A B2B Buyer’s Guide to Shear Mixer Machine: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for shear mixer machine

In today’s competitive manufacturing landscape, sourcing the right shear mixer machine is crucial for companies aiming to enhance their production efficiency and product quality. With the increasing complexity of formulations and the demand for consistent results, international B2B buyers face the challenge of navigating a diverse market filled with varying technologies and suppliers. This guide is designed to simplify that journey, providing a comprehensive overview of shear mixer machines, including their types, applications across different industries, and critical factors to consider when vetting suppliers.

Within these pages, you will discover the essential features of high shear mixers, from laboratory models ideal for R&D to large-scale production units that optimize operational efficiency. We will delve into the specific applications relevant to various sectors, including food and beverage, pharmaceuticals, and cosmetics, ensuring that you can match the right equipment to your unique needs. Additionally, this guide addresses the cost implications and potential ROI of investing in shear mixing technology, empowering you to make informed purchasing decisions.

By equipping yourself with actionable insights and expert recommendations, you will be better positioned to select a shear mixer that not only meets your production demands but also aligns with your strategic business goals. Whether you’re operating in Africa, South America, the Middle East, or Europe, this guide serves as your roadmap to mastering the global market for shear mixer machines.

Understanding shear mixer machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High Shear Batch Mixer | Operates in batch mode, high-speed rotor/stator design | Pharmaceuticals, Food & Beverage, Cosmetics | Pros: Efficient mixing, reduced time; Cons: Limited to batch processing. |

| In-Line High Shear Mixer | Continuous flow, integrated into production lines | Chemical Processing, Paints & Coatings | Pros: High throughput, consistent results; Cons: Higher initial investment. |

| Laboratory High Shear Mixer | Designed for R&D, small-scale production, versatile configurations | Research & Development, Quality Control | Pros: Scalable, precise control; Cons: Limited capacity compared to industrial units. |

| Multi-Shaft Mixer | Multiple shafts for complex formulations, high viscosity handling | Adhesives, Sealants, Heavy Pastes | Pros: Excellent for viscous materials; Cons: More complex maintenance. |

| Flashmix Powder/Liquid Mixer | Rapid powder incorporation, ideal for high viscosity materials | Food Processing, Pharmaceuticals | Pros: Fast mixing, reduces agglomerates; Cons: May require specific setup for certain powders. |

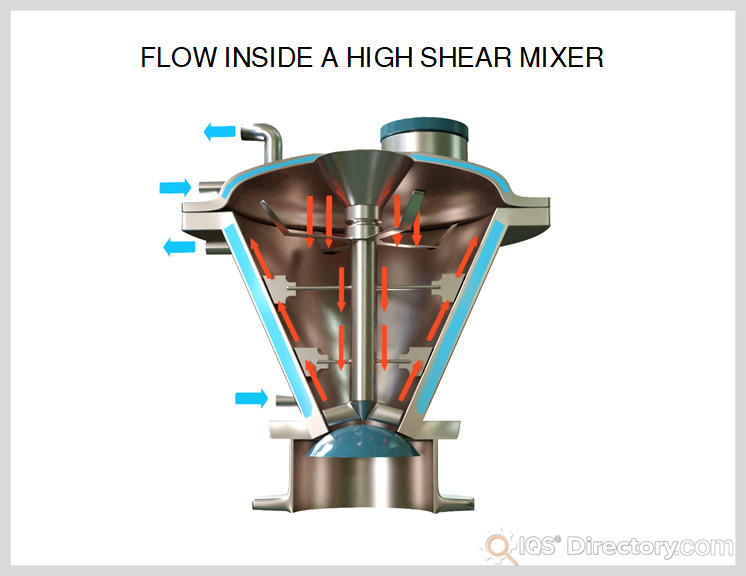

What are the characteristics of High Shear Batch Mixers?

High shear batch mixers are designed to operate in batch mode, utilizing a high-speed rotor and stator system to achieve rapid mixing and emulsification. They are particularly effective for applications requiring the reduction of particle size and the creation of stable emulsions. Industries such as pharmaceuticals, food and beverage, and cosmetics frequently utilize these mixers due to their efficiency in reducing mixing times and improving product quality. Buyers should consider their batch size requirements and the need for frequent changeovers when evaluating this type.

