A B2B Buyer’s Guide to Steel Reinforcement Price: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for steel reinforcement price

In the ever-evolving global market, navigating the complexities of steel reinforcement price presents a formidable challenge for B2B buyers, particularly those sourcing materials for construction projects in regions like Africa, South America, the Middle East, and Europe. Fluctuations in pricing, influenced by raw material availability, geopolitical factors, and local demand, can significantly impact project budgets and timelines. This comprehensive guide is designed to empower international buyers with the insights needed to make informed purchasing decisions regarding steel reinforcement products.

Within these pages, you’ll find a detailed exploration of various types of steel reinforcement, including carbon steel rebar and specialty options, along with their applications in construction. We delve into supplier vetting strategies to help you identify reliable partners, ensuring quality and compliance with local standards. Additionally, we provide an in-depth analysis of cost factors, offering strategies to mitigate expenses while maintaining project integrity.

By equipping B2B buyers with the knowledge and tools to navigate the steel reinforcement market, this guide aims to simplify the sourcing process, enhance negotiation capabilities, and ultimately contribute to the successful execution of construction projects across diverse global landscapes. Whether you’re a seasoned procurement professional or new to the field, the insights offered here will be invaluable in achieving your project objectives efficiently and effectively.

Understanding steel reinforcement price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Carbon Steel Rebar | High tensile strength, cost-effective, widely available | General construction, infrastructure projects | Pros: Economical; Cons: Susceptible to corrosion without treatment. |

| Epoxy-Coated Rebar | Coated with epoxy to prevent rust, longer lifespan | Marine structures, bridges, and highways | Pros: Corrosion-resistant; Cons: Higher initial cost. |

| Galvanized Rebar | Coated with zinc for enhanced corrosion resistance | Foundations, retaining walls, and pavements | Pros: Durable; Cons: Can be more expensive than uncoated options. |

| Stainless Steel Rebar | Made from stainless steel, excellent corrosion resistance | High-end projects, coastal areas | Pros: Long-lasting; Cons: Significantly higher cost. |

| Fiber-Reinforced Polymer Rebar | Lightweight, non-corrosive, and high strength-to-weight ratio | Specialty applications, seismic zones | Pros: Lightweight; Cons: Limited availability and higher costs. |

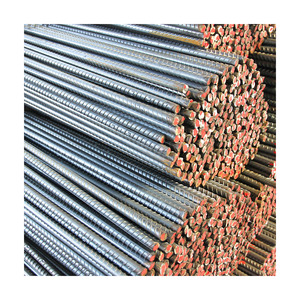

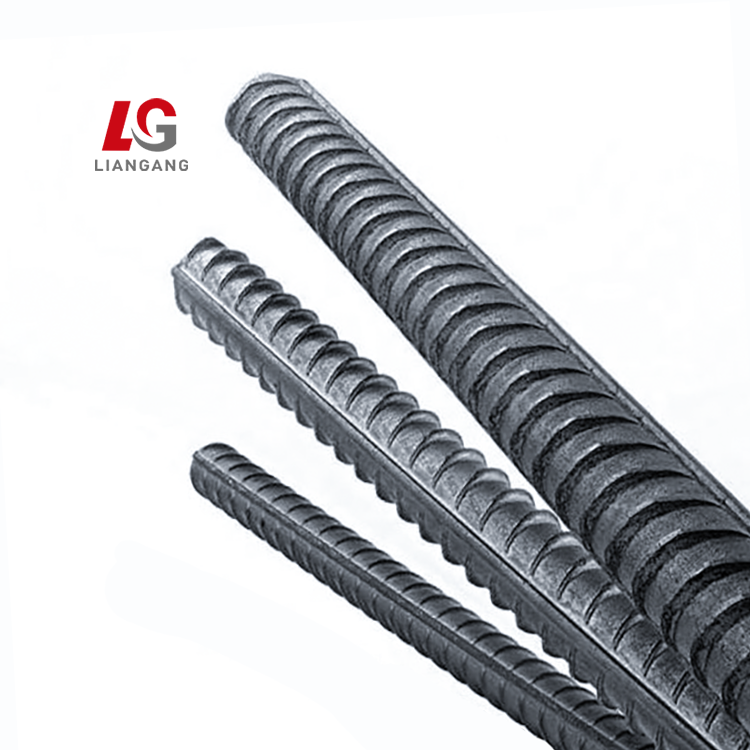

What are the Characteristics and Suitability of Carbon Steel Rebar?

Carbon steel rebar is the most common type used in construction due to its availability and cost-effectiveness. Typically produced in grades like 40 and 60, it offers high tensile strength suitable for a variety of applications, including residential and commercial buildings. However, buyers should consider its susceptibility to corrosion, particularly in humid or coastal environments. Proper treatment or protective coatings can mitigate this issue, making it a versatile choice for many projects.

Illustrative image related to steel reinforcement price

How Does Epoxy-Coated Rebar Enhance Durability?

Epoxy-coated rebar is designed for environments where corrosion is a significant concern. The epoxy coating provides a protective barrier, making it ideal for use in marine structures and regions with high moisture levels. While the initial cost is higher compared to carbon steel, the long-term savings on maintenance and replacement can justify the investment. B2B buyers should evaluate the specific environmental conditions of their projects to determine the suitability of this option.

What Advantages Does Galvanized Rebar Offer?

Galvanized rebar is coated with zinc to enhance its corrosion resistance, making it suitable for foundations, retaining walls, and pavements. This type of rebar offers a balance between cost and durability, providing a longer lifespan than uncoated steel. Buyers should weigh the additional cost against the expected lifespan and maintenance needs of their projects. It’s a solid choice for structures exposed to harsh weather conditions.

Why Choose Stainless Steel Rebar for High-End Projects?

