A B2B Buyer’s Guide to Steel Washer: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for steel washer

In today’s competitive global market, sourcing high-quality steel washers can pose significant challenges for B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. The selection process often involves navigating various suppliers, understanding different washer types, and assessing their applications across industries. This guide serves as a comprehensive resource, equipping international buyers with the insights necessary to make informed purchasing decisions.

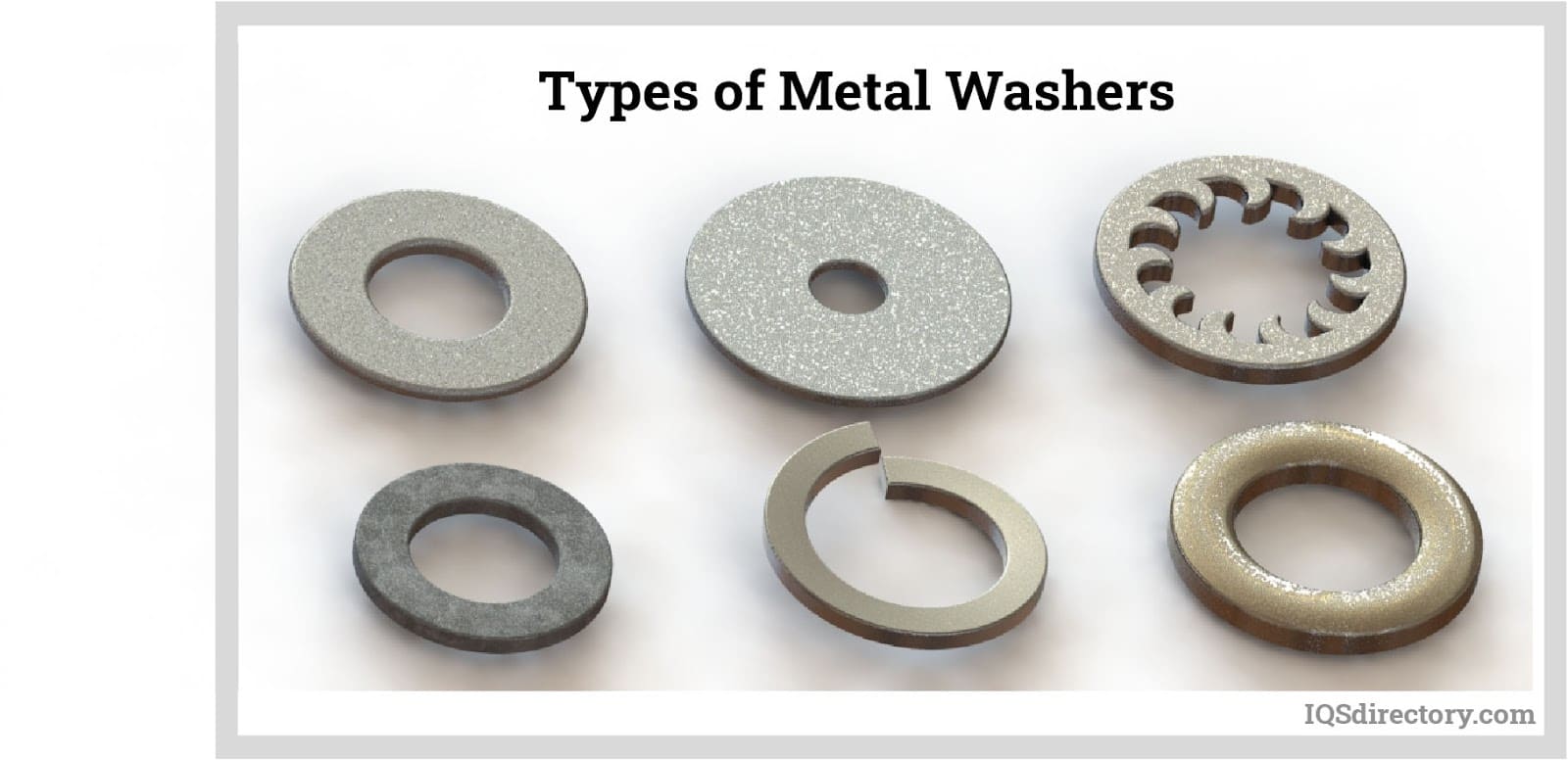

We delve into the myriad types of steel washers available, including flat, lock, and fender washers, and explore their specific uses in construction, automotive, and marine applications. Additionally, we provide a framework for vetting suppliers to ensure reliability and quality, alongside an analysis of cost considerations and market trends. By addressing these critical aspects, this guide empowers businesses to optimize their procurement strategies, ensuring they not only meet their operational needs but also enhance their competitive edge.

Whether you’re a manufacturer in Vietnam or a construction firm in Saudi Arabia, understanding the nuances of steel washers will enable you to streamline your supply chain and improve project outcomes. With actionable insights and expert recommendations, this guide is designed to elevate your sourcing experience and foster successful partnerships in the global marketplace.

Understanding steel washer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flat Washers | Thin, flat disks that distribute load evenly | Construction, automotive, machinery | Pros: Versatile, easy to source. Cons: Limited load distribution compared to others. |

| Lock Washers | Designed to prevent loosening due to vibration | Heavy machinery, automotive, aerospace | Pros: Excellent holding power. Cons: May require more precise installation. |

| Fender Washers | Larger outside diameter for better load distribution | Marine applications, automotive | Pros: Reduces risk of pull-through. Cons: Bulkier, may not fit all applications. |

| Sealing Washers | Incorporate a rubber or plastic seal for leak prevention | Plumbing, HVAC systems | Pros: Effective in preventing leaks. Cons: Limited temperature tolerance. |

| Split Lock Washers | Have a split design that increases friction and locking | General fastening, automotive | Pros: Improved grip, prevents loosening. Cons: Can be more expensive than flat washers. |

What Are Flat Washers and Where Are They Used?

