A B2B Buyer’s Guide to Tungsten Carbide Vs Titanium Rings: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for tungsten carbide vs titanium rings

In the competitive landscape of jewelry manufacturing, sourcing high-quality tungsten carbide and titanium rings presents a unique challenge for B2B buyers. Understanding the nuances between these two popular materials is essential for making informed purchasing decisions that meet both customer expectations and market demands. This comprehensive guide delves into the critical aspects of tungsten carbide versus titanium rings, examining their properties, applications, and market trends.

We will explore the various types of rings available, the specific applications that each material best serves, and the factors to consider when vetting suppliers. Additionally, we will discuss cost implications and the value propositions of each material in different regional markets, particularly focusing on the needs of international buyers from Africa, South America, the Middle East, and Europe, including key players in Germany and Vietnam.

By equipping B2B buyers with actionable insights and a thorough understanding of tungsten carbide and titanium rings, this guide aims to empower businesses to make strategic procurement decisions. Whether you’re looking to enhance your product offerings or optimize your supply chain, navigating the complexities of these materials will ultimately lead to improved customer satisfaction and a stronger market position.

Understanding tungsten carbide vs titanium rings Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tungsten Carbide Rings | High density, scratch-resistant, and durable | Jewelry manufacturing, industrial use | Pros: Extremely durable, scratch-resistant; Cons: Brittle, can crack under impact. |

| Titanium Rings | Lightweight, corrosion-resistant, hypoallergenic | Fashion jewelry, medical applications | Pros: Lightweight, hypoallergenic; Cons: Less scratch-resistant than tungsten. |

| Black Titanium Rings | Enhanced aesthetic appeal, can be anodized for color | Fashion jewelry, corporate gifts | Pros: Unique look, customizable; Cons: May show wear over time. |

| Tungsten Carbide with Inlays | Combination of tungsten with other materials (wood, resin) | Custom jewelry, unique wedding bands | Pros: Aesthetic variety, unique designs; Cons: Inlays may be less durable. |

| Titanium with Zirconium | Offers unique color variations, strong yet lightweight | Specialty jewelry, fashion accessories | Pros: Unique aesthetic, lightweight; Cons: Color may fade over time. |

What Are the Characteristics of Tungsten Carbide Rings?

Tungsten carbide rings are renowned for their exceptional hardness and scratch resistance, making them ideal for heavy-duty use in various industrial applications. They are often used in jewelry manufacturing due to their ability to maintain a polished finish over time. However, their brittleness can lead to cracking if subjected to extreme force. B2B buyers should consider the intended use and potential for wear and tear when selecting tungsten carbide rings for their product lines.

How Do Titanium Rings Stand Out in the Market?

Titanium rings are celebrated for their lightweight nature and hypoallergenic properties, making them suitable for everyday wear, especially in fashion jewelry and medical applications. Their corrosion resistance ensures longevity, but they are not as scratch-resistant as tungsten carbide. B2B buyers should evaluate the balance between durability and comfort when sourcing titanium rings, particularly for customers with sensitive skin.

Why Are Black Titanium Rings Gaining Popularity?

Black titanium rings provide a modern aesthetic, often achieved through anodization, allowing for unique color variations. They are increasingly popular in the fashion jewelry sector and corporate gifting. While they offer a distinctive look, buyers should be mindful that the surface may wear over time, potentially affecting the ring’s appearance. This consideration is crucial for B2B buyers aiming to meet consumer expectations for quality and style.

What Are the Benefits of Tungsten Carbide Rings with Inlays?

Tungsten carbide rings with inlays offer a unique blend of durability and aesthetic appeal, combining tungsten with materials like wood or resin. This variation allows for personalized designs, making them attractive for custom jewelry and wedding bands. However, the inlays may not match the durability of tungsten, which is a key consideration for B2B buyers focusing on product longevity and customer satisfaction.

How Does Titanium with Zirconium Enhance Jewelry Options?

Titanium rings combined with zirconium provide a unique color palette and strong yet lightweight design. This combination is ideal for specialty jewelry and fashion accessories, appealing to consumers looking for distinctive pieces. B2B buyers should note that while the aesthetic appeal is high, there may be concerns regarding color retention over time, which could influence purchasing decisions based on customer preferences.

Key Industrial Applications of tungsten carbide vs titanium rings

| Industry/Sector | Specific Application of tungsten carbide vs titanium rings | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Engine components and fasteners | High strength-to-weight ratio reduces fuel costs | Compliance with industry standards, weight specifications |

| Oil & Gas | Drill bits and casing | Enhanced durability extends equipment lifespan | Resistance to corrosion, sourcing from certified suppliers |

| Medical Devices | Surgical instruments and implants | Biocompatibility ensures patient safety | Certification for medical use, hypoallergenic properties |

| Manufacturing | Tooling and machinery components | Increased productivity due to reduced wear | Precision manufacturing capabilities, quality assurance |

| Jewelry & Fashion | Custom rings and accessories | Unique designs attract diverse customer segments | Material sourcing, customization options, market trends |

How Are Tungsten Carbide and Titanium Rings Utilized in Aerospace Applications?

In the aerospace sector, tungsten carbide and titanium rings are integral to the manufacturing of engine components and fasteners. Their high strength-to-weight ratio significantly contributes to fuel efficiency, making them valuable in aircraft design. International buyers, particularly from regions like Europe and the Middle East, must ensure compliance with stringent aerospace regulations and standards to guarantee safety and performance. The lightweight nature of titanium, paired with the durability of tungsten carbide, addresses the industry’s need for reliable yet efficient materials.

What Role Do Tungsten Carbide and Titanium Rings Play in Oil and Gas?

In the oil and gas industry, tungsten carbide rings are commonly used in drill bits and casing due to their exceptional hardness and wear resistance. This durability is crucial in extreme drilling conditions, where equipment faces high pressure and abrasive materials. Buyers in Africa and South America should prioritize sourcing materials that resist corrosion and meet industry certifications to ensure longevity and reliability in challenging environments. The enhanced lifespan of tungsten carbide components can lead to significant cost savings in operations.

How Are Tungsten Carbide and Titanium Rings Applied in Medical Devices?

For medical devices, titanium rings are favored for surgical instruments and implants due to their biocompatibility and hypoallergenic properties. This ensures patient safety and minimizes the risk of allergic reactions. Suppliers must focus on sourcing titanium that meets medical-grade standards, which is particularly important for international buyers in regions like Europe and the Middle East. The use of tungsten carbide in tools also enhances their durability, providing medical professionals with reliable instruments that withstand rigorous use.