Stainless steel rebar is renowned for its exceptional corrosion resistance and longevity, making it ideal for high-end construction projects, particularly in coastal or industrial environments. While significantly more expensive than other types, its durability can lead to reduced maintenance costs over time. For B2B buyers, the choice of stainless steel rebar often hinges on the project’s budget and the anticipated environmental challenges.

What are the Benefits and Limitations of Fiber-Reinforced Polymer Rebar?

Fiber-reinforced polymer (FRP) rebar is a lightweight, non-corrosive alternative to traditional steel options. Its high strength-to-weight ratio makes it suitable for specialty applications, including seismic zones. However, its limited availability and higher costs can be a barrier for some buyers. B2B purchasers should assess the specific needs of their projects, including weight restrictions and environmental factors, when considering FRP rebar.

Illustrative image related to steel reinforcement price

Key Industrial Applications of steel reinforcement price

| Industry/Sector | Specific Application of Steel Reinforcement Price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Reinforced Concrete Structures | Enhanced structural integrity and longevity | Compliance with local building codes and standards |

| Infrastructure Development | Road and Bridge Construction | Improved load-bearing capacity and safety | Availability of various grades and lengths of rebar |

| Mining and Heavy Industry | Support Structures for Heavy Equipment | Increased durability in harsh environments | Sourcing from reliable suppliers with quality certifications |

| Renewable Energy | Wind Turbine Foundations | Stability and resistance to environmental stress | Cost competitiveness and availability of specialized rebar |

| Residential Building | Foundation and Framing | Cost-effective strength and support for buildings | Local availability and logistics for timely delivery |

How is Steel Reinforcement Price Utilized in Construction?

In the construction industry, steel reinforcement is critical for creating reinforced concrete structures. The price of steel reinforcement directly impacts project budgets and timelines. Buyers must ensure they are sourcing from suppliers who can provide rebar that meets local building codes and standards. In regions like Africa and South America, where construction projects are often large-scale, understanding fluctuations in steel reinforcement prices can lead to significant cost savings in overall project expenses.

What Role Does Steel Reinforcement Play in Infrastructure Development?

Infrastructure development projects, such as roads and bridges, rely heavily on steel reinforcement to improve load-bearing capacities and ensure safety. The price of steel reinforcement is a crucial factor in project feasibility and planning. Buyers must consider the availability of various grades and lengths of rebar, as well as the logistics of transporting these materials to often remote project sites. For international buyers, especially in the Middle East and Europe, the ability to negotiate competitive pricing can significantly enhance project viability.

How is Steel Reinforcement Used in Mining and Heavy Industry?

In the mining and heavy industry sectors, steel reinforcement is essential for constructing support structures that withstand harsh environments and heavy loads. The price of steel reinforcement can vary widely based on quality and sourcing, making it vital for businesses to establish relationships with reliable suppliers. Buyers should prioritize sourcing from companies that hold quality certifications to ensure durability and compliance with industry standards. This is particularly important in regions like Africa, where mining operations face unique challenges.

Illustrative image related to steel reinforcement price

Why is Steel Reinforcement Important for Renewable Energy Projects?

Steel reinforcement is crucial for the foundations of renewable energy structures, such as wind turbines. The price of steel reinforcement can influence the overall cost of these projects, impacting their financial viability. Buyers must look for cost-competitive options while ensuring the rebar can withstand environmental stresses. In regions like South America and Europe, where renewable energy projects are rapidly expanding, understanding the nuances of steel reinforcement pricing can lead to better investment decisions.

How Does Steel Reinforcement Benefit Residential Building Projects?

In residential building applications, steel reinforcement is used in foundations and framing to provide strength and stability. The price of steel reinforcement is a significant factor for developers aiming to maintain budget efficiency while ensuring quality. Buyers should focus on local availability to minimize logistics costs and ensure timely delivery. In markets like Africa and Brazil, where residential construction is booming, understanding steel reinforcement pricing can lead to substantial savings and project success.

3 Common User Pain Points for ‘steel reinforcement price’ & Their Solutions

Scenario 1: Navigating Price Volatility in Steel Reinforcement

The Problem:

B2B buyers often face significant challenges due to the volatility of steel reinforcement prices. Fluctuating costs can derail project budgets and timelines, especially for large-scale construction operations. For example, a contractor in Brazil may have secured a contract based on a specific price for rebar but finds that the cost has surged unexpectedly due to global supply chain issues or increased demand. This unpredictability can lead to strained relationships with clients, reduced profit margins, and the potential for project delays.

The Solution:

To mitigate the impacts of price volatility, B2B buyers should adopt a proactive sourcing strategy. One effective approach is to establish long-term relationships with multiple suppliers across different regions. By diversifying the supply base, buyers can compare prices and secure more favorable terms. Additionally, implementing a hedging strategy—such as locking in prices through futures contracts or bulk purchasing agreements—can provide financial protection against sudden price spikes. It’s also beneficial to stay informed about market trends and economic indicators that affect steel prices. Regular communication with suppliers about their pricing forecasts can help buyers make more informed purchasing decisions.

