A B2B Buyer’s Guide to Shoelace Eyelet: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for shoelace eyelet

In the dynamic landscape of the global footwear industry, sourcing high-quality shoelace eyelets can present significant challenges for B2B buyers. These small but vital components not only influence the durability and functionality of footwear but also impact the overall design aesthetic. This guide serves as a comprehensive resource for international buyers navigating the intricacies of the shoelace eyelet market. It covers a variety of eyelet types, their applications across different footwear categories, and crucial factors such as supplier vetting and cost considerations.

As buyers from Africa, South America, the Middle East, and Europe—particularly countries like Brazil and Vietnam—look to enhance their product offerings, understanding the nuances of shoelace eyelets becomes essential. This guide empowers decision-makers with actionable insights, enabling them to evaluate suppliers effectively, understand market trends, and make informed purchasing decisions that align with their business goals. By addressing key aspects of eyelet sourcing, from material choices to installation techniques, we aim to equip B2B buyers with the knowledge necessary to foster successful partnerships and drive product innovation in their respective markets. Whether you’re a manufacturer seeking reliable components or a retailer looking to enhance your footwear line, this guide is your go-to resource for navigating the shoelace eyelet landscape.

Understanding shoelace eyelet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Basic Eyelets | Simple holes, often reinforced with stitching | Casual shoes, dress shoes | Pros: Cost-effective, easy to install. Cons: May wear out quickly under heavy use. |

| Reinforced Eyelets | Encircled with metal or plastic grommets | Work shoes, boots | Pros: High durability, reduces wear and tear. Cons: Higher cost than basic eyelets. |

| Hook Eyelets | Designed as hooks for quick lacing | Hiking boots, athletic footwear | Pros: Provides a secure fit, ideal for performance. Cons: Limited aesthetic options. |

| Hidden Eyelets | Located beneath the upper layer for a sleek look | Formal shoes, fashion footwear | Pros: Aesthetic appeal, maintains shoe structure. Cons: More complex installation. |

| TPU Eyelets | Made from thermoplastic polyurethane for flexibility | High-performance sneakers | Pros: High durability, resistant to environmental factors. Cons: Higher production costs. |

What Are Basic Eyelets and When Should They Be Used?

Basic eyelets are simple perforations in the shoe material, often reinforced with stitching to prevent fraying. They are commonly used in casual and dress shoes where durability requirements are moderate. B2B buyers should consider basic eyelets for lower-cost footwear lines, as they offer an economical solution for standard applications. However, their lifespan may be limited in high-use scenarios, making them less suitable for performance-oriented footwear.

What Are Reinforced Eyelets and Their Benefits for B2B Buyers?

Reinforced eyelets are characterized by their encirclement with metal or plastic grommets, enhancing strength and durability. These eyelets are ideal for work shoes and boots, where heavy use and stress on the laces are expected. For B2B buyers, investing in reinforced eyelets means fewer replacements and reduced long-term costs, despite their higher initial price. Their robust design also minimizes wear and tear, making them a preferred choice for industrial applications.

How Do Hook Eyelets Enhance Performance in Specialized Footwear?

Hook eyelets replace traditional holes with hooks, allowing for rapid lacing adjustments. They are particularly useful in hiking boots and athletic footwear, where a secure fit is crucial for performance and safety. B2B buyers should consider hook eyelets when sourcing footwear designed for active use, as they facilitate quick adjustments and enhance user experience. However, the aesthetic options may be limited, which could impact style-conscious brands.

What Makes Hidden Eyelets a Preferred Choice for Formal Footwear?

Hidden eyelets are strategically placed beneath the upper layer of the shoe, providing a sleek and clean appearance. These eyelets are primarily used in formal and fashion footwear, where aesthetics are paramount. For B2B buyers, hidden eyelets offer a unique selling point in luxury markets but require more complex installation processes. Brands should weigh the benefits of visual appeal against the potential increase in manufacturing complexity.

Why Choose TPU Eyelets for High-Performance Footwear?

TPU (thermoplastic polyurethane) eyelets are known for their flexibility and durability, making them suitable for high-performance sneakers. They offer excellent resistance to environmental factors such as moisture and temperature fluctuations. B2B buyers should consider TPU eyelets for athletic and performance-oriented footwear, as they enhance product longevity and user satisfaction. However, the cost associated with TPU materials may be higher, necessitating careful budget considerations.

Key Industrial Applications of shoelace eyelet

| Industry/Sector | Specific Application of shoelace eyelet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear Manufacturing | Integration in athletic and casual shoes | Ensures secure fit and enhances performance, reducing returns | Quality of materials, compatibility with production machinery, and volume pricing. |

| Safety and Workwear | Use in industrial boots and safety shoes | Provides durability and safety, crucial for worker protection | Compliance with safety standards, material strength, and customization options. |

| Fashion and Apparel | Decorative use in high-end fashion footwear | Enhances aesthetic appeal, attracting a premium market | Variety of designs, materials (metal, plastic), and trend alignment. |

| Outdoor and Adventure Gear | Application in hiking boots and specialized footwear | Increases reliability in harsh conditions, enhancing user experience | Resistance to environmental factors, weight considerations, and ease of installation. |

| Sports Equipment | Incorporation in sports-specific footwear | Maximizes athlete performance and comfort | Performance metrics, durability under stress, and brand alignment. |

How Are Shoelace Eyelets Used in Footwear Manufacturing?

In the footwear manufacturing sector, shoelace eyelets are vital for integrating functionality with design. They facilitate the threading of laces, ensuring shoes fit securely, which is essential for athletic and casual shoes. Buyers from regions like Africa and South America should prioritize quality materials that withstand wear and tear, as well as compatibility with existing production processes. Sourcing eyelets that meet these criteria can minimize returns due to fit issues, ultimately enhancing customer satisfaction.

What Role Do Shoelace Eyelets Play in Safety and Workwear?

In the safety and workwear industry, shoelace eyelets are crucial for reinforcing the structure of industrial boots and safety shoes. These eyelets ensure that laces can be tightened securely, providing essential foot support and protection for workers in hazardous environments. Buyers must consider compliance with safety standards, such as ASTM or ISO certifications, and the durability of materials. Selecting eyelets that withstand heavy use can significantly reduce replacement costs and improve worker safety.

