A B2B Buyer’s Guide to Three Way Pneumatic Valve: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for three way pneumatic valve

In the increasingly interconnected global market, sourcing three-way pneumatic valves presents both significant opportunities and challenges for international B2B buyers. The complexity of selecting the right valve—whether for controlling the flow of liquids, gases, or for specialized applications in industries such as food processing, pharmaceuticals, or manufacturing—demands a thorough understanding of product specifications and supplier capabilities. This guide is designed to navigate the intricacies of the three-way pneumatic valve market, providing insights into various types, including stainless steel and automated options, along with their applications across different sectors.

Throughout this comprehensive resource, buyers will find essential information on how to effectively vet suppliers, assess product quality, and make cost-effective purchasing decisions. Key considerations such as compliance with international standards, durability under varying pressure conditions, and technological advancements like pneumatic actuation will be explored. By equipping B2B buyers from regions like Africa, South America, the Middle East, and Europe—including key markets like Germany and Brazil—with the tools and knowledge necessary to make informed decisions, this guide aims to streamline the sourcing process. Ultimately, understanding the nuances of three-way pneumatic valves can empower buyers to optimize their operations and enhance productivity while mitigating risks associated with procurement in a competitive landscape.

Understanding three way pneumatic valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 3-Way Normally Closed | Closes one port by default, allowing flow through the other two | Industrial automation, HVAC systems | Pros: Simple operation, reliable for on/off control. Cons: Limited to specific flow directions. |

| 3-Way Normally Open | Keeps one port open by default, allowing flow through the other two | Water treatment, chemical processing | Pros: Ideal for continuous flow applications. Cons: Less control over flow direction. |

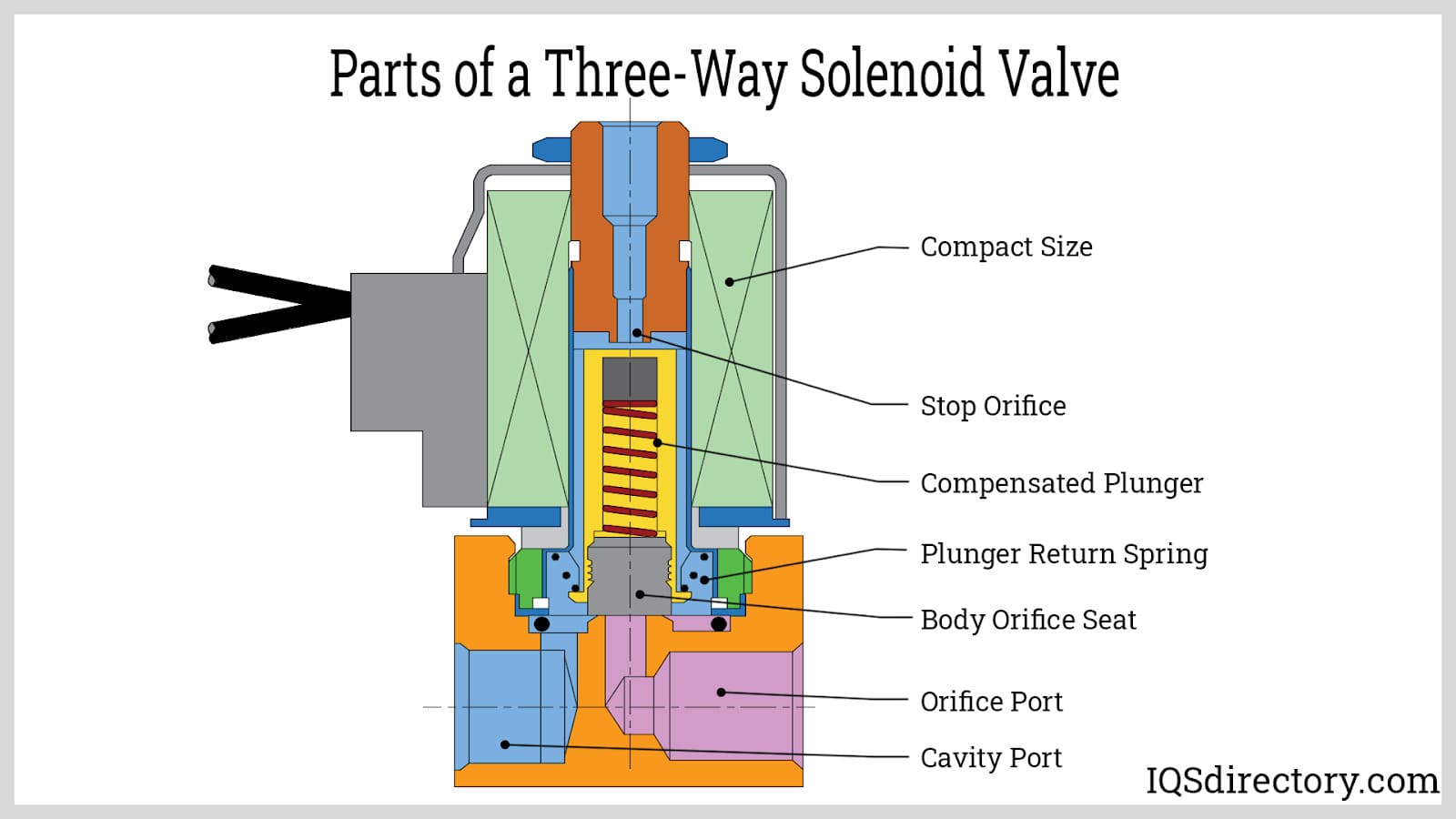

| 3-Way Solenoid Valve | Electrically actuated, can be normally open or closed | Robotics, packaging machinery | Pros: Fast response time, programmable. Cons: Requires electrical power, may be more complex. |

| 3-Way Pneumatic Actuated Ball Valve | Full port design for high flow capacity, available in various materials | Food processing, oil and gas | Pros: Durable, suitable for high pressures. Cons: Higher cost compared to other types. |

| 3-Way Push Button Valve | Manual operation via push button, typically stainless steel | Laboratory settings, small-scale automation | Pros: User-friendly, easy maintenance. Cons: Limited to manual operation, not suitable for automated systems. |

What are the Characteristics of 3-Way Normally Closed Valves?

3-way normally closed valves are designed to shut off one port while allowing flow through the other two. This configuration is particularly beneficial in industrial automation and HVAC systems where controlling the flow of air or fluids is essential. Buyers should consider the valve’s pressure rating and material compatibility with the fluid being handled, ensuring it meets operational requirements. The simplicity of operation and reliability for on/off control make this type a popular choice, although it is limited to specific flow directions.

