A B2B Buyer’s Guide to Stainless Steel Metal Grate: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for stainless steel metal grate

In the evolving landscape of global commerce, sourcing high-quality stainless steel metal grates poses a significant challenge for B2B buyers, especially in emerging markets like Nigeria and Brazil. As industries increasingly prioritize durability, safety, and aesthetic appeal, understanding the nuances of stainless steel grating becomes essential. This guide serves as a comprehensive resource, delving into various types of stainless steel metal grates, their diverse applications, and vital considerations for supplier vetting. Whether for industrial flooring, pedestrian walkways, or architectural features, the right grating solution can enhance both functionality and visual appeal.

Navigating the complexities of international procurement can be daunting, particularly when evaluating cost versus quality. This guide empowers B2B buyers by offering insights into pricing structures, material specifications, and installation requirements, ensuring informed purchasing decisions. We will explore the different grating types—such as welded and riveted options—along with their respective load-bearing capacities, maintenance needs, and sustainability credentials. Additionally, we will highlight key factors for assessing suppliers, including certifications, delivery timelines, and customer support, tailored specifically for buyers across Africa, South America, the Middle East, and Europe. With this knowledge, businesses can confidently select the most suitable stainless steel metal grate solutions to meet their operational demands and enhance their competitive edge.

Understanding stainless steel metal grate Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Welded Bar Grating | High strength, low maintenance, slip-resistant | Industrial flooring, catwalks, platforms | Pros: Durable, customizable; Cons: Heavier, may require more support. |

| Swage-Locked Grating | Lightweight, offers high load-bearing capacity | Pedestrian walkways, heavy-duty applications | Pros: Easy installation, corrosion-resistant; Cons: Limited design options. |

| Press-Locked Grating | Versatile, robust construction | Commercial spaces, architectural features | Pros: Cost-effective, good load distribution; Cons: May not suit all applications. |

| Riveted Grating | Traditional construction method, aesthetic appeal | Decorative applications, architectural projects | Pros: Attractive finish, strong; Cons: Higher cost, less common. |

| Dovetail Grating | Unique interlocking design for stability | Bridges, transportation infrastructure | Pros: Excellent strength, easy to install; Cons: Specific to certain applications. |

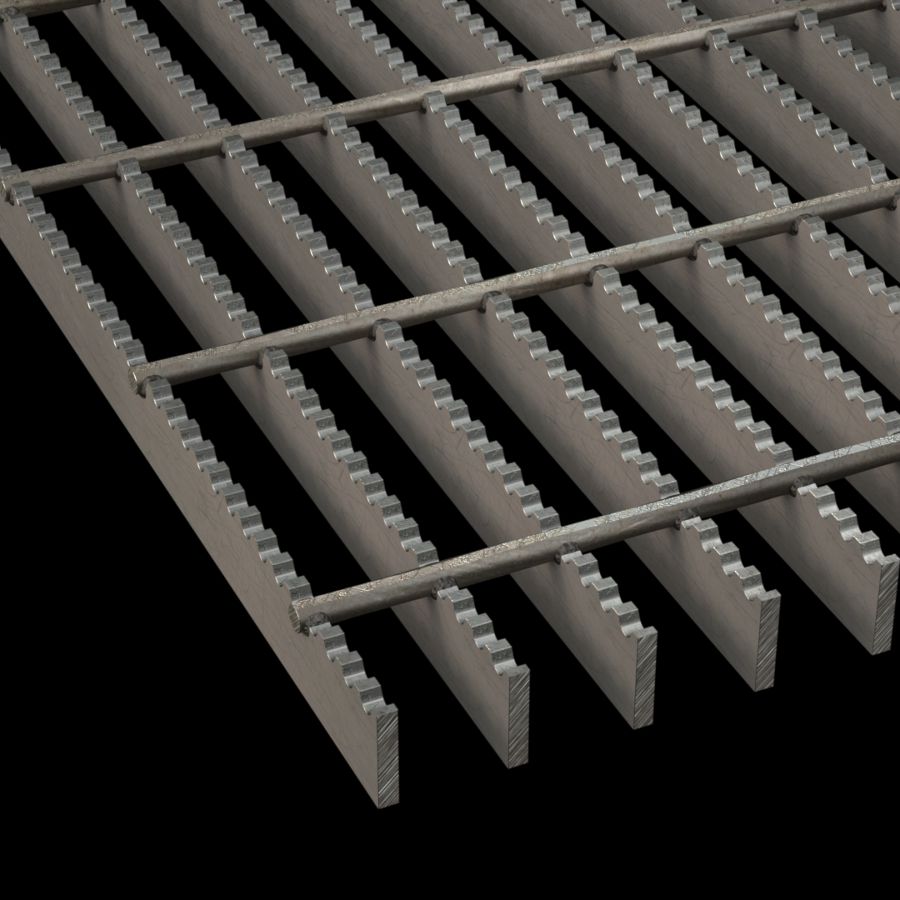

What Are the Key Characteristics of Welded Bar Grating?

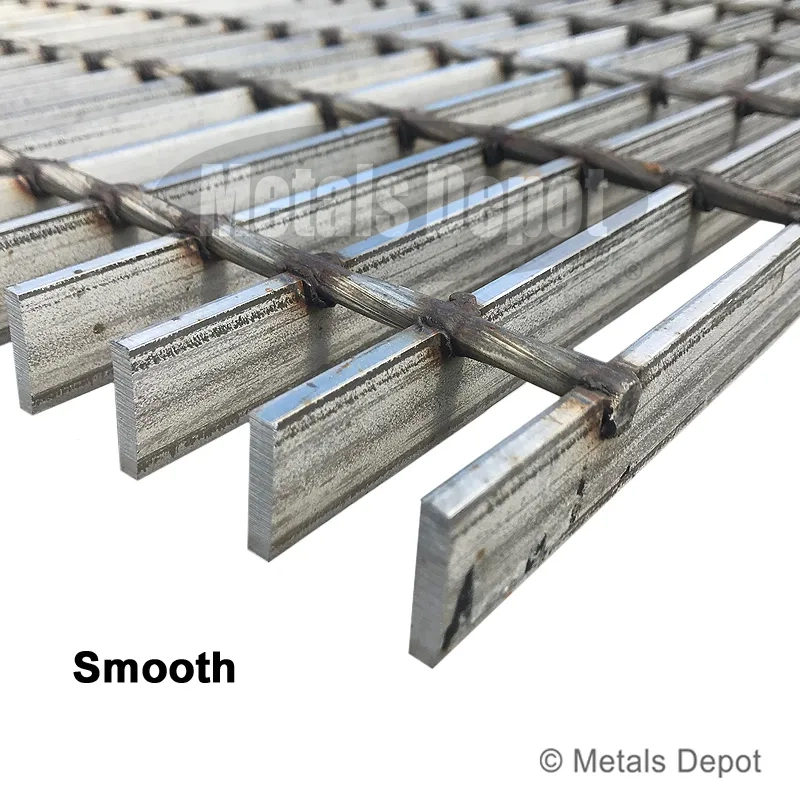

Welded bar grating is renowned for its durability and slip-resistant surface, making it an excellent choice for heavy-duty industrial applications. Constructed by welding together steel bars, it offers a robust solution for environments requiring high load-bearing capabilities. Buyers should consider the specific load requirements and span lengths, as this type typically necessitates additional support due to its weight. Customization options are available, allowing for tailored solutions that meet unique project specifications.