How do In-Line High Shear Mixers enhance production efficiency?

In-line high shear mixers facilitate continuous mixing by integrating seamlessly into production lines. Their design allows for consistent material flow, which is ideal for industries such as chemical processing and paints and coatings. The ability to maintain a steady output while ensuring uniform mixing makes these mixers a popular choice for large-scale operations. However, prospective buyers should assess the initial investment costs and the need for specialized installation, as these factors can impact overall budget and operational efficiency.

Why are Laboratory High Shear Mixers crucial for R&D?

Laboratory high shear mixers are specifically engineered for research and development purposes, allowing for small-scale production that can be easily scaled up. Their versatility in accommodating various vessel sizes and formulations makes them invaluable for R&D departments. These mixers provide precise control over mixing parameters, ensuring reproducibility in results. Buyers should prioritize features such as ease of cleaning, flexibility in configurations, and the ability to handle different materials when selecting a laboratory mixer.

What advantages do Multi-Shaft Mixers offer for complex formulations?

Multi-shaft mixers are designed to handle complex formulations, particularly those with high viscosity. They utilize multiple shafts to ensure thorough mixing and dispersion of ingredients, making them suitable for industries like adhesives, sealants, and heavy pastes. While they excel in achieving uniformity in challenging materials, buyers must consider the complexity of maintenance and the potential for longer cleaning times, which can affect production schedules.

How does the Flashmix Powder/Liquid Mixer improve processing times?

The Flashmix powder/liquid mixer is engineered for rapid incorporation of powders into liquids, making it particularly effective for high viscosity materials. This type of mixer is widely used in food processing and pharmaceuticals, where quick mixing and agglomerate-free results are essential. The ability to significantly reduce processing times can lead to enhanced operational efficiency. Buyers should evaluate the specific requirements for powder types and the setup needed to optimize performance when considering this mixer.