Flat washers are among the most common types of washers, featuring a simple design that allows them to distribute the load of a fastener over a larger surface area. This makes them ideal for applications in construction, automotive, and machinery, where they help prevent damage to the surface being fastened. When purchasing flat washers, buyers should consider the material (steel vs. stainless steel), thickness, and whether a coating is required for corrosion resistance, especially in outdoor or industrial environments.

How Do Lock Washers Enhance Fastener Security?

Lock washers are specifically engineered to prevent fasteners from loosening due to vibrations or dynamic loads. These washers are commonly used in heavy machinery, automotive applications, and aerospace engineering, where the integrity of the fastening system is critical. Buyers should look for variations such as internal or external tooth designs to match the specific needs of their applications. It’s essential to ensure compatibility with the bolt size and type to maximize effectiveness.

What Makes Fender Washers Unique?

Fender washers have a larger outer diameter compared to standard flat washers, which allows for better load distribution and increased stability. They are particularly useful in marine applications and automotive settings, where they can help prevent pull-through in softer materials. When sourcing fender washers, B2B buyers should consider the material and coating options available, as well as the specific diameter needed for their projects.

Why Choose Sealing Washers for Plumbing Applications?

Sealing washers are designed with an integrated rubber or plastic seal that provides excellent leak prevention capabilities, making them ideal for plumbing and HVAC systems. These washers are crucial in ensuring tight seals in joints where liquids or gases are present. Buyers should assess the temperature and pressure ratings of sealing washers to ensure they meet the requirements of their specific applications, as these factors can significantly affect performance.

How Do Split Lock Washers Work?

Split lock washers feature a split design that enhances their grip on fasteners, thereby preventing loosening. They are used in various general fastening applications, including automotive and machinery assembly. When purchasing split lock washers, buyers should consider the material, size, and whether they need additional features like corrosion resistance. While they may be more expensive than flat washers, their effectiveness in maintaining fastener integrity can justify the investment.

Key Industrial Applications of steel washer

| Industry/Sector | Specific Application of Steel Washer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Load Distribution in Structural Frameworks | Enhances stability and safety of structures, reducing failure risk | Need for high-grade steel, compliance with local standards |

| Automotive | Fastening Components in Vehicle Assembly | Ensures reliability and performance of critical automotive parts | Requirement for corrosion resistance and custom sizing |

| Marine | Sealing and Fastening in Shipbuilding | Protects against harsh marine conditions, prolonging equipment life | Sourcing from certified suppliers for marine-grade materials |

| Renewable Energy | Supporting Wind Turbine Assemblies | Increases efficiency and durability of renewable energy systems | Need for high tensile strength and weather resistance |

| Industrial Machinery | Vibration Damping in Heavy Equipment | Reduces wear and tear, extending equipment lifespan | Availability of various sizes and grades for specific needs |

How Are Steel Washers Utilized in the Construction Industry?

In the construction sector, steel washers are critical for load distribution in structural frameworks. They are placed under bolts and nuts to spread the load evenly, preventing material damage and ensuring the integrity of the structure. Buyers from international markets, especially in regions like Africa and South America, should prioritize high-grade steel washers that comply with local building codes and standards to enhance safety and durability.

What Role Do Steel Washers Play in the Automotive Sector?

Within the automotive industry, steel washers are essential for fastening components during vehicle assembly. They ensure that critical parts remain secure under various operating conditions, which is vital for vehicle reliability and safety. International buyers must consider corrosion-resistant coatings and custom sizing to meet specific design requirements, particularly in regions with harsh climates, such as the Middle East.

How Are Steel Washers Used in Marine Applications?

In marine applications, steel washers provide sealing and fastening capabilities in shipbuilding. They protect against the corrosive effects of saltwater, thus enhancing the longevity of marine equipment. For buyers in Europe and Africa, sourcing from certified suppliers who offer marine-grade materials is crucial to ensure compliance with maritime safety regulations and to withstand extreme environmental conditions.

Why Are Steel Washers Important in Renewable Energy Projects?

Steel washers are vital in supporting wind turbine assemblies, where they enhance the efficiency and durability of renewable energy systems. By providing a stable connection between components, they help reduce vibration and wear, ultimately leading to increased operational efficiency. Buyers in South America and Europe should focus on sourcing high-tensile-strength washers with weather-resistant properties to ensure reliability in diverse climates.

How Do Steel Washers Contribute to Industrial Machinery?

In the realm of industrial machinery, steel washers serve as vibration dampers, reducing wear and tear on heavy equipment. Their role in maintaining the integrity of machinery connections can significantly extend the lifespan of equipment, leading to cost savings for businesses. When sourcing for this application, international buyers should look for a wide variety of sizes and grades to meet specific operational requirements, ensuring optimal performance in their machinery.

3 Common User Pain Points for ‘steel washer’ & Their Solutions

Scenario 1: Sourcing Quality Steel Washers for Diverse Applications

The Problem: B2B buyers often face difficulties in sourcing high-quality steel washers that meet specific project requirements. Variability in material quality can lead to performance issues, such as premature failure in structural applications. For instance, a construction company in South America might require washers that can withstand high tension loads, but they receive subpar products that fail under pressure, resulting in costly project delays and safety concerns.