How Does Swage-Locked Grating Compare for Heavy-Duty Applications?

Swage-locked grating is designed for applications that demand both lightweight construction and high load-bearing capacity. This type utilizes a unique locking mechanism that allows for quick installation while maintaining structural integrity. It is ideal for pedestrian walkways and other heavy-duty applications. When purchasing, consider the specific environmental conditions, as swage-locked grating offers excellent corrosion resistance, making it suitable for both indoor and outdoor settings.

What Makes Press-Locked Grating a Popular Choice?

Press-locked grating is characterized by its versatile construction and cost-effectiveness, making it a popular option for commercial spaces and architectural features. This type is robust and provides good load distribution, which is essential for various applications. Buyers should evaluate the specific environmental requirements and aesthetic preferences, as press-locked grating can be customized with different finishes. However, it may not be suitable for all high-load scenarios.

What Are the Advantages of Riveted Grating in Decorative Applications?

Riveted grating utilizes a traditional construction method that provides both strength and aesthetic appeal, making it a preferred choice for decorative applications. This type can enhance the visual aspect of architectural projects while maintaining functionality. However, buyers should be aware that riveted grating tends to be more expensive and less commonly available. It is essential to assess the balance between aesthetic needs and budget constraints when considering this option.

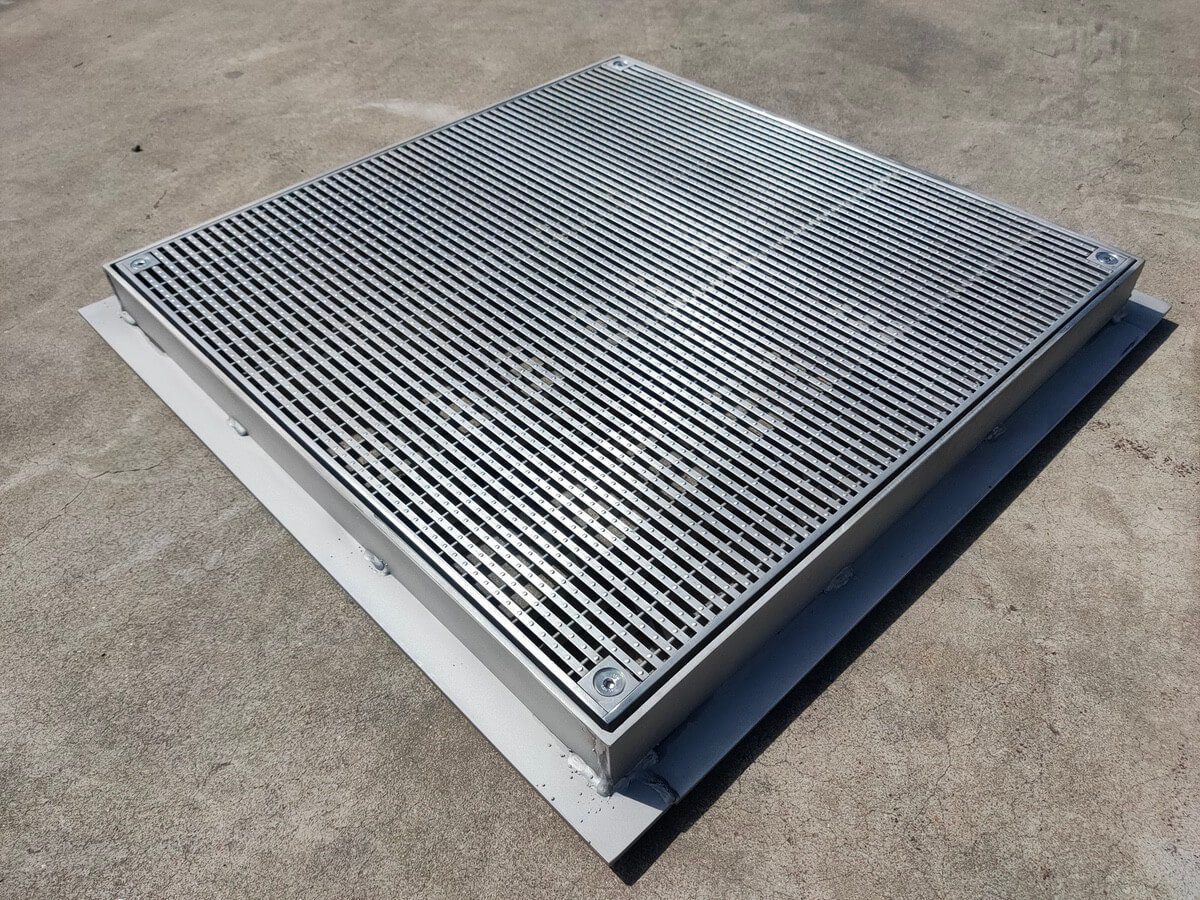

Illustrative image related to stainless steel metal grate

How Does Dovetail Grating Benefit Transportation Infrastructure?

Dovetail grating features a unique interlocking design that enhances stability, making it particularly well-suited for transportation infrastructure such as bridges. Its strength and ease of installation are key advantages for large-scale projects. Buyers should consider the specific load requirements and environmental conditions when selecting dovetail grating, as its design is tailored for specific applications. This type is an investment in long-term durability and performance.

Key Industrial Applications of stainless steel metal grate

| Industry/Sector | Specific Application of stainless steel metal grate | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Flooring in processing plants | Ensures hygiene and safety, preventing contamination | Compliance with food safety regulations and easy cleaning |

| Oil & Gas | Walkways and platforms in refineries | High durability and resistance to harsh environments | Corrosion resistance and load-bearing capacity |

| Construction & Architecture | Stair treads and railings | Aesthetic appeal combined with safety and functionality | Customization options and adherence to local building codes |

| Water Treatment | Grating for filtration systems | Enhances operational efficiency and reduces maintenance | Resistance to chemical exposure and compliance with standards |

| Mining & Heavy Industry | Support structures and access platforms | Provides structural integrity under heavy loads | Heavy-duty specifications and sourcing for local conditions |

How is Stainless Steel Metal Grate Used in the Food & Beverage Industry?

In food processing plants, stainless steel metal grates are commonly utilized as flooring systems to ensure hygiene and safety. Their corrosion-resistant properties prevent contamination from spills, making them ideal for environments where cleanliness is paramount. Buyers must consider compliance with food safety regulations and select grates that facilitate easy cleaning and maintenance, ensuring they meet international standards for food production.

What Role Does Stainless Steel Grating Play in the Oil & Gas Sector?

In the oil and gas industry, stainless steel grating is essential for constructing walkways and platforms in refineries and offshore rigs. Its high durability and resistance to harsh chemicals and extreme weather conditions enhance safety and longevity. B2B buyers should prioritize sourcing grating that meets specific load-bearing requirements and corrosion resistance to ensure operational reliability in challenging environments.

How is Stainless Steel Grating Beneficial in Construction & Architecture?

Stainless steel grating finds extensive use in stair treads and railings within construction and architectural projects. It offers a modern aesthetic while ensuring safety and functionality. When sourcing these products, buyers should seek customization options that align with local building codes and design specifications, ensuring that the grating not only meets safety standards but also enhances the overall visual appeal of the structure.

