A B2B Buyer’s Guide to Spring Loaded Hinges: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for spring loaded hinges

In the competitive landscape of industrial hardware, sourcing high-quality spring loaded hinges can be a daunting challenge for B2B buyers. Whether you’re in Africa, South America, the Middle East, or Europe, the need for reliable and efficient hardware solutions is paramount. This comprehensive guide on spring loaded hinges addresses critical aspects such as types, applications, supplier vetting, and cost considerations, equipping you with the knowledge needed to make informed purchasing decisions.

Spring loaded hinges serve a vital function in various industries, from manufacturing and construction to furniture and automotive applications. Understanding the diverse options available, including spring-loaded-to-open and spring-loaded-to-close hinges, will help you identify the best fit for your specific needs. Moreover, the guide delves into the importance of material selection, torque specifications, and customization possibilities, ensuring that your choices align with operational requirements and durability standards.

By providing actionable insights and expert recommendations, this guide empowers international B2B buyers to navigate the complexities of the global market for spring loaded hinges. You’ll gain the confidence to evaluate suppliers effectively, negotiate costs, and select the right products that enhance your operational efficiency. Embrace this opportunity to streamline your sourcing process and elevate your procurement strategy in a rapidly evolving marketplace.

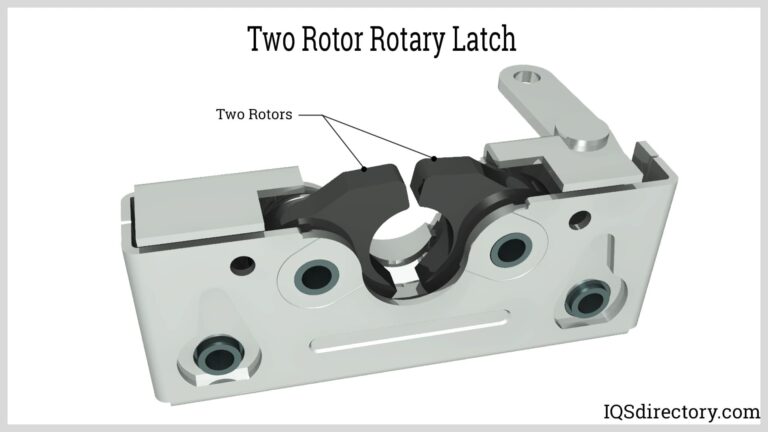

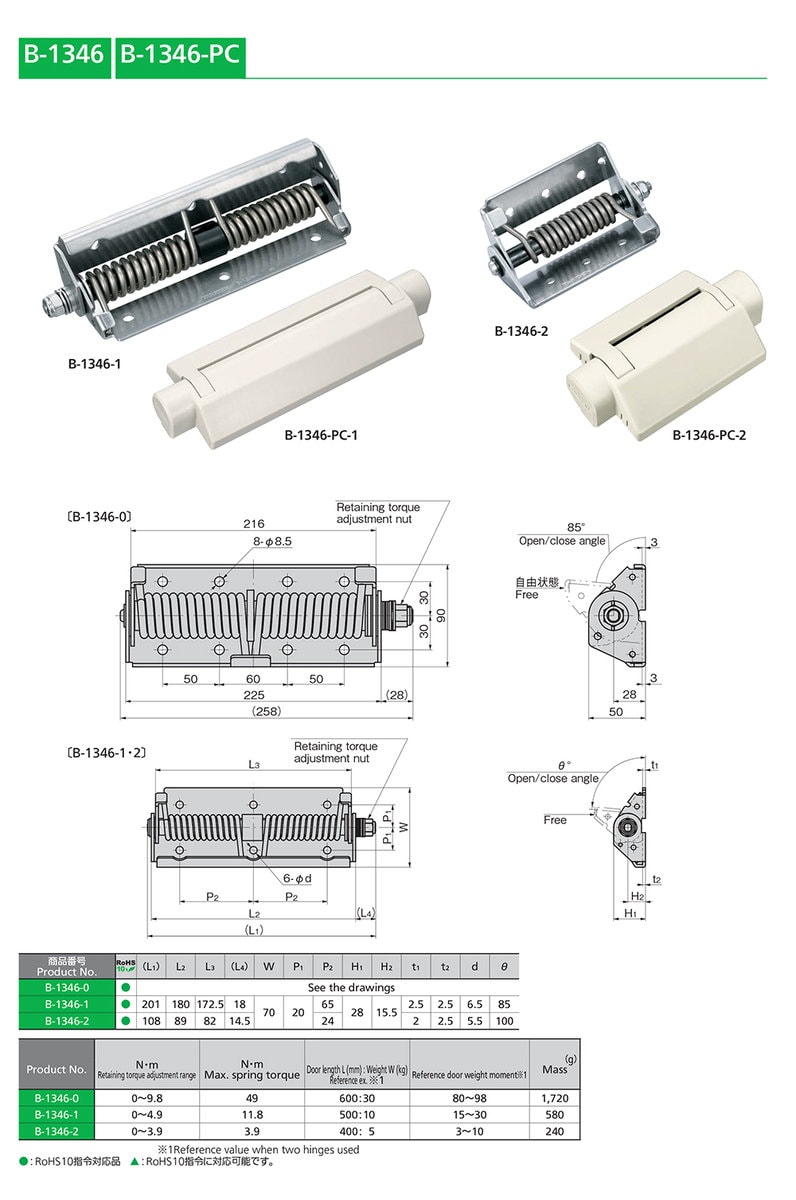

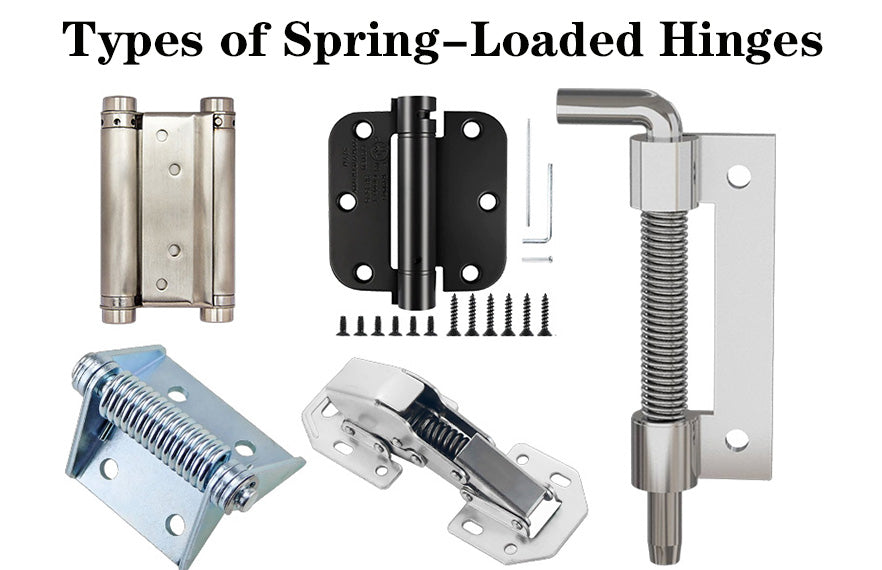

Understanding spring loaded hinges Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Spring-Loaded-to-Close | Springs push leaves together to close the door | Industrial doors, cabinets, and enclosures | Pros: Reliable closure; Cons: May require adjustment for specific applications. |

| Spring-Loaded-to-Open | Springs push leaves apart to keep the door open | Fire doors, access panels, and safety enclosures | Pros: Facilitates easy access; Cons: Limited to specific design applications. |

| Continuous Spring Hinges | Long, continuous design for even weight distribution | Heavy-duty doors, gates, and large cabinets | Pros: Enhanced durability; Cons: More complex installation. |

| Cover Hinges | Designed for quick access to small openings | Electrical panels, machinery access, and cabinets | Pros: Cost-effective; Cons: Limited load capacity. |

| Custom Spring Hinges | Tailored specifications to meet unique requirements | Specialized industrial applications | Pros: Perfect fit for unique needs; Cons: Higher cost and longer lead times. |

What are the Characteristics of Spring-Loaded-to-Close Hinges?

