A B2B Buyer’s Guide to Tamper Resistant Bags: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for tamper resistant bags

Navigating the complex landscape of sourcing tamper resistant bags can be a daunting challenge for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The need for secure packaging solutions that ensure the integrity of valuable products is paramount, especially in industries such as pharmaceuticals, cash handling, and logistics. This comprehensive guide aims to equip buyers with essential insights into the various types of tamper resistant bags available, their specific applications, and the critical factors to consider when vetting suppliers.

Within these pages, you will discover a detailed overview of the diverse range of tamper evident bags, including cash deposit bags, document pouches, and custom solutions tailored to meet unique needs. We will delve into the practical applications of these products, exploring how they enhance security and boost consumer confidence. Additionally, this guide provides valuable insights into pricing structures, helping buyers make informed decisions that align with their budgetary constraints.

By understanding the nuances of tamper resistant bags, buyers can navigate their procurement process with confidence, ensuring they select reliable suppliers that meet international standards. This guide is designed to empower B2B buyers to make informed purchasing decisions that not only safeguard their products but also enhance their overall operational efficiency.

Understanding tamper resistant bags Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tamper-Evident Ziplock Bags | Features a reclosable zipper and a perforated tear strip. | Food packaging, pharmaceuticals, retail products | Pros: Reusable, easy to seal. Cons: May require careful handling to avoid accidental opening. |

| Wicketed Tamper-Evident Bags | Stackable design on a wire wicket for easy loading and sealing. | High-volume packaging, retail, and logistics | Pros: Efficient for bulk packing. Cons: Initial setup may require specialized equipment. |

| RF Shielding Tamper Bags | Provides electromagnetic interference protection alongside tamper evidence. | Electronics, data transfer, secure communications | Pros: Dual protection for sensitive items. Cons: Higher cost due to specialized materials. |

| Heavy-Duty Tamper Bags | Constructed from thicker materials for enhanced durability. | Industrial applications, hazardous materials | Pros: Increased protection against physical damage. Cons: Bulkier and may be more expensive. |

| Custom Tamper-Evident Solutions | Tailored sizes and features based on specific business needs. | All sectors requiring unique packaging solutions | Pros: Fully meets specific requirements. Cons: Higher minimum order quantities and longer lead times. |

What Are Tamper-Evident Ziplock Bags and Their Uses in B2B?

Tamper-evident ziplock bags are designed for secure packaging, featuring a reclosable zipper and a perforated tear strip that indicates whether the bag has been opened. These bags are commonly used in food packaging, pharmaceuticals, and retail products, providing a reliable way to ensure product integrity. B2B buyers should consider the ease of sealing and reusability, but they must also be cautious about handling to avoid accidental openings during transit.

How Do Wicketed Tamper-Evident Bags Enhance Efficiency?

Wicketed tamper-evident bags are mounted on a wire wicket, allowing for quick and efficient loading. This design is particularly beneficial for businesses engaged in high-volume packaging, such as retail and logistics. Wicketed bags streamline the packing process, but businesses need to invest in specialized equipment for optimal use. The efficiency gained can significantly reduce labor costs, making them a valuable choice for bulk operations.

What Are RF Shielding Tamper Bags and Their Importance?

RF shielding tamper bags combine tamper-evidence with protection against electromagnetic interference, making them essential for businesses dealing with sensitive electronics and data transfer. These bags ensure that the contents remain secure from unauthorized access and electromagnetic threats. While they offer unparalleled protection, buyers should be prepared for higher costs due to the specialized materials used in their construction.

Why Choose Heavy-Duty Tamper Bags for Industrial Applications?

Heavy-duty tamper bags are made from thicker materials, providing enhanced durability and protection against physical damage. These bags are ideal for industrial applications and the transport of hazardous materials, where the integrity of the packaging is crucial. While they offer superior protection, buyers must consider the trade-off of increased bulk and potential higher costs, which could impact shipping logistics.