The Solution: To mitigate these risks, buyers should establish relationships with reputable suppliers who provide detailed specifications for their steel washers, including material grade, tensile strength, and corrosion resistance. Buyers should seek suppliers that offer certifications for their products, such as ISO or ASTM standards, to ensure compliance with industry benchmarks. When placing orders, it’s crucial to specify not only the size and type of washer but also the intended application to ensure the supplier understands the performance requirements. Additionally, conducting periodic quality checks on received products can help maintain standards and prevent future issues.

Scenario 2: Understanding the Importance of Washer Types and Their Applications

The Problem: Many B2B buyers are unaware of the different types of steel washers and their specific applications, leading to improper selections that can compromise project integrity. For example, a manufacturer in Europe might use flat washers in a high-vibration environment where lock washers would be more appropriate, resulting in fastener loosening and assembly failures.

The Solution: To address this knowledge gap, buyers should invest time in understanding the various types of washers, such as flat washers, lock washers, and fender washers, and their distinct benefits. Educational resources, such as product datasheets and application guides provided by manufacturers, can be invaluable. Furthermore, collaborating with suppliers who offer technical support and expertise can help buyers make informed decisions. For projects with unique requirements, consider consulting with an engineer or a fastener specialist who can recommend the best washer types for specific applications, ensuring optimal performance and reliability.

Scenario 3: Managing Inventory and Reducing Waste in Steel Washer Procurement

The Problem: Efficient inventory management is a common challenge for B2B buyers, particularly in industries with fluctuating demand. A construction firm in Africa may over-purchase steel washers in anticipation of a large project, only to find that project delayed, leading to excess inventory that can rust or become obsolete over time. This not only ties up capital but also increases storage costs and waste.

Illustrative image related to steel washer

The Solution: To optimize inventory levels, buyers should implement a just-in-time (JIT) procurement strategy that aligns orders with project timelines. This can involve close collaboration with suppliers to establish flexible delivery schedules based on real-time project needs. Utilizing inventory management software can also aid in tracking usage rates and forecasting future needs accurately. Additionally, buyers might consider bulk purchasing agreements with suppliers that include return policies for surplus stock, allowing for a balance between having adequate supplies and minimizing waste. Regularly reviewing and analyzing purchasing patterns can further enhance decision-making processes, ensuring that procurement aligns with actual usage and project requirements.

Strategic Material Selection Guide for steel washer

What Are the Key Properties of Common Materials Used in Steel Washers?

When selecting materials for steel washers, it is essential to consider their properties, performance characteristics, and how they align with specific application requirements. Here, we analyze four common materials: carbon steel, stainless steel, galvanized steel, and alloy steel.

How Does Carbon Steel Perform in Steel Washers?

Carbon steel is a popular choice for manufacturing steel washers due to its excellent mechanical properties and cost-effectiveness. It exhibits high strength and hardness, making it suitable for applications that require load-bearing capabilities. However, carbon steel is prone to corrosion when exposed to moisture or harsh environments, which can limit its usability in certain applications.

Pros:

– High strength and durability.

– Cost-effective compared to other materials.

Cons:

– Susceptible to rust and corrosion.

– Limited suitability in high-humidity or corrosive environments.

Impact on Application:

Carbon steel washers are ideal for general-purpose applications in dry environments, such as machinery assembly and construction. However, they may not be suitable for marine or chemical environments where corrosion resistance is critical.

Illustrative image related to steel washer

Considerations for International Buyers:

Buyers from regions like Africa and South America should be aware of the climatic conditions that may affect the longevity of carbon steel washers. Compliance with local standards (e.g., ASTM) is also necessary to ensure product reliability.

What Advantages Does Stainless Steel Offer for Steel Washers?

Stainless steel is renowned for its corrosion resistance, making it an excellent choice for applications exposed to moisture, chemicals, or extreme temperatures. It maintains its strength at elevated temperatures and has a smooth surface finish, which helps prevent fastener loosening.

Pros:

– Exceptional corrosion resistance.

– Maintains mechanical properties in high-temperature applications.

Cons:

– Higher cost compared to carbon steel.

– More challenging to machine and manufacture.

Impact on Application:

Stainless steel washers are widely used in marine, automotive, and food processing industries due to their durability and resistance to rust. They are ideal for applications where hygiene and cleanliness are paramount.

Considerations for International Buyers:

International buyers, especially from the Middle East and Europe, should ensure compliance with standards like DIN or JIS for stainless steel grades. Understanding the specific grade of stainless steel (e.g., 304, 316) is crucial for application suitability.

How Does Galvanized Steel Enhance Steel Washer Performance?

Galvanized steel washers are carbon steel washers coated with zinc to improve corrosion resistance. This coating protects the underlying steel from moisture and environmental factors, making galvanized washers suitable for outdoor applications.

Pros:

– Cost-effective corrosion protection.

– Suitable for outdoor and humid environments.

Cons:

– Zinc coating may wear off over time.

– Less suitable for high-temperature applications.

Impact on Application:

Galvanized steel washers are commonly used in construction, automotive, and outdoor equipment where exposure to moisture is a concern. They provide a balance between cost and performance for many applications.

Considerations for International Buyers:

Buyers in regions with high humidity, such as Southeast Asia, should consider galvanized washers for outdoor applications. Compliance with local galvanization standards is essential for ensuring long-term performance.

What Role Does Alloy Steel Play in Steel Washers?

Alloy steel, which includes various elements to enhance specific properties, is known for its high strength and toughness. It can withstand high loads and is often used in heavy-duty applications.