Illustrative image related to tungsten carbide vs titanium rings

In What Ways Are Tungsten Carbide and Titanium Rings Used in Manufacturing?

In manufacturing, tungsten carbide and titanium rings are employed in tooling and machinery components that require high durability and resistance to wear. The increased productivity resulting from reduced downtime due to equipment failure is a significant benefit for businesses. International buyers should consider sourcing from manufacturers that offer precision engineering capabilities and robust quality assurance processes. The ability to customize components for specific applications can further enhance operational efficiency.

How Are Tungsten Carbide and Titanium Rings Integrated into Jewelry and Fashion?

In the jewelry and fashion industry, tungsten carbide and titanium rings are popular for custom rings and accessories. Their unique designs and durability appeal to a diverse customer base, making them an attractive product line for retailers. Buyers must stay informed about market trends and consumer preferences, ensuring that they source materials that allow for customization and innovation in design. Understanding the sourcing dynamics in various regions, including Europe and South America, can help businesses capitalize on emerging fashion trends.

3 Common User Pain Points for ‘tungsten carbide vs titanium rings’ & Their Solutions

Scenario 1: Weight Concerns for Heavy-Duty Use

The Problem: When sourcing rings for clients in industries like construction or manufacturing, B2B buyers often face the challenge of balancing durability and comfort. Tungsten carbide rings, while highly scratch-resistant, can be significantly heavier than titanium rings. This weight can be uncomfortable for workers who wear rings daily, leading to potential complaints or returns. Buyers must consider the specific needs of their clientele and the environments in which these rings will be used.

The Solution: To address this issue, B2B buyers should conduct thorough market research to understand the preferences and needs of their target audience. When sourcing rings, consider offering a range of options that includes both tungsten carbide and titanium. For clients requiring heavy-duty performance, titanium rings offer a lighter alternative without sacrificing strength. Additionally, providing samples for clients to try can help them gauge comfort levels. Highlight the benefits of titanium’s corrosion resistance and hypoallergenic properties to appeal to clients who may have sensitivities or work in harsh conditions.

Scenario 2: Emergency Removal Challenges

The Problem: A common concern for B2B buyers is the safety of their customers, especially when it comes to emergency scenarios. Tungsten carbide rings, while durable, can present challenges in emergency situations where quick removal is necessary. If a person suffers an injury, tungsten rings can be difficult to remove without specialized tools, leading to potential delays in medical assistance. This raises significant concerns for buyers who want to ensure their products are safe for everyday wear.

The Solution: To mitigate this risk, B2B buyers should educate their customers on the differences in emergency removal between tungsten carbide and titanium rings. Buyers can provide detailed information on the benefits of titanium, which is easier to remove in emergencies and can typically be cut with standard tools. Offering a comprehensive guide on ring care and emergency procedures can also enhance customer confidence. Furthermore, consider collaborating with emergency services to create awareness of the risks associated with tungsten and the advantages of choosing titanium for safety-conscious clients.

Illustrative image related to tungsten carbide vs titanium rings

Scenario 3: Allergic Reactions and Skin Sensitivities

The Problem: B2B buyers often encounter clients with skin sensitivities or allergies when it comes to metals used in rings. Tungsten carbide rings may contain nickel, which can cause allergic reactions in some individuals. This issue can lead to dissatisfaction and returns, complicating the sales process. Buyers need to be aware of these sensitivities to ensure they are providing safe and suitable options for their customers.

The Solution: To address this concern, buyers should prioritize sourcing hypoallergenic materials like titanium, which is known for being safe for most skin types. Providing detailed specifications about the composition of the rings can help reassure customers about their safety. Additionally, consider offering educational resources on how to choose the right ring based on skin sensitivities. Hosting workshops or webinars about the benefits of hypoallergenic rings can further position the buyer as a knowledgeable resource in the market. By emphasizing the hypoallergenic properties of titanium and transparently communicating material compositions, buyers can build trust and enhance customer satisfaction.

Strategic Material Selection Guide for tungsten carbide vs titanium rings

What Are the Key Properties of Tungsten Carbide in Rings?

Tungsten carbide, an alloy of tungsten and carbon, is known for its exceptional hardness and scratch resistance, making it a popular choice for rings. It can withstand high temperatures and pressures, which is essential for durability in everyday wear. However, its brittleness is a significant drawback; while it is resistant to scratching, it can crack or shatter under impact. This characteristic limits its suitability for high-impact environments, where a more resilient material might be preferred.