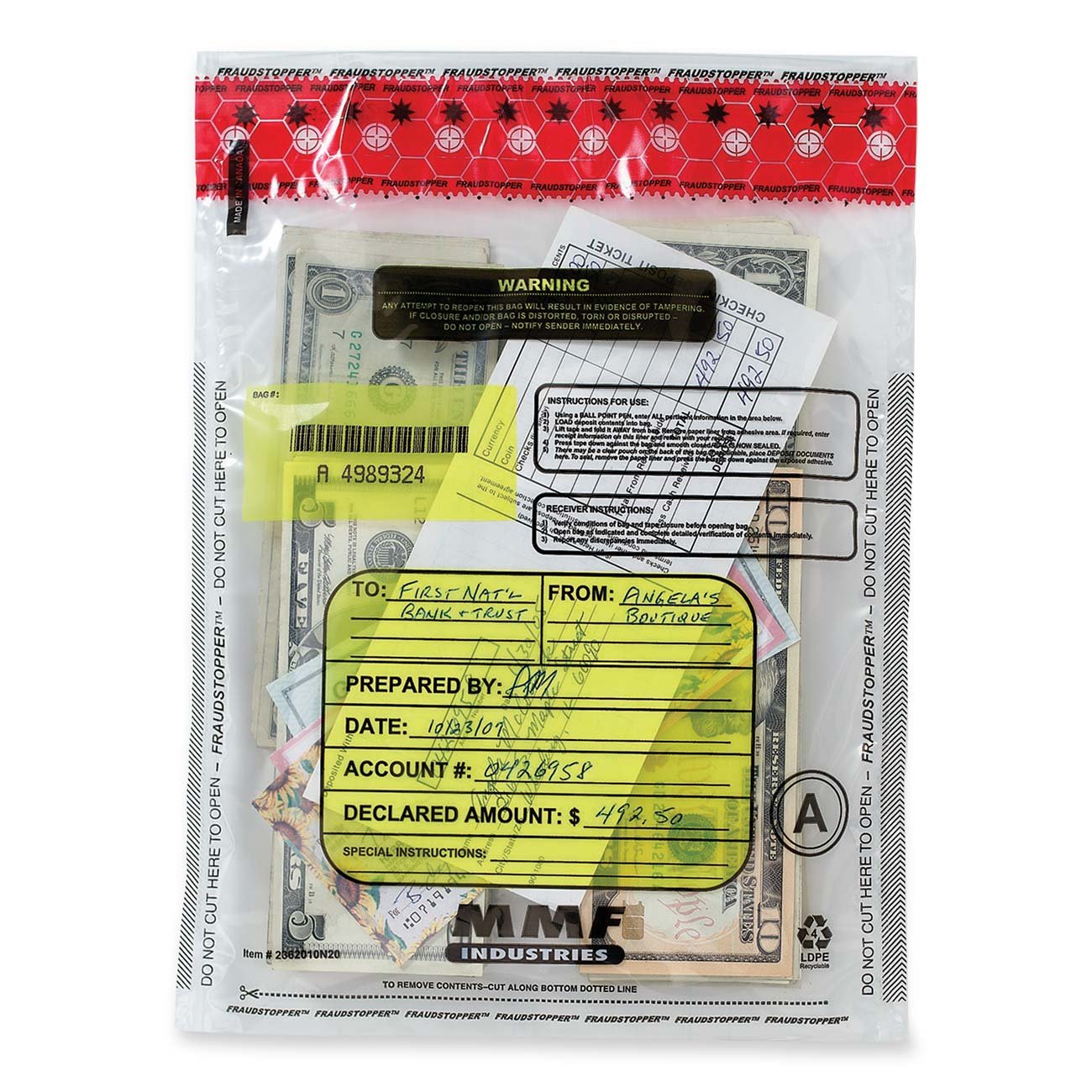

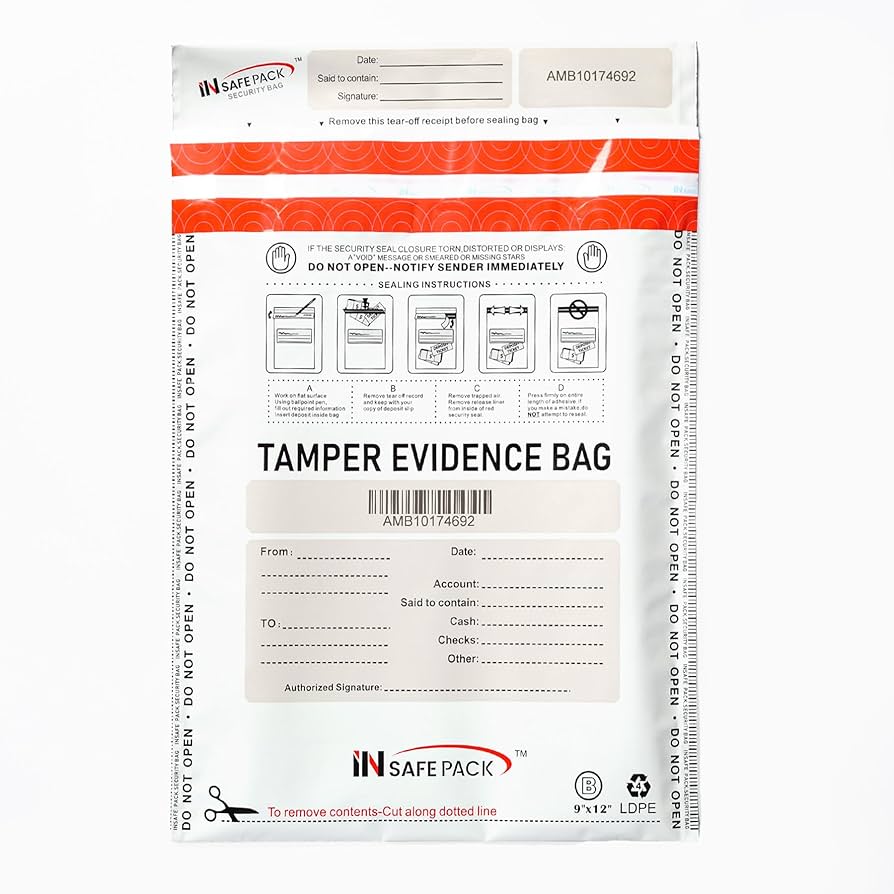

Illustrative image related to tamper resistant bags

How Can Custom Tamper-Evident Solutions Benefit Your Business?

Custom tamper-evident solutions allow businesses to specify sizes and features that meet their unique packaging needs. This flexibility is advantageous for companies across all sectors that require tailored packaging solutions. However, buyers should be aware of higher minimum order quantities and longer lead times associated with custom orders. Investing in custom solutions can lead to improved brand presentation and product security, ultimately enhancing customer trust.

Key Industrial Applications of tamper resistant bags

| Industry/Sector | Specific Application of Tamper Resistant Bags | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pharmaceuticals | Secure transport of drugs and medical supplies | Ensures product integrity and compliance with regulations | Compliance with health standards, customizable sizes, and materials |

| Retail | Cash handling and deposit bags | Protects cash during transit, reduces theft risk | Secure sealing options, varying sizes, and durability |

| Logistics & Shipping | Shipment of sensitive documents and electronics | Provides evidence of tampering, ensuring safe delivery | Lightweight options, moisture resistance, and clear visibility |

| Food & Beverage | Packaging perishable goods | Maintains freshness, prevents contamination | Food safety certifications, reusability, and thermal stability |

| Government & Security | Handling sensitive documents and ballots | Guarantees confidentiality and integrity of contents | Custom branding options, tamper-evident features, and tracking capabilities |

How Are Tamper Resistant Bags Used in the Pharmaceutical Industry?

In the pharmaceutical sector, tamper resistant bags are essential for the secure transport of drugs and medical supplies. These bags provide a visible indication of tampering, ensuring that products remain sealed until they reach their intended destination. This is particularly crucial for compliance with strict health regulations. International B2B buyers should consider sourcing bags that meet local health standards, offer customizable sizes to accommodate various products, and are made from materials that resist damage during transit.

What Role Do Tamper Resistant Bags Play in Retail Cash Handling?

In retail environments, tamper resistant bags are commonly used for cash handling and deposits. These bags are designed to protect cash during transit, significantly reducing the risk of theft and ensuring that cash is securely stored until it reaches the bank. For businesses in regions like Africa and South America, sourcing durable bags that can withstand environmental factors and provide secure sealing options is vital. Buyers should also seek bags that can be customized to fit specific cash handling processes.

Why Are Tamper Resistant Bags Important in Logistics and Shipping?

For logistics and shipping companies, tamper resistant bags are critical for the secure shipment of sensitive documents and electronics. These bags provide clear evidence of tampering, ensuring that the contents arrive safely at their destination. This is especially important in regions with high theft rates. When sourcing these bags, businesses should prioritize lightweight options that do not add to shipping costs, as well as moisture-resistant materials that protect contents from environmental damage.

How Do Tamper Resistant Bags Benefit the Food and Beverage Sector?

In the food and beverage industry, tamper resistant bags are used to package perishable goods, maintaining freshness and preventing contamination. These bags ensure that food products remain sealed until they reach consumers, which is vital for compliance with food safety regulations. Buyers in this sector should consider sourcing bags that are certified for food safety, offer reusability, and possess thermal stability to withstand varying temperatures during transport.