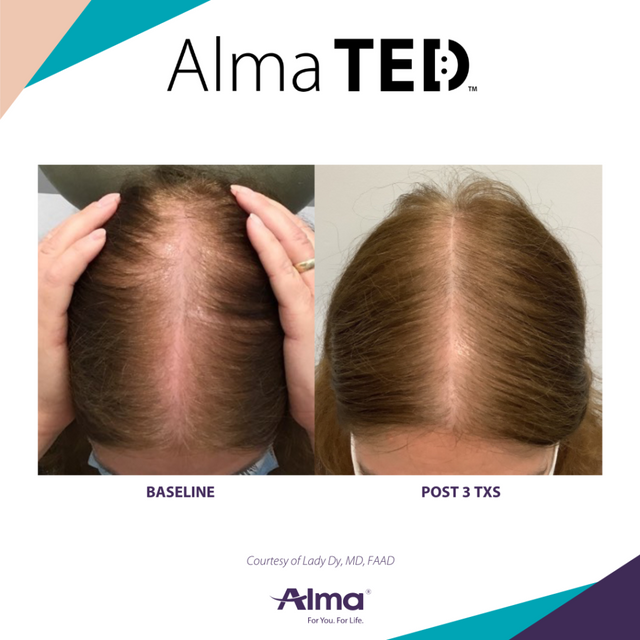

Scenario 2: Understanding Quality versus Cost in Steel Reinforcement

The Problem:

In the pursuit of cost savings, B2B buyers might compromise on the quality of steel reinforcement, leading to subpar materials that can jeopardize project integrity. For instance, a construction manager in Vietnam may choose the cheapest available rebar, only to discover later that it does not meet the necessary tensile strength specifications. This oversight can result in structural failures, increased liability, and costly rework, ultimately impacting the project’s bottom line.

Illustrative image related to steel reinforcement price

The Solution:

To avoid the pitfalls of sacrificing quality for lower prices, buyers should prioritize comprehensive quality assessments. This includes conducting thorough research on material grades and specifications before making a purchase. Implementing a standardized evaluation process for potential suppliers can help ensure that only high-quality materials are selected. Additionally, buyers can engage third-party quality assurance services to verify that the steel reinforcement meets industry standards. Educating project teams on the importance of quality over cost is also crucial; this fosters a culture of accountability where everyone understands that investing in superior materials can lead to long-term savings and enhanced project success.

Scenario 3: Streamlining Procurement Processes for Steel Reinforcement

The Problem:

B2B buyers often struggle with inefficient procurement processes that lead to delays and increased costs when sourcing steel reinforcement. For example, a project manager in South America may face bureaucratic hurdles or lack of coordination among various departments, resulting in missed deadlines and rushed orders that inflate prices. These inefficiencies can be particularly damaging in fast-paced construction environments where timing is critical.

The Solution:

Streamlining procurement processes requires a multi-faceted approach. Implementing an integrated procurement software solution can enhance visibility across the supply chain, enabling better tracking of orders and inventory levels. Establishing clear communication channels among procurement, engineering, and project management teams can also minimize delays and ensure that everyone is aligned on material needs and timelines. Additionally, adopting Just-In-Time (JIT) inventory practices can help manage stock levels efficiently, reducing excess inventory costs and ensuring materials are available when needed without overcommitting resources. Regular training and workshops on procurement best practices can empower teams to navigate the complexities of sourcing steel reinforcement more effectively, ultimately leading to better pricing and project outcomes.

Strategic Material Selection Guide for steel reinforcement price

What Are the Key Properties of Common Steel Reinforcement Materials?

When selecting materials for steel reinforcement, understanding the properties of different types of steel is crucial for ensuring optimal performance in construction applications. The most common materials used for steel reinforcement include carbon steel, stainless steel, galvanized steel, and fiber-reinforced polymer (FRP). Each material has distinct properties that affect its performance, cost, and suitability for various applications.

Illustrative image related to steel reinforcement price

How Does Carbon Steel Compare as a Reinforcement Material?

Carbon steel is the most widely used material for steel reinforcement due to its excellent tensile strength and affordability. It typically comes in grades such as Grade 40 and Grade 60, indicating their tensile strength in thousands of pounds. Carbon steel has a relatively high resistance to deformation under load, making it suitable for a range of construction applications. However, it is susceptible to corrosion, which can be a significant drawback in humid or saline environments.

Pros:

– High tensile strength and durability.

– Low cost compared to other materials.

– Availability in various grades.

Cons:

– Prone to rust and corrosion without protective coatings.

– Limited performance in highly corrosive environments.

Impact on Application:

Carbon steel is ideal for structural applications in buildings, bridges, and roads. However, in regions with high humidity or exposure to seawater, additional protective measures are necessary to mitigate corrosion.

Illustrative image related to steel reinforcement price

What Advantages Does Stainless Steel Offer for Reinforcement?

Stainless steel is known for its corrosion resistance, making it an excellent choice for environments where moisture or chemicals are present. It is available in various grades, such as 304 and 316, which provide different levels of corrosion resistance. The higher initial cost of stainless steel is often justified by its longevity and reduced maintenance requirements.

Pros:

– Exceptional corrosion resistance.

– Long lifespan with minimal maintenance.

– Aesthetic appeal for visible structures.

Cons:

– Higher cost compared to carbon steel.

– More challenging to work with due to its hardness.

Impact on Application:

Stainless steel is particularly suitable for marine construction, wastewater treatment facilities, and structures exposed to harsh environments. International buyers should ensure compliance with relevant standards, such as ASTM A955, to guarantee quality.

Illustrative image related to steel reinforcement price

Why Choose Galvanized Steel for Reinforcement?

Galvanized steel is carbon steel that has been coated with zinc to enhance its corrosion resistance. This material is often used in applications where exposure to moisture is expected, offering a cost-effective solution for reinforcing structures. The zinc coating provides a sacrificial layer that protects the underlying steel from rust.

Pros:

– Cost-effective corrosion protection.

– Good durability and strength.

– Readily available in various sizes.

Cons:

– The zinc coating can wear off over time, especially in harsh conditions.

– Not as strong as stainless steel.

Impact on Application:

Galvanized steel is commonly used in residential and commercial construction, particularly in areas with moderate exposure to moisture. B2B buyers from regions with high humidity should consider the expected lifespan of the zinc coating.

What Role Does Fiber-Reinforced Polymer (FRP) Play in Reinforcement?