Pros:

– Superior strength and toughness.

– Can be tailored for specific performance characteristics.

Cons:

– Higher manufacturing complexity and cost.

– May require specific heat treatment processes.

Impact on Application:

Alloy steel washers are ideal for heavy machinery, automotive, and aerospace applications where high strength is critical. They are designed for high-stress environments and can be customized for specific needs.

Illustrative image related to steel washer

Considerations for International Buyers:

Buyers should ensure that alloy steel washers meet relevant international standards (e.g., ASTM) and consider the specific alloy composition for their application needs.

Summary Table of Material Selection for Steel Washers

| Material | Typical Use Case for steel washer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General-purpose applications | High strength and durability | Susceptible to rust and corrosion | Low |

| Stainless Steel | Marine, automotive, food processing | Exceptional corrosion resistance | Higher cost and machining difficulty | High |

| Galvanized Steel | Outdoor and construction applications | Cost-effective corrosion protection | Zinc coating may wear off | Medium |

| Alloy Steel | Heavy machinery and aerospace | Superior strength and toughness | Higher manufacturing complexity | High |

This guide aims to provide B2B buyers with actionable insights into material selection for steel washers, ensuring informed decisions that align with their specific application requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for steel washer

What are the Main Stages in the Manufacturing Process of Steel Washers?

Manufacturing steel washers involves a series of well-defined stages to ensure high-quality products. The process typically includes material preparation, forming, assembly, and finishing.

Material Preparation

The journey begins with selecting high-quality raw materials, often in the form of steel coils. These coils are inspected for defects and must meet specific material standards, such as ASTM A36 for carbon steel. The material is then cut to size using precision shearing or laser cutting techniques, allowing for minimal waste and accurate dimensions.

Illustrative image related to steel washer

What Techniques are Used in Forming Steel Washers?

After material preparation, the forming stage utilizes various techniques such as stamping, cold heading, or machining. Stamping is the most common method, where a die is used to cut and shape washers from flat steel. This method is efficient for mass production and ensures consistent quality.

Cold heading may also be employed for thicker washers, where the material is shaped under high pressure without heating, resulting in strong and durable products. For specialized washers, machining techniques such as CNC (Computer Numerical Control) turning can be utilized for precise dimensions and complex shapes.

How is Assembly Conducted in Steel Washer Manufacturing?

Once formed, the washers may undergo an assembly process, especially if they are part of a more complex fastening system, such as lock washers or fender washers. This may involve combining multiple components, ensuring that each part fits securely and functions as intended. Quality checks are integrated throughout this stage to guarantee compatibility and performance.

What Finishing Processes are Commonly Used for Steel Washers?

The final stage of manufacturing involves finishing processes that enhance the durability and corrosion resistance of steel washers. Common techniques include galvanizing, where a protective zinc coating is applied, and powder coating, which adds a durable color finish. These processes not only improve aesthetics but also extend the lifespan of washers, making them suitable for various environments, including marine and industrial applications.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is a critical aspect of steel washer manufacturing, ensuring that products meet industry standards and customer expectations. International standards such as ISO 9001 are essential for maintaining a quality management system that promotes consistent product quality and continuous improvement.

Illustrative image related to steel washer

What Industry-Specific Standards Apply to Steel Washers?

In addition to general standards, specific certifications may be relevant depending on the application. For instance, CE marking is crucial for products sold in the European market, indicating compliance with safety and environmental regulations. Similarly, the American Petroleum Institute (API) provides standards for washers used in the oil and gas industry, ensuring they can withstand harsh conditions.

What Are the Key Quality Control Checkpoints in Steel Washer Production?

Quality control (QC) is woven throughout the manufacturing process, involving several checkpoints to ensure product integrity. These checkpoints typically include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections occur during the manufacturing stages to identify and rectify any issues in real-time.

- Final Quality Control (FQC): Completed washers undergo thorough testing to confirm they meet all quality standards and specifications before shipment.

What Common Testing Methods Are Used to Ensure Steel Washer Quality?

B2B buyers should be aware of the various testing methods employed to verify the quality of steel washers. Common testing techniques include:

- Tensile Testing: Evaluates the strength and ductility of the material.

- Hardness Testing: Measures the material’s resistance to deformation.

- Dimensional Inspection: Ensures that the washers meet specified measurements and tolerances.

- Corrosion Resistance Testing: Assesses the effectiveness of protective coatings.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are several methods to ensure supplier reliability:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures in place. This firsthand observation can provide insights into the supplier’s operational standards.

-

Quality Assurance Reports: Requesting detailed QA reports can help buyers understand how the supplier maintains quality throughout the manufacturing process. These reports should outline the testing methods used and the results of various quality checks.

-

Third-Party Inspections: Engaging a third-party inspection agency can provide an unbiased evaluation of the supplier’s quality control processes. These agencies can conduct thorough assessments and provide certification that the products meet international standards.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate various nuances related to quality control and certification. Different regions may have specific regulations and standards that impact product compliance. For instance, buyers in Europe may prioritize CE marking, while those in the Middle East may look for compliance with Gulf Standards Organization (GSO) regulations.

Additionally, understanding the local market’s expectations is crucial. Buyers should be aware of any regional certifications that may enhance their product’s marketability and acceptance. Engaging with local representatives or consultants can provide valuable insights into these nuances.

