve Materials?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider compliance with local standards such as ASTM (American Society for Testing and Materials), DIN (Deutsches Institut für Normung), and JIS (Japanese Industrial Standards). Understanding the specific requirements for pressure ratings, chemical compatibility, and temperature limits is crucial. Furthermore, regional preferences for materials based on climate and application can influence purchasing decisions.

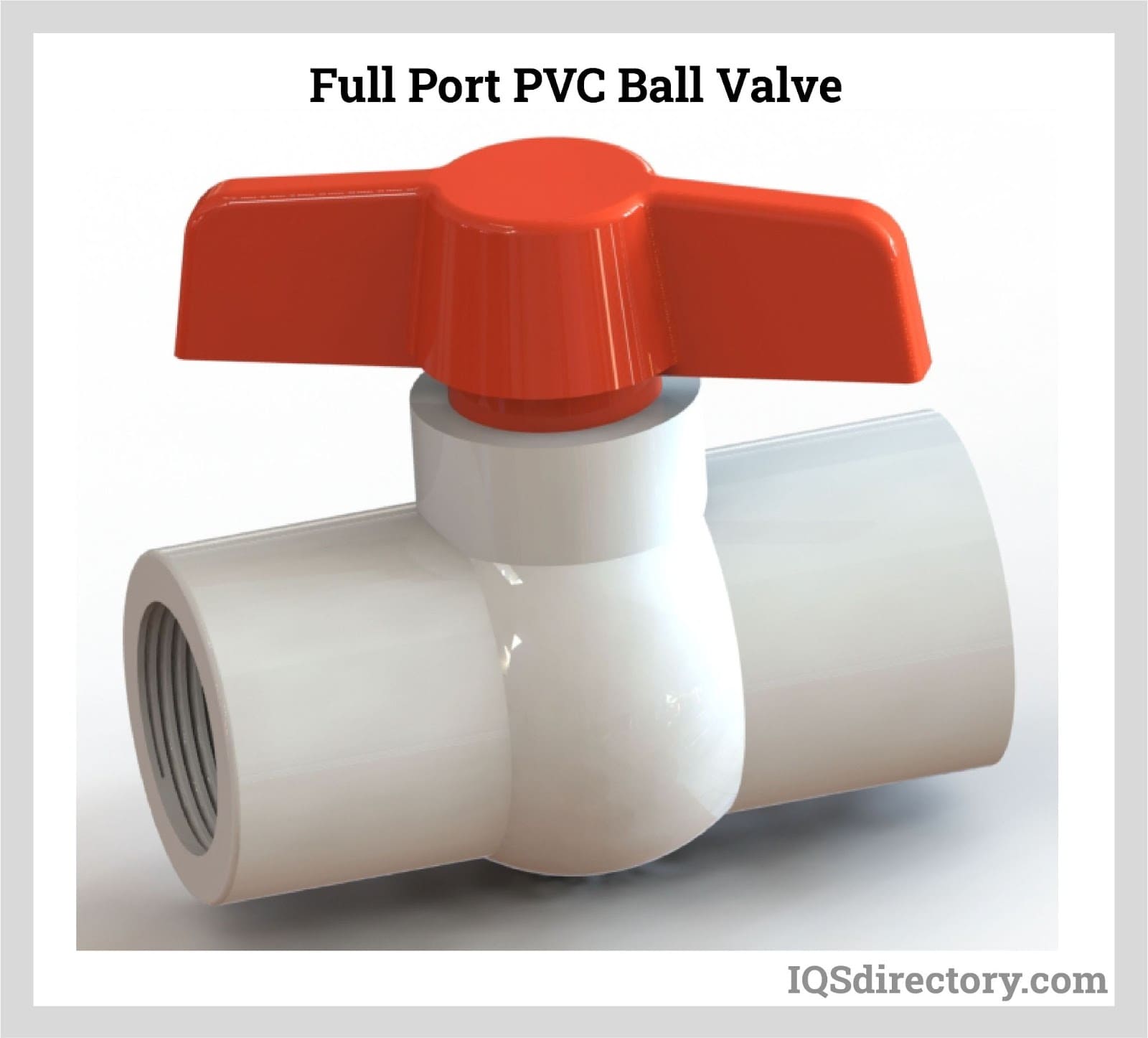

Illustrative image related to valve pvc pipe

| Material | Typical Use Case for valve pvc pipe | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Irrigation systems, non-potable water | Cost-effective and lightweight | Brittle under UV exposure | Low |