FRP is an innovative alternative to traditional steel reinforcement, consisting of a polymer matrix reinforced with fibers (usually glass or carbon). It is lightweight, non-corrosive, and offers high tensile strength. FRP is particularly beneficial in applications where weight reduction is critical.

Pros:

– Lightweight and easy to handle.

– Excellent corrosion resistance.

– Non-magnetic and non-conductive.

Cons:

– Higher initial cost compared to steel.

– Limited availability and manufacturing complexity.

Impact on Application:

FRP is increasingly used in specialized applications, such as bridges and structures in corrosive environments. International buyers should be aware of the specific standards governing FRP materials, such as ASTM D7957.

Summary Table of Steel Reinforcement Materials

| Material | Typical Use Case for steel reinforcement price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Structural beams, bridges, and roads | High tensile strength | Prone to corrosion | Low |

| Stainless Steel | Marine structures, wastewater treatment | Exceptional corrosion resistance | Higher cost | High |

| Galvanized Steel | Residential and commercial construction | Cost-effective corrosion protection | Zinc coating wears off over time | Medium |

| Fiber-Reinforced Polymer (FRP) | Specialized applications, bridges | Lightweight and non-corrosive | Higher initial cost | High |

This analysis provides insights into the strategic selection of materials for steel reinforcement, helping international B2B buyers make informed decisions that align with their specific project requirements and regional conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for steel reinforcement price

What Are the Key Stages in the Manufacturing Process of Steel Reinforcement?

The manufacturing of steel reinforcement, commonly known as rebar, involves several critical stages that ensure the final product meets both performance and safety standards. Understanding these stages is vital for B2B buyers, as they can significantly influence pricing, quality, and delivery timelines.

-

Material Preparation

The process begins with the selection of raw materials, primarily steel billets or scrap steel. These materials undergo a rigorous inspection to ensure they meet the required specifications. Once approved, they are heated to a high temperature (around 1,200°C) to enhance their malleability. -

Forming

After heating, the steel is passed through a series of rollers in a process known as hot rolling. This reduces the diameter of the steel and shapes it into the desired form—typically round bars with specific diameters ranging from #3 (10mm) to #18 (57mm). The hot rolling process is critical, as it not only shapes the steel but also affects its mechanical properties. -

Assembly

In larger production facilities, the forming stage may also include the assembly of multiple rebars into bundles or coils, depending on the specifications required by clients. This assembly process is crucial for maintaining consistency and facilitating easier transportation. -

Finishing

The final stage involves surface treatment processes such as galvanization or epoxy coating, which enhance the corrosion resistance of the rebar. A cooling process follows, where the rebar is cooled down to room temperature, ensuring it retains its structural integrity.

What Quality Control Standards Are Relevant for Steel Reinforcement?

Quality assurance is paramount in the manufacturing of steel reinforcement. Adhering to international and industry-specific standards ensures that the rebar produced is safe, durable, and fit for purpose.

-

International Standards

Compliance with ISO 9001 is essential, as it outlines the requirements for a quality management system. Manufacturers must establish and maintain processes that consistently provide products that meet customer and regulatory requirements. -

Industry-Specific Standards

In addition to ISO standards, various certifications may apply depending on the target market. For example, in Europe, the CE marking is crucial, indicating that the product meets EU safety, health, and environmental protection requirements. In the Middle East, standards set by the Gulf Cooperation Council (GCC) might be applicable.

How Is Quality Control Implemented Throughout the Manufacturing Process?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to catch defects early and ensure compliance with standards.

-

Incoming Quality Control (IQC)

This initial checkpoint involves the inspection of raw materials upon arrival at the facility. The goal is to verify that the materials meet specified standards before they enter the production line. -

In-Process Quality Control (IPQC)

Throughout the manufacturing stages, continuous monitoring takes place. This includes checking dimensions, mechanical properties, and surface finishes. Statistical process control techniques may be applied to ensure consistency and detect any deviations from established norms. -

Final Quality Control (FQC)

After the manufacturing process, a comprehensive inspection is conducted. This includes mechanical testing (tensile strength, yield strength) and non-destructive testing methods (ultrasonic testing) to ensure the rebar meets all specified requirements.

What Testing Methods Are Commonly Used in Steel Reinforcement Quality Assurance?

Several testing methods are employed to ascertain the quality and safety of steel reinforcement:

- Tensile Testing: Measures the strength and ductility of the rebar, ensuring it can withstand necessary loads.

- Bend Testing: Assesses the rebar’s ability to bend without cracking, which is crucial for construction applications.

- Ultrasonic Testing: A non-destructive method used to detect internal flaws in the steel, ensuring structural integrity.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control practices is essential to avoid costly mistakes and ensure the reliability of materials. Here are effective strategies:

-

Supplier Audits

Conducting on-site audits of the supplier’s manufacturing facilities can provide insight into their processes and quality control measures. This hands-on approach allows buyers to assess compliance with international standards and best practices. -

Review of Quality Reports

Requesting detailed quality assurance reports, including results from IQC, IPQC, and FQC stages, can give buyers a comprehensive view of the manufacturer’s performance. -

Third-Party Inspections

Engaging third-party inspection agencies can offer an unbiased assessment of the manufacturing processes and the quality of the finished products. Many suppliers are willing to accommodate such inspections to enhance buyer confidence.

What Are the QC and Certification Nuances for International B2B Buyers?

Navigating the complexities of quality control and certification can be challenging for B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe.

-

Regional Standards Awareness: Buyers should familiarize themselves with the specific standards applicable in their regions. For instance, while ISO certifications are widely recognized, local standards may vary significantly, impacting acceptance and compliance.

-

Documentation and Traceability: Maintaining thorough documentation and traceability for all products is crucial. This includes certificates of conformity and material test reports, which may be required during customs clearance or for project compliance.

