A B2B Buyer’s Guide to Solderless Connector: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for solderless connector

In today’s fast-paced global market, sourcing reliable solderless connectors can present significant challenges for B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. The demand for efficient, cost-effective connection solutions has risen sharply, driven by industries ranging from automotive to electronics. This comprehensive guide addresses the complexities of navigating the solderless connector market, providing insights into various types of connectors, their applications, and the critical factors to consider when vetting suppliers.

From understanding the nuances of different solderless terminal designs to evaluating their performance in specific environments, this guide empowers international buyers to make informed purchasing decisions. We will delve into the intricacies of product specifications, compatibility considerations, and pricing structures, enabling you to select the best connectors for your projects. Additionally, we will cover essential topics such as installation techniques, maintenance tips, and market trends that impact availability and pricing.

By leveraging the actionable insights presented in this guide, B2B buyers in regions like Nigeria and Vietnam can confidently approach the solderless connector market, ensuring that they choose high-quality products that meet their unique operational needs. Whether you are upgrading existing systems or embarking on new projects, this resource is designed to facilitate successful sourcing and procurement strategies in an increasingly competitive landscape.

Understanding solderless connector Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Grip Connectors | Easy installation, no tools required, color-coded | LED strip lighting, signage, displays | Pros: Quick setup, versatile. Cons: Less durable in high-vibration areas. |

| Ring Terminals | Circular connection, available in various gauges | Automotive, industrial machinery | Pros: Secure connections, easy to install. Cons: Limited to specific wire sizes. |

| Spade Terminals | Flat design for quick connections, offers locking | Electrical panels, appliances | Pros: Fast and reliable. Cons: Requires compatible connectors for secure fit. |

| Heat Shrink Butt Connectors | Waterproof, heat-shrink for corrosion resistance | Outdoor lighting, automotive applications | Pros: Durable and weatherproof. Cons: Requires heat source for installation. |

| Screw Terminal Connectors | Allows multiple wires to connect via screws | Power distribution, control panels | Pros: Flexible for various wire sizes. Cons: More time-consuming to install. |

What Are Grip Connectors and Where Are They Used?

Grip connectors are designed for quick and easy installations, particularly in LED lighting applications. Their lightweight and durable design allows for secure connections without the need for professional tools, making them ideal for B2B buyers in the signage and display sectors. When considering grip connectors, businesses should evaluate their project requirements, including the specific LED strip compatibility and whether outdoor installations are necessary, as weatherproof options are available.

How Do Ring Terminals Benefit Automotive and Industrial Applications?

Ring terminals are circular connectors that enable secure connections to studs or bolts, making them a popular choice in automotive and industrial machinery applications. They come in various wire gauge options, allowing flexibility in matching the terminal to the wire size. B2B buyers should consider the specific amperage and voltage requirements of their applications to ensure compatibility. While they provide a strong connection, buyers must also be aware of their limitations regarding wire size.

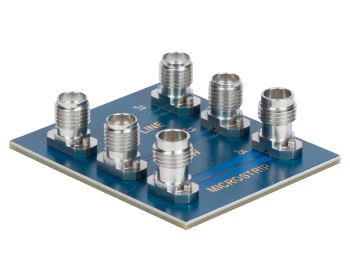

Illustrative image related to solderless connector

What Advantages Do Spade Terminals Offer for Electrical Panels?

Spade terminals are flat connectors that allow for quick connections and disconnections, making them suitable for use in electrical panels and appliances. Their design facilitates easy integration into existing setups, providing a reliable electrical connection. B2B purchasers should assess the compatibility of spade terminals with their equipment, as well as the need for locking mechanisms to prevent accidental disconnection. While they offer speed and ease of use, attention must be paid to ensuring a secure fit.

Why Choose Heat Shrink Butt Connectors for Outdoor Applications?

Heat shrink butt connectors are ideal for applications requiring waterproof and corrosion-resistant connections, such as outdoor lighting and automotive uses. Their unique design incorporates heat-shrink tubing that seals connections against moisture and environmental factors, enhancing durability. When purchasing these connectors, businesses should consider the installation process, as they require a heat source, which may impact project timelines. Despite the need for additional tools, their long-lasting performance in harsh conditions makes them a valuable choice.

What Are the Benefits of Screw Terminal Connectors in Power Distribution?

Screw terminal connectors allow multiple wires to connect securely via screws, making them a staple in power distribution and control panels. Their versatility in accommodating various wire sizes makes them attractive to B2B buyers managing diverse electrical setups. However, the installation process can be more time-consuming compared to other solderless options, which may affect project schedules. Buyers should weigh the benefits of flexibility against the potential for increased labor costs when considering screw terminal connectors.

Key Industrial Applications of solderless connector

| Industry/Sector | Specific Application of solderless connector | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics Manufacturing | Connecting components in circuit boards and devices | Reduces assembly time and labor costs, ensuring reliability | Ensure compatibility with component specifications and voltage ratings |

| Automotive | Wiring harness assembly for vehicles | Enhances durability and simplifies repairs, promoting safety | Look for connectors that meet automotive standards and environmental resistance |

| Renewable Energy | Solar panel connections and wind turbine wiring | Facilitates quick installations and maintenance, optimizing efficiency | Verify connectors are rated for outdoor use and high voltage applications |

| Construction | Electrical installations in buildings and infrastructure | Streamlines electrical work, reducing labor and installation time | Consider local regulations and standards for electrical installations |

| Telecommunications | Data and signal connections in networking equipment | Improves signal integrity and reduces downtime, enhancing performance | Source connectors that support high-frequency applications and data integrity |

How Are Solderless Connectors Used in Electronics Manufacturing?

In the electronics manufacturing sector, solderless connectors are crucial for connecting various components on circuit boards. They eliminate the need for soldering, which can be time-consuming and requires skilled labor. By using solderless connectors, manufacturers can achieve faster assembly times and reduce labor costs, all while ensuring reliable connections. International buyers should ensure that the connectors meet specific component specifications, including voltage ratings and compatibility with other electronic parts, to maintain quality standards.

What Role Do Solderless Connectors Play in the Automotive Industry?

Solderless connectors are widely used in automotive wiring harness assemblies, providing a secure and reliable means of connecting wires in vehicles. These connectors enhance the durability of electrical systems, making them resistant to vibrations and environmental factors. This is especially important for international buyers in regions with varied climates, as connectors must meet stringent automotive standards. When sourcing, businesses should prioritize connectors that comply with automotive regulations and ensure they are suited for high-temperature and moisture-resistant applications.