How Do 3-Way Normally Open Valves Function?

3-way normally open valves maintain one port in an open position, facilitating continuous flow through the remaining ports. They are commonly used in applications like water treatment and chemical processing where uninterrupted flow is critical. When purchasing, buyers should evaluate the valve’s materials and ensure they can withstand the operational pressures and temperatures. While these valves are advantageous for continuous flow, they offer less control over flow direction, which may be a drawback in certain applications.

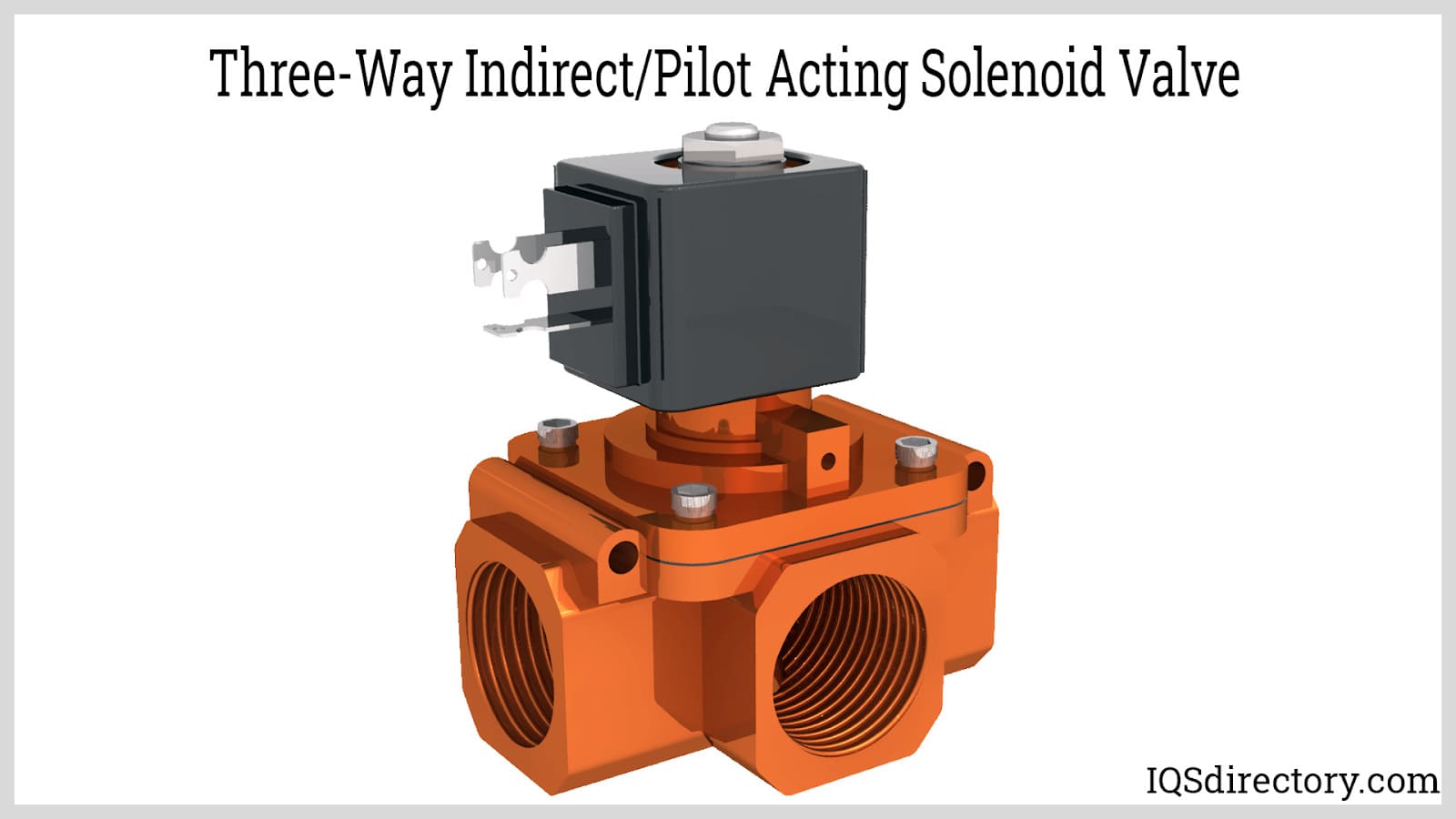

What Are the Advantages of 3-Way Solenoid Valves?

3-way solenoid valves are electrically actuated, providing a fast and responsive control mechanism. They can be configured as normally open or normally closed, making them versatile for various applications, including robotics and packaging machinery. B2B buyers should consider the electrical requirements and ensure that the valve integrates seamlessly with existing automation systems. The quick response time and programmability are significant advantages, though the need for an electrical power source can complicate installation and maintenance.

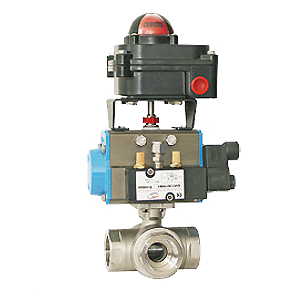

Why Choose 3-Way Pneumatic Actuated Ball Valves?

These valves feature a full port design, allowing for high flow capacity, and are available in a range of materials suited for applications like food processing and oil and gas. When selecting a pneumatic actuated ball valve, buyers should assess the pressure and temperature ratings, as well as compatibility with the media being transported. While they tend to be more expensive than other valve types, their durability and efficiency in high-pressure environments can justify the investment.

How Do 3-Way Push Button Valves Benefit Users?

3-way push button valves offer manual control through a simple push-button mechanism, often made from stainless steel for durability. They are ideal for laboratory settings and small-scale automation where user-friendliness is essential. Buyers should consider the valve’s maintenance needs and operational limits, as these valves are not suitable for automated systems. Their ease of use and low maintenance requirements are significant benefits, although they lack the automation capabilities of other valve types.

Key Industrial Applications of three way pneumatic valve

| Industry/Sector | Specific Application of three way pneumatic valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Mixing and distributing ingredients in production | Enhances efficiency and consistency in production | Ensure compliance with food safety standards and materials suitable for food processing. |

| Chemical Processing | Controlling flow in chemical reactions | Increases safety and precision in handling chemicals | Look for valves that can withstand corrosive substances and high pressures. |

| Oil and Gas | Flow direction control in pipeline operations | Improves operational reliability and safety | Consider valves with high-temperature ratings and robust materials for harsh environments. |

| Water Treatment | Regulating water flow in treatment plants | Optimizes treatment processes and reduces waste | Select valves designed for durability and resistance to waterborne contaminants. |

| HVAC Systems | Managing airflow in heating and cooling systems | Enhances energy efficiency and system performance | Focus on valves that support variable flow control and are compatible with existing systems. |

How Are Three Way Pneumatic Valves Used in the Food and Beverage Industry?

