A B2B Buyer’s Guide to Tortilla Maker Machine: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for tortilla maker machine

In the ever-evolving landscape of global food production, sourcing a reliable tortilla maker machine presents a significant challenge for international B2B buyers. As the demand for authentic, fresh tortillas rises across Africa, South America, the Middle East, and Europe, businesses must navigate an array of options to find the perfect equipment that meets their specific needs. This comprehensive guide is designed to empower buyers by exploring the diverse types of tortilla machines available, their applications in various culinary settings, and the nuances of supplier vetting.

From small-scale artisanal producers to large industrial operations, understanding the intricacies of tortilla machine specifications, production capacities, and cost structures is crucial. Additionally, we will delve into the essential considerations for selecting a trustworthy supplier, ensuring that you receive high-quality, NSF-certified equipment that complies with international health and safety standards.

By providing actionable insights and expert advice, this guide aims to facilitate informed purchasing decisions, helping businesses not only to enhance their product offerings but also to create a lasting impression on their customers through the authentic flavors of freshly made tortillas. As you embark on this journey, let us help you streamline your sourcing process and unlock the full potential of your culinary ventures.

Understanding tortilla maker machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tabletop Corn Tortilla Maker | Compact design, NSF certified, easy to operate | Small restaurants, food trucks | Pros: Space-efficient, high-quality output. Cons: Limited production capacity. |

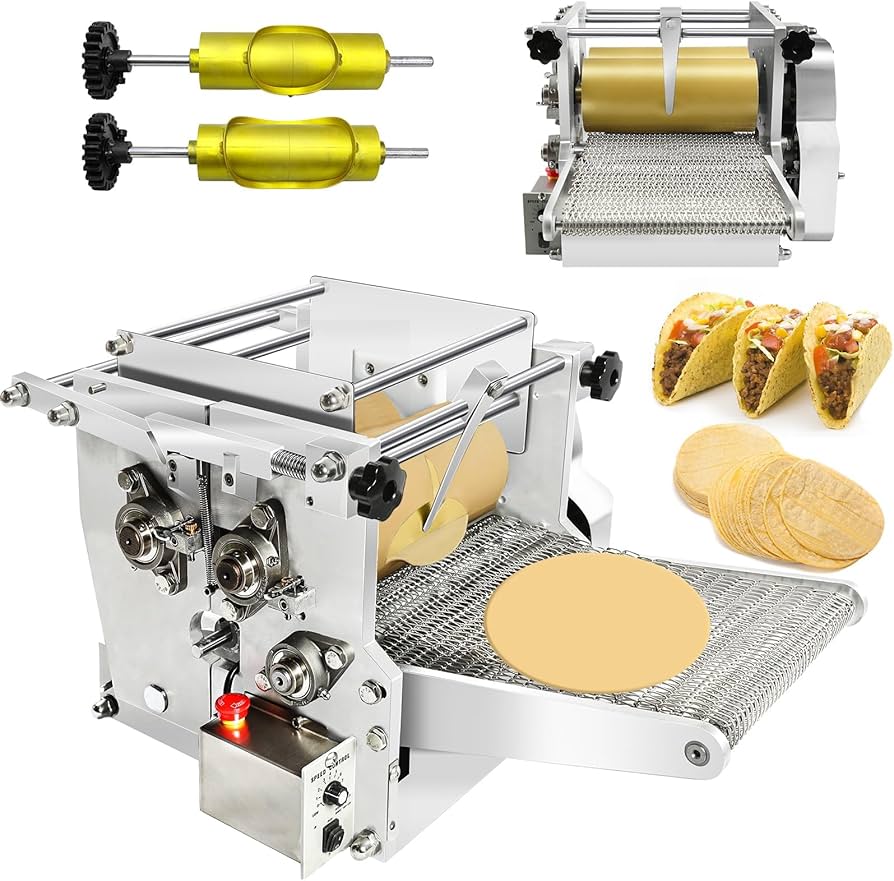

| Roller Tortilla Machine | Versatile, produces various shapes and sizes | Medium to large scale restaurants | Pros: Efficient for high-volume production. Cons: Higher initial investment. |

| Hopper Tortilla Machine | Traditional design, suitable for artisanal production | Small bakeries, local markets | Pros: Authentic taste, easy to use. Cons: Slower output compared to modern machines. |

| Multi-Purpose Tortilla Machine | Capable of making both corn and wheat tortillas | Diverse food businesses, catering | Pros: Versatile, cost-effective for varied menus. Cons: May require adjustments for different doughs. |

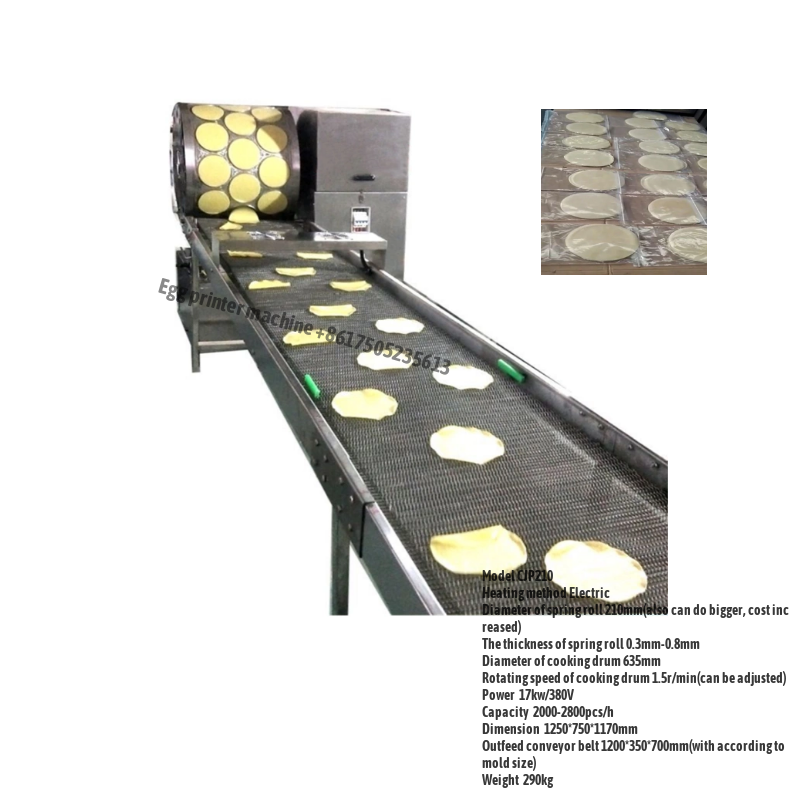

| Nixtamalization Equipment | Specialized for preparing corn for tortilla making | Factories, large-scale production | Pros: Essential for authentic tortillas, improves flavor. Cons: Requires additional space and investment. |

What Are the Characteristics of Tabletop Corn Tortilla Makers?