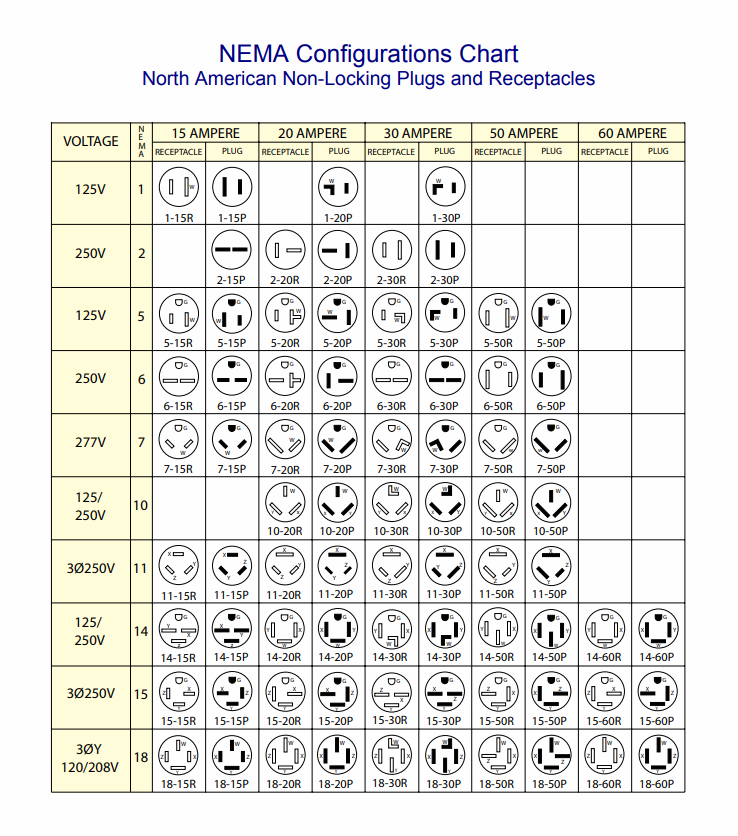

Illustrative image related to solderless connector

How Are Solderless Connectors Beneficial in Renewable Energy Projects?

In the renewable energy sector, solderless connectors are essential for establishing connections in solar panels and wind turbines. They facilitate quick installations and allow for easy maintenance, which is critical for optimizing energy efficiency. For international B2B buyers, it is vital to verify that the connectors are rated for outdoor use and can withstand high voltage applications. This ensures that the systems remain operational under various environmental conditions, maximizing return on investment.

In What Ways Do Solderless Connectors Enhance Construction Projects?

In construction, solderless connectors simplify electrical installations in buildings and infrastructure. They allow for quick and efficient wiring, reducing both labor costs and installation time. For businesses operating in diverse international markets, it is important to consider local regulations and standards that govern electrical installations. Sourcing connectors that comply with these standards will help ensure safety and reliability in electrical systems, ultimately fostering trust with clients and stakeholders.

Why Are Solderless Connectors Critical in Telecommunications?

Solderless connectors are vital in telecommunications for establishing data and signal connections in networking equipment. They help improve signal integrity and reduce downtime, which is essential for maintaining high performance in communication systems. International buyers should focus on sourcing connectors that support high-frequency applications and ensure data integrity. This is particularly important in markets where network reliability is crucial for business operations, highlighting the importance of quality and performance in sourcing decisions.

3 Common User Pain Points for ‘solderless connector’ & Their Solutions

Scenario 1: Difficulty in Ensuring Reliable Connections in High-Vibration Environments

The Problem: B2B buyers in industries such as automotive, manufacturing, or telecommunications often face challenges with solderless connectors in high-vibration settings. Connectors can become loose or disengaged due to constant movement or vibration, leading to intermittent failures or complete disconnections. This can result in costly downtime, delays in project timelines, and a negative impact on overall operational efficiency.

The Solution: To mitigate this issue, consider sourcing solderless connectors designed specifically for high-vibration environments. These connectors typically feature locking mechanisms or additional strain relief that secures the connection more firmly. When specifying products, focus on connectors made from durable materials that can withstand mechanical stress. Implementing regular maintenance checks and using adhesive compounds or protective enclosures can also enhance reliability. Educate your teams on proper installation techniques to ensure that connectors are seated correctly, which can significantly reduce the risk of disconnection in dynamic settings.

Scenario 2: Challenges with Compatibility Across Different Wire Gauges

The Problem: B2B buyers often encounter compatibility issues when attempting to use solderless connectors with various wire gauges in their projects. This can lead to improper connections, increased resistance, and potential failures in electrical performance. Such discrepancies can be particularly frustrating for projects requiring specific electrical characteristics or compliance with industry standards.

The Solution: When selecting solderless connectors, ensure they are compatible with the range of wire gauges your application demands. Look for connectors that offer a versatile range of compatibility, such as those that can accommodate 20 to 22 AWG wires. Additionally, consult technical datasheets and manufacturer specifications to verify compatibility before purchasing. It may also be beneficial to stock a variety of connector types to address different project needs. For best practices, consider training your staff on proper wire preparation techniques, including stripping lengths and securing connections to enhance overall performance.

Scenario 3: Difficulty in Achieving Weatherproof Connections for Outdoor Applications

The Problem: For B2B buyers in construction, landscaping, or outdoor event management, ensuring that solderless connectors are weatherproof is a common pain point. Exposure to moisture, dust, and extreme temperatures can compromise the integrity of electrical connections, leading to failures and safety hazards. This concern is particularly relevant in regions with fluctuating climates, making it imperative for buyers to find reliable solutions.

The Solution: To address weatherproofing challenges, select solderless connectors specifically designed for outdoor use. These connectors often come with protective features such as silicone sealing or heat-shrink tubing that prevents moisture ingress. When sourcing these connectors, verify their IP (Ingress Protection) rating to ensure they meet the necessary standards for outdoor applications. Additionally, consider investing in weatherproof junction boxes that house multiple connections and provide an extra layer of protection against the elements. Educate your installation teams about the importance of proper sealing techniques and regular inspections to maintain connection integrity over time.

Strategic Material Selection Guide for solderless connector

What Materials Are Commonly Used for Solderless Connectors?