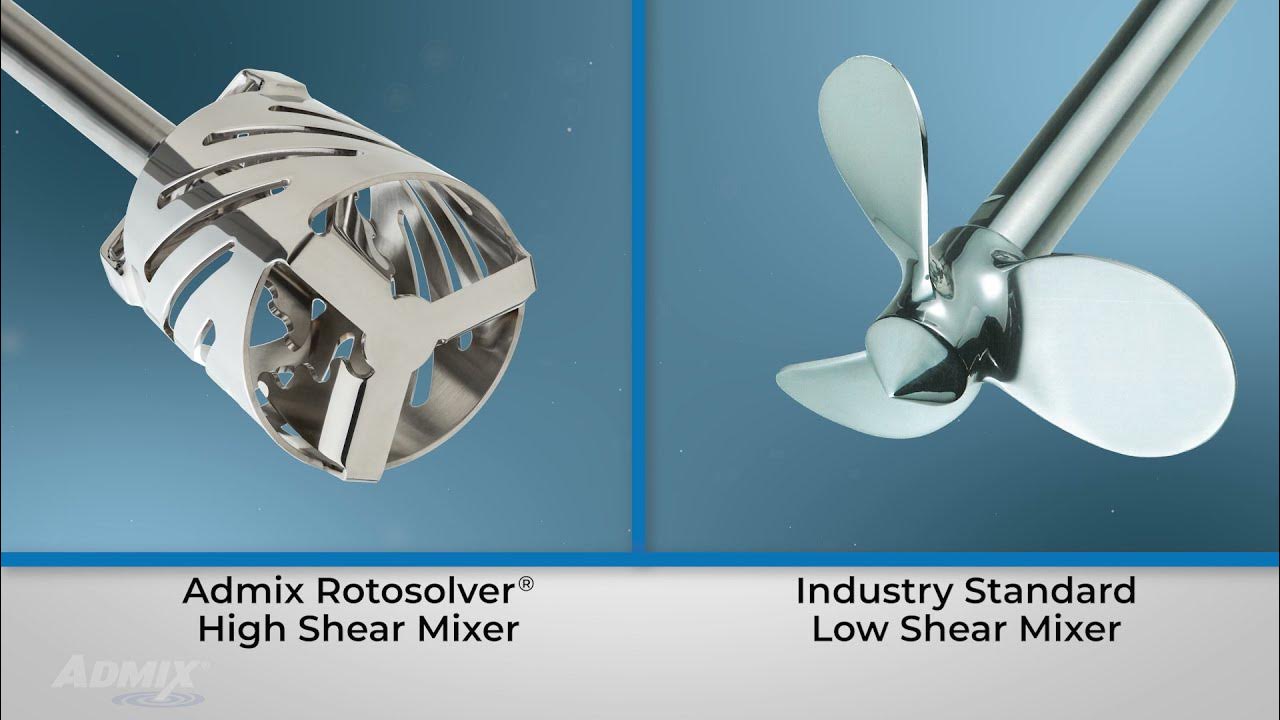

Illustrative image related to shear mixer machine

Key Industrial Applications of shear mixer machine

| Industry/Sector | Specific Application of shear mixer machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Emulsification of sauces and dressings | Improved product consistency and reduced processing time | Compliance with food safety standards and ease of cleaning |

| Pharmaceuticals | Homogenization of creams and ointments | Enhanced product stability and bioavailability | Need for sanitary design and regulatory compliance |

| Cosmetics | Mixing of emulsions for lotions and creams | Better texture and stability of cosmetic products | Material compatibility and customization options |

| Chemicals | Dispersing pigments in coatings | Improved color uniformity and reduced waste | Versatility for various viscosities and materials |

| Construction | Mixing of adhesives and sealants | Increased adhesion quality and reduced curing time | Ability to handle high-viscosity materials and large batches |

How Are Shear Mixer Machines Used in the Food and Beverage Industry?

In the food and beverage sector, shear mixer machines are primarily employed for emulsifying sauces, dressings, and other mixtures. They effectively blend oil and water-based ingredients, ensuring a stable emulsion. This process solves common issues like separation and inconsistent texture. For international buyers, particularly in emerging markets like Africa and South America, sourcing mixers that comply with local food safety regulations is crucial. Additionally, ease of cleaning and maintenance is a significant consideration, given the high standards for hygiene in food production.

What Role Do Shear Mixers Play in the Pharmaceutical Sector?

In pharmaceuticals, shear mixers are essential for the homogenization of creams, ointments, and suspensions. By reducing droplet size and ensuring uniform distribution, these machines enhance the stability and bioavailability of active ingredients. This is particularly important for international buyers who must meet stringent regulatory standards. Buyers should prioritize mixers with sanitary designs that facilitate easy cleaning and comply with GMP (Good Manufacturing Practice) requirements, especially in regions with strict health regulations.

How Are Shear Mixers Beneficial for Cosmetics Production?

Shear mixer machines are widely used in the cosmetics industry to create stable emulsions for lotions, creams, and other beauty products. By achieving a smooth and consistent texture, these mixers help manufacturers produce high-quality cosmetic formulations. For B2B buyers in Europe and the Middle East, selecting mixers that offer customization options for different formulations is vital. Additionally, the compatibility of materials used in the mixer with cosmetic ingredients is a critical factor to consider to prevent contamination.

Why Are Shear Mixers Important in Chemical Manufacturing?

In the chemical industry, shear mixers play a crucial role in dispersing pigments and additives in coatings and other formulations. The ability to achieve uniform color and consistency leads to enhanced product quality and reduced waste. For international buyers, especially in developing regions, the versatility of mixers to handle various viscosities and materials is essential. Buyers should also consider sourcing equipment that can accommodate large batch sizes to meet production demands efficiently.

How Do Shear Mixers Enhance Adhesive and Sealant Production?

Shear mixer machines are vital in the construction industry for mixing adhesives and sealants. They improve the quality of adhesion and reduce curing times, which can significantly impact project timelines. For B2B buyers, particularly in emerging markets, the ability to handle high-viscosity materials is crucial. When sourcing mixers, buyers should evaluate the equipment’s capacity for large batches and its efficiency in maintaining consistent quality throughout the mixing process.

3 Common User Pain Points for ‘shear mixer machine’ & Their Solutions

Scenario 1: Inconsistent Product Quality in High-Volume Production

The Problem: For manufacturers utilizing shear mixer machines, maintaining product consistency during high-volume production can be a significant challenge. Variability in raw material quality, temperature fluctuations, or improper machine settings can lead to inconsistent mixing results. This inconsistency may result in products that fail to meet quality standards, leading to customer dissatisfaction and costly reworks.

