A B2B Buyer’s Guide to Steel Beam For Roof Rack: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for steel beam for roof rack

Navigating the global market for steel beams for roof racks can present significant challenges for international B2B buyers, particularly when sourcing robust and reliable materials. With increasing demand for versatile and durable roof rack solutions in regions such as Africa, South America, the Middle East, and Europe, understanding the intricacies of this market is crucial. This guide aims to provide a comprehensive overview of the various types of steel beams available, their applications in different industries, and essential considerations for supplier vetting and cost evaluation.

International buyers face unique hurdles, including fluctuating material costs, varying quality standards, and the need for compliance with regional regulations. By delving into the characteristics of different steel beam types, such as I-beams and square tubing, this guide equips buyers with the insights needed to make informed purchasing decisions. Furthermore, it highlights key features to look for, including strength, corrosion resistance, and ease of installation, ensuring that your chosen steel beam meets both functional and aesthetic requirements.

Ultimately, this guide empowers B2B buyers to navigate the complexities of sourcing steel beams for roof racks effectively, fostering confidence in their purchasing choices. By understanding market dynamics and evaluating potential suppliers, buyers can secure high-quality materials that enhance their product offerings and meet customer demands in a competitive landscape.

Understanding steel beam for roof rack Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Lo-Profile Cross Beams | 1/8″ steel construction, multiple accessory slots | Overland vehicles, adventure racks | Pros: Lightweight, easy installation; Cons: Limited load capacity compared to heavier beams. |

| Hi-Rise Utility Cross Beams | CNC clamps, low-profile design, high clamping force | Roof-top tents, heavy-duty cargo management | Pros: High strength, versatile; Cons: More expensive, may require specific mounting systems. |

| Structural I-Beams | Heavy-duty, pre-engineered, adjustable arms | Industrial storage, construction support | Pros: Exceptional load-bearing capacity; Cons: Higher weight and installation complexity. |

| Square Steel Tubing | Available in various sizes, customizable designs | Custom roof racks, specialized vehicles | Pros: Customizable, lightweight; Cons: May require additional fabrication and assembly time. |

| Cantilever Racks | Double-sided configurations, adjustable arms | Lumber yards, long material storage | Pros: Space-efficient, robust design; Cons: Requires significant floor space for installation. |

What are Lo-Profile Cross Beams and Their Applications?

Lo-Profile Cross Beams are crafted from 1/8″ steel, designed with multiple accessory slots for versatility in mounting additional gear. These beams are particularly suited for overland vehicles and adventure racks, making them ideal for B2B buyers in the outdoor recreation sector. Their lightweight nature and ease of installation provide an attractive option for businesses looking to enhance their vehicle’s cargo capabilities without adding excessive weight. However, their load capacity may not match that of heavier alternatives.

How Do Hi-Rise Utility Cross Beams Stand Out?

Hi-Rise Utility Cross Beams utilize CNC clamps and a low-profile design to provide substantial clamping force, making them suitable for mounting roof-top tents and other heavy-duty accessories. They are particularly beneficial for businesses in the outdoor and adventure sectors that require robust solutions for transporting equipment. While their high strength and versatility are significant advantages, the price point and potential need for specific mounting systems may be considerations for budget-conscious buyers.