When selecting solderless connectors, the choice of material is critical to ensure optimal performance and longevity. Here, we analyze four common materials used in solderless connectors: copper, aluminum, brass, and plastic. Each material has unique properties, advantages, and limitations that can significantly impact their suitability for various applications.

How Does Copper Perform in Solderless Connectors?

Copper is the most widely used material for solderless connectors due to its excellent electrical conductivity and thermal properties. It can handle high temperatures and pressures, making it suitable for a range of applications, including automotive and industrial settings.

Pros: Copper connectors are durable, resistant to corrosion (especially when coated), and offer low electrical resistance, which enhances performance. They are also relatively easy to manufacture and can be found in various forms, such as ring terminals and spade connectors.

Cons: The primary drawback of copper is its cost, as it tends to be more expensive than alternatives like aluminum. Additionally, copper can be prone to oxidation if not properly treated, which can affect conductivity over time.

Impact on Application: Copper is particularly effective in high-performance applications where low resistance is crucial, such as in power distribution systems. However, buyers should consider the need for corrosion-resistant coatings in humid or corrosive environments.

What Role Does Aluminum Play in Solderless Connectors?

Aluminum is another popular choice, especially in applications where weight is a concern, such as aerospace and automotive industries. It offers a good balance between conductivity and weight.

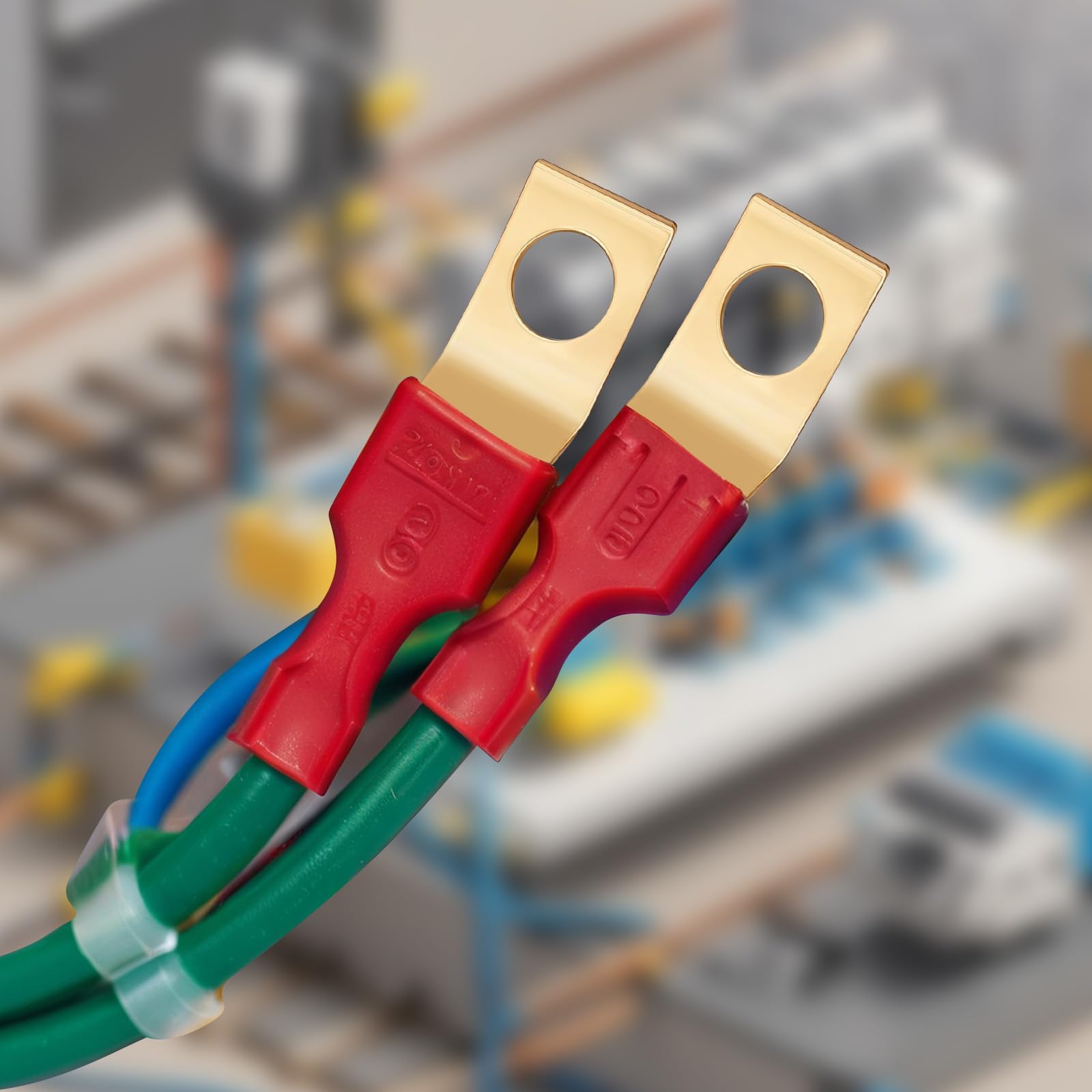

Illustrative image related to solderless connector

Pros: Aluminum connectors are lightweight, cost-effective, and have decent corrosion resistance. They are suitable for applications where reducing weight is essential without compromising performance.

Cons: Aluminum has a higher electrical resistance compared to copper, which can lead to increased heat generation in high-current applications. Additionally, aluminum connectors can be more challenging to manufacture due to the need for specific joining techniques, such as crimping.

Impact on Application: Aluminum is ideal for applications where weight savings are critical, but buyers must ensure that the specific application does not exceed the material’s electrical limits.

Illustrative image related to solderless connector

How Does Brass Compare in Solderless Connectors?

Brass, an alloy of copper and zinc, is often used in solderless connectors due to its strength and resistance to corrosion.

Pros: Brass connectors offer good mechanical strength and corrosion resistance, making them suitable for various environments. They also have decent conductivity, although not as high as pure copper.

Cons: The cost of brass can vary, but it is generally more expensive than aluminum. Additionally, brass may not perform as well in high-temperature applications compared to copper.

Impact on Application: Brass is commonly used in marine applications due to its resistance to saltwater corrosion. However, international buyers should ensure compliance with specific marine standards in their regions.

What Are the Benefits of Using Plastic in Solderless Connectors?

Plastic materials are often used for insulation and housing in solderless connectors, providing electrical isolation and protection from environmental factors.