Tabletop corn tortilla makers are compact, NSF certified machines designed for small-scale operations. They are user-friendly and ideal for restaurants with limited kitchen space, such as food trucks or small dining establishments. These machines typically produce high-quality tortillas quickly, ensuring freshness and consistency. B2B buyers should consider the machine’s production capacity and ease of cleaning when making a purchase, as these factors will influence daily operations.

How Do Roller Tortilla Machines Enhance Production Efficiency?

Roller tortilla machines stand out for their versatility, allowing for the production of tortillas in various shapes and sizes, including chips and nachos. These machines are designed for medium to large-scale restaurants, where high-volume output is crucial during peak hours. B2B buyers should weigh the initial investment against the potential return on investment through increased sales and efficiency. Additionally, ease of maintenance is a key consideration for long-term use.

Why Choose Hopper Tortilla Machines for Artisanal Production?

Hopper tortilla machines are favored for their traditional design, making them suitable for artisanal production. They excel in creating authentic tortillas with a homemade taste, appealing to niche markets such as local bakeries and farmers’ markets. While these machines are easier to operate, buyers should be aware that they may have slower output compared to more advanced models. Understanding the target market and production needs is essential for B2B buyers considering this option.

What Are the Benefits of Multi-Purpose Tortilla Machines?

Multi-purpose tortilla machines are designed to produce both corn and wheat tortillas, making them highly versatile for diverse food businesses. They are particularly beneficial for catering services or restaurants with varied menus, allowing operators to adapt to customer preferences without investing in multiple machines. B2B buyers should consider the machine’s adaptability and ease of switching between dough types, as this can enhance operational flexibility.

How Do Nixtamalization Equipment Improve Tortilla Authenticity?

Nixtamalization equipment is essential for preparing corn in the traditional way, enhancing the flavor and texture of tortillas. This specialized machinery is geared towards factories and large-scale production facilities. While it requires a significant investment and additional space, the resulting product is of superior quality, appealing to businesses aiming for authenticity. B2B buyers should evaluate the potential market demand for high-quality tortillas to justify the investment in this equipment.

Key Industrial Applications of tortilla maker machine

| Industry/Sector | Specific Application of Tortilla Maker Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service | Restaurant Tortilla Production | Enhances menu authenticity and customer experience | NSF certification, machine size, and production capacity |

| Retail | Tortilla Manufacturing for Supermarkets | Increases product variety and freshness | Production volume, equipment versatility, and maintenance support |

| Catering | Event-Based Tortilla Supply | Provides fresh, customizable options for events | Portability, ease of use, and rapid production capabilities |

| Snack Food Manufacturing | Production of Tortilla Chips | Expands product line and meets consumer demand | Quality of output, scalability, and raw material compatibility |

| Bakery | Integration with Bread Products | Diversifies offerings and attracts new customers | Compatibility with existing equipment, size, and production speed |

How is the Tortilla Maker Machine Used in the Food Service Industry?

In the food service sector, particularly in restaurants, tortilla maker machines are essential for producing fresh tortillas on-site. This not only enhances the authenticity of Mexican dishes but also significantly improves the overall dining experience. By providing fresh tortillas, restaurants can differentiate themselves from competitors who rely on pre-packaged options. For international buyers, especially in regions like South America and the Middle East, sourcing NSF-certified machines ensures compliance with local health standards, while considering production capacity is crucial for handling peak dining hours.

What is the Role of Tortilla Maker Machines in Retail?

Retailers, particularly supermarkets and grocery stores, utilize tortilla maker machines to manufacture fresh tortillas for their customers. This application enables them to offer a wider variety of tortilla products, including different sizes and flavors, meeting the growing consumer demand for fresh, high-quality food items. When sourcing these machines, retailers should focus on production volume capabilities and the versatility of the equipment to accommodate various tortilla types, ensuring they can meet diverse customer preferences.

How Do Catering Services Benefit from Tortilla Maker Machines?

Catering companies leverage tortilla maker machines to provide fresh tortillas for events, allowing them to offer customizable food options that enhance their service. This capability is particularly valuable for catering to large gatherings where freshness and quality are paramount. Buyers in the catering industry should prioritize machines that are portable and easy to operate, enabling quick production during events. Additionally, the ability to produce tortillas in bulk can help caterers manage costs while delivering high-quality offerings.

How Do Snack Food Manufacturers Use Tortilla Maker Machines?

In snack food manufacturing, tortilla maker machines are crucial for producing tortilla chips and other snack products. These machines allow manufacturers to expand their product lines and meet increasing consumer demand for fresh and innovative snack options. When sourcing equipment for this application, businesses should evaluate the quality of the output, scalability for increased production, and compatibility with raw materials to ensure efficiency and product consistency.

What Benefits Can Bakeries Gain from Using Tortilla Maker Machines?

Bakeries can integrate tortilla maker machines into their operations to diversify their product offerings by including tortillas alongside traditional baked goods. This not only attracts new customers but also capitalizes on the growing trend of fusion cuisine. When sourcing these machines, bakeries should consider compatibility with existing equipment, the size of the machine to fit their production space, and the speed of production to meet customer demand without compromising quality.