| CPVC | Hot water applications, industrial processes | Higher temperature resistance | More expensive than PVC | Medium |

| ABS | Drainage and venting | Excellent impact resistance | Less chemical resistance | Low |

| Brass/Stainless Steel | Potable water systems, high-pressure applications | High durability and pressure capability | Higher cost and corrosion potential | High |

This strategic material selection guide provides essential insights for international B2B buyers, aiding them in making informed decisions tailored to their specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for valve pvc pipe

What Are the Main Stages in the Manufacturing Process of PVC Valve Pipes?

The manufacturing process of PVC valve pipes involves several critical stages, ensuring that the final product meets the necessary quality standards.

-

Material Preparation: The first stage involves sourcing high-quality PVC resin. This resin is often mixed with various additives to enhance properties such as UV resistance, impact strength, and thermal stability. Suppliers must ensure that the raw materials comply with international standards like ASTM D1784 for PVC, which dictates the physical and chemical properties required for pipe materials.

-

Forming: The prepared PVC is then subjected to various forming techniques, including extrusion and injection molding. In extrusion, the PVC material is heated and forced through a die to create a continuous pipe or valve shape. Injection molding, on the other hand, involves injecting molten PVC into a mold to form specific valve components. These methods allow for precise control over dimensions and ensure uniformity across batches.

-

Assembly: After forming, the individual components of the valve, such as the body, handle, and seals, are assembled. This stage may involve additional processes like threading or socketing, depending on the design specifications. Manufacturers often utilize automated assembly lines to enhance efficiency and reduce human error.

-

Finishing: The final stage includes surface treatment and finishing processes. This can involve sanding, polishing, or applying protective coatings. The goal is to enhance aesthetic qualities and improve resistance to environmental factors. Proper finishing also ensures that the valves are free from defects that could affect their performance.

How Is Quality Assurance Implemented in PVC Valve Pipe Manufacturing?

Quality assurance is a crucial aspect of the manufacturing process that ensures products meet predefined standards and customer expectations.

-

International and Industry-Specific Standards: Manufacturers often adhere to international quality standards such as ISO 9001, which outlines criteria for a quality management system. Additionally, industry-specific certifications like CE marking for the European market and API standards for the oil and gas sector are vital for compliance and market acceptance.

-

Quality Control Checkpoints: Quality control involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specifications. Any non-conforming materials are rejected or reprocessed.

– In-Process Quality Control (IPQC): During manufacturing, regular inspections and tests are conducted to verify that processes adhere to quality standards. This includes checking dimensions, tolerances, and visual inspections for defects.

– Final Quality Control (FQC): Once the product is assembled, a comprehensive final inspection is performed. This may involve functional testing, pressure testing, and visual inspections to ensure that the valves operate correctly and meet all specifications. -

Common Testing Methods: Various testing methods are employed to validate the quality of PVC valve pipes. These include:

– Hydrostatic Testing: To check for leaks and ensure the valve can withstand the required pressure.

– Impact Testing: To assess the durability of the valves under sudden stress.

– Thermal Testing: To evaluate how the material performs under different temperature conditions.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must ensure that their suppliers maintain high-quality standards to avoid potential issues down the line. Here are several strategies to verify supplier quality control:

-

Supplier Audits: Conducting regular audits of potential suppliers can provide insights into their quality control processes. Buyers should assess the manufacturing facilities, quality management systems, and compliance with international standards. An audit can reveal whether the supplier adheres to best practices in manufacturing and quality assurance.