In the food and beverage sector, three way pneumatic valves are crucial for mixing and distributing ingredients during production. These valves ensure precise control over the flow of liquids, which is vital for maintaining product consistency and quality. International buyers in this sector must prioritize valves that comply with food safety regulations, ensuring that materials are suitable for food contact. Additionally, these valves should be easy to clean and maintain to prevent contamination.

Illustrative image related to three way pneumatic valve

What Role Do Three Way Pneumatic Valves Play in Chemical Processing?

In chemical processing, three way pneumatic valves are employed to control the flow of reactants and products in various chemical reactions. They enhance safety by allowing for quick shut-off and direction changes, minimizing the risk of spills or leaks. Buyers should focus on sourcing valves that can handle corrosive chemicals and high pressures, often requiring materials such as stainless steel or specialized plastics. Understanding the specific chemical properties and operational conditions is essential for selecting the right valve.

How Are Three Way Pneumatic Valves Essential in Oil and Gas Operations?

In the oil and gas industry, three way pneumatic valves are utilized for flow direction control in pipelines and processing facilities. These valves contribute to operational reliability by enabling efficient management of fluid transport and minimizing downtime. Buyers must consider valves with high-temperature ratings and robust materials that can withstand the harsh conditions typical in oil and gas environments. Ensuring that the valves meet industry standards for safety and performance is critical.

In What Ways Do Three Way Pneumatic Valves Optimize Water Treatment Processes?

Three way pneumatic valves are instrumental in regulating water flow in treatment plants, facilitating the separation and purification of water. Their precise control helps optimize treatment processes, reducing waste and improving efficiency. Buyers should look for valves designed to resist waterborne contaminants and ensure long-term durability, as these factors are crucial for maintaining effective water treatment operations. Compliance with environmental regulations is also a key consideration for sourcing.

How Do Three Way Pneumatic Valves Improve HVAC Systems?

In HVAC systems, three way pneumatic valves manage airflow, allowing for effective heating and cooling control. By enabling variable flow control, these valves enhance energy efficiency and overall system performance. Buyers should prioritize valves that are compatible with existing HVAC systems and are designed for easy integration and maintenance. Additionally, selecting valves that can adapt to different operational conditions will ensure optimal performance in varying climates and usage scenarios.

Illustrative image related to three way pneumatic valve

3 Common User Pain Points for ‘three way pneumatic valve’ & Their Solutions

Scenario 1: Difficulty in Choosing the Right Valve Configuration for Applications

The Problem: B2B buyers often face the challenge of selecting the appropriate three-way pneumatic valve configuration for specific applications, especially when dealing with different media such as gases, liquids, or slurries. With various configurations available—such as mixing, diverting, or isolating—making the wrong choice can lead to inefficient processes, increased downtime, or even equipment damage. This decision-making process can become overwhelming, particularly in industries like food processing, chemicals, or pharmaceuticals where the stakes are high.

The Solution: To effectively choose the right valve configuration, buyers should conduct a thorough analysis of their application requirements. This includes understanding the type of media being controlled, pressure and temperature conditions, and the specific flow path needed (mixing or diverting). It is advisable to collaborate with valve manufacturers who can provide application-specific insights and guidance. Moreover, utilizing simulation software can help visualize the flow dynamics and assess the performance of different valve configurations before making a purchase. Always request technical data sheets and case studies to validate the valve’s performance in similar applications.

Scenario 2: Maintenance Challenges Leading to Operational Downtime

The Problem: Maintenance issues with three-way pneumatic valves can lead to unplanned downtime, significantly impacting production schedules and operational efficiency. Common issues include valve leaks, sticking mechanisms, and wear and tear of seals, particularly in environments with high cycles or extreme temperatures. B2B buyers often struggle with identifying the root causes of these issues and may lack the resources or knowledge to perform effective maintenance.

The Solution: Implementing a proactive maintenance strategy is essential. Buyers should consider investing in high-quality valves designed for durability, such as those made from stainless steel with robust sealing technology. Regularly scheduled maintenance checks can help identify wear before it leads to failure. Additionally, training staff on valve operation and maintenance can enhance their ability to troubleshoot issues. Using condition monitoring tools can also provide real-time data on valve performance, allowing for timely interventions before problems escalate into costly downtime.

Scenario 3: Compatibility Issues with Existing Systems

The Problem: B2B buyers frequently encounter compatibility issues when integrating new three-way pneumatic valves into existing systems. This can arise from discrepancies in sizing, connection types, or actuator requirements, leading to delays in implementation and additional costs for modifications. The frustration is compounded when suppliers fail to provide comprehensive compatibility information, leaving buyers with uncertainties about whether the new components will function as intended.

Illustrative image related to three way pneumatic valve

The Solution: To mitigate compatibility issues, buyers should engage in thorough pre-purchase evaluations. This includes detailed assessments of existing system specifications, such as pipe diameters, flow rates, and actuator configurations. When sourcing three-way pneumatic valves, it’s crucial to work closely with manufacturers who can provide detailed compatibility information and support. Additionally, buyers should consider modular valve designs that offer flexibility in connection types and sizes. Documenting current system configurations and sharing these with suppliers can also ensure that the new valves will integrate seamlessly, reducing the risk of incompatibility and associated costs.

Strategic Material Selection Guide for three way pneumatic valve

What Materials Are Commonly Used for Three Way Pneumatic Valves?

When selecting materials for three-way pneumatic valves, it’s essential to consider their properties, advantages, and limitations to ensure optimal performance in various applications. Below, we analyze four common materials used in the manufacturing of these valves: stainless steel, brass, plastic, and aluminum.

How Does Stainless Steel Perform in Three Way Pneumatic Valves?

Stainless steel is a popular choice for three-way pneumatic valves due to its excellent corrosion resistance and high strength. It typically has a temperature rating of up to 350°F and can handle pressures up to ANSI Class 150. The durability of stainless steel makes it suitable for demanding environments, including food processing and chemical applications.

Pros: Stainless steel offers high durability and resistance to corrosion, making it ideal for harsh environments. It also has a polished finish that can be beneficial for sanitary applications.

Illustrative image related to three way pneumatic valve

Cons: The primary drawback is its cost, which is generally higher than other materials. Manufacturing complexity can also be an issue, as stainless steel may require specialized machining.

Impact on Application: Stainless steel’s compatibility with a wide range of media, including corrosive substances, makes it versatile for various industries.