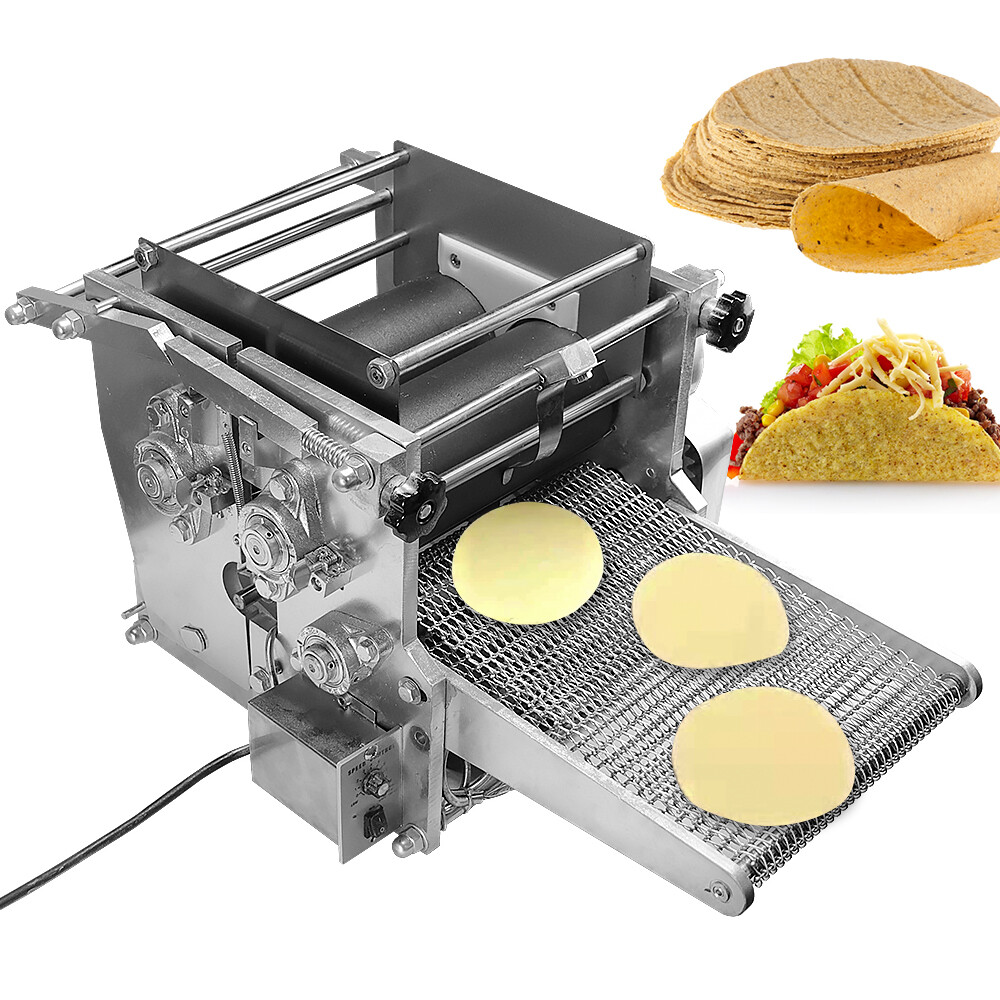

Illustrative image related to tortilla maker machine

3 Common User Pain Points for ‘tortilla maker machine’ & Their Solutions

Scenario 1: Inefficient Production Capacity During Peak Hours

The Problem: Many restaurants and food manufacturers face the challenge of meeting demand during peak hours. When customer traffic surges, traditional tortilla-making processes often fall short, leading to delays and unsatisfied customers. This not only affects service quality but can also lead to lost sales opportunities and a negative impact on brand reputation. For B2B buyers, this scenario underscores the need for a reliable tortilla maker machine that can handle high-volume production without compromising quality.

The Solution: To effectively address this challenge, businesses should consider investing in high-capacity tortilla maker machines designed for commercial use. Machines like the NSF-certified roller or hopper models are engineered to produce large quantities of tortillas efficiently. When sourcing these machines, it is crucial to assess their production speed, ease of operation, and maintenance requirements. Establishing partnerships with reputable suppliers that offer robust customer support and training can also enhance operational efficiency. Furthermore, integrating smart technology features, such as automatic temperature control and programmable settings, can optimize production and ensure consistency during high-demand periods.

Scenario 2: Quality Control Issues in Tortilla Production

The Problem: Maintaining consistent quality in tortilla production is a significant concern for B2B buyers. Variability in texture, size, and flavor can lead to customer dissatisfaction and inconsistency in menu offerings. This is particularly critical in regions where authentic flavors are paramount, such as Latin America and Europe. Buyers must navigate the complexities of selecting a machine that not only produces tortillas but does so with precision to meet their specific culinary standards.

The Solution: To combat quality control issues, businesses should invest in tortilla maker machines that offer customizable settings for thickness, temperature, and cooking time. When selecting a machine, it’s essential to look for models that allow for precise adjustments and have built-in quality assurance features. Additionally, implementing a quality monitoring system that includes regular testing of tortilla samples for consistency can help maintain high standards. Training staff on proper machine operation and maintenance can further minimize errors and enhance product quality. Collaborating with suppliers who provide comprehensive training and ongoing support can ensure that teams are well-equipped to handle the machinery effectively.

Scenario 3: High Operating Costs and Maintenance Challenges

The Problem: Operating a tortilla maker machine can involve significant costs related to energy consumption, maintenance, and repairs. For businesses, especially those in emerging markets, these expenses can be a substantial burden, affecting overall profitability. Many B2B buyers are concerned about the longevity of their investment and the potential for unexpected breakdowns that could disrupt their operations.

Illustrative image related to tortilla maker machine

The Solution: To mitigate high operating costs and maintenance challenges, B2B buyers should prioritize energy-efficient tortilla maker machines. Machines that utilize advanced technologies to reduce energy consumption can lead to significant savings over time. Additionally, investing in machines made from durable, high-quality materials can decrease the frequency of repairs and prolong the lifespan of the equipment. Buyers should also inquire about warranty options and the availability of spare parts from suppliers to ensure quick repairs when needed. Establishing a routine maintenance schedule and training staff on basic troubleshooting can further reduce downtime and enhance operational efficiency. By selecting the right equipment and implementing proactive maintenance strategies, businesses can optimize their operational costs and maintain smooth tortilla production.

Strategic Material Selection Guide for tortilla maker machine

What Are the Key Materials Used in Tortilla Maker Machines?