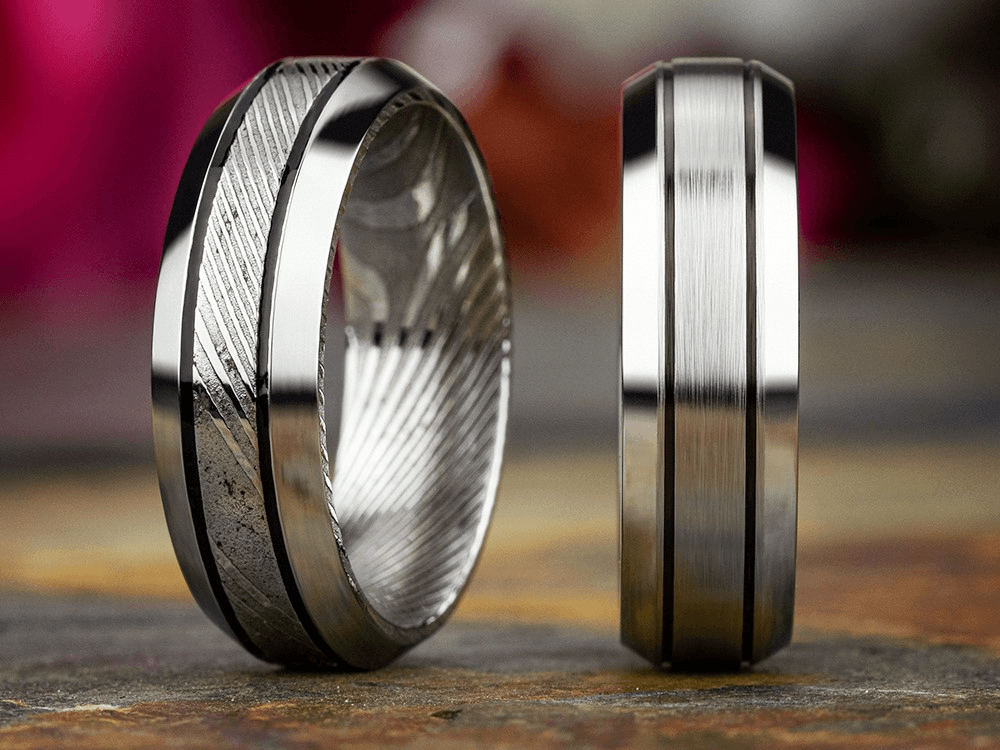

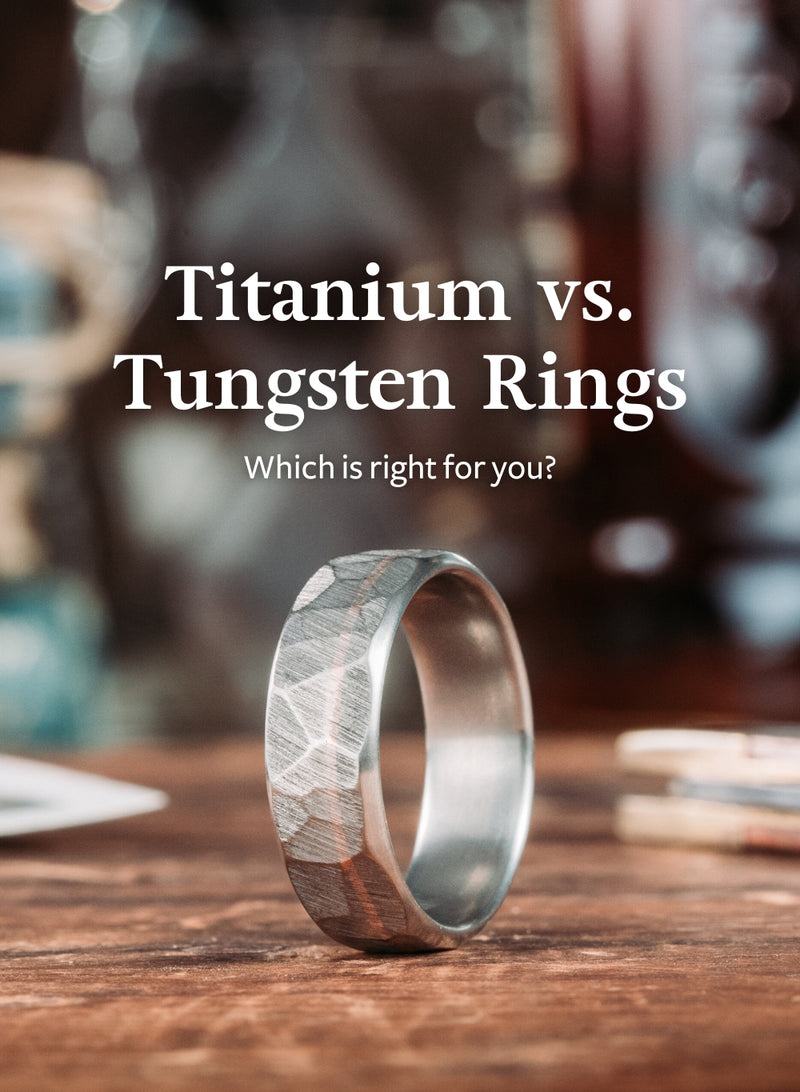

How Does Titanium Compare in Terms of Performance and Durability?

Titanium is renowned for its lightweight nature and corrosion resistance, making it an excellent choice for rings that need to endure daily wear and tear. Unlike tungsten carbide, titanium is not as hard, but it is significantly tougher and less prone to cracking. This makes titanium rings more suitable for individuals with active lifestyles or those working in demanding environments. Furthermore, titanium’s hypoallergenic properties make it ideal for sensitive skin, which is a crucial consideration for many consumers.

Illustrative image related to tungsten carbide vs titanium rings

What Are the Manufacturing Complexities and Cost Considerations?

When evaluating tungsten carbide and titanium for rings, the manufacturing process plays a critical role. Tungsten carbide requires specialized equipment for machining and polishing due to its hardness, which can lead to higher production costs. Conversely, titanium is easier to work with, allowing for more intricate designs and lower manufacturing costs. However, the price of titanium can vary significantly based on market conditions and purity levels, making it essential for B2B buyers to consider these factors when sourcing materials.

What Should International B2B Buyers Consider When Choosing Between These Materials?

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, compliance with local standards is paramount. Tungsten carbide and titanium must meet various international standards, such as ASTM, DIN, and JIS, to ensure quality and safety. Additionally, buyers should be aware of regional preferences; for instance, European markets may favor titanium due to its hypoallergenic nature, while other regions might prioritize the durability of tungsten carbide. Understanding these nuances can help buyers make informed decisions that align with market demands.

Summary Table of Material Properties and Considerations

| Material | Typical Use Case for tungsten carbide vs titanium rings | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Tungsten Carbide | Wedding bands, industrial applications | Exceptional scratch resistance | Brittle; prone to cracking under impact | High |

| Titanium | Wedding bands, fashion rings, medical implants | Lightweight and hypoallergenic | Less scratch-resistant than tungsten | Medium |

This analysis provides a comprehensive overview of tungsten carbide and titanium as materials for rings, highlighting their respective properties, advantages, and limitations. Understanding these factors will empower B2B buyers to make informed purchasing decisions that align with their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for tungsten carbide vs titanium rings

What Are the Key Stages in the Manufacturing Process for Tungsten Carbide and Titanium Rings?

The manufacturing processes for tungsten carbide and titanium rings involve several critical stages, each requiring precision and expertise to ensure the final product meets industry standards and customer expectations. Understanding these stages helps B2B buyers assess suppliers based on their capabilities and quality assurance practices.

Illustrative image related to tungsten carbide vs titanium rings

Material Preparation: What Materials Are Used in Tungsten Carbide and Titanium Rings?

The first stage involves sourcing high-quality raw materials. For tungsten carbide rings, the primary material is tungsten powder combined with carbon to create a tungsten carbide alloy. This alloy is known for its hardness and scratch resistance. Conversely, titanium rings are manufactured from titanium metal, which is lightweight, corrosion-resistant, and hypoallergenic.