What Is the Importance of Tamper Resistant Bags for Government and Security Applications?

Tamper resistant bags are crucial in government and security sectors for handling sensitive documents and ballots. These bags ensure the confidentiality and integrity of the contents, which is essential for maintaining public trust in governmental processes. B2B buyers in this field should look for bags that offer custom branding options, tamper-evident features, and tracking capabilities to enhance accountability and transparency throughout the handling process.

3 Common User Pain Points for ‘tamper resistant bags’ & Their Solutions

Scenario 1: Inconsistent Quality and Durability of Tamper Resistant Bags

The Problem: B2B buyers often face challenges in ensuring the quality and durability of tamper resistant bags. A common issue arises when bags fail during transport, leading to compromised contents and potential financial losses. This inconsistency not only damages trust with customers but can also result in regulatory scrutiny, especially in industries like pharmaceuticals or food services where safety is paramount.

The Solution: To mitigate this issue, buyers should prioritize sourcing from reputable manufacturers with a proven track record. Request samples and perform quality tests, focusing on the bag’s material thickness (measured in mils), seal strength, and tamper-evident features. It is also beneficial to check for compliance with industry standards such as FDA and USDA regulations. Establishing a close relationship with suppliers can lead to better insights into product specifications and allow for tailored solutions that meet specific needs, ensuring reliability and performance in high-stakes environments.

Scenario 2: Complexity in Selecting the Right Size and Type of Tamper Resistant Bags

The Problem: Many B2B buyers struggle with selecting the appropriate size and type of tamper resistant bags for their unique products. Miscalculations can lead to wasted materials, increased costs, and operational inefficiencies. For instance, using bags that are too small may result in damaged products, while overly large bags can lead to inadequate protection and poor presentation.

The Solution: To address this challenge, buyers should conduct a thorough assessment of their product dimensions and the requirements for tamper evidence. Utilize sizing charts provided by manufacturers and consider the bag’s intended use—whether for cash handling, medical supplies, or sensitive documents. It’s also helpful to consult with suppliers to gain insights into which bag types have worked best for similar applications. Customization options should be explored for businesses with specific needs, as many manufacturers offer bespoke solutions that can enhance both functionality and branding.

Scenario 3: Difficulty in Ensuring Compliance and Regulatory Standards

The Problem: B2B buyers, particularly in regulated industries like healthcare and food services, often face challenges in ensuring that their tamper resistant bags comply with various legal and safety standards. Non-compliance can result in significant penalties, product recalls, and damage to the brand’s reputation. This concern is heightened for international buyers who must navigate different regulations across countries.

The Solution: To ensure compliance, buyers should thoroughly research the regulatory landscape in their target markets. This includes understanding local and international standards for packaging materials, especially for food-grade and pharmaceutical applications. Collaborating with suppliers who provide detailed documentation and certifications for their products is essential. Additionally, buyers should implement regular audits and reviews of their packaging processes to ensure ongoing compliance. Engaging with legal or compliance experts can also help navigate complex regulations, ensuring that all aspects of packaging meet necessary standards and provide peace of mind in operations.

Strategic Material Selection Guide for tamper resistant bags

What Are the Key Materials Used in Tamper Resistant Bags?

When selecting tamper resistant bags for various applications, the choice of material is pivotal in ensuring product integrity, compliance, and cost-effectiveness. Here, we analyze four common materials used in the manufacture of tamper resistant bags, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Polyethylene Perform in Tamper Resistant Bags?

Polyethylene (PE) is one of the most widely used materials for tamper resistant bags due to its versatility and affordability. It offers excellent chemical resistance, making it suitable for packaging a variety of products, including food and pharmaceuticals. Key properties include a temperature range of -40°F to 180°F, making it suitable for both cold and warm environments.

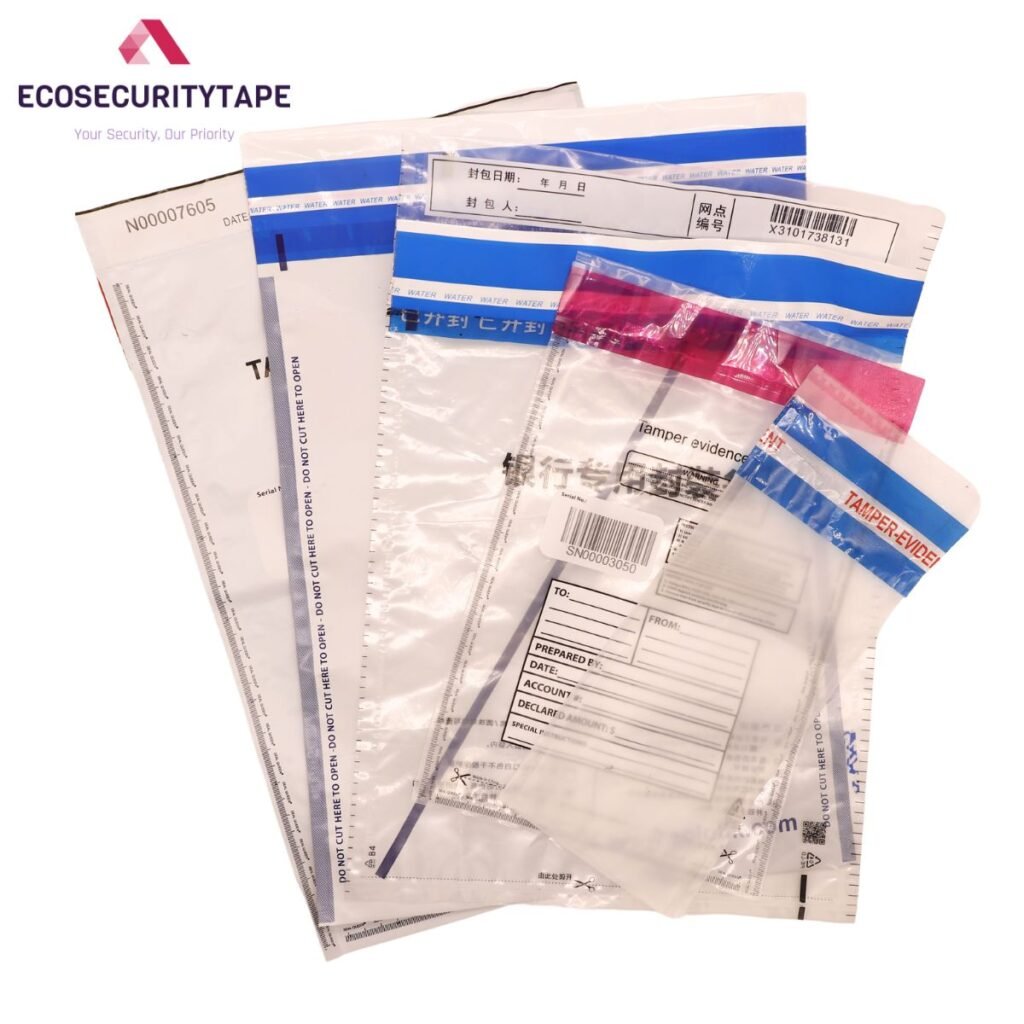

Illustrative image related to tamper resistant bags

Pros: Polyethylene is lightweight, flexible, and cost-effective, which makes it an excellent choice for bulk purchasing. It is also recyclable, appealing to environmentally conscious businesses.