Considerations for International Buyers: Buyers from regions like Europe may require compliance with standards such as DIN or ASTM, which often mandate the use of specific grades of stainless steel for certain applications.

What Are the Benefits of Using Brass for Three Way Pneumatic Valves?

Brass is another commonly used material, especially in applications involving water and gas. It has a good temperature rating, typically around 250°F, and can handle moderate pressure.

Illustrative image related to three way pneumatic valve

Pros: Brass is relatively inexpensive and easy to machine, making it a cost-effective option for many applications. Its good corrosion resistance against non-corrosive media is also a significant advantage.

Cons: Brass is less durable than stainless steel and may not be suitable for high-pressure or corrosive environments. It can also be susceptible to dezincification, which can compromise its integrity over time.

Impact on Application: Brass is ideal for applications involving water and air but may not be suitable for aggressive chemicals.

Considerations for International Buyers: Buyers should ensure that the brass used complies with local regulations regarding lead content, especially in drinking water applications.

How Does Plastic Compare in Three Way Pneumatic Valve Applications?

Plastic valves, often made from materials like PVC or polypropylene, are lightweight and resistant to corrosion. They can handle temperatures up to 180°F and are suitable for low-pressure applications.

Pros: The lightweight nature of plastic makes installation easier, and its corrosion resistance is excellent for applications involving aggressive chemicals. Additionally, plastic valves are generally less expensive than metal alternatives.

Cons: The primary limitation is their lower temperature and pressure ratings, which restrict their use in high-demand applications. They are also less durable than metal options.

Impact on Application: Plastic valves are ideal for chemical processing and water treatment applications but may not be suitable for high-pressure systems.

Considerations for International Buyers: Buyers should look for compliance with international standards, such as ASTM for plastic materials, to ensure quality and safety.

What Advantages Does Aluminum Offer for Three Way Pneumatic Valves?

Aluminum is a lightweight alternative that offers good corrosion resistance and strength. It typically has a temperature rating of around 250°F and can handle moderate pressures.

Illustrative image related to three way pneumatic valve

Pros: Aluminum is lightweight, making it easier to handle and install. It also offers good corrosion resistance and is generally more affordable than stainless steel.

Cons: While aluminum is durable, it may not be as strong as stainless steel and can be susceptible to corrosion in certain environments, particularly when exposed to saltwater.

Impact on Application: Aluminum valves are suitable for air and gas applications but may not be ideal for corrosive liquids.

Considerations for International Buyers: Buyers should ensure that aluminum valves meet relevant standards, such as JIS or ASTM, particularly for applications in industries like automotive or aerospace.

Summary Table of Material Selection for Three Way Pneumatic Valves

| Material | Typical Use Case for three way pneumatic valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, chemical applications | High durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Brass | Water and gas applications | Cost-effective and easy to machine | Less durable and susceptible to dezincification | Medium |

| Plastic | Chemical processing, water treatment | Lightweight and corrosion resistant | Lower temperature and pressure ratings | Low |

| Aluminum | Air and gas applications | Lightweight and affordable | Less strength and corrosion susceptibility | Medium |

This guide provides a comprehensive overview of the materials commonly used in three-way pneumatic valves, enabling B2B buyers to make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for three way pneumatic valve

What Are the Key Manufacturing Processes for Three-Way Pneumatic Valves?

The manufacturing of three-way pneumatic valves is a complex endeavor that involves multiple stages, each crucial for ensuring the final product meets the rigorous demands of various industries. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Three-Way Pneumatic Valves?

The first step in the manufacturing process is material preparation. High-quality materials such as stainless steel, brass, or plastic are selected based on the intended application of the valve. The chosen materials undergo rigorous testing for mechanical properties, corrosion resistance, and thermal stability. This ensures that the components can withstand the pressures and temperatures they will face in operation.

Once the materials are confirmed, they are processed into appropriate shapes and sizes. This may involve cutting, machining, or forging, depending on the specific requirements of the valve design. Precision is key in this stage to ensure that all parts fit together seamlessly during assembly.

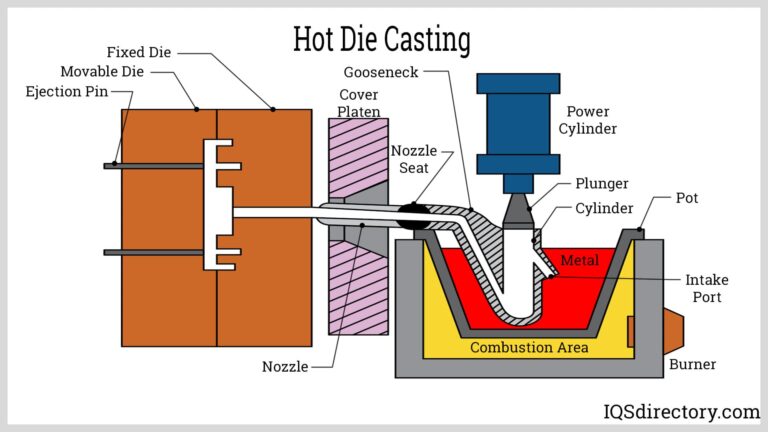

What Techniques Are Used in Forming Three-Way Pneumatic Valves?

The forming stage is where the raw materials are shaped into the components that will make up the valve. Techniques such as CNC machining, casting, or injection molding are commonly employed. CNC machining provides high precision and allows for complex geometries, which is critical for ensuring optimal flow characteristics in the valve.

For larger-scale production, casting or injection molding may be favored due to cost efficiency and speed. The choice of technique often depends on the valve’s size, design complexity, and the volume of production required. Each technique must adhere to strict tolerances to ensure that the valve operates correctly and efficiently.

How Are Three-Way Pneumatic Valves Assembled?

Assembly is a critical phase where all the manufactured components come together. During this process, individual parts such as the body, actuator, and seals are carefully fitted. Automated assembly lines are often used to improve efficiency and reduce human error. Quality checks are integrated into the assembly line, where each component is inspected for defects before being combined with others.

Additionally, the assembly process often includes the installation of pneumatic actuators, which can be spring-return or double-acting, depending on the valve’s design. Proper alignment and installation are crucial to ensure that the valve operates smoothly and reliably under pressure.

What Finishing Processes Are Essential for Three-Way Pneumatic Valves?

Finishing processes enhance the durability and aesthetic appeal of the valve. Common finishing techniques include polishing, anodizing, or applying protective coatings. Polishing ensures a smooth surface finish, which is vital for minimizing friction and wear during operation. Anodizing, particularly for aluminum components, increases corrosion resistance and extends the lifespan of the valve.