Conclusion

In-depth knowledge of the manufacturing processes and quality assurance protocols for steel washers is vital for B2B buyers. By understanding the stages of production, relevant quality standards, testing methods, and how to verify supplier credibility, buyers can make informed decisions that ensure the reliability and performance of their fastening solutions. This comprehensive approach not only mitigates risks but also fosters long-term partnerships with trusted suppliers across the globe.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘steel washer’

In the competitive landscape of international B2B sourcing, procuring steel washers requires a systematic approach to ensure quality, reliability, and cost-effectiveness. This checklist serves as a practical guide for buyers, particularly those engaging with suppliers across Africa, South America, the Middle East, and Europe.

Illustrative image related to steel washer

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to establish clear technical specifications for the steel washers you need. This includes dimensions, grades (e.g., Grade 2, Grade 8), and any specific material requirements such as corrosion resistance. Understanding these parameters helps streamline supplier selection and ensures compatibility with your project requirements.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in steel washers. Utilize online platforms, trade directories, and industry networks to compile a list of candidates. Pay attention to their reputation, years in business, and product range, as these factors can significantly impact reliability and quality.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications and comply with international standards, such as ISO 9001 for quality management. Certifications not only indicate adherence to quality control measures but also enhance trust in their manufacturing processes. Request documentation and assess their commitment to quality assurance.

Step 4: Request Samples for Testing

Before placing a bulk order, request samples of the steel washers to conduct quality assessments. Testing for dimensions, material integrity, and performance under stress can prevent costly mistakes later. Ensure that the samples meet your specifications and consider conducting tests in your operational environment.

Step 5: Analyze Pricing and Terms

Once you have shortlisted suppliers, analyze their pricing structures and terms of service. Look beyond just the price per unit; consider bulk discounts, payment terms, and shipping costs. Understanding the total cost of ownership is vital for making an informed decision that aligns with your budget.

Step 6: Assess Production Capabilities

Investigate the production capacity and lead times of your shortlisted suppliers. Understanding their manufacturing capabilities ensures they can meet your demand within your required timeframe. Inquire about their flexibility to accommodate future orders or changes in specifications.

Step 7: Establish Communication and Support Channels

Effective communication is crucial for a successful supplier relationship. Ensure that your chosen supplier has clear lines of communication and responsive customer support. Establishing a good rapport can facilitate problem resolution and foster a collaborative approach to future projects.

Illustrative image related to steel washer

By following this checklist, B2B buyers can systematically approach the procurement of steel washers, ensuring they make informed decisions that meet their technical, budgetary, and operational needs.

Comprehensive Cost and Pricing Analysis for steel washer Sourcing

What Are the Key Cost Components in Steel Washer Sourcing?

When sourcing steel washers, understanding the cost structure is crucial for B2B buyers. The primary components of cost include:

-

Materials: The cost of raw materials like carbon steel or stainless steel significantly influences the overall pricing. Fluctuations in global steel prices, driven by demand and supply dynamics, can lead to variations in sourcing costs.

-

Labor: Labor costs vary by region, with countries having different wage structures. For instance, labor-intensive production may be more cost-effective in regions with lower wage rates, impacting the final price of the washers.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, including utilities, factory maintenance, and administrative expenses. Efficient manufacturing processes can help reduce these overheads.

-

Tooling: The initial investment in tooling for manufacturing specific washer types can be substantial. Buyers should consider how tooling costs are amortized over production volumes, as larger orders often reduce per-unit tooling costs.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability and compliance with industry standards. While it adds to costs, the long-term benefits of reduced returns and enhanced customer satisfaction are significant.

-

Logistics: Transportation and warehousing costs are vital, particularly for international buyers. Shipping methods, distance, and local infrastructure can all influence logistics expenses.

-

Margin: Supplier margins can vary based on market positioning and competition. Understanding the typical margins in the industry can aid in negotiating better pricing.

What Factors Influence Steel Washer Pricing?

Several key factors affect the pricing of steel washers, which are particularly relevant for international buyers:

Illustrative image related to steel washer

-

Volume/MOQ: Larger orders often lead to lower prices per unit due to economies of scale. Buyers should assess their needs and negotiate minimum order quantities (MOQs) that align with their purchasing strategy.

-

Specifications/Customization: Custom washers designed for specific applications may incur higher costs. Buyers need to weigh the benefits of customization against the potential price increases.

-

Materials and Quality Certifications: The choice between standard and high-grade materials (like 18-8 or 316 stainless steel) will affect the price. Additionally, certifications (e.g., ISO, ASTM) may add to costs but can ensure product reliability.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can influence pricing. A well-established supplier may charge a premium for their products but offer superior quality and service.

-

Incoterms: Understanding the terms of shipment (e.g., FOB, CIF) is essential. They dictate who bears the shipping costs and risks, impacting the total landed cost for buyers.

How Can Buyers Optimize Their Sourcing Strategy for Steel Washers?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several strategies can enhance sourcing efficiency:

-

Negotiation: Engage in discussions with suppliers to secure better pricing and terms. Leverage volume commitments and long-term relationships to improve negotiation outcomes.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO) rather than just the upfront price. Factors such as durability, maintenance, and replacement frequency should be considered in the TCO analysis.

-

Pricing Nuances: Be aware of regional pricing differences. For example, sourcing from emerging markets may yield lower prices but could involve trade-offs in quality or delivery times.

-

Market Research: Conduct thorough market analysis to stay informed about price trends and supplier performance. This knowledge can empower buyers during negotiations and help identify the best sourcing options.

Conclusion

Understanding the comprehensive cost structure and pricing influences for steel washer sourcing is essential for B2B buyers. By analyzing cost components, recognizing pricing influencers, and implementing strategic sourcing techniques, buyers can enhance their procurement effectiveness and achieve better overall value. Always consider that prices may vary based on market conditions, supplier negotiations, and specific requirements. Thus, a proactive approach will lead to more informed and beneficial sourcing decisions.