Illustrative image related to shoelace eyelet

How Are Shoelace Eyelets Used in Fashion and Apparel?

In the fashion and apparel industry, shoelace eyelets serve a dual purpose of functionality and aesthetics. They are often used in high-end footwear to enhance the overall design, appealing to fashion-conscious consumers. For B2B buyers, sourcing eyelets that align with current fashion trends and offer a variety of designs can differentiate their products in a competitive market. Additionally, the choice of materials—whether metallic for a chic look or plastic for a more casual style—can influence consumer perceptions and sales.

What Is the Importance of Shoelace Eyelets in Outdoor and Adventure Gear?

Shoelace eyelets are especially important in outdoor and adventure gear, particularly in hiking boots and specialized footwear. They must be designed to withstand extreme conditions, ensuring that footwear remains functional and reliable. International buyers should focus on sourcing eyelets that offer resistance to moisture and temperature fluctuations, as these factors can significantly affect performance. Proper installation and durability can enhance user experience, making it essential to select high-quality options.

How Are Shoelace Eyelets Incorporated in Sports Equipment?

In the sports equipment sector, shoelace eyelets are integrated into footwear designed for specific athletic activities, such as running or basketball. They play a critical role in maximizing performance by allowing athletes to adjust the fit according to their needs. Buyers should look for eyelets that can endure high levels of tension and stress, ensuring they do not compromise performance during critical moments. Additionally, aligning with reputable suppliers that offer consistent quality can enhance brand credibility in the competitive sports market.

Illustrative image related to shoelace eyelet

3 Common User Pain Points for ‘shoelace eyelet’ & Their Solutions

Scenario 1: Eyelet Durability Issues in High-Performance Footwear

The Problem: B2B buyers in the footwear manufacturing sector often encounter challenges related to the durability of shoelace eyelets, particularly in high-performance athletic shoes. These eyelets are subjected to significant stress during athletic activities, leading to wear and tear that can compromise the shoe’s overall integrity. Buyers may find that eyelets can crack or pull out, resulting in product returns and dissatisfied customers, which is particularly damaging in competitive markets.

The Solution: To mitigate durability issues, buyers should prioritize sourcing eyelets made from high-quality materials, such as reinforced metal or durable thermoplastic polyurethane (TPU). When specifying eyelets for high-performance shoes, it’s crucial to consider the type of activity the shoe is designed for and match the eyelet material accordingly. Implementing rigorous quality control measures during the manufacturing process can also help. This includes stress testing eyelets to ensure they can withstand the expected loads. Collaborating with suppliers who offer customizable eyelet solutions can provide options tailored to specific performance requirements, ensuring that the products meet both durability and aesthetic standards.

Scenario 2: Inconsistent Eyelet Sizing Across Product Lines

The Problem: Another common pain point for B2B buyers is the inconsistency in eyelet sizing across different shoe models within the same brand. This inconsistency can lead to complications during production, such as mismatched shoelaces that do not fit properly, resulting in delays and increased costs. Buyers may struggle to maintain a streamlined inventory, leading to confusion and inefficiencies in the supply chain.

Illustrative image related to shoelace eyelet

The Solution: To address sizing inconsistencies, buyers should establish clear specifications for eyelet dimensions during the design phase and ensure that these are communicated effectively to all stakeholders involved in production. Maintaining a standardized eyelet size across various models can simplify the procurement process and enhance operational efficiency. Additionally, utilizing advanced software tools for inventory management can help track eyelet sizes and usage, allowing for better forecasting and reducing the likelihood of mismatches. Regular audits of eyelet inventory can also ensure that the correct sizes are readily available, minimizing production downtime.