Illustrative image related to three way pneumatic valve

After finishing, the valves undergo additional quality checks to ensure that the surface treatments meet the specified requirements. This stage is critical for applications in corrosive environments, such as chemical processing or food production.

What Quality Assurance Measures Are Implemented in Three-Way Pneumatic Valve Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that each valve meets international standards and customer expectations. Various international and industry-specific standards guide this process.

Which International Standards Are Relevant for Quality Assurance?

ISO 9001 is a widely recognized standard for quality management systems, ensuring that manufacturers maintain consistent quality throughout their processes. Compliance with ISO 9001 demonstrates a commitment to quality and customer satisfaction. Other relevant standards may include CE marking for compliance with European safety regulations and API standards for valves used in the oil and gas industry.

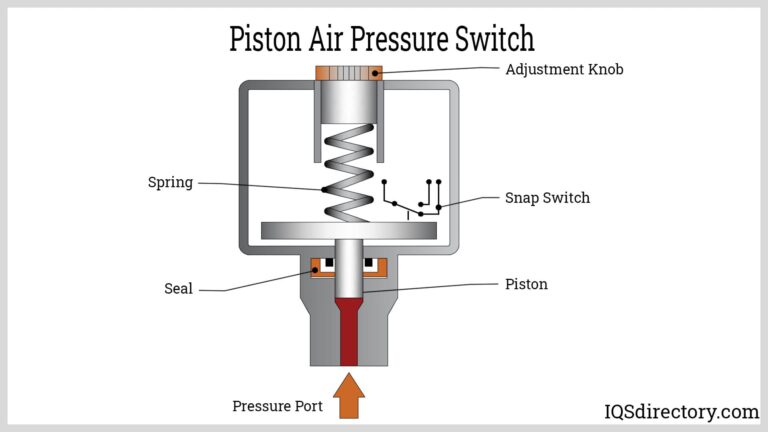

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch defects early. These checkpoints typically include:

Illustrative image related to three way pneumatic valve

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials for quality and compliance with specifications before they enter the production process.

-

In-Process Quality Control (IPQC): During manufacturing, various tests and inspections are conducted to ensure that components meet the required tolerances and specifications. This includes checks on dimensions, material properties, and assembly accuracy.

-

Final Quality Control (FQC): The final inspection occurs after the valves are fully assembled. This includes functional testing, pressure testing, and leak testing to ensure that each valve operates as intended and meets the necessary safety standards.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control processes of suppliers:

-

Supplier Audits: Conducting on-site audits can provide invaluable insights into a supplier’s manufacturing processes and quality assurance practices. This allows buyers to assess compliance with relevant standards and identify potential risks.

-

Quality Assurance Reports: Requesting detailed quality assurance reports can help buyers understand a supplier’s testing methodologies and results. These reports should include information on batch testing, failure rates, and corrective actions taken.

-

Third-Party Inspections: Engaging independent third-party inspection services can offer an unbiased evaluation of a supplier’s quality control measures. These inspections can be particularly beneficial for international buyers who may not have the capacity for on-site audits.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is crucial. Different regions may have varying standards and regulations that affect the importation and use of pneumatic valves.

For instance, European buyers often prioritize CE marking to ensure compliance with EU regulations, while buyers in the Middle East may focus on local standards that pertain to specific industries. Understanding these differences can help buyers make informed decisions and avoid potential compliance issues.

Moreover, establishing a strong relationship with suppliers who have a proven track record of quality assurance can significantly enhance the reliability and performance of the valves procured. Engaging in transparent communication about quality expectations and certifications can lead to better alignment and satisfaction for both parties.

Conclusion

The manufacturing processes and quality assurance measures for three-way pneumatic valves are integral to ensuring that these critical components meet industry standards and customer expectations. By understanding these processes, international B2B buyers can make informed purchasing decisions, ensuring they select suppliers that prioritize quality and reliability.

Illustrative image related to three way pneumatic valve

Practical Sourcing Guide: A Step-by-Step Checklist for ‘three way pneumatic valve’

Introduction

This practical sourcing guide is designed for B2B buyers seeking to procure three-way pneumatic valves. With applications spanning various industries—from manufacturing to food processing—selecting the right valve is critical for operational efficiency and reliability. This checklist will help you navigate the procurement process effectively, ensuring that you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly define your technical specifications. Consider factors such as the valve type (e.g., normally closed, normally open), size, pressure ratings, and materials (like stainless steel for corrosion resistance). This clarity will streamline discussions with suppliers and prevent misunderstandings that could lead to costly errors.

Step 2: Assess Application Requirements

Evaluate the specific application requirements for the pneumatic valve. Identify the medium (air, water, gas, etc.) and its properties (temperature, viscosity, etc.) that the valve will handle. Understanding these requirements will help you select a valve that performs optimally under your operational conditions and enhances system efficiency.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure reliability and quality. Request company profiles, product certifications, and references from businesses in similar industries. It’s vital to assess their experience and reputation, as this can significantly influence the performance and longevity of your pneumatic valves.

Step 4: Verify Compliance and Certifications

Ensure that the suppliers adhere to relevant industry standards and regulations. Look for certifications like ISO 9001 or specific compliance with local and international standards (e.g., ANSI, ASTM). This verification helps mitigate risks associated with non-compliance, which can lead to operational disruptions or legal issues.

Illustrative image related to three way pneumatic valve

Step 5: Request Samples for Testing

Before making a bulk purchase, request samples of the three-way pneumatic valves for testing. Evaluate their performance in real-world conditions to ensure they meet your specifications. This step not only confirms quality but also gives you confidence in the valve’s compatibility with your existing systems.

Step 6: Analyze Pricing and Terms

Once you have narrowed down your options, analyze pricing structures and payment terms. Compare the total cost of ownership, including installation, maintenance, and potential warranties. Understanding the full financial implications will help you make a cost-effective decision that aligns with your budgetary constraints.

Step 7: Plan for After-Sales Support

Inquire about the after-sales support and service provided by the supplier. Consider aspects like warranty coverage, technical assistance, and availability of spare parts. Strong after-sales support is crucial for maintaining operational efficiency and minimizing downtime in case of issues with the valves.

By following this checklist, B2B buyers can navigate the complex landscape of sourcing three-way pneumatic valves with greater confidence, ensuring they select the right products for their specific operational needs.

Comprehensive Cost and Pricing Analysis for three way pneumatic valve Sourcing

What Are the Key Cost Components in Sourcing Three-Way Pneumatic Valves?

When evaluating the cost structure of three-way pneumatic valves, several components come into play. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly affects the cost. Common materials include stainless steel, brass, and plastic, with stainless steel often being the most expensive due to its corrosion resistance and durability. The specific application can necessitate higher-grade materials, increasing costs.