When selecting materials for tortilla maker machines, several factors come into play, including durability, cost, and compliance with international standards. The following analysis examines four common materials used in these machines: stainless steel, aluminum, cast iron, and food-grade plastic. Each material has unique properties that can significantly affect the machine’s performance and suitability for various applications.

How Does Stainless Steel Perform in Tortilla Maker Machines?

Stainless steel is widely regarded as the industry standard for food processing equipment, including tortilla makers. It offers excellent corrosion resistance, making it ideal for environments where moisture and food acids are present. The material can withstand high temperatures and pressures, ensuring consistent performance during tortilla production.

Pros: Stainless steel is durable and easy to clean, which is crucial for maintaining hygiene standards. It also complies with international food safety regulations, making it a preferred choice for B2B buyers in regions like Europe and the Middle East.

Cons: The primary drawback is its higher cost compared to other materials. Additionally, manufacturing stainless steel components can be more complex, which may lead to longer lead times.

Illustrative image related to tortilla maker machine

What Are the Advantages of Aluminum in Tortilla Maker Machines?

Aluminum is another popular material for tortilla machines, particularly in smaller or more portable models. It is lightweight and has good thermal conductivity, allowing for even heat distribution during cooking.

Pros: The lower cost of aluminum makes it an attractive option for startups or smaller businesses. Its lightweight nature also facilitates easier handling and transport.

Cons: However, aluminum is less durable than stainless steel and can be prone to warping under high heat. It also requires a protective coating to prevent corrosion, which can complicate maintenance and increase costs.

Illustrative image related to tortilla maker machine

How Does Cast Iron Compare as a Material for Tortilla Makers?

Cast iron is often used in traditional tortilla presses due to its excellent heat retention properties. It is particularly effective for producing tortillas that require a specific texture and flavor.

Pros: Cast iron is incredibly durable and can last for generations if properly maintained. It also provides a unique cooking surface that enhances the flavor of the tortillas.

Cons: The weight of cast iron can be a disadvantage, making it less suitable for portable applications. Additionally, it requires regular seasoning to maintain its non-stick properties, which can be a drawback for some users.

What Role Does Food-Grade Plastic Play in Tortilla Maker Machines?

Food-grade plastic is commonly used in components that require flexibility and ease of cleaning. It is often found in parts like handles, covers, and other non-structural elements.

Pros: The primary advantage of food-grade plastic is its cost-effectiveness and ease of manufacturing. It is also lightweight and can be molded into complex shapes, making it versatile for various applications.

Illustrative image related to tortilla maker machine

Cons: However, plastic is less durable compared to metals and may degrade over time, especially when exposed to high temperatures. This can limit its use in high-performance machines.

Summary Table of Material Selection for Tortilla Maker Machines

| Material | Typical Use Case for tortilla maker machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, cooking surfaces | Excellent durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Portable machines, small-scale production | Lightweight and cost-effective | Less durable, prone to warping | Medium |

| Cast Iron | Traditional presses and cooking surfaces | Exceptional heat retention and flavor enhancement | Heavy and requires maintenance | Medium |

| Food-Grade Plastic | Handles, covers, non-structural components | Cost-effective and easy to mold | Less durable, may degrade over time | Low |

This strategic material selection guide provides essential insights for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. Understanding the properties, advantages, and limitations of these materials can aid in making informed purchasing decisions that align with specific operational needs and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for tortilla maker machine

What Are the Main Stages of Manufacturing a Tortilla Maker Machine?

The manufacturing process of a tortilla maker machine involves several critical stages, ensuring that each component meets stringent quality standards. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

The process begins with selecting high-quality materials that comply with international standards. Common materials include stainless steel for durability and hygiene, as well as various plastics for components requiring flexibility. Suppliers often conduct materials testing to ensure they meet specifications for strength and resistance to corrosion. -

Forming

This stage involves the shaping of machine components through techniques such as casting, machining, and injection molding. Advanced CNC (Computer Numerical Control) machines are frequently employed to achieve precise dimensions and tolerances. For instance, rollers and plates are machined to ensure even heat distribution and consistent tortilla thickness. -

Assembly

After individual components are formed, they are assembled into the final product. This may involve both manual and automated processes, depending on the complexity of the machine. Skilled technicians ensure that each part fits together seamlessly, and that mechanical systems function properly. During assembly, alignment and calibration are critical to achieving optimal performance. -

Finishing

The final stage includes surface treatments such as polishing, coating, and assembly of electrical components. This not only enhances the aesthetic appeal but also improves the machine’s resistance to wear and tear. Quality checks are integrated into this stage, ensuring that every machine is operational before it leaves the factory.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is a fundamental aspect of the manufacturing process for tortilla maker machines. It ensures that the products meet both international and industry-specific standards, thereby reducing defects and enhancing customer satisfaction.

Illustrative image related to tortilla maker machine

-

International Standards Compliance

Many manufacturers adhere to ISO 9001, which outlines criteria for a quality management system. Compliance with ISO 9001 demonstrates a commitment to consistent quality and customer satisfaction. Additionally, machines may need to meet CE marking requirements for products sold in Europe, ensuring they comply with health, safety, and environmental protection standards. -

Industry-Specific Standards

For machines specifically used in food production, compliance with standards from organizations like the American National Standards Institute (ANSI) and the American Society for Quality (ASQ) is crucial. These standards guide manufacturers in maintaining hygiene and safety during the production process.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) involves several checkpoints throughout the manufacturing process, ensuring that potential issues are identified and addressed promptly.

-

Incoming Quality Control (IQC)

This initial checkpoint involves inspecting materials and components upon arrival at the manufacturing facility. Suppliers provide certificates of compliance, and materials undergo testing for quality and specifications. This step is critical for preventing defective components from entering the production line. -

In-Process Quality Control (IPQC)

Throughout the manufacturing process, IPQC checks are conducted at various stages. This includes monitoring machine settings during forming and assembly to ensure they meet specified tolerances. Regular audits of the production process help identify any deviations that could lead to defects. -

Final Quality Control (FQC)

Once the tortilla maker machine is fully assembled, a comprehensive final inspection is conducted. This includes testing for functionality, safety, and compliance with relevant standards. Common testing methods include performance tests, safety checks, and durability assessments, ensuring that the machine operates efficiently and safely.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential for ensuring product reliability.