Both materials undergo rigorous testing before they are used. Tungsten carbide powder is often screened for purity and particle size, while titanium is typically assessed for its grade, with Grade 5 titanium (Ti-6Al-4V) being one of the most common for jewelry applications.

How Are Tungsten Carbide and Titanium Rings Formed?

The forming stage varies significantly between tungsten carbide and titanium due to the distinct properties of each material.

-

Tungsten Carbide Forming: The tungsten carbide powder is mixed with a binding agent and then pressed into a mold. This process, known as cold isostatic pressing, allows for the creation of complex shapes. After molding, the rings undergo a sintering process where they are heated at high temperatures in a controlled atmosphere, allowing the particles to bond and solidify.

-

Titanium Forming: Titanium rings are typically manufactured through forging or machining processes. In forging, the titanium is heated and shaped under pressure, enhancing its strength. For precision designs, machining may be employed, where material is cut away from a solid block of titanium to achieve the desired dimensions.

What Finishing Techniques Are Used in the Production of Tungsten Carbide and Titanium Rings?

Finishing is crucial for both types of rings, as it impacts both aesthetic appeal and functionality.

-

Finishing Tungsten Carbide Rings: After sintering, tungsten carbide rings undergo polishing and surface treatments. Techniques such as diamond polishing are common, resulting in a high-shine finish that enhances the ring’s durability. Additional options include plating or coating for aesthetic variations.

-

Finishing Titanium Rings: Titanium can be anodized to produce a range of colors and finishes. This process not only enhances the visual appeal but also increases corrosion resistance. Other finishing techniques may include bead blasting or satin finishing, providing a matte look.

What Quality Assurance Practices Are Essential for Tungsten Carbide and Titanium Rings?

Quality assurance is a critical component in the manufacturing of tungsten carbide and titanium rings. It ensures that products meet international standards and are suitable for the global market.

Which International Standards Are Relevant for Quality Assurance?

B2B buyers should be aware of various international quality standards that manufacturers may comply with, including:

-

ISO 9001: This standard focuses on quality management systems and emphasizes continuous improvement and customer satisfaction. Compliance indicates that the manufacturer has a structured approach to quality control.

-

CE Marking: In Europe, products must meet certain safety and environmental protection requirements. CE marking signifies that the rings comply with relevant EU legislation.

-

API Standards: For buyers in specific industries, such as oil and gas, adherence to American Petroleum Institute (API) standards may be necessary, especially if the rings are used in industrial applications.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are vital at different stages of the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, periodic checks are conducted to monitor for defects and deviations from specifications. This step is crucial for both tungsten carbide and titanium rings, as it allows for immediate corrective actions.

-

Final Quality Control (FQC): After the rings are completed, a thorough inspection is performed to assess the final product’s quality. This may include visual inspections, dimensional checks, and surface quality assessments.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to ensure that their suppliers maintain rigorous quality control standards. Here are some actionable strategies:

What Methods Can Buyers Use to Assess Supplier Quality?

-

Audits: Conducting regular audits of the manufacturing facility can provide insights into the supplier’s processes and compliance with quality standards. Buyers should look for documented evidence of quality control measures in place.

-

Reports: Requesting quality assurance reports can help buyers understand the supplier’s track record. These reports should include data on defect rates, compliance with standards, and corrective actions taken for any issues.

-

Third-Party Inspections: Engaging third-party inspection services can offer an impartial assessment of the manufacturing processes and quality assurance practices. These inspectors can verify that the supplier adheres to relevant standards and provides high-quality products.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly those from Africa, South America, the Middle East, and Europe, must navigate specific challenges related to quality control:

Illustrative image related to tungsten carbide vs titanium rings

-

Cultural Differences: Understanding regional practices and expectations regarding quality can vary significantly. Buyers should be aware of these differences and establish clear communication with suppliers.

-

Regulatory Compliance: Different countries may have varying regulations regarding materials and manufacturing processes. Buyers should ensure that suppliers can comply with local laws and international standards.

-

Logistics and Supply Chain Considerations: Quality assurance does not end with manufacturing. Buyers must consider the entire supply chain, including transportation and storage conditions, which can impact product quality.

By understanding the manufacturing processes and quality assurance practices involved in the production of tungsten carbide and titanium rings, B2B buyers can make informed decisions, ensuring they partner with suppliers that prioritize quality and compliance. This knowledge is essential for establishing long-term relationships and maintaining high standards in their product offerings.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tungsten carbide vs titanium rings’

This guide serves as a practical checklist for B2B buyers looking to source tungsten carbide and titanium rings. The goal is to streamline the decision-making process by outlining essential steps to ensure you select the right product and supplier for your needs.

Step 1: Define Your Technical Specifications

Understanding the specific requirements for tungsten carbide and titanium rings is crucial. Consider factors such as weight, hardness, hypoallergenic properties, and intended use (e.g., wedding bands or industrial applications). This clarity will guide your sourcing efforts and ensure that you communicate effectively with suppliers.

Illustrative image related to tungsten carbide vs titanium rings

Step 2: Research Market Trends and Pricing

Stay informed about current market trends related to tungsten and titanium rings. Analyze pricing structures in different regions, especially focusing on Africa, South America, the Middle East, and Europe. Understanding the market landscape will help you negotiate better deals and identify competitive pricing.

Step 3: Evaluate Potential Suppliers

Before committing, vet suppliers thoroughly to ensure reliability and quality. Request company profiles, product samples, and references from buyers in your industry or region. It’s essential to assess their manufacturing capabilities and quality control processes to avoid future issues with product quality.

- Check Certifications: Verify any industry certifications or compliance with international standards. This adds an extra layer of assurance regarding product quality and supplier credibility.

Step 4: Assess Material Quality and Composition

Differentiate between the types of tungsten and titanium alloys available. Tungsten carbide is known for its scratch resistance but can be brittle, while titanium is lightweight and hypoallergenic. Request detailed material specifications from suppliers to ensure they meet your quality standards.

Step 5: Review Customization Options

Customization can set your offerings apart in the market. Inquire about the supplier’s ability to provide custom designs or finishes for tungsten carbide and titanium rings. This flexibility can cater to diverse customer preferences and enhance your brand’s appeal.