-

Quality Control Reports: Requesting detailed quality control reports from suppliers can help buyers understand the testing methods employed and the results obtained. These reports should provide information on IQC, IPQC, and FQC processes, along with any corrective actions taken for non-conforming products.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control measures. These services can perform inspections at various stages of the manufacturing process and provide certification that the products meet required standards.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, must navigate various quality control and certification nuances:

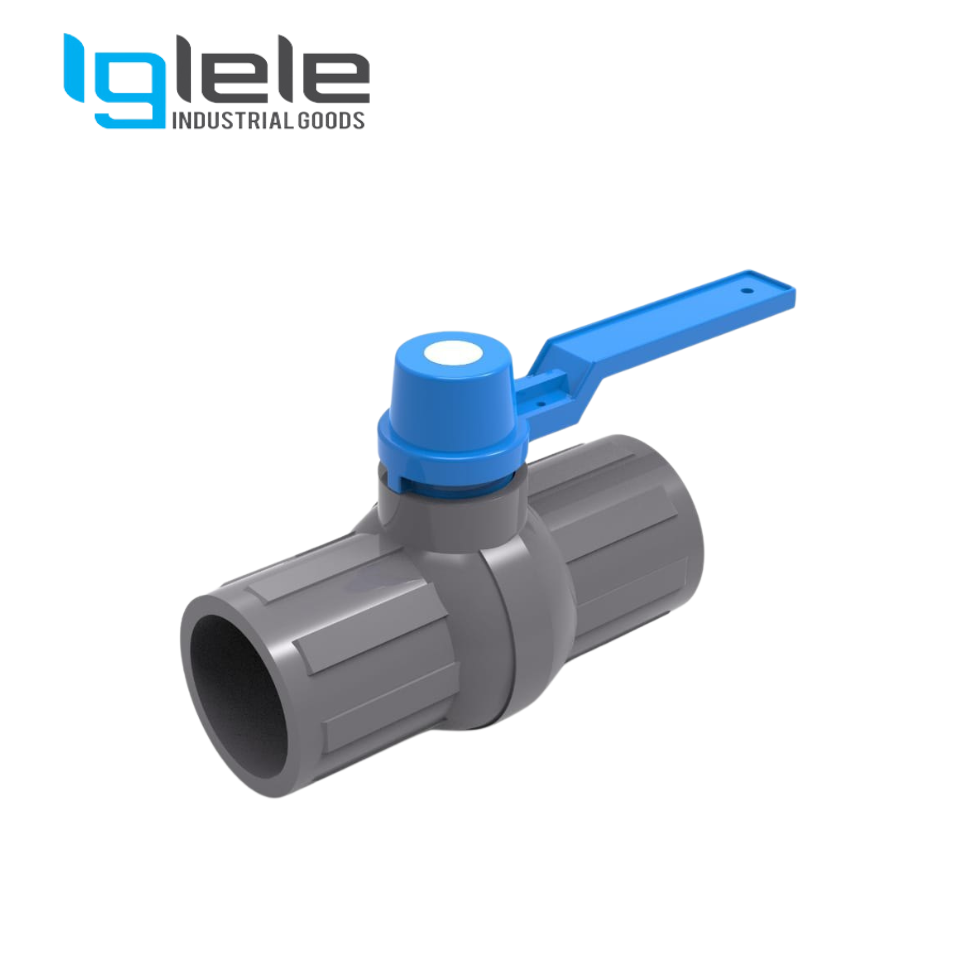

Illustrative image related to valve pvc pipe

-

Understanding Regional Standards: Different regions may have specific regulations and standards. For example, European buyers must ensure compliance with EU directives, while Middle Eastern buyers may have unique local standards. Familiarity with these regulations is essential to avoid compliance issues.

-

Language and Documentation: Ensure that all quality documentation, including certifications and reports, is available in a language that is easily understood by the buyer. This is critical for effective communication and understanding of the quality assurance processes.

-

Cultural Considerations: Cultural differences may influence business practices, including how quality assurance is perceived. Buyers should be aware of these differences and approach negotiations and communications with sensitivity to local customs.

By understanding the manufacturing processes and quality assurance protocols for PVC valve pipes, B2B buyers can make informed decisions and select reliable suppliers that meet their quality expectations. Proper diligence in verifying supplier quality can significantly reduce the risks associated with purchasing these critical components.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘valve pvc pipe’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to procure valve PVC pipes, ensuring a systematic approach to sourcing. By following these steps, buyers can make informed decisions that align with their technical requirements, budget constraints, and supplier capabilities, ultimately leading to successful procurement outcomes.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring the products meet your operational needs. Consider factors such as the type of valve (e.g., ball, check, or butterfly), diameter, pressure ratings, and material compatibility. A well-defined specification will help you communicate your needs effectively to suppliers and avoid costly mistakes.