Pros: Plastic connectors are lightweight, cost-effective, and resistant to moisture and chemicals. They can be manufactured in various colors and shapes, enhancing usability and identification.

Cons: Plastic connectors may not withstand high temperatures or heavy mechanical stress as well as metal connectors. They can also degrade over time when exposed to UV light or extreme temperatures.

Impact on Application: Plastic connectors are ideal for low-voltage applications, such as LED lighting and consumer electronics. However, international buyers should consider local regulations regarding plastic materials, especially in regions with stringent environmental laws.

Summary Table of Material Selection for Solderless Connectors

| Material | Typical Use Case for solderless connector | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Power distribution, automotive | Excellent electrical conductivity | Higher cost, prone to oxidation | High |

| Aluminum | Aerospace, automotive | Lightweight and cost-effective | Higher electrical resistance | Medium |

| Brass | Marine applications | Good corrosion resistance | More expensive than aluminum | Medium |

| Plastic | LED lighting, consumer electronics | Lightweight and moisture-resistant | Limited temperature tolerance | Low |

This guide provides a strategic overview of material selection for solderless connectors, aiding international B2B buyers in making informed decisions that align with their specific application needs and regional compliance standards.

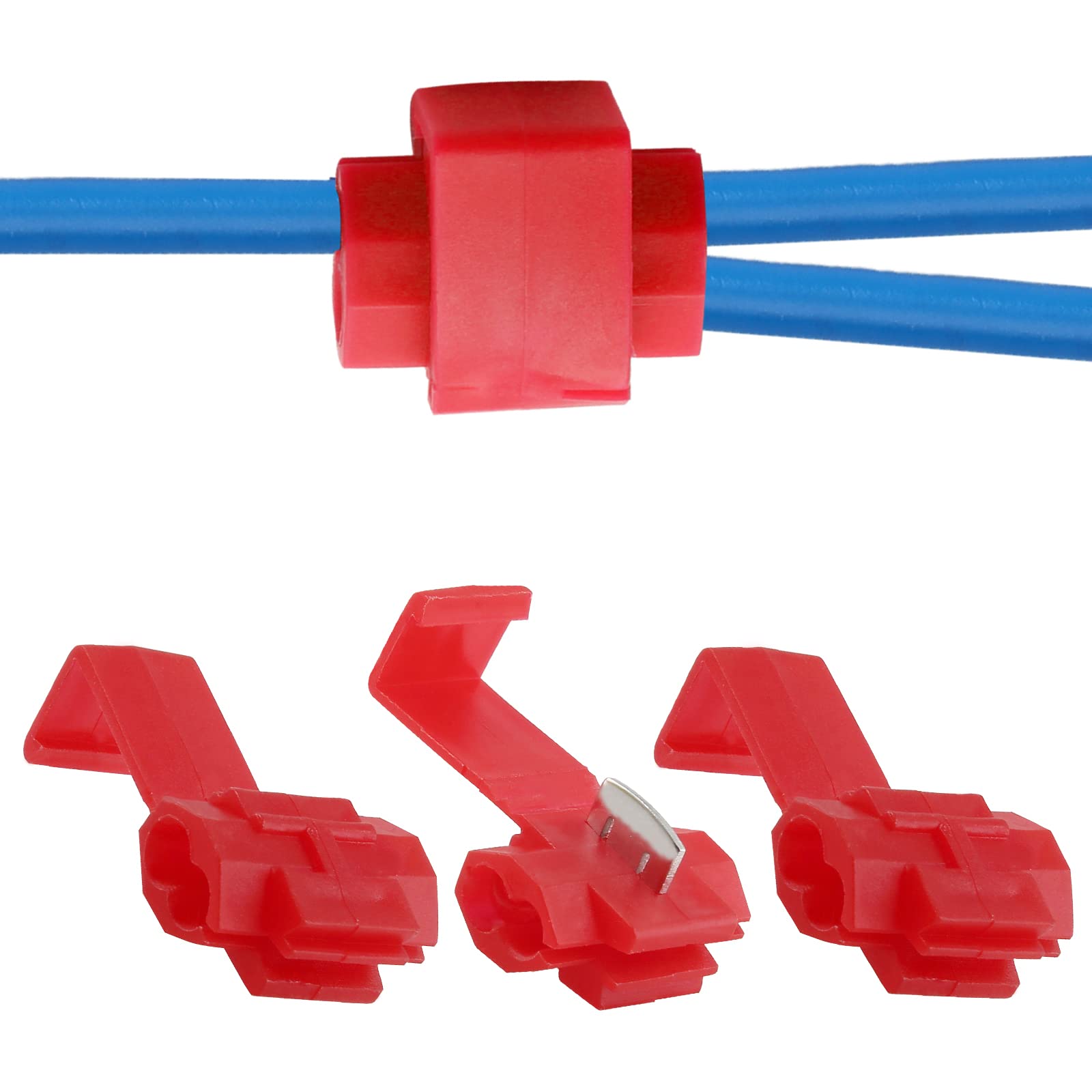

Illustrative image related to solderless connector

In-depth Look: Manufacturing Processes and Quality Assurance for solderless connector

What Are the Main Stages of Manufacturing Solderless Connectors?

The manufacturing process for solderless connectors involves several critical stages that ensure the final product meets both functional and quality standards. Understanding these stages can help B2B buyers assess potential suppliers effectively.

How Is Material Prepared for Solderless Connectors?

The first step in the manufacturing process is material preparation. Typically, solderless connectors are made from high-quality copper or aluminum, chosen for their excellent conductivity and corrosion resistance. The materials are sourced from reputable suppliers and undergo strict quality checks upon arrival.

Once received, the materials are cut to size, and any impurities are removed through processes such as surface cleaning or chemical treatments. This ensures that the raw materials are free from defects, which could impact the performance of the final connectors.

What Forming Techniques Are Used in Solderless Connector Manufacturing?

After material preparation, the next stage is forming. This involves shaping the raw materials into the desired connector profiles. Various techniques are employed, including stamping, extrusion, and molding.

For instance, stamping is commonly used to create flat connectors, where metal sheets are punched into specific shapes. Extrusion may be used for creating wire connectors, where heated metal is forced through a die to form continuous shapes.

The choice of forming technique depends on the connector design and the volume of production. Advanced machinery, such as CNC machines, is often used to ensure precision and consistency in the forming process.