In What Ways is Stainless Steel Grating Used in Water Treatment?

In water treatment facilities, stainless steel metal grates serve as critical components in filtration systems. Their ability to withstand chemical exposure and high moisture levels enhances operational efficiency while minimizing maintenance needs. Buyers should focus on sourcing grates that comply with environmental regulations and are designed for durability in demanding conditions, ensuring long-term functionality and reliability.

Why is Stainless Steel Grating Important in Mining & Heavy Industry?

In the mining and heavy industry sectors, stainless steel grating is used for support structures and access platforms due to its ability to handle heavy loads. The rugged nature of stainless steel ensures structural integrity, making it a preferred choice for demanding applications. Buyers should consider the specific environmental conditions and load requirements when sourcing grating, ensuring that it meets the necessary heavy-duty specifications for their projects.

3 Common User Pain Points for ‘stainless steel metal grate’ & Their Solutions

Scenario 1: Sourcing Quality Stainless Steel Grates for Harsh Environments

The Problem: B2B buyers in industries such as oil and gas, food processing, and wastewater management often encounter the challenge of sourcing stainless steel grates that can withstand harsh environmental conditions. Corrosion resistance, load-bearing capacity, and compliance with industry standards are crucial factors. Buyers may find themselves overwhelmed by the variety of products available, each with different grades of stainless steel, finishes, and specifications. This can lead to costly mistakes if the wrong material is selected for a specific application, resulting in premature failure and increased maintenance costs.

The Solution: To ensure the selection of high-quality stainless steel grates suitable for tough environments, buyers should prioritize sourcing from reputable manufacturers who provide detailed material specifications, including the grade of stainless steel (e.g., 304 vs. 316), load ratings, and corrosion resistance features. It’s essential to request samples and conduct on-site evaluations to assess the grates’ performance in real-world conditions. Additionally, engaging with manufacturers who offer customization options can help meet specific project requirements. Establishing a clear communication channel for technical support and guidance during the selection process can further streamline sourcing efforts, ensuring the right product is chosen for the intended application.

Scenario 2: Ensuring Compliance with Industry Standards

The Problem: In sectors such as construction and food processing, compliance with local and international standards (like ADA, OSHA, or HACCP) is critical for safety and operational efficiency. Buyers often struggle to find stainless steel grates that not only meet these regulatory requirements but also fit their specific applications. Non-compliance can lead to legal penalties, project delays, or safety hazards, making it a significant concern for B2B buyers.

The Solution: To navigate compliance effectively, buyers should familiarize themselves with the relevant standards applicable to their industry and region. When sourcing stainless steel grates, they should look for products that explicitly state compliance with these standards in their specifications. Collaborating with suppliers who have a proven track record of delivering compliant products is vital. Requesting documentation, such as certification or test results, can provide additional assurance. Furthermore, considering professional consultation with compliance experts during the planning stages can prevent costly oversight and ensure all products meet necessary regulations.

Scenario 3: Addressing Maintenance and Longevity Concerns

The Problem: B2B buyers often face the challenge of maintaining stainless steel grates in environments prone to heavy foot traffic or exposure to harsh chemicals. Over time, wear and tear can lead to safety issues and increased replacement costs. Buyers may find it difficult to assess the long-term durability of the grates, particularly when balancing initial costs against potential maintenance and replacement needs.

The Solution: To mitigate maintenance concerns, buyers should consider investing in stainless steel grates designed for high durability and low maintenance. Features such as slip-resistant surfaces and easy-to-clean designs can enhance safety and reduce upkeep efforts. It is also beneficial to conduct a life-cycle cost analysis to understand the long-term financial implications of different grate options. Buyers can consult with manufacturers about coatings or finishes that enhance corrosion resistance and longevity. Establishing a routine inspection and maintenance schedule can help identify potential issues early, extending the lifespan of the grates and optimizing their performance in the long run.

Strategic Material Selection Guide for stainless steel metal grate

What Are the Key Properties of Common Materials for Stainless Steel Metal Grate?

When selecting materials for stainless steel metal grates, it is essential to consider various factors, including performance characteristics, durability, and application suitability. Below, we analyze four common materials used in stainless steel grating, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

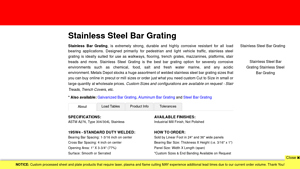

1. 304 Stainless Steel

Key Properties:

304 stainless steel is known for its excellent corrosion resistance and high-temperature tolerance, making it suitable for a variety of environments. It can withstand temperatures up to 870°C (1600°F) in intermittent service and offers good weldability.

Pros & Cons:

The primary advantage of 304 stainless steel is its affordability and versatility. However, it is less resistant to corrosion in chloride environments compared to other grades, which can limit its use in coastal or marine applications.

Impact on Application:

304 stainless steel grates are commonly used in food processing, chemical processing, and architectural applications due to their hygienic properties. However, in environments with high salt exposure, the risk of pitting corrosion increases.

International Considerations:

Buyers in regions like Africa and South America should ensure compliance with local standards (e.g., ASTM A240) and consider environmental factors that may affect material performance.