Step 6: Understand the Logistics and Shipping Process

Evaluate the supplier’s shipping options, lead times, and logistics capabilities. Understanding these aspects is critical for timely delivery and inventory management. Discuss potential shipping costs and customs regulations, especially if sourcing from international suppliers.

Step 7: Establish Clear Terms and Conditions

Negotiate clear terms of sale, including payment terms, warranty, and return policies. This step is vital to protect your investment and ensure a smooth transaction process. Having well-defined terms can prevent misunderstandings and foster a positive relationship with your supplier.

By following these steps, B2B buyers can make informed decisions when sourcing tungsten carbide and titanium rings, ensuring they select products that align with their business needs and customer expectations.

Comprehensive Cost and Pricing Analysis for tungsten carbide vs titanium rings Sourcing

When considering the sourcing of tungsten carbide versus titanium rings, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis delves into the various cost components, price influencers, and offers actionable tips for negotiating favorable terms.

Illustrative image related to tungsten carbide vs titanium rings

What Are the Key Cost Components in Tungsten Carbide and Titanium Rings?

Materials: The fundamental cost difference between tungsten carbide and titanium rings arises from the raw materials themselves. Tungsten carbide, an alloy of tungsten and carbon, tends to be less expensive than titanium, which is known for its lightweight and corrosion-resistant properties. However, the final cost also depends on market fluctuations in metal prices, which can vary significantly across regions.

Labor: Labor costs can differ based on the complexity of the manufacturing process. Titanium requires more specialized handling due to its properties, potentially leading to higher labor costs. Conversely, tungsten carbide rings are generally easier to produce, allowing for lower labor expenses.

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment. Tungsten carbide’s manufacturing process may involve more energy-intensive steps, which could elevate overhead costs.

Tooling and Quality Control (QC): Tooling costs are substantial, especially for custom designs. The precision required for both materials demands high-quality tooling, particularly for tungsten carbide, which is harder to work with. Additionally, QC processes must ensure that both types of rings meet industry standards, impacting overall costs.

Logistics: Shipping and handling costs can vary significantly based on the destination. For international buyers, understanding Incoterms is critical, as they dictate who bears the cost and risk during transportation.

Margin: Suppliers typically mark up the price to cover their operational costs and to achieve a profit. The margin can be influenced by the supplier’s location, brand reputation, and market demand.

What Price Influencers Should Buyers Consider?

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced per-unit costs. Buyers should negotiate MOQs that align with their sales forecasts to optimize pricing.

Specifications and Customization: Customized rings will naturally incur higher costs due to the additional labor and materials involved. Buyers should clearly define their specifications to avoid unexpected costs during production.

Illustrative image related to tungsten carbide vs titanium rings

Quality and Certifications: Rings that meet specific quality standards or certifications (e.g., ISO) may command higher prices. Buyers should assess whether the added cost aligns with their market needs.

Supplier Factors: The supplier’s experience, reliability, and location can significantly affect pricing. Engaging with reputable suppliers who have proven track records can mitigate risks and ensure product quality.

Incoterms: Understanding the implications of shipping terms is crucial for cost management. Terms like FOB (Free On Board) or CIF (Cost Insurance and Freight) can shift financial responsibility, influencing overall costs.

How Can Buyers Negotiate Effectively for Tungsten Carbide and Titanium Rings?

Leverage Total Cost of Ownership (TCO): When negotiating, consider not just the purchase price but the TCO, which includes maintenance, durability, and replacement costs. Emphasizing the long-term value can justify a higher upfront cost.

Explore Pricing Nuances for International Markets: Buyers in regions like Africa, South America, the Middle East, and Europe should be aware of local market conditions, tariffs, and import duties that can affect the final pricing. Conducting thorough market research can provide leverage during negotiations.

Build Strong Relationships: Establishing a good rapport with suppliers can lead to better pricing and terms. Long-term partnerships often yield more favorable conditions than one-off transactions.

Conclusion

In summary, B2B buyers must navigate a complex landscape of cost components and price influencers when sourcing tungsten carbide and titanium rings. By understanding these dynamics and employing effective negotiation strategies, buyers can achieve optimal pricing and ensure they secure high-quality products that meet their specific needs. While indicative prices can fluctuate, being informed and prepared is essential for successful sourcing in the global market.

Alternatives Analysis: Comparing tungsten carbide vs titanium rings With Other Solutions

Exploring Alternatives to Tungsten Carbide and Titanium Rings

In the realm of jewelry, particularly wedding bands, tungsten carbide and titanium rings are prominent choices due to their strength, durability, and aesthetic appeal. However, buyers should consider alternative materials and solutions that may better align with their specific needs and preferences. This analysis will explore two viable alternatives: stainless steel rings and precious metal rings, comparing them against tungsten carbide and titanium.

| Comparison Aspect | Tungsten Carbide Vs Titanium Rings | Stainless Steel Rings | Precious Metal Rings |

|---|---|---|---|

| Performance | Extremely scratch-resistant; tungsten is brittle, while titanium is more flexible and durable. | Good scratch resistance; less durable than tungsten but more flexible. | Highly malleable; can scratch easily but offers a classic look. |

| Cost | Moderate to high; tungsten is generally more affordable than titanium. | Low to moderate; very budget-friendly. | High; gold, platinum, and silver can be expensive. |

| Ease of Implementation | Requires professional sizing; emergency removal can be challenging, especially with tungsten. | Easy to size and remove; can be cut with standard tools. | Customization may require professional help; emergency removal varies. |

| Maintenance | Low maintenance; regular cleaning recommended to keep shine. | Low maintenance; easy to clean but may tarnish over time. | Higher maintenance; requires regular polishing to prevent tarnishing. |

| Best Use Case | Ideal for those seeking durability and scratch resistance; suitable for active lifestyles. | Best for budget-conscious buyers; suitable for everyday wear. | Perfect for traditionalists seeking luxury and timeless designs. |

What Are the Advantages and Disadvantages of Stainless Steel Rings?

Stainless steel rings serve as a practical alternative to tungsten carbide and titanium. They are lightweight, affordable, and offer good scratch resistance. Additionally, stainless steel is less brittle, making it a safer option for those who engage in physical activities. However, they may lack the premium feel of tungsten or titanium and can tarnish over time, requiring occasional maintenance to retain their luster.

How Do Precious Metal Rings Compare?