Cons: While durable, polyethylene can be susceptible to punctures and tears under extreme conditions. Additionally, its lower resistance to UV light can lead to degradation over time, affecting the bag’s integrity.

Impact on Application: Polyethylene is compatible with a wide range of media, including liquids and solids, but may not be ideal for highly volatile substances.

International Considerations: Buyers from regions such as Africa and South America should ensure compliance with local regulations regarding food safety and environmental standards, such as those set by ASTM or ISO.

What Are the Advantages of Using Polypropylene for Tamper Resistant Bags?

Polypropylene (PP) is another popular choice for tamper resistant bags, particularly in applications requiring higher strength and clarity. It has a temperature tolerance of -20°F to 200°F, making it suitable for a variety of conditions.

Pros: Polypropylene is more resistant to punctures and tears compared to polyethylene, providing better protection for contents. Its clarity also allows for easy visibility of the bag’s contents, enhancing security.

Cons: Polypropylene can be more expensive than polyethylene, which may affect budget-conscious buyers. Additionally, it is less flexible, which may limit its use in certain applications.

Impact on Application: This material is ideal for packaging items like documents, electronics, and pharmaceuticals, where visibility and protection are paramount.

International Considerations: European buyers may prefer polypropylene due to its compliance with stricter packaging regulations, including those related to recycling and sustainability.

How Does Nylon Compare in Terms of Tamper Resistance?

Nylon is often used for tamper resistant bags that require enhanced durability and resistance to abrasion. It can withstand temperatures ranging from -40°F to 300°F, making it suitable for extreme conditions.

Pros: Nylon bags are exceptionally strong and resistant to tearing, making them ideal for heavy-duty applications. They also provide excellent barrier properties against moisture and gases.

Cons: The primary drawback of nylon is its higher cost compared to polyethylene and polypropylene. Additionally, it may require specialized sealing equipment, complicating the manufacturing process.

Illustrative image related to tamper resistant bags

Impact on Application: Nylon is well-suited for packaging sensitive items, such as medical supplies or high-value electronics, where protection is critical.

International Considerations: Buyers in the Middle East and Africa should ensure that nylon bags meet local regulations regarding safety and environmental impact, as well as considering the cost implications of importing higher-end materials.

What Role Does PVC Play in Tamper Resistant Bags?

Polyvinyl chloride (PVC) is another material used in the production of tamper resistant bags, particularly for applications requiring high clarity and strength. It has a temperature range of 0°F to 140°F.

Illustrative image related to tamper resistant bags

Pros: PVC provides excellent clarity and is highly resistant to chemicals, making it suitable for various applications, including packaging for pharmaceuticals and cosmetics.

Cons: PVC can be more rigid than other materials, which may limit its flexibility. Additionally, environmental concerns regarding PVC’s production and disposal can deter some buyers.

Impact on Application: PVC is ideal for applications where visibility and chemical resistance are crucial, but its rigidity may limit its use in flexible packaging solutions.

International Considerations: Buyers from Europe should be aware of the stringent regulations surrounding PVC use, including compliance with REACH and other environmental standards.

Summary Table of Material Properties for Tamper Resistant Bags

| Material | Typical Use Case for tamper resistant bags | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene | Food and general packaging | Lightweight and cost-effective | Susceptible to punctures | Low |

| Polypropylene | Documents and electronics | Higher strength and clarity | More expensive | Med |

| Nylon | Medical supplies and high-value items | Exceptional durability | Higher cost and complex sealing | High |

| PVC | Pharmaceuticals and cosmetics | Excellent clarity and chemical resistance | Rigid and environmental concerns | Med |

This strategic overview provides B2B buyers with essential insights into material selection for tamper resistant bags, enabling informed decisions tailored to their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for tamper resistant bags

What Are the Main Stages of Manufacturing Tamper-Resistant Bags?

The manufacturing of tamper-resistant bags involves several critical stages, each designed to ensure the final product meets stringent quality and security standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with sourcing high-quality materials, typically low-density polyethylene (LDPE) or linear low-density polyethylene (LLDPE). These materials are selected for their durability, flexibility, and ability to provide tamper-evident features. Suppliers must ensure that the raw materials meet specific international standards, such as FDA and USDA compliance for food safety, especially for bags used in the food industry.

-

Forming: In this stage, the prepared materials are processed into sheets or films. Advanced techniques such as blown film extrusion or cast film extrusion are employed to create the desired thickness and properties. The thickness can vary depending on the application; common options include 2 mil, 3 mil, and 4 mil. The films are then cut into the appropriate sizes, accounting for additional space for sealing and any design elements required for branding or labeling.

-

Assembly: After forming, the sheets are subjected to processes that create the bag structure. This typically involves bottom-loading designs where products are inserted from the bottom and sealed at the top. The bags often incorporate a perforated tear strip above a zipper seal, which provides tamper evidence. Heat sealing is a common technique used to secure the bags, ensuring they remain closed until the perforation is torn.

-

Finishing: The final stage includes quality checks and packaging. Bags are inspected for defects, such as seal integrity and material consistency. This stage may also involve printing or labeling, adding branding, and ensuring compliance with regulatory requirements. Automated systems are increasingly used to enhance efficiency and accuracy in this stage.

How Is Quality Assurance Implemented in Tamper-Resistant Bag Manufacturing?

Quality assurance is critical in ensuring that tamper-resistant bags meet both international standards and specific industry requirements. The following outlines key elements of quality control (QC) in the manufacturing process.

-

International Standards Compliance: Manufacturers of tamper-resistant bags often adhere to ISO 9001 standards, which focus on quality management systems. This certification ensures that the processes in place consistently meet customer and regulatory requirements. Additionally, industry-specific standards such as CE marking for products sold in Europe or API standards for pharmaceutical applications may also apply.