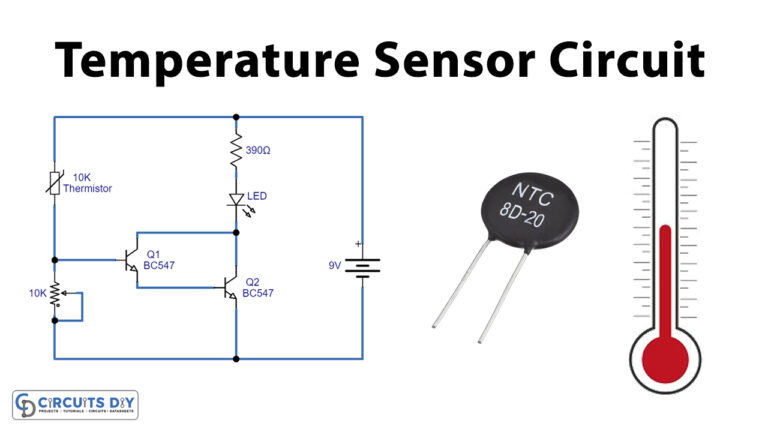

The Solution: To combat this issue, B2B buyers should invest in advanced shear mixer machines equipped with real-time monitoring and control features. Look for mixers that offer integrated sensors to monitor temperature, viscosity, and mixing speed. Utilizing a mixer with automated adjustments can help maintain optimal mixing conditions. Additionally, conducting regular training for operators on machine settings and maintaining a strict quality assurance protocol will ensure the production process remains efficient and consistent. Establishing a feedback loop between production data and quality control can also help in swiftly identifying and addressing any deviations.

Scenario 2: Difficulty in Scaling Up from Laboratory to Production

The Problem: Many manufacturers face difficulties when transitioning from laboratory-scale mixing to full-scale production. The shear mixer settings that work in a lab environment may not yield the same results when scaled up, leading to unexpected production issues such as poor emulsification or inadequate dispersion. This gap can result in significant delays and increased costs as companies struggle to find a solution.

The Solution: To ensure a smooth scale-up process, B2B buyers should select shear mixers that are designed for seamless transition from lab to production. Look for equipment that allows for consistent operation across different scales, such as mixers with similar rotor/stator designs and operational parameters in both environments. Utilizing pilot plants for initial trials can also provide valuable insights into how the mixing process will behave at larger scales. Additionally, consider partnering with manufacturers that offer technical support and consultation during the transition phase, ensuring that the equipment is properly calibrated and optimized for larger batches.

Scenario 3: High Operational Costs Due to Inefficient Mixing Processes

The Problem: High operational costs are a common concern for businesses utilizing shear mixer machines. Inefficient mixing processes can lead to longer cycle times, increased energy consumption, and the necessity for additional equipment to achieve desired results. These inefficiencies not only impact the bottom line but can also hinder competitiveness in the market.

The Solution: To reduce operational costs, B2B buyers should focus on acquiring high-efficiency shear mixers that can perform multiple functions, thus eliminating the need for separate machines. Look for models that reduce mixing times by up to 90% and have the ability to handle various formulations with ease. Implementing a preventive maintenance program can also prolong the lifespan of the equipment and ensure it operates at peak efficiency. Additionally, consider investing in training for staff on best practices for operating the mixer and optimizing its capabilities, which can further reduce waste and improve overall productivity.

Strategic Material Selection Guide for shear mixer machine

What Are the Key Properties of Stainless Steel for Shear Mixer Machines?

Stainless steel is a widely used material in the manufacturing of shear mixer machines due to its excellent properties. It offers high corrosion resistance, making it suitable for mixing a variety of media, including acidic and basic substances. The temperature and pressure ratings of stainless steel components are generally high, allowing for versatility in applications ranging from food processing to pharmaceuticals.

Pros and Cons: The durability of stainless steel is a significant advantage, as it can withstand harsh environments and mechanical wear. However, the cost is relatively high compared to other materials, which may impact initial investment budgets. Manufacturing complexity can also be a concern, as stainless steel components often require specialized machining and finishing processes.

Impact on Application: Stainless steel is compatible with a wide range of products, ensuring that it does not react adversely with the media being mixed. This makes it a preferred choice in industries where product purity is critical, such as food and pharmaceuticals.