Precious metal rings, such as those made from gold, platinum, or silver, are timeless choices that appeal to traditionalists. They can be custom-designed to suit personal preferences and styles, offering a unique touch. However, precious metals are generally more expensive and can be prone to scratching and tarnishing, necessitating regular maintenance. For buyers seeking luxury and a classic aesthetic, precious metals remain a favored choice despite the higher cost.

Conclusion: How to Choose the Right Ring Material for Your Needs?

When selecting between tungsten carbide, titanium rings, and their alternatives, B2B buyers must consider several factors, including performance, cost, ease of maintenance, and specific use cases. Tungsten carbide and titanium offer exceptional durability and scratch resistance, making them suitable for active lifestyles. Meanwhile, stainless steel provides a budget-friendly option with reasonable durability, and precious metals cater to those desiring elegance and a classic aesthetic. Ultimately, the right choice depends on the buyer’s priorities, whether they lean towards durability, cost-effectiveness, or luxury.

Essential Technical Properties and Trade Terminology for tungsten carbide vs titanium rings

What Are the Key Technical Properties of Tungsten Carbide vs. Titanium Rings?

When evaluating tungsten carbide and titanium rings, understanding their technical specifications is essential for B2B buyers. Here are some critical properties to consider:

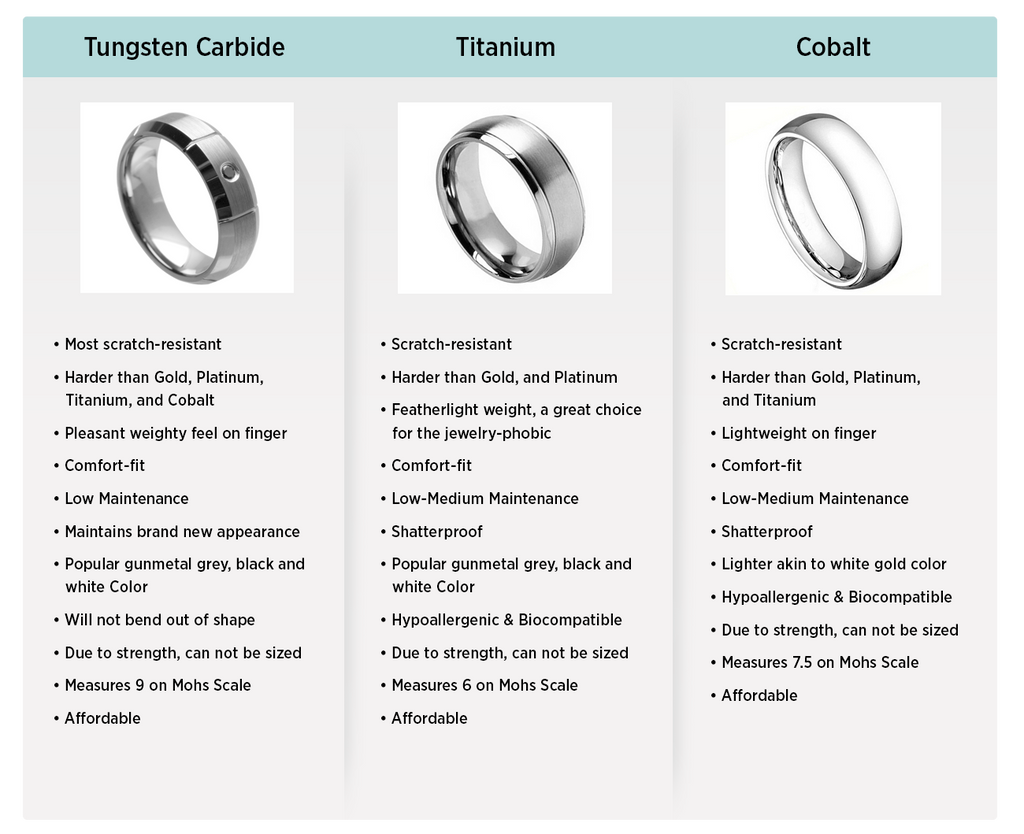

1. Material Composition

- Tungsten Carbide: A compound of tungsten and carbon, tungsten carbide is renowned for its hardness and scratch resistance. This makes it ideal for users requiring durability in their rings, such as those in manual labor sectors.

- Titanium: Composed primarily of titanium, this metal is lightweight, corrosion-resistant, and hypoallergenic. Its properties make it suitable for consumers with sensitive skin, enhancing its appeal in markets focused on comfort and wearability.

2. Hardness and Scratch Resistance

- Hardness Rating: Tungsten carbide ranks high on the Mohs scale (around 8.5), which signifies its extreme resistance to scratching. This property is particularly valuable in markets where aesthetic integrity over time is crucial.

- Titanium Hardness: While titanium is also strong, it is softer compared to tungsten carbide (around 6 on the Mohs scale). This means it is more susceptible to scratches, making it less ideal for individuals in demanding environments.

3. Weight and Density

- Weight Considerations: Tungsten carbide rings are significantly heavier than titanium rings. For buyers prioritizing comfort and ease of wear, titanium offers a lightweight alternative, appealing to a broader audience.

- Density: Tungsten carbide has a density of about 15.6 g/cm³, while titanium is approximately 4.5 g/cm³. This difference can influence consumer preferences based on how they perceive the feel of the ring.

4. Hypoallergenic Properties

- Titanium Hypoallergenic: Being hypoallergenic, titanium is less likely to cause skin reactions, making it a preferred choice in markets where sensitivity to materials is a concern.

- Nickel Content in Tungsten: Tungsten carbide may contain nickel, which can lead to allergic reactions in some individuals. This aspect is vital for B2B buyers focusing on health and safety standards.

What Are Common Trade Terms in the Tungsten Carbide and Titanium Ring Industry?

Familiarity with industry terminology is essential for effective communication in the B2B environment. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or products that may be marketed by another manufacturer. In the context of rings, an OEM might create tungsten carbide or titanium rings that are branded under different names, allowing for diverse market offerings.

2. MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity of a product that a supplier is willing to sell. Understanding this term is crucial for B2B buyers as it affects inventory management and pricing strategies.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific quantities of products. For buyers looking to procure tungsten carbide or titanium rings, issuing an RFQ can help in obtaining competitive pricing and assessing supplier capabilities.

4. Incoterms (International Commercial Terms)

These are standardized terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help B2B buyers manage shipping, insurance, and liability effectively, particularly in regions like Africa and South America.