Spring-loaded-to-close hinges are engineered to push the hinge leaves together, effectively closing the door or panel when released. These hinges are ideal for environments where secure closure is necessary, such as industrial doors and cabinet applications. Buyers should consider the torque required for their specific application, as different weights and frequencies of use may demand varying levels of spring tension. Reliability and ease of maintenance are key advantages, though adjustments may be necessary to ensure optimal performance.

How Do Spring-Loaded-to-Open Hinges Function?

Spring-loaded-to-open hinges operate in the opposite manner, using springs that push the leaves apart to keep the door open. This type is commonly used in fire doors and access panels, where safety and quick access are priorities. When purchasing, it is crucial to evaluate the mounting position and the direction of force applied by the spring to ensure proper function. While they provide convenience and ease of access, they may not be suitable for all designs due to their specific operational mechanics.

What are the Benefits of Continuous Spring Hinges?

Continuous spring hinges feature a long, continuous design that provides uniform weight distribution across larger doors and gates. This design enhances durability and strength, making them suitable for heavy-duty applications. When selecting continuous spring hinges, buyers should consider the installation complexity and the specific load requirements. Although they offer superior performance and longevity, the installation process may require additional expertise compared to standard hinge types.

What Makes Cover Hinges a Smart Choice?

Cover hinges are specifically designed for quick access to small openings, making them perfect for applications like electrical panels and machinery access. They offer a cost-effective solution for securing and covering access points while maintaining ease of use. Buyers should assess the load capacity and material suitability for their specific applications. While cover hinges are economical and straightforward, their limited capacity can be a drawback for heavier applications.

Why Consider Custom Spring Hinges?

Custom spring hinges are designed to meet unique specifications that standard hinges may not fulfill. They cater to specialized industrial applications where dimensions, strength, and functionality must be tailored. When considering custom options, buyers should weigh the benefits of a perfect fit against the potential for higher costs and longer lead times. Custom hinges can provide significant advantages in terms of performance and compatibility, particularly in complex installations where standard products fall short.

Key Industrial Applications of spring loaded hinges

| Industry/Sector | Specific Application of Spring Loaded Hinges | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Automated assembly lines for machinery access | Improved efficiency and safety in operations | Durability, weight capacity, and resistance to wear |

| Transportation | Bus and truck compartments for easy access | Enhanced operational efficiency and safety | Corrosion resistance, customization options, and load ratings |

| Construction | Doors and gates in industrial buildings | Increased security and ease of access | Material specifications, size variations, and compliance with local regulations |

| Marine | Access hatches on boats and ships | Enhanced safety and functionality in marine environments | Waterproof finishes, material strength, and weight considerations |

| Electronics | Protective covers for electrical panels | Improved safety and ease of maintenance | Compatibility with existing setups, torque specifications, and material choices |

How Are Spring Loaded Hinges Used in Manufacturing?

In manufacturing, spring loaded hinges are commonly utilized in automated assembly lines to facilitate easy access to machinery. They allow doors and panels to open and close with minimal effort, which enhances operational efficiency and safety. Buyers in this sector should prioritize hinges that offer durability and a high weight capacity, as these factors directly impact the longevity and reliability of the equipment in high-use environments.

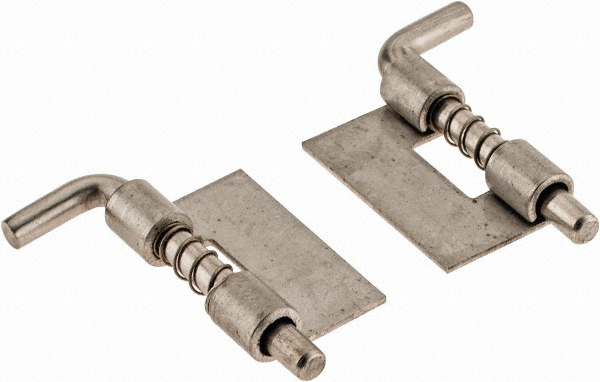

与spring loaded hinges相关的说明性图片

What Role Do Spring Loaded Hinges Play in Transportation?

In the transportation industry, spring loaded hinges are essential for compartments in buses and trucks, enabling quick access for maintenance and loading. Their design promotes operational efficiency while ensuring that compartments remain securely closed during transit. When sourcing these hinges, businesses should consider corrosion resistance and customization options to meet specific vehicle designs and load ratings, especially in regions with varied climates.

How Are Spring Loaded Hinges Beneficial in Construction?

In construction, spring loaded hinges are frequently employed on doors and gates within industrial buildings. They provide a secure closure while allowing for quick access, which is vital for safety and operational efficiency. Buyers should focus on material specifications and size variations to ensure compliance with local regulations and standards, particularly in regions with stringent building codes.

Why Are Spring Loaded Hinges Important in Marine Applications?

Marine applications utilize spring loaded hinges for access hatches on boats and ships, ensuring safety and functionality in harsh environments. These hinges must withstand exposure to water and salt, making material strength and waterproof finishes critical factors for sourcing. Businesses in this sector should prioritize hinges that provide reliable performance under marine conditions, enhancing both safety and operational efficiency.

How Do Spring Loaded Hinges Improve Safety in Electronics?

In the electronics sector, spring loaded hinges are used for protective covers on electrical panels, facilitating easy access for maintenance while ensuring safety. They help prevent accidental openings and provide a secure closure when not in use. Buyers should ensure compatibility with existing setups, paying close attention to torque specifications and material choices to maintain functionality and safety standards in their applications.

3 Common User Pain Points for ‘spring loaded hinges’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Torque for Spring Loaded Hinges

The Problem:

B2B buyers often encounter challenges when trying to select the appropriate torque for spring loaded hinges. This is critical because the hinge’s torque affects its performance in applications, such as cabinet doors or industrial equipment. Buyers may miscalculate the necessary torque, leading to hinges that are either too stiff—causing difficulties in operation—or too loose, resulting in doors that don’t stay closed. This misalignment can lead to increased maintenance costs, operational inefficiencies, and even potential safety hazards.

The Solution:

To effectively specify the right torque for spring loaded hinges, B2B buyers should start by conducting a thorough analysis of their application requirements. This includes understanding the weight of the door or panel, the frequency of use, and the environmental conditions (e.g., temperature, humidity) that might affect hinge performance. It is advisable to request torque samples from manufacturers to test in real-world scenarios before finalizing the order. Many suppliers offer a range of torque options; thus, experimenting with several stock items can help identify the optimal solution. Additionally, buyers should consult with engineers to calculate the necessary torque considering factors like friction and wear over time, ensuring a precise fit for their specific needs.