Alternatives Analysis: Comparing steel washer With Other Solutions

When evaluating fastening solutions for various industrial applications, it is crucial to consider alternatives to steel washers. Steel washers are widely recognized for their load distribution capabilities and durability, but there are other options available that may better suit specific requirements based on performance, cost, and application context. This analysis compares steel washers with nylon washers and rubber washers, both of which serve similar functions but have distinct characteristics.

| Comparison Aspect | Steel Washer | Nylon Washer | Rubber Washer |

|---|---|---|---|

| Performance | High strength; excellent load distribution | Moderate strength; good for lightweight applications | Flexible; good vibration dampening |

| Cost | Generally low-cost; varies with grade | Typically low-cost; lower than steel | Moderate cost; varies based on type |

| Ease of Implementation | Easy to install; widely available | Easy to install; lightweight | Easy to install; requires careful sizing |

| Maintenance | Minimal; corrosion resistance varies | Minimal; resistant to many chemicals | Low; may degrade over time in harsh conditions |

| Best Use Case | Heavy-duty applications in construction and manufacturing | Electrical applications, lightweight fastening | Vibration dampening in automotive or machinery |

What Are the Advantages and Disadvantages of Nylon Washers Compared to Steel Washers?

Nylon washers are an excellent alternative for specific applications, particularly where electrical insulation is required. Their moderate strength makes them suitable for lighter loads, and they are resistant to corrosion and various chemicals. However, nylon washers may not withstand high temperatures or heavy loads as effectively as steel washers, limiting their use in demanding environments.

How Do Rubber Washers Compare to Steel Washers in Performance?

Rubber washers are primarily valued for their flexibility and ability to absorb vibrations, making them ideal for applications in the automotive and machinery sectors where movement is prevalent. They provide a good seal against moisture and dust, enhancing durability in certain settings. On the downside, rubber washers may degrade over time when exposed to extreme temperatures or harsh chemicals, potentially leading to premature failure.

Illustrative image related to steel washer

Conclusion: How Can B2B Buyers Choose the Right Fastening Solution?

Choosing the right fastening solution involves a careful analysis of specific project requirements, including load capacity, environmental conditions, and budget constraints. Steel washers excel in heavy-duty applications, while nylon and rubber washers provide advantages in lightweight or vibration-sensitive scenarios. B2B buyers should assess their unique needs, considering factors like performance, cost, and maintenance, to make an informed decision that aligns with their operational goals. By understanding the strengths and weaknesses of each alternative, buyers can select the most suitable solution for their applications.

Essential Technical Properties and Trade Terminology for steel washer

What Are the Key Technical Properties of Steel Washers?

Understanding the technical properties of steel washers is crucial for B2B buyers, particularly when selecting the right fasteners for various applications. Here are some essential specifications:

-

Material Grade

Steel washers are available in various grades, such as Grade 2, Grade 5, and Grade 8. The grade indicates the washer’s tensile strength and suitability for specific applications. For instance, Grade 8 washers are recommended for high-stress environments, while Grade 2 is adequate for lighter applications. Selecting the appropriate grade ensures durability and reliability in fastening assemblies, reducing the risk of failure. -

Outside Diameter (OD)

The outside diameter is a critical measurement that affects load distribution and compatibility with other fasteners. Washers are available in a range of diameters, typically from 1/4 inch to 3 inches or more. A properly sized washer distributes the load effectively, preventing material damage and prolonging the lifespan of the fastener connection. For B2B buyers, ensuring the right OD is essential to maintain structural integrity. -

Washer Thickness

Thickness affects the washer’s ability to handle load and prevent pull-through. Standard thicknesses range from 0.02 inches to over 0.2 inches, depending on the application. Thicker washers generally provide better load distribution and increased resistance to deformation. For buyers, understanding the thickness required for specific applications helps in selecting the right washer to enhance performance. -

Coating Options

Steel washers can come with various coatings, such as zinc plating or galvanization, to enhance corrosion resistance. In environments subject to moisture or chemicals, these coatings are vital for preventing rust and extending the service life of the fasteners. B2B buyers should assess the environmental conditions of their applications to choose appropriately coated washers. -

Tolerance

Tolerance levels in manufacturing indicate the permissible deviation from specified dimensions. Tight tolerances are critical in precision applications, ensuring a snug fit between washers and fasteners. For B2B buyers, understanding tolerance levels can help in quality assurance and compatibility with other components.

What Are Common Trade Terms in the Steel Washer Industry?

Familiarity with industry terminology can significantly streamline communication and procurement processes. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are used in another company’s end products. In the context of steel washers, OEMs may require specific washer designs or materials tailored to their equipment. B2B buyers often engage with OEMs for customized solutions. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of an item that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory and budget effectively. For instance, if a supplier has a MOQ of 500 washers, buyers need to assess their demand to avoid excess stock. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. This is particularly useful for bulk purchases of steel washers, allowing buyers to compare offers and negotiate better deals. A well-structured RFQ can lead to more favorable pricing and terms. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps B2B buyers clarify shipping, insurance, and delivery responsibilities, which is crucial for smooth cross-border transactions. -

Lead Time

Lead time refers to the duration from placing an order to receiving the product. For steel washers, lead times can vary based on manufacturing processes and supplier capabilities. Buyers should consider lead times in their project planning to ensure timely delivery of components. -

Fastener Coating

This term refers to the protective finishes applied to fasteners, including washers, to prevent corrosion and wear. Options like zinc plating, black oxide, and galvanization are common. Buyers need to evaluate the appropriate coating based on the application environment to ensure optimal performance.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing steel washers, leading to improved project outcomes and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the steel washer Sector

What Are the Key Market Drivers and Trends Affecting the Steel Washer Industry?