-

Supplier Audits

Conducting supplier audits allows buyers to assess the manufacturing facility’s adherence to quality standards. During these audits, buyers can evaluate the processes, equipment, and personnel involved in production. This firsthand insight is invaluable in determining whether the supplier meets the required quality benchmarks. -

Quality Reports

Requesting detailed quality reports from suppliers can provide a clear picture of their QC practices. These reports should include data on defect rates, compliance with standards, and results from internal quality checks. Analyzing these reports helps buyers gauge the supplier’s commitment to quality. -

Third-Party Inspections

Engaging third-party inspection agencies can offer an unbiased evaluation of the manufacturing process. These agencies can verify compliance with international standards and assess the overall quality of the products. This additional layer of verification is particularly important for buyers unfamiliar with local suppliers.

What Are the Specific Quality Control Nuances for International B2B Buyers?

International buyers face unique challenges when assessing quality control in tortilla maker machine manufacturing. Understanding these nuances can help mitigate risks.

Illustrative image related to tortilla maker machine

-

Regional Standards Variability

Different regions may have varying standards for quality and safety. For instance, machines produced for the European market must comply with CE standards, while those for the U.S. market may need to meet ANSI requirements. Buyers should familiarize themselves with these standards to ensure compliance. -

Cultural Differences in Quality Perception

Cultural perceptions of quality can vary significantly between regions. What is considered acceptable in one market may not be in another. Thus, international buyers should establish clear quality expectations and communicate them effectively with suppliers. -

Logistics and Supply Chain Considerations

The logistics of international shipping can impact the quality of machines upon arrival. Buyers should account for potential delays, damages, or alterations in product conditions during transit. Establishing agreements with suppliers regarding packaging and handling can help minimize these risks.

By understanding the manufacturing processes and quality assurance measures in place for tortilla maker machines, B2B buyers can make informed decisions when selecting suppliers. Ensuring compliance with international standards and implementing rigorous quality control practices is key to fostering successful business relationships and delivering high-quality products to end-users.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tortilla maker machine’

When sourcing a tortilla maker machine, it’s essential for B2B buyers to follow a structured approach to ensure they select the right equipment for their business needs. This guide provides a comprehensive checklist that will help you navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Before exploring suppliers, clearly outline your technical requirements. Consider the type of tortillas you plan to produce (corn, wheat, or both), the desired production capacity, and the machine’s dimensions. Understanding these specifications ensures that you select a machine that meets your operational needs and fits within your production space.

Step 2: Research Supplier Reputation

Investigate potential suppliers to gauge their credibility in the industry. Look for suppliers with a proven track record, and verify their years of experience and customer feedback. A reputable supplier can provide insights and support throughout the purchasing process, ensuring a smoother transition into your operations.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This will help you understand their capabilities and reliability. Consider suppliers who offer after-sales support and training, as this can significantly impact your operational efficiency.

Step 4: Verify Certifications and Compliance

Ensure that the tortilla maker machine meets relevant health and safety standards, such as NSF certification. This is particularly important if you are exporting to regions with strict regulations, like North America or the EU. Compliance with these standards not only guarantees product safety but also enhances your business’s credibility.

Step 5: Assess Machine Features and Capabilities

Different machines come with varying features that can impact your production. Look for machines that offer flexibility in production volumes, ease of cleaning, and user-friendly controls. Additionally, consider whether the machine can handle different types of tortillas or if it requires additional equipment for specific production needs.

Step 6: Request Samples and Conduct Testing

Before finalizing your purchase, request samples of tortillas produced by the machine. This allows you to assess the quality and consistency of the product. If possible, arrange for a demonstration at the supplier’s facility to see the machine in action and evaluate its performance firsthand.

Illustrative image related to tortilla maker machine

Step 7: Negotiate Terms and Finalize Purchase

Once you’ve selected a supplier and machine, it’s time to negotiate terms. Discuss pricing, payment plans, delivery timelines, and warranty conditions. Ensure that all agreements are documented to avoid misunderstandings later. A well-negotiated contract protects your investment and sets clear expectations for both parties.

By following this checklist, B2B buyers can navigate the sourcing process for tortilla maker machines with confidence, ensuring they invest in equipment that meets their production needs and quality standards.

Comprehensive Cost and Pricing Analysis for tortilla maker machine Sourcing

What Are the Key Cost Components in Sourcing Tortilla Maker Machines?

When sourcing tortilla maker machines, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality stainless steel is preferred for hygiene and durability but comes at a higher price compared to less robust materials.

-

Labor: Labor costs can vary based on the location of manufacturing. Countries with lower labor costs can offer competitive pricing, but this may affect quality control.

-

Manufacturing Overhead: This includes utilities, rent, and indirect labor costs associated with production. Efficient manufacturing processes can help minimize these overheads, translating to better pricing for buyers.

-

Tooling: Initial tooling costs can be substantial, especially for custom machines. For standard models, these costs are amortized over larger production runs, reducing the price per unit.

-

Quality Control (QC): Investment in quality assurance processes ensures that machines meet required standards, potentially increasing costs but providing assurance of reliability and performance.

-

Logistics: Shipping costs, including freight and insurance, are critical, particularly for international buyers. Incoterms will determine which party bears these costs and risks.

-

Margin: Manufacturers typically add a margin to cover their operational costs and profit. This varies by supplier, market demand, and competitive landscape.

How Do Price Influencers Affect Tortilla Maker Machine Costs?

Several factors can influence the pricing of tortilla maker machines:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for bulk pricing, significantly reducing the unit cost. Understanding the MOQ can help buyers negotiate better deals.

-

Specifications and Customization: Custom machines tailored to specific production needs can lead to higher costs. Standard models are usually more cost-effective but may not fully meet unique operational requirements.

-

Materials Quality and Certifications: Machines built with NSF-certified materials often command higher prices due to their compliance with health and safety standards. Buyers should weigh the importance of certification against cost.

-

Supplier Factors: The reputation, experience, and location of the supplier can greatly influence pricing. Established suppliers may charge a premium for their reliability and service.

-

Incoterms: Understanding the shipping terms can affect the total cost. For instance, “CIF” (Cost, Insurance, Freight) includes shipping in the price, while “FOB” (Free on Board) places the shipping responsibility on the buyer.