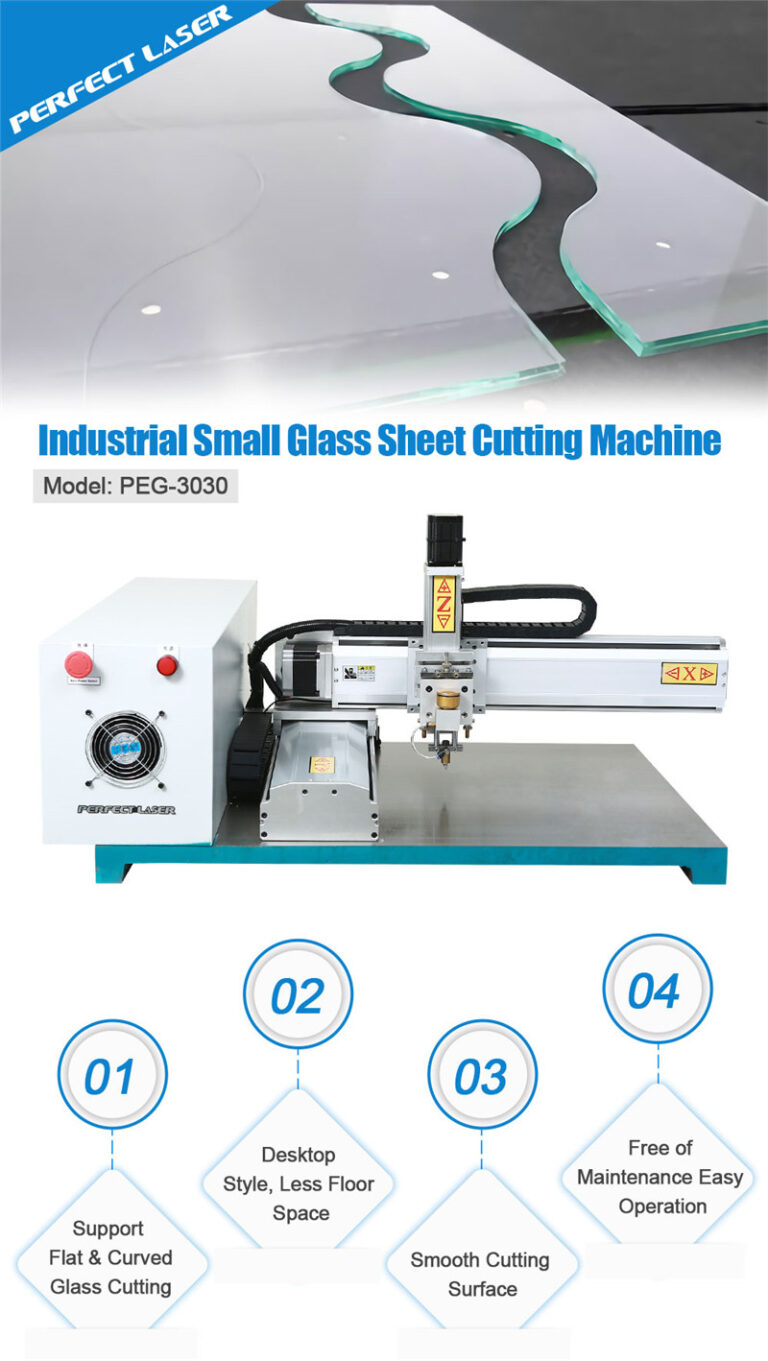

Scenario 3: Difficulty in Eyelet Installation and Maintenance

The Problem: B2B manufacturers may face challenges related to the installation and maintenance of shoelace eyelets, particularly when transitioning from manual to automated processes. Improper installation can lead to eyelet misalignment or damage, which not only affects the shoe’s functionality but can also lead to increased production costs due to waste and rework. Additionally, maintenance of eyelet integrity over time can be overlooked, leading to long-term product issues.

The Solution: To streamline the installation process, buyers should invest in advanced machinery that automates eyelet installation while ensuring precision. Semi-automatic eyelet machines can improve consistency and reduce the risk of human error during installation. Furthermore, implementing a regular maintenance schedule for eyelet inspection and replacement can help prolong the lifespan of the footwear. Training staff on proper lacing techniques and eyelet care can also enhance product longevity. By prioritizing these practices, manufacturers can ensure a more efficient production process while enhancing product quality and customer satisfaction.

Strategic Material Selection Guide for shoelace eyelet

What Materials Are Commonly Used for Shoelace Eyelets?

When selecting materials for shoelace eyelets, it is essential to consider their properties, advantages, and limitations to ensure optimal performance and suitability for various footwear applications. Below is an analysis of four common materials used in the production of shoelace eyelets.

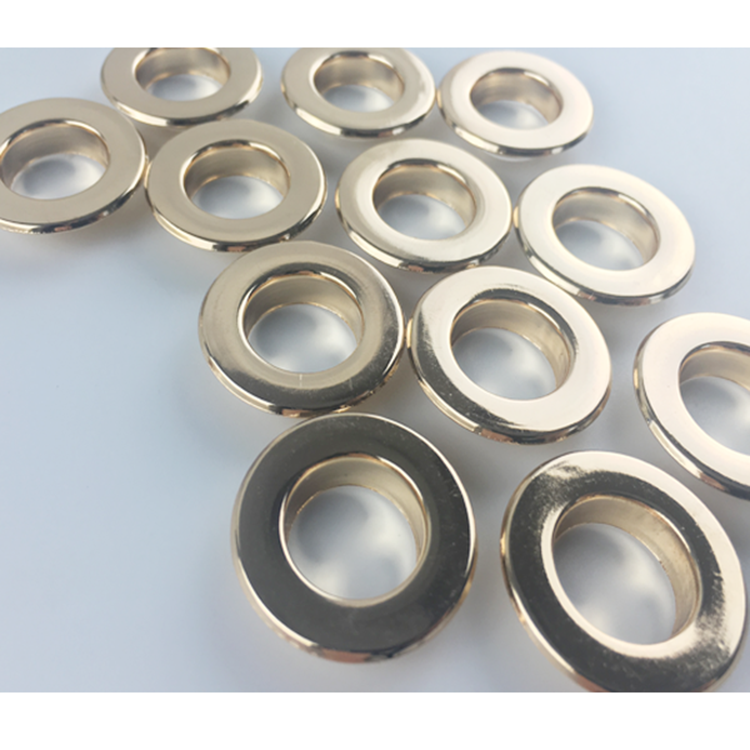

Illustrative image related to shoelace eyelet

How Does Metal Influence the Performance of Shoelace Eyelets?

Key Properties: Metal eyelets, typically made from brass, stainless steel, or aluminum, offer high strength and excellent corrosion resistance. They can withstand significant pressure and temperature variations, making them suitable for various environmental conditions.

Pros & Cons: The primary advantage of metal eyelets is their durability and longevity, which makes them ideal for heavy-duty applications like hiking boots and work shoes. However, they can be heavier than other materials, potentially affecting the overall weight of the footwear. Additionally, the manufacturing process can be more complex and costly due to the need for specialized tools for installation.

Impact on Application: Metal eyelets are particularly effective in environments where moisture is present, as they resist rust and corrosion. This makes them a preferred choice for outdoor and industrial footwear.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards for metal components, such as ASTM or DIN, to guarantee quality and safety.

What Role Do Plastic Eyelets Play in Footwear Design?

Key Properties: Plastic eyelets are lightweight and can be produced in various colors and designs. They typically offer moderate temperature resistance and are less prone to corrosion compared to metal.

Illustrative image related to shoelace eyelet

Pros & Cons: The main advantage of plastic eyelets is their cost-effectiveness and versatility in design, making them suitable for casual and athletic shoes. However, they may not provide the same level of durability as metal, especially in high-stress applications. Additionally, they can warp under extreme temperatures.

Impact on Application: Plastic eyelets are commonly used in running shoes and casual footwear, where weight savings and aesthetic appeal are priorities.

Considerations for International Buyers: Buyers should be aware of the varying quality standards for plastics in different regions, particularly in Europe, where regulations on chemical content can affect material selection.

How Do TPU Eyelets Enhance Performance in High-End Footwear?

Key Properties: Thermoplastic polyurethane (TPU) eyelets are known for their elasticity, abrasion resistance, and ability to maintain structural integrity under stress. They also exhibit excellent temperature and chemical resistance.

Pros & Cons: TPU eyelets are highly durable and suitable for high-performance athletic footwear, providing a balance between flexibility and strength. However, they are generally more expensive than plastic and may require more complex manufacturing processes.

Impact on Application: These eyelets are ideal for specialized footwear designed for sports and outdoor activities, where performance and durability are critical.