-

Labor: Labor costs can vary based on the manufacturing location. Regions with higher labor costs (e.g., Western Europe) may lead to higher overall prices. Conversely, sourcing from regions with lower labor costs (e.g., parts of Africa and South America) can provide savings, but may come with trade-offs in terms of quality control.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, equipment maintenance, and administrative expenses. Manufacturers with advanced technologies may have lower overhead costs per unit due to increased efficiency.

-

Tooling: The initial investment in tooling for custom valve designs can be substantial. For standard valves, tooling costs are typically amortized over larger production runs, making them less impactful on per-unit costs.

-

Quality Control (QC): Ensuring the valves meet industry standards and certifications (e.g., ISO, ANSI) can add to costs. However, investing in quality control can reduce long-term costs related to returns and maintenance.

-

Logistics: Shipping and handling costs vary significantly depending on the supplier’s location and the buyer’s destination. Incoterms (International Commercial Terms) play a crucial role in determining who bears these costs and risks.

-

Margin: Suppliers typically mark up their prices to cover operational costs and ensure profitability. Understanding the competitive landscape can help buyers negotiate better pricing.

How Do Price Influencers Affect the Sourcing of Three-Way Pneumatic Valves?

Several factors influence the pricing of three-way pneumatic valves, which can significantly affect the total cost for buyers.

-

Volume/MOQ (Minimum Order Quantity): Bulk purchasing often leads to significant cost reductions. Suppliers are generally more willing to offer discounts on larger orders, so understanding the MOQ is crucial for cost savings.

-

Specifications and Customization: Custom valves tailored to specific applications can incur higher costs due to the specialized manufacturing processes. Buyers should balance the need for customization against budget constraints.

-

Material Quality and Certifications: Higher quality materials and relevant certifications can justify higher prices. Buyers must assess whether the benefits of these materials align with their operational needs.

-

Supplier Factors: The reputation, reliability, and geographical location of the supplier can influence pricing. Established suppliers with a proven track record may command higher prices due to perceived reliability.

-

Incoterms: The chosen Incoterms affect the total cost of ownership by determining liability for shipping, insurance, and tariffs. Understanding these terms can help buyers avoid unexpected costs.

What Are the Best Practices for Negotiating Prices on Three-Way Pneumatic Valves?

Effective negotiation strategies can lead to more favorable pricing and terms when sourcing three-way pneumatic valves.

-

Research Market Prices: Understanding the market rates for similar products is essential. This knowledge equips buyers with leverage in negotiations.

-

Highlight Long-Term Relationships: Emphasizing the potential for future orders can incentivize suppliers to provide better pricing or terms.

-

Total Cost of Ownership (TCO): Consider all costs associated with the valve over its lifecycle, including installation, maintenance, and potential downtime. A slightly higher upfront cost may be justified if it leads to lower operational costs.

-

Be Open to Alternative Suppliers: Diversifying suppliers can lead to more competitive pricing. Engaging with multiple suppliers can also provide insights into market trends and pricing fluctuations.

-

Understand Local Market Dynamics: For buyers in regions like Africa and South America, understanding local economic conditions, import tariffs, and logistics can provide strategic advantages in negotiations.

Disclaimer on Indicative Prices

Prices for three-way pneumatic valves can vary widely based on specifications, materials, and supplier factors. It is essential for buyers to obtain detailed quotes tailored to their specific requirements to ensure accurate budgeting and planning.

Illustrative image related to three way pneumatic valve

Alternatives Analysis: Comparing three way pneumatic valve With Other Solutions

Understanding Alternatives to Three Way Pneumatic Valves

In the realm of industrial automation and fluid control, three way pneumatic valves are a well-known solution for directing air flow in various applications. However, several alternatives exist that can also effectively manage fluid dynamics. This section explores these alternatives, focusing on how they compare against three way pneumatic valves in terms of performance, cost, implementation ease, maintenance, and best use cases.

| Comparison Aspect | Three Way Pneumatic Valve | Solenoid Valve | Ball Valve |

|---|---|---|---|

| Performance | Excellent for air and gas control, fast actuation | Good for liquid and gas, slower response | High flow capacity, low pressure drop |

| Cost | Moderate, depending on materials and specifications | Generally lower initial cost | Higher due to material and design complexity |

| Ease of Implementation | Requires pneumatic system setup | Easy to integrate with electrical systems | Requires careful installation and alignment |

| Maintenance | Moderate; requires regular checks | Low; minimal wear and tear | Low; very durable with minimal parts |

| Best Use Case | Air control in automation, HVAC systems | General liquid and gas flow control | High flow applications, mixing processes |

What Are the Pros and Cons of Solenoid Valves?

Pros: Solenoid valves are known for their cost-effectiveness and ease of integration into existing electrical systems. They can control a variety of fluids and gases and are suitable for applications that require quick on/off control. Their low maintenance needs make them an attractive option for many industries.

Cons: However, solenoid valves typically have slower response times compared to pneumatic valves. They may not perform as well in high-pressure applications and can be limited in terms of flow capacity. Additionally, they often require an electrical supply, which may not be feasible in all operational environments.

How Do Ball Valves Compare in Industrial Applications?

Pros: Ball valves excel in applications that require high flow rates and low pressure drops. Their design allows for quick and efficient flow control, making them ideal for mixing and distributing fluids. They are also highly durable, with minimal wear, leading to lower maintenance costs over time.

Cons: The initial cost of ball valves can be higher than that of three way pneumatic valves, particularly if constructed from high-quality materials. Additionally, they require precise installation and alignment, which can complicate the implementation process in some setups. In scenarios where rapid actuation is needed, ball valves may not always be the best choice.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate fluid control solution depends on various factors, including the specific application, operating environment, and budget constraints. Three way pneumatic valves are particularly advantageous for applications requiring fast actuation and air control. In contrast, solenoid valves provide a cost-effective solution for general flow control, while ball valves offer durability and efficiency for high flow applications. B2B buyers should carefully assess their operational needs, considering both the technical specifications and the long-term cost implications of each alternative before making a decision.

Essential Technical Properties and Trade Terminology for three way pneumatic valve

What Are the Essential Technical Properties of a Three-Way Pneumatic Valve?

Understanding the key technical specifications of three-way pneumatic valves is crucial for B2B buyers. These specifications directly impact the valve’s performance, reliability, and suitability for specific applications.

