A B2B Buyer’s Guide to Solenoid Parts: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for solenoid parts

In today’s interconnected world, sourcing high-quality solenoid parts can pose significant challenges for international B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. With the increasing demand for automation and fluid control in diverse industries, understanding the intricacies of solenoid components is essential for making informed purchasing decisions. This guide delves into the various types of solenoid parts, including valve bodies, coils, and seals, as well as their specific applications across sectors like manufacturing, agriculture, and automotive.

As you navigate the global market for solenoid parts, this comprehensive resource offers invaluable insights on supplier vetting, cost considerations, and key performance indicators. You’ll learn how to assess product quality and reliability, ensuring that you procure the right components that meet your operational needs. Additionally, the guide highlights the importance of compatibility between solenoid parts and their intended applications, helping you avoid costly downtime and inefficiencies.

By equipping you with the knowledge to make strategic purchasing decisions, this guide empowers B2B buyers in countries like Brazil and Nigeria to effectively navigate the complexities of the solenoid parts market. With a focus on actionable strategies and expert recommendations, you will be well-prepared to enhance your procurement processes and drive your business’s success in a competitive landscape.

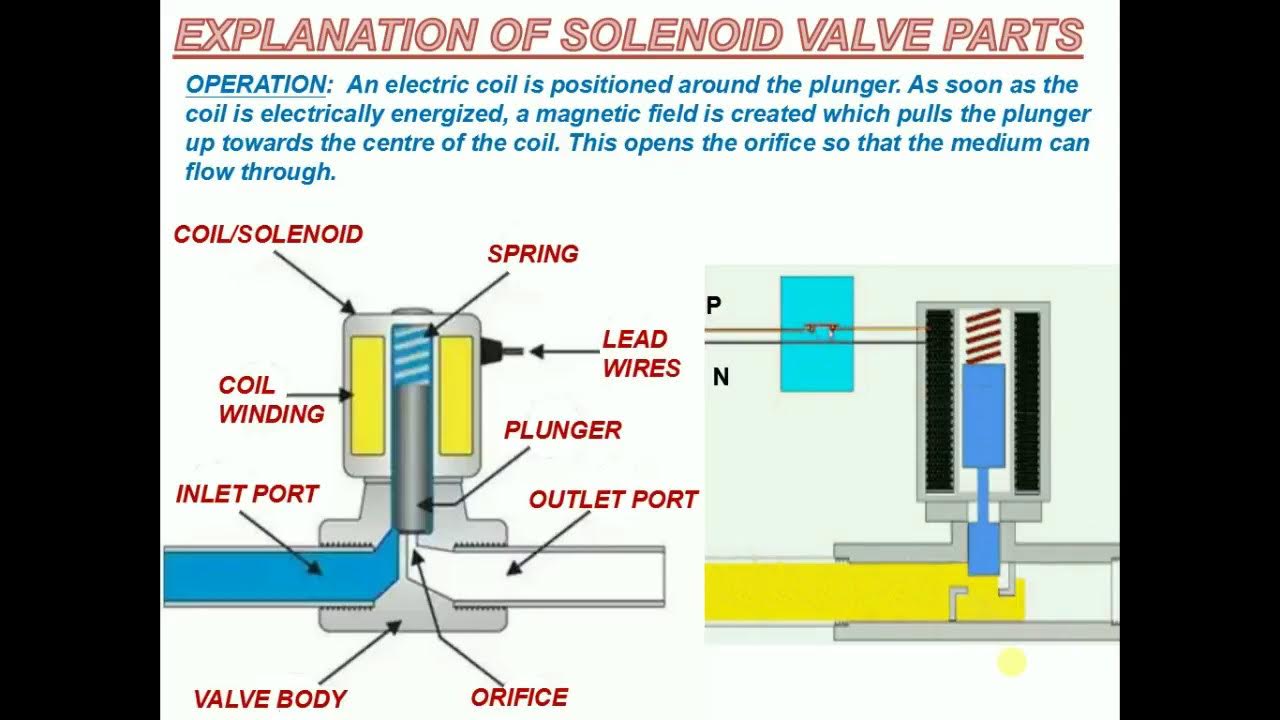

Understanding solenoid parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 2-Way Solenoid Valves | Simple design with one inlet and one outlet port. | Fluid control in HVAC, irrigation, and automation systems. | Pros: Cost-effective, easy to install. Cons: Limited control options. |

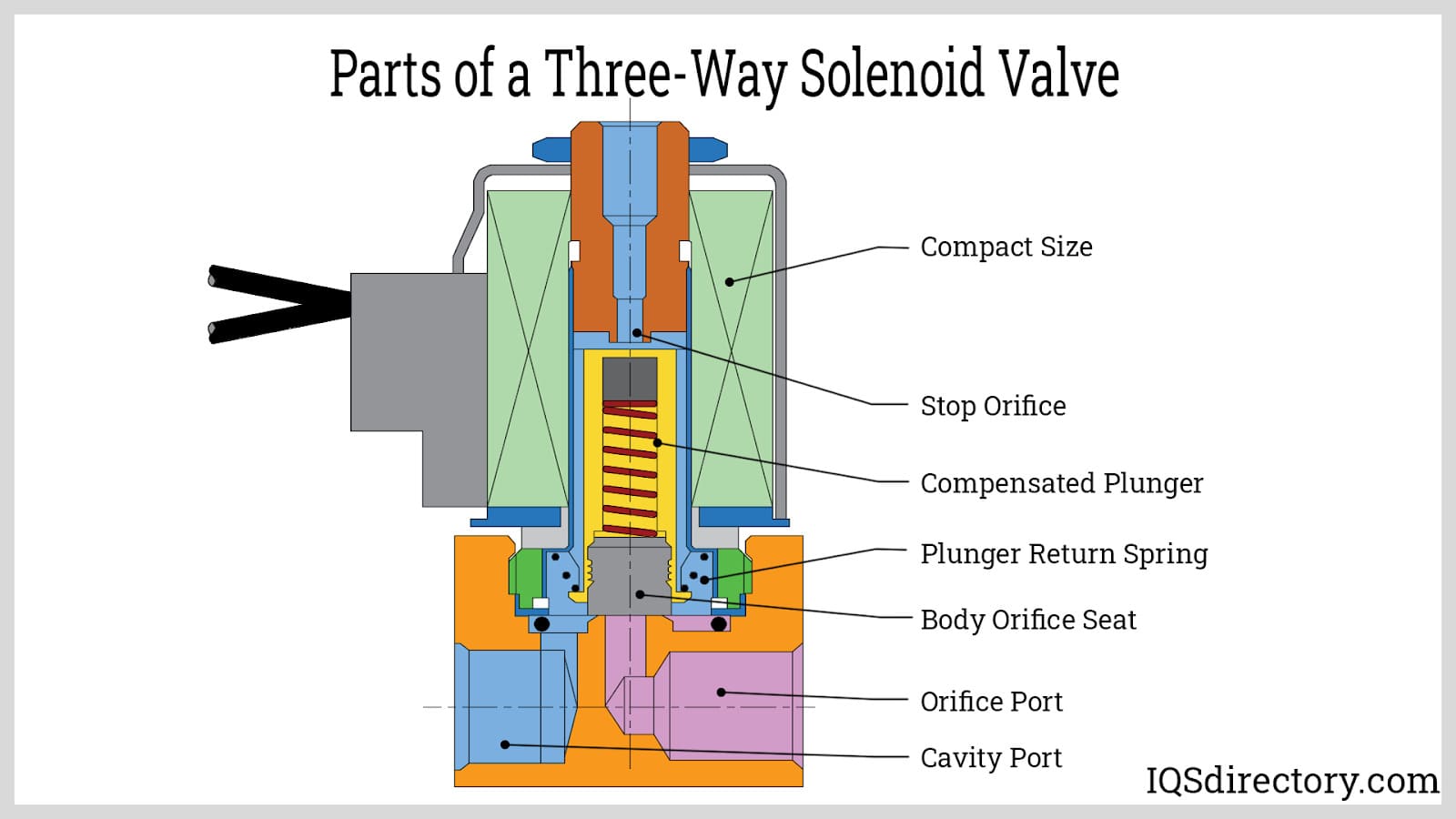

| 3-Way Solenoid Valves | Three ports allowing for multiple flow paths. | Pneumatic systems, fluid mixing applications. | Pros: Versatile flow control. Cons: More complex installation. |

| Proportional Solenoid Valves | Adjustable flow rate based on electrical input. | Industrial process control and automation. | Pros: Precise flow regulation. Cons: Higher initial cost. |

| Pneumatic Solenoid Valves | Designed specifically for gas or air flow control. | Automation in factories, HVAC systems. | Pros: Efficient for gas applications. Cons: Limited to air/gas media. |

| Solenoid Coil | Essential for generating magnetic field to operate the valve. | Integral to all solenoid valve types. | Pros: Critical for valve function. Cons: Can fail due to overheating. |