Considerations for International Buyers: For buyers in regions like Africa, South America, the Middle East, and Europe, compliance with international standards such as ASTM and DIN is crucial. Additionally, buyers should consider local regulations regarding food safety and chemical handling, which may dictate the use of stainless steel in certain applications.

How Does Carbon Steel Compare for Shear Mixer Machines?

Carbon steel is another common material used in shear mixer machines, particularly for less corrosive applications. It has good tensile strength and can handle significant mechanical stress, making it suitable for heavy-duty mixing tasks.

Pros and Cons: The primary advantage of carbon steel is its cost-effectiveness, as it is generally cheaper than stainless steel. However, its susceptibility to corrosion limits its application in environments where moisture or aggressive chemicals are present. This can lead to increased maintenance costs over time.

Illustrative image related to shear mixer machine

Impact on Application: Carbon steel is best suited for mixing non-corrosive materials, such as certain polymers or dry powders. It may not be suitable for applications requiring stringent hygiene standards, such as food or pharmaceutical production.

Considerations for International Buyers: Buyers should be aware of local corrosion resistance standards and the potential need for protective coatings to extend the lifespan of carbon steel components. Additionally, understanding the local market’s acceptance of carbon steel in specific applications is vital.

What Role Does Plastic Play in Shear Mixer Machine Construction?

Plastics, particularly high-performance polymers, are increasingly being used in shear mixer machines for specific applications. These materials offer excellent chemical resistance and can be engineered to withstand a range of temperatures and pressures.

Pros and Cons: The lightweight nature of plastics can reduce overall equipment weight, making installation and maintenance easier. However, their durability may not match that of metals, and they can be more susceptible to wear and tear under high-stress conditions.

Impact on Application: Plastics are ideal for mixing aggressive chemicals or in environments where metal contamination is a concern. They are commonly used in industries such as cosmetics and pharmaceuticals, where purity is paramount.

Illustrative image related to shear mixer machine

Considerations for International Buyers: Buyers should ensure that the selected plastics meet international standards for chemical resistance and safety. Additionally, understanding the specific grades of plastics that comply with local regulations is essential for ensuring product quality.

How Do Alloys Enhance Shear Mixer Machine Performance?

Alloys, particularly those that combine metals like nickel or molybdenum with stainless steel, can significantly enhance the performance of shear mixer machines. These materials are designed to withstand extreme conditions, including high temperatures and corrosive environments.

Pros and Cons: The primary advantage of using alloys is their enhanced durability and resistance to wear and corrosion. However, they can be more expensive and may require specialized manufacturing processes, which can increase lead times.

Impact on Application: Alloys are particularly beneficial in industries such as petrochemicals and pharmaceuticals, where equipment must endure harsh conditions without compromising product integrity.

Considerations for International Buyers: Buyers should evaluate the specific alloy compositions and their compliance with international standards. Understanding local market preferences for specific alloys can also influence purchasing decisions.

Summary Table of Material Selection for Shear Mixer Machines

| Material | Typical Use Case for shear mixer machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food and pharmaceutical applications | High corrosion resistance | Higher initial cost | High |

| Carbon Steel | Heavy-duty mixing of non-corrosive materials | Cost-effective | Susceptible to corrosion | Low |

| Plastic | Cosmetics and chemical mixing | Lightweight and chemically resistant | Less durable under high stress | Medium |

| Alloys | Petrochemical and pharmaceutical industries | Enhanced durability and corrosion resistance | Higher cost and manufacturing complexity | High |

This guide provides actionable insights for international B2B buyers, helping them make informed decisions based on material properties, application suitability, and regional compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for shear mixer machine

What Are the Main Stages in the Manufacturing Process of Shear Mixer Machines?