Considerations for International Buyers: Buyers should verify compliance with specific performance standards relevant to athletic footwear in their regions, such as JIS in Japan or EN standards in Europe.

Illustrative image related to shoelace eyelet

What Are the Benefits of Fabric Eyelets in Casual Footwear?

Key Properties: Fabric eyelets are typically made from woven materials or reinforced fabrics, providing a softer touch and aesthetic appeal. They are less durable than metal or TPU but can be designed to match the shoe’s upper material.

Pros & Cons: The advantage of fabric eyelets is their lightweight nature and ability to blend seamlessly with the shoe design, making them popular in casual and fashion-forward footwear. However, they may not withstand heavy wear and tear as effectively as other materials.

Impact on Application: Fabric eyelets are best suited for casual shoes and sneakers, where style and comfort are prioritized over extreme durability.

Considerations for International Buyers: When sourcing fabric eyelets, buyers should consider the environmental impact of the materials and ensure compliance with sustainability standards that are increasingly important in markets like Europe.

Summary Table of Material Selection for Shoelace Eyelets

| Material | Typical Use Case for shoelace eyelet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Metal | Heavy-duty footwear (hiking boots, work shoes) | High durability and corrosion resistance | Heavier and more complex to manufacture | High |

| Plastic | Casual and athletic shoes | Lightweight and cost-effective | Less durable, may warp under heat | Low |

| TPU | High-performance athletic footwear | Excellent flexibility and abrasion resistance | More expensive and complex to produce | Medium |

| Fabric | Casual shoes and sneakers | Aesthetic appeal and lightweight | Less durable than other materials | Low |

This strategic material selection guide provides B2B buyers with essential insights into the various materials used for shoelace eyelets, enabling informed decisions that align with their product requirements and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for shoelace eyelet

What Are the Key Stages in the Manufacturing Process of Shoelace Eyelets?

The manufacturing process for shoelace eyelets typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage plays a critical role in ensuring that the final product meets the quality standards expected by B2B buyers.

How Is Material Prepared for Shoelace Eyelet Production?

Material preparation begins with the selection of suitable materials, which can be metal, plastic, or other composites, depending on the intended application. For metal eyelets, materials such as brass, aluminum, or stainless steel are common, chosen for their strength and resistance to corrosion. In contrast, plastic eyelets are often made from high-density polyethylene (HDPE) or thermoplastic polyurethane (TPU), providing flexibility and durability.

Once the material is selected, it is cut into appropriate shapes and sizes for eyelet production. This may involve sheet metal cutting for metal eyelets or injection molding for plastic versions. Proper handling and storage of materials are crucial to avoid contamination or damage that could affect the eyelet’s performance.

What Techniques Are Used for Forming Shoelace Eyelets?

The forming stage involves shaping the prepared materials into eyelets. For metal eyelets, techniques such as stamping or die-casting are commonly used. These methods allow for high-speed production while maintaining precision in dimensions and tolerances.

Plastic eyelets, on the other hand, typically undergo injection molding. This process involves melting plastic pellets and injecting the molten material into a mold, where it cools and solidifies into the desired shape. Advanced molding techniques can also incorporate features like reinforcement ribs or specific surface textures to enhance functionality.

How Are Shoelace Eyelets Assembled and Finished?

Assembly may involve additional steps, particularly for reinforced eyelets that require the attachment of metal or plastic grommets. Automated assembly lines are often employed to ensure consistent quality and efficiency. The eyelets may also undergo surface treatments, such as anodizing for metal parts or UV coating for plastics, to enhance durability and aesthetic appeal.

Finishing touches often include quality checks and cleaning processes to remove any residues from production. This ensures that the eyelets are free from defects and ready for packaging.

What Are the International Standards for Quality Assurance in Eyelet Manufacturing?

Quality assurance is paramount in the manufacturing of shoelace eyelets, and several international standards govern this process. ISO 9001 is a widely recognized quality management standard that outlines the requirements for a quality management system (QMS). Companies that comply with ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

Additionally, industry-specific standards, such as CE marking for products sold within the European Economic Area, ensure that eyelets meet safety, health, and environmental protection requirements. Other relevant certifications may include API (American Petroleum Institute) for specialized applications in industrial sectors.

What Are the Key Quality Control Checkpoints in Eyelet Production?

Quality control (QC) is integrated at various stages of the manufacturing process, with specific checkpoints established to monitor product quality.

-

Incoming Quality Control (IQC): This initial checkpoint verifies that the raw materials meet specified quality standards before they enter the production process. This may involve visual inspections, material testing, and verification of supplier certifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC checks ensure that production methods are followed correctly, and that any deviations from standards are identified and rectified immediately. This may include monitoring dimensions, tolerances, and surface finishes.

-

Final Quality Control (FQC): After production, FQC involves a thorough inspection of the finished eyelets. This may include functional testing, visual inspections for defects, and verification of compliance with international standards.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are several actionable steps:

-

Supplier Audits: Conducting audits of potential suppliers can provide insight into their manufacturing practices and quality control measures. This includes assessing their compliance with ISO 9001 and other relevant standards.

-

Requesting Quality Reports: Buyers should request detailed quality reports that outline the QC processes employed by the supplier. This documentation should include results from IQC, IPQC, and FQC, as well as any corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These inspections can be particularly valuable for verifying compliance with international standards.

What Common Testing Methods Are Used to Ensure Eyelet Quality?

Various testing methods are employed to ensure the quality of shoelace eyelets. Common methods include:

Illustrative image related to shoelace eyelet

-

Visual Inspection: A basic yet effective method for detecting surface defects, such as scratches, corrosion, or dimensional inaccuracies.

-

Mechanical Testing: This may include tensile strength tests to assess the eyelet’s ability to withstand pulling forces without deforming or breaking.

-

Corrosion Resistance Testing: For metal eyelets, testing for resistance to corrosion in various environments can ensure long-term durability, especially in humid or salty conditions.

-

Functional Testing: This involves assessing how well the eyelets perform in real-world applications, ensuring they can withstand the rigors of daily use.

How Do Quality Control Nuances Affect International B2B Buyers?

B2B buyers from different regions may face unique challenges regarding quality control. For example, differences in regulatory requirements can impact the types of certifications and quality standards that suppliers must adhere to. Buyers should be aware of these nuances and consider local regulations when selecting suppliers.