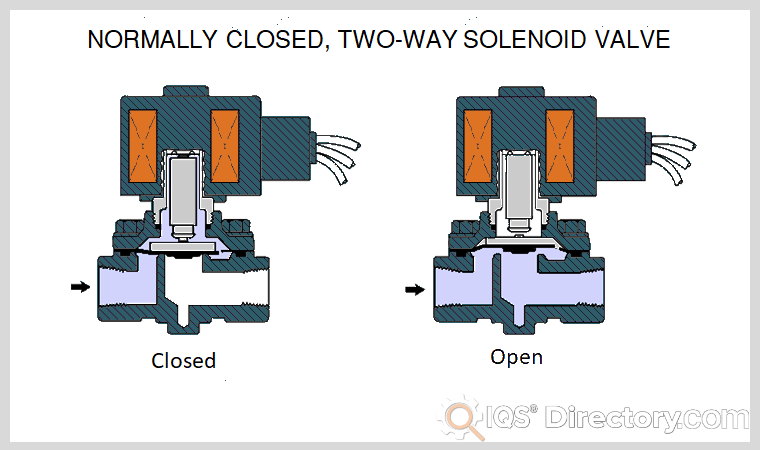

What are the characteristics of 2-Way Solenoid Valves?

2-way solenoid valves are the most basic type, featuring a straightforward design that includes one inlet and one outlet port. They are primarily used for on/off fluid control, making them ideal for applications in HVAC systems, irrigation, and various automation processes. When purchasing 2-way valves, buyers should consider the fluid type, pressure ratings, and the material compatibility of the valve body and seals to ensure longevity and performance.

How do 3-Way Solenoid Valves differ in functionality?

3-way solenoid valves are characterized by their three ports, allowing them to either direct fluid between different paths or mix fluids from multiple sources. This versatility makes them suitable for pneumatic systems and fluid mixing applications. B2B buyers should evaluate the specific flow requirements and installation complexity, as well as the potential need for additional control systems, when selecting 3-way valves.

Why consider Proportional Solenoid Valves for industrial applications?

Proportional solenoid valves offer the ability to adjust the flow rate based on the electrical input, making them essential in industrial process control and automation. Their precision in flow regulation is a significant advantage, particularly in applications requiring variable control. However, buyers should be aware of the higher initial costs and the need for compatible control systems to maximize their functionality.

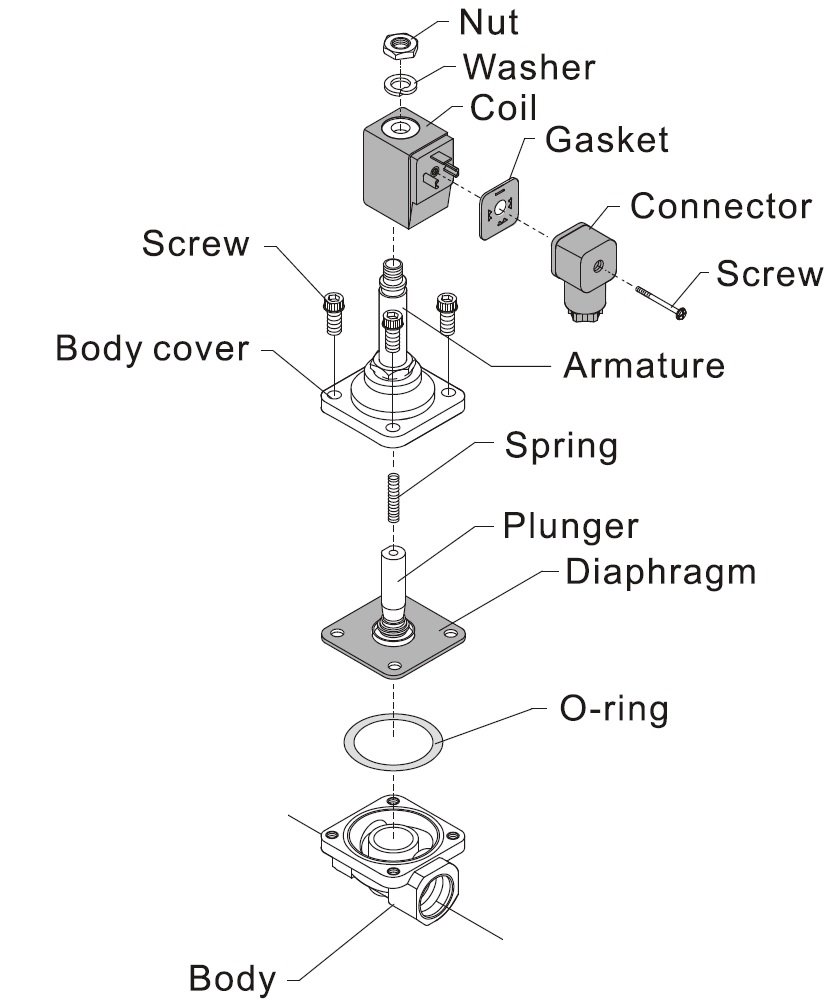

Illustrative image related to solenoid parts

What are the key features of Pneumatic Solenoid Valves?

Pneumatic solenoid valves are specifically designed to control the flow of gases or air, making them integral to automation in factories and HVAC systems. They typically feature durable designs to withstand the pressures associated with gas flow. Buyers should consider the valve’s compatibility with the specific gas type, pressure ratings, and installation requirements to ensure optimal performance.