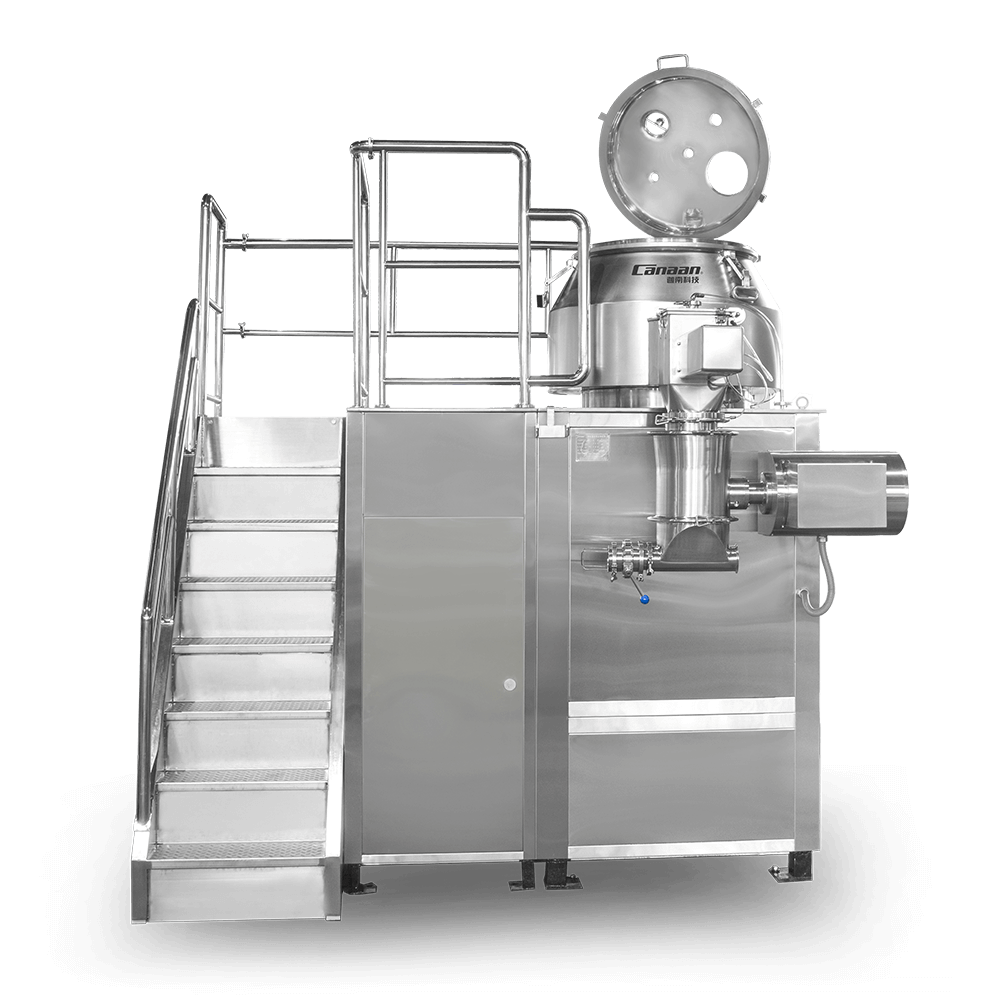

The manufacturing process of shear mixer machines involves several critical stages to ensure that the final product meets quality and performance standards. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Shear Mixer Machines?

The first step in the manufacturing process is material preparation. This involves selecting high-quality raw materials, typically stainless steel for wetted parts, which are essential for durability and corrosion resistance. Suppliers often conduct rigorous inspections of raw materials to ensure compliance with industry standards.

Illustrative image related to shear mixer machine

Once the materials are sourced, they undergo cutting and machining to create the necessary components like rotors, stators, and housings. Advanced CNC (Computer Numerical Control) machines are commonly used in this phase to achieve precise dimensions and tolerances, ensuring that each component fits together seamlessly.

What Techniques Are Employed in Forming Shear Mixer Components?

Forming techniques vary depending on the design specifications and the materials used. Common methods include:

- Casting: Often employed for complex shapes, casting allows for the production of intricate components like housings or frames.

- Forging: This technique is utilized for producing strong, durable parts, particularly those that require high strength-to-weight ratios, such as rotors.

- Machining: After initial forming, machining processes like milling and turning refine the components to exact specifications.

These techniques are essential for maintaining the quality and performance of the shear mixer machine, as any deviation can lead to inefficiencies in mixing operations.

How Are Shear Mixer Machines Assembled?

The assembly of shear mixer machines involves bringing together all the components manufactured in the earlier stages. This phase often includes several sub-steps:

- Component Inspection: Each part is thoroughly inspected for defects before assembly.

- Sub-Assembly: Smaller assemblies, such as rotor/stator combinations, are created before being integrated into the main unit.