Additionally, cultural differences in business practices and communication can influence how quality issues are handled. Establishing clear communication channels and expectations regarding quality standards can help mitigate misunderstandings and ensure that both parties are aligned.

By understanding the manufacturing processes and quality assurance practices for shoelace eyelets, B2B buyers can make informed decisions when selecting suppliers, ultimately enhancing their product offerings and ensuring customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘shoelace eyelet’

This guide aims to provide international B2B buyers with a practical checklist for sourcing shoelace eyelets effectively. By following these steps, you can ensure that you procure high-quality eyelets that meet your specific needs and standards.

Step 1: Define Your Technical Specifications

Before you start sourcing, clearly outline the technical specifications for the eyelets you need. Consider factors such as material (metal, plastic, or fabric), size, and type (e.g., reinforced, hook, or hidden). Defining these specifications will help you narrow down potential suppliers and ensure that the products meet your quality standards.

Illustrative image related to shoelace eyelet

Step 2: Research Market Trends and Requirements

Understanding current market trends and regional requirements is vital for making informed sourcing decisions. Research the specific demands in your target markets—such as Africa, South America, the Middle East, and Europe—to identify popular eyelet types and materials. This insight will guide you in selecting products that resonate with your clientele.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure reliability and quality. Request company profiles, certifications, and case studies to gauge their experience and reputation in the industry. Focus on suppliers who have a proven track record in your target regions, as they will better understand local market dynamics.

Step 4: Request Samples for Quality Assessment

Once you have shortlisted suppliers, request samples of the eyelets you are interested in. This step is crucial for assessing the quality, durability, and suitability of the eyelets for your specific applications. Pay attention to details like the finish, reinforcement, and overall craftsmanship, as these factors can significantly affect the performance of the eyelets in your products.

Step 5: Check Compliance with Industry Standards

Ensure that the eyelets you are sourcing comply with relevant industry standards and regulations. This may include safety standards, environmental regulations, and quality certifications. Compliance not only protects your business from potential legal issues but also enhances your product’s credibility in the market.

Step 6: Negotiate Pricing and Terms

Once you have selected a supplier, engage in negotiations regarding pricing, payment terms, and delivery timelines. Be clear about your budget and ensure that you understand any additional costs, such as shipping or customs duties. Establishing favorable terms can improve your profit margins and streamline your procurement process.

Illustrative image related to shoelace eyelet

Step 7: Establish a Quality Control Process

Implement a quality control process to monitor the eyelets upon arrival. This could involve visual inspections, testing for durability, and ensuring that the products meet your technical specifications. Having a quality control mechanism in place will help you maintain high standards in your final products and avoid costly returns or complaints.

By following this checklist, you can navigate the sourcing process for shoelace eyelets efficiently, ensuring that you find the right products that align with your business needs and market demands.

Comprehensive Cost and Pricing Analysis for shoelace eyelet Sourcing

What Are the Key Cost Components in Sourcing Shoelace Eyelets?

When sourcing shoelace eyelets, understanding the cost structure is crucial for international B2B buyers. The primary components include:

-

Materials: The cost of materials varies significantly based on the type of eyelet. Metal eyelets, often used for their durability in boots and work shoes, typically incur higher material costs compared to plastic or fabric options. Material quality, including certifications like ISO or ASTM standards, can also impact pricing.

-

Labor: Labor costs encompass the workforce involved in manufacturing eyelets, including machine operators and quality control personnel. Regions with lower labor costs, such as parts of Southeast Asia, may offer competitive pricing, while countries with higher labor standards may see increased costs.

-

Manufacturing Overhead: This includes expenses related to facility operations, utilities, and equipment maintenance. Overhead can fluctuate based on location and the scale of production, with larger manufacturers often achieving economies of scale.

-

Tooling: The initial investment in tools and molds for producing eyelets can be significant, particularly for custom designs. This upfront cost is amortized over the production run, affecting per-unit pricing.

-

Quality Control (QC): Implementing stringent QC processes is essential to ensure that eyelets meet functional and aesthetic standards. The cost of QC can vary based on the complexity of the inspection processes and the level of certification required.

-

Logistics: Shipping and handling costs are critical, especially for international transactions. Factors such as distance, shipping method, and customs duties can substantially influence overall costs.

-

Margin: Suppliers will typically add a margin to cover their operational costs and profit. This margin can vary based on the supplier’s market position, service level, and the competitive landscape.

How Do Pricing Influencers Impact Shoelace Eyelet Sourcing?

Several factors can influence the pricing of shoelace eyelets, making it essential for buyers to consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs. Suppliers may offer discounts based on volume, incentivizing bulk purchases.

-

Specifications and Customization: Custom designs, finishes, or sizes can lead to increased costs due to additional tooling and production complexities. Buyers should balance the need for customization with budget considerations.

-

Material Quality and Certifications: Eyelets made from higher-quality materials or those with specific certifications will typically cost more. Buyers should weigh the benefits of quality against the associated costs.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with a proven track record may charge higher prices but offer better reliability and service.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can impact the total cost by defining responsibilities for shipping and customs. Different terms may lead to variations in pricing structures.

What Tips Can Help Buyers Negotiate Better Prices?

To ensure cost efficiency when sourcing shoelace eyelets, buyers should consider the following strategies:

-

Negotiate Terms: Engaging in open discussions about pricing and terms can lead to favorable outcomes. Suppliers may be willing to adjust prices based on long-term relationships or guaranteed order volumes.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on initial costs, buyers should consider the TCO, which includes maintenance, replacement, and shipping costs over the product’s lifecycle.

-

Research Market Trends: Understanding current market conditions and competitor pricing can provide leverage during negotiations. Buyers who are well-informed can advocate for better pricing.

-

Consider Local Suppliers: Sourcing from local suppliers may reduce shipping costs and lead times, enhancing overall efficiency and potentially lowering the total cost.

-

Flexibility in Specifications: Being open to alternative materials or designs can sometimes yield cost savings. Suppliers may have existing stock or capabilities that align with such flexibility.