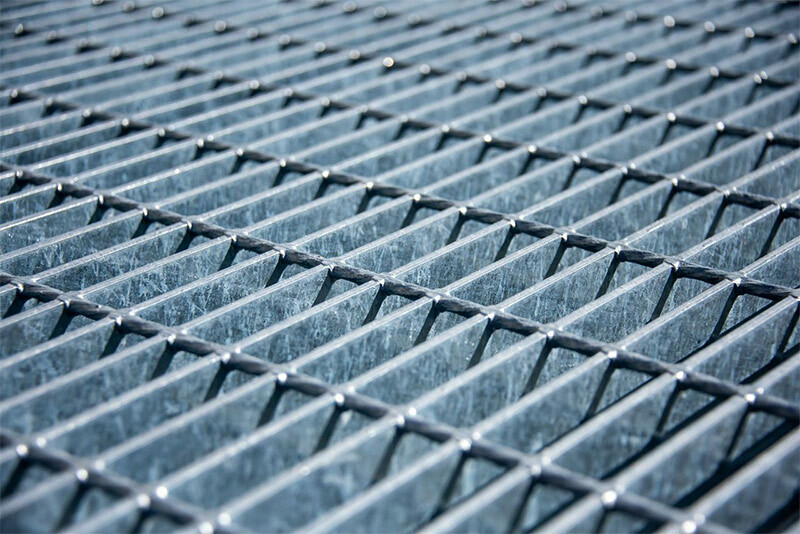

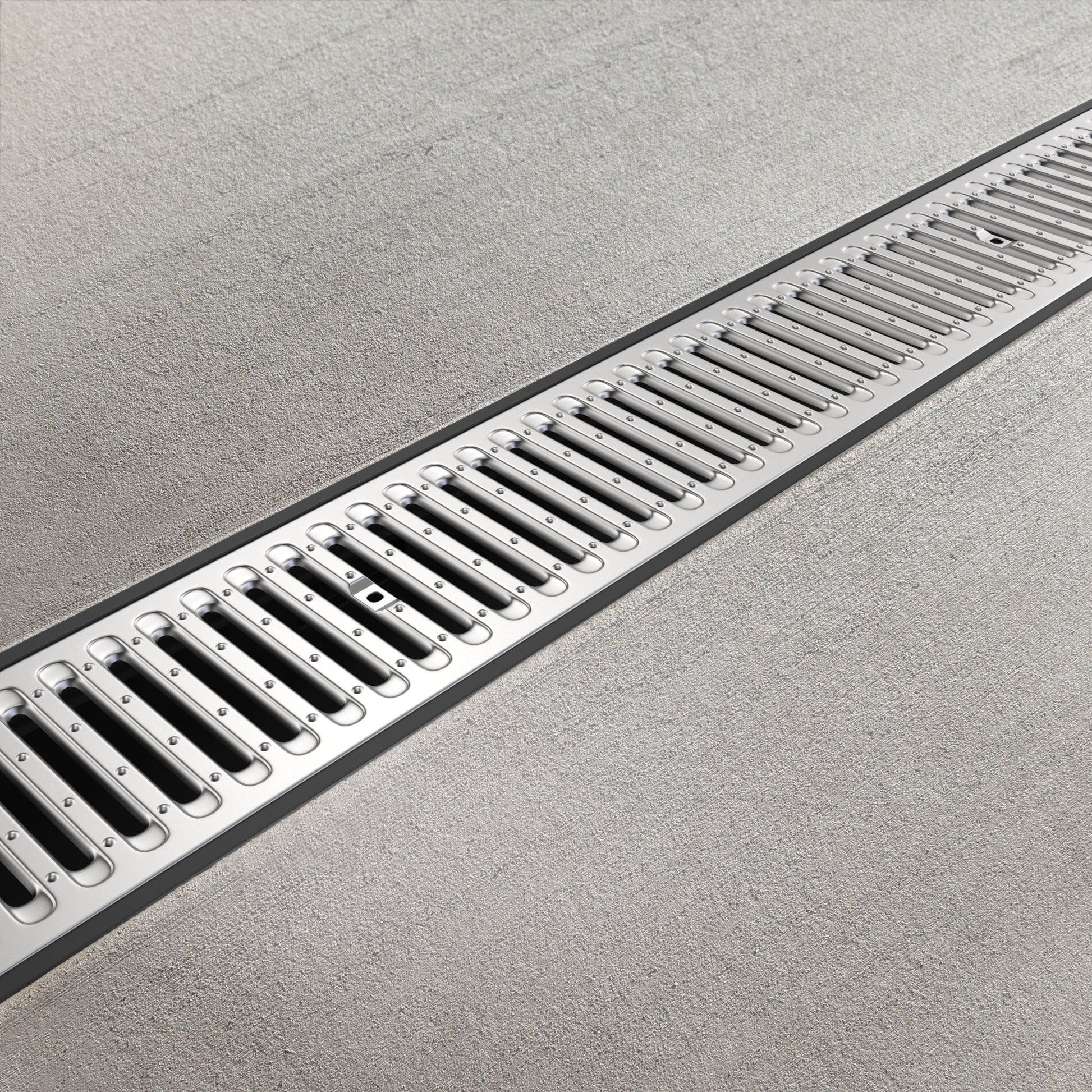

Illustrative image related to stainless steel metal grate

2. 316 Stainless Steel

Key Properties:

316 stainless steel offers superior corrosion resistance, especially against chlorides and acids, making it ideal for harsh environments. It can handle temperatures up to 870°C (1600°F) and maintains structural integrity under stress.

Pros & Cons:

The key advantage of 316 stainless steel is its enhanced durability in corrosive environments. However, it comes at a higher cost compared to 304 stainless steel, which may be a consideration for budget-conscious projects.

Impact on Application:

This material is ideal for marine applications, chemical processing, and pharmaceutical industries due to its resistance to corrosion and staining. It is particularly suited for environments where hygiene is crucial.

International Considerations:

Compliance with standards like ASTM A240 and DIN 17440 is essential for buyers in Europe and the Middle East. Additionally, understanding local market preferences for corrosion-resistant materials can guide procurement decisions.

3. Galvanized Steel

Key Properties:

Galvanized steel is carbon steel coated with a layer of zinc to enhance its corrosion resistance. It is effective in environments where moisture is present but can degrade over time in highly corrosive settings.

Pros & Cons:

The primary advantage of galvanized steel is its cost-effectiveness and ease of availability. However, it is less durable than stainless steel and can suffer from rust formation if the zinc coating is compromised.

Impact on Application:

Galvanized steel grates are often used in outdoor applications, such as walkways and industrial platforms. However, they are not suitable for food processing or chemical environments due to potential contamination from rust.

International Considerations:

When sourcing galvanized steel, buyers should verify compliance with relevant standards (e.g., ASTM A123) and assess local environmental conditions that may affect the longevity of the material.

4. Aluminum Grating

Key Properties:

Aluminum grating is lightweight, corrosion-resistant, and has good thermal conductivity. It can withstand moderate loads and is often used in applications where weight is a concern.

Pros & Cons:

The main advantage of aluminum grating is its lightweight nature, which simplifies installation and reduces structural load. However, it has lower load-bearing capacity compared to stainless steel, making it less suitable for heavy-duty applications.

Impact on Application:

Aluminum grates are commonly used in pedestrian walkways, platforms, and architectural applications. They are not recommended for high-load industrial environments.

International Considerations:

International buyers should consider local standards (e.g., ASTM B221) when sourcing aluminum grating and evaluate the specific load requirements of their applications.

Summary Table of Material Selection for Stainless Steel Metal Grate

| Material | Typical Use Case for stainless steel metal grate | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 304 Stainless Steel | Food processing, architectural applications | Affordable and versatile | Less corrosion resistance in chloride areas | Medium |

| 316 Stainless Steel | Marine applications, chemical processing | Superior corrosion resistance | Higher cost compared to 304 | High |

| Galvanized Steel | Outdoor walkways, industrial platforms | Cost-effective | Can rust if zinc coating is compromised | Low |

| Aluminum Grating | Pedestrian walkways, lightweight structures | Lightweight and easy to install | Lower load-bearing capacity | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for stainless steel metal grate

What Are the Key Stages in the Manufacturing Process of Stainless Steel Metal Grates?

The manufacturing of stainless steel metal grates involves several critical stages that ensure the final product meets the required standards for quality and durability. Understanding these stages can aid B2B buyers in making informed purchasing decisions.

Material Preparation: What Steps Are Involved?

The first step in the manufacturing process is material preparation. Stainless steel, known for its corrosion resistance and durability, is typically sourced in the form of sheets or bars. Manufacturers select the appropriate grade of stainless steel, commonly 304 or 316, based on the specific application requirements. The material is then cleaned and cut to the desired dimensions. This initial step is crucial as it sets the foundation for the quality of the final product.