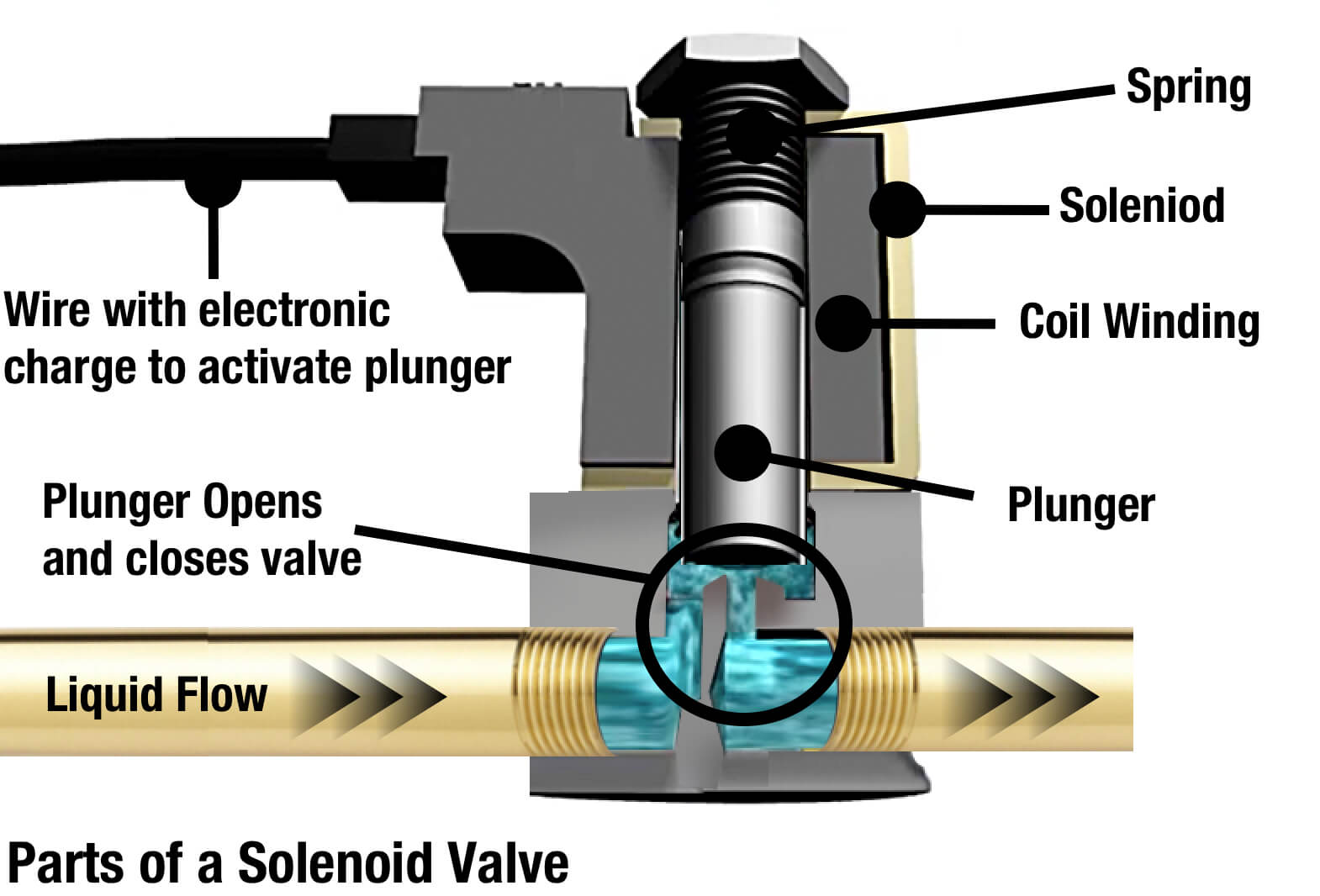

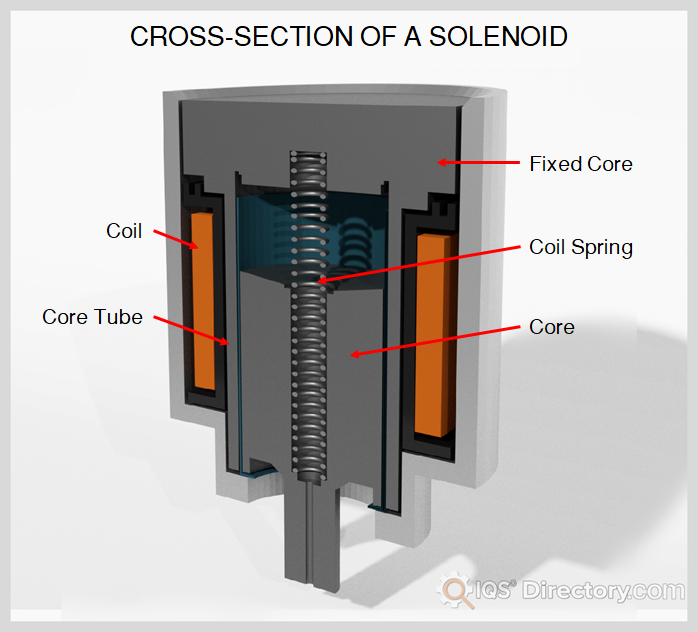

How important is the Solenoid Coil in valve operation?

The solenoid coil is a critical component of all solenoid valves, responsible for generating the magnetic field necessary to operate the valve. It can be a point of failure if subjected to overheating or electrical issues. When purchasing solenoid coils, buyers should focus on quality, electrical specifications, and compatibility with the valve type to avoid operational disruptions.

Key Industrial Applications of solenoid parts

| Industry/Sector | Specific Application of solenoid parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Fuel injection systems | Enhanced efficiency and performance in fuel delivery | Compatibility with fuel types and pressure ratings |

| Agriculture | Irrigation control systems | Improved water management and crop yield | Durability in harsh environments and corrosion resistance |

| HVAC | Temperature regulation in heating/cooling systems | Energy savings and consistent climate control | Energy efficiency ratings and operating voltage |

| Manufacturing | Automation in assembly lines | Increased productivity and reduced labor costs | Reliability and response time of solenoid components |

| Water Treatment | Control of chemical dosing in treatment processes | Improved water quality and compliance with regulations | Material compatibility with chemicals and pressure ratings |

How Are Solenoid Parts Applied in the Automotive Industry?

In the automotive sector, solenoid parts are integral to fuel injection systems, where they control the precise delivery of fuel into the combustion chamber. This enhances engine efficiency, reduces emissions, and optimizes performance. For international buyers, particularly in regions like Brazil and Nigeria, sourcing solenoid components that can withstand varying fuel qualities and pressures is crucial. Buyers should focus on manufacturers that provide detailed specifications on compatibility with local fuel standards.

What Role Do Solenoid Parts Play in Agriculture?

Solenoid parts are vital in modern irrigation control systems, allowing for automated management of water flow to crops. This automation leads to improved water conservation and increased agricultural productivity. Buyers from Africa and South America should seek solenoid components that are resistant to environmental factors such as UV exposure and soil corrosion. Additionally, ensuring that these parts can operate effectively under varying voltage conditions common in rural areas is essential.

How Are Solenoid Parts Utilized in HVAC Systems?

In HVAC applications, solenoid parts regulate the flow of refrigerants and air, contributing to temperature control and energy efficiency. By facilitating precise adjustments in heating and cooling systems, businesses can achieve significant energy savings and maintain optimal indoor climates. European buyers should prioritize sourcing solenoids that meet energy efficiency standards and are compatible with a range of refrigerants to ensure compliance with regional regulations.

In What Ways Are Solenoid Parts Used in Manufacturing Automation?

Manufacturing industries leverage solenoid parts for automation in assembly lines, where they control the movement of materials and components. This automation results in higher productivity levels and reduced labor costs. International B2B buyers should consider the reliability and response time of solenoid components, as these factors directly impact operational efficiency. It is also important to evaluate the supplier’s ability to provide timely support and replacement parts to minimize downtime.

How Do Solenoid Parts Contribute to Water Treatment Processes?

In water treatment facilities, solenoid parts are used to control the dosing of chemicals necessary for purification processes. This ensures compliance with health and safety regulations while improving water quality. Buyers in the Middle East, where water scarcity is a significant concern, should focus on sourcing solenoid components that are chemically resistant and capable of handling high-pressure applications. Understanding the specific requirements of local water treatment standards is also essential for successful procurement.

3 Common User Pain Points for ‘solenoid parts’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Solenoid Parts

The Problem: B2B buyers often struggle to find reliable suppliers of solenoid parts that meet their specific quality standards. This challenge is exacerbated in regions like Africa and South America, where access to premium components may be limited. Poor-quality solenoid parts can lead to frequent failures, increased downtime, and ultimately, higher operational costs. Buyers may also face difficulties in verifying the reliability of suppliers, leading to uncertainty about the quality of components they are purchasing.

The Solution: To effectively source high-quality solenoid parts, buyers should establish relationships with reputable manufacturers known for their stringent quality control processes. Conducting thorough market research to identify suppliers who provide certifications—such as ISO 9001—can help ensure that the components meet international standards. Additionally, buyers should request product samples or visit manufacturing facilities if possible. Utilizing online marketplaces with verified reviews and ratings can also be beneficial. Building long-term partnerships with reliable suppliers can lead to better pricing, consistent quality, and improved service.