Important Disclaimer on Pricing

Prices for shoelace eyelets can fluctuate based on market conditions, material availability, and other factors. It is essential for buyers to request quotes tailored to their specific needs and to factor in the potential for price changes in their budgeting processes.

Alternatives Analysis: Comparing shoelace eyelet With Other Solutions

Exploring Alternatives to Shoelace Eyelets: A Comparative Analysis

In the realm of footwear design, shoelace eyelets serve a crucial function by providing secure lacing options. However, there are alternative solutions that can achieve similar goals, each with its own set of advantages and drawbacks. This analysis will compare shoelace eyelets against two viable alternatives: hook-and-loop fasteners and elastic laces.

| Comparison Aspect | Shoelace Eyelet | Hook-and-Loop Fastener | Elastic Laces |

|---|---|---|---|

| Performance | High; allows for precise adjustment of fit | Moderate; limited adjustability compared to laces | High; offers flexibility and ease of use |

| Cost | Low to moderate; depends on material (metal vs. plastic) | Low; generally inexpensive | Moderate; higher initial cost but reusable |

| Ease of Implementation | Simple installation; requires basic tools | Easy; requires no special tools | Simple; typically no installation required |

| Maintenance | Moderate; may require replacement if damaged | Low; durable and requires little upkeep | Low; minimal maintenance needed |

| Best Use Case | Formal and athletic footwear | Casual and children’s shoes | Sports and casual footwear |

What Are the Benefits and Drawbacks of Hook-and-Loop Fasteners?

Hook-and-loop fasteners, commonly known as Velcro, provide a simple solution to secure footwear without the need for traditional laces. The primary advantage of this system is its ease of use, especially for children or individuals with mobility issues. It allows for quick adjustments and does not require tying, which can be a significant benefit in fast-paced environments. However, the performance may fall short compared to shoelace eyelets, as they offer limited adjustability and can wear out over time, losing their grip. They are best suited for casual and children’s footwear, where ease of use is a priority over performance.

How Do Elastic Laces Compare to Shoelace Eyelets?

Elastic laces are an innovative alternative that combines the functionality of traditional laces with the convenience of a slip-on shoe. They stretch to accommodate the foot, providing a comfortable fit without the need for constant re-tying. The initial investment in elastic laces can be higher than traditional eyelets, but they are reusable and offer significant time savings in lacing and un-lacing shoes. Elastic laces are particularly popular in athletic footwear, as they provide a snug fit that can enhance performance during activities. However, they may not deliver the same level of customization in fit as shoelace eyelets, making them less ideal for formal footwear.

How Should B2B Buyers Choose the Right Footwear Solution?

When selecting between shoelace eyelets and alternative fastening systems, B2B buyers should consider the target market and specific application of the footwear. For high-performance athletic shoes or formal designs, shoelace eyelets may be the best choice due to their durability and ability to allow precise fit adjustments. Alternatively, for children’s shoes or casual styles, hook-and-loop fasteners may offer the practicality and ease of use that consumers seek. Elastic laces serve as a versatile option for athletic and casual footwear, providing a balance of convenience and performance. Ultimately, the decision should align with the intended use, target audience, and desired price point to ensure the best fit for market demands.

Essential Technical Properties and Trade Terminology for shoelace eyelet

What Are the Key Technical Properties of Shoelace Eyelets?

Understanding the essential specifications of shoelace eyelets is crucial for B2B buyers, as these properties directly influence product quality, durability, and overall performance in various footwear applications. Here are the critical specifications to consider:

1. Material Composition

Eyelets are primarily made from materials such as metal (e.g., brass, stainless steel) or plastic (e.g., nylon, TPU). The choice of material affects not only the aesthetic appeal but also the durability and functionality of the eyelets. Metal eyelets generally offer higher strength and resistance to wear, making them suitable for heavy-duty footwear, while plastic eyelets are often used in lighter shoes.

2. Diameter and Hole Size

The diameter of the eyelet and the corresponding hole size are vital specifications that determine the compatibility with shoelaces. A precise fit ensures that laces can be threaded easily without excessive friction, which can lead to premature wear. For B2B buyers, understanding the required dimensions is essential to ensure that eyelets fit the intended shoe design and lacing system.

3. Reinforcement Type

Reinforced eyelets may include grommets or additional stitching that increases the strength and longevity of the eyelet. This is particularly important for high-performance or heavy-use footwear, where eyelet durability can significantly impact the shoe’s overall lifespan. Buyers should assess the reinforcement type based on the expected usage conditions of the footwear.

4. Tolerance Levels

Tolerance refers to the acceptable deviation from specified dimensions. In the context of shoelace eyelets, maintaining tight tolerance levels is critical for ensuring consistent quality across batches. For manufacturers, this means fewer defects and returns, while buyers benefit from reliable product performance and reduced replacement costs.

5. Finish and Coating

The finish of an eyelet (e.g., polished, matte, or coated) affects not only the visual appeal but also the corrosion resistance and overall durability. A proper finish can enhance the longevity of metal eyelets, making them suitable for various environmental conditions. Buyers should consider the finish that aligns with their product’s design and usage requirements.

What Are the Common Trade Terminology and Concepts Related to Shoelace Eyelets?

Familiarity with industry jargon is crucial for effective communication in B2B transactions. Here are some common terms you should know:

Illustrative image related to shoelace eyelet

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of shoelace eyelets, it indicates that the manufacturer produces eyelets specifically for brands that incorporate them into their footwear designs. This relationship is vital for ensuring quality and compatibility.

2. MOQ (Minimum Order Quantity)

MOQ specifies the minimum number of units that a supplier is willing to sell. Understanding MOQ is critical for buyers as it impacts inventory management and cost efficiency. Buyers should negotiate MOQs that align with their production needs while ensuring they can meet demand without excess stock.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers requesting pricing and terms for specific products or services. For shoelace eyelets, an RFQ would include details about material, dimensions, and quantities. This process helps buyers gauge market prices and supplier capabilities.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. They clarify who is responsible for shipping, insurance, and tariffs, which is essential for cost management. Understanding Incoterms is crucial for B2B buyers engaged in cross-border transactions involving shoelace eyelets.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the products. In the context of shoelace eyelets, shorter lead times can enhance supply chain efficiency and product availability. Buyers should inquire about lead times to align their production schedules accordingly.