5. Tolerance

Tolerance refers to the permissible limit or limits of variation in a physical dimension of a product. For tungsten carbide and titanium rings, understanding tolerances is crucial for ensuring quality and fit, especially in customized products.

6. Customization

Customization allows buyers to tailor products to specific needs, such as engraving or altering dimensions. This term is increasingly important in markets where personalized jewelry is in demand, reflecting a growing trend among consumers.

Illustrative image related to tungsten carbide vs titanium rings

By grasping these technical properties and industry terms, B2B buyers can make informed decisions that align with their business needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the tungsten carbide vs titanium rings Sector

What Are the Key Market Trends Impacting Tungsten Carbide and Titanium Rings?

The global market for tungsten carbide and titanium rings is influenced by several key drivers, including consumer preferences for durability, aesthetics, and customization options. The rise in online retail platforms has enabled international B2B buyers to access a wider range of products and suppliers, particularly from regions like Africa, South America, and Europe. Emerging technologies, such as 3D printing and advanced alloy formulations, are revolutionizing the production processes, allowing for more intricate designs and faster turnaround times. Furthermore, the growing trend towards personalization in wedding and fashion jewelry is pushing manufacturers to offer customizable options, thereby enhancing the appeal of both tungsten carbide and titanium rings.

From a sourcing perspective, buyers are increasingly looking for suppliers who can provide high-quality materials at competitive prices. The distinction between tungsten carbide and titanium rings in terms of weight, scratch resistance, and hypoallergenic properties is becoming a focal point for consumers, particularly in markets such as Germany and Vietnam, where quality and durability are highly valued. Additionally, the ongoing economic shifts in various regions, influenced by trade agreements and tariffs, are shaping purchasing decisions, prompting buyers to explore alternative sources and materials to mitigate costs.

How Does Sustainability and Ethical Sourcing Affect Tungsten Carbide and Titanium Rings?

Sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the tungsten carbide and titanium rings market. The environmental impact of mining operations for these metals has raised concerns about ecological degradation and the depletion of natural resources. As a result, buyers are increasingly prioritizing suppliers who can demonstrate responsible sourcing practices, such as utilizing recycled materials or adhering to stringent environmental regulations.

Furthermore, the market is witnessing a surge in demand for ‘green’ certifications, which assure buyers of the ethical sourcing of materials. Certifications like the Responsible Jewellery Council (RJC) and Fair Trade can enhance a supplier’s credibility and appeal to eco-conscious consumers. This trend is particularly relevant in Europe, where regulations around sustainability are becoming more stringent. By choosing suppliers with robust sustainability practices, B2B buyers not only contribute to environmental protection but also align their brands with consumer values, potentially increasing market share in a competitive landscape.

How Has the Tungsten Carbide and Titanium Rings Market Evolved?

The evolution of the tungsten carbide and titanium rings market can be traced back to the increasing consumer demand for durable and stylish alternatives to traditional precious metals. Initially, tungsten carbide was primarily used in industrial applications due to its hardness and scratch resistance. However, its unique properties soon caught the attention of jewelry designers, leading to its introduction in the consumer market.

Titanium, known for its lightweight and hypoallergenic characteristics, has been a favorite among consumers seeking comfort and durability in jewelry. As technological advancements in metallurgy and manufacturing processes emerged, both metals began to be recognized for their potential in the fashion and wedding band sectors. Today, the market is characterized by a blend of innovation and tradition, where consumers are not only looking for durability and style but also ethical considerations in their purchasing decisions. This evolution reflects a broader shift in consumer behavior towards more informed and responsible buying practices, making it essential for B2B buyers to stay abreast of these trends to remain competitive.

Frequently Asked Questions (FAQs) for B2B Buyers of tungsten carbide vs titanium rings

-

How do I determine the right metal for my customers’ needs: tungsten carbide or titanium?

To determine the best metal for your customers, consider their lifestyle and preferences. Tungsten carbide is known for its exceptional scratch resistance and durability, making it ideal for individuals in physically demanding jobs. However, it’s heavier and more prone to cracking under severe impact. Titanium, being lighter and hypoallergenic, is better suited for customers who prioritize comfort and have sensitive skin. Conducting surveys or interviews with your target market can provide insights into their preferences and help you tailor your offerings accordingly. -

What are the key differences in pricing between tungsten carbide and titanium rings?

Pricing varies based on the metal’s properties and market demand. Tungsten carbide rings tend to be more affordable due to the relative abundance of materials and simpler manufacturing processes. In contrast, titanium rings often come at a premium price because of their lightweight nature and hypoallergenic qualities, which appeal to a specific market segment. Always evaluate the cost of raw materials, labor, and production processes when setting prices, and ensure that your pricing strategy aligns with the perceived value by your customers. -

What customization options should I offer for tungsten carbide and titanium rings?

Customization is a significant selling point in the jewelry market. For tungsten carbide, consider offering options such as different finishes (polished, brushed, or matte) and inlays (wood, carbon fiber, or precious stones). For titanium, provide choices in color treatment, engraving, and even mixed materials (like titanium with zirconium). Offering a range of sizes and styles can cater to diverse customer preferences. Ensure that your production capabilities can meet customization demands efficiently to enhance customer satisfaction. -

What minimum order quantities (MOQs) should I set for tungsten carbide and titanium rings?

Setting MOQs depends on your production capacity and market demand. For tungsten carbide rings, a typical MOQ might range from 50 to 100 pieces, as the manufacturing process can be more cost-effective in larger batches. For titanium rings, due to the specialized techniques involved, MOQs might be higher, around 100 to 200 pieces. Always assess your supply chain’s capabilities and your target market’s purchasing behavior to determine the most viable MOQ that balances profitability with accessibility for your buyers. -

How can I vet suppliers of tungsten carbide and titanium rings for quality assurance?

To ensure you partner with reliable suppliers, start by checking their certifications and industry standards compliance (e.g., ISO certifications). Request samples to evaluate the quality of their products firsthand. Look for suppliers with a strong reputation in the market and positive reviews from previous clients. Establishing a long-term relationship through regular communication and site visits can also help maintain quality assurance. Additionally, consider engaging third-party quality inspectors to conduct audits before finalizing any contracts. -

What are the payment terms typically used in international trade for tungsten carbide and titanium rings?