Scenario 2: Inconsistent Performance Across Different Environments

The Problem:

Another common issue faced by B2B buyers is the inconsistency in hinge performance when used in varying environmental conditions. For instance, a spring loaded hinge that works well in a controlled indoor environment may fail to operate effectively in harsher conditions, such as high humidity or extreme temperatures. This can lead to premature wear, corrosion, or even complete malfunction, which can disrupt operations and lead to costly downtime.

The Solution:

To mitigate the risks associated with environmental variability, buyers should prioritize sourcing hinges made from materials specifically designed for resilience in challenging conditions. Stainless steel or zinc-plated options are generally more durable and resistant to corrosion. Additionally, it’s crucial to discuss the intended environment with suppliers, who can recommend the best finishes and materials based on their product range. Implementing routine inspections and maintenance schedules can also help identify issues before they lead to failures. Buyers may also consider custom spring loaded hinges that meet specific environmental standards, providing an added layer of assurance regarding their operational longevity.

Scenario 3: Challenges with Installation and Alignment

The Problem:

Improper installation and alignment of spring loaded hinges can lead to operational issues, including misalignment of doors or panels, which can affect their functionality and durability. Buyers often struggle with ensuring that the hinges are mounted correctly, leading to frustration and increased labor costs. In some cases, this misalignment can also result in safety concerns, particularly in industrial settings where heavy doors are involved.

The Solution:

To address installation challenges, buyers should invest in training for their maintenance and installation teams to ensure they understand the nuances of spring loaded hinge installation. Providing detailed installation manuals and guidelines can also significantly reduce the risk of errors. When selecting hinges, consider those with features designed to facilitate easier installation, such as pre-drilled holes or alignment guides. Furthermore, using adjustable hinges can help fine-tune alignment during the installation process. Engaging with suppliers who offer technical support and resources can also enhance the installation experience, ensuring that hinges operate correctly from the outset.

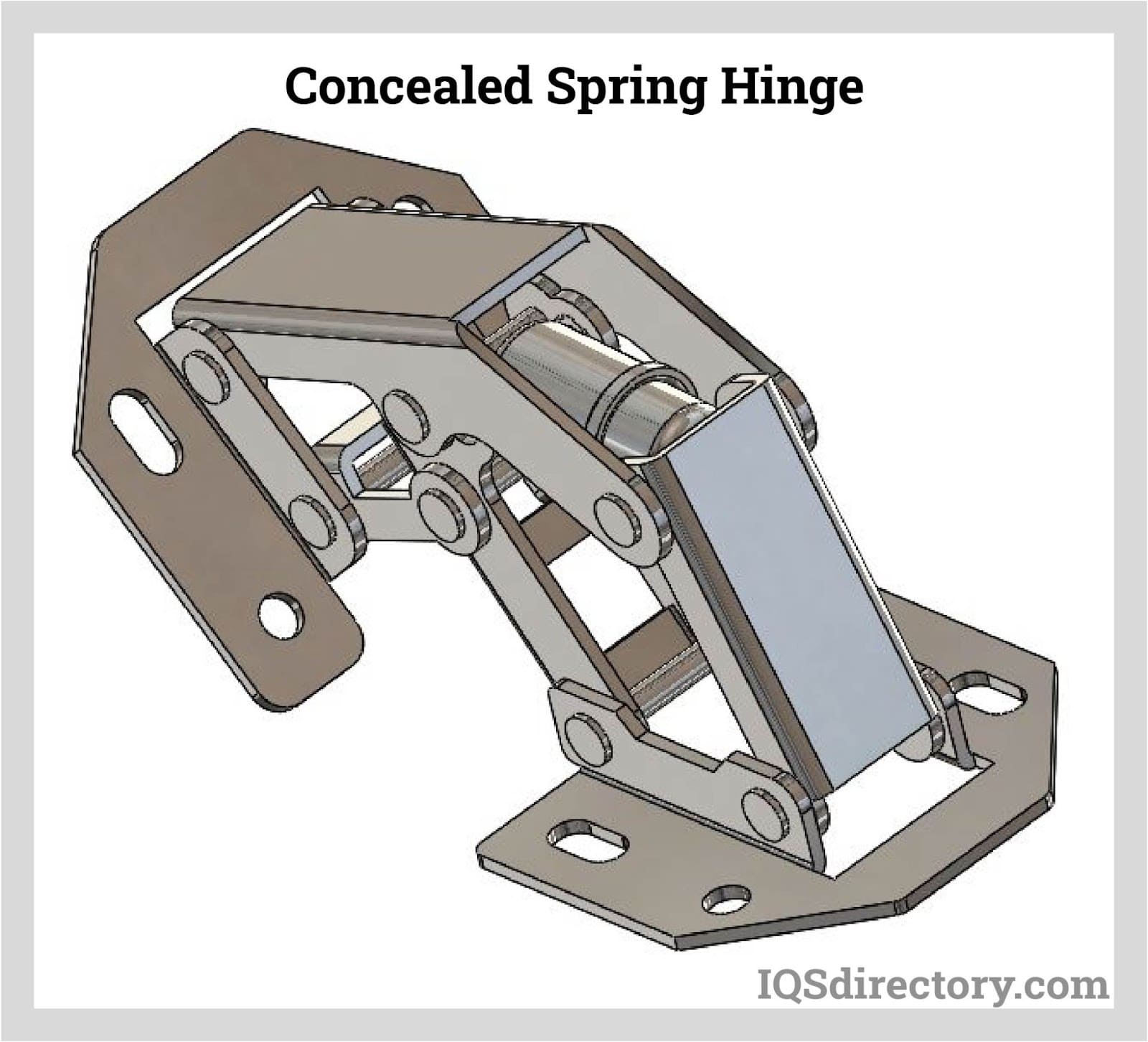

Strategic Material Selection Guide for spring loaded hinges

What Are the Key Materials for Spring Loaded Hinges?

When selecting materials for spring loaded hinges, several factors come into play, including performance properties, cost, and suitability for specific applications. Below, we analyze four common materials used in the manufacturing of spring loaded hinges: steel, stainless steel, aluminum, and brass.

How Does Steel Perform in Spring Loaded Hinges?

Steel is a widely used material for spring loaded hinges due to its strength and durability. It typically has a high tensile strength, making it suitable for heavy-duty applications. However, steel is prone to corrosion if not properly treated or coated, limiting its use in humid or corrosive environments.

Pros: Steel hinges are cost-effective and can handle high loads, making them ideal for industrial applications. They are also readily available and can be easily manufactured into various shapes and sizes.

Cons: The primary drawback is their susceptibility to rust, which necessitates protective coatings or finishes, adding to the overall cost and manufacturing complexity.

Impact on Application: Steel hinges are best suited for environments where exposure to moisture is minimal. They are commonly used in industrial doors, cabinets, and machinery.

Considerations for International Buyers: Buyers from regions with high humidity, such as parts of Africa and South America, should consider the necessity of protective coatings. Compliance with international standards like ASTM for steel quality is also crucial.

What Are the Advantages of Using Stainless Steel for Spring Loaded Hinges?