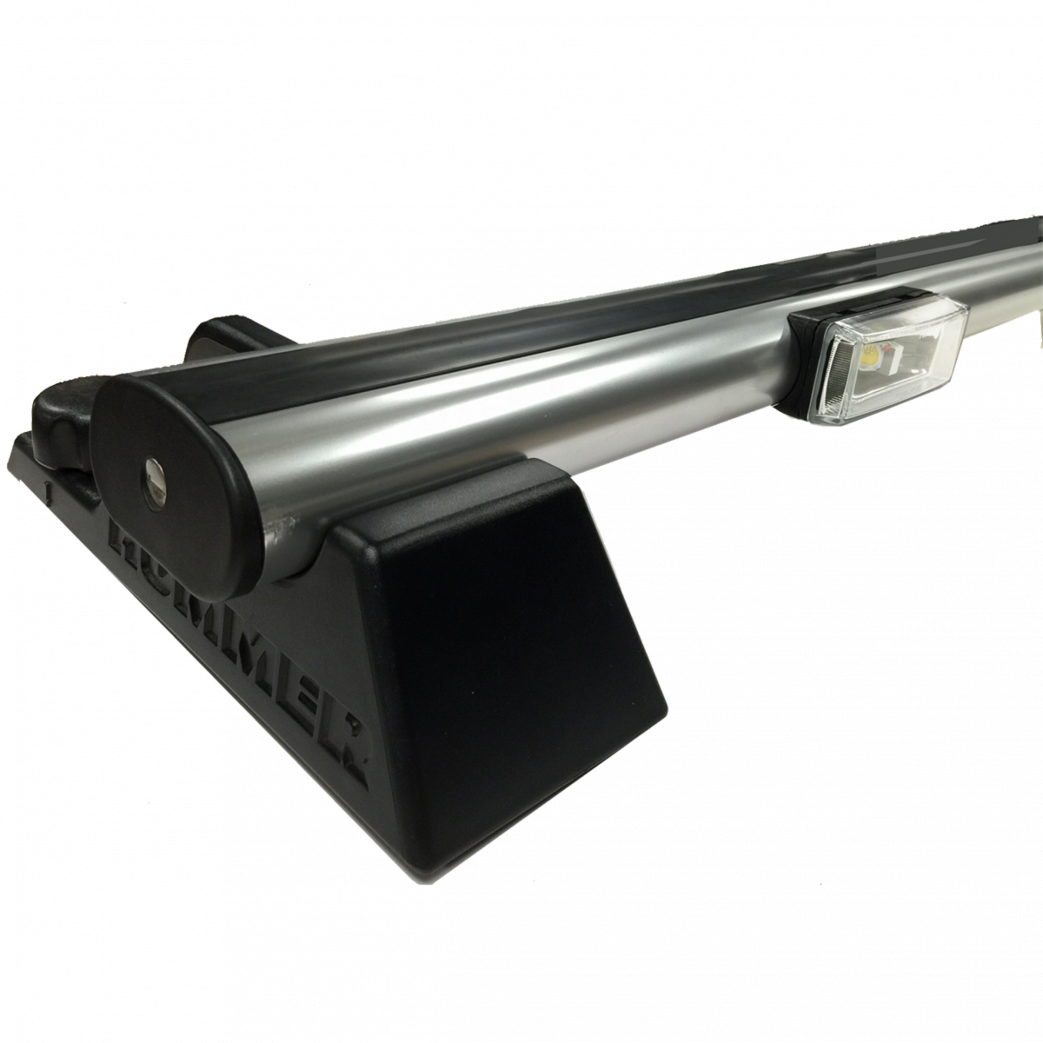

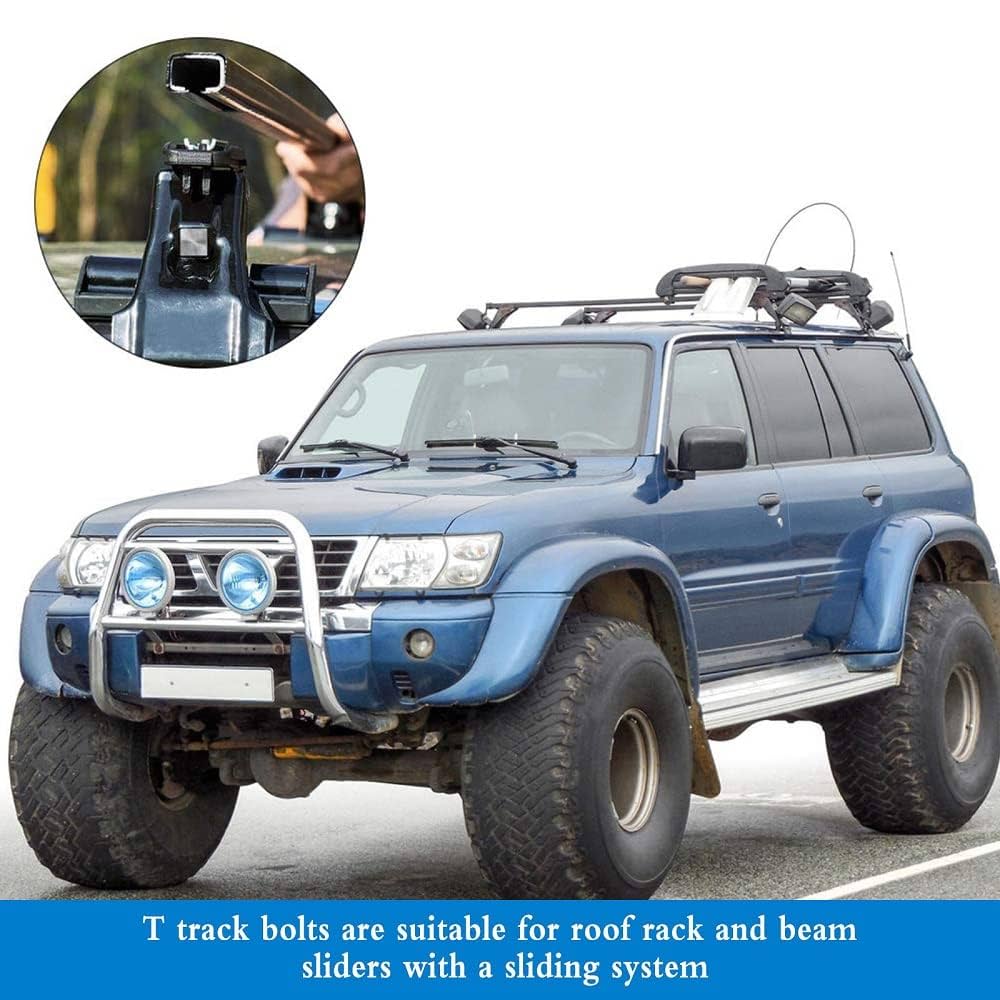

Illustrative image related to steel beam for roof rack

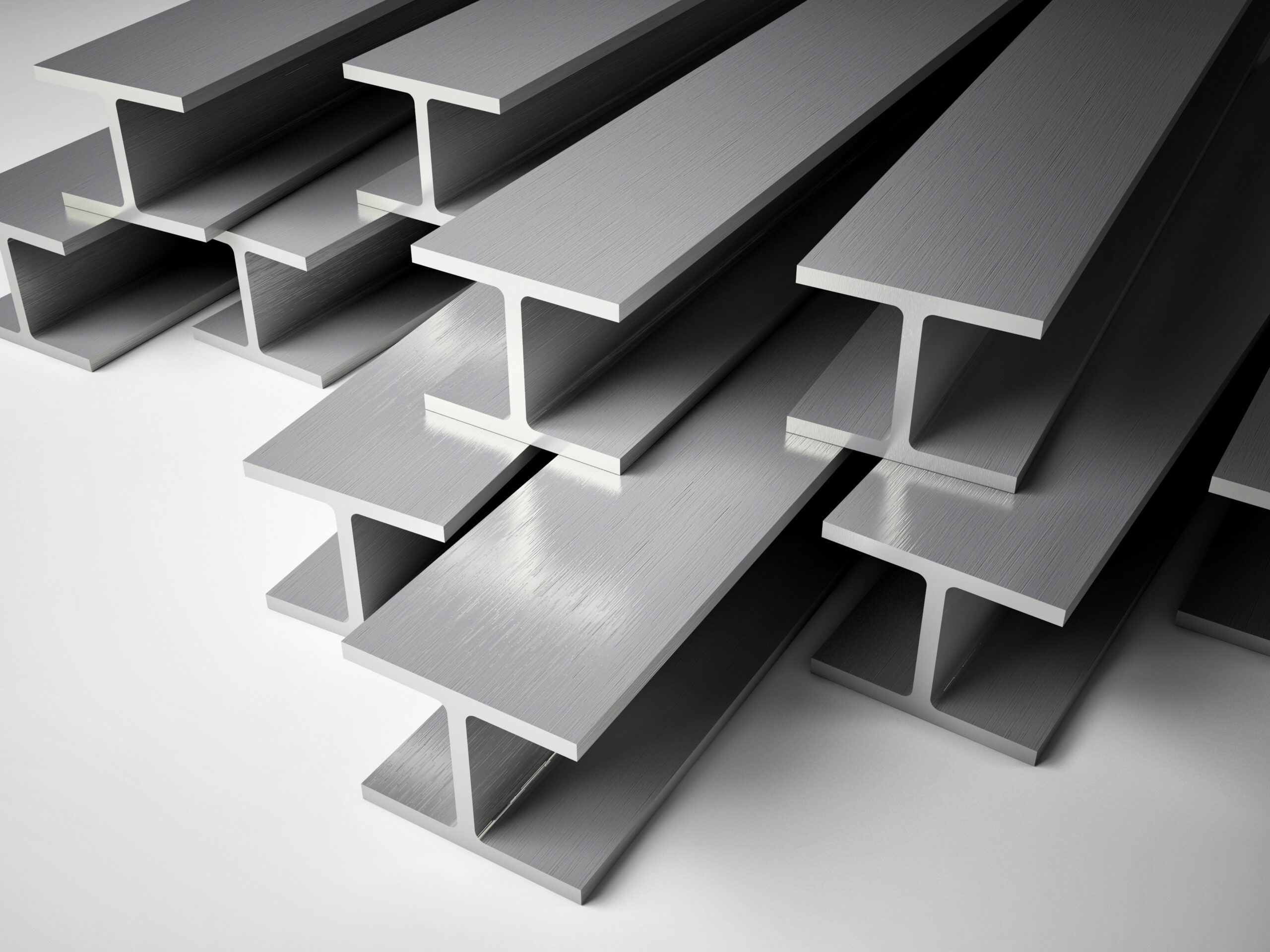

Why Choose Structural I-Beams for Heavy-Duty Applications?