-

Quality Control Checkpoints: Various checkpoints are established throughout the manufacturing process:

– Incoming Quality Control (IQC): At this stage, raw materials are tested for compliance with specifications before being used in production. This helps prevent defects from the outset.

– In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted to monitor the production processes. Parameters such as temperature, pressure, and sealing times are closely monitored to ensure optimal conditions.

– Final Quality Control (FQC): After production, finished products undergo rigorous testing. This may include visual inspections, seal strength testing, and tamper-evidence functionality checks. -

Common Testing Methods: Testing methods for tamper-resistant bags include:

– Seal Strength Tests: To ensure that the heat seals maintain integrity and do not fail under stress.

– Tamper Evidence Tests: Assessing whether the bags adequately show signs of tampering when opened.

– Environmental Testing: Evaluating how the bags perform under various conditions, such as temperature and humidity, to ensure they maintain their integrity in different environments.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial to ensure product reliability and compliance.

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes and quality control systems firsthand. This can include reviewing documentation, inspecting equipment, and assessing adherence to standards.

-

Quality Assurance Reports: Suppliers should provide detailed quality assurance reports that outline testing results, compliance certifications, and any corrective actions taken in response to previous quality issues. Regular reporting helps maintain transparency and builds trust.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control practices. These agencies often have specific expertise in packaging materials and can conduct thorough evaluations.

-

Certifications and Compliance Documentation: Buyers should request copies of relevant certifications (e.g., ISO 9001, CE) and compliance documentation. This information provides insight into the supplier’s commitment to maintaining quality standards.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must be aware of certain nuances when it comes to quality control and compliance in different regions.

-

Regulatory Differences: Each region may have distinct regulatory requirements that must be adhered to. For instance, European markets may have stricter compliance standards compared to those in Africa or South America. Understanding these nuances is critical to avoid costly compliance issues.

-

Cultural Considerations: Business practices and attitudes towards quality may vary across cultures. Building strong relationships with suppliers from different regions can facilitate better communication and understanding of quality expectations.

-

Logistics and Supply Chain Considerations: The complexity of international logistics can affect product quality. Factors such as shipping conditions, handling practices, and storage conditions must be considered when assessing the potential risks to product integrity.

-

Local Market Preferences: Buyers should also be aware of local market preferences and expectations regarding packaging. For instance, certain regions may prioritize eco-friendly packaging solutions, necessitating discussions with suppliers about sustainable practices and materials.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when selecting suppliers for tamper-resistant bags, ensuring they receive products that meet their operational needs and compliance standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tamper resistant bags’

In the competitive landscape of B2B procurement, ensuring the security of your products during transit and storage is paramount. This practical sourcing guide outlines essential steps for international buyers looking to procure tamper-resistant bags, helping you make informed decisions and safeguard your goods.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for tamper-resistant bags is crucial for ensuring they meet your operational needs. Consider the size, thickness, and material of the bags, as these factors can affect both durability and usability. For instance, heavier bags (4 Mil) offer greater protection for high-value items, while lighter options (2 Mil) may suffice for less critical applications.

Step 2: Research Compliance and Regulatory Standards

Understanding the compliance requirements specific to your region is essential when sourcing tamper-resistant bags. Look for suppliers whose products meet international standards such as FDA, USDA, and other relevant certifications. This not only ensures product safety but also protects your business from potential legal liabilities.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure reliability and quality. Request detailed company profiles, including their production capabilities, quality control measures, and customer testimonials. Additionally, seeking references from other businesses in similar industries can provide insight into their performance and reliability.

Step 4: Request Samples for Quality Assessment

Once you’ve shortlisted potential suppliers, request samples of their tamper-resistant bags. Assess the quality of the materials, the effectiveness of the tamper-evident features, and the overall craftsmanship. Testing samples in real-world scenarios can help you determine if they meet your requirements for functionality and durability.

Step 5: Negotiate Pricing and Terms

Engage in negotiations to secure favorable pricing and terms that align with your budget and operational needs. Consider bulk purchasing discounts, payment terms, and shipping costs. Establishing a clear agreement can help prevent misunderstandings and ensure a smooth procurement process.

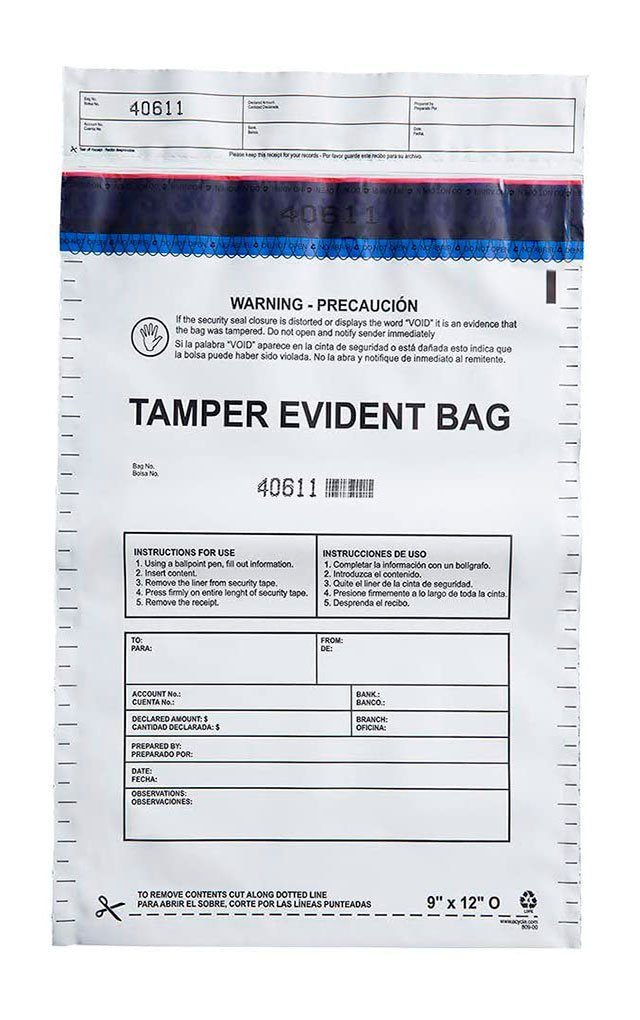

Illustrative image related to tamper resistant bags

Step 6: Verify Supplier Certifications

Ensure that your chosen supplier holds relevant certifications that reflect their commitment to quality and safety standards. Certifications such as ISO or compliance with regional regulations can provide assurance of their manufacturing processes and product integrity. This step is vital for maintaining the trust of your customers.