Illustrative image related to valve pvc pipe

Step 2: Identify Your Application Requirements

Different applications may necessitate specific features in PVC valves. For instance, if the valves will be used in corrosive environments, ensure they are resistant to chemicals and have appropriate seals. Understanding the application will guide you in selecting the right valve type, whether it’s for potable water, wastewater, or industrial processes.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a proven track record in delivering high-quality PVC valves, as well as those that offer robust customer support and after-sales service.

- Check Certifications: Verify that suppliers adhere to international quality standards, such as ASTM or ISO certifications.

- Assess Experience: Consider suppliers with experience in your specific market or application to ensure they understand regional regulations and challenges.

Step 4: Request Samples and Quotes

Obtaining samples allows you to evaluate the quality and functionality of the valve PVC pipes before making a bulk purchase. Request detailed quotes that include pricing, delivery timelines, and terms of service. This step is essential for comparing different suppliers and ensuring you’re getting the best value for your investment.

Step 5: Negotiate Terms and Conditions

Once you’ve narrowed down your options, initiate negotiations with your selected suppliers. Discuss payment terms, warranty conditions, and delivery schedules. A clear agreement on these aspects can help prevent misunderstandings and ensure a smooth procurement process.

- Include Penalties for Delays: Consider including clauses that address penalties for missed deadlines to safeguard your project timelines.

- Confirm After-Sales Support: Ensure that the supplier provides adequate support for installation and maintenance.

Step 6: Finalize Your Purchase Order

After negotiations, finalize your purchase order with clear documentation. Include all agreed-upon specifications, pricing, and delivery dates. A well-documented order minimizes the risk of disputes and ensures that both parties have a clear understanding of the transaction.

Step 7: Monitor Delivery and Quality Control

Upon delivery, inspect the valve PVC pipes to confirm they meet your specifications and quality standards. Implement a quality control process to address any discrepancies immediately. Monitoring the delivery phase ensures that your operations can proceed without delays due to procurement issues.

By following this checklist, B2B buyers can enhance their sourcing efficiency and secure high-quality valve PVC pipes that meet their specific needs.

Comprehensive Cost and Pricing Analysis for valve pvc pipe Sourcing

What Are the Key Cost Components in Sourcing PVC Valve Pipes?

When sourcing PVC valve pipes, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

Illustrative image related to valve pvc pipe

-

Materials: The type of PVC resin used significantly affects pricing. Higher-grade materials may incur additional costs but offer enhanced durability and resistance to chemicals, which can be beneficial in industrial applications.

-

Labor: Labor costs can vary based on geographic location and the complexity of manufacturing. Skilled labor is often required for specialized valve designs or customizations, impacting overall costs.

-

Manufacturing Overhead: This encompasses utilities, facility maintenance, and indirect labor. Efficient production processes can minimize these overheads, leading to cost savings.

-

Tooling: Custom molds and tools for unique valve designs add to the initial investment. However, these costs can be amortized over large production runs, making them less significant for high-volume orders.

-

Quality Control (QC): Ensuring compliance with industry standards and certifications can introduce additional costs. Regular inspections and testing are essential, particularly for valves used in critical applications.

-

Logistics: Shipping and handling costs, which can fluctuate based on distance and mode of transport, are significant. Incoterms also play a critical role in determining which party is responsible for various logistics costs.

-

Margin: Suppliers typically add a markup to cover their costs and ensure profitability. This margin can vary widely based on the supplier’s market position and the competitive landscape.

How Do Price Influencers Affect PVC Valve Pipe Costs?

Several factors influence the pricing of PVC valve pipes:

-

Volume/MOQ: Larger orders often qualify for discounts due to economies of scale. Understanding the Minimum Order Quantity (MOQ) can help buyers negotiate better terms.