- Final Assembly: The complete machine is assembled, ensuring that all components fit correctly and function as intended.

During assembly, manufacturers often employ jigs and fixtures to maintain accuracy and repeatability. This systematic approach helps in achieving a high level of consistency across multiple units.

What Are the Finishing Processes for Shear Mixer Machines?

Finishing processes are crucial for enhancing the aesthetic appeal and functional performance of shear mixer machines. These processes typically include:

- Surface Treatment: Techniques such as polishing, anodizing, or coating are used to improve corrosion resistance and reduce friction.

- Painting: Non-wetted parts may receive a protective paint finish to enhance durability.

- Quality Control Inspections: After finishing, each machine undergoes a final inspection to verify that it meets the required specifications and standards.

What Quality Assurance Measures Are Commonly Implemented?

Quality assurance (QA) is a vital aspect of the manufacturing process for shear mixer machines. Manufacturers often adhere to international standards such as ISO 9001, which provides a framework for quality management systems. Additionally, industry-specific certifications like CE (European Conformity) or API (American Petroleum Institute) may be pursued depending on the application of the mixers.

How Are Quality Control Checkpoints Established?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify defects early.

- Final Quality Control (FQC): Before shipping, each machine undergoes rigorous testing to confirm it meets performance and safety standards.

What Testing Methods Are Commonly Used for Shear Mixer Machines?

Testing methods for shear mixer machines can include:

- Performance Testing: Verifying mixing efficiency, speed, and capacity.

- Durability Testing: Assessing how well the machine withstands prolonged use and harsh conditions.

- Safety Testing: Ensuring that all safety features function correctly, including emergency shut-off mechanisms.

Such testing helps manufacturers provide evidence of product reliability and safety, which is crucial for B2B buyers.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, especially from regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential to mitigate risks. Here are actionable steps:

- Supplier Audits: Conducting on-site audits can provide insights into the supplier’s manufacturing processes, quality control measures, and overall operational efficiency.

- Requesting Quality Reports: Buyers should ask for detailed quality reports, including test results and compliance documentation with relevant standards.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control practices and product performance.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with international suppliers, B2B buyers should be aware of several nuances in quality control:

- Regulatory Compliance: Different regions have varying compliance requirements. Understanding local regulations is crucial for ensuring that products meet import standards.

- Cultural Differences: Approaches to quality assurance may differ by region. Building strong relationships with suppliers can help navigate these differences effectively.

- Logistics Considerations: Shipping and handling can affect product quality. Buyers should ensure that suppliers have robust logistics plans to mitigate potential damages during transit.

By understanding the manufacturing processes and quality assurance measures associated with shear mixer machines, international B2B buyers can make informed purchasing decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘shear mixer machine’

Introduction

This practical sourcing guide provides B2B buyers with a structured checklist for procuring shear mixer machines. Understanding the complexities of these machines and their applications is crucial to ensure that you select the right equipment for your specific needs, enhancing operational efficiency and product quality.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements for the shear mixer machine. Consider factors such as mixing capacity, viscosity of materials, and the specific processes (e.g., emulsifying, homogenizing) the mixer will perform.

– Capacity Needs: Determine the volume you will be mixing, as this influences the type and size of the machine required.

– Material Characteristics: Assess the properties of the materials to be mixed, including viscosity and temperature sensitivity.

Step 2: Research Market Options

Conduct thorough research on the available shear mixer machines in the market. Focus on reputable manufacturers and their product offerings, ensuring they align with your specifications.

– Product Range: Look for suppliers that offer a variety of models, including laboratory and industrial options.

– Innovation and Technology: Evaluate the technology used in their mixers, such as rotor/stator designs that enhance mixing efficiency.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions.

– Reputation and Experience: Assess how long the supplier has been in the market and their track record with shear mixers.

– Customer Testimonials: Seek feedback from existing customers regarding their experiences with both the equipment and customer service.

Step 4: Verify Compliance and Certifications

Ensure that the shear mixer machines comply with international quality and safety standards relevant to your industry. This is vital for legal compliance and operational safety.

– Certifications: Check for ISO certifications, CE marking, and any other relevant industry certifications that indicate quality and safety.