What Buyer Tips Should International B2B Buyers Consider When Sourcing?

To maximize value when sourcing tortilla maker machines, consider the following tips:

-

Negotiate Wisely: Always be prepared to negotiate pricing based on your volume and commitment level. Suppliers may offer discounts for long-term contracts or larger orders.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, energy consumption, and potential downtime costs. A slightly higher upfront investment in a reliable machine can lead to significant savings over time.

-

Understand Pricing Nuances: Different regions may have unique pricing structures due to local demand, supply chain factors, and economic conditions. For buyers in Africa, South America, the Middle East, and Europe, conducting market research is essential to understand local pricing dynamics.

-

Request Multiple Quotes: Engage with multiple suppliers to compare pricing, terms, and service offerings. This can provide leverage in negotiations and ensure you secure the best deal.

-

Consider After-Sales Support: Evaluate the supplier’s support services, including installation, training, and maintenance. A supplier that offers comprehensive support can save costs in the long run by minimizing operational disruptions.

Conclusion

In conclusion, a thorough understanding of the cost components and price influencers involved in sourcing tortilla maker machines will empower B2B buyers to make informed decisions. By leveraging negotiation tactics and evaluating total cost of ownership, international buyers can optimize their investments and enhance their operational efficiency. Always be aware of indicative pricing, as costs can fluctuate based on market conditions and specific requirements.

Alternatives Analysis: Comparing tortilla maker machine With Other Solutions

Understanding Alternatives to Tortilla Maker Machines

When considering equipment for tortilla production, it’s essential to evaluate various options available in the market. Tortilla maker machines offer convenience and efficiency, but there are alternative solutions that may better suit specific business needs. This analysis will compare tortilla maker machines against traditional manual methods and other automated solutions, allowing B2B buyers to make informed decisions based on their unique requirements.

Illustrative image related to tortilla maker machine

| Comparison Aspect | Tortilla Maker Machine | Manual Tortilla Press | Commercial Flatbread Machine |

|---|---|---|---|

| Performance | High output, consistent quality | Low output, variable quality | Very high output, suitable for mass production |

| Cost | Moderate to high initial investment | Low initial cost | High initial investment, but cost-effective at scale |

| Ease of Implementation | Easy to set up, minimal training required | Requires skill and practice | Requires trained personnel for operation |

| Maintenance | Requires regular servicing and parts replacement | Minimal maintenance | High maintenance due to complexity |

| Best Use Case | Restaurants and food production facilities | Small operations, artisanal production | Large-scale production, bakeries |

Exploring the Alternatives

Manual Tortilla Press

Manual tortilla presses are simple devices that allow users to create tortillas by applying pressure on dough. They are typically made of cast iron or aluminum and are ideal for small-scale production.

Pros:

– Low initial investment makes them accessible for small businesses or startups.

– Simple to operate, requiring no electricity or advanced training.

– Offers an artisanal touch that can appeal to niche markets.

Cons:

– Limited output capacity, which can hinder larger operations during peak hours.

– The quality of tortillas may vary based on the user’s skill level and technique.

– Labor-intensive, requiring significant time and effort for large batches.

Commercial Flatbread Machine

Commercial flatbread machines are designed for high-volume production and can create a variety of flatbreads, including tortillas, pita, and naan. These machines are typically more advanced and can automate multiple steps in the production process.

Pros:

– Extremely high production capacity, suitable for large-scale operations.

– Consistent quality and uniformity in product size and thickness.

– Can be programmed for various types of flatbreads, offering versatility.

Cons:

– High initial purchase cost and potential additional costs for installation and training.

– Requires skilled personnel to operate and maintain.

– Maintenance can be complex and costly due to the machinery’s advanced technology.

Making the Right Choice for Your Business

When selecting the appropriate solution for tortilla production, B2B buyers should consider their specific operational needs, budget constraints, and production goals. Tortilla maker machines are ideal for businesses seeking efficiency and consistency, particularly in restaurants and food production facilities. On the other hand, manual presses might be more suitable for artisanal producers or small operations looking to create authentic products with a personal touch. Lastly, commercial flatbread machines are perfect for large-scale producers needing high output and versatility.

Ultimately, the choice will depend on evaluating these factors to ensure alignment with business objectives, production volume, and quality standards. By carefully considering these alternatives, businesses can select the most suitable equipment for their tortilla-making needs.

Essential Technical Properties and Trade Terminology for tortilla maker machine

What Are the Key Technical Properties of Tortilla Maker Machines?

When considering a tortilla maker machine for business operations, understanding its technical specifications is crucial. Here are some essential properties to evaluate:

Illustrative image related to tortilla maker machine

-

Material Grade

The material used in manufacturing tortilla machines significantly affects durability and hygiene. Stainless steel is preferred due to its resistance to corrosion and ease of cleaning, which is vital in food production settings. Machines made from high-grade materials ensure longevity and compliance with health standards, which can be a selling point in markets with strict regulations. -

Production Capacity

Measured in tortillas per hour, production capacity determines the machine’s efficiency during peak business hours. A higher capacity allows businesses to meet customer demand without delays, making it essential for restaurants and commercial kitchens. Understanding this metric helps buyers assess whether the machine aligns with their operational needs. -

Power Consumption

Evaluating the power requirements of a tortilla maker machine is critical for operational cost management. Machines with lower power consumption reduce electricity costs, making them more economical in the long run. Buyers should consider the machine’s energy efficiency rating to predict ongoing operational expenses. -

Size and Footprint

The physical dimensions of the machine dictate where it can be placed in a kitchen or production area. Compact machines that offer high output are especially valuable in smaller spaces. Understanding the footprint helps in planning the layout of commercial kitchens, ensuring there is adequate space for operations. -

Ease of Maintenance

Machines that are easy to clean and maintain reduce downtime and labor costs. Features such as removable parts and straightforward assembly can significantly improve operational efficiency. Buyers should inquire about maintenance requirements and whether the manufacturer provides support or resources for upkeep.

Which Trade Terminology Is Important for Understanding Tortilla Maker Machines?