Structural I-Beams are known for their heavy-duty construction, pre-engineered designs, and adjustable arms, making them ideal for industrial storage and construction support. Their exceptional load-bearing capacity caters to businesses that require reliable solutions for heavy materials. However, the increased weight and complexity of installation can be a drawback for some buyers, particularly those with limited space or resources for installation.

What Are the Benefits of Using Square Steel Tubing?

Square Steel Tubing is a versatile option available in various sizes, allowing for customizable designs tailored to specific business needs. This type of beam is frequently used in custom roof racks for specialized vehicles, appealing to businesses in niche markets. Its lightweight nature is a significant advantage, though it may require additional fabrication and assembly time, which could impact project timelines for some companies.

How Do Cantilever Racks Provide Efficient Storage Solutions?

Cantilever Racks are designed with double-sided configurations and adjustable arms, making them ideal for lumber yards and long material storage. Their space-efficient design allows businesses to maximize storage capacity while maintaining easy access to materials. Although they are robust and provide excellent support, the requirement for significant floor space can be a limitation for businesses with constrained operational areas.

Key Industrial Applications of steel beam for roof rack

| Industry/Sector | Specific Application of Steel Beam for Roof Rack | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Overland and Adventure Vehicle Accessories | Enhanced cargo capacity and stability for outdoor adventures | Durability, weight capacity, and corrosion resistance |

| Construction | Temporary Storage Solutions | Efficient and safe storage of construction materials on-site | Load-bearing capacity and compliance with safety standards |

| Transportation & Logistics | Roof Racks for Delivery Vehicles | Increased payload capability and optimized vehicle efficiency | Compatibility with vehicle models and ease of installation |

| Outdoor Recreation | Roof Racks for Camping Gear | Secure transportation of outdoor equipment, maximizing space | Lightweight design and resistance to environmental factors |

| Retail | Display Racks for Outdoor Equipment | Attractive presentation and easy access for customers | Versatility in design and ability to support various products |

How is Steel Beam for Roof Rack Used in the Automotive Sector?

In the automotive industry, steel beams are essential for overland and adventure vehicle accessories. These beams provide robust structural support for roof racks that carry heavy loads such as camping gear and recreational equipment. This application not only enhances cargo capacity but also ensures stability during transit, addressing the common concern of load shifting. Buyers should prioritize sourcing beams with high durability and corrosion resistance, especially in regions with harsh climates, such as the Middle East and South America.

Illustrative image related to steel beam for roof rack

What Role Does Steel Beam Play in Construction Applications?

In construction, steel beams are utilized for temporary storage solutions, particularly for holding materials like lumber and equipment on job sites. These racks facilitate efficient organization and easy access to materials, enhancing workflow and safety. The ability to bear significant loads is crucial, and buyers must consider compliance with local safety regulations and the specific load requirements of their projects. Ensuring that the beams are treated for weather resistance can be particularly important in regions prone to heavy rains or humidity.

How Are Steel Beams Beneficial for Transportation and Logistics?

Steel beams serve a vital role in the transportation and logistics sector by providing roof racks for delivery vehicles. These beams enable increased payload capability, allowing companies to optimize their delivery operations. The importance of compatibility with various vehicle models cannot be overstated, as seamless installation can significantly reduce operational downtime. Buyers should also consider the weight of the beams, as lighter options can improve fuel efficiency and lower transportation costs.

In What Ways Do Steel Beams Support Outdoor Recreation?

For the outdoor recreation industry, steel beams are critical in constructing roof racks designed to transport camping gear and other outdoor equipment. These racks secure items during travel, solving issues related to space limitations and load security. Buyers in this sector should focus on lightweight yet strong options that can withstand diverse environmental conditions, ensuring long-lasting performance during outdoor adventures.

Illustrative image related to steel beam for roof rack

How Do Retailers Utilize Steel Beams for Product Displays?

Retailers, particularly those specializing in outdoor equipment, leverage steel beams to create display racks. These racks not only provide an attractive presentation for products but also ensure easy access for customers, enhancing the shopping experience. Versatility in design is key, as retailers may need to adjust racks for various products. Buyers should consider sourcing beams that are both aesthetically pleasing and capable of supporting a range of weights, ensuring they meet the demands of their diverse inventory.

3 Common User Pain Points for ‘steel beam for roof rack’ & Their Solutions

Scenario 1: Difficulty in Ensuring Structural Integrity for Heavy Loads

The Problem:

B2B buyers often face challenges in guaranteeing the structural integrity of steel beams when used for roof racks, especially when carrying heavy loads such as equipment or materials. This is particularly relevant in industries like construction and logistics, where the risk of load failure can lead to costly damages or even injuries. Buyers may struggle to determine the appropriate steel grade, thickness, and design specifications that can support their intended use while adhering to local regulations and safety standards.

The Solution:

To address these concerns, it is crucial to engage with reputable suppliers who provide detailed specifications and load ratings for their steel beams. Buyers should prioritize sourcing beams that are made from high-strength materials, such as 1/8″ hot-rolled steel, which can offer the durability needed for heavy loads. Additionally, conducting a thorough analysis of the load distribution and using beams with multiple accessory slots can enhance stability. It’s advisable to consult with engineers or structural experts to ensure the selected beams are designed to meet or exceed safety requirements. Regular maintenance checks should also be instituted to monitor wear and prevent structural failure over time.

Scenario 2: Challenges in Installation and Compatibility with Existing Systems

The Problem:

B2B buyers frequently encounter compatibility issues when attempting to install steel beams for roof racks onto existing vehicle systems or structures. This problem can lead to extended downtimes and increased labor costs, especially if the installation process requires significant modifications or custom fabrication. Buyers may also find it difficult to source the right mounting hardware or clamps that work seamlessly with their current setup.

The Solution:

To mitigate these installation challenges, buyers should choose steel beams designed for universal compatibility with various mounting systems. Look for products that come with detailed installation instructions and all necessary hardware to ensure a straightforward setup process. It is beneficial to select beams that feature standardized dimensions, such as 2″ diameter tubes, which are more likely to fit existing rack systems. Engaging in pre-installation assessments or consulting with installation professionals can provide insights into potential compatibility issues. Furthermore, leveraging online resources and community forums can also offer valuable tips from other buyers who have faced similar challenges.

Illustrative image related to steel beam for roof rack

Scenario 3: Managing Corrosion and Longevity in Varied Climates

The Problem:

For B2B buyers operating in diverse climates, managing corrosion and ensuring the longevity of steel beams is a significant concern. Regions with high humidity, salt exposure, or extreme temperatures can accelerate the deterioration of steel, leading to increased maintenance costs and reduced operational efficiency. Buyers may feel overwhelmed by the need to balance cost-effectiveness with the durability required for long-term use.