-

Specifications and Customization: Custom designs or specific performance requirements typically increase costs. Clear communication of specifications can help suppliers provide accurate quotes.

-

Material Quality and Certifications: Premium materials and certified products often come at a higher price. Buyers should consider the Total Cost of Ownership (TCO) rather than just initial purchase price when evaluating options.

-

Supplier Factors: Supplier reputation, reliability, and location can affect pricing. Established suppliers may charge more due to their proven track record, while new entrants may offer lower prices to capture market share.

-

Incoterms: The chosen Incoterms determine responsibilities for shipping, insurance, and tariffs, impacting the final cost. Buyers should understand these terms to avoid unexpected expenses.

What Buyer Tips Can Help Optimize PVC Valve Pipe Sourcing Costs?

B2B buyers can adopt several strategies to enhance cost efficiency when sourcing PVC valve pipes:

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Suppliers may be willing to offer discounts or flexible payment terms to secure significant contracts.

-

Evaluate Total Cost of Ownership: Consider long-term costs, including maintenance and replacement, rather than focusing solely on upfront pricing. Investing in higher-quality valves may reduce future expenses related to failures or replacements.

-

Understand Pricing Nuances for International Purchases: Buyers from regions like Africa, South America, and the Middle East should be aware of additional costs related to tariffs, shipping delays, and currency fluctuations. Establishing relationships with local distributors can help mitigate these issues.

-

Stay Informed on Market Trends: Price trends for PVC and valve components can fluctuate due to market demand, supply chain disruptions, or geopolitical factors. Regularly reviewing market conditions can help buyers time their purchases more effectively.

Disclaimer on Indicative Prices

The prices mentioned in various sources can serve as a guideline but may not reflect the final costs incurred. Factors such as order size, customization, and supplier negotiations will ultimately determine the final pricing. Always request updated quotes to ensure accurate budgeting for your sourcing needs.

Alternatives Analysis: Comparing valve pvc pipe With Other Solutions

Exploring Alternatives to Valve PVC Pipe: Key Comparisons for B2B Buyers

In the quest for effective fluid control solutions, businesses often evaluate various options to find the best fit for their specific needs. This section provides a detailed comparison of PVC valve pipes against two viable alternatives: metal valves and CPVC (Chlorinated Polyvinyl Chloride) valves. Understanding these alternatives will help B2B buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Valve PVC Pipe | Metal Valves | CPVC Valves |

|---|---|---|---|

| Performance | Excellent chemical resistance; lightweight | High durability; suitable for high pressure | Good chemical resistance; slightly less than PVC |

| Cost | Generally low cost | Higher initial investment | Moderate cost, between PVC and metal |

| Ease of Implementation | Easy to install; lightweight | Requires skilled labor for installation | Similar to PVC, easy to handle |

| Maintenance | Low maintenance; resistant to corrosion | Requires regular inspections; prone to rust | Low maintenance; resistant to corrosion |

| Best Use Case | Ideal for non-potable water systems | Best for high-pressure applications | Suitable for hot water applications |

What Are the Pros and Cons of Metal Valves Compared to Valve PVC Pipe?

Metal valves, typically made from materials like brass or stainless steel, offer exceptional durability and can withstand high-pressure applications. They are ideal for industrial settings where strength and longevity are paramount. However, the cost of metal valves is significantly higher than that of PVC options, and they may require more complex installation processes, including welding or threading. Additionally, metal valves are prone to corrosion if not properly maintained, necessitating regular inspections and potential replacements.

Illustrative image related to valve pvc pipe

How Do CPVC Valves Compare to Valve PVC Pipe?

CPVC valves serve as a hybrid solution between PVC and metal valves. They offer superior resistance to higher temperatures compared to standard PVC, making them suitable for hot water applications. Like PVC, they are lightweight and easy to install, reducing labor costs. However, CPVC tends to be more expensive than PVC but less so than metal valves. One drawback is that while CPVC provides good chemical resistance, it may not be as robust as PVC in certain aggressive chemical environments.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right valve solution, B2B buyers should consider the specific requirements of their applications. For non-potable water systems or chemical handling where cost-effectiveness and low maintenance are priorities, PVC valves are an excellent choice. Conversely, for high-pressure systems that require durability and robustness, metal valves may be the better option despite their higher cost. If the application involves hot water, CPVC valves could offer the ideal balance between performance and cost. Ultimately, understanding the unique characteristics of each option will empower buyers to make informed decisions that align with their operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for valve pvc pipe

What Are the Key Technical Properties of PVC Valve Pipes for B2B Buyers?