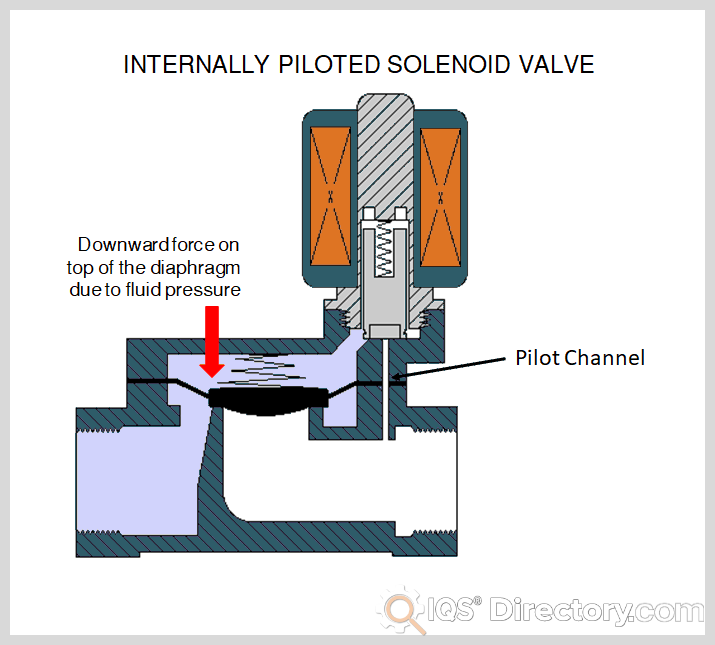

Scenario 2: Misalignment of Solenoid Specifications with Application Needs

The Problem: Many B2B buyers encounter issues when the specifications of solenoid parts do not align with their application requirements. This misalignment can stem from misunderstandings about the required voltage, pressure ratings, or the specific type of solenoid valve needed (e.g., normally open vs. normally closed). Such discrepancies can lead to operational inefficiencies and costly rework, affecting project timelines and budgets.

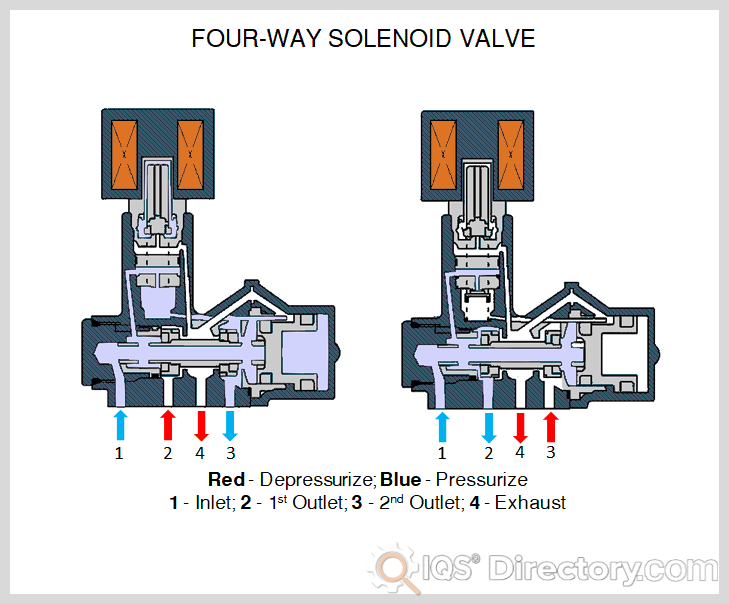

Illustrative image related to solenoid parts

The Solution: To prevent specification mismatches, buyers should engage in a comprehensive needs assessment before making a purchase. This involves understanding the operational environment, fluid characteristics, and pressure requirements of their systems. Collaborating with engineers or technical consultants can help clarify these specifications. Buyers should also consider requesting detailed datasheets from suppliers, which outline the operational parameters and limitations of each solenoid part. Additionally, leveraging simulation software to model how different solenoid parts will perform in specific applications can provide valuable insights and ensure that the right components are selected.

Scenario 3: Challenges in Maintenance and Replacement of Solenoid Parts

The Problem: Another common pain point for B2B buyers is the maintenance and timely replacement of solenoid parts. Over time, components such as seals and coils may wear out, leading to decreased performance or failures. In regions where access to replacement parts is limited, this can result in prolonged downtimes, affecting production schedules and customer satisfaction.

The Solution: Implementing a proactive maintenance strategy is essential for minimizing downtime associated with solenoid parts. Buyers should create a maintenance schedule that includes regular inspections of solenoid components, particularly seals and coils, which are prone to wear. Keeping a well-stocked inventory of critical replacement parts—such as solenoid rebuild kits—can facilitate quick repairs and reduce downtime. Additionally, establishing a relationship with local suppliers or distributors who can provide prompt access to these parts can further enhance operational efficiency. Educating staff on basic troubleshooting techniques can also empower teams to address minor issues before they escalate into significant problems.

Strategic Material Selection Guide for solenoid parts

What Are the Key Properties of Common Materials Used in Solenoid Parts?

When selecting materials for solenoid parts, it is essential to consider properties that directly impact performance, such as temperature and pressure ratings, as well as corrosion resistance. The most commonly used materials include brass, stainless steel, plastic, and aluminum. Each material has unique properties that make it suitable for specific applications.

How Does Brass Perform as a Material for Solenoid Parts?

Brass is a favored choice for solenoid valve bodies and internal components due to its excellent machinability and corrosion resistance. It typically withstands temperatures up to 150°C and pressures around 10 bar, making it suitable for various industrial applications.

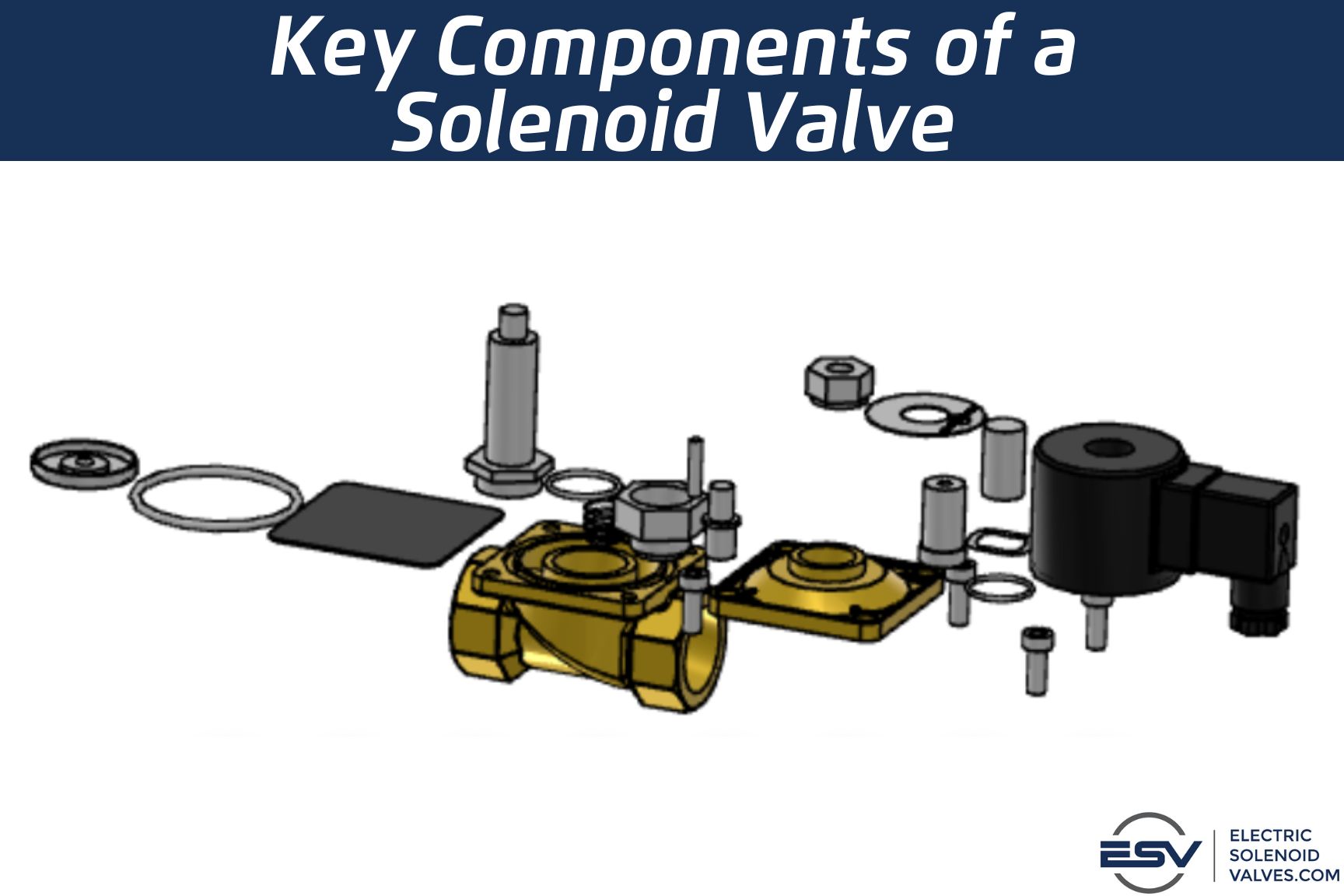

Illustrative image related to solenoid parts

Pros: Brass is durable, cost-effective, and provides good thermal conductivity. It is also resistant to rust, which is beneficial in humid environments.