The Solution:

To combat corrosion issues, it is essential to select steel beams that have undergone protective treatments such as zinc plating or powder coating, which enhance their resistance to environmental factors. Buyers should consider sourcing beams with UV-stabilized components, as these materials are less likely to degrade under intense sunlight. Additionally, implementing a regular maintenance schedule that includes inspections and protective coatings can help prolong the life of the beams. Educating staff about proper loading techniques and care can also minimize wear and tear, ultimately leading to more efficient operations and lower replacement costs.

Strategic Material Selection Guide for steel beam for roof rack

When selecting materials for steel beams used in roof racks, it is essential to consider various factors that can influence performance, durability, and cost. Below, we analyze four common materials, highlighting their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Mild Steel for Roof Rack Beams?

Mild steel, often referred to as low carbon steel, is widely used for roof rack beams due to its favorable properties. It exhibits good weldability, ductility, and strength, making it suitable for various applications. Mild steel typically has a yield strength of around 250 MPa and can withstand moderate temperatures without significant deformation. However, it is prone to corrosion, which necessitates protective coatings or treatments.

Pros:

– Cost-effective and readily available.

– Excellent machinability and weldability.

– Good strength-to-weight ratio.

Illustrative image related to steel beam for roof rack

Cons:

– Requires protective coatings to prevent rust.

– Lower strength compared to higher-grade steels.

Impact on Application:

Mild steel is suitable for applications where weight is a concern, but it may not be ideal for environments with high humidity or corrosive elements.

Considerations for International Buyers:

Buyers should ensure compliance with local standards such as ASTM A36 or equivalent. In regions like the Middle East and Africa, where humidity can be high, additional corrosion protection may be necessary.

How Does Stainless Steel Compare for Roof Rack Beams?

Stainless steel, particularly grades like 304 and 316, is known for its excellent corrosion resistance and aesthetic appeal. These materials can withstand harsh environmental conditions, making them suitable for outdoor applications. Stainless steel also has a higher tensile strength than mild steel, with yield strengths ranging from 210 MPa to 520 MPa depending on the grade.

Pros:

– Exceptional resistance to corrosion and staining.

– High strength and durability.

– Low maintenance requirements.

Illustrative image related to steel beam for roof rack

Cons:

– Higher cost compared to mild steel.

– More challenging to machine and weld.

Impact on Application:

Stainless steel is ideal for applications exposed to saltwater or chemicals, ensuring longevity and reliability.

Considerations for International Buyers:

Compliance with standards such as ASTM A240 is critical. Buyers in coastal areas or regions with high salinity should prioritize stainless steel to avoid rapid degradation.

What Are the Advantages of Aluminum for Roof Rack Beams?

Aluminum is a lightweight alternative to steel, offering excellent strength-to-weight ratios. It is naturally corrosion-resistant due to its oxide layer, making it suitable for various environmental conditions. Aluminum beams can typically handle temperatures up to 600°F without losing structural integrity.

Pros:

– Lightweight, reducing the overall weight of the roof rack.

– Naturally resistant to corrosion.

– Easy to fabricate and assemble.

Illustrative image related to steel beam for roof rack

Cons:

– Lower strength compared to steel, requiring larger cross-sections for the same load capacity.

– More expensive than mild steel.

Impact on Application:

Aluminum is ideal for applications where weight savings are critical, such as in off-road vehicles or for carrying lighter loads.

Considerations for International Buyers:

Ensure compliance with standards such as ASTM B221. Buyers should consider local manufacturing capabilities for aluminum fabrication, especially in regions with less infrastructure.

How Does High-Strength Steel Enhance Roof Rack Performance?

High-strength steel, such as those classified under ASTM A992, offers superior strength and reduced weight compared to conventional mild steel. With yield strengths exceeding 300 MPa, these materials are ideal for heavy-duty applications. They also provide excellent resistance to deformation under heavy loads.

Pros:

– High strength allows for reduced material usage.

– Excellent fatigue resistance.

– Suitable for heavy-duty applications.

Cons:

– Higher cost compared to mild steel.

– More complex manufacturing processes may be required.

Impact on Application:

High-strength steel is particularly beneficial for roof racks designed to carry heavy loads or withstand extreme conditions.

Considerations for International Buyers:

Buyers should verify compliance with local standards such as ASTM A992 or equivalent. In regions like South America, where heavy loads are common, high-strength steel may be a preferred choice.

Summary Table of Material Selection for Steel Beam Roof Racks

| Material | Typical Use Case for Steel Beam for Roof Rack | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Mild Steel | General-purpose roof racks | Cost-effective and readily available | Prone to corrosion | Low |

| Stainless Steel | Outdoor and marine applications | Exceptional corrosion resistance | Higher cost | High |

| Aluminum | Lightweight roof racks for off-road vehicles | Lightweight and easy to fabricate | Lower strength compared to steel | Med |

| High-Strength Steel | Heavy-duty applications | High strength allows for reduced weight | More complex manufacturing processes | Med |

This guide provides a comprehensive overview of material selection for steel beams used in roof racks, enabling international B2B buyers to make informed decisions based on their specific needs and environmental conditions.

Illustrative image related to steel beam for roof rack

In-depth Look: Manufacturing Processes and Quality Assurance for steel beam for roof rack

What Are the Main Stages in the Manufacturing Process of Steel Beams for Roof Racks?

The manufacturing process of steel beams for roof racks involves several critical stages, each designed to ensure high quality and durability. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step involves sourcing high-quality raw materials, typically hot-rolled steel or cold-rolled steel, depending on the specific requirements of the roof rack. The steel is then cut to size using precision cutting techniques, such as plasma cutting or laser cutting, which ensure minimal waste and precise dimensions. This stage may also involve quality checks to confirm that the material meets specified standards for yield strength and ductility.

Forming

Once the materials are prepared, they undergo forming processes. Techniques such as CNC machining, stamping, or bending are employed to shape the steel into the desired profile, such as I-beams or rectangular tubes. This step is crucial as the structural integrity of the roof rack heavily relies on the accuracy of the forming process. Advanced technologies like hydroforming or roll forming may be utilized to achieve complex shapes while maintaining strength.

Assembly

Following the forming stage, the components are assembled. This may involve welding, bolting, or riveting, depending on the design specifications. Automated welding systems can enhance precision and speed, while skilled labor ensures that joints are robust and meet safety standards. During assembly, manufacturers should conduct in-process quality checks to catch any defects early in the production cycle.

Finishing

The final stage is finishing, which includes surface treatments to enhance durability and aesthetics. Common finishing techniques include powder coating, galvanizing, or painting. These processes not only improve the visual appeal but also protect against corrosion, which is particularly important in harsh environments. Quality assurance during this stage ensures that the coating thickness and adhesion meet industry standards.

How Is Quality Assurance Implemented in the Manufacturing of Steel Beams for Roof Racks?