Illustrative image related to shoelace eyelet

By comprehending these technical properties and trade terminology, B2B buyers can make informed decisions, ensuring they source the right shoelace eyelets for their footwear products.

Navigating Market Dynamics and Sourcing Trends in the shoelace eyelet Sector

What Are the Current Market Dynamics and Key Trends in the Shoelace Eyelet Sector?

The shoelace eyelet sector is experiencing significant transformation driven by several global factors. One of the primary market drivers is the increasing demand for customization in footwear. Consumers are seeking unique designs, prompting manufacturers to explore diverse materials and eyelet types. Countries such as Brazil and Vietnam are becoming manufacturing hubs, leveraging cost-effective labor and advanced technologies to produce high-quality eyelets.

Emerging B2B technology trends include the rise of automation in eyelet production. Automated eyelet machines streamline manufacturing processes, reducing production time and enhancing precision. Furthermore, digital platforms are facilitating better communication between suppliers and buyers, allowing for real-time updates on inventory and order status. This connectivity is particularly valuable for international buyers from regions like Africa and the Middle East, where traditional supply chain methods may pose challenges.

Another noteworthy trend is the shift towards lightweight and durable materials, such as thermoplastic polyurethane (TPU), which are being used for performance footwear. This shift not only meets the demands of athletic and casual shoe markets but also aligns with the growing emphasis on sustainability in manufacturing practices. As international buyers navigate these dynamics, understanding regional preferences and material innovations will be essential for making informed sourcing decisions.

How Important is Sustainability and Ethical Sourcing in the Shoelace Eyelet Sector?

Sustainability and ethical sourcing have become pivotal in the shoelace eyelet industry, reflecting broader trends across the global supply chain. The environmental impact of manufacturing processes is under scrutiny, with buyers increasingly prioritizing suppliers that adopt eco-friendly practices. This includes the use of recycled materials for eyelets and the reduction of waste during production.

Illustrative image related to shoelace eyelet

Ethical supply chains are crucial not only for compliance with international standards but also for building brand reputation. For B2B buyers, ensuring that suppliers adhere to fair labor practices and environmental regulations is essential. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX can serve as benchmarks for assessing the sustainability of materials used in eyelet production.

Furthermore, the demand for ‘green’ materials is rising, with buyers looking for eyelets made from biodegradable or recyclable substances. By aligning sourcing strategies with sustainability goals, companies can enhance their market position and appeal to environmentally conscious consumers.

What is the Evolution and History of Shoelace Eyelets in the Footwear Industry?

The shoelace eyelet has evolved significantly since its inception, reflecting advancements in both materials and manufacturing processes. Initially, eyelets were simple holes reinforced with stitching or rudimentary metal rings. As footwear design progressed, manufacturers began incorporating more durable materials like brass and aluminum, enhancing the functionality and aesthetic appeal of eyelets.

Illustrative image related to shoelace eyelet

The industrial revolution marked a turning point, with the introduction of machinery that allowed for mass production of eyelets. This shift not only improved consistency but also reduced costs, making it feasible for a wider range of footwear styles to incorporate eyelets. Today, innovations in materials such as TPU and the integration of automated processes continue to shape the industry, paving the way for more sophisticated and sustainable designs.

Understanding the historical context of shoelace eyelets can provide B2B buyers with valuable insights into current trends and future developments, enabling them to make informed decisions in their sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of shoelace eyelet

-

How do I choose the right material for shoelace eyelets?

Choosing the right material for shoelace eyelets depends on the intended use of the footwear. Metal eyelets are ideal for heavy-duty applications like boots due to their durability and resistance to wear. Plastic eyelets are suitable for lighter footwear, such as athletic shoes, where weight reduction is important. Additionally, consider environmental factors; for instance, metal can corrode in humid climates, while plastic may warp under extreme heat. Always align the eyelet material with the shoe’s design and functional requirements to ensure optimal performance. -

What is the best eyelet type for different shoe designs?

The best eyelet type varies based on the shoe design and its functional needs. For casual and formal shoes, basic or reinforced eyelets are often sufficient, providing a balance of durability and aesthetics. Athletic shoes benefit from hook eyelets, which allow for quick adjustments and secure fitting. For specialized footwear like hiking boots, reinforced eyelets are essential to withstand stress from rigorous use. Consider the shoe’s target market and performance requirements when selecting the appropriate eyelet type. -

How do I verify the quality of shoelace eyelets before purchasing?

To verify the quality of shoelace eyelets, request samples from potential suppliers to assess their durability, finish, and compatibility with your shoe designs. Conduct visual inspections for surface imperfections, and perform functional tests such as lacing to ensure smooth operation. Additionally, inquire about the supplier’s quality assurance processes and certifications to confirm that their products meet industry standards. Establishing a quality assurance protocol can help mitigate risks associated with defective products. -

What are the minimum order quantities (MOQs) for shoelace eyelets?

Minimum order quantities for shoelace eyelets can vary widely based on the supplier and the type of eyelet. Typically, MOQs range from 1,000 to 10,000 pieces, depending on material and customization options. Some suppliers may offer lower MOQs for standard products, while custom eyelets often require larger orders. It’s advisable to discuss your specific needs with suppliers to negotiate MOQs that align with your production schedules and budget constraints. -

What payment terms should I expect when sourcing shoelace eyelets internationally?

Payment terms for international purchases of shoelace eyelets often include options like upfront payment, partial payment upon order confirmation, and the balance before shipment. Common methods include wire transfers, letters of credit, and payment through escrow services for added security. It’s important to clarify payment terms during negotiations to avoid misunderstandings and ensure a smooth transaction. Always consider the financial stability of the supplier and the risks associated with international trade when finalizing payment arrangements. -

How do I navigate customs and logistics for importing shoelace eyelets?

Navigating customs and logistics for importing shoelace eyelets involves understanding the regulations of both the exporting and importing countries. Ensure you have all necessary documentation, including invoices, packing lists, and certificates of origin, to facilitate customs clearance. Partnering with a reliable freight forwarder can streamline the shipping process and help you manage tariffs and taxes effectively. Staying informed about trade agreements and regulations in your region can also prevent delays and additional costs. -

Can I customize shoelace eyelets for my brand?