-

Cultural and Regulatory Considerations: Understanding the cultural and regulatory landscapes of the supplier’s country can influence negotiations and compliance. Buyers should consider the reliability and reputation of suppliers within their local contexts.

By grasping the intricacies of manufacturing processes and quality assurance in steel reinforcement, B2B buyers can make informed decisions that enhance their procurement strategies and project outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘steel reinforcement price’

To assist international B2B buyers in effectively sourcing steel reinforcement, this practical guide outlines essential steps to ensure informed decisions. Understanding the complexities of steel reinforcement pricing is crucial for successful procurement, especially in diverse markets across Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the steel reinforcement you require. This includes determining the grade (e.g., Grade 40 or Grade 60), size, and length of the rebar needed for your projects. Defining these details upfront helps suppliers understand your needs and ensures you receive accurate quotes.

Step 2: Conduct Market Research

Invest time in researching current market trends and price fluctuations for steel reinforcement. Pay attention to factors such as raw material costs, regional supply and demand, and seasonal variations. This knowledge will empower you to negotiate effectively and make informed decisions about timing and volume.

Illustrative image related to steel reinforcement price

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. Request company profiles, case studies, and references from other buyers within your industry or region. Look for suppliers with a proven track record of reliability and quality, as this will minimize risks in your procurement process.

- Check Certifications: Ensure that suppliers have the necessary certifications, such as ISO or ASTM standards, which indicate compliance with quality and safety regulations.

- Assess Production Capacity: Inquire about their production capabilities to ensure they can meet your order volumes and delivery timelines.

Step 4: Request Detailed Quotations

Ask for detailed quotations from shortlisted suppliers. A comprehensive quote should include pricing, delivery terms, payment conditions, and potential discounts for bulk orders. This transparency allows you to compare offers accurately and identify the best value for your investment.

Step 5: Negotiate Terms and Conditions

Once you receive quotations, engage in negotiation to secure the most favorable terms. Discuss pricing, payment terms, lead times, and warranties. Effective negotiation can lead to significant cost savings and improved service levels.

- Consider Long-term Partnerships: If you anticipate ongoing needs, explore options for establishing a long-term partnership, which can lead to better pricing and service agreements.

Step 6: Verify Supply Chain Reliability

Assess the reliability of the supplier’s supply chain. This includes understanding their sourcing of raw materials, production processes, and logistics. A robust supply chain reduces the risk of delays and ensures timely delivery of materials when you need them.

Step 7: Finalize and Monitor Your Order

After choosing a supplier, finalize the order and monitor its progress. Maintain open communication with the supplier to address any issues that may arise during production or shipment. This proactive approach helps ensure that your order meets your expectations upon delivery.

By following these steps, B2B buyers can navigate the complexities of sourcing steel reinforcement effectively, ensuring they secure quality materials at competitive prices while minimizing risks.

Comprehensive Cost and Pricing Analysis for steel reinforcement price Sourcing

What Are the Key Cost Components in Steel Reinforcement Pricing?

Understanding the cost structure of steel reinforcement is essential for B2B buyers aiming to optimize their procurement strategies. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The price of raw steel significantly influences the overall cost. Fluctuations in global steel prices due to supply chain disruptions or tariffs can directly impact sourcing costs. Buyers should keep abreast of market trends to anticipate price changes.

-

Labor: Labor costs vary by region and can be substantial, especially in regions with higher wage standards. The skill level required for manufacturing processes also plays a role in labor costs, particularly for specialized rebar types.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, including utilities, maintenance, and administrative expenses. Efficient manufacturing processes can help minimize overhead, thus reducing overall costs.

-

Tooling: Investment in tooling and machinery is a significant upfront cost. Buyers should consider suppliers’ capabilities to leverage advanced technologies that can offer better pricing due to efficiency gains.

-

Quality Control: Ensuring that the steel reinforcement meets industry standards involves costs related to testing and certification. Buyers should verify that suppliers have robust QC processes in place, which can affect both price and product reliability.

-

Logistics: Transportation costs can vary greatly depending on the distance from the supplier to the project site. Factors such as shipping mode, weight, and volume can influence logistics costs, making it essential for buyers to consider these in their total cost assessments.

-

Margin: Supplier margin is the profit added to the cost of production. Buyers should explore multiple suppliers to understand pricing variations and negotiate better terms.

How Do Price Influencers Affect Steel Reinforcement Costs?

Several factors influence the pricing of steel reinforcement:

-

Volume/MOQ: Purchasing in bulk can lead to significant discounts, making it imperative for buyers to assess their needs against Minimum Order Quantities (MOQs) set by suppliers.

-

Specifications/Customization: Custom rebar sizes or grades might incur additional costs. Buyers should clearly define their specifications to avoid unexpected expenses.

-

Materials Quality/Certifications: Higher quality materials or certifications (such as ISO or ASTM compliance) can raise costs but may be necessary for specific projects. Buyers should balance cost against quality requirements to ensure project integrity.

-

Supplier Factors: Supplier reputation, reliability, and financial stability can influence pricing. Established suppliers may command higher prices but offer better service and quality assurance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international buyers. These terms define the responsibilities of buyers and sellers in shipping and can impact overall costs.

What Are the Best Negotiation Strategies for B2B Buyers?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to better pricing and terms:

-

Leverage Relationships: Building long-term relationships with suppliers can foster better negotiation outcomes. Suppliers may offer better pricing to repeat customers or those with whom they have established trust.

-

Total Cost of Ownership (TCO): When negotiating, consider the TCO, which includes not just the purchase price but also logistics, installation, and maintenance costs. Highlighting TCO can provide leverage in negotiations.

-

Explore Multiple Quotes: Obtaining quotes from several suppliers can provide valuable benchmarks and negotiating power. This practice helps ensure competitive pricing and terms.