Stainless steel is favored for its excellent corrosion resistance, making it suitable for both indoor and outdoor applications. It maintains its strength and appearance over time, even when exposed to harsh environmental conditions.

Pros: The primary advantage of stainless steel is its durability and resistance to corrosion, which extends the lifespan of the hinge. It is also aesthetically pleasing, making it suitable for visible applications.

Cons: Stainless steel is generally more expensive than regular steel, which can impact budget-sensitive projects. Additionally, its manufacturing process is more complex, often requiring specialized equipment.

Impact on Application: Stainless steel hinges are ideal for applications in marine environments, food processing, and other industries where hygiene and corrosion resistance are paramount.

Considerations for International Buyers: Compliance with standards such as DIN and JIS for stainless steel grades is essential. Buyers in Europe, particularly Germany, may prioritize these standards for quality assurance.

与spring loaded hinges相关的说明性图片

How Does Aluminum Compare for Spring Loaded Hinges?

Aluminum is lightweight and offers good corrosion resistance, making it a popular choice for applications requiring reduced weight. While not as strong as steel, aluminum can be alloyed to enhance its mechanical properties.

Pros: The lightweight nature of aluminum makes it easy to handle and install. It is also resistant to corrosion, which is beneficial in various environments.

Cons: Aluminum hinges may not support as heavy loads as steel or stainless steel, limiting their use in high-stress applications. They can also be more expensive than standard steel options.

Impact on Application: Aluminum is well-suited for applications in the automotive and aerospace industries, where weight savings are critical.

Considerations for International Buyers: Buyers should be aware of specific aluminum grades and their compliance with international standards. For example, certain grades may be preferred in European markets for specific applications.

与spring loaded hinges相关的说明性图片

What Role Does Brass Play in Spring Loaded Hinges?

Brass is often used for decorative applications due to its aesthetic appeal and resistance to corrosion. It is softer than steel, which can be advantageous in low-stress environments.

Pros: The visual appeal of brass makes it a popular choice for consumer products and architectural applications. It also has good machinability and can be easily shaped.

Cons: Brass is not suitable for high-load applications due to its lower strength compared to other metals. It can also be more expensive, particularly for larger components.

与spring loaded hinges相关的说明性图片

Impact on Application: Brass hinges are commonly used in furniture, cabinetry, and decorative applications where appearance is important.

Considerations for International Buyers: Compliance with material standards and certifications is important, especially in regions like Europe, where quality assurance is prioritized.

Summary Table of Material Selection for Spring Loaded Hinges

| Material | Typical Use Case for spring loaded hinges | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Industrial doors, cabinets | High strength and load capacity | Susceptible to corrosion | Low |

| Stainless Steel | Marine environments, food processing | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Automotive, aerospace applications | Lightweight and good corrosion resistance | Lower load capacity | Medium |

| Brass | Decorative applications, furniture | Aesthetic appeal and machinability | Not suitable for high-load applications | Medium |

This guide provides a comprehensive overview of material considerations for spring loaded hinges, helping international B2B buyers make informed decisions based on their specific application needs and regional requirements.

与spring loaded hinges相关的说明性图片

In-depth Look: Manufacturing Processes and Quality Assurance for spring loaded hinges

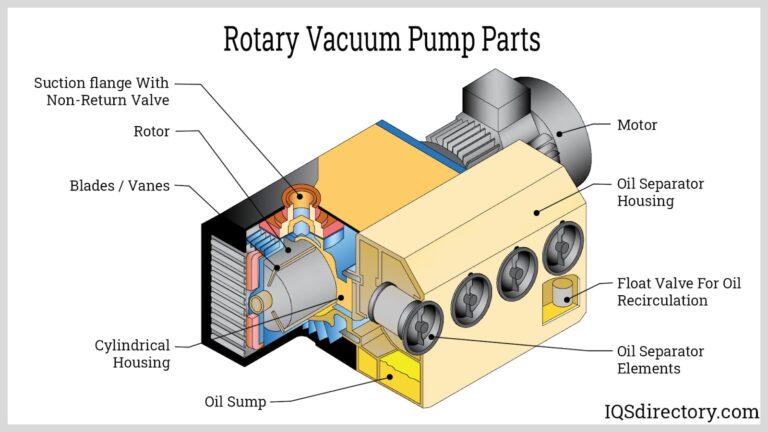

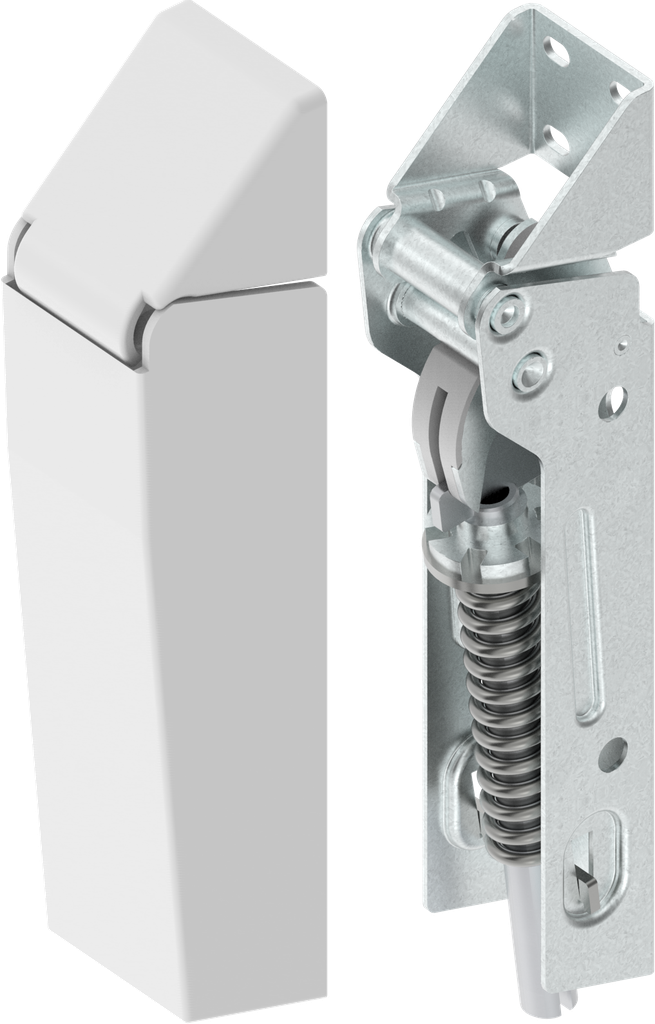

What Are the Key Manufacturing Processes for Spring Loaded Hinges?

The manufacturing of spring loaded hinges involves several critical stages that ensure product integrity and functionality. Understanding these processes is essential for B2B buyers looking for reliable suppliers.

Material Preparation: What Materials Are Used in Manufacturing?

The first stage in the manufacturing process is material preparation. Spring loaded hinges are typically made from metals such as stainless steel, plain steel, and aluminum, with some variations including brass and bronze for specific applications. Each material offers unique properties, such as corrosion resistance and strength, making them suitable for different environments and usages. Suppliers should provide detailed specifications on the materials used, including grades and treatments, to ensure compatibility with the intended application.

How Are Spring Loaded Hinges Formed?