1. Material Grade

The material composition of a three-way pneumatic valve significantly affects its durability and compatibility with various media. Common materials include stainless steel, brass, and plastic. Stainless steel, for instance, offers excellent corrosion resistance, making it ideal for harsh environments, such as chemical processing. Buyers should consider the material’s compatibility with the fluids being handled to prevent corrosion and ensure longevity.

2. Pressure Rating

This specification indicates the maximum pressure the valve can withstand. Typically measured in psi (pounds per square inch), pressure ratings can vary widely depending on the valve’s design and materials. It is essential for buyers to select valves that meet or exceed the operational pressure of their systems to avoid failure or leaks, which can lead to costly downtimes.

3. Temperature Range

The operating temperature range defines the minimum and maximum temperatures at which the valve can function effectively. It is crucial for applications involving extreme heat or cold, such as in food processing or HVAC systems. Knowing this range helps ensure that the valve will operate efficiently without degrading or failing prematurely.

4. Port Size and Configuration

Port size refers to the diameter of the valve’s inlet and outlet connections. Common sizes range from ½ inch to 4 inches. The configuration—whether it’s L-port or T-port—affects how fluids are directed through the valve. Buyers must match the port size and configuration to their piping systems to ensure proper flow and functionality.

5. Actuation Type

Three-way valves can be actuated pneumatically or electrically. Pneumatic actuators use compressed air for operation, while electric actuators rely on electrical signals. Understanding the actuation type is vital for integration with existing control systems and ensuring optimal performance in automated environments.

What Are Common Trade Terms Related to Three-Way Pneumatic Valves?

Familiarity with industry terminology helps B2B buyers navigate purchasing processes more efficiently. Here are some key terms related to three-way pneumatic valves:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of valves, OEMs often provide specialized products tailored to specific industrial applications. Buyers should consider sourcing from reputable OEMs to ensure quality and compatibility.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management. Buyers should negotiate MOQs that align with their needs to avoid excess inventory or missed opportunities.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products. For buyers of three-way pneumatic valves, issuing an RFQ can facilitate competitive pricing and help clarify specifications, ensuring they receive the best options available.

4. Incoterms

These are international commercial terms that define the responsibilities of buyers and sellers in global trade. Understanding Incoterms is essential for B2B buyers to navigate shipping costs, insurance, and risk management associated with the procurement of valves from international suppliers.

5. Lead Time

Lead time refers to the amount of time between placing an order and receiving the goods. Buyers must consider lead times when planning their procurement processes, especially for critical applications that require timely delivery to avoid operational delays.

6. Certification

Certification indicates that the valve meets specific industry standards and regulations, such as ISO or ASME. Ensuring that valves are certified can provide peace of mind regarding quality and compliance, which is essential for industries with strict regulatory requirements.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing three-way pneumatic valves, ensuring they select the right products for their applications.

Navigating Market Dynamics and Sourcing Trends in the three way pneumatic valve Sector

What Are the Key Market Dynamics and Trends Affecting the Three-Way Pneumatic Valve Sector?

The global market for three-way pneumatic valves is witnessing significant growth, driven by several factors, including industrial automation, increased demand for process control, and advancements in pneumatic technologies. As industries across Africa, South America, the Middle East, and Europe embrace automation, the need for reliable and efficient fluid control systems becomes paramount. For B2B buyers, understanding these dynamics is crucial for making informed sourcing decisions.

Emerging technologies such as IoT and Industry 4.0 are reshaping the landscape of pneumatic valve applications. The integration of smart sensors and data analytics into valve systems allows for real-time monitoring and predictive maintenance, thereby enhancing operational efficiency and reducing downtime. Additionally, the trend towards modular and compact designs in pneumatic valves is gaining traction, catering to industries that require space-saving solutions without compromising performance.

Illustrative image related to three way pneumatic valve

Another noteworthy trend is the increasing customization of three-way pneumatic valves to meet specific operational needs. B2B buyers are increasingly seeking valves that can be tailored to fit unique applications, whether in chemical processing, food and beverage, or HVAC systems. This demand for customization is prompting manufacturers to invest in advanced manufacturing techniques, such as 3D printing and CNC machining, to deliver bespoke solutions swiftly.

How Can Sustainability and Ethical Sourcing Impact the Three-Way Pneumatic Valve Sector?

As the global focus on sustainability intensifies, B2B buyers are increasingly prioritizing environmentally responsible sourcing practices in the three-way pneumatic valve sector. The production and disposal of industrial valves can have significant environmental impacts, making it essential for companies to consider the lifecycle of the products they procure. Sustainable practices not only mitigate environmental risks but also enhance corporate reputations and foster customer loyalty.

One key aspect of sustainability in valve manufacturing is the use of eco-friendly materials and processes. Buyers should look for suppliers who utilize certified materials, such as those bearing green certifications, which demonstrate a commitment to reducing environmental footprints. For example, valves made from recycled stainless steel or those featuring low-emission manufacturing processes can significantly lessen the ecological impact.

Moreover, ethical sourcing extends beyond materials to include fair labor practices and responsible supply chain management. Buyers should engage with suppliers who maintain transparency in their sourcing practices, ensuring that their supply chains do not exploit labor or contribute to environmental degradation. By prioritizing sustainability and ethical sourcing, B2B buyers can align their procurement strategies with global sustainability goals, ultimately driving positive change in the industry.

Illustrative image related to three way pneumatic valve

What Is the Historical Evolution of Three-Way Pneumatic Valves in the B2B Landscape?

The evolution of three-way pneumatic valves dates back to the early days of pneumatic technology, where simple mechanical systems dominated the landscape. Initially, these valves were primarily used in basic applications, such as controlling air flow in pneumatic systems. However, as industrial processes became more complex, the need for advanced control solutions emerged.

In the late 20th century, the introduction of automation and computerized control systems revolutionized the use of pneumatic valves. Manufacturers began developing more sophisticated designs, incorporating features like solenoid actuation and advanced sealing technologies to enhance reliability and performance. This evolution laid the groundwork for the modern three-way pneumatic valves we see today, which are essential components in a wide range of industries, from manufacturing to food processing.

Today, the emphasis is on high-performance, energy-efficient solutions that align with the demands of Industry 4.0. As the sector continues to innovate, the historical context of three-way pneumatic valves serves as a foundation for understanding their significance in contemporary B2B applications.

Frequently Asked Questions (FAQs) for B2B Buyers of three way pneumatic valve

1. How do I choose the right three-way pneumatic valve for my application?

Selecting the appropriate three-way pneumatic valve involves understanding your specific application requirements, including flow direction, media type, and pressure ratings. Assess whether you need a normally open or normally closed valve based on your system’s operational needs. Additionally, consider the valve’s materials, especially for corrosive environments, and ensure compatibility with your existing piping systems. Consulting with suppliers who offer technical support can also help you make an informed decision.