-

Be Aware of Pricing Nuances: International markets may have unique pricing structures influenced by local economic conditions, tariffs, and regulations. Familiarity with these factors will help buyers make informed decisions.

Disclaimer on Indicative Prices

It’s important to note that prices for steel reinforcement can vary significantly based on market conditions, regional factors, and supplier-specific pricing strategies. Buyers should always seek updated quotes and verify pricing with multiple sources before making procurement decisions.

Illustrative image related to steel reinforcement price

Alternatives Analysis: Comparing steel reinforcement price With Other Solutions

Understanding Alternatives to Steel Reinforcement Pricing

In the construction and infrastructure sectors, steel reinforcement is a critical component for ensuring structural integrity. However, as international markets evolve, B2B buyers are increasingly exploring alternative solutions that may offer cost benefits, improved performance, or unique advantages depending on project requirements. This analysis will compare steel reinforcement pricing with two viable alternatives: Fiber Reinforced Polymer (FRP) and Pre-stressed Concrete.

Comparison Table

| Comparison Aspect | Steel Reinforcement Price | Fiber Reinforced Polymer (FRP) | Pre-stressed Concrete |

|---|---|---|---|

| Performance | High tensile strength and durability | Excellent tensile strength, lightweight | High load-bearing capacity |

| Cost | Moderate to high | Generally higher upfront cost | Moderate to high |

| Ease of Implementation | Standard installation procedures | Requires specialized skills for installation | Requires careful design and engineering |

| Maintenance | Low maintenance, corrosion can be an issue | Very low maintenance, corrosion-resistant | Moderate, depends on environmental conditions |

| Best Use Case | General construction, highways, bridges | Marine structures, corrosive environments | Large-span structures, bridges, and high-load applications |

In-Depth Analysis of Alternatives

What are the Benefits and Drawbacks of Fiber Reinforced Polymer (FRP)?

Fiber Reinforced Polymer (FRP) is gaining traction as a lightweight alternative to traditional steel reinforcement. Its primary advantages include exceptional tensile strength and resistance to corrosion, making it ideal for use in harsh environments such as marine structures or chemical plants. However, the initial investment can be significantly higher than steel reinforcement, which may deter cost-sensitive projects. Additionally, the installation of FRP requires specialized skills and knowledge, which can complicate project timelines.

How Does Pre-stressed Concrete Compare to Steel Reinforcement?

Pre-stressed concrete is another alternative that is particularly effective for large-span applications such as bridges and parking garages. By placing steel tendons under tension before the concrete is poured, this method enhances the material’s load-bearing capacity and minimizes deflection. While the overall cost can be comparable to steel reinforcement, pre-stressed concrete requires careful design and engineering to ensure proper execution, which can complicate the implementation process. Maintenance is generally moderate, but it can vary depending on environmental factors.

Conclusion: How to Choose the Right Solution for Your Needs

For B2B buyers evaluating options for structural reinforcement, the choice between steel reinforcement, FRP, and pre-stressed concrete hinges on specific project requirements, budget constraints, and long-term maintenance considerations. Steel reinforcement remains a robust choice for many traditional applications, while FRP offers advantages in corrosive environments, and pre-stressed concrete excels in large, load-bearing structures. Conducting a thorough analysis of the project scope, environmental conditions, and financial implications will guide buyers in selecting the most suitable solution for their unique needs.

Essential Technical Properties and Trade Terminology for steel reinforcement price

What Are the Key Technical Properties of Steel Reinforcement?

Understanding the technical properties of steel reinforcement is crucial for B2B buyers to ensure they select the appropriate materials for their construction projects. Here are some critical specifications:

-

Material Grade

Steel reinforcement bars (rebars) come in various grades, such as Grade 40, Grade 60, and Grade 75, indicating their yield strength in thousands of pounds per square inch (psi). For example, Grade 60 rebar can withstand 60,000 psi. Selecting the right grade is vital as it affects the structural integrity and durability of concrete constructions. -

Diameter

The diameter of rebar typically ranges from #3 (3/8 inch) to #18 (2.26 inches). The choice of diameter impacts load-bearing capacity, spacing, and anchoring methods. Larger diameters are generally used in high-stress applications, making it essential for buyers to match the diameter with project specifications. -

Tensile Strength

This property measures the maximum stress a material can withstand while being stretched or pulled before breaking. Higher tensile strength in rebar enhances the overall strength of concrete structures, making it a critical factor in high-rise buildings and bridges. -

Corrosion Resistance

Corrosion-resistant rebar, such as epoxy-coated or galvanized options, is crucial in environments exposed to moisture or chemicals. These materials prevent deterioration over time, thereby extending the life of a structure. This property is particularly important for projects in coastal or industrial areas. -

Ductility

Ductility refers to the ability of steel to deform under tensile stress without breaking. High ductility is essential for structures that may experience dynamic loads, such as earthquakes. Understanding ductility helps buyers choose the right rebar for seismic-resistant designs. -

Tolerance

Tolerance specifications define the allowable deviation from the standard dimensions of rebar. Meeting these tolerances is essential for ensuring proper fit and performance in construction applications. Buyers should verify that suppliers adhere to industry standards to avoid complications during installation.

What Are the Common Trade Terms Related to Steel Reinforcement Pricing?

Navigating the steel reinforcement market requires familiarity with specific trade terminology. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are then sold under another company’s brand. For B2B buyers, understanding OEM relationships can help identify reliable suppliers and ensure quality standards. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of products a supplier is willing to sell. This is crucial for cost management; understanding the MOQ can help buyers avoid excess inventory and optimize procurement budgets. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing for specific products or services. Submitting an RFQ can streamline the procurement process, ensuring that buyers receive competitive offers tailored to their needs. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), helps buyers understand shipping costs and risks. -

Lead Time

Lead time refers to the amount of time from placing an order until delivery is received. Understanding lead times is essential for project scheduling and inventory management, particularly for large-scale construction projects. -

Steel Surcharge

A steel surcharge is an additional cost added to the base price of steel products, often due to fluctuations in raw material prices. Awareness of surcharges helps buyers budget more effectively and anticipate changes in pricing.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions regarding steel reinforcement purchases, ultimately leading to successful project outcomes.