The forming process involves shaping the prepared materials into the required hinge components. This can be achieved through various techniques, including stamping, bending, and machining. Stamping is particularly common for producing the hinge leaves, where metal sheets are cut and formed using dies. Precision is crucial during this stage to ensure that the parts fit together seamlessly.

与spring loaded hinges相关的说明性图片

In addition to stamping, forming may include processes like deep drawing and laser cutting for more complex designs. The choice of forming method can impact the hinge’s performance, so buyers should inquire about the techniques used and the associated tolerances.

What Steps Are Involved in Assembling Spring Loaded Hinges?

Assembly is where the individual components come together to form a complete spring loaded hinge. This process typically involves inserting the spring mechanism into the hinge leaves and securing them with pins or screws. The assembly must be executed with precision to ensure that the spring tension is correctly calibrated. Variations in spring tension can affect the hinge’s performance, so it’s essential to communicate specific requirements to the supplier.

Automated assembly lines are increasingly used to enhance efficiency and consistency, but manual assembly may still be employed for custom orders or specialized applications. B2B buyers should consider the level of automation when evaluating suppliers, as this can influence lead times and production costs.

与spring loaded hinges相关的说明性图片

What Finishing Techniques Are Applied to Spring Loaded Hinges?

The final stage of manufacturing is finishing, which enhances the hinge’s durability and aesthetic appeal. Common finishing techniques include plating, anodizing, and powder coating. Plating, particularly with zinc or nickel, offers corrosion resistance, while anodizing is often used for aluminum hinges to increase surface hardness.

It’s vital for buyers to understand the finishing processes applied, as these can significantly impact the product’s lifespan and performance in specific environments. Suppliers should provide certifications or test results related to the finishing processes to verify their effectiveness.

How Is Quality Assurance Managed in Spring Loaded Hinge Production?

Quality assurance (QA) is a vital component of the manufacturing process for spring loaded hinges, ensuring that products meet international standards and customer specifications. The following outlines the key aspects of QA in this sector.

What International Standards Should B2B Buyers Look For?

Many manufacturers adhere to international standards like ISO 9001, which focuses on quality management systems. Compliance with these standards indicates that a supplier has established processes for maintaining quality throughout the production cycle. Additionally, industry-specific certifications such as CE marking for products sold in Europe or API standards for those used in oil and gas applications may also be relevant.

Buyers should confirm that suppliers possess relevant certifications and inquire about their processes for maintaining compliance with these standards.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) involves several checkpoints throughout the manufacturing process, typically categorized into three main types: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

IQC: This stage involves inspecting raw materials upon arrival to ensure they meet specified standards. This is crucial for preventing defects from entering the production process.

-

IPQC: Continuous monitoring occurs during the manufacturing process, checking dimensions, spring tension, and assembly integrity. This ensures that any deviations are identified and corrected promptly.

-

FQC: Before shipment, final inspections are conducted to verify that the finished hinges meet all required specifications and performance standards. This often includes functional testing under conditions that simulate end-use.

How Can B2B Buyers Verify Supplier Quality Control Processes?

To ensure that a supplier’s quality control processes are robust, B2B buyers can take several steps:

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing practices and quality assurance measures. Buyers should consider scheduling on-site visits to assess QC processes firsthand.

-

Request Documentation: Suppliers should be able to provide quality control documentation, including inspection reports and compliance certifications. This documentation serves as proof of adherence to quality standards.

-

Third-Party Inspections: Engaging third-party inspectors can provide an unbiased assessment of a supplier’s production quality. This is particularly valuable for international buyers who may not be able to conduct on-site audits.

-

Evaluate Testing Methods: Inquire about the testing methods used to assess the performance of spring loaded hinges. Common methods include tensile strength tests, fatigue testing, and corrosion resistance evaluations.

What Nuances Should International B2B Buyers Consider for Quality Assurance?

International B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should consider several nuances when evaluating quality assurance in spring loaded hinges:

-

Cultural Differences: Understanding cultural attitudes towards quality can influence supplier relationships. Buyers should be aware of the expectations and norms in different regions to foster effective communication.

-

Regulatory Compliance: Different regions may have specific regulatory requirements that impact product specifications. Buyers should ensure that suppliers are knowledgeable about and compliant with these regulations.

-

Logistics and Supply Chain: Consider how quality assurance practices are maintained throughout the supply chain. Delays or issues in logistics can impact product quality, so it’s essential to assess the entire supply chain.

By understanding the manufacturing processes and quality assurance measures for spring loaded hinges, B2B buyers can make informed decisions and select suppliers that meet their stringent quality requirements. This knowledge not only ensures product reliability but also fosters long-term partnerships with manufacturers committed to excellence.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘spring loaded hinges’

This guide aims to provide B2B buyers with a practical checklist for sourcing spring-loaded hinges, ensuring they make informed decisions tailored to their specific needs.

Step 1: Define Your Technical Specifications

Understanding the specific requirements for your application is crucial. Begin by determining the size, weight capacity, and intended use of the spring-loaded hinges. Consider factors such as whether you need hinges that are spring-loaded to close or open, as this will significantly influence performance and functionality.

- Key Considerations:

- Open width and length must match your application.

- Assess the required torque; this determines how easily the hinge operates under load.

Step 2: Research Material Options

Material selection is vital for durability and performance. Spring-loaded hinges are commonly made from materials such as stainless steel, plain steel, and aluminum. Each material offers different benefits in terms of strength, corrosion resistance, and weight.

- Material Insights:

- Stainless Steel: Ideal for outdoor applications due to its rust resistance.

- Aluminum: Lightweight and suitable for portable or less heavy-duty applications.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Look for manufacturers with a strong reputation in your industry. Request detailed company profiles, case studies, and references from other buyers, particularly those in regions similar to your own.

与spring loaded hinges相关的说明性图片

- Supplier Vetting Tips:

- Investigate their experience with international shipping, especially if sourcing from Africa, South America, the Middle East, or Europe.

- Check for customer reviews and testimonials on their website or third-party platforms.

Step 4: Check for Compliance and Certifications

Ensure that the spring-loaded hinges meet relevant industry standards and regulations. Compliance with certifications can indicate a supplier’s commitment to quality and safety.

- Important Certifications to Look For:

- ISO certifications, which reflect adherence to international quality management standards.

- Material safety data sheets (MSDS) that confirm the materials used are safe and compliant.

Step 5: Request Samples for Testing

Always request samples of the spring-loaded hinges before placing a bulk order. Testing samples allows you to evaluate the hinge’s functionality, torque, and overall suitability for your application.

- Sample Testing Benefits:

- Ensures the hinge operates as expected within your specific setup.

- Allows for adjustments in torque or size before finalizing your order.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, negotiate terms that suit your business needs. Discuss pricing, minimum order quantities, lead times, and return policies.

- Negotiation Points:

- Consider long-term partnership benefits, such as volume discounts.

- Clarify warranty terms and after-sales support.

Step 7: Finalize Your Order and Monitor Delivery

After agreeing on terms, finalize your order and maintain regular communication with the supplier throughout the delivery process. Monitoring ensures that any potential issues can be addressed promptly.

- Delivery Monitoring Tips:

- Use tracking systems provided by the supplier to stay updated on shipping status.

- Prepare to inspect the hinges upon arrival to confirm they meet your specifications.