When selecting PVC valve pipes, understanding their technical properties is crucial for ensuring they meet operational needs and industry standards. Here are some essential specifications:

-

Material Grade

PVC (Polyvinyl Chloride) is the primary material used for valve pipes due to its excellent corrosion resistance and durability. The material grade can affect performance in various applications, including chemical resistance and pressure tolerance. Buyers should consider the specific material grade (such as ASTM D1784) to ensure compatibility with their intended use, particularly in industries like water treatment and chemical processing. -

Pressure Rating (PSI)

Pressure rating indicates the maximum pressure that a valve can withstand without failure. Common ratings range from 0 to 200 PSI, depending on the valve type. For B2B buyers, selecting a valve with the appropriate pressure rating is vital to prevent leaks or burst failures in high-pressure applications, ensuring reliability and safety in operations. -

Temperature Tolerance

Temperature tolerance defines the range of temperatures a valve can handle before deformation or failure occurs. For PVC valves, this typically ranges from ambient temperatures up to 140°F (60°C). Understanding the temperature limits is essential for applications involving hot liquids or environments, as exceeding these limits can lead to premature failure. -

Inlet and Outlet Diameter

The inlet and outlet diameter specifications dictate the flow capacity and compatibility with existing piping systems. Common diameters include 1/2″, 1″, and 2″. For B2B buyers, selecting the right size ensures optimal flow rates and proper fitting with other system components, which is crucial for maintaining efficiency in fluid transport. -

Connection Type

PVC valve pipes can have various connection types, such as slip-joint, threaded, or spigot connections. The choice of connection impacts installation complexity and the ability to service the valve in the future. For procurement professionals, understanding these connection types is key to ensuring compatibility with existing infrastructure and ease of maintenance.

What Are Common Trade Terms Used in the PVC Valve Pipe Industry?

Familiarity with industry terminology can enhance communication and negotiation with suppliers. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the PVC valve industry, an OEM might supply valves to larger plumbing or industrial firms. Understanding OEM relationships is important for buyers seeking reliable sourcing channels and product quality assurance. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This can vary widely among manufacturers. For B2B buyers, knowing the MOQ is crucial for budgeting and inventory management, especially for smaller companies or those trying new products. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotations for specific products. In the context of PVC valves, buyers often use RFQs to gather pricing and availability from multiple vendors, aiding in informed decision-making and competitive bidding. -

Incoterms (International Commercial Terms)

Incoterms are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps B2B buyers navigate logistics and avoid misunderstandings about delivery obligations and costs. -

True Union Valve

A true union valve is designed to allow for easy removal and maintenance without cutting into the piping. This feature is particularly beneficial in industrial applications where valves need to be serviced frequently. Understanding this term helps buyers select valves that offer convenience and lower long-term maintenance costs.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when procuring PVC valve pipes, ensuring they meet their operational needs effectively.

Navigating Market Dynamics and Sourcing Trends in the valve pvc pipe Sector

What Are the Key Market Dynamics and Trends in the Valve PVC Pipe Sector?

The global valve PVC pipe market is witnessing robust growth, driven by increasing demand across various sectors such as construction, agriculture, and water management. Key market dynamics include a rising focus on infrastructure development, particularly in emerging economies in Africa and South America, where urbanization is accelerating the need for reliable plumbing systems. In Europe and the Middle East, stringent regulations on water quality and environmental standards are further bolstering the demand for high-quality PVC valves that ensure efficient fluid control.

Emerging technologies are reshaping sourcing strategies, with digital platforms facilitating smoother transactions between buyers and suppliers. For B2B buyers, this means greater access to a diverse range of products, competitive pricing, and enhanced transparency in sourcing. Innovations in manufacturing, such as 3D printing, are also streamlining the production of custom valve solutions, catering to specific project requirements. Additionally, the integration of IoT technologies in valve systems is enabling real-time monitoring and control, which is becoming increasingly essential for industrial applications.