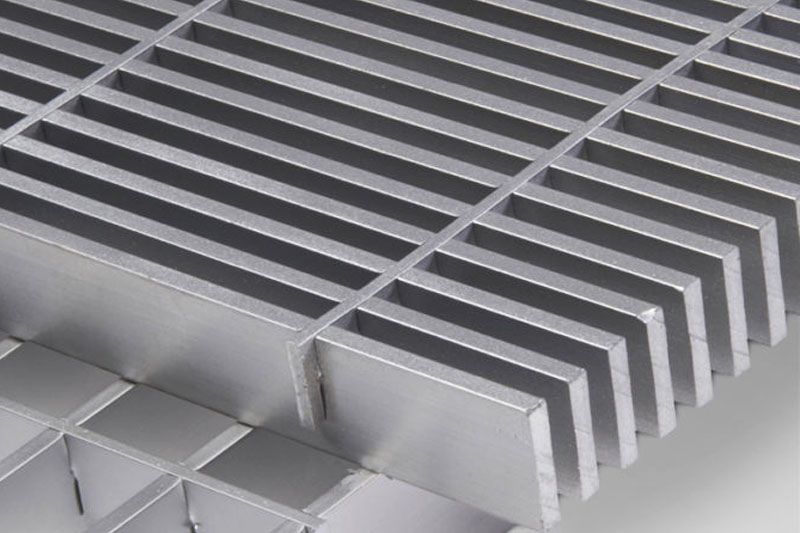

Illustrative image related to stainless steel metal grate

How Is Stainless Steel Grate Formed?

Once the material is prepared, it undergoes forming, which includes several techniques such as welding, swaging, and pressing.

- Welding: This method involves joining stainless steel bars at their intersections. Various welding techniques, including MIG and TIG welding, are employed to ensure strong and durable joints.

- Swaging: In this process, the bars are shaped and locked together without the need for additional fasteners. Swaging enhances the structural integrity of the grate.

- Pressing: This technique is often used for creating specific shapes and profiles in the grating. The material is subjected to high pressure to achieve the desired form.

These techniques allow manufacturers to produce different types of grating, such as welded, riveted, and swage-locked grates, tailored to specific load-bearing requirements.

What Is the Assembly Process Like?

The assembly stage involves integrating the formed components into a complete grate. This may include additional steps such as:

- Cutting: Grates may need to be cut to specific sizes based on customer requirements.

- Notching and Banding: These processes can enhance the installation and functionality of the grates, especially for stair treads or custom applications.

- Surface Preparation: Prior to finishing, grates may undergo treatments to remove any surface impurities or oxidation, ensuring a clean surface for the finishing process.

What Finishing Techniques Are Commonly Used for Stainless Steel Grates?

Finishing is an essential stage that enhances both the aesthetics and functionality of stainless steel grates. Common finishing techniques include:

- Passivation: This chemical treatment enhances corrosion resistance by creating a protective oxide layer.

- Polishing: This process improves the visual appeal and can enhance slip resistance, making the grates suitable for various applications.

- Coating: Although stainless steel is inherently resistant to corrosion, additional coatings can be applied for specific environments, such as marine or industrial settings.

The choice of finishing depends on the intended application and environmental exposure, which is crucial for buyers to consider.

What Quality Assurance Measures Are in Place for Stainless Steel Grates?

Quality assurance (QA) is integral to the manufacturing of stainless steel grates, ensuring that products meet international and industry-specific standards.

Which International Standards Should B2B Buyers Be Aware Of?

Manufacturers often adhere to international standards such as ISO 9001, which outlines criteria for quality management systems. Additionally, industry-specific certifications, such as CE marking for European markets and API standards for industrial applications, ensure that products meet safety and performance requirements.

What Are the Key Quality Control Checkpoints?

Quality control (QC) typically involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they are used in production. Suppliers must provide certificates of compliance to ensure that materials meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing stages, random inspections are conducted to monitor compliance with specifications. This includes checking weld integrity, dimensional accuracy, and surface quality.

-

Final Quality Control (FQC): Before shipping, finished products undergo a final inspection to ensure they meet all customer and regulatory requirements. This includes load testing and visual inspections for defects.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential.

-

Audits: Regular audits of suppliers can provide insight into their manufacturing processes and adherence to quality standards. Buyers should request audit reports to evaluate compliance with international standards.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of quality. These agencies can conduct inspections at various stages of production, ensuring that products meet specifications before shipment.

-

Documentation: Requesting detailed QC reports, including test results and certifications, can help buyers assess the quality of the products being sourced. Documentation should be transparent and easily accessible.

What Nuances Should International Buyers Consider Regarding Quality Control?

When sourcing stainless steel grates internationally, buyers should be mindful of several nuances:

-

Cultural and Regulatory Differences: Different regions may have varying standards and practices. Understanding local regulations and quality standards is vital for compliance and ensuring product suitability.

-

Communication: Establishing clear communication channels with suppliers can help mitigate misunderstandings regarding quality expectations. Buyers should specify their requirements and seek confirmations throughout the process.

-

Lead Times and Logistics: Consideration of lead times is crucial, especially for custom orders. Buyers should discuss potential delays in production due to local regulations or material sourcing challenges, particularly in regions with less predictable supply chains.

By understanding the manufacturing processes and quality assurance measures in place for stainless steel metal grates, B2B buyers can make informed decisions and choose suppliers that align with their quality expectations and project requirements.

Illustrative image related to stainless steel metal grate

Practical Sourcing Guide: A Step-by-Step Checklist for ‘stainless steel metal grate’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure stainless steel metal grates. With a focus on durability, corrosion resistance, and application versatility, stainless steel grating is essential in various industrial and architectural projects. Following this checklist will help ensure that you make informed decisions, optimize procurement processes, and secure high-quality products that meet your specific needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical specifications required for your project. This includes load-bearing capacity, dimensions, and application environments. For instance, consider whether the grate will be used in pedestrian areas or for heavy machinery, as this will dictate the necessary strength and design.

- Load Requirements: Identify the weight and type of traffic that the grate will support.

- Dimensions: Specify the height, width, and thickness to ensure compatibility with existing structures.

Step 2: Research Material Options

Select the appropriate grade of stainless steel based on your project’s environmental conditions. Stainless steel varies in composition, influencing its corrosion resistance and overall durability.

- Common Grades: For harsh environments, consider 304 or 316 grades, with 316 offering superior corrosion resistance.

- Finish Types: Decide if a specific finish is needed for aesthetics or enhanced traction, such as serrated or grooved surfaces.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your specifications and deliver quality products. Request detailed company profiles, including their experience in the industry and customer references.

- Certifications: Verify if the suppliers have relevant certifications, such as ISO 9001, which indicates quality management standards.

- Client Testimonials: Seek feedback from past clients, especially those in similar industries or geographical locations.

Step 4: Request Samples

Before making a bulk purchase, request samples of the stainless steel grates you are considering. This allows you to assess the quality and suitability of the product for your specific application.

- Testing: Inspect the samples for structural integrity, surface finish, and overall workmanship.

- Compatibility Check: Ensure that the samples fit well with your existing installations or design plans.

Step 5: Inquire About Lead Times and Availability

Understanding the lead times and availability of your chosen grates is crucial for project planning. Delays in procurement can impact overall project timelines.

- Production Capacity: Ask about the supplier’s production capabilities to ensure they can meet your order quantities.

- Shipping Options: Discuss shipping methods and timelines, especially if sourcing internationally, to avoid unexpected delays.

Step 6: Review Pricing and Payment Terms

Evaluate the pricing structures of potential suppliers and ensure they fit within your budget. Transparent pricing helps avoid hidden costs that could arise later.

- Bulk Discounts: Inquire about bulk purchasing options, which may lead to significant cost savings.

- Payment Flexibility: Discuss payment terms, including deposits and credit options, to ensure they align with your financial processes.