Following this structured checklist will streamline your sourcing process for spring-loaded hinges, helping you to secure high-quality products that meet your operational requirements.

Comprehensive Cost and Pricing Analysis for spring loaded hinges Sourcing

What Are the Key Cost Components in Sourcing Spring Loaded Hinges?

When sourcing spring loaded hinges, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The choice of materials significantly impacts costs. Common materials include stainless steel, aluminum, and zinc-plated steel. Higher-grade materials, like stainless steel, offer durability and corrosion resistance but come at a premium.

-

Labor: Labor costs can vary based on the complexity of manufacturing and the location of production. Regions with lower labor costs may offer competitive pricing, but this can sometimes come at the expense of quality.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, equipment maintenance, and facility costs. Efficient production processes can help minimize these overheads.

-

Tooling: Custom tooling can be a significant upfront cost, particularly for specialized designs. However, investing in high-quality tooling can lead to better long-term value and precision in hinge production.

-

Quality Control: Implementing stringent QC processes is essential for ensuring product reliability. While it adds to the cost, it prevents costly returns and enhances customer satisfaction.

-

Logistics: Shipping costs can fluctuate based on distance, mode of transportation, and trade agreements. International buyers should factor in import duties and taxes, which can further influence the total cost.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding this margin can aid in negotiations and help buyers identify the best value.

How Do Pricing Influencers Affect Spring Loaded Hinges Costs?

Several factors can influence the pricing of spring loaded hinges, including volume, specifications, materials, quality certifications, supplier factors, and Incoterms.

-

Volume/MOQ: Bulk purchases often lead to lower per-unit costs. Establishing a minimum order quantity (MOQ) can provide leverage for negotiating better pricing.

-

Specifications and Customization: Custom designs or specific performance requirements can increase costs. Buyers should weigh the need for customization against potential savings from standard products.

-

Materials: The choice of material directly impacts the final price. Buyers should consider the balance between cost and the required performance characteristics.

-

Quality and Certifications: Products with industry certifications or higher quality standards may command a premium. However, they often lead to lower failure rates and reduced warranty claims.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers with a proven track record may charge more, but they often provide better service and product consistency.

-

Incoterms: The shipping terms outlined in Incoterms can significantly influence costs. Understanding who is responsible for shipping, insurance, and tariffs can help buyers better estimate total expenses.

What Are the Best Negotiation Strategies for International Buyers?

For B2B buyers in regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to cost savings.

-

Leverage Total Cost of Ownership: Consider not just the purchase price but also the long-term costs associated with maintenance, durability, and potential failures. This holistic view can justify a higher initial investment.

-

Negotiate Based on Volume: If planning to place large orders, use this as leverage to negotiate lower prices. Suppliers may offer discounts for larger quantities, especially if they can plan production accordingly.

-

Request Multiple Quotes: Obtaining quotes from several suppliers can provide a clearer picture of the market rate and help in negotiations. It also encourages suppliers to remain competitive.

-

Explore Local Suppliers: Sourcing from local suppliers can reduce logistics costs and lead to faster delivery times. Additionally, it may provide opportunities for better communication and customization.

-

Understand Pricing Nuances: Be aware of the local market conditions, currency fluctuations, and potential tariffs that could affect pricing. This knowledge can inform negotiation tactics and help avoid unexpected costs.

In conclusion, understanding the comprehensive cost structure and pricing influencers in sourcing spring loaded hinges is essential for international B2B buyers. By leveraging negotiation strategies and focusing on total cost considerations, buyers can make informed purchasing decisions that align with their operational needs and budget constraints.

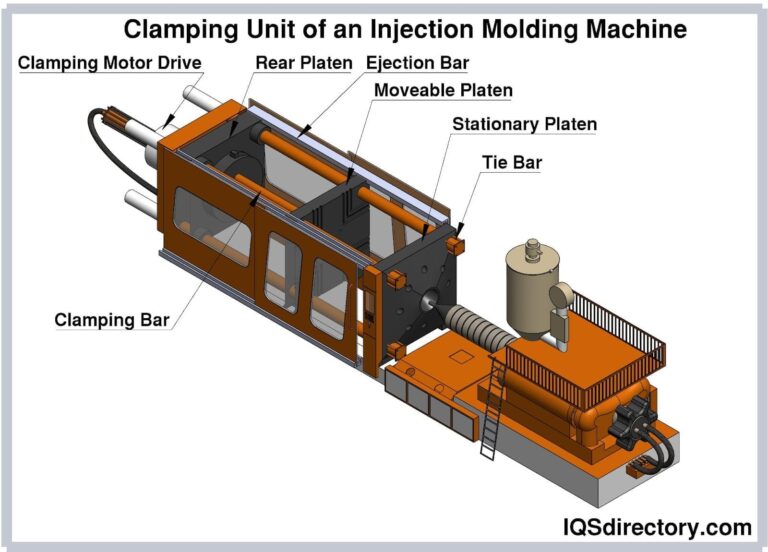

Alternatives Analysis: Comparing spring loaded hinges With Other Solutions

Exploring Alternatives to Spring Loaded Hinges

When considering the optimal solution for door and cabinet applications, spring loaded hinges are just one option among several viable alternatives. Each solution has unique advantages and potential drawbacks that can impact performance, cost, and maintenance. Understanding these alternatives is crucial for B2B buyers aiming to make informed decisions tailored to their specific operational needs.

| Comparison Aspect | Spring Loaded Hinges | Gas Springs | Hydraulic Dampers |

|---|---|---|---|

| Performance | Excellent for self-closing/opening applications | Provides smooth motion control; adjustable force | Offers controlled movement; dampening effect |

| Cost | Moderate initial investment; cost-effective for bulk | Higher initial costs; longevity may justify investment | Generally higher costs; specialized applications |

| Ease of Implementation | Relatively easy to install; requires minimal modifications | Requires precise installation; may need support brackets | More complex installation; may require additional space |

| Maintenance | Low maintenance; durable options available | Low maintenance; occasional checks needed | Moderate maintenance; seals may need replacement |

| Best Use Case | Ideal for doors that need to close automatically | Best for applications requiring variable resistance | Suitable for applications needing smooth, controlled movement |

Analyzing Alternatives in Detail

Gas Springs

Gas springs are a popular alternative to spring loaded hinges, particularly in applications that require adjustable force. They provide a smooth opening and closing action, which can be fine-tuned based on the specific requirements of the application. However, gas springs typically come with a higher upfront cost and may require more precise installation techniques, including support brackets for proper functionality. While they offer a longer lifespan and low maintenance, the complexity of installation can be a drawback for some buyers.

Hydraulic Dampers

Hydraulic dampers are designed for applications where controlled movement is essential. They excel in providing a dampening effect, which can be crucial in preventing sudden slams or jarring movements. However, hydraulic dampers generally involve higher costs and a more complex installation process, which may require additional space and structural modifications. Maintenance is moderate since seals can wear over time, necessitating occasional replacements. They are best suited for specialized applications where smooth, controlled motion is a priority.

与spring loaded hinges相关的说明性图片

Making the Right Choice for Your Needs

When choosing between spring loaded hinges and alternative solutions, it is essential for B2B buyers to evaluate their specific application requirements, including performance needs, budget constraints, and installation capabilities. Spring loaded hinges offer a cost-effective, low-maintenance solution for automatic door closures, making them ideal for a wide range of applications. However, for projects that demand adjustable force or smooth motion control, gas springs or hydraulic dampers may provide superior performance despite their higher costs and installation complexity.