Yes, many suppliers offer customization options for shoelace eyelets, allowing you to tailor colors, materials, sizes, and even branding elements like logos. Customization can enhance your product’s market appeal and align with your brand identity. When requesting customized eyelets, provide detailed specifications and consider lead times, as custom orders may take longer to produce. Communicate clearly with your supplier to ensure that your vision is accurately realized in the final product. -

What are the common defects to watch out for in shoelace eyelets?

Common defects in shoelace eyelets include surface corrosion (especially in metal eyelets), misalignment, cracks, and irregular sizing. These issues can affect the performance and aesthetic of the footwear. Conducting thorough inspections during quality checks can help identify these defects before production. Additionally, implementing a return policy with your supplier for defective products can safeguard your business against losses and ensure high-quality output in your shoe designs.

Top 9 Shoelace Eyelet Manufacturers & Suppliers List

1. Chicago School of Shoemaking – Sneaker Eyelets Only

Domain: chicagoschoolofshoemaking.com

Registered: 2011 (14 years)

Introduction: {“product_name”: “Sneaker or Shoe Eyelets Only”, “description”: “Best only used for leather, not fabric.”, “price”: “$8.00”, “pack_size”: “32 eyelets”, “hole_size”: “3/16th inch”, “metal_finish_choices”: [“White”, “Black”, “Brass”, “Antique Brass”, “Nickel”], “weight”: “0.03 lbs”, “dimensions”: “3 × 0.75 × 0.75 in”, “note”: “You’ll need an eyelet setter for a 3/16th eyelet. Eyelets are a one piece…

2. QCMachinery – Eyelets for Footwear

Domain: qcmachinery.com

Registered: 2014 (11 years)

Introduction: Eyelets on a shoe are reinforced holes, typically made of metal or plastic, through which shoelaces are threaded. They secure the fit of the shoe and adjust its tightness. Eyelets can be categorized into basic eyelets, reinforced eyelets, hook eyelets, and hidden eyelets. Basic eyelets are simple holes, reinforced eyelets feature grommets for added strength, hook eyelets allow for quick lacing, an…

3. Reddit – Shoelace Eyelet Reinforcement

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Shoelace eyelet reinforcement designed to prevent shoelace eyelets from ripping. Based on a bath curtain eyelet design, it distributes force to enhance durability. Customizable in OpenSCAD, with STL and SCAD files available on Thingiverse (https://www.thingiverse.com/thing:6657124). Features include a plastic washer securing the eyelet shaft outside the shoe and a larger washer inside for added se…

4. Heddels – Eyelets Explained

Domain: heddels.com

Registered: 2015 (10 years)

Introduction: Eyelets are holes in shoes for threading shoelaces, allowing for tightening. There are several types of eyelets, each with unique characteristics:

1. **Punched Eyelets**: The most common type, made by punching a hole through the shoe upper, often reinforced with metal. They can be visible or hidden, with hidden eyelets providing a cleaner aesthetic but being harder to adjust.

2. **Webbing Eyelet…

5. Brettuns Village – Precision Eyelets & Grommets

Domain: brettunsvillage.com

Registered: 1999 (26 years)

Introduction: Brettuns Village offers a variety of eyelets, lacing eyelets, grommets, and lacing hooks designed for precision crafting. These tools are essential for leather crafting, allowing enthusiasts and professionals to enhance their projects. The collection includes high-quality items that cater to different crafting needs, ensuring outstanding results in leather craftsmanship.

6. Ironlace – Unbreakable Boot Laces

Domain: ironlace.com

Registered: 2011 (14 years)

Introduction: Ironlace™ Unbreakable Boot Laces & Shoelaces – $15.99; Ironlace™ Paracord 550 Boot Laces and Shoelaces – $6.99; Unbreakable laces are 10x stronger than steel and 20x tougher than Kevlar.

7. Keene – Hiking Shoe Repair

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Repairing Ripped Hiking Shoe Fabric Eyelets; Tools required: Drill, Drill bit, Block of scrap wood; Brand mentioned: Keene boots; Warranty information: Keene has a warranty claim form on their website.

8. Fieggen – Straight Bar Lacing

Domain: fieggen.com

Registered: 1999 (26 years)

Introduction: Straight Bar Lacing is a shoelacing method characterized by horizontal “bars” on the outside and hidden verticals on the inside, providing a neat appearance and relieving pressure on the upper ridge of the foot. It is suitable for shoes with even numbers of eyelet pairs (e.g., 8 pairs = 16 eyelets) and can be adapted for odd numbers with workarounds. The method is also known as “Lydiard Lacing” af…

9. Weaver Leather Supply – Boot Hooks and Speed Lace Hooks

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Boot Hooks and Speed Lace Hooks – Weaver Leather Supply offers a variety of boot hook eyelets and speed laces essential for repair work. The products come in different sizes and styles to accommodate various repair needs. Key details include:

– **Sizes Available**: 1/4″, 3/8″, 1/2″, 5/8″, 3/4″.

– **Materials**: Solid Brass, Steel.

– **Color Options**: Antique Brass, Brass, Gunmetal, Nickel, Shiny…

Strategic Sourcing Conclusion and Outlook for shoelace eyelet

As the global footwear market evolves, the strategic sourcing of shoelace eyelets has become increasingly vital for manufacturers seeking to enhance product quality and consumer satisfaction. The choice of materials—be it durable metal, versatile plastic, or innovative TPU—directly impacts both the longevity of the footwear and the overall aesthetic appeal. Understanding the specific needs of different markets, particularly in Africa, South America, the Middle East, and Europe, can help buyers make informed decisions that align with regional preferences and performance requirements.

Investing in high-quality eyelets not only ensures better functionality and durability but also contributes to the brand’s reputation for quality. As trends shift towards sustainability and eco-friendly practices, sourcing eyelets from responsible manufacturers will play a key role in meeting consumer expectations.

To remain competitive, B2B buyers should prioritize strategic partnerships with suppliers who offer innovative solutions and reliable support. By staying ahead of industry trends and embracing advanced sourcing strategies, businesses can position themselves for success in the dynamic footwear landscape. Now is the time to evaluate your sourcing strategies and make decisions that will lead to long-term growth and profitability.

Illustrative image related to shoelace eyelet

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.