The steel washer market is experiencing significant transformation driven by several global factors. Key among these is the increasing demand for robust fastening solutions across various sectors, including construction, automotive, and industrial machinery. As infrastructure projects proliferate in emerging economies, particularly in regions like Africa and South America, the need for high-quality steel washers is surging. Additionally, technological advancements in manufacturing processes, such as automation and precision engineering, are enhancing product quality and reducing costs, making steel washers more accessible to B2B buyers.

Another notable trend is the growing emphasis on customization. International buyers are increasingly seeking suppliers who can provide tailored solutions to meet specific project requirements, whether in terms of size, material grade, or coating options. This shift is further fueled by the rise of e-commerce platforms, enabling buyers from diverse regions, including Vietnam and Saudi Arabia, to source products directly from manufacturers with greater ease and efficiency.

Moreover, the adoption of digital technologies in supply chain management is reshaping how buyers interact with suppliers. Real-time tracking, inventory management systems, and data analytics are becoming essential tools for B2B buyers, enabling them to make informed purchasing decisions and optimize their procurement processes.

How Is Sustainability and Ethical Sourcing Impacting the Steel Washer Market?

Sustainability has become a cornerstone of modern sourcing strategies, particularly in the steel washer sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny as businesses strive to minimize their carbon footprint. B2B buyers are increasingly prioritizing suppliers who implement sustainable practices, such as using recycled materials and adopting energy-efficient manufacturing techniques.

Ethical sourcing is also gaining traction, as companies recognize the importance of transparency in their supply chains. Buyers are looking for suppliers who can provide proof of compliance with environmental and labor standards, ensuring that their products are sourced responsibly. This shift is prompting manufacturers to obtain certifications, such as ISO 14001 for environmental management and Fair Trade for ethical labor practices.

In response to these demands, many steel washer suppliers are investing in “green” certifications and materials. For example, using stainless steel with a lower environmental impact during production is becoming a popular choice. By aligning their sourcing strategies with sustainability goals, B2B buyers can not only enhance their brand reputation but also contribute positively to the environment.

What Is the Historical Context of Steel Washers in B2B Transactions?

The evolution of steel washers can be traced back to the industrial revolution when the need for reliable fastening solutions became paramount in machinery and construction. Initially crafted from basic materials, the design and manufacturing processes have significantly advanced over the decades, resulting in a wide array of washer types and materials, including various grades of steel and stainless steel.

As industries expanded globally, the standardization of washer sizes and grades emerged, facilitating international trade. Today, the steel washer market is characterized by an extensive range of products designed to meet the diverse needs of various sectors. The historical context underscores the importance of continuous innovation and adaptation in the steel washer sector, highlighting its critical role in supporting modern engineering and construction projects worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of steel washer

-

How do I choose the right steel washer for my application?

Selecting the appropriate steel washer involves considering several factors, including the load requirements, environmental conditions, and compatibility with fasteners. For heavy-duty applications, Grade 8 washers are recommended for their superior strength, while galvanized or stainless steel options are ideal for corrosion resistance in harsh environments. Additionally, ensure that the washer’s diameter and thickness match the specifications of the bolts or nuts being used to prevent binding and ensure a secure fit. -

What are the advantages of using steel washers over other materials?

Steel washers offer excellent strength and durability, making them suitable for high-load applications in various industries. They are cost-effective compared to other materials like stainless steel, especially for bulk purchases. Steel washers can also be treated with coatings such as zinc or galvanization to enhance corrosion resistance, making them versatile for both indoor and outdoor use. Overall, steel washers are a reliable choice for ensuring the longevity and integrity of mechanical assemblies. -

What minimum order quantities (MOQs) should I expect when sourcing steel washers?

MOQs for steel washers can vary significantly depending on the supplier and the specific type of washer needed. Generally, manufacturers may set MOQs ranging from 100 to 1,000 pieces for standard sizes and types. For custom orders or specialized washers, the MOQ may be higher due to the added complexity of production. It’s advisable to discuss MOQs upfront with suppliers to align your purchasing needs with their production capabilities. -

How can I ensure quality when sourcing steel washers internationally?

To ensure quality, it is essential to vet potential suppliers thoroughly. Request certifications such as ISO 9001 or equivalent quality management certifications to verify their adherence to quality standards. Additionally, ask for product samples to assess the material and workmanship. Establishing clear quality assurance processes, including third-party inspections, can also help mitigate risks associated with international sourcing. -

What payment terms should I negotiate with international suppliers?

When negotiating payment terms, consider options such as letters of credit, advance payments, or net payment terms (e.g., net 30 or net 60 days) to balance risk and cash flow. Discussing partial payments upon order confirmation and final payment upon delivery can also be beneficial. Ensure that all terms are clearly documented in a purchase agreement to avoid misunderstandings. -

What logistics considerations should I be aware of when importing steel washers?

Logistics plays a crucial role in the timely delivery of steel washers. Factors to consider include shipping methods (air vs. sea), customs regulations, and potential tariffs or duties applicable in your region. Collaborate with a reliable freight forwarder to navigate these complexities and ensure compliance with international shipping laws. Additionally, factor in lead times for production and shipping when planning your inventory. -

How can I customize steel washers for specific applications?