Step 7: Plan for Logistics and Distribution

Consider the logistics involved in receiving and distributing your tamper-resistant bags. Evaluate shipping options, lead times, and inventory management systems to streamline the process. Effective logistics planning ensures that you have the necessary supplies on hand when needed, minimizing disruptions to your operations.

By following this checklist, you can navigate the sourcing process for tamper-resistant bags with confidence, ensuring that you select products that meet your security needs while also aligning with your business objectives.

Illustrative image related to tamper resistant bags

Comprehensive Cost and Pricing Analysis for tamper resistant bags Sourcing

When sourcing tamper resistant bags, understanding the cost structure and pricing factors is critical for international B2B buyers. This section delves into the various cost components associated with tamper resistant bags, the influencers on pricing, and essential tips for buyers to ensure cost-efficiency and value.

What Are the Key Cost Components of Tamper Resistant Bags?

The cost structure for tamper resistant bags encompasses several critical components:

-

Materials: The primary cost driver is the raw materials used in the production of tamper resistant bags. Common materials include low-density polyethylene (LDPE) and linear low-density polyethylene (LLDPE), which vary in price based on market fluctuations. Higher quality materials often come at a premium but provide better durability and security.

-

Labor: Labor costs can significantly impact the overall pricing, particularly in regions where wages are higher. Automation in manufacturing can reduce labor costs but may require upfront investment.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, maintenance, and equipment depreciation. Overhead can vary based on the production scale and facility location.

-

Tooling: Custom molds and dies for specialized bag shapes or sizes incur additional costs. Custom tooling can be a significant upfront investment but is often essential for creating unique products.

-

Quality Control (QC): Ensuring that each batch of bags meets industry standards involves QC processes, which add to production costs. Implementing strict QC can enhance product reliability but may increase overall pricing.

-

Logistics: Shipping and handling costs, which can fluctuate based on distance, weight, and shipping method, should be factored in. International shipping often involves additional tariffs and customs fees.

-

Margin: Suppliers typically include a profit margin in their pricing. This can vary based on the supplier’s market position, competition, and perceived value of the product.

How Do Volume and Specifications Influence Pricing?

Pricing for tamper resistant bags is significantly influenced by several factors:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often provide better pricing for larger orders. Understanding the MOQ can help buyers negotiate better terms, especially if they can commit to higher volumes.

-

Specifications and Customization: Custom sizes, thicknesses, and features (like tear strips or resealable options) can affect pricing. Customization usually leads to higher costs due to the need for specialized production processes.

-

Quality and Certifications: Bags that meet specific regulatory standards (such as FDA or USDA compliance) may be priced higher. Certifications can add credibility but also reflect the quality of materials and manufacturing processes.

-

Supplier Factors: Different suppliers have varying pricing strategies based on their reputation, market position, and geographic location. It’s crucial to assess multiple suppliers to find the best balance of price and quality.

-

Incoterms: The agreed terms of delivery (Incoterms) can significantly impact total costs. Buyers should consider who bears the shipping costs and risks, as this can affect the overall price structure.

What Tips Can Help Buyers Negotiate Better Prices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, here are some strategic tips:

-

Negotiate Terms: Don’t hesitate to negotiate pricing based on order volume, long-term partnership potential, and payment terms. Suppliers may be willing to offer discounts for larger commitments or prompt payment.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also associated costs such as shipping, storage, and potential waste. A lower upfront cost may not always translate to better value if it leads to higher operational costs later.

-

Understand Pricing Nuances: Be aware of pricing fluctuations due to currency exchange rates, local economic conditions, and seasonal demand variations. This knowledge can be advantageous during negotiations.

-

Build Relationships with Suppliers: Establishing a solid relationship with suppliers can lead to better pricing and terms over time. A trusted partnership often results in more favorable conditions for both parties.

In conclusion, a comprehensive understanding of the cost components, pricing influencers, and negotiation strategies can empower B2B buyers in their sourcing of tamper resistant bags. This diligence not only ensures competitive pricing but also enhances the overall value derived from such critical packaging solutions.

Alternatives Analysis: Comparing tamper resistant bags With Other Solutions

Exploring Alternatives to Tamper Resistant Bags

In the realm of secure packaging solutions, tamper resistant bags are widely recognized for their effectiveness in protecting sensitive contents. However, various alternatives exist that may better suit specific business needs. This analysis compares tamper resistant bags with two viable alternatives: security seals and lockable containers. Each option offers unique features that can cater to different operational requirements, cost considerations, and security levels.

Comparison Table

| Comparison Aspect | Tamper Resistant Bags | Security Seals | Lockable Containers |

|---|---|---|---|

| Performance | Highly effective in showing tampering | Provides visual tampering evidence | Offers robust protection and security |

| Cost | Generally low to moderate | Low cost per unit | Higher initial investment |

| Ease of Implementation | Simple to use and apply | Quick application | Requires setup and space |

| Maintenance | Minimal upkeep required | No maintenance needed | May require occasional checks |

| Best Use Case | Cash handling, document transport | Shipping, sealing packages | High-value items storage |

In-Depth Analysis of Alternatives

Security Seals

Security seals are an economical alternative that provides a visual indication of tampering. They are often used in shipping and logistics, where packages need to be secured against unauthorized access. The primary advantage of security seals is their low cost, making them an attractive choice for businesses looking to enhance security without significant expenditure. However, they lack the physical barrier that tamper resistant bags provide, which may be a drawback for sensitive items. They are best suited for applications where the primary concern is to deter tampering rather than prevent access.

Lockable Containers

Lockable containers offer a higher level of security compared to tamper resistant bags. They are designed to house valuable items securely, making them ideal for industries such as pharmaceuticals or high-value electronics. The significant advantage of lockable containers is their durability and the additional layer of security provided by locks. However, they typically come with a higher price tag and may require more physical space for storage. Furthermore, they can be cumbersome to transport, which may limit their practicality for some businesses. Lockable containers are best used in scenarios where maximum security is paramount and the budget allows for a more substantial investment.

Making the Right Choice for Your Business Needs

When selecting a secure packaging solution, B2B buyers should evaluate their specific requirements, including the nature of the contents, budget constraints, and logistical considerations. Tamper resistant bags are ideal for businesses focused on affordability and ease of use, particularly in cash handling or document transport. Conversely, security seals may suit those needing a cost-effective solution for shipping, while lockable containers are better for high-value items requiring robust protection. By understanding the strengths and weaknesses of each alternative, businesses can make informed decisions that align with their operational goals and security needs.

Essential Technical Properties and Trade Terminology for tamper resistant bags

Tamper-resistant bags serve a critical function in securing and protecting valuable contents during transport and storage. Understanding the essential technical properties and terminology associated with these bags is vital for B2B buyers to make informed purchasing decisions.