Cons: However, brass can be susceptible to dezincification, especially in chlorinated environments, which can weaken the material over time.

Impact on Application: Brass is compatible with a wide range of media, including water, air, and certain oils. However, care should be taken when using it with aggressive chemicals.

Considerations for International Buyers: Compliance with standards such as ASTM B36 and DIN 17660 is crucial. Buyers in regions like Africa and South America should ensure that the brass used meets local regulations regarding lead content.

Illustrative image related to solenoid parts

What Advantages Does Stainless Steel Offer for Solenoid Parts?

Stainless steel is another popular material, especially for applications requiring high corrosion resistance and durability. It can handle temperatures up to 200°C and high pressures, making it ideal for harsh environments.

Pros: Its strength and resistance to corrosion make stainless steel suitable for aggressive media, including acids and bases.

Cons: The primary drawback is its higher cost compared to brass and its complexity in manufacturing, which can lead to longer lead times.

Impact on Application: Stainless steel is excellent for applications involving corrosive fluids or environments, such as chemical processing.

Illustrative image related to solenoid parts

Considerations for International Buyers: Buyers should look for compliance with standards like ASTM A276 and JIS G4303 to ensure material quality. In regions with stringent environmental regulations, stainless steel is often preferred.

Why Choose Plastic for Solenoid Parts?

Plastic materials, such as polyamide (nylon) and polyvinyl chloride (PVC), are used in solenoid valves primarily for their lightweight and cost-effective properties. They can typically handle temperatures up to 80°C and moderate pressures.

Pros: Plastics are resistant to corrosion and are often less expensive than metal options. They also offer excellent electrical insulation properties.

Cons: However, plastics can be less durable than metals and may not withstand high temperatures or pressures as effectively.

Impact on Application: Plastic solenoid parts are ideal for applications involving non-corrosive fluids or gases, such as water or air.

Illustrative image related to solenoid parts

Considerations for International Buyers: Compliance with standards like ASTM D638 and DIN 53455 is important, especially in sectors like food and beverage where material safety is critical.

What Role Does Aluminum Play in Solenoid Part Manufacturing?

Aluminum is a lightweight alternative often used for solenoid valve bodies and components. It generally withstands temperatures up to 100°C and moderate pressures.

Pros: Aluminum is lightweight, cost-effective, and offers good corrosion resistance, making it suitable for various applications.

Cons: However, it is not as strong as stainless steel and may not be suitable for high-pressure applications.

Impact on Application: Aluminum is commonly used in applications involving air and water but may not be suitable for aggressive chemicals.

Considerations for International Buyers: Buyers should ensure that aluminum components comply with standards such as ASTM B211 and EN 573 to guarantee quality and performance.

Summary Table of Material Selection for Solenoid Parts

| Material | Typical Use Case for solenoid parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | General industrial applications | Good machinability and corrosion resistance | Susceptible to dezincification | Medium |

| Stainless Steel | Chemical processing applications | High corrosion resistance and durability | Higher cost and manufacturing complexity | High |

| Plastic | Non-corrosive fluid applications | Lightweight and cost-effective | Less durable and lower temperature tolerance | Low |

| Aluminum | Air and water applications | Lightweight and good corrosion resistance | Not suitable for high-pressure environments | Medium |

This strategic material selection guide provides international B2B buyers with insights into the advantages and limitations of common materials used in solenoid parts, aiding in informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for solenoid parts

What Are the Main Stages of the Manufacturing Process for Solenoid Parts?

The manufacturing of solenoid parts involves a series of well-defined stages that ensure the final product meets the required specifications and quality standards. Understanding these stages is crucial for B2B buyers seeking reliable suppliers.

Material Preparation: What Materials Are Used for Solenoid Parts?

The first stage in the manufacturing process is material preparation. Common materials used for solenoid parts include stainless steel, brass, copper, and various plastics. Each material is selected based on its specific properties, such as corrosion resistance, strength, and conductivity. For instance, stainless steel is often chosen for its durability and resistance to environmental factors, while copper is favored for its excellent electrical conductivity.

Materials undergo quality checks upon arrival at the manufacturing facility. This initial inspection, known as Incoming Quality Control (IQC), ensures that all materials meet the necessary specifications before they proceed to further processing.

Illustrative image related to solenoid parts

How Are Solenoid Parts Formed?

The next stage is forming, which involves various techniques depending on the part being manufactured. Common methods include machining, stamping, and injection molding.

-

Machining: This process is widely used for creating precise components like the valve body and armature tube. CNC (Computer Numerical Control) machines are often employed for their accuracy and ability to handle complex shapes.

-

Stamping: This method is typically used for producing components like shading rings and seals. It is efficient for high-volume production and ensures uniformity across parts.

-

Injection Molding: Used primarily for plastic components, this technique allows for intricate designs and rapid production cycles.

Each method must be carefully monitored to maintain tolerances and specifications, which directly affect the performance of the solenoid parts.

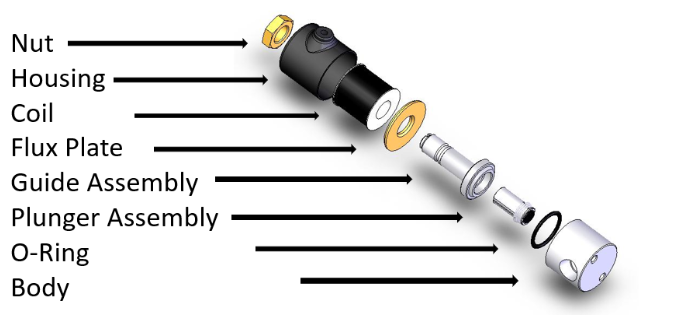

What Is the Assembly Process Like for Solenoid Parts?

Assembly is a critical stage where individual components come together to form the complete solenoid valve. This process typically involves:

-

Component Cleaning: Prior to assembly, components are cleaned to remove any debris or contaminants that could affect performance.

-

Sequential Assembly: Parts are assembled in a specific order, often starting with the installation of the solenoid coil and progressing to the plunger and spring.

-

Fit and Function Testing: As components are assembled, they are tested for fit and function to ensure they operate correctly. This may include checking the movement of the plunger within the armature tube.

What Finishing Techniques Are Applied to Solenoid Parts?

The final stage of manufacturing solenoid parts involves finishing processes that enhance both functionality and aesthetics. Common finishing techniques include:

-

Surface Treatment: Processes such as anodizing or plating can improve corrosion resistance and wear properties.

-

Quality Coatings: Applying lubricants or protective coatings can reduce friction and extend the lifespan of moving components.

-

Final Inspection: After finishing, a thorough inspection is conducted to ensure that all parts meet the required specifications.

What Quality Control Measures Are Implemented in Solenoid Part Manufacturing?

Quality assurance is paramount in the manufacturing of solenoid parts, particularly for international B2B buyers who require consistency and reliability.

Which International Standards Guide Quality Control?

Manufacturers often adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards demonstrates a commitment to quality and continuous improvement. Additionally, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant, particularly for solenoid valves used in critical applications like oil and gas.

What Are the Key Checkpoints in the Quality Control Process?

Quality control in the manufacturing of solenoid parts typically includes several checkpoints:

-

Incoming Quality Control (IQC): As mentioned earlier, this step verifies the quality of raw materials before they enter the manufacturing process.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, random samples may be taken to ensure that production remains within tolerances.

-

Final Quality Control (FQC): After assembly, each solenoid part undergoes a final inspection to confirm that it meets all specifications and performance criteria.