Navigating the purchasing landscape for tortilla maker machines involves familiarizing oneself with industry-specific jargon. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of tortilla machines, buyers may engage directly with OEMs for custom solutions or specific features tailored to their business needs. -

MOQ (Minimum Order Quantity)

MOQ indicates the minimum number of units a supplier is willing to sell. Understanding the MOQ is vital for businesses planning their inventory and budget. It can affect cash flow, especially for smaller enterprises that may not need large quantities at once. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price offers from suppliers. This process is essential for obtaining competitive pricing and evaluating different manufacturers. Including specific requirements in an RFQ ensures that responses are relevant and facilitate informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms are standardized terms that define the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms helps businesses understand shipping costs, risks, and liability, which is particularly important when importing equipment from other countries. -

HACCP (Hazard Analysis Critical Control Point)

HACCP is a systematic approach to food safety that identifies and controls potential hazards in food production. For tortilla makers, compliance with HACCP standards is critical for ensuring the safety and quality of the tortillas produced. Buyers should verify that the machines meet these standards. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is crucial for inventory management and ensuring that businesses can meet their operational demands without interruptions.

By grasping these technical properties and industry terms, B2B buyers can make more informed decisions when investing in tortilla maker machines, ultimately enhancing their operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the tortilla maker machine Sector

What Are the Key Trends Influencing the Tortilla Maker Machine Market?

The tortilla maker machine sector is experiencing significant growth, driven by the rising demand for authentic and fresh food products, particularly in regions like Africa, South America, the Middle East, and Europe. The global shift towards healthier eating habits is prompting foodservice operators to incorporate fresh tortillas into their menus, which in turn fuels the demand for efficient tortilla-making equipment. Additionally, the rise of food delivery services and casual dining has created a need for machines that can produce high volumes of tortillas quickly and consistently.

Emerging technologies are also reshaping the market landscape. Automation and smart technology integration in tortilla machines are becoming increasingly popular, allowing businesses to optimize production processes and reduce labor costs. Features such as programmable settings and IoT capabilities are appealing to B2B buyers seeking to enhance operational efficiency. Furthermore, the trend towards customization in food products has led manufacturers to develop versatile machines capable of producing different types of tortillas (corn, wheat) and even related products like chips and tostadas.

International B2B buyers must consider sourcing from manufacturers that comply with regional health and safety standards, such as NSF certification in North America. This compliance not only ensures product quality but also mitigates risks associated with cross-border transactions. As the market evolves, staying informed about these trends will enable B2B buyers to make strategic sourcing decisions that align with market demands.

How Are Sustainability and Ethical Sourcing Shaping the Tortilla Maker Machine Sector?

Sustainability is becoming a critical focus for businesses across the tortilla maker machine sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, is prompting buyers to seek out machines made from sustainable materials and with energy-efficient designs. B2B buyers are increasingly prioritizing equipment that minimizes their carbon footprint and supports their own sustainability goals.

Ethical sourcing practices are equally important, as buyers look to partner with manufacturers who maintain transparent supply chains and uphold fair labor practices. Certifications such as ISO 14001 for environmental management and fair trade certifications can serve as indicators of a manufacturer’s commitment to sustainability and ethical practices. B2B buyers should ensure that their suppliers not only meet regulatory requirements but also align with their own corporate social responsibility (CSR) objectives.

Investing in ‘green’ certified machines not only enhances a company’s brand image but can also lead to cost savings in the long run through reduced energy consumption and waste management. By selecting suppliers who prioritize sustainability, B2B buyers can strengthen their market position while contributing positively to global environmental efforts.

Illustrative image related to tortilla maker machine

How Has the Tortilla Maker Machine Market Evolved Over Time?

The evolution of the tortilla maker machine market can be traced back to the traditional methods of tortilla production, which relied heavily on manual labor. Initially, small, artisanal operations dominated the market, utilizing basic hand-press machines. As demand for tortillas grew, especially in North America and Latin America, manufacturers began to innovate, leading to the development of more sophisticated machines capable of higher production volumes.

The introduction of automated tortilla machines revolutionized the industry, enabling restaurants and food manufacturers to streamline operations and meet increasing consumer demand. Over the past few decades, advancements in technology have further enhanced machine capabilities, integrating features such as programmable settings and hygienic design standards. Today, the market continues to evolve with an emphasis on sustainability, efficiency, and versatility, catering to a diverse range of culinary preferences and production needs.

Understanding this historical context helps B2B buyers appreciate the advancements in technology and manufacturing practices that can influence their purchasing decisions today.

Frequently Asked Questions (FAQs) for B2B Buyers of tortilla maker machine

-

How do I select the right tortilla maker machine for my business?

Choosing the right tortilla maker machine depends on several factors, including your production volume, the type of tortillas you wish to produce (corn, wheat, or both), and available space in your facility. Assess your business needs by considering the expected customer demand and the types of dishes you plan to offer. Additionally, look for machines that are easy to operate, maintain, and clean. Consulting with suppliers about their products and seeking recommendations from other restaurant owners can also provide valuable insights. -

What is the best tortilla maker machine for small to medium-sized businesses?

For small to medium-sized businesses, a tabletop or semi-automatic tortilla maker is often ideal. These machines are compact yet capable of producing a sufficient volume of tortillas without occupying too much space. Models such as the Ventura Flex Tabletop Tortilla Machine are specifically designed for restaurant environments, offering ease of use and high efficiency. Additionally, consider machines that offer versatility for both corn and wheat tortillas, allowing you to cater to a wider range of customer preferences. -

What customization options should I consider when purchasing a tortilla maker machine?

Customization options can significantly enhance the efficiency and functionality of your tortilla maker machine. Consider features such as adjustable thickness settings, different mold shapes for various tortilla sizes, and the ability to produce additional products like chips or tostadas. Additionally, inquire if suppliers offer branding options or color choices that align with your restaurant’s theme. Discussing your specific requirements with manufacturers can help you find a machine tailored to your business needs. -

What are the minimum order quantities (MOQ) for tortilla maker machines?