Quality assurance (QA) is essential in the manufacturing of steel beams for roof racks, ensuring that the products meet international standards and customer expectations. Several international and industry-specific standards govern this process, including ISO 9001, CE marking, and API specifications.

Understanding International Standards

ISO 9001 is a globally recognized standard that outlines the requirements for a quality management system (QMS). Manufacturers seeking to comply with this standard must demonstrate their ability to consistently provide products that meet customer and regulatory requirements. CE marking signifies that a product meets European health, safety, and environmental protection standards, which is crucial for buyers in Europe.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial inspection assesses the raw materials upon arrival. Testing for chemical composition and mechanical properties ensures that only materials meeting the required specifications are used.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, IPQC involves monitoring processes such as forming and assembly. Techniques like visual inspections and dimensional checks are employed to ensure compliance with design specifications.

-

Final Quality Control (FQC): After assembly and finishing, FQC involves comprehensive testing of the final product. Common methods include tensile testing, impact testing, and non-destructive testing (NDT) methods like ultrasonic or magnetic particle inspection. These tests verify the structural integrity and durability of the beams.

What Testing Methods Are Commonly Used in Quality Assurance for Steel Beams?

Testing methods play a vital role in ensuring that steel beams for roof racks meet safety and performance standards. Some of the most commonly used testing methods include:

-

Tensile Testing: This evaluates the material’s strength and ductility, determining how much load the beam can handle before failure.

-

Impact Testing: This assesses the toughness of the steel, especially in low-temperature conditions, ensuring that the beams can withstand sudden shocks.

-

Fatigue Testing: This method examines the beam’s performance under repeated loading and unloading, simulating real-world conditions where roof racks are subjected to dynamic forces.

-

Corrosion Resistance Testing: Given the outdoor applications of roof racks, tests for corrosion resistance, such as salt spray testing, are essential to ensure longevity and reliability.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must conduct due diligence when selecting suppliers for steel beams for roof racks. Here are several strategies to verify supplier quality control practices:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes, quality control systems, and adherence to international standards. This firsthand assessment can reveal the supplier’s commitment to quality.

-

Requesting Quality Reports: Suppliers should be able to provide documentation detailing their quality control processes, test results, and compliance with industry standards. This information can help buyers evaluate the reliability of the supplier.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These independent entities can perform audits and testing to verify that the products meet specified standards before shipment.

What Quality Control Nuances Should International B2B Buyers Consider?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, there are unique considerations regarding quality control:

-

Understanding Local Regulations: Different countries may have varying regulations regarding material standards and safety requirements. Buyers must ensure that the products comply with local laws in their respective markets.

-

Cultural and Communication Barriers: Language differences and cultural nuances can affect the clarity of specifications and quality expectations. Clear, documented communications can help mitigate misunderstandings.

-

Logistics and Shipping Considerations: Quality can be affected during transportation. Buyers should consider suppliers that have robust packaging and shipping processes to minimize damage during transit.

-

Post-Purchase Support: Understanding the supplier’s ability to provide after-sales support, including warranty and service options, is crucial for maintaining product quality over time.

By taking these steps, B2B buyers can ensure they partner with reliable suppliers who prioritize quality, ultimately leading to enhanced safety and performance of their steel beams for roof racks.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘steel beam for roof rack’

In the competitive landscape of B2B procurement, sourcing the right steel beams for roof racks is crucial for ensuring product quality and performance. This guide outlines a systematic approach to help international buyers efficiently navigate the sourcing process, ensuring they make informed decisions tailored to their specific needs.

Step 1: Define Your Technical Specifications

Start by outlining the technical requirements for your steel beams. Consider factors such as load capacity, dimensions, and material specifications (e.g., steel grade and thickness). This clarity will help you communicate effectively with suppliers and ensure that the products meet your operational demands.

- Load Capacity: Assess how much weight the roof rack will carry, including additional accessories.

- Dimensions: Specify the length and width that fit your vehicle or intended application.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in steel beams for roof racks. Look for companies with a strong track record in your industry and positive customer reviews.

Illustrative image related to steel beam for roof rack

- Supplier Background: Evaluate their history, production capabilities, and market presence.

- Product Range: Ensure they offer a variety of steel beam options to meet different specifications.

Step 3: Verify Supplier Certifications

Confirm that potential suppliers possess relevant certifications and quality standards. This step is essential for ensuring compliance with international manufacturing standards.

- ISO Certifications: Check for ISO 9001 or similar certifications that indicate quality management systems.

- Material Certifications: Ensure that the steel used meets recognized standards (e.g., ASTM, EN).

Step 4: Evaluate Material Quality and Performance

Assess the quality of the materials used in the manufacturing of the steel beams. High-quality materials will enhance durability and performance, which is vital for safety and longevity.

- Steel Grade: Look for high-grade steel that offers strength and resistance to corrosion.

- Testing Standards: Inquire about the testing processes for load-bearing and durability.

Step 5: Request Samples and Specifications

Before finalizing any orders, request samples or detailed specifications of the steel beams. This step allows you to verify quality firsthand and ensure the product meets your requirements.

Illustrative image related to steel beam for roof rack

- Sample Evaluation: Assess the samples for weight, strength, and finish.

- Technical Data Sheets: Request detailed documentation about the materials used, including load capacity and structural integrity.

Step 6: Discuss Pricing and Payment Terms

Engage in discussions regarding pricing structures and payment options. Understanding the financial aspects upfront can prevent misunderstandings later in the procurement process.

- Bulk Discounts: Inquire about pricing for larger orders to optimize costs.

- Payment Flexibility: Evaluate payment terms and conditions that accommodate your financial planning.

Step 7: Establish Shipping and Delivery Logistics

Finally, consider the logistics of shipping and delivery. Efficient logistics can significantly impact your project timelines and overall satisfaction.

- Shipping Options: Discuss available shipping methods and estimated delivery times.

- Customs and Duties: Be aware of any import regulations and duties that may affect costs and timelines.

By following these steps, B2B buyers can streamline their sourcing process for steel beams intended for roof racks, ensuring they select the best options available in the market while mitigating risks associated with procurement.

Comprehensive Cost and Pricing Analysis for steel beam for roof rack Sourcing

Understanding the cost structure and pricing dynamics for sourcing steel beams for roof racks is crucial for B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis will provide actionable insights into various cost components, pricing influencers, and practical tips for effective negotiation.

Illustrative image related to steel beam for roof rack

What Are the Key Cost Components for Steel Beams in Roof Racks?

When evaluating the total cost of steel beams for roof racks, several components come into play:

-

Materials: The primary material, typically high-quality steel, significantly influences the cost. Options like 1/8″ hot-rolled steel may vary in price based on market demand, local availability, and the quality of the steel (e.g., galvanized vs. non-galvanized).

-

Labor: Labor costs are variable and depend on the complexity of the manufacturing process. Regions with higher labor costs will see a direct impact on the final price, whereas lower-cost labor regions may offer more competitive pricing.