How Are Solderless Connectors Assembled?

Once the components are formed, the assembly stage begins. In this phase, different parts of the connector are brought together. For solderless connectors, this often involves crimping wires into terminals or using mechanical fasteners to secure connections.

Quality assurance is crucial during this stage to ensure each connection is secure and meets specified tolerances. Automated assembly lines may be utilized to enhance efficiency while maintaining quality control.

What Finishing Processes Are Applied to Solderless Connectors?

Finishing processes enhance the durability and functionality of solderless connectors. Common finishing techniques include plating, which adds a layer of material (such as nickel or gold) to improve conductivity and prevent corrosion.

Additionally, connectors may undergo insulation processes, such as applying heat-shrink tubing or other coatings, to protect the connections from environmental factors. Quality checks are also performed to ensure the finishing meets international standards and customer specifications.

What Quality Assurance Standards Are Relevant for Solderless Connectors?

Quality assurance (QA) is a critical component of the manufacturing process for solderless connectors. Adhering to established standards ensures that products are reliable and safe for use in various applications.

Which International Standards Should Buyers Look For?

B2B buyers should look for suppliers that comply with international quality standards such as ISO 9001. This certification indicates that the manufacturer has implemented a quality management system that meets customer and regulatory requirements.

In addition to ISO standards, industry-specific certifications such as CE marking (for products sold in Europe) and API certification (for products used in the oil and gas industry) can be significant indicators of quality and compliance.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process.

-

Incoming Quality Control (IQC): This is the first checkpoint, where raw materials are inspected upon arrival. Key parameters such as material composition, dimensions, and surface quality are evaluated to ensure they meet specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are conducted to monitor critical parameters such as temperature, pressure, and dimensional accuracy. This helps identify any deviations from the desired quality early in the process.

-

Final Quality Control (FQC): Once the connectors are fully assembled, a final inspection is performed. This may include electrical testing, dimensional checks, and visual inspections to ensure that the connectors are free from defects and function as intended.

How Can B2B Buyers Verify Supplier Quality Assurance?

For B2B buyers, verifying a supplier’s quality assurance practices is essential to ensure they receive high-quality products. Here are some actionable steps buyers can take:

What Documentation Should Buyers Request?

Buyers should request documentation that includes quality control reports, certifications, and test results. This documentation provides insights into the supplier’s quality management processes and compliance with international standards.

How Can Audits and Inspections Enhance Supplier Verification?

Conducting audits or on-site inspections can provide a deeper understanding of a supplier’s manufacturing practices. During these audits, buyers can assess the manufacturing environment, review quality control processes, and verify compliance with international standards.

Engaging third-party inspection services can also provide an unbiased assessment of the supplier’s capabilities and adherence to quality standards. This is particularly important for international buyers from regions like Africa, South America, the Middle East, and Europe, where varying standards may exist.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate various challenges related to quality control when sourcing solderless connectors.

Illustrative image related to solderless connector

How Do Regional Standards Impact Quality Assurance?

Different regions may have specific quality standards and regulations that affect the manufacturing of solderless connectors. For instance, products sold in Europe must comply with CE regulations, while North American markets may have different requirements.

Understanding these regional nuances is critical for B2B buyers to ensure compliance and avoid costly delays or rejections at customs. Buyers should work closely with suppliers to confirm that all necessary certifications and documentation are in place.

What Are the Common Testing Methods for Solderless Connectors?

Common testing methods for solderless connectors include:

- Electrical Testing: Ensures proper conductivity and performance under load conditions.

- Mechanical Testing: Evaluates the strength and durability of the connectors under various stress conditions.

- Environmental Testing: Assesses the connectors’ performance in different environmental conditions, such as temperature and humidity variations.

By understanding these testing methods, B2B buyers can better evaluate the quality and reliability of solderless connectors from their suppliers.

Conclusion

In summary, the manufacturing processes and quality assurance practices for solderless connectors are critical for ensuring product reliability and performance. By understanding these processes, B2B buyers can make informed decisions, validate supplier capabilities, and ultimately enhance their procurement strategies. This knowledge is especially valuable for international buyers navigating diverse regulatory landscapes and quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘solderless connector’

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure solderless connectors. It is designed to streamline the sourcing process, ensuring that buyers make informed decisions that align with their specific technical and business needs.

Illustrative image related to solderless connector

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications of the solderless connectors required for your projects. This includes the type of connector (e.g., grip connectors, butt connectors), wire gauge compatibility, and environmental considerations such as moisture or heat resistance. Establishing these parameters early helps ensure that the products you source will meet your operational demands.

Step 2: Research and Identify Reliable Suppliers

Conduct thorough research to identify suppliers that specialize in solderless connectors. Look for suppliers with a proven track record and positive customer reviews, particularly those who serve industries similar to yours. Prioritize suppliers that demonstrate reliability, quality assurance, and responsiveness to customer inquiries.

Step 3: Evaluate Supplier Certifications and Compliance

Verify that potential suppliers hold the necessary certifications and adhere to relevant industry standards. This may include certifications like ISO, RoHS, or UL, depending on your market and application. Ensuring compliance not only guarantees product safety and quality but also mitigates risks associated with regulatory non-compliance.

Step 4: Request Product Samples

Before placing a bulk order, request samples of the solderless connectors you are considering. Testing samples allows you to evaluate the product’s performance, ease of installation, and compatibility with your existing systems. This hands-on assessment can help prevent costly mistakes and ensure that the connectors meet your specifications.

Step 5: Assess Pricing and Payment Terms

Compare pricing from different suppliers to ensure you receive competitive rates without compromising on quality. Additionally, review payment terms to determine what works best for your financial strategy. Look for flexible payment options, such as net terms or bulk order discounts, which can enhance cash flow management.

Step 6: Consider After-Sales Support and Warranty

Evaluate the level of after-sales support offered by suppliers. Reliable support can be crucial for troubleshooting and maintaining your solderless connectors over time. Additionally, inquire about warranty options, as robust warranty policies can provide peace of mind and assurance of product quality.

Step 7: Finalize the Order and Establish Communication Channels

Once you have selected a supplier, finalize your order while ensuring clear communication regarding delivery timelines and order specifics. Establish ongoing communication channels for updates and future orders. This proactive approach fosters a strong supplier relationship, facilitating smoother transactions in the long run.

By following this checklist, B2B buyers can navigate the sourcing process for solderless connectors effectively, ensuring that they select the best products for their needs while minimizing risks and maximizing value.