Minimum order quantities (MOQ) can vary significantly among suppliers. For smaller businesses, some manufacturers may allow a single unit purchase, especially for tabletop models. However, for larger industrial machines, MOQs might range from 5 to 10 units or more. It’s essential to communicate your needs clearly with potential suppliers and explore options that fit within your budget and production plans. Some suppliers may also offer flexible financing or leasing options if purchasing outright is not feasible. -

What payment terms should I expect when sourcing tortilla maker machines internationally?

Payment terms can vary by supplier and region but generally include options such as wire transfers, letters of credit, or payment upon delivery. Many suppliers may require a deposit upfront (typically 30-50%) with the balance due upon shipment or delivery. It’s crucial to clarify payment terms before finalizing any agreements to avoid misunderstandings. Additionally, inquire about any financing options available for larger purchases, as some manufacturers offer installment plans to ease upfront costs. -

How do I ensure quality assurance when purchasing a tortilla maker machine?

To ensure quality assurance, it’s essential to vet suppliers thoroughly. Look for manufacturers with certifications such as NSF, which indicates compliance with health and safety standards. Request samples or demos of the machines to assess performance and durability. Additionally, check customer reviews and testimonials to gauge satisfaction levels. Establishing a relationship with suppliers who provide warranties and after-sales support can also help ensure you receive a quality product. -

What are the logistics considerations for importing tortilla maker machines?

Logistics is a critical aspect of importing tortilla maker machines. Consider factors such as shipping costs, import duties, and customs clearance processes specific to your country. Collaborating with a freight forwarder can streamline the logistics process and ensure compliance with regulations. Additionally, confirm the estimated delivery times and packaging methods with suppliers to mitigate any potential damage during transit. Understanding these logistics will help you plan better and avoid delays in your operations. -

How do I find reliable suppliers for tortilla maker machines in international markets?

Finding reliable suppliers requires thorough research and due diligence. Start by attending industry trade shows and exhibitions where manufacturers showcase their products. Online marketplaces and B2B platforms can also connect you with international suppliers. Look for companies with a strong export history and positive customer feedback. Engaging in discussions with other businesses in your network can provide referrals and insights into trustworthy manufacturers. Always ask for references and conduct background checks before making a commitment.

Top 6 Tortilla Maker Machine Manufacturers & Suppliers List

1. Mexican Tortilla Machine – Authentic Corn & Wheat Equipment

Domain: mexicantortillamachine.com

Registered: 2015 (10 years)

Introduction: The Original Mexican Tortilla Machines offer a variety of products including Corn Tortilla Machines, Wheat Tortilla Machines, Hopper Machines, Roller Machines, and Restaurant & Countertop Equipment. They provide CE Certified and NSF Certified Tortilla Machines known for hygienic materials and compliance with health and safety standards. The machines are designed for both small and industrial produ…

2. Reddit – Tortilla Maker

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: machine to make tortillas, 100% mexican

3. WebstaurantStore – Commercial Tortilla Makers & Presses

Domain: webstaurantstore.com

Registered: 2003 (22 years)

Introduction: Commercial Tortilla Makers & Presses: Electric & Manual

Types of Products:

– Tortilla Presses

– Tortilla Grills

– Corn Grinders

– Corn Tortilla Machines

– Pizza Dough Presses

Power Types:

– Electric

– Manual

Operation Types:

– Air Automatic

– Electromechanical Automatic

– Hydraulic Automatic

– Manual

Press Dimensions:

– 12″ Round

– 14″ Round

– 15″ x 15″ Rectangular

– 16″ x 20″ Rectangular

– 18…

4. Super Tortilla Machines – Dough Mixer 110 lb

Domain: supertortillamachines.com

Registered: 2012 (13 years)

Introduction: SUPER TORTILLA MACHINES offers a variety of tortilla machines for both corn and wheat flour production, including:

1. **Dough Mixer 110 lb** – Price range: $3,790.00 – $5,290.00

2. **T5000 All Electric Flour Tortilla Machine with Automatic Grill** – Price range: $29,499.00 – $29,899.00

3. **C3000 DUPLEX PREMIER Corn Tortilla Machine** – Price range: $31,349.00 – $35,899.00

4. **Customized 16″ Pla…

5. Tortilla Machine – Home Use Guide

Domain: forum.toolsinaction.com

Registered: 2010 (15 years)

Introduction: User is looking for a tortilla machine for home use that is easy to use, durable, and can make both corn and flour tortillas. They are considering both electric and manual options but are unsure which is better for consistent results. They plan to make small batches for family meals and prefer a machine that is easy to clean. They are also curious about making blue corn tortillas.

6. Tortilla Masters Equipment – Tortilla Machine

Domain: chefsdeal.com

Registered: 2007 (18 years)

Introduction: {“category”:”Commercial Tortilla Grills, Makers & Presses”,”total_products”:56,”brands”:[“Antunes”,”BakeMax”,”DoughXpress”,”Dutchess Bakers”,”Jade”,”Proluxe”,”Somerset”,”Star”,”Tortilla Masters Equipment”,”Winco”],”price_range”:{“min_price”:0,”max_price”:50866},”product_types”:[“Tortilla Machine”,”Tortilla Dough Press”,”Tortilla Grill”],”power_types”:[“Electric”,”Gas”],”operation_types”:[“Air Auto…

Strategic Sourcing Conclusion and Outlook for tortilla maker machine

How Can Strategic Sourcing Enhance Your Tortilla Production?

In summary, strategic sourcing of tortilla maker machines is pivotal for international B2B buyers looking to enhance their culinary offerings and operational efficiency. By investing in high-quality, NSF-certified machines, businesses can ensure hygiene, consistency, and superior taste in their products, catering to the growing demand for authentic, fresh tortillas across global markets. The right machinery not only boosts productivity but also plays a crucial role in customer satisfaction and brand loyalty.

As you consider your sourcing options, remember that engaging with reputable suppliers who understand the nuances of local and international markets can significantly streamline your procurement process. Look for vendors that offer tailored solutions, including equipment combos and comprehensive support, to meet your specific production needs.

Looking ahead, the tortilla market is poised for growth, driven by increasing consumer preferences for fresh and authentic food experiences. Now is the time to act. Embrace this opportunity to elevate your offerings and secure your position in the market by investing in advanced tortilla making technology. Connect with suppliers today to explore how you can revolutionize your tortilla production and delight your customers.

Illustrative image related to tortilla maker machine

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.