-

Manufacturing Overhead: This includes costs related to the operational expenses of the manufacturing facility, such as utilities, rent, and administrative expenses. Efficient production processes can help minimize these costs.

-

Tooling: Custom tooling for specific designs or specifications can add to initial costs. Standardized products may incur lower tooling costs, making them more appealing for bulk orders.

-

Quality Control (QC): Ensuring quality through rigorous testing and compliance with international standards (e.g., ISO certifications) may increase upfront costs but can lead to savings in the long term through reduced failures and warranty claims.

-

Logistics: Transportation and shipping costs can vary significantly based on distance, mode of transport, and Incoterms agreed upon. Buyers should consider these factors when budgeting for total costs.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding the typical mark-up in the industry can help buyers negotiate better.

How Do Price Influencers Affect Sourcing Steel Beams?

Several factors can influence pricing for steel beams used in roof racks:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for volume discounts, which can significantly lower the per-unit price. Buyers should assess their needs and consider bulk purchasing to optimize costs.

-

Specifications and Customization: Custom requirements, such as specific dimensions or additional features, can drive up costs. Standard products may offer a more favorable price point.

-

Quality and Certifications: Higher quality materials and certifications can result in a premium price but may provide better durability and performance, which is crucial for roof racks subjected to heavy loads.

-

Supplier Factors: Supplier reputation, reliability, and geographic location can influence pricing. Established suppliers may charge more due to their proven track record, but they often provide better customer service and product quality.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) can affect the final landed cost. Understanding these terms is vital for managing shipping risks and costs effectively.

What Tips Can Help Buyers Negotiate Better Prices?

-

Leverage Volume Discounts: When possible, consolidate orders to meet MOQ thresholds. This can lead to significant cost savings per unit.

-

Assess Total Cost of Ownership (TCO): Consider not just the purchase price, but also the long-term costs associated with maintenance, durability, and potential warranty claims.

-

Research and Compare Suppliers: Don’t settle for the first quote. Gather multiple quotes and conduct thorough supplier evaluations based on quality, reliability, and customer feedback.

-

Negotiate Terms and Prices: Engage in open discussions about pricing, payment terms, and delivery schedules. Suppliers may be willing to adjust prices based on your commitment to future orders.

-

Understand International Pricing Nuances: For buyers in regions like Africa or South America, be aware of additional tariffs, import duties, and local regulations that may affect costs. Building relationships with local distributors can also provide insights into market dynamics.

Conclusion

In summary, a comprehensive understanding of the cost structure and pricing dynamics for steel beams in roof racks enables B2B buyers to make informed decisions. By considering the various cost components, understanding price influencers, and applying strategic negotiation techniques, buyers can optimize their sourcing strategies for better value and performance.

Alternatives Analysis: Comparing steel beam for roof rack With Other Solutions

Understanding Alternatives for Roof Rack Solutions

When considering the best solution for roof racks, it’s essential to evaluate alternatives to the traditional steel beam. Each option has its unique characteristics that can impact performance, cost, and suitability for specific applications. This analysis compares steel beams for roof racks with two viable alternatives: aluminum cross bars and structural steel cantilever racks.

Comparison Table

| Comparison Aspect | Steel Beam For Roof Rack | Aluminum Cross Bars | Structural Steel Cantilever Racks |

|---|---|---|---|

| Performance | High strength; capable of carrying heavy loads; corrosion-resistant with proper coating | Lightweight; good strength-to-weight ratio; suitable for moderate loads | Extremely durable; designed for heavy-duty storage; customizable for various loads |

| Cost | Generally higher due to material and manufacturing | Mid-range; often more affordable than steel options | Variable; can be cost-effective for large-scale storage solutions |

| Ease of Implementation | Moderate; requires specific mounting hardware and skills for installation | Easy; typically designed for straightforward installation with minimal tools | Moderate; may require professional installation depending on the complexity |

| Maintenance | Low; requires periodic checks for corrosion | Low; resistant to rust; requires less upkeep | Low; durable but may require occasional inspections for structural integrity |

| Best Use Case | Ideal for heavy-duty applications needing maximum load capacity | Best for lighter loads and applications where weight savings are critical | Excellent for industrial storage solutions or when used as a support structure |

Detailed Breakdown of Alternatives

Aluminum Cross Bars

Aluminum cross bars are a popular alternative due to their lightweight nature and good strength-to-weight ratio. They are particularly suitable for applications where reducing vehicle weight is crucial, such as in off-road or fuel-efficient vehicles. The installation process is generally straightforward, requiring minimal tools and expertise. However, while they offer decent performance for moderate loads, they may not be suitable for extremely heavy or bulky items. Additionally, aluminum can be more prone to bending under excessive load compared to steel options.

Illustrative image related to steel beam for roof rack

Structural Steel Cantilever Racks

Structural steel cantilever racks are designed for high-density storage solutions, making them an excellent choice for industrial applications. These racks are incredibly durable and can handle heavy loads, making them perfect for storing long materials like lumber or pipes. They can be customized to fit various storage needs, and their bolted connections allow for easy expansion or modification. However, they are typically more complex to install and may require professional assistance, which can increase initial costs. Their strength and versatility make them a go-to option for businesses with significant storage requirements.

Conclusion: How to Choose the Right Roof Rack Solution

Selecting the right roof rack solution depends on several factors, including load requirements, installation capabilities, and budget. For B2B buyers, understanding the specific needs of their application is crucial. If heavy-duty performance is essential, steel beams remain a strong choice. However, for lighter loads or applications where weight savings are a priority, aluminum cross bars may be more suitable. Meanwhile, structural steel cantilever racks serve as a robust solution for industrial storage needs. By carefully evaluating these alternatives against their operational requirements, buyers can make informed decisions that enhance efficiency and safety in their operations.

Essential Technical Properties and Trade Terminology for steel beam for roof rack

What Are the Key Technical Properties of Steel Beams for Roof Racks?

When selecting steel beams for roof racks, understanding critical technical specifications is essential for ensuring durability, safety, and performance. Here are several key properties to consider:

-

Material Grade

The material grade indicates the composition and strength of the steel. Common grades for roof rack beams include ASTM A36 and A572, which provide excellent tensile strength and ductility. Choosing the right material grade is vital as it directly affects the load-bearing capacity and longevity of the roof rack, especially under varying environmental conditions. -

Thickness

The thickness of the steel beams, often measured in inches or millimeters, is a crucial factor influencing strength and weight. Common thicknesses for roof rack beams range from 1/8″ to 1/4″. Thicker beams generally offer more strength but can increase the overall weight of the rack, potentially affecting fuel efficiency and ease of installation. -

Load Capacity

Load capacity refers to the maximum weight that a roof rack can safely support. This specification is influenced by the beam’s design, material properties, and construction method. Understanding load capacity is essential for buyers, as it determines the types of equipment or cargo that can be safely transported. -

Corrosion Resistance

Many roof rack beams are treated with coatings such as powder coating or galvanization to enhance their resistance to corrosion. This property is especially important for buyers in humid or coastal regions, where exposure to moisture can lead to premature deterioration. Corrosion resistance extends the life of the product and reduces maintenance costs. -

Weld Quality

The quality of the welds used in the construction of the beams can significantly impact the structural integrity of the roof rack. High-quality welding ensures that joints can withstand stress without failure. Buyers should inquire about welding standards and techniques used during manufacturing to ensure the safety and reliability of the product. -

Finish

The finish of the steel beams affects both aesthetics and functionality. Options such as powder coating provide a protective layer that enhances durability while preventing scratches and rust. A good finish not only improves appearance but also minimizes maintenance requirements.