Illustrative image related to steel reinforcement price

Navigating Market Dynamics and Sourcing Trends in the steel reinforcement price Sector

What Are the Key Trends Influencing the Steel Reinforcement Price Market?

The global steel reinforcement market is currently shaped by several key dynamics, driven by various factors including economic growth, infrastructure demands, and technological advancements. A significant driver is the rapid urbanization and infrastructural development in emerging markets, particularly in Africa and South America. Countries such as Brazil and Vietnam are investing heavily in construction and civil engineering projects, which is propelling the demand for steel reinforcement products.

In addition, the ongoing shift towards digitalization in sourcing practices is transforming how B2B buyers engage with suppliers. Technologies such as blockchain for supply chain transparency and artificial intelligence for demand forecasting are becoming increasingly prevalent. These innovations enable buyers to make more informed purchasing decisions, optimize inventory management, and enhance supplier collaboration.

Moreover, fluctuations in raw material costs, geopolitical tensions, and trade policies are affecting steel prices globally. Buyers must stay attuned to these market dynamics, as they can significantly impact pricing strategies. For instance, disruptions in production due to environmental regulations or labor strikes can lead to sudden price hikes. Understanding these trends will empower international buyers to navigate the complexities of the steel reinforcement market effectively.

How Can Sustainability and Ethical Sourcing Impact Steel Reinforcement Prices?

Sustainability is becoming a critical consideration in the steel reinforcement sector, influencing both sourcing decisions and pricing strategies. The environmental impact of steel production is significant, contributing to carbon emissions and resource depletion. As such, B2B buyers are increasingly prioritizing suppliers who adopt sustainable practices and offer ‘green’ certifications. These certifications, such as LEED (Leadership in Energy and Environmental Design) and ISO 14001, indicate a commitment to minimizing environmental impact.

Illustrative image related to steel reinforcement price

The importance of ethical supply chains cannot be overstated. Buyers are now more aware of the social implications of their sourcing decisions, including labor practices and community impact. Suppliers who demonstrate ethical sourcing practices are likely to gain a competitive advantage, as they not only meet regulatory requirements but also align with the values of socially conscious buyers.

Furthermore, the adoption of recycled materials in steel production is gaining traction. Not only does this practice reduce waste, but it also often leads to cost savings, which can be passed on to the buyer. By focusing on sustainability and ethical sourcing, international B2B buyers can enhance their brand reputation and meet the growing demand for responsible business practices, ultimately influencing the pricing landscape of steel reinforcement products.

How Has the Steel Reinforcement Market Evolved Over Time?

The evolution of the steel reinforcement market can be traced back to the industrial revolution, where the introduction of steel revolutionized construction practices. Initially, steel reinforcement was limited to basic applications; however, with advancements in metallurgy and engineering, its use has expanded significantly. The development of higher-grade rebar, capable of withstanding greater loads and environmental stresses, has enabled the construction of more complex structures.

The late 20th century saw a surge in global construction activities, particularly in developing nations, further driving demand. This period also marked the introduction of various standards and regulations to ensure quality and safety in construction materials. Today, the market is characterized by a blend of traditional manufacturing methods and cutting-edge technologies, such as automated production lines and advanced quality control systems, positioning the steel reinforcement sector for continued growth amidst evolving global demands.

Frequently Asked Questions (FAQs) for B2B Buyers of steel reinforcement price

-

1. How do I solve fluctuating steel reinforcement prices?

Fluctuating steel reinforcement prices can be managed by establishing long-term contracts with suppliers to lock in rates. Additionally, staying informed about market trends, tariffs, and geopolitical factors can help predict price changes. Buyers should also consider diversifying their supplier base to mitigate risks associated with single-source dependency. Implementing a just-in-time inventory system can further reduce exposure to price volatility, allowing for more strategic purchasing decisions. -

2. What is the best type of steel reinforcement for construction projects?

The best type of steel reinforcement depends on the specific requirements of your construction project. Common options include carbon steel rebar, which offers high tensile strength, and epoxy-coated rebar for corrosion resistance in harsh environments. For projects in seismic zones, using high-strength deformed rebar is advisable. Assessing the local climate, soil conditions, and project specifications will guide you in selecting the most suitable type of rebar for optimal performance and durability. -

3. How can I ensure the quality of steel reinforcement products?

To ensure the quality of steel reinforcement products, request certifications from suppliers that comply with international standards, such as ASTM or ISO. Conducting third-party inspections during production and before shipment can further validate quality. Establishing a robust quality assurance program that includes regular audits of suppliers can help maintain high standards. Additionally, collaborating with experienced engineers can provide insights into the most reliable sources and product specifications. -

4. What are typical payment terms for international steel reinforcement purchases?

Payment terms for international steel reinforcement purchases can vary significantly depending on the supplier and buyer’s relationship. Common terms include letters of credit (LC), which offer security to both parties, and advance payments or partial payments upon order confirmation. It’s essential to negotiate terms that align with your cash flow and project timelines. Additionally, understanding the currency exchange implications and transaction fees is crucial for managing costs effectively. -

5. How do I vet suppliers of steel reinforcement effectively?

Vetting suppliers involves assessing their credibility, reliability, and capability to meet your specific needs. Start by checking their business licenses and certifications, and look for customer reviews and references. Conducting site visits or requesting product samples can provide insights into their production processes and quality control measures. Engaging in discussions about their supply chain practices and delivery capabilities will further ensure they align with your operational requirements. -