Step 7: Finalize Contractual Agreements

Once you have selected a supplier, ensure that all terms are clearly documented in a contractual agreement. This should cover specifications, delivery timelines, payment terms, and warranties.

- Warranties and Support: Look for warranties on the product and inquire about after-sales support for installation or maintenance.

- Dispute Resolution: Include terms for resolving potential disputes, ensuring a smooth procurement process.

By following this checklist, B2B buyers can systematically approach the procurement of stainless steel metal grates, ensuring that their needs are met with precision and quality.

Comprehensive Cost and Pricing Analysis for stainless steel metal grate Sourcing

What Are the Key Cost Components in Sourcing Stainless Steel Metal Grates?

When considering the procurement of stainless steel metal grates, understanding the cost structure is essential. The primary cost components include:

Illustrative image related to stainless steel metal grate

-

Materials: Stainless steel is a premium material known for its durability and corrosion resistance. The price fluctuates based on global market trends, alloy composition, and the supplier’s location. Buyers should consider the type of stainless steel (e.g., 304, 316) which can significantly impact costs.

-

Labor: Labor costs vary by region and the complexity of the manufacturing process. In areas with higher labor costs, such as Europe, the overall pricing may be higher compared to regions like Africa or South America, where labor can be less expensive.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, such as utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can reduce overhead, influencing the final price.

-

Tooling: Custom tooling for specific grating designs or sizes can add to initial costs. However, investing in high-quality tooling can lead to better precision and lower defect rates in the long run.

-

Quality Control (QC): Ensuring that products meet industry standards and client specifications incurs additional costs. Effective QC processes are vital for maintaining the integrity of the products, especially for applications in sensitive industries like food processing or pharmaceuticals.

-

Logistics: Shipping costs can vary significantly based on distance, shipping method, and weight. International buyers should factor in potential tariffs and customs duties, which can further affect the total cost.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and risks. Understanding the typical margins in different regions can assist buyers in negotiating better prices.

How Do Price Influencers Affect Stainless Steel Metal Grate Procurement?

Several factors can influence the pricing of stainless steel metal grates:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often result in lower per-unit costs. Buyers should consider consolidating orders to meet MOQs, which can lead to significant savings.

-

Specifications and Customization: Custom designs or specific load-bearing requirements can increase costs. Buyers should clearly outline their needs to avoid unexpected charges.

-

Material Quality and Certifications: High-quality materials and certifications (e.g., ISO, ASTM) may command higher prices but can ensure compliance and durability, offering long-term savings.

-

Supplier Factors: Supplier reliability, reputation, and location can influence pricing. Engaging with multiple suppliers for quotes can help buyers gauge the market and negotiate effectively.

-

Incoterms: Understanding the delivery terms (e.g., FOB, CIF) is crucial as it dictates who bears the costs and risks during shipping. This can significantly impact the overall cost structure.

What Buyer Tips Can Help Achieve Cost-Efficiency in Sourcing?

To maximize cost-efficiency when sourcing stainless steel metal grates, consider the following strategies:

-

Negotiate Effectively: Open discussions with suppliers about pricing, especially for bulk orders. Many suppliers are willing to negotiate terms that can lead to favorable pricing.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, potential replacements, and operational costs. Investing in higher-quality grates may reduce long-term expenses.

-

Understand Pricing Nuances for International Procurement: Buyers from regions like Africa or South America should be aware of local market conditions, currency fluctuations, and geopolitical factors that may affect pricing.

-

Stay Informed on Market Trends: Regularly monitor the stainless steel market and industry developments. Being aware of changes can help buyers time their purchases more strategically.

Disclaimer on Indicative Prices

Pricing for stainless steel metal grates can vary widely based on the factors discussed. It is advisable for buyers to obtain multiple quotes and confirm current market prices, as they can fluctuate based on material costs and demand dynamics.

Alternatives Analysis: Comparing stainless steel metal grate With Other Solutions

Introduction to Alternative Solutions for Metal Grating

When selecting a grating solution for various applications, it’s essential to consider alternatives to stainless steel metal grating. While stainless steel is known for its durability, corrosion resistance, and aesthetic appeal, other materials and technologies can also meet specific project needs. This analysis will compare stainless steel metal grating with two viable alternatives: fiberglass reinforced plastic (FRP) grating and aluminum grating. Each material offers distinct benefits and drawbacks, making it crucial for B2B buyers to understand the implications of their choices.

Comparison Table

| Comparison Aspect | Stainless Steel Metal Grate | Fiberglass Reinforced Plastic (FRP) Grating | Aluminum Grating |

|---|---|---|---|

| Performance | High load-bearing capacity, slip-resistant | Good chemical resistance, lightweight | Strong, lightweight, corrosion-resistant |

| Cost | Higher initial cost | Moderate cost, lower than stainless steel | Generally lower than stainless steel |

| Ease of Implementation | Requires specific tools for installation | Easy to cut and install, often no special tools required | Moderate, requires specific fasteners |

| Maintenance | Low maintenance, resistant to rust | Low maintenance, but can be prone to UV degradation | Low maintenance, susceptible to denting |

| Best Use Case | Industrial environments, architectural applications | Chemical plants, outdoor settings | Commercial and industrial applications |

Detailed Breakdown of Alternatives

Fiberglass Reinforced Plastic (FRP) Grating

FRP grating is a composite material that offers excellent chemical resistance, making it suitable for environments where corrosive substances are prevalent. One of its key advantages is its lightweight nature, which simplifies transportation and installation. However, it is essential to note that FRP can degrade under prolonged exposure to UV light, leading to potential structural failures over time. While it is generally less expensive than stainless steel, the need for periodic replacement in harsh conditions can offset initial savings.

Aluminum Grating

Aluminum grating is known for its lightweight properties and ease of handling. It exhibits good corrosion resistance, making it ideal for various applications, including industrial and commercial settings. The cost of aluminum grating is usually lower than that of stainless steel, providing a budget-friendly option without sacrificing too much strength. However, aluminum can be more susceptible to denting and damage under heavy loads compared to stainless steel, which may limit its use in high-traffic areas.

Illustrative image related to stainless steel metal grate

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate grating solution, B2B buyers must evaluate their specific requirements, including environmental conditions, load-bearing needs, and budget constraints. Stainless steel metal grating is an excellent choice for applications demanding high strength and corrosion resistance, particularly in industrial and architectural settings. However, alternatives like FRP and aluminum grating can provide cost-effective and lightweight options for specific use cases. By carefully considering the performance, cost, ease of implementation, maintenance needs, and best use cases of each material, buyers can make informed decisions that align with their project goals and operational demands.

Essential Technical Properties and Trade Terminology for stainless steel metal grate

What Are the Key Technical Properties of Stainless Steel Metal Grate?

1. Material Grade

Stainless steel grates are typically made from various grades of stainless steel, such as 304 and 316. Grade 304 is known for its excellent corrosion resistance and is suitable for most applications, while Grade 316 offers enhanced resistance to chlorides and is ideal for marine or chemical environments. Understanding the material grade is crucial for B2B buyers, as it directly impacts durability, maintenance, and the overall lifespan of the product.

2. Load-Bearing Capacity

The load-bearing capacity indicates the maximum weight a grating can support without failure. This property is essential for applications that experience heavy traffic or equipment loads, such as industrial flooring or pedestrian walkways. Buyers need to specify their load requirements during the procurement process to ensure safety and compliance with industry standards.