What Are Common Trade Terms Related to Steel Beams for Roof Racks?

Familiarity with industry terminology can facilitate smoother transactions and clearer communication between buyers and suppliers. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is crucial for buyers looking for compatible components for their roof rack systems. -

MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units that a supplier is willing to sell. This term is significant for buyers as it impacts purchasing decisions, especially for smaller businesses or startups that may not need large quantities. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing information for specific products or services. This process is essential for buyers to compare prices, negotiate terms, and ensure they receive competitive offers. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international rules that clarify the responsibilities of buyers and sellers regarding shipping, risk, and costs. Familiarity with these terms helps buyers understand shipping logistics and cost implications, ensuring smooth international transactions. -

Lead Time

Lead time refers to the duration between placing an order and receiving the product. Understanding lead times is critical for supply chain management, enabling businesses to plan their inventory and avoid disruptions. -

Certification Standards

Certification standards, such as ISO or ASTM, ensure that products meet specific safety and quality benchmarks. Buyers should seek products that comply with relevant certification standards to guarantee reliability and performance.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing steel beams for roof racks, ensuring they select reliable products that meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the steel beam for roof rack Sector

What Are the Current Market Dynamics and Key Trends in the Steel Beam for Roof Rack Sector?

The steel beam for roof rack sector is experiencing a significant transformation driven by several global factors. Increasing consumer demand for versatile outdoor recreational vehicles, particularly in regions like Africa, South America, the Middle East, and Europe, has intensified the need for high-quality, durable roof racks. B2B buyers are increasingly focused on products that offer both strength and lightweight properties, leading to innovations in materials and manufacturing techniques. For instance, advancements in steel processing have allowed manufacturers to produce beams that are not only robust but also cost-effective.

Emerging technologies in sourcing are also reshaping the landscape. Digital platforms for procurement and supply chain management are becoming more prevalent, providing buyers with greater transparency and efficiency in sourcing steel beams. Additionally, the rise of e-commerce is enabling international buyers to access a wider array of suppliers, facilitating competitive pricing and improved service offerings.

Another key trend is the increasing emphasis on customization. Buyers are looking for tailored solutions that meet specific vehicle models and load requirements. This trend is particularly noticeable in the aftermarket sector, where specialized steel beams are designed for various outdoor and adventure vehicles. As a result, suppliers that can offer adaptable solutions are likely to gain a competitive advantage.

How Is Sustainability and Ethical Sourcing Impacting the Steel Beam for Roof Rack Market?

Sustainability and ethical sourcing have become critical considerations for B2B buyers in the steel beam for roof rack sector. As environmental awareness grows, companies are under pressure to adopt practices that minimize their ecological footprint. The steel industry, traditionally associated with high carbon emissions, is now witnessing a shift towards greener manufacturing processes. This includes the use of recycled materials and energy-efficient production methods, which not only reduce environmental impact but also appeal to eco-conscious consumers.

Illustrative image related to steel beam for roof rack

The importance of ethical supply chains cannot be overstated. Buyers are increasingly seeking suppliers that demonstrate a commitment to fair labor practices and responsible sourcing of raw materials. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as benchmarks for companies looking to establish credibility in this area. By prioritizing suppliers that adhere to these standards, buyers can enhance their brand reputation and meet the growing demand for socially responsible products.

Furthermore, the integration of sustainable materials into the production of steel beams—such as using low-carbon steel or innovative coatings that reduce corrosion—can provide additional value. Buyers who align their sourcing strategies with these sustainability goals are likely to find a competitive edge in an increasingly conscientious market.

What Is the Historical Evolution of Steel Beams in Roof Rack Applications?

The evolution of steel beams in roof rack applications can be traced back several decades, reflecting broader advancements in material science and engineering. Initially, roof racks were constructed using basic steel materials that offered limited strength and durability. As outdoor recreational activities gained popularity, particularly in the late 20th century, the demand for more robust and versatile roof rack systems surged.

In response, manufacturers began to innovate, introducing high-strength steel alloys and advanced fabrication techniques. This evolution has led to the development of specialized steel beams designed to withstand significant loads while maintaining a lightweight profile. The introduction of technologies such as CNC machining and laser cutting has further refined production processes, enabling greater precision and customization.

Today, the market is characterized by a diverse range of steel beam options tailored to various vehicle types and consumer needs. This historical progression not only underscores the importance of innovation in the sector but also highlights the ongoing commitment to enhancing performance and safety in roof rack applications.

Illustrative image related to steel beam for roof rack

Frequently Asked Questions (FAQs) for B2B Buyers of steel beam for roof rack

-

How do I ensure the quality of steel beams for roof racks?

To guarantee the quality of steel beams, request certifications such as ISO 9001 or ASTM standards from potential suppliers. These certifications indicate adherence to international quality management systems and material specifications. Additionally, consider ordering samples or conducting inspections at the manufacturing site to assess the workmanship and materials used. Establishing a quality assurance process, including third-party inspections or audits, can further mitigate risks associated with subpar materials. -

What is the best steel type for roof rack beams?

The ideal steel for roof rack beams is typically high-strength, low-alloy steel, such as ASTM A572 or A992, which offers excellent strength-to-weight ratios. These materials are engineered to withstand heavy loads and resist corrosion, essential for outdoor applications. It’s important to consider the specific load requirements of your application, as well as the environmental conditions it will face, to select the most suitable steel type for durability and performance. -

How can I customize steel beams for my specific needs?

Customization options for steel beams often include varying lengths, widths, thicknesses, and additional features such as mounting points or finishes. When discussing your requirements with suppliers, provide detailed specifications, including load capacities and intended applications. Many manufacturers can also offer design assistance or engineering support to optimize the beams for your particular use case, ensuring you receive a tailored solution that meets your operational needs. -

What are the typical minimum order quantities (MOQs) for steel beams?

Minimum order quantities for steel beams can vary widely depending on the supplier and the type of product. Generally, MOQs can range from a few units to several tons. It’s advisable to discuss your requirements directly with suppliers to understand their MOQs and whether they can accommodate smaller orders, especially for new buyers or those testing a product before committing to larger purchases. -

What payment terms should I expect when sourcing steel beams internationally?