Ultimately, the right choice will depend on the unique demands of your project, ensuring that you select a solution that not only meets your operational needs but also aligns with your budget and maintenance capabilities.

Essential Technical Properties and Trade Terminology for spring loaded hinges

What Are the Key Technical Properties of Spring Loaded Hinges?

When selecting spring loaded hinges for industrial applications, understanding their technical specifications is crucial for ensuring optimal performance and durability. Here are some essential properties to consider:

-

Material Grade

The material used in spring loaded hinges significantly impacts their strength and corrosion resistance. Common materials include stainless steel, zinc-plated steel, and aluminum. Stainless steel is favored for its durability and resistance to rust, making it suitable for outdoor or high-moisture environments. Choosing the right material grade ensures longevity and reduces maintenance costs. -

Torque Rating

Torque rating measures the amount of force required to open or close the hinge. This is expressed in inch-pounds (in-lb) and varies depending on the specific application and load requirements. A properly specified torque rating prevents hinges from being too stiff or too loose, ensuring smooth operation. For B2B buyers, understanding torque ratings is essential for matching hinges to their intended use, thereby enhancing operational efficiency. -

Open Width and Length

The dimensions of the hinge—specifically, the open width and length—are critical for fitting within the design specifications of doors, cabinets, or panels. These dimensions dictate how much space the hinge will occupy and how it will function within the overall assembly. Accurate measurements are vital for ensuring compatibility and avoiding installation issues, which can lead to increased costs and delays. -

Spring Action Type

Spring loaded hinges come in two main types: spring-loaded-to-open and spring-loaded-to-close. The choice between these types depends on the application requirements, such as whether a door needs to remain open or closed when not in use. Understanding the action type is essential for ensuring that the hinge operates in alignment with the user’s needs and safety standards. -

Tolerance Levels

Tolerance refers to the allowable deviation from specified dimensions. High tolerance levels ensure that hinges fit precisely within their intended applications, which is critical for maintaining structural integrity and performance. For manufacturers and OEMs, specifying appropriate tolerances can prevent costly adjustments and rework during production.

What Are Common Trade Terms Related to Spring Loaded Hinges?

Navigating the purchasing process for spring loaded hinges involves understanding industry jargon and trade terminology. Here are several important terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, sourcing hinges from OEMs can ensure compatibility and reliability, as these manufacturers typically adhere to industry standards and specifications. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it affects inventory levels and cash flow. Buyers should negotiate MOQs that align with their operational needs to avoid overstocking or stockouts. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For buyers, issuing an RFQ allows for competitive bidding, enabling them to obtain the best price and terms for spring loaded hinges. It’s an essential step in the procurement process. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods. Familiarity with Incoterms is vital for B2B buyers to understand their obligations concerning shipping, insurance, and tariffs, thereby avoiding unexpected costs and delays. -

Custom Specifications

Custom specifications refer to tailored requirements for products that differ from standard offerings. For buyers in need of unique spring loaded hinge solutions, understanding how to communicate custom specifications effectively ensures that the final product meets their specific operational needs.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when sourcing spring loaded hinges, ultimately enhancing their operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the spring loaded hinges Sector

What Are the Current Market Dynamics and Key Trends in the Spring Loaded Hinges Sector?

The spring loaded hinges market is experiencing significant growth, driven by increasing demand across various industries such as automotive, aerospace, and industrial manufacturing. The global push for automation and efficiency is leading manufacturers to seek innovative solutions that enhance product functionality, reliability, and user experience. Additionally, the rise of e-commerce has heightened the need for robust logistics and shipping solutions, further propelling the demand for durable and reliable hinges.

Emerging technologies, such as smart manufacturing and Industry 4.0, are influencing sourcing trends. International B2B buyers are increasingly leveraging data analytics and IoT to optimize their supply chains. This shift allows for real-time tracking of inventory levels and demand forecasting, enabling companies to make informed purchasing decisions. Furthermore, the trend towards customization is notable, with buyers seeking bespoke solutions tailored to specific applications, which can enhance operational efficiency and reduce waste.

For international buyers from regions like Africa, South America, the Middle East, and Europe, understanding regional market dynamics is crucial. Diverse regulatory environments and varying consumer preferences necessitate a localized approach to sourcing. Buyers should be aware of logistical challenges, including shipping times and tariffs, which can impact overall procurement strategies. Establishing relationships with suppliers who have a strong local presence can facilitate smoother transactions and quicker response times.

How Does Sustainability and Ethical Sourcing Impact the Spring Loaded Hinges Industry?

Sustainability is becoming an increasingly important factor in the procurement process for spring loaded hinges. Buyers are now more aware of the environmental impact of their sourcing decisions, pushing manufacturers to adopt eco-friendly practices. The use of recyclable materials, such as stainless steel and aluminum, is on the rise, as they offer durability without compromising environmental integrity.

Furthermore, ethical sourcing is gaining traction, with buyers prioritizing suppliers that maintain transparent supply chains and uphold labor rights. Certifications such as ISO 14001 for environmental management and Fair Trade practices are becoming critical benchmarks for supplier selection. By choosing vendors that align with these values, buyers not only enhance their brand reputation but also contribute to a more sustainable future.

Incorporating ‘green’ materials into spring loaded hinges production not only meets regulatory requirements but also appeals to a growing segment of environmentally-conscious consumers. As such, international buyers should consider the sustainability credentials of their suppliers, as this can significantly influence their competitive edge in the marketplace.

What Is the Brief Evolution and History of Spring Loaded Hinges?

The design of spring loaded hinges has evolved significantly since their inception. Initially used in basic applications, such as doors and cabinets, these hinges have transformed into sophisticated components integral to modern machinery and equipment. The early 20th century saw the introduction of materials like stainless steel and aluminum, which improved durability and corrosion resistance, making them ideal for various industrial applications.

As technology progressed, so did the functionality of spring loaded hinges. The integration of advanced spring mechanisms allowed for greater torque and customizability, catering to the unique requirements of different sectors. Today, these hinges are not only functional but also contribute to the aesthetic appeal of products, with various finishes and styles available.