Comprehensive Cost and Pricing Analysis for solderless connector Sourcing

What Are the Key Cost Components in Solderless Connector Manufacturing?

Understanding the cost structure of solderless connectors is essential for B2B buyers aiming to optimize their sourcing strategies. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margin.

-

Materials: The choice of materials significantly affects the cost. Common materials include copper for conductors, polyolefin for insulation, and various metals for connectors. High-quality materials can enhance performance and longevity but may increase initial costs.

-

Labor: Labor costs vary based on geographic location and the complexity of manufacturing processes. Skilled labor is often needed for quality assurance and assembly, particularly in regions with higher wage standards.

-

Manufacturing Overhead: This encompasses utilities, rent, and equipment depreciation. Efficient manufacturing processes can reduce overhead, making it crucial for suppliers to optimize their operations.

-

Tooling: Initial tooling costs for custom designs can be significant. However, for high-volume orders, these costs can be amortized over the production run, decreasing the per-unit price.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability and safety, particularly for applications in critical industries. While this may increase upfront costs, it can reduce long-term expenses related to returns and warranty claims.

-

Logistics: Shipping costs, customs duties, and insurance must also be factored in. These can vary greatly depending on the destination and the chosen Incoterms, which dictate the responsibilities of buyers and sellers.

-

Margin: Supplier profit margins can vary based on market competition and the uniqueness of the product. Understanding typical margins in your specific market can aid in negotiating better prices.

What Price Influencers Should Buyers Consider When Sourcing Solderless Connectors?

Several factors can influence the pricing of solderless connectors:

-

Volume/MOQ: Minimum Order Quantities (MOQ) often dictate pricing tiers. Larger orders typically benefit from reduced per-unit costs, making it advantageous for buyers to consolidate orders when possible.

-

Specifications and Customization: Custom specifications, such as unique connector shapes or materials, can significantly increase costs. Standardized products are generally more cost-effective.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like UL or CE) can raise costs but are often necessary for compliance in certain markets. Buyers should weigh the importance of these factors against their budget.

-

Supplier Factors: Supplier reputation, reliability, and location can impact pricing. Established suppliers with a track record of quality may charge a premium, but their reliability can justify the higher cost.

-

Incoterms: The choice of Incoterms affects logistics costs and responsibilities. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help in accurately calculating total landed costs.

What Negotiation Strategies Can B2B Buyers Employ to Ensure Cost Efficiency?

When engaging with suppliers, B2B buyers can utilize several strategies to enhance cost efficiency:

-

Volume Consolidation: Whenever possible, consolidate orders to meet MOQs and benefit from bulk pricing.

-

Long-Term Contracts: Establishing long-term relationships with suppliers can lead to negotiated discounts and more favorable payment terms.

-

Total Cost of Ownership (TCO): Look beyond initial costs to consider maintenance, potential failures, and the cost of replacements. This holistic view can guide better purchasing decisions.

-

Market Research: Conduct thorough market research to understand standard pricing and trends in different regions, particularly in emerging markets like Africa and South America.

-

Cultural Sensitivity: Understanding cultural nuances in negotiation styles can facilitate smoother discussions, especially when dealing with international suppliers from diverse regions.

What Pricing Nuances Should International Buyers Be Aware Of?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several pricing nuances are critical:

-

Currency Fluctuations: Exchange rates can significantly impact final costs. Buyers should consider hedging strategies to mitigate this risk.

-

Import Duties and Tariffs: Different countries have varying import regulations and tariffs that can affect the overall cost of goods. Familiarity with these regulations can prevent unexpected expenses.

-

Logistics and Delivery Times: Longer shipping routes can increase costs and lead times. Buyers should factor these into their overall sourcing strategy.

-

Regulatory Compliance: Ensure that products meet local compliance standards to avoid costly delays or penalties.

-

Local Partnerships: Establishing relationships with local distributors or suppliers can streamline sourcing and reduce overall costs.

By understanding these cost components, price influencers, and negotiation strategies, B2B buyers can make informed decisions that align with their budgetary and operational needs, ultimately leading to successful sourcing of solderless connectors.

Alternatives Analysis: Comparing solderless connector With Other Solutions

When evaluating electrical connectivity solutions, it’s essential to consider various options available in the market. While solderless connectors are widely recognized for their ease of use and reliability, there are alternative solutions that may better fit specific needs depending on the application, environment, and budget. This analysis will compare solderless connectors with two viable alternatives: traditional soldering and heat shrink connectors.

| Comparison Aspect | Solderless Connector | Traditional Soldering | Heat Shrink Connectors |

|---|---|---|---|

| Performance | Reliable for low to moderate loads; quick connections | High reliability for all load types; best for permanent connections | Good for moisture resistance; decent for moderate loads |

| Cost | Generally low-cost; no specialized tools required | Moderate to high; requires skill and tools | Low to moderate; requires heat source |

| Ease of Implementation | Very easy; no tools needed for basic connections | Requires skill and tools; time-consuming | Simple to use; requires heat application |

| Maintenance | Low maintenance; connections can be easily reconfigured | Requires rework for changes; permanent | Minimal maintenance; durable if applied correctly |

| Best Use Case | Temporary installations, prototyping, and quick repairs | Permanent installations, high-reliability applications | Automotive, outdoor, and moisture-sensitive applications |

What Are the Advantages and Disadvantages of Traditional Soldering?

Traditional soldering remains a benchmark for electrical connections, particularly in applications requiring high reliability and durability. The primary advantage is the strong and permanent connections it provides, making it ideal for high-load scenarios. However, the drawbacks include the need for specialized tools and skills, which can increase installation time and costs. This method is not recommended for environments where frequent changes are needed, as it can become labor-intensive to modify existing connections.

How Do Heat Shrink Connectors Compare to Solderless Connectors?

Heat shrink connectors offer a middle ground between solderless connectors and traditional soldering. These connectors involve inserting wires into a heat-shrinkable tube and applying heat to create a secure, moisture-resistant bond. The advantages include their affordability and ease of use, making them suitable for DIY projects and automotive applications. However, they require a heat source and can be less robust than soldered connections in high-vibration environments. Additionally, while they provide moisture resistance, improper application can lead to failure, highlighting the need for careful installation.

Conclusion: How Should B2B Buyers Choose the Right Solution?