Illustrative image related to valve pvc pipe

How Is Sustainability Influencing Sourcing Decisions in the Valve PVC Pipe Sector?

Sustainability is a crucial factor influencing sourcing decisions in the valve PVC pipe sector. The environmental impact of PVC production and disposal has led to heightened scrutiny and a shift toward sustainable practices. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and sustainable manufacturing processes. This includes sourcing PVC from recycled materials and ensuring compliance with environmental regulations.

Moreover, certifications such as ISO 14001 for environmental management and other ‘green’ certifications are becoming essential for suppliers aiming to appeal to conscientious buyers. Companies that adopt these practices not only reduce their environmental footprint but also enhance their brand reputation and customer loyalty. As global awareness of climate change and resource conservation grows, buyers are likely to favor suppliers who can offer eco-friendly alternatives, thereby shaping the future landscape of the valve PVC pipe market.

What Is the Historical Context of the Valve PVC Pipe Market?

The valve PVC pipe sector has evolved significantly since the introduction of PVC as a material in the 20th century. Initially, PVC was primarily used for electrical insulation, but its unique properties—such as corrosion resistance, lightweight nature, and versatility—soon made it popular in plumbing and industrial applications. The introduction of various valve types, including ball, check, and butterfly valves, expanded the functionality of PVC pipes.

Over the decades, advancements in manufacturing technologies and materials science have further refined the production processes, leading to more durable and reliable valve solutions. As industries increasingly seek cost-effective and efficient options, the adoption of PVC valves has surged, establishing them as a staple in modern piping systems. This historical context highlights the ongoing innovation and adaptability of the valve PVC pipe sector, which continues to meet the evolving demands of global markets.

Frequently Asked Questions (FAQs) for B2B Buyers of valve pvc pipe

-

How do I choose the right PVC valve for my application?

Selecting the right PVC valve involves understanding the specific requirements of your application. Consider factors such as the type of fluid being transported, the required flow rate, and the pressure conditions. For instance, ball valves are ideal for on/off control, while check valves prevent backflow. Additionally, assess the valve’s compatibility with your existing piping system and its material specifications, including temperature and chemical resistance. Always consult with suppliers to ensure the selected valve meets your operational needs. -

What is the best PVC valve type for industrial applications?

For industrial applications, true union ball valves are often the best choice due to their ease of maintenance and adaptability. These valves allow for disassembly without disturbing the piping, making cleaning and repairs straightforward. Other effective options include butterfly valves for large flow applications and check valves for preventing backflow in systems. When selecting a valve, consider the specific demands of your application, including pressure ratings and the nature of the fluids involved. -

What should I consider when sourcing PVC valves internationally?

When sourcing PVC valves from international suppliers, consider factors such as compliance with local regulations and industry standards. It’s crucial to verify the supplier’s certifications and quality assurance processes. Additionally, evaluate their shipping capabilities, lead times, and potential tariffs or duties that may affect total costs. Communication is key; ensure that the supplier can meet your language and service expectations. Building a reliable relationship with your supplier can significantly enhance your procurement process. -

What are the typical minimum order quantities (MOQs) for PVC valves?

Minimum order quantities for PVC valves can vary widely depending on the supplier and the specific product. Generally, MOQs can range from 50 to 500 units, with custom orders potentially requiring higher quantities. It’s essential to discuss your needs with suppliers upfront to determine their MOQ policies and negotiate terms that align with your purchasing strategy. Consider consolidating orders with other products to meet MOQs without overextending your budget. -

How can I ensure the quality of PVC valves from suppliers?

To ensure the quality of PVC valves, it’s advisable to request samples before placing large orders. Conduct thorough research on the supplier’s reputation, including customer reviews and case studies. Ask about their manufacturing processes and quality control measures, such as ISO certifications. Additionally, consider third-party inspections or certifications that validate the valves’ performance and compliance with industry standards. Regular communication and feedback can help maintain quality throughout your partnership. -

What payment terms should I expect when sourcing PVC valves?