This evolution reflects broader trends in manufacturing and design, where efficiency, sustainability, and user experience are paramount. For B2B buyers, understanding this historical context can provide insights into the capabilities and potential of modern spring loaded hinges, aiding in more informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of spring loaded hinges

-

1. How do I choose the right spring loaded hinge for my application?

Selecting the appropriate spring loaded hinge involves evaluating the application’s specific requirements. First, determine whether you need a hinge that is spring-loaded-to-open or spring-loaded-to-close, as this will depend on the direction in which the hinge will be mounted. Next, consider the size, material, and torque specifications required for your application. If standard options do not meet your needs, consult with manufacturers for customization possibilities. Testing samples in your application can also help ensure you achieve the desired performance. -

2. What materials are commonly used for spring loaded hinges?

Spring loaded hinges are typically manufactured from materials such as stainless steel, aluminum, and plain steel. Each material offers different advantages; for instance, stainless steel is corrosion-resistant, making it ideal for outdoor or humid environments, while aluminum is lightweight and cost-effective. Additionally, some hinges may be offered in brass or bronze for aesthetic purposes. When selecting materials, consider factors such as environmental conditions, load requirements, and budget constraints. -

3. How can I customize my spring loaded hinges?

Customization of spring loaded hinges is often available to meet specific application needs. This may include adjustments in length, width, material, and spring tension. To initiate the customization process, communicate your requirements clearly to the manufacturer, including desired torque specifications and dimensions. It’s advisable to start with standard options to see if they suffice before proceeding with custom designs, as this can save both time and costs. -

4. What is the minimum order quantity (MOQ) for spring loaded hinges?

Minimum order quantities for spring loaded hinges can vary significantly between suppliers. Some manufacturers may offer low MOQs for standard products, while custom orders often require larger quantities to justify production costs. It’s essential to discuss your needs with potential suppliers, as they may offer flexibility depending on your project requirements or establish a pricing tier based on order volume. -

5. What payment terms should I expect when sourcing spring loaded hinges internationally?

Payment terms for international purchases of spring loaded hinges can differ by supplier and region. Common arrangements include upfront payment, partial payment upon order confirmation, and balance upon delivery. Some suppliers may also offer credit terms for established customers. It’s crucial to clarify payment methods accepted (e.g., wire transfer, credit card) and any additional costs such as tariffs or shipping fees, which could impact your total budget. -

6. How do I ensure quality assurance when sourcing spring loaded hinges?

Quality assurance is vital when sourcing spring loaded hinges, especially for international transactions. Request certifications and quality control processes from suppliers, such as ISO 9001 or other relevant industry standards. Additionally, consider ordering samples for inspection before committing to larger orders. Engaging third-party inspection services can also provide an added layer of assurance, ensuring that the hinges meet your specifications and quality expectations. -

7. What logistics considerations should I keep in mind when importing spring loaded hinges?

When importing spring loaded hinges, logistics is a critical factor. Consider the shipping method (air or sea), which will affect delivery time and costs. Also, be aware of customs regulations and potential duties that may apply to your imports, which can vary by country. Establish a reliable shipping partner to handle the logistics and ensure that all necessary documentation is in order, including invoices, packing lists, and customs declarations. -

8. How can I evaluate and vet suppliers of spring loaded hinges?

To effectively evaluate suppliers of spring loaded hinges, start by researching their reputation within the industry. Look for customer reviews, case studies, and testimonials to gauge their reliability. Request references and verify their manufacturing capabilities and quality control measures. Additionally, consider visiting their facilities if possible or requesting virtual tours. Engaging in direct communication regarding your needs and their response times can also provide insights into their customer service and operational efficiency.

Top 7 Spring Loaded Hinges Manufacturers & Suppliers List

1. Guden – Spring Hinges

Domain: guden.com

Registered: 1995 (30 years)

Introduction: Guden offers a variety of Spring Hinges for industrial doors and cabinets, available in lengths from 1.10 inches to 8.75 inches. They are spring-loaded to open and close, with options for same-day shipment. The stock hinges can be customized to meet specific requirements. Available materials include steel, zinc plated steel, stainless steel, and aluminum. The hinges come in both spring-loaded-to-o…

2. HingeOutlet – Spring Hinges for Commercial Doors

Domain: hingeoutlet.com

Registered: 2004 (21 years)

Introduction: Spring Hinges for Commercial Doors – HingeOutlet offers a wide variety of spring hinges specifically designed for commercial applications. Key features include: Free Shipping on orders over $160, expert support available at 888-250-8133, and a comprehensive selection of door hinges and hardware suitable for both commercial and residential use. The product range includes heavy-duty options, various…

3. Therma-Tru – Spring Loaded Hinge

Domain: store.thermatru.com

Registered: 1995 (30 years)

Introduction: {“product_name”: “Spring Loaded Hinge”, “price”: “$37.49”, “SKU”: “HG58SL-1H”, “shipping_info”: “Expected to ship within 3 business days”, “available_colors”: [“Oil Rubbed Bronze”, “Brushed Nickel”, “Black Nickel”, “Polished Chrome”, “Stainless Steel”, “Zinc Dichromate”], “backorder_info”: “Oil Rubbed Bronze is backordered and will ship as soon as it is back in stock.”, “features”: “Genuine Therma…

4. House of Antique Hardware – Heavy Duty Swinging Door Floor Hinge

Domain: houseofantiquehardware.com

Registered: 1999 (26 years)

Introduction: Spring Hinge – Self Closing Door Hinges

1. Heavy Duty Swinging Door Floor Hinge with Solid Brass Cover Plates

– Max Door Weight: 90 lbs

– Features: Adjustable spring tension, solid brass cover plates

– Price: $169.90

2. Standard Duty Swinging Door Floor Hinge with Plated-Steel Cover Plates

– Max Door Weight: 70 lbs

– Features: Adjustable spring tension, multiple opening stops

-…

5. Sierra Pacific Engineering – Spring Loaded Hinges

Domain: spep.com

Registered: 1997 (28 years)

Introduction: Spring Loaded Hinges from Sierra Pacific Engineering and Products (SPEP) are designed for various applications, featuring a spring mechanism that allows doors or panels to automatically return to a predetermined position. Key benefits include precision engineering, durability, versatility, and safety. Available materials include stainless steel and steel, with finishes such as zinc-plated, milled,…

6. Therma-Tru – Spring-Loaded Hinge Installation Guide

Domain: projectcenter.thermatru.com

Registered: 1995 (30 years)

Introduction: Spring-Loaded Hinge; Tools Required: Safety Glasses, Hex Wrench, Pliers; Materials Required: Spring-Loaded Hinge, Cross Pin; Steps: 1) Determine the Number of Spring Loaded Hinges, 2) Locate the Hex Adjustment Hole, 3) Insert Allen Wrench, 4) Adjust Tension, 5) Insert the Cross Pin, 6) Remove Hex Key, 7) Snip off the Cross Pin; Notes: Too much tension will reduce the life of the spring; Once the c…

7. McMaster-Carr – Spring-Loaded Hinges

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster-Carr – Spring-Loaded Hinges, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for spring loaded hinges

As you evaluate your options for sourcing spring loaded hinges, it is essential to recognize the pivotal role of strategic sourcing in optimizing your procurement processes. The diversity in materials, sizes, and functionalities—from spring-loaded-to-open to spring-loaded-to-close—offers tailored solutions for various applications across industries. By leveraging suppliers with extensive inventories and customization capabilities, you can ensure that your specific requirements are met efficiently and cost-effectively.

Furthermore, understanding the importance of torque and strength specifications will enhance your decision-making, allowing for the selection of hinges that not only fit your design but also meet performance expectations. Building strong partnerships with reputable manufacturers is crucial for accessing timely support, samples, and engineering insights, which are invaluable as you navigate the complexities of hinge selection.

Looking ahead, the global market for spring loaded hinges is set to expand, driven by advancements in manufacturing technologies and increasing demand across sectors. Now is the time to engage with suppliers who can provide innovative solutions tailored to your needs. Embrace the opportunity to optimize your supply chain, enhance product functionality, and stay ahead in your industry by exploring strategic sourcing for spring loaded hinges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

与spring loaded hinges相关的说明性图片

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.