What Are the Key Technical Properties of Tamper-Resistant Bags?

-

Material Grade

The material used in tamper-resistant bags typically includes low-density polyethylene (LDPE) or linear low-density polyethylene (LLDPE). These materials offer flexibility and durability, essential for withstanding the rigors of handling and transport. A higher material grade often translates to better puncture resistance and a longer lifespan, which is crucial for businesses looking to minimize replacement costs. -

Thickness (Mil)

The thickness of tamper-resistant bags is measured in mils (1 mil = 1/1000 of an inch). Common thicknesses range from 2 mil to 4 mil, with thicker bags providing enhanced protection against tearing and puncturing. For B2B buyers, selecting the appropriate thickness is vital based on the type of contents being packaged; heavier items require thicker bags for optimal safety. -

Sealing Mechanism

Most tamper-resistant bags feature heat-sealed closures, which provide a secure seal that demonstrates tampering if the bag is opened. The effectiveness of the sealing mechanism is crucial for maintaining the integrity of the contents. Buyers should consider whether a heat seal or a zip-lock mechanism better suits their operational needs, especially in terms of reusability and ease of access. -

Tamper-Evident Features

Tamper-evident bags are designed with features such as perforated tear strips that clearly indicate if a bag has been opened. These features are essential for industries that require strict adherence to security protocols, such as pharmaceuticals and cash handling. Understanding these features helps businesses comply with legal and regulatory requirements regarding product safety. -

Size and Tolerance

Size specifications are generally listed as width by length and do not include the additional lip for sealing. Tolerances of +/- 1/8″ on size and +/- 10% on thickness are common. Selecting the right size is crucial to ensure that products fit securely within the bag without excess space that could lead to movement and potential damage. -

Compliance Standards

Many tamper-resistant bags must meet specific compliance standards, such as FDA and USDA regulations for food safety. These standards assure buyers that the materials used are safe for their intended applications. Being aware of compliance is essential for businesses, especially those in regulated industries, to avoid legal repercussions and ensure consumer safety.

What Are Common Trade Terms in the Tamper-Resistant Bag Industry?

-

OEM (Original Equipment Manufacturer)

In the context of tamper-resistant bags, OEM refers to companies that produce bags based on the specifications provided by other businesses. Understanding OEM relationships can help buyers find manufacturers that can customize products to meet specific needs. -

MOQ (Minimum Order Quantity)

MOQ indicates the minimum number of bags a buyer must purchase from a manufacturer. Knowing the MOQ is essential for budgeting and inventory planning, as it can significantly impact overall procurement costs. -

RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests pricing and terms from suppliers. For B2B buyers, submitting an RFQ can help gather competitive pricing and options from multiple manufacturers, facilitating better purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. Familiarity with these terms is crucial for B2B transactions involving tamper-resistant bags, as they outline shipping costs, risk, and delivery responsibilities. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is critical for inventory management, ensuring that businesses can meet customer demands without delays. -

Custom Solutions

Many manufacturers offer custom solutions for tamper-resistant bags, allowing buyers to specify sizes, colors, and features. Customization can enhance branding and meet specific operational needs, making it an important consideration for B2B buyers.

By comprehensively understanding these properties and terms, international B2B buyers can make informed decisions that align with their operational requirements and regulatory compliance.

Navigating Market Dynamics and Sourcing Trends in the tamper resistant bags Sector

What Are the Global Drivers Shaping the Tamper-Resistant Bags Market?

The tamper-resistant bags market is experiencing significant growth, driven by increasing global regulatory requirements for secure packaging and heightened concerns around product integrity. Industries such as pharmaceuticals, banking, and e-commerce are particularly influenced by these factors, as they seek to protect sensitive materials and maintain consumer trust. The rise of e-commerce has further accelerated demand for secure packaging solutions, with businesses looking to enhance the safety and reliability of their shipping processes.

Emerging technologies are also impacting the sourcing landscape. The integration of smart packaging, which can provide real-time tracking and tamper alerts, is gaining traction among B2B buyers. This trend is particularly relevant for international buyers in Africa and South America, where logistical challenges necessitate robust security measures. Additionally, the shift towards digital transactions in banking and retail sectors has led to increased adoption of tamper-evident cash deposit bags and other security solutions.

How Are Sustainability and Ethical Sourcing Influencing the Tamper-Resistant Bags Sector?

As environmental concerns continue to gain prominence, the importance of sustainability in the tamper-resistant bags sector cannot be overstated. B2B buyers are increasingly seeking suppliers who can demonstrate a commitment to sustainable practices, including the use of recyclable materials and eco-friendly production processes. Many manufacturers are now offering bags made from low-density polyethylene (LDPE) that are both recyclable and compliant with various environmental standards.

Ethical sourcing is equally crucial. Businesses are more aware of the implications of their supply chains and are prioritizing partnerships with suppliers who adhere to fair labor practices and environmental regulations. Certifications such as ISO 14001 for environmental management and FSC certification for responsible sourcing are becoming essential criteria for B2B buyers. By aligning with suppliers who share these values, companies can enhance their brand reputation and appeal to environmentally-conscious consumers.

What Is the Historical Context of Tamper-Resistant Bags in B2B Markets?

The evolution of tamper-resistant bags dates back several decades, driven primarily by the need for enhanced security in various industries. Initially developed for the banking sector to secure cash deposits, these bags have since expanded into multiple applications, including pharmaceuticals and food services. The introduction of tamper-evident features, such as perforated seals and heat-sealed closures, has made these bags indispensable for businesses that prioritize product integrity and consumer safety.

As regulations around product packaging have tightened globally, the demand for tamper-resistant solutions has grown exponentially. This historical context is crucial for understanding the current landscape, as businesses navigate the complexities of sourcing reliable and compliant packaging solutions in an increasingly interconnected world.

Frequently Asked Questions (FAQs) for B2B Buyers of tamper resistant bags

-

How do I choose the right size of tamper resistant bag for my products?

Selecting the right size of tamper resistant bags involves measuring your products accurately. The bag dimensions are typically listed as width by length, excluding the sealing lip. It’s advisable to choose a bag that is slightly larger than your product for easy insertion and sealing. A good rule of thumb is to allow an additional ½ inch to 1 inch for sealing space. This ensures a snug fit without risking damage to the contents during packing and transport. -

What types of tamper resistant bags are best for international shipping?