Payment terms can vary among suppliers, but standard practices include options like advance payment, letter of credit, or net 30/60 days after delivery. It’s important to clarify these terms upfront to avoid misunderstandings later. Some suppliers may offer discounts for early payments or bulk orders. Always ensure that the payment method aligns with your company’s financial policies and provides adequate protection against potential risks in international transactions. -

What logistics considerations should I keep in mind when importing PVC valves?

Logistics play a crucial role in the importation of PVC valves. Key considerations include shipping methods (air vs. sea), lead times, and the reliability of freight forwarders. Be aware of import regulations in your country, including necessary documentation, tariffs, and customs procedures. Additionally, factor in storage solutions upon arrival, especially if you anticipate delays in distribution. Establishing a good relationship with logistics providers can streamline the process and reduce costs. -

Can I customize PVC valves for specific applications?

Yes, many suppliers offer customization options for PVC valves, including size, connection types, and additional features such as locking handles or specialized seals. Customization can enhance the functionality of the valves for specific applications, ensuring better performance and integration with existing systems. Discuss your requirements with potential suppliers, and request prototypes or samples to evaluate before committing to larger orders. Customization can often lead to improved operational efficiency and reliability in your processes.

Top 4 Valve Pvc Pipe Manufacturers & Suppliers List

1. Commercial Industrial Supply – PVC Valves

Domain: commercial-industrial-supply.com

Registered: 2009 (16 years)

Introduction: PVC Valves – Commercial Industrial Supply offers a variety of PVC valves suitable for commercial and industrial applications. Key product types include: PVC Ball Valves, PVC True Union Ball Valves, Compact Ball Valves, PVC 3 Way Ball Valves, PVC Gate Valves, PVC Check Valves (including Ball Check, Wafer Check, and Swing Check), PVC Butterfly Valves, PVC Diaphragm Valves, and PVC Foot Valves. The v…

2. PVC Fittings Online – PVC Ball Valves

Domain: pvcfittingsonline.com

Registered: 2011 (14 years)

Introduction: PVC ball valves are commonly used in landscaping and allow for quick on/off flow control while creating a watertight seal. They are suitable for applications in pools, laboratories, food and beverage industries, water treatment, life science, and chemical applications. The valves feature a ball that rotates on a 90-degree axis, allowing water to flow freely when in the “on” position and stopping f…

3. Piscinarium – PVC Valves and Pipes

4. Clear PVC Pipe – Check and Ball Valves

Domain: clearpvcpipe.com

Registered: 1998 (27 years)

Introduction: 1. Check Valve, Clear PVC, Sizes: 1/2 in. to 1 in., Socket, True Union [DISCONTINUED], Sale price: From $22.00

2. Ball Check Valve, Sizes: 1/2 in. to 4 in., Threaded or Socket, EPDM or FPM, PVC or CPVC, Sale price: From $23.00

3. Ball Valve, Sizes: 1/2 in. to 4 in., Threaded or Socket, EPDM or FPM, PVC or CPVC, Sale price: From $26.10

4. Spring Check Valve, Sizes: 1/2 in. to 4 in., Threaded or Soc…

Strategic Sourcing Conclusion and Outlook for valve pvc pipe

In navigating the competitive landscape of valve PVC pipe procurement, strategic sourcing emerges as a critical factor for success. By leveraging the corrosion resistance, lightweight nature, and versatility of PVC valves, international B2B buyers can enhance their operational efficiency across various applications, from industrial processes to agricultural systems. Understanding the diverse types of valves available—such as ball, check, and butterfly valves—enables businesses to select the right products tailored to their specific needs.

Moreover, maintaining a robust supplier network is essential to ensure quality and reliability in sourcing. International buyers should prioritize suppliers who offer comprehensive product ranges and flexible delivery options, particularly those that understand the unique challenges of markets in Africa, South America, the Middle East, and Europe.

Looking forward, the demand for high-quality, cost-effective PVC valve solutions will continue to rise. B2B buyers are encouraged to explore partnerships that not only meet their immediate needs but also align with long-term sustainability goals. Embrace the opportunity to innovate and optimize your supply chain by sourcing strategically—your business’s future success depends on it.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to valve pvc pipe

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.