Most manufacturers offer customization options for steel washers, including variations in size, thickness, and coating. When seeking customization, provide detailed specifications, including dimensions, material grade, and any specific performance requirements. Discuss your needs with the supplier early in the process to determine feasibility, production timelines, and any potential cost implications associated with custom orders. -

What are the common types of steel washers used in industrial applications?

Common types of steel washers include flat washers, lock washers, and fender washers. Flat washers are used for load distribution and to prevent pull-through, while lock washers are designed to prevent loosening under vibration. Fender washers have a larger outer diameter, ideal for distributing load over a wider surface area. Each type serves distinct purposes, so understanding their applications can help you select the right washer for your specific industrial needs.

Top 7 Steel Washer Manufacturers & Suppliers List

1. FastCo – Flat Washers

Domain: fastcoinc.com

Registered: 1999 (26 years)

Introduction: Flat washers are fastening products designed to be placed under the head of a bolt or nut to provide a smooth bearing surface and distribute the fastener load over a wider area. Available in steel and stainless steel materials, with coating options for enhanced corrosion resistance. Fastco offers wholesale flat washers in a range of sizes, materials, and coatings, including USS and SAE flat washer…

2. Manasquan Fasteners – Key Product

Domain: manasquanfasteners.com

Registered: 2001 (24 years)

Introduction: Key Product Details:

– Product Types: Flat Washers, Fender Washers, Split Lock Washers, SAE Flat Washers

– Material: 18-8 Stainless Steel, 316 Stainless Steel

– Sizes Available: Up to 1″ diameter, including various dimensions such as 1/4″, 5/16″, 3/8″, 1/2″, 5/8″, 3/4″, 1-3/8″, and custom sizes like 1/4″ x 1″, 1/4″ x 2″, etc.

– Sold by the piece, with bulk pricing available for orders of 100 piece…

3. Jay-Cee Sales & Rivet – Metal Flat Washers

Domain: rivetsonline.com

Registered: 2009 (16 years)

Introduction: Metal Washers are thin, disc-shaped pieces of material used between a fastener and the mating material for load distribution, as spacers, preload indicators, and in applications where the hole diameter exceeds the fastener head diameter. Jay-Cee Sales & Rivet offers a variety of metal flat washers in different sizes and thicknesses, including aluminum, copper, zinc-plated steel, and 18-8 stainless…

4. Fastener Superstore – Flat Washers

Domain: fastenersuperstore.com

Registered: 2004 (21 years)

Introduction: Flat Washers are available in a wide range of materials and finishes. Several styles are offered, including machine screw, SAE, and USS types. They can be used with machine screws and various bolts. SAE flat washers are common in the automotive industry, while USS style is used for various manufacturing applications.

5. Lawson Products – Specialty Washers

Domain: lawsonproducts.com

Registered: 1997 (28 years)

Introduction: Washers: Beveled Washers, Fender Washers, Fiber Washers, Finishing Washers, Flat Washers, Lock Washers, Machinery Bushings, Sealing Washers, Specialty Washers, Structural Washers, Washer Assortments.

6. Fastenere – Washers

Domain: fastenere.com

Registered: 2016 (9 years)

Introduction: Washers are an important component in fastening systems using bolts and screws. They help disperse load, reduce friction, protect surfaces, and prevent loosening. Types of washers include: 1. Flat Washers – Provide a wider bearing surface to disperse load weight and reduce chances of loosening. 2. Cup Washers – Offer a finished look and prevent screw heads from pulling through larger pilot holes. …

7. Albany County Fasteners – Flat Washers, Stainless Steel 304

Domain: albanycountyfasteners.com

Registered: 2007 (18 years)

Introduction: {‘product_name’: ‘Flat Washers, Stainless Steel 304’, ‘material’: ‘304 Stainless Steel’, ‘corrosion_resistant’: ‘Yes’, ‘marine_grade’: ‘Yes’, ‘product_type’: ‘Flat Washers’, ‘color’: ‘Silver’, ‘system_of_measurement’: ‘Inch’, ‘tolerance’: ‘Actual measurements may vary slightly +/- depending on production run within IFI Tolerances’, ‘sizes’: [{‘size’: ‘#4’, ‘inner_diameter’: ‘0.125″‘, ‘outer_diamet…

Strategic Sourcing Conclusion and Outlook for steel washer

What Are the Key Insights on Strategic Sourcing for Steel Washers?

In the evolving landscape of industrial fasteners, particularly steel washers, strategic sourcing emerges as a vital approach for B2B buyers. By understanding the diverse applications of steel washers—from construction to marine environments—buyers can optimize their supply chains and ensure the selection of the right materials tailored to their specific needs. The importance of quality cannot be overstated; high-grade washers enhance durability and performance, reducing long-term operational costs.

Illustrative image related to steel washer

Furthermore, leveraging local suppliers and manufacturers in regions like Africa, South America, the Middle East, and Europe can facilitate faster delivery times and lower shipping costs. Establishing relationships with reliable partners who offer customization and a wide range of products ensures that businesses can meet the unique demands of their projects efficiently.

How Can International Buyers Prepare for Future Trends in Steel Washer Sourcing?

Looking ahead, international B2B buyers are encouraged to adopt a proactive sourcing strategy. This involves staying informed about market trends, innovations in materials, and potential supply chain disruptions. Embracing digital procurement tools can also streamline purchasing processes and foster better supplier relationships. As the global demand for quality fasteners continues to rise, now is the time to invest in strategic sourcing practices that will position your business for success. Engage with trusted suppliers, explore new materials, and ensure your projects are built on a foundation of quality and reliability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to steel washer

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.