2. What are the advantages of using stainless steel three-way pneumatic valves?

Stainless steel three-way pneumatic valves offer several advantages, including corrosion resistance, durability, and the ability to withstand high temperatures and pressures. These valves are ideal for demanding applications such as food processing, pharmaceuticals, and chemical handling. Their robust construction ensures longevity and reliability, reducing maintenance costs over time. Moreover, stainless steel valves are often easier to clean and sanitize, making them suitable for industries with strict hygiene standards.

3. What is the typical lead time for ordering three-way pneumatic valves internationally?

Lead times for international orders of three-way pneumatic valves can vary significantly based on factors like the supplier’s location, production capacity, and shipping logistics. Generally, you can expect a lead time ranging from 4 to 12 weeks. It’s crucial to discuss timelines with your supplier upfront and consider potential delays due to customs clearance or shipping complications. Establishing a clear communication channel with your supplier can help manage expectations and ensure timely delivery.

4. What minimum order quantities (MOQs) should I expect when sourcing three-way pneumatic valves?

Minimum order quantities for three-way pneumatic valves can differ widely depending on the manufacturer and product specifications. Typically, MOQs may range from 10 to 100 units. For specialized or customized valves, MOQs may be higher. It’s advisable to communicate your needs with potential suppliers to negotiate MOQs that align with your project requirements, especially if you are testing a new product line or entering a new market.

Illustrative image related to three way pneumatic valve

5. How can I vet suppliers of three-way pneumatic valves?

To effectively vet suppliers, start by researching their industry reputation, certifications, and experience in manufacturing pneumatic valves. Request references or case studies from previous clients, particularly those in your industry. Additionally, evaluate their production capabilities, quality assurance processes, and customer service responsiveness. Engaging in direct communication and potentially visiting their manufacturing facilities can provide insights into their operational standards and commitment to quality.

6. What payment terms are common when purchasing three-way pneumatic valves?

Payment terms for three-way pneumatic valves can vary by supplier and region but often include options like net 30, net 60, or upfront payment. Some suppliers may offer financing or letter of credit arrangements for larger orders. It’s essential to clarify payment terms and conditions before finalizing the purchase to avoid misunderstandings. Also, consider discussing potential discounts for early payments or bulk orders to optimize your procurement costs.

7. What quality assurance measures should be in place when sourcing three-way pneumatic valves?

Quality assurance measures are critical in ensuring that the three-way pneumatic valves meet industry standards and your specific requirements. Suppliers should provide certifications such as ISO 9001 to demonstrate their commitment to quality management. Additionally, request detailed product specifications, test reports, and warranty information. Implementing a quality inspection process upon delivery can help catch any defects or discrepancies before installation, safeguarding your operations.

8. How can I manage logistics and shipping for international orders of three-way pneumatic valves?

Managing logistics for international orders involves careful planning and coordination with your supplier and freight forwarder. Determine the best shipping method based on cost, urgency, and reliability. Ensure that all documentation, such as customs declarations and invoices, is accurate to avoid delays. Additionally, consider using Incoterms to define responsibilities for shipping costs and risks. Staying informed about import regulations in your country can also help streamline the process and prevent potential complications.

Top 7 Three Way Pneumatic Valve Manufacturers & Suppliers List

1. McMaster – Three-Way Air Valves

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Three-Way Air Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Strahman Group – IS-3WF Pneumatic Actuator Ball Valves

Domain: strahmangroup.com

Registered: 2021 (4 years)

Introduction: {“Product Name”: “IS-3WF (3-Way SS Flanged) Pneumatic Actuator Ball Valves”, “Price”: “$841.00”, “Code”: “IS-3WLF-05-52-DA-PN”, “Availability”: “In stock”, “Valve Size Options”: [“1/2”, “1-1/4”, “1-1/2”, “2”, “2-1/2”, “3”, “3/4”, “4”], “Actuator Type”: [“Pneumatic – Double Acting”, “Pneumatic – Spring Return”], “Body Material”: [“Stainless Steel”, “Aluminum”], “Port Type”: [“L-Port”, “T-Port”], “F…

3. Valworx – Stainless 3-Way L-Port Ball Valve

Domain: valworx.com

Registered: 2007 (18 years)

Introduction: Stainless 3-Way L-Port Ball Valve, Air Actuated, Spring Return

4. Valveman – 3-Way Ball Valves

Domain: valveman.com

Registered: 2009 (16 years)

Introduction: 3-Way Ball Valves are designed for versatile flow control across various applications. Available in premium full port options made from stainless steel, lead-free brass, and bronze, these valves ensure durability and long-lasting service. They can mix, divert, or isolate media such as air, water, oil, gas, or chemicals. Key types include L-Ported and T-Ported configurations, which determine flow c…

5. Pneumadyne – 3-Way 3-Position Valves

Domain: pneumadyne.com

Registered: 1995 (30 years)

Introduction: 3-Way 3-Position Valves are dual function products that contain two valves in one body with a common input and common exhaust. They can be used as independent 3-way valves or as a 4-way (5/3) with an Open Center. Common applications include pneumatic pilot control for hydraulic valves or controlling the motion of air motors. Features include anodized and electroless nickel plating for corrosion an…

6. Emerson – Three-Way Solenoid Valves

Domain: emerson.com

Registered: 1995 (30 years)

Introduction: This company, Emerson – Three-Way Solenoid Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Watson McDaniel – 3-Way Control Valves

Domain: watsonmcdaniel.com

Registered: 1996 (29 years)

Introduction: 3-Way Control Valves from Watson McDaniel include the HB Series in both Pneumatic and Electric configurations (EC, SK, ES). These valves are designed for controlling the flow of fluids in various applications.

Strategic Sourcing Conclusion and Outlook for three way pneumatic valve

The strategic sourcing of three-way pneumatic valves presents a significant opportunity for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Understanding the diverse applications and configurations—ranging from stainless steel options to automated designs—enables businesses to select valves that optimize operational efficiency and reduce costs.

By leveraging strategic sourcing, companies can build strong supplier relationships, ensuring access to high-quality products while navigating regional regulations and market dynamics. This proactive approach not only facilitates better inventory management but also enhances the overall supply chain resilience, ultimately leading to improved customer satisfaction.

As industries continue to evolve, the demand for reliable and innovative pneumatic solutions will only grow. International buyers are encouraged to stay informed about technological advancements and regulatory changes that may impact their sourcing strategies. Engage with trusted suppliers who can provide tailored solutions to meet specific operational needs. The future of pneumatic systems is bright, and now is the time to invest in the right components to drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.