Illustrative image related to stainless steel metal grate

3. Open Area Percentage

The open area percentage refers to the proportion of the grating panel that is open space versus solid material. Higher open area percentages provide better drainage and airflow, making them suitable for applications in wet or high-traffic areas. Buyers should assess the specific needs of their applications, such as drainage requirements or aesthetic considerations, when choosing the right open area percentage.

4. Tolerance

Tolerance defines the permissible limit of variation in dimensions for the grating panels. It ensures that the panels fit correctly during installation and maintain structural integrity. B2B buyers must understand tolerance specifications to avoid costly adjustments or replacements after installation.

5. Surface Finish

Stainless steel grating can come in various surface finishes, such as mill finish, polished, or coated. Each finish offers different benefits, such as increased traction or aesthetic appeal. Selecting the appropriate finish is important for applications that require safety features or specific visual standards.

6. Construction Type

Different construction types, such as welded, swage-locked, or press-locked, offer distinct advantages in terms of strength, weight, and assembly. For instance, welded grates are typically more robust and suitable for heavy-duty applications, while press-locked options may be lighter and easier to install. Understanding these distinctions helps buyers make informed decisions based on their specific project requirements.

What Are Common Trade Terms Used in the Stainless Steel Grate Industry?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are used in another company’s end product. In the context of stainless steel grates, buyers may work with OEMs to ensure that custom specifications are met for their applications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers, as it can affect purchasing decisions and inventory management. Buyers should confirm MOQs before placing orders to ensure they meet their project needs without overcommitting.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products or services. This process is crucial for B2B transactions, as it allows buyers to compare offers and negotiate terms effectively.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers, as they dictate who bears shipping costs, risks, and insurance responsibilities during transport.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. In industries where timely delivery is critical, understanding lead times is crucial for effective project planning and execution.

6. Custom Fabrication

Custom fabrication involves modifying standard grating products to meet specific project requirements, such as size, shape, or finish. B2B buyers often need this service to ensure that the grating fits their unique applications, making it an important consideration during the purchasing process.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions that enhance project efficiency, safety, and overall satisfaction with their stainless steel grate purchases.

Navigating Market Dynamics and Sourcing Trends in the stainless steel metal grate Sector

What Are the Key Trends Shaping the Global Stainless Steel Metal Grate Market?

The stainless steel metal grate market is experiencing significant growth driven by several global factors. Increasing urbanization, particularly in developing regions like Africa and South America, is propelling demand for durable, corrosion-resistant materials in construction and infrastructure projects. Emerging economies are investing heavily in industrial applications, where stainless steel grating is preferred due to its strength, safety, and aesthetic appeal. Furthermore, sectors such as food processing and pharmaceuticals are increasingly adopting stainless steel grates for their hygienic properties, with an emphasis on compliance with health regulations.

Technological advancements are also influencing sourcing trends. The rise of e-commerce platforms enables B2B buyers to access a broader range of suppliers, facilitating price comparisons and enhancing procurement efficiency. Digital tools such as Building Information Modeling (BIM) are becoming essential for architects and engineers, allowing them to visualize and specify grating solutions accurately. Additionally, the integration of supply chain management software is streamlining sourcing processes, helping companies manage inventory and procurement more effectively.

Another notable trend is the shift toward customized solutions. As projects become more specialized, buyers are increasingly seeking tailored grating options that meet specific load requirements, dimensions, and surface finishes. This trend is particularly prevalent in regions like Europe and the Middle East, where architectural standards are stringent, and aesthetics play a crucial role in material selection.

How Are Sustainability and Ethical Sourcing Influencing the Stainless Steel Metal Grate Sector?

Sustainability has become a pivotal concern in the stainless steel metal grate sector, influencing both production methods and sourcing decisions. The environmental impact of manufacturing processes is under scrutiny, prompting suppliers to adopt more eco-friendly practices. Stainless steel itself is a sustainable choice, being 100% recyclable without loss of quality, thus reducing waste in the supply chain.

B2B buyers are increasingly prioritizing ethical sourcing, seeking suppliers who demonstrate a commitment to sustainable practices. This includes obtaining certifications such as ISO 14001 for environmental management systems and using materials that comply with green building standards. Certifications like LEED (Leadership in Energy and Environmental Design) are becoming essential for projects in regions like North America and Europe, where clients demand transparency regarding the environmental footprint of their materials.

Moreover, ethical sourcing extends to labor practices. Buyers are more inclined to work with manufacturers who provide fair wages and safe working conditions. This trend is particularly relevant in developing markets, where establishing ethical supply chains can enhance brand reputation and foster long-term relationships with clients.

How Has the Stainless Steel Metal Grate Sector Evolved Over Time?

The evolution of the stainless steel metal grate sector reflects broader advancements in material science and industrial applications. Initially popularized for its corrosion resistance in marine and industrial environments, stainless steel grating has diversified into various sectors, including architecture and transportation.

In the early 20th century, stainless steel was primarily used in high-corrosion environments. As technology advanced, manufacturers began to explore different fabrication methods, such as welded and swage-locked constructions, enhancing the strength and versatility of grating products. The introduction of advanced coatings and finishes has further expanded its applications, making stainless steel grating suitable for both functional and aesthetic uses.

Today, the stainless steel metal grate market is characterized by innovation and customization, with suppliers continually developing new products to meet the specific needs of diverse industries. This evolution not only reflects changing market demands but also highlights the sector’s adaptability in an increasingly competitive global landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of stainless steel metal grate

-

How do I choose the right stainless steel metal grate for my application?

Choosing the right stainless steel metal grate involves assessing your specific application needs, such as load-bearing requirements, environmental conditions, and safety standards. Consider factors like the type of traffic (pedestrian or vehicular), exposure to corrosive elements, and whether ADA compliance is necessary. It’s crucial to evaluate the construction type (welded, swage-locked, or press-locked) and the open area percentage for drainage or airflow. Consulting with a supplier can provide insights tailored to your project’s demands. -

What is the best type of stainless steel metal grate for industrial applications?

For industrial applications, heavy-duty welded stainless steel grates are often the best choice due to their strength and durability. These grates can withstand significant weight loads and are resistant to corrosion, making them suitable for harsh environments. Consider the specific load requirements and the type of traffic expected. Additionally, the surface finish can enhance slip resistance, which is vital for worker safety. Always review the supplier’s specifications to ensure compliance with industry standards. -

What customization options are available for stainless steel metal grates?

Many suppliers offer customization options for stainless steel metal grates, including size, shape, and surface finish. You can specify dimensions to fit your project, select different bar spacing for drainage needs, and choose finishes that enhance traction or aesthetic appeal. Additional features, such as notching or cut-outs for utilities, may also be available. Discuss your requirements with the manufacturer to explore all customization possibilities, ensuring the final product meets your exact specifications. -

What are the typical minimum order quantities (MOQ) for stainless steel metal grates?

Minimum order quantities (MOQ) for stainless steel metal grates can vary significantly by supplier and product type. Generally, MOQs can range from a few panels for standard sizes to larger quantities for custom or specialized products. When sourcing, inquire about the MOQ for the specific grates you need, as some suppliers may offer flexibility based on your requirements or long-term partnership agreements. Understanding the MOQ can help you manage your inventory and budget effectively. -

What payment terms should I expect when sourcing stainless steel metal grates internationally?