For B2B buyers considering solderless connectors versus alternatives, the decision should be guided by specific project requirements. If the goal is fast, temporary connections without the need for professional tools, solderless connectors are the most effective choice. Conversely, for projects demanding high reliability and permanence, traditional soldering is superior. Heat shrink connectors serve well in applications where moisture resistance is crucial, such as in automotive or outdoor settings. Ultimately, evaluating the performance needs, budget constraints, and installation capabilities will guide buyers to the most suitable connectivity solution for their specific applications.

Essential Technical Properties and Trade Terminology for solderless connector

What are the Key Technical Properties of Solderless Connectors?

Understanding the essential technical properties of solderless connectors is crucial for B2B buyers who aim to ensure quality and compatibility in their electrical applications. Here are some of the critical specifications to consider:

-

Material Grade

The material used in solderless connectors significantly impacts durability and conductivity. Common materials include copper, brass, and aluminum. Copper connectors offer excellent conductivity, making them ideal for high-performance applications. Buyers should assess the material grade based on the specific electrical requirements and environmental conditions where the connectors will be deployed. -

Wire Gauge Compatibility

Wire gauge refers to the thickness of the wire that the connector can accommodate, typically measured in AWG (American Wire Gauge). Solderless connectors are designed to fit specific wire gauges, often ranging from 20 AWG to 10 AWG. Understanding wire gauge compatibility ensures that the connectors will securely fit the wires, preventing overheating and electrical failures. -

Amperage Rating

The amperage rating defines the maximum current a connector can handle without overheating. This is crucial for ensuring safety and performance in electrical systems. For instance, connectors rated for 5 amps might be suitable for low-power applications, while those rated for 15 amps or more are designed for heavier loads. Buyers must align the amperage rating with the expected current in their applications. -

Temperature Range

Solderless connectors operate effectively within specified temperature ranges. This property is vital in environments exposed to extreme temperatures, such as outdoor installations or industrial settings. Knowing the temperature range helps buyers select connectors that will maintain performance without risk of failure due to heat or cold. -

Ingress Protection (IP) Rating

The IP rating indicates how well a connector is protected against dust and moisture. Connectors with higher ratings (e.g., IP67) are suitable for outdoor or harsh environments, where exposure to elements can cause corrosion or electrical shorts. This property is particularly relevant for buyers in regions with diverse weather conditions.

What Common Terms Should B2B Buyers Know When Purchasing Solderless Connectors?

Familiarity with industry jargon can streamline the purchasing process and facilitate better communication with suppliers. Here are some essential terms to understand:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications helps buyers ensure that the solderless connectors are compatible with their existing systems or equipment. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is important for B2B buyers, as it can affect budgeting and inventory management. Knowing the MOQ helps buyers plan their orders effectively, especially when entering new markets or launching new projects. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and other terms from suppliers for specific products. This practice is essential for ensuring competitive pricing and understanding supplier capabilities. Buyers should provide detailed specifications in their RFQ to receive accurate and relevant quotes. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping and freight. Familiarity with these terms helps B2B buyers understand their obligations regarding shipping costs, insurance, and delivery, which is particularly important in international transactions. -

Lead Time

Lead time refers to the duration between placing an order and receiving the product. This term is critical for project planning, as delays in lead time can impact timelines and budgets. Buyers should inquire about lead times when placing orders to ensure timely project execution.

By understanding these technical properties and industry terms, B2B buyers can make informed decisions when selecting solderless connectors, ultimately ensuring the success of their electrical projects.

Navigating Market Dynamics and Sourcing Trends in the solderless connector Sector

What Are the Global Market Drivers for Solderless Connectors?

The solderless connector market is experiencing significant growth, driven by the increasing demand for efficient, cost-effective, and easy-to-install electrical solutions across various sectors. Key factors fueling this demand include the rapid expansion of the LED lighting industry, where solderless connectors simplify installations and reduce labor costs. Additionally, the automotive sector is shifting towards more sophisticated electrical systems, further enhancing the need for reliable solderless connections. Emerging markets in Africa, South America, and the Middle East are particularly promising, as infrastructure development and urbanization boost the demand for reliable electrical systems.

What Are the Current and Emerging Sourcing Trends in Solderless Connectors?

B2B buyers are increasingly leveraging digital platforms for sourcing solderless connectors, enhancing supply chain transparency and efficiency. The rise of e-commerce has enabled international buyers to access a broader range of products and suppliers, facilitating competitive pricing and expedited procurement processes. Furthermore, innovations in connector designs—such as heat shrink technology and modular connectors—are gaining traction, allowing for greater flexibility in applications. In addition, customization options are becoming more prevalent, enabling businesses to meet specific project requirements, particularly in niche markets such as renewable energy and smart home technologies.

How Are Sustainability and Ethical Sourcing Impacting the Solderless Connector Market?

Sustainability is becoming a crucial consideration in the solderless connector sector, as buyers increasingly seek products with minimal environmental impact. The industry is witnessing a shift towards the use of eco-friendly materials and manufacturing processes, with suppliers adopting green certifications to attract environmentally conscious customers. Ethical sourcing practices are also gaining importance, as companies prioritize transparency in their supply chains to ensure responsible sourcing of raw materials. This trend is particularly relevant for international buyers in regions like Africa and South America, where local sourcing can significantly reduce carbon footprints and foster community development.

What Are the Benefits of Green Certifications and Materials in Solderless Connectors?

Green certifications, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals), are increasingly sought after by B2B buyers. These certifications not only ensure compliance with environmental regulations but also signal a commitment to sustainability, enhancing brand reputation. The use of recyclable materials and eco-friendly production methods can further differentiate products in a competitive marketplace. By prioritizing suppliers with green credentials, businesses can align their procurement strategies with broader corporate social responsibility (CSR) goals, appealing to a growing base of environmentally aware consumers.

How Has the Solderless Connector Market Evolved Over Time?

The evolution of solderless connectors can be traced back to the need for simpler, more efficient electrical connections that do not require specialized tools or skills for installation. Initially, these connectors were primarily used in consumer electronics, but their applications have expanded dramatically to include automotive, industrial, and residential lighting systems. Advances in materials science and manufacturing technology have led to the development of more robust and versatile connectors, capable of handling higher current loads and operating in diverse environmental conditions. This evolution reflects the industry’s response to the growing complexity of electrical systems and the demand for reliable, user-friendly solutions in an increasingly electrified world.