What Testing Methods Are Commonly Used for Solenoid Parts?

Testing methods for solenoid parts can include:

-

Electrical Testing: This checks for continuity and ensures that the solenoid coil is functioning correctly.

-

Leak Testing: Particularly important for solenoid valves, this test ensures that there are no leaks in the assembled unit.

-

Functional Testing: This involves simulating operational conditions to verify that the solenoid opens and closes as intended.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those in international markets such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential for ensuring product reliability.

What Audit Processes Should Buyers Consider?

Buyers should conduct supplier audits to assess the manufacturing processes and quality control measures in place. This can include:

Illustrative image related to solenoid parts

-

On-site Audits: Visiting the manufacturing facility provides insight into the operational standards and practices.

-

Documentation Review: Requesting documentation related to quality processes, including inspection reports and compliance certifications.

How Can Third-Party Inspections Enhance Confidence?

Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices. These inspections can be particularly useful for buyers who may not have the resources to conduct thorough audits themselves.

What Unique Quality Control Nuances Should International Buyers Be Aware Of?

International buyers should be aware of potential nuances in quality control that may vary by region. For instance, certain countries may have specific regulatory requirements that affect manufacturing practices. Understanding these regional differences can help buyers make informed decisions when selecting suppliers.

By comprehensively understanding the manufacturing processes and quality assurance protocols for solenoid parts, B2B buyers can enhance their procurement strategies, ensuring they partner with reliable suppliers that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘solenoid parts’

When sourcing solenoid parts, international B2B buyers must navigate a complex landscape of technical specifications, supplier capabilities, and regulatory requirements. This guide provides a structured checklist to ensure you make informed decisions that align with your operational needs and quality standards.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to establish clear technical specifications for the solenoid parts you need. This includes understanding the specific type of solenoid valve (e.g., 2-way, 3-way), the materials required (such as stainless steel or brass), and the operational parameters like voltage and pressure ratings. Clearly defined specifications help streamline your search and ensure compatibility with existing systems.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in solenoid parts. Utilize industry-specific directories, trade shows, and online marketplaces to compile a list of manufacturers and distributors. Pay attention to their experience in the industry, product range, and customer reviews to gauge their reliability and expertise.

Step 3: Evaluate Supplier Certifications

It’s crucial to verify that suppliers hold relevant certifications, such as ISO 9001 or other industry-specific quality standards. These certifications indicate a commitment to quality management practices and can significantly reduce the risk of sourcing inferior products. Request documentation to confirm compliance and ensure that the supplier adheres to international quality standards.

Step 4: Request Samples and Technical Data Sheets

Before placing large orders, request samples of the solenoid parts along with technical data sheets. Evaluating samples allows you to assess the quality, functionality, and compatibility with your systems. Technical data sheets provide essential information about the specifications, materials, and performance metrics, enabling better decision-making.

Step 5: Assess Pricing and Payment Terms

Gather pricing information from multiple suppliers to compare costs effectively. Consider not only the unit price but also the total cost of ownership, including shipping, taxes, and potential duties. Additionally, clarify payment terms, including deposit requirements and payment methods, to avoid any financial surprises later in the process.

Step 6: Inquire About Lead Times and Availability

Lead time can significantly impact your project timelines, so it’s essential to inquire about the availability of the solenoid parts you need. Confirm production and delivery timelines with the supplier to ensure they align with your project schedules. Suppliers should provide transparent timelines and options for expedited shipping if required.

Step 7: Establish After-Sales Support and Warranty Terms

Finally, assess the level of after-sales support provided by the supplier. Understand their warranty terms and procedures for handling defective parts or returns. A supplier with strong after-sales support can be invaluable in minimizing downtime and ensuring that your operations run smoothly.

Illustrative image related to solenoid parts

By following these steps, you can streamline your sourcing process for solenoid parts and ensure that you partner with suppliers who meet your technical, quality, and operational requirements.

Comprehensive Cost and Pricing Analysis for solenoid parts Sourcing

Understanding the cost structure and pricing dynamics of solenoid parts is crucial for international B2B buyers looking to optimize their sourcing strategies. This analysis breaks down the cost components, identifies pricing influencers, and offers practical tips for effective negotiation and purchasing.

What are the Key Cost Components in Solenoid Parts Sourcing?

The total cost of solenoid parts comprises several components:

-

Materials: The primary materials used in solenoid parts include metals like brass and stainless steel, plastics, and specialized alloys. The choice of material directly impacts the cost, as high-quality materials often come at a premium. Buyers should ensure that the selected materials match the operational requirements of their applications to avoid costly failures.

-

Labor: Labor costs can vary significantly based on the manufacturing location. Regions with lower labor costs may offer more competitive pricing, but this can sometimes come at the expense of quality. Understanding the local labor market in supplier countries is essential for evaluating overall costs.

-

Manufacturing Overhead: This includes expenses related to the production process, such as utilities, equipment maintenance, and facility costs. Suppliers with efficient manufacturing processes may offer lower overhead costs, which can be passed on to buyers.

-

Tooling: Custom tooling for specific solenoid parts can lead to increased initial costs. However, these costs can be amortized over larger production runs, making them more cost-effective for bulk orders.

-

Quality Control (QC): Ensuring the reliability of solenoid parts is critical, especially in industries where failure can lead to significant downtime or safety risks. Investing in robust QC processes can increase upfront costs but can lead to long-term savings by reducing defects and warranty claims.

-

Logistics: Shipping and handling costs are significant, particularly for international buyers. Incoterms can influence these costs, as they dictate who bears the responsibility for shipping and insurance during transit.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. This margin can vary based on market demand, competition, and the supplier’s positioning in the marketplace.

What Influences Pricing for Solenoid Parts?

Several factors can influence the pricing of solenoid parts, particularly in international markets:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit prices due to economies of scale. Buyers should assess their needs and consider negotiating for better pricing on bulk purchases.

-

Specifications and Customization: Custom specifications can lead to increased costs due to the need for specialized tooling or materials. Buyers should weigh the benefits of customization against potential price increases.

-

Material Quality and Certifications: Higher quality and certified materials (e.g., ISO certifications) may command higher prices but can be essential for applications that require reliability and compliance with industry standards.

-

Supplier Factors: The reputation, location, and production capabilities of suppliers can impact pricing. Established suppliers with a track record of quality and reliability may offer higher prices but provide peace of mind.

-

Incoterms: These terms define the responsibilities of buyers and sellers in shipping. Understanding these can help buyers anticipate additional costs associated with transportation and insurance.

What Tips Can Help Buyers Negotiate Better Prices?

-

Leverage Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the total cost of ownership, which includes maintenance, operational efficiency, and potential downtime. This perspective can justify higher initial costs if long-term savings are evident.

-

Negotiate Terms and Conditions: Engaging in negotiations regarding payment terms, delivery schedules, and warranty conditions can lead to more favorable purchasing agreements.

-

Research Market Trends: Staying informed about global market trends, especially in regions like Africa, South America, the Middle East, and Europe, can provide insights into pricing fluctuations and supplier availability.

-

Be Aware of Pricing Nuances: International buyers should be cognizant of currency fluctuations, import duties, and local taxes that can affect the final price. Working with local distributors or agents may mitigate some of these complexities.

Disclaimer on Indicative Prices

Prices for solenoid parts can vary widely based on multiple factors, including market conditions and supplier negotiations. The figures provided here are indicative and should be confirmed through direct supplier communication for accuracy.