Payment terms for international transactions often include options such as letters of credit, advance payments, or net 30/60/90 terms. It’s important to negotiate favorable terms based on your business relationship and order size. Ensure that payment methods are secure and consider using an escrow service for larger transactions to protect both parties. Always clarify any additional costs, such as shipping or tariffs, that may affect the total price. -

How do I vet suppliers for steel beams in international markets?

To vet suppliers effectively, conduct thorough research including checking their business licenses, certifications, and customer references. Utilize platforms like Alibaba or Global Sources to view ratings and reviews. Engaging with suppliers through video calls can provide insights into their operations and quality control processes. Additionally, consider visiting manufacturing facilities if feasible, or hiring third-party inspection services to evaluate the supplier’s capabilities and reliability. -

What logistics considerations should I keep in mind when importing steel beams?

Logistics for importing steel beams involve assessing shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder with experience in handling heavy cargo. Understand the import duties applicable in your country, and ensure all shipping documents, including bills of lading and customs declarations, are accurately prepared. Plan for potential delays due to inspections or customs clearance to maintain your project timelines. -

What factors affect the pricing of steel beams for roof racks?

The pricing of steel beams is influenced by various factors, including material costs, manufacturing processes, and global market demand. Fluctuations in raw material prices, such as steel and other alloys, can significantly impact overall costs. Additional elements include customization options, order volume, and shipping expenses. Establishing a long-term relationship with suppliers can sometimes lead to better pricing and terms, especially for bulk orders.

Top 9 Steel Beam For Roof Rack Manufacturers & Suppliers List

1. Metal Cloak – JT Gladiator OverCab Cross Beam System

Domain: metalcloak.com

Registered: 2006 (19 years)

Introduction: Product Name: JT Gladiator / JL & JK Wrangler OverCab Cross Beam System

Product ID: R75503

Material: 1/8″ Hot Rolled Steel

Finish: Black Powder Coat

Compatibility: 2019 – Current JT Gladiator

Features:

– Strong 1/8″ Steel Beams

– Anti Slip Accessory Mounting Structure

– Multiple Accessory Slots

– Multi-Mount 2″ Clamps

– UV Stabilized Nylon Components

– 16 Grip Dots

– Zinc Plated Corrosion Resista…

2. Adventure Rack Systems – BakPak HiRise Utility & RTT Cross Beam

Domain: adventureracksystems.com

Registered: 2020 (5 years)

Introduction: {“Product ID”:”R77701″,”Product Name”:”BakPak HiRise Utility & RTT Cross Beam, Pair”,”Material”:”Formed 1/8″ steel”,”Clamps”:”Beefy CNC Clamps with Threaded Bolt Holes”,”Design”:”Low Profile Stealth Design”,”Compatibility”:”Mounts Directly to the BakPak Rack System”,”Mounting Capability”:”Mounts Most Roof Top Tents/Accessories”,”Included Hardware”:”All Needed Mounting Hardware”,”Finish”:”Black Tex…

3. Metals Depot – Galvanized Steel Beams

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: Galvanized Steel Beams are A36 hot rolled, mild steel beams that have been hot dipped in a zinc rich galvanizing process. They offer rust-free protection for up to 30 years and maintain comparable strength with a durable hard surface coating. Available in Wide Flange and Standard I-Beam shapes, they can be cut, machined, or welded using common methods for regular steel. Specifications include ASTM…

4. Sunbelt – Structural Steel Cantilever Racks

Domain: sunbelt-rack.com

Registered: 2013 (12 years)

Introduction: Structural steel I-beam cantilever racks designed for high-density storage of long-length materials. Features include: constructed of structural steel I-beams, available in double- and single-sided configurations, various column and arm sizes to meet load requirements, 3 to 5 levels of storage, arms adjustable in 4″ increments, bolted arm and base connections, and national installation service ava…

5. Tuyoung – 220 lb Lockable Roof Rack Beam

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“item_name”: “220 lb Lockable Roof Rack Beam”, “price”: “$105.74”, “original_price”: “$112.49”, “discount”: “6% off”, “shipping”: “FREE”, “condition”: “New”, “quantity_available”: “1”, “brand”: “Tuyoung”, “item_number”: “146538651472”}

6. MCSW – Steel Support Beams

Domain: mcswusa.com

Registered: 2016 (9 years)

Introduction: Steel support beams are structural components used in construction for heavy loads over large spans. They are made of steel for strength and durability, essential for carrying the weight of floors, roofs, and walls, as well as supporting other structural elements like columns. Types of beams include: I-Beams (H-Beams), W-Beams (wide-flange beams), S-Beams (tapered flanges), and Box beams (hollow r…

7. Buyabeam – Structural Steel Beams

Domain: buyabeam.com

Registered: 2019 (6 years)

Introduction: Types of Structural Steel Beams: I beams, H beams, W beams, T beams, RSJs (rolled steel joists), Universal columns, Parallel flange channels (PFC), Hollow steel sections (HSS). Uses: Industrial or commercial buildings, residential applications, bespoke structural frames, bridges. Features: Excellent tensile strength, durability, low weight, quick fabrication, solid reinforcement, tremendous streng…

8. Broward Screen and Window – Steel Columns

Domain: browardscreenandwindow.com

Registered: 2012 (13 years)

Introduction: Steel columns provide vertical support for patios, custom made to fit specific needs, primed to prevent rust damage. It is crucial to replace steel columns before they rust completely to avoid damage to the carrier beam or roof. The Carrier Beam is nailed under the roof and distributes the weight of the roof evenly across all columns.

9. Sprinter – Lightweight Windsurf Rack

Domain: sprinter-source.com

Registered: 2006 (19 years)

Introduction: Lightweight rack for windsurf boards and sails; total weight capacity under 50 lbs; temporary rack made from 1″ PVC tubing; designed to attach to roof beams; uses roof rack tie-down straps for stabilization; concerns about the strength of roof beams; suggestions for building a light frame supported by the floor; alternative materials mentioned include super-strut metal railing and butterfly bolts;…

Strategic Sourcing Conclusion and Outlook for steel beam for roof rack

In conclusion, the strategic sourcing of steel beams for roof racks is essential for B2B buyers aiming to enhance product offerings and operational efficiency. By prioritizing quality materials, such as formed 1/8″ steel with corrosion-resistant finishes, companies can ensure durability and reliability in their roof rack systems. Moreover, understanding the unique features—like anti-slip mounting structures and customizable accessory slots—can significantly improve product versatility and customer satisfaction.

For international buyers in regions such as Africa, South America, the Middle East, and Europe, leveraging strategic sourcing not only optimizes cost-effectiveness but also aligns with local market demands. Investing in high-quality steel beam solutions can differentiate your offerings in a competitive landscape, fostering long-term partnerships and sustained growth.

As the demand for robust and efficient roof rack solutions continues to rise, now is the time to engage with reputable suppliers and manufacturers. Explore the latest innovations and build a resilient supply chain that meets the evolving needs of your customers. Embrace the future of roof rack solutions with confidence and strategic foresight.

Illustrative image related to steel beam for roof rack

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.