Conclusion: What Should B2B Buyers Consider in Their Sourcing Strategy?

As international B2B buyers navigate the solderless connector market, understanding the dynamics of global trends, sustainability, and technological advancements is crucial. By focusing on suppliers who prioritize ethical sourcing and environmental responsibility, businesses can enhance their operational efficiency while contributing to a sustainable future. Leveraging digital platforms for procurement will also facilitate access to a wider range of products, enabling buyers to make informed decisions that align with their specific needs and values.

Frequently Asked Questions (FAQs) for B2B Buyers of solderless connector

-

How do I troubleshoot issues with solderless connectors not functioning?

To troubleshoot solderless connectors that aren’t working, first ensure all connections are secure and correctly aligned with the positive and negative terminals of your LED strips or devices. Inspect for any visible damage or corrosion on the connectors and wires. If the lights are still not functioning, check the power supply to ensure it is providing the correct voltage. If problems persist, consider consulting a qualified electrician to evaluate your setup and recommend necessary adjustments. -

What is the best type of solderless connector for outdoor applications?

For outdoor applications, look for solderless connectors specifically designed with weatherproof features. These connectors typically come with silicone end caps or heat-shrink tubing that protects against moisture and environmental factors. Ensure they are rated for outdoor use and compatible with your specific LED or electrical systems. Products with a robust grip and durable materials will also enhance performance and longevity in outdoor settings. -

How can I ensure the quality of solderless connectors from international suppliers?

To ensure quality when sourcing solderless connectors from international suppliers, request certifications and compliance documents that verify product standards. Conduct thorough supplier vetting by checking reviews, references, and their track record in the industry. Consider ordering samples to assess the product quality firsthand. Additionally, inquire about their quality assurance processes and whether they perform routine testing on their connectors before shipment. -

What are typical minimum order quantities (MOQs) for solderless connectors?

Minimum order quantities (MOQs) for solderless connectors can vary significantly based on the supplier and the type of connector. Generally, MOQs can range from as low as 100 units to several thousand. It is essential to discuss your specific needs with potential suppliers to understand their MOQs and see if they offer flexibility, especially for first-time orders or trial purchases. -

What payment terms are commonly accepted when purchasing solderless connectors internationally?

When purchasing solderless connectors internationally, common payment terms include wire transfers, letters of credit, and online payment platforms. Some suppliers may also accept PayPal or escrow services for added security. It’s advisable to clarify payment options before confirming an order and to understand any upfront deposits required. Ensure you also discuss currency exchange rates and potential transaction fees that may apply. -

What customization options are available for solderless connectors?

Many suppliers offer customization options for solderless connectors, including variations in wire length, gauge, and connector types. You may also request specific colors or branding elements for the connectors. To explore customization, discuss your requirements with suppliers directly, as this can enhance compatibility with your existing systems and improve the overall functionality of your projects. -

How do I handle logistics and shipping for international orders of solderless connectors?

When handling logistics for international orders of solderless connectors, choose a reliable shipping partner experienced in international freight. Discuss shipping options with your supplier, including air freight for faster delivery or sea freight for cost-effective options. Be aware of customs regulations and import duties in your country, as these can impact your total costs. Tracking shipments and confirming delivery timelines can also help manage expectations. -

What are the advantages of using solderless connectors over traditional soldering methods?

Solderless connectors offer several advantages over traditional soldering methods, including quicker installation times and the ability to easily disconnect and reconnect components. They eliminate the need for specialized soldering tools and skills, making them more accessible for various applications. Additionally, solderless connectors can reduce the risk of heat damage to sensitive components, ensuring a more reliable connection in many environments.

Top 4 Solderless Connector Manufacturers & Suppliers List

1. Polar Wire – Solderless Connectors

Domain: store.polarwire.com

Registered: 1999 (26 years)

Introduction: Solderless Connectors – Polar Wire offers a variety of solderless connectors including heat seal terminals, ring terminals, splices, spade and hook terminals, quick disconnects, snap plugs, and various types of non-insulated and insulated terminals. The product range includes connectors like closed end HydraLink, multiLink butt connectors, weather pack terminals, and mechanical connectors such as …

2. BTF-LIGHTING – 4 Pin Connector Kit

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: BTF-LIGHTING 4 Pin 10mm 0.39in Width Transparent Connector Kit, includes 8pcs Corner Connectors, 4pcs Gapless Solderless Connectors, 4pcs 5.9in Long 22AWG Extension Wires, supports WS2815, WS2813, etc.

3. TE Connectivity – Solderless Terminals

Domain: connectorsupplier.com

Registered: 2003 (22 years)

Introduction: Solderless terminals provide a simplified wire joining solution, advantageous for applications requiring disconnection for repairs or design changes. TE Connectivity pioneered crimping technology for these terminals, making them simpler, more reliable, and cost-effective compared to soldering. They are used in various markets, including automotive and industrial applications. Types of solderless t…

4. LED Supply – Solderless Strip Connectors

Domain: ledsupply.com

Registered: 2002 (23 years)

Introduction: Solderless Strip Connectors allow for quick and easy connections without soldering. They are available for various types of LED strips including single color, RGB, RGBW, and COB. Key products include: 1. 2-Pin Corner Connector for 10mm LED Strips (Part #: 5050-90) – Sale Price: $1.27 2. COB EZ Click-Tight LED Strip Connector (Part #: EZ-COB-XXX) – Sale Price: $2.56 3. Corner (L) Connector for AC50…

Strategic Sourcing Conclusion and Outlook for solderless connector

In conclusion, the strategic sourcing of solderless connectors presents a significant opportunity for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The versatility and ease of installation offered by solderless connectors not only reduce labor costs but also enhance efficiency in various applications, from LED lighting to automotive wiring. By leveraging local suppliers and manufacturers, buyers can ensure quality and reliability while also supporting regional economies.

Moreover, as the demand for innovative electrical solutions grows, investing in solderless connectors can position companies to stay ahead of industry trends. Buyers should prioritize suppliers who offer a diverse range of products, including waterproof and heat-shrink options, to cater to specific project requirements.

Looking ahead, the solderless connector market is poised for growth, driven by advancements in technology and increased adoption across sectors. International B2B buyers are encouraged to engage with manufacturers and distributors to explore customized solutions that meet their unique needs. By taking proactive steps in sourcing, companies can optimize their operations and drive future success in an increasingly competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to solderless connector