For international shipping, consider using tamper evident bags that are durable and compliant with international regulations. Look for bags made from high-quality polyethylene that can withstand various environmental conditions. Additionally, bags that are both tamper-evident and waterproof can provide extra protection for sensitive items. Ensure that the bags have clear labeling and are easy to seal and reopen, which can enhance security and user convenience during transit. -

What customization options are available for tamper resistant bags?

Many suppliers offer customization options for tamper resistant bags, including size, color, thickness, and branding. Custom printing of logos or specific information can enhance your brand visibility and ensure compliance with specific regulations. When discussing customization, inquire about minimum order quantities (MOQs) and lead times, as these can vary significantly between suppliers. Tailored solutions help you meet unique packaging needs while maintaining product integrity. -

What are the typical minimum order quantities (MOQs) for tamper resistant bags?

Minimum order quantities for tamper resistant bags can vary widely based on the manufacturer and customization options. Standard MOQs often range from 500 to 5,000 bags, but many suppliers offer flexibility for larger orders or specific customization needs. It’s essential to discuss MOQs upfront with your supplier to ensure they align with your purchasing capacity and inventory management strategies. -

What payment terms should I expect when sourcing tamper resistant bags?

Payment terms can differ significantly between suppliers, but common practices include upfront payment, net 30, or net 60 terms. For international transactions, consider using secure payment methods like letters of credit or escrow services to mitigate risks. Always clarify payment conditions, including currency, payment methods, and any additional fees for international transactions. Establishing clear terms upfront can help prevent misunderstandings and streamline the procurement process. -

How do I vet suppliers of tamper resistant bags?

Vetting suppliers is crucial for ensuring quality and reliability. Start by checking their certifications, such as ISO compliance, which indicates adherence to industry standards. Request samples to evaluate the quality of the bags and inquire about their manufacturing processes. Additionally, look for reviews or testimonials from other international buyers. Establishing a relationship with a supplier who understands your market and regulatory requirements can significantly enhance your sourcing experience. -

What quality assurance measures should I consider for tamper resistant bags?

Quality assurance is vital when sourcing tamper resistant bags. Ensure that your supplier conducts rigorous testing for durability, tamper evidence, and compliance with food safety standards if applicable. Ask about their quality control processes, including inspections during production and pre-shipment. Establishing clear quality benchmarks and expectations will help maintain product integrity and minimize the risk of receiving substandard bags. -

How can I ensure timely logistics and delivery for tamper resistant bags?

To ensure timely logistics and delivery, coordinate closely with your supplier regarding shipping methods and timelines. Discuss options such as air freight for urgent needs or sea freight for cost-effectiveness on larger orders. Understanding customs regulations in your destination country is crucial to prevent delays. Consider working with a logistics partner who has experience in international shipping to streamline the process and ensure that your tamper resistant bags arrive on schedule.

Top 5 Tamper Resistant Bags Manufacturers & Suppliers List

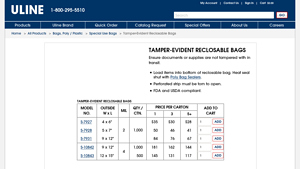

1. Uline – Tamper-Evident Reclosable Bags

Domain: uline.com

Registered: 1995 (30 years)

Introduction: Tamper-Evident Reclosable Bags ensure documents or supplies are not tampered with in transit. They are heat sealable with Poly Bag Sealers and feature a perforated strip that must be torn to open. The bags are FDA and USDA compliant. Available models include: S-7927 (4 x 6″, 1,000 qty, $35), S-7928 (5 x 7″, 50 qty, $46), S-7931 (9 x 12″, 84 qty, $76), S-10842 (9 x 12″, 1,000 qty, $181), S-10843 (1…

2. Royal Bag – Tamper Evident Reclosable Bags

Domain: royalbag.com

Registered: 2002 (23 years)

Introduction: Tamper Evident Reclosable Bags are designed to show evidence of tampering when opened, ensuring contents remain secure until intended use. Features include:

– Bottom loading design with heat seal closure after product insertion.

– Perforated tear strip above the zipper for easy access.

– Available in three thicknesses: 2 Mil (Standard Weight), 3 Mil (Medium Weight), and 4 Mil (Heavy Weight).

– Sid…

3. Novolex – Tamper-Evident Products

Domain: novolex.com

Registered: 2000 (25 years)

Introduction: Tamper-Evident Products include: 1. TamperFlag™ Containers – Rigid containers with a clear tamper-evident feature for point-of-sale visibility. 2. Tamper-Evident Paper Shopping Bags – Load & Seal® and Load & Fold® bags with easy-to-peel adhesive strips or foldable tops, sturdy paper twist handles, and wide openings for easy loading. 3. Tamper-Evident Plastic Bags – Load & Seal® delivery bags for s…

4. BitBox – Tamper-Evident Security Bags

Domain: bitbox.swiss

Registered: 2020 (5 years)

Introduction: Tamper-evident security bags for secure storage of Bitcoin backups. Key features include: 360-degree protection against undetected access, mechanical manipulation, steam and moisture, heat, freezing, and solvents. Easy to use with quick sealing, unique numbering, and a tear-off receipt. Made from strong, tear-resistant LDPE foil with double shrink-welded seams and micro security-print. Transparent…

5. Tamper-Proof Bags – Secure & Reliable Solutions

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Tamper-proof bags are made from robust, leak-resistant polyethylene designed to withstand tears and punctures. They feature a strong adhesive seal to secure contents. Common uses include securing crime scene evidence, shipping semi-fragile items, and branding opportunities. Evidence bags are made from high-quality paper or durable plastic, designed for collecting, transporting, and preserving phys…

Strategic Sourcing Conclusion and Outlook for tamper resistant bags

In today’s competitive landscape, the strategic sourcing of tamper-resistant bags is not merely an operational necessity but a critical component of safeguarding product integrity and consumer trust. As B2B buyers from regions such as Africa, South America, the Middle East, and Europe increasingly prioritize security in packaging, understanding the diverse options—from cash deposit bags to custom solutions—becomes essential. The ability to demonstrate that products have remained untouched until they reach the end user not only enhances credibility but also mitigates risks associated with tampering and fraud.

Investing in high-quality tamper-evident solutions can lead to significant operational efficiencies, particularly when considering factors such as ease of use, compliance with international safety standards, and the flexibility offered by customizable options. By aligning your sourcing strategy with reliable suppliers, you can ensure that your packaging solutions meet the specific needs of your market while fostering long-term partnerships.

Looking ahead, the demand for innovative tamper-resistant solutions is poised to grow. B2B buyers are encouraged to explore emerging technologies and trends that enhance product security. Take the proactive step today—engage with suppliers who can deliver tailored solutions that not only protect your products but also elevate your brand’s reputation in a global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.