Alternatives Analysis: Comparing solenoid parts With Other Solutions

Understanding Alternatives to Solenoid Parts

In the world of industrial automation and control systems, solenoid parts are widely recognized for their reliability in controlling fluid flow. However, various alternative technologies can achieve similar objectives, offering unique advantages and potential drawbacks. This section explores these alternatives, enabling B2B buyers to make informed decisions based on their specific applications and operational requirements.

| Comparison Aspect | Solenoid Parts | Pneumatic Actuators | Electric Motor Valves |

|---|---|---|---|

| Performance | High precision, fast response | Good for larger volumes | Continuous control and power |

| Cost | Moderate initial cost, replacement parts needed | Higher upfront cost, low running costs | Variable cost based on size and power |

| Ease of Implementation | Simple installation and integration | Requires additional air supply | More complex, may need controllers |

| Maintenance | Regular checks on seals and coils | Minimal maintenance, check air supply | Periodic maintenance needed |

| Best Use Case | Fluid control in small to medium applications | Heavy-duty applications with high flow | Applications needing precise positioning |

In-Depth Look at Alternatives

Pneumatic Actuators

Pneumatic actuators utilize compressed air to create motion and control the flow of fluids. They are particularly effective in applications requiring substantial force and speed, making them suitable for heavy-duty tasks in industries such as manufacturing and automotive. The main advantages of pneumatic actuators include their ability to handle high flow rates and their durability in harsh environments. However, the need for a reliable air supply system can increase initial setup costs and complexity.

Electric Motor Valves

Electric motor valves, which use electric motors to operate the valve mechanism, offer continuous and precise control over fluid flow. These valves are ideal for applications requiring fine-tuning and automation, such as in HVAC systems and process control. While they provide excellent control and can be integrated into smart systems, their installation may be more complex and costly compared to solenoid parts. Additionally, they require periodic maintenance to ensure optimal performance, which can be a consideration for budget-conscious buyers.

Making the Right Choice for Your Business Needs

When selecting the appropriate solution for your industrial automation needs, consider the specific requirements of your application. Solenoid parts are often the best choice for smaller systems where space and cost are critical. In contrast, pneumatic actuators may be better suited for high-demand applications that require robust performance. Electric motor valves can be ideal for applications where precision and automation are paramount. By evaluating performance, cost, ease of implementation, maintenance, and best use cases, B2B buyers can make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for solenoid parts

What Are the Key Technical Properties of Solenoid Parts?

Understanding the critical specifications of solenoid parts is essential for B2B buyers to make informed purchasing decisions. Here are some key properties to consider:

Illustrative image related to solenoid parts

1. Material Grade

The material grade of solenoid components, such as the valve body and internal parts, affects durability and compatibility with various media types. Common materials include stainless steel, brass, and plastic. For example, stainless steel is highly resistant to corrosion, making it suitable for harsh environments. Selecting the appropriate material ensures longevity and reduces the risk of failure in demanding applications.

2. Operating Pressure

Operating pressure is a critical specification that indicates the maximum pressure at which the solenoid valve can function effectively. This property is crucial for preventing valve failure and ensuring safety in applications involving high-pressure fluids. Buyers should carefully match the operating pressure of the solenoid parts with the requirements of their systems to avoid costly downtime or equipment damage.

3. Tolerance Levels

Tolerance levels refer to the acceptable limits of variation in the dimensions of solenoid components. These specifications are vital for ensuring that parts fit together correctly and function as intended. High-precision tolerances lead to better performance, especially in applications requiring tight control over fluid flow. For B2B buyers, understanding tolerances helps in selecting parts that will integrate seamlessly into existing systems.

Illustrative image related to solenoid parts

4. Coil Voltage Rating

The coil voltage rating specifies the electrical power needed to energize the solenoid. This property is essential for compatibility with existing electrical systems. Solenoids are available in various voltage ratings, including AC and DC options. Buyers must choose the correct voltage rating to ensure reliable operation and prevent overheating or burnout of the solenoid.

5. Response Time

Response time is the duration it takes for the solenoid to open or close once energized. This specification is critical in applications where quick actuation is necessary, such as in automated systems. A shorter response time enhances the efficiency of operations, making it a key consideration for B2B buyers looking to improve system performance.

What Are Common Trade Terms in Solenoid Parts Procurement?

Familiarity with industry jargon can streamline the procurement process and facilitate better communication between buyers and suppliers. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are used in another company’s end products. In the context of solenoid parts, understanding OEM specifications ensures that buyers are sourcing high-quality parts that meet industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell. Knowing the MOQ is crucial for B2B buyers, as it can impact inventory management and cash flow. Buyers should negotiate MOQs to align with their project needs and budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products or services. This process helps in comparing offers and ensuring competitive pricing. Including detailed specifications in an RFQ can lead to more accurate quotes and better supplier relationships.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps B2B buyers understand shipping costs and risks associated with international purchases, ensuring smooth transactions.

5. Lead Time

Lead time is the period between placing an order and receiving the goods. Understanding lead times is essential for project planning and inventory management. Buyers should inquire about lead times when negotiating contracts to ensure timely delivery of solenoid parts.

By grasping these technical properties and trade terms, B2B buyers can enhance their procurement strategies, ensuring that they select the right solenoid parts for their applications while optimizing costs and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the solenoid parts Sector

What Are the Key Trends Influencing the Global Solenoid Parts Market?

The global solenoid parts market is witnessing significant growth, driven by the increasing demand for automation across various industries such as automotive, manufacturing, and healthcare. As businesses seek to enhance operational efficiency, the adoption of solenoid valves and associated parts is becoming essential. Key trends include the rise of Industry 4.0, which emphasizes smart manufacturing and interconnected systems. This shift is prompting manufacturers to develop advanced solenoid technologies that offer better reliability and performance.

Emerging technologies such as IoT (Internet of Things) are also influencing sourcing trends. B2B buyers are increasingly looking for suppliers that offer solenoid components with integrated smart features, enabling remote monitoring and control. This trend is particularly relevant for buyers in regions like Africa and South America, where infrastructural advancements are making automation more accessible. Moreover, the emphasis on cost-effectiveness is driving businesses to explore global sourcing options, allowing them to capitalize on competitive pricing from manufacturers in Asia and Europe.

Additionally, the growing focus on customization is reshaping the market dynamics. Buyers are seeking tailored solutions that cater to specific application needs, prompting suppliers to enhance their product offerings. This trend underscores the importance of maintaining flexible supply chains and fostering strong relationships with manufacturers to ensure timely delivery of customized solenoid parts.

How Can Sustainability and Ethical Sourcing Impact B2B Buyers in the Solenoid Parts Sector?

Sustainability is becoming a critical consideration for B2B buyers in the solenoid parts sector. The environmental impact of manufacturing processes and materials used in solenoid components is under scrutiny, prompting businesses to adopt greener practices. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable manufacturing, such as using recyclable materials and minimizing waste.

Ethical sourcing is also gaining traction, as companies are held accountable for their supply chains. Buyers are encouraged to select suppliers that adhere to ethical labor practices and demonstrate transparency in their sourcing methods. Certifications such as ISO 14001, which focuses on effective environmental management systems, and other green certifications can serve as valuable indicators of a supplier’s commitment to sustainability.

By aligning with suppliers who prioritize sustainability and ethical practices, B2B buyers not only contribute to environmental conservation but also enhance their brand reputation. This trend is particularly pertinent in regions like Europe, where regulatory frameworks increasingly demand compliance with sustainability standards. Embracing these principles can lead to stronger partnerships and long-term business success.

Illustrative image related to solenoid parts

What Is the Historical Context of Solenoid Parts Development for Today’s B2B Buyers?

The development of solenoid parts can be traced back to the early 19th century, with the invention of the electromagnetic solenoid by Joseph Henry. This innovation laid the foundation for the modern solenoid valve, which has evolved significantly over the years. Initially utilized in simple on/off applications, solenoid valves have transformed into sophisticated components capable of precise control in various industrial applications.

By the mid-20th century, advancements in materials and manufacturing processes led to the widespread adoption of solenoid valves in diverse sectors, including automotive and aerospace. The introduction of electronic controls further enhanced their functionality, allowing for automation and improved efficiency. Today, solenoid parts are integral to modern industrial systems, underscoring the importance of understanding their historical evolution for B2B buyers seeking reliable and innovative solutions.

This historical perspective not only informs buyers about the technical advancements in solenoid technology but also highlights the ongoing need for innovation in response to emerging market demands. As B2B buyers navigate the complexities of sourcing solenoid parts, recognizing the legacy and continuous evolution of these components can provide valuable insights into future trends and opportunities.

Frequently Asked Questions (FAQs) for B2B Buyers of solenoid parts

-

How do I troubleshoot solenoid valve performance issues?