Payment terms can vary significantly based on the supplier and the buyer’s negotiation power. Common terms include a 30% deposit upfront, with the remaining balance due upon completion of the order or before shipment. Some suppliers might offer letters of credit or PayPal for secure transactions. It’s essential to clarify payment methods, currency preferences, and any potential fees in advance to avoid disputes later. Building a trustworthy relationship with your suppliers can also facilitate more favorable payment terms over time. -

What logistics considerations should I keep in mind when importing tungsten carbide and titanium rings?

When importing these rings, consider shipping methods, customs regulations, and potential tariffs in the destination country. Evaluate whether air freight or sea freight is more economical based on your order size and urgency. Partnering with logistics companies experienced in jewelry imports can streamline the process. Additionally, ensure that all necessary documentation, such as invoices and certificates of origin, is prepared to avoid delays at customs. Understanding local regulations can also help mitigate risks associated with international trade. -

How do I handle customer returns and warranty claims for tungsten carbide and titanium rings?

Establish a clear return and warranty policy that outlines the conditions under which returns are accepted, such as defects in materials or craftsmanship. Typically, offering a warranty of 1-2 years for manufacturing defects can enhance customer trust. Make the return process straightforward, providing customers with easy-to-follow instructions and prepaid shipping labels when necessary. Regularly review feedback on your return policy to identify areas for improvement and ensure it meets customer expectations.

Top 9 Tungsten Carbide Vs Titanium Rings Manufacturers & Suppliers List

1. Wedding Bands – Material Comparison

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Tungsten, Titanium, and Steel are compared as wedding band materials. The discussion includes pros and cons of each type, general price ranges, and personal preferences for non-matching bands.

2. Rustic & Main – Tungsten vs. Titanium Rings

Domain: rusticandmain.com

Registered: 2014 (11 years)

Introduction: This company, Rustic & Main – Tungsten vs. Titanium Rings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Just Men’s Rings – Titanium & Tungsten Carbide Jewelry

Domain: justmensrings.com

Registered: 2006 (19 years)

Introduction: Titanium and tungsten carbide are popular materials for men’s jewelry. Key differences include:

1. Price: Both are affordable alternatives to precious metals, with prices varying by style and quality.

2. Composition: Titanium is alloyed with aluminum and vanadium, while tungsten carbide is a compound of tungsten mixed with nickel or cobalt.

3. Hardness: Tungsten carbide is harder (9 on Mohs sca…

4. The Gentleman’s Smith – Tungsten & Titanium Rings

Domain: thegentlemanssmith.com.au

Introduction: Tungsten and Titanium rings are popular choices for wedding rings. Tungsten (Tungsten Carbide) is known for being strong, affordable, fashionable, and durable, with a substantial feel and high scratch resistance. Titanium is lighter, slightly cheaper, and more hypoallergenic, but more prone to scratches. Tungsten is denser than Gold, while Titanium is about 1/4 the weight of Gold but 3 times stron…

5. Van Sweden Jewelers – Titanium and Tungsten Wedding Bands

Domain: vanswedenjewelers.com

Registered: 2009 (16 years)

Introduction: Titanium and tungsten are both popular materials for wedding bands. Titanium is lightweight, hypoallergenic, and highly durable, making it a great choice for those with sensitive skin. It can be easily shaped and comes in various finishes. Tungsten, on the other hand, is known for its incredible hardness and scratch resistance, making it an ideal option for those who want a ring that will maintain…

6. Larson Jewelers – Titanium and Tungsten Wedding Bands

Domain: larsonjewelers.com

Registered: 2007 (18 years)

Introduction: Titanium and tungsten wedding bands are popular for both men and women, available in various colors and styles with unique inlays and etchings. Titanium bands are highly customizable, and there are unisex options as well as feminine designs. An example is the Quasar tungsten wedding band featuring a blue-green opal inlay.

7. ModGents – Durable Alternative Rings

Domain: modgents.com

Registered: 2017 (8 years)

Introduction: Tungsten, titanium, and carbon fiber rings are durable, affordable alternatives to traditional precious metals. Tungsten rings are known for their hardness and scratch resistance, making them ideal for those who work with their hands, but they cannot be resized and may shatter under extreme impact. Titanium rings are lightweight, strong, and biocompatible, resisting scratches and impacts without s…

8. Happy Laulea – Titanium and Tungsten Rings

Domain: happylaulea.com

Registered: 2015 (10 years)

Introduction: Titanium and tungsten are both popular materials for rings, each with unique properties. Titanium is lightweight, hypoallergenic, and highly resistant to corrosion, making it a great choice for those with sensitive skin. It is also more affordable than tungsten. On the other hand, tungsten is known for its incredible hardness and scratch resistance, making it an excellent choice for durability. Ho…

9. Men’s Tungsten Online – Wedding Bands

Domain: menstungstenonline.com

Registered: 2010 (15 years)

Introduction: Titanium and tungsten carbide are popular alternatives to precious metals for wedding bands. Tungsten carbide rates a nine out of ten on the Mohs scale of mineral hardness, making it highly scratch-resistant, while titanium rates a six, offering more flexibility and resistance to cracking. Tungsten carbide is dense and heavy, giving it a substantial feel, whereas titanium is extremely light. Both …

Strategic Sourcing Conclusion and Outlook for tungsten carbide vs titanium rings

What Are the Key Takeaways for Sourcing Tungsten Carbide and Titanium Rings?

In the competitive landscape of wedding bands and everyday jewelry, understanding the distinct characteristics of tungsten carbide and titanium is essential for informed sourcing decisions. Titanium offers a lightweight, hypoallergenic option, ideal for consumers seeking comfort and style without compromising on durability. In contrast, tungsten carbide presents a heavier, more scratch-resistant alternative, appealing to those prioritizing toughness and affordability.

Illustrative image related to tungsten carbide vs titanium rings

The strategic sourcing of these materials not only influences product quality but also impacts customer satisfaction and brand loyalty. For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, leveraging these insights will enable you to align product offerings with market demands, ensuring a competitive edge.

How Can You Enhance Your Sourcing Strategy?

As you consider your sourcing strategies, prioritize partnerships with suppliers who understand the nuances of these materials and can provide customization options to meet diverse customer preferences. Embrace innovation in design and manufacturing processes to cater to evolving consumer tastes. By investing in high-quality materials and fostering strong supplier relationships, you can position your business for long-term success in the jewelry market. Take action today to refine your sourcing strategies and capitalize on the growing demand for tungsten carbide and titanium rings.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to tungsten carbide vs titanium rings