6. What is the minimum order quantity (MOQ) for steel reinforcement?

The minimum order quantity (MOQ) for steel reinforcement varies by supplier and product type. Generally, suppliers may set MOQs based on production costs, shipping logistics, and inventory management. For bulk orders, MOQs may be lower, while specialty items or custom sizes often come with higher MOQs. Communicating your project needs with suppliers can facilitate negotiations around MOQs, potentially allowing for smaller orders if justified by project constraints. -

7. How do logistics impact the pricing of steel reinforcement?

Logistics significantly impact the pricing of steel reinforcement due to factors like shipping costs, delivery timelines, and customs duties. Buyers should consider the total landed cost, which includes transportation, insurance, and tariffs, to get an accurate picture of expenses. Choosing suppliers closer to your project site can reduce shipping costs and transit times. Additionally, understanding local regulations and potential delays in customs clearance is vital for effective planning and budget management. -

8. Are there customization options available for steel reinforcement?

Yes, many suppliers offer customization options for steel reinforcement, including varying lengths, diameters, and coatings to meet specific project requirements. Customization may involve additional lead times and costs, so it’s essential to communicate your needs clearly during the procurement process. Suppliers may also provide engineering support for specialized applications, ensuring that the reinforcement meets structural standards and local building codes.

Top 6 Steel Reinforcement Price Manufacturers & Suppliers List

1. Metals Depot® – Steel Rebar

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: Metals Depot® – Buy Rebar Online! Steel Rebar, also known as Concrete Reinforcing Bar, is primarily used to strengthen concrete and prevent cracking. A615 Rebar absorbs stress and weight, distributing tensions from concrete’s expansion and contraction. It is also used for ornamental applications due to its ribbed appearance and low cost. Available Grades: Grade 40 (min yield 40,000 lbs/sqin) and G…

2. Steel Supply – Carbon Steel Rebar

Domain: steelsupplylp.com

Registered: 2005 (20 years)

Introduction: This company, Steel Supply – Carbon Steel Rebar, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Wireless Estimator – Reinforcing Steel Pricing

Domain: wirelessestimator.com

Registered: 2002 (23 years)

Introduction: Reinforcing Steel Pricing: Per Linear Foot – 1/4″ #2: 0.170 lbs, $0.21; 3/8″ #3: 0.376 lbs, $0.34; 1/2″ #4: 0.668 lbs, $0.47; 5/8″ #5: 1.043 lbs, $0.66; 3/4″ #6: 1.502 lbs, $0.84; 7/8″ #7: 2.044 lbs, $1.02; 1″ #8: 2.670 lbs, $1.25; 1-1/8″ #9: 3.400 lbs, $1.53; 1-1/4″ #10: 4.303 lbs, $1.85; 1-3/8″ #11: 5.313 lbs, $2.13. Per Pound – 1/4″ #2: 0.170 lbs, $1.21; 3/8″ #3: 0.376 lbs, $0.90; 1/2″ #4: 0.66…

4. Trading Economics – Steel Rebar Futures

Domain: tradingeconomics.com

Registered: 2006 (19 years)

Introduction: Steel rebar futures held above CNY 3,080 per tonne in mid-September 2025. Chinese steelmakers produced 2.09 Mt of crude steel per day in early September, up 7.8% from a year earlier. Crude steel output in August declined for a third straight month. Steel fell to 3,077 CNY/T on September 16, 2025, down 0.68% from the previous day. Over the past month, Steel’s price has fallen 2.50%, but it is still…

5. Daily Metal Price – Steel Rebar

Domain: dailymetalprice.com

Registered: 2016 (9 years)

Introduction: Steel Rebar Price (USD / Metric Ton) for the Last Month

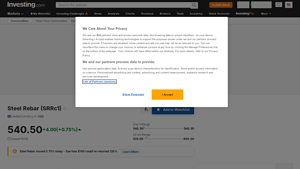

6. Investing.com – SRRc1 Key Stock Information

Domain: investing.com

Registered: 1995 (30 years)

Introduction: {“symbol”:”SRRc1″,”price”:”540.50″,”exchange”:”London Stock Exchange”,”day_range”:”540.50 – 540.50″,”52_week_range”:”535.00 – 609.00″,”prev_close”:”536.5″,”open”:”540.5″,”volume”:”0″,”1_year_change”:”-7.5%”,”settlement_day”:”N/A”,”settlement_type”:”Cash”,”contract_size”:”10 tonnes”,”tick_size”:”0.01″,”tick_value”:”0.1″,”point_value”:”1 = $10″,”months”:”FGHJKMNQUVXZ”}

Strategic Sourcing Conclusion and Outlook for steel reinforcement price

In navigating the complex landscape of steel reinforcement pricing, strategic sourcing emerges as an indispensable tool for B2B buyers. Understanding market trends, including fluctuations driven by global supply chain dynamics and regional demand variations, is vital. Key takeaways highlight the importance of establishing strong relationships with suppliers, leveraging bulk purchasing power, and staying informed on market intelligence to secure favorable pricing.

As international buyers from regions such as Africa, South America, the Middle East, and Europe seek to optimize their procurement strategies, focusing on sustainability and quality assurance will further enhance their competitive edge. Engaging with diverse suppliers can also mitigate risks associated with price volatility and availability.

Looking ahead, the steel reinforcement market is poised for continued evolution. By embracing strategic sourcing practices, B2B buyers can not only navigate current challenges but also position themselves for future growth opportunities. Now is the time to take proactive steps in refining your sourcing strategies, ensuring your business is well-prepared to thrive in an increasingly competitive environment. Consider reaching out to industry experts and suppliers to explore innovative solutions tailored to your specific needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.