To troubleshoot solenoid valve performance, start by checking for electrical issues. Ensure that the solenoid coil is receiving power and that there are no breaks in the wiring. Inspect the valve for blockages or debris that could impede the plunger’s movement. If leaks are present, examine seals and gaskets for wear. Regular maintenance, including cleaning and replacing worn parts, can significantly improve performance and extend the life of the valve. -

What is the best solenoid valve type for my application?

Choosing the best solenoid valve depends on your application’s specific requirements, such as media type, pressure, and flow rate. For water applications, a direct-acting solenoid valve made from brass or stainless steel is often recommended. If you need to control air or gas, consider a 3-way valve for more versatility. Always consult with suppliers about the materials and specifications to ensure compatibility with your system and operational needs. -

What are the minimum order quantities (MOQ) for solenoid parts?

Minimum order quantities for solenoid parts can vary widely among suppliers. Typically, MOQs range from 10 to 100 units, depending on the part and the supplier’s policies. When sourcing from international suppliers, consider discussing your specific needs to negotiate favorable terms, especially if you require a diverse range of parts. Additionally, bulk orders can lead to cost savings and better lead times. -

How can I verify the quality of solenoid parts from suppliers?

To verify the quality of solenoid parts, request certifications such as ISO 9001 or industry-specific quality standards. Ask for samples to conduct your own tests before placing a large order. Additionally, consider suppliers with a strong reputation and positive customer reviews. Engaging in direct communication to discuss quality assurance processes can also provide insights into their manufacturing practices. -

What payment terms should I expect when sourcing solenoid parts internationally?

Payment terms can differ significantly based on the supplier and your location. Common terms include net 30 or net 60 days after delivery, but upfront payments or deposits may be required, especially for custom orders. It’s advisable to clarify payment methods—such as wire transfer, credit card, or letters of credit—before finalizing agreements. Understanding your supplier’s terms will help manage cash flow effectively. -

What are the typical lead times for custom solenoid parts?

Lead times for custom solenoid parts can vary based on complexity, volume, and supplier capabilities. Generally, expect lead times ranging from 4 to 12 weeks. Factors such as the manufacturing process, material availability, and shipping logistics can impact these timelines. It is crucial to discuss your project timeline with suppliers upfront to ensure timely delivery and avoid disruptions in your operations. -

How do I ensure proper installation of solenoid parts?

Proper installation of solenoid parts is critical for optimal performance. Always follow the manufacturer’s installation guidelines, paying close attention to orientation and connections. Use appropriate tools and avoid over-tightening fittings, which can damage components. It may also be beneficial to consult with an engineer or technician experienced in solenoid systems to ensure that installation is performed correctly. -

What logistics considerations should I keep in mind when importing solenoid parts?

When importing solenoid parts, consider shipping methods, customs regulations, and potential tariffs. Work with reliable freight forwarders who understand international shipping requirements. It’s essential to factor in lead times for customs clearance and any documentation needed for smooth transit. Additionally, evaluate the total landed cost, including shipping and duties, to make informed purchasing decisions that align with your budget.

Top 3 Solenoid Parts Manufacturers & Suppliers List

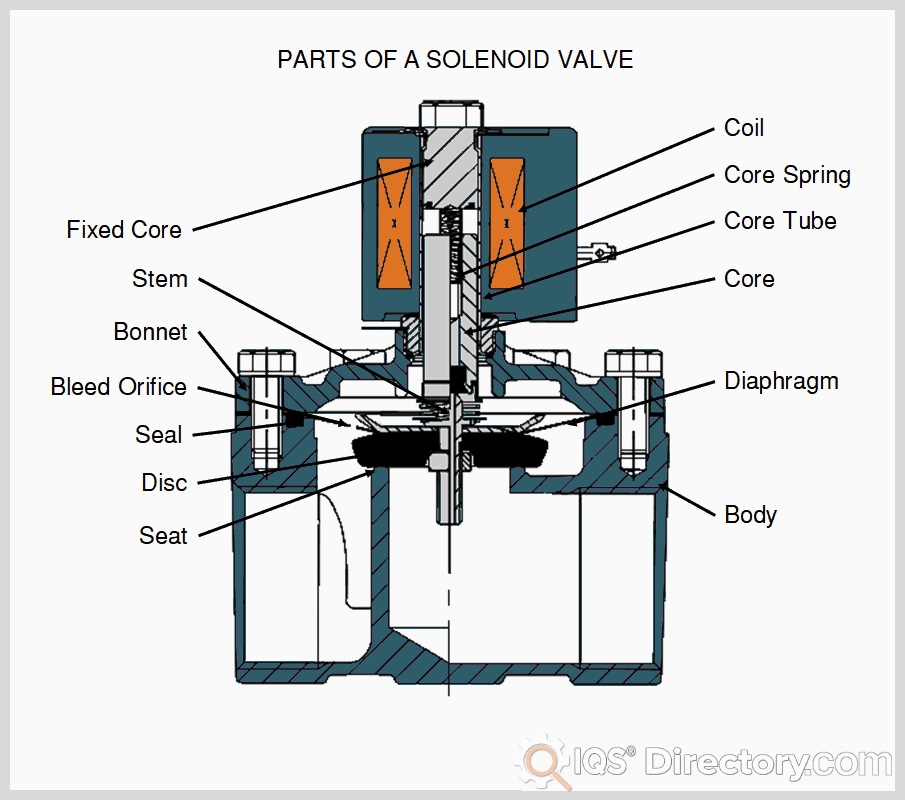

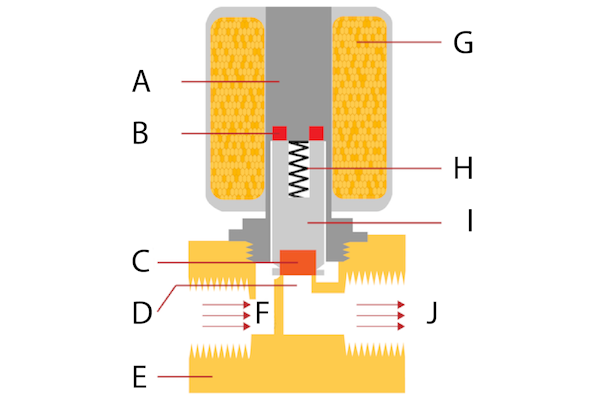

1. Tameson – Solenoid Valve Parts

Domain: tameson.com

Registered: 2015 (10 years)

Introduction: Solenoid valve parts include: Armature tube (A), Shading rings (B), Seal (C), Orifice (D), Valve body (E), Inlet port (F), Solenoid coil (G), Spring (H), Plunger (I), and Outlet port (J). The armature tube guides the plunger, shading rings prevent vibration in AC coils, the seal shuts off the valve, the orifice connects inlet and outlet ports, the valve body connects to piping, the inlet port allo…

2. Nitrous Express – Solenoid Rebuild Parts

Domain: nitrousexpress.com

Registered: 1997 (28 years)

Introduction: Solenoid rebuild parts and accessories for nitrous systems, including various solenoid types, rebuild kits, and individual components to maintain and enhance performance.

3. Espresso Parts – Premium Solenoid Valves

Domain: espressoparts.com

Registered: 1997 (28 years)

Introduction: This company, Espresso Parts – Premium Solenoid Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for solenoid parts

In navigating the complex landscape of solenoid parts, strategic sourcing emerges as a vital approach for international B2B buyers. By understanding the key components—such as the valve body, solenoid coil, and seals—businesses can ensure they select high-quality parts that enhance operational efficiency and reduce downtime. Furthermore, sourcing from reputable suppliers who offer comprehensive revision kits can lead to significant cost savings and improved maintenance practices.

For buyers from Africa, South America, the Middle East, and Europe, investing in reliable solenoid parts is not merely a procurement task; it is a strategic decision that can drive long-term success. As the demand for automation and efficient fluid control continues to grow, aligning with suppliers who are committed to quality and innovation will be crucial.

Looking ahead, we encourage you to actively engage with trusted manufacturers and suppliers, explore the latest advancements in solenoid technology, and prioritize sustainable sourcing practices. By doing so, you will not only enhance your supply chain resilience but also position your business to thrive in an increasingly competitive marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.