Payment terms for international sourcing of stainless steel metal grates can vary widely depending on the supplier and the specific agreement. Common arrangements include payment upfront, 30% deposit with the balance upon shipment, or net 30 days after delivery. Always clarify payment terms during negotiations, considering factors such as currency exchange rates and transaction fees. Establishing clear terms can help mitigate risks and ensure a smooth purchasing process. -

How can I vet suppliers of stainless steel metal grates effectively?

Vetting suppliers is crucial to ensure quality and reliability. Start by researching potential suppliers’ credentials, including certifications like ISO and their track record in the industry. Request samples of their products to assess quality and durability. Additionally, seek reviews or testimonials from other buyers and inquire about their production capabilities and lead times. Engaging in direct communication can also provide insights into their customer service and responsiveness. -

What quality assurance measures should I consider when sourcing stainless steel metal grates?

When sourcing stainless steel metal grates, inquire about the supplier’s quality assurance (QA) processes. Effective QA measures include regular inspections, adherence to international standards, and material certifications. Request documentation such as test reports and certifications for the stainless steel used. Understanding the supplier’s QA protocols ensures that the products you receive meet your specifications and are suitable for your intended application. -

What logistical considerations should I keep in mind when importing stainless steel metal grates?

Logistical considerations are key when importing stainless steel metal grates. Start by understanding shipping options, transit times, and costs based on your location. Be aware of customs regulations and duties applicable to your import, which can vary by country. Establish clear communication with your supplier regarding packaging and delivery methods to prevent damage during transport. Additionally, consider working with a logistics partner who specializes in international shipping to streamline the process and mitigate potential challenges.

Top 8 Stainless Steel Metal Grate Manufacturers & Suppliers List

1. MetalsDepot® – Stainless Steel Bar Grating

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: MetalsDepot® – Stainless Steel Bar Grating – Extremely strong, durable, and highly corrosive resistant for load bearing applications. Designed for pedestrian and light vehicle traffic, suitable for walkways, flooring, trench grates, mezzanines, platforms, stair treads, etc. Ideal for corrosive environments like chemical, food, salt and fresh water marine, and acidic environments. Available in prec…

2. McNichols – Stainless Steel Bar Grating

Domain: mcnichols.com

Registered: 1996 (29 years)

Introduction: {‘item_number’: ‘6801312732’, ‘product_line’: ‘Bar Grating’, ‘construction_type’: ‘Standard-Duty Welded’, ‘bearing_bar_shape’: ‘Rectangular Bar’, ‘series_type’: ‘GW-100 (19-W-4)’, ‘product_spacing’: ’19-W-4′, ‘primary_material’: ‘Stainless Steel (SS)’, ‘alloy_grade’: ‘Type 304’, ‘material_finish’: ‘Mill Finish’, ‘bearing_bar_size’: ‘1″ Height x 3/16″ Thick Rectangular Bar’, ‘bearing_bar_height’: ‘…

3. McMaster – Stainless Steel Grating

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Stainless Steel Grating, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. PR Metals – Grating Solutions

Domain: prmetals.com

Registered: 2001 (24 years)

Introduction: {“product_categories”: [“Grating”, “Stair Treads”, “Wire Mesh”, “Perforated Metal”, “Ladder Rungs”, “Handrail & Ladder”, “Fiberglass Shapes”, “Expanded Metal”, “Grating Accessories”], “materials”: [“Carbon Steel”, “Stainless Steel”, “Aluminum”, “Fiberglass”], “spacing_options”: [“38W4”, “30W4”, “22W4”, “19W4”, “19P4”, “19S4”, “19W2”, “15W4”, “15W2”, “11W4”, “11P4”, “11W2”, “7P4”], “depth_options”:…

5. Grating Pacific – Stainless Steel Bar Grating

Domain: gratingpacific.com

Registered: 1997 (28 years)

Introduction: Stainless Steel Bar Grating is manufactured from alloy types 304, 304L, 316, and 316L, making it ideal for sanitary or highly corrosive environments and architectural applications. It is available in three construction methods: type ‘WS’ welded, type ‘SLS’ swage locked, and type ‘DTS’ dovetail. The bearing bar spacings range from 19/16″ (1-3/16″) to 7/16″ on center, with cross bars at 4″ or 2″ on …

6. Amarco Products – ST-58 Stainless Steel Grating

Domain: amarcoproducts.com

Registered: 2005 (20 years)

Introduction: {“model”:”ST-58″,”type”:”Stainless Steel Grating”,”thickness”:”5/8 inch”,”material”:”304 Type Stainless Steel”,”rolling_load”:”1,000 pounds”,”tread_spacing”:”0.233 inches on center”,”applications”:[“High-Traffic Entryways”,”Commercial Vestibules”,”Corporate Office Entrances”],”custom_fabrication”:”Yes”,”max_dimensions”:{“width”:”94 inches”,”length”:”61 inches”},”weight_per_sqft”:”Approx. 2.0 lbs”,…

7. Brown-Campbell – Stainless Steel Bar Grating

Domain: brown-campbell.com

Registered: 1996 (29 years)

Introduction: Stainless Steel Bar Grating available in welded, press-locked, and swaged constructions. Suitable for corrosive environments such as chemical, food, and hydro processing areas. Key items include:

– Item# BS118: 19SW4, 1″ x 1/8″, Welded, Smooth, Stainless Steel, Mill Finish, Sizes: 24″ x 288″, 36″ x 288″

– Item# BS1316: 19SW4, 1″ x 3/16″, Welded, Smooth, Stainless Steel, Mill Finish, Sizes: 24″ x…

8. Direct Metals® – Stainless Steel Bar Gratings

Domain: directmetals.com

Registered: 1998 (27 years)

Introduction: Direct Metals® offers a full line of stainless steel bar gratings, specifically T304 stainless steel, which is an industrial grade suitable for various applications. The stainless steel bar grating is available in both smooth and serrated surfaces. Custom services such as sand blasting, passivating, and electro-polishing are available upon request. The T304 light duty and heavy duty stainless stee…

Strategic Sourcing Conclusion and Outlook for stainless steel metal grate

As global industries increasingly recognize the advantages of stainless steel metal grating, strategic sourcing becomes pivotal for B2B buyers aiming to enhance operational efficiency and durability in their projects. This material not only boasts exceptional corrosion resistance and hygiene but also offers a modern aesthetic that aligns with contemporary architectural standards. Buyers should consider various types of grating, including welded and swaged options, to meet specific load-bearing requirements while ensuring compliance with safety standards such as ADA.

Investing in stainless steel grating translates to lower maintenance costs and longer product lifespans, making it a smart choice for sectors ranging from construction to food processing. Furthermore, the eco-friendly aspect of stainless steel, being infinitely recyclable, aligns with the growing emphasis on sustainability in global supply chains.

Looking forward, B2B buyers in regions like Africa, South America, the Middle East, and Europe are encouraged to engage with reputable suppliers to explore tailored solutions that meet their unique needs. Embrace the opportunity to enhance your projects with high-quality stainless steel grating that promises both performance and aesthetic appeal. Start your strategic sourcing journey today to secure the best value for your investments.

Illustrative image related to stainless steel metal grate

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.