– Safety Standards: Verify that the equipment adheres to safety regulations applicable in your region, particularly in industries like food processing or pharmaceuticals.

Step 5: Request Demonstrations and Trials

Whenever possible, request product demonstrations or trials to assess the performance of the shear mixer machine firsthand. This allows you to evaluate the machine’s efficiency and suitability for your processes.

– Trial Runs: Understand if the supplier offers trial runs to see how the machine handles your specific materials.

– Performance Metrics: Pay attention to mixing times, consistency of results, and ease of operation during the demonstration.

Step 6: Compare Pricing and Terms

Once you have shortlisted potential suppliers, compare their pricing structures and terms of sale. This includes not only the initial purchase price but also maintenance, warranties, and support services.

– Total Cost of Ownership: Consider long-term costs including spare parts, service contracts, and energy consumption.

– Negotiation Opportunities: Don’t hesitate to negotiate terms, as suppliers may offer discounts for bulk purchases or long-term commitments.

Step 7: Finalize the Purchase and Prepare for Installation

After selecting the supplier, finalize the purchase agreement, ensuring all terms are clearly outlined. Prepare for the installation process by coordinating with the supplier regarding delivery and setup.

– Installation Support: Confirm if the supplier provides installation services or if you need to arrange for third-party assistance.

– Training: Ensure that training is included for your team to operate the machine effectively from the outset.

By following this checklist, B2B buyers can make informed decisions when sourcing shear mixer machines, ultimately enhancing their production capabilities and ensuring quality output.

Illustrative image related to shear mixer machine

Comprehensive Cost and Pricing Analysis for shear mixer machine Sourcing

When sourcing shear mixer machines, understanding the cost structure and pricing dynamics is crucial for B2B buyers. This section delves into the key components of costs, price influencers, and practical tips for negotiating and managing expenses effectively.

What Are the Key Cost Components of Shear Mixer Machines?

The cost structure of shear mixer machines typically comprises several essential components:

-

Materials: The primary materials include high-grade stainless steel, which ensures durability and resistance to corrosion. The quality and source of materials directly affect the overall cost, with premium materials leading to higher prices.

-

Labor: Labor costs encompass both skilled and unskilled workers involved in the manufacturing process. Skilled labor is necessary for assembly and quality control, impacting the overall pricing.

-

Manufacturing Overhead: This includes costs related to utilities, factory space, and equipment maintenance. Efficient manufacturing processes can reduce overhead costs, allowing suppliers to offer more competitive pricing.

-

Tooling: The initial investment in tooling and equipment is significant, especially for customized mixers. This cost is often amortized over the production volume, influencing the price per unit.

-

Quality Control (QC): Implementing rigorous QC measures ensures that the mixers meet industry standards and specifications. This adds to the cost but is essential for maintaining product quality and reliability.

-

Logistics: Shipping and handling costs can vary widely based on the destination, shipping method, and dimensions of the equipment. International shipping may involve additional tariffs and customs fees.

-

Margin: Suppliers include a margin to ensure profitability, which can vary based on competition, demand, and the supplier’s market positioning.

What Influences the Price of Shear Mixer Machines?

Several factors can influence the pricing of shear mixer machines:

-

Volume/MOQ: Suppliers often provide discounts for bulk purchases or higher minimum order quantities (MOQs). Understanding your volume requirements can lead to significant cost savings.

-

Specifications and Customization: Custom features, such as specialized rotor designs or additional functionalities, can increase costs. Buyers should evaluate the necessity of customizations against their budget and operational needs.

-

Material Quality and Certifications: Machines that meet specific certifications (e.g., ISO, CE) or utilize superior materials may command higher prices. Buyers should weigh the benefits of these certifications against the cost.

-

Supplier Factors: Established suppliers with a strong reputation may charge more due to perceived reliability and service support. Conversely, newer or less known suppliers might offer competitive pricing to gain market entry.

-

Incoterms: The terms of shipping and delivery (e.g., FOB, CIF) play a significant role in the total cost. Buyers should understand the implications of these terms on pricing and logistics.

What Tips Can Help Buyers Negotiate Better Prices?

B2B buyers should consider the following strategies to enhance cost-efficiency:

-

Negotiation: Engage in discussions with suppliers to explore flexible pricing options. Highlighting potential long-term relationships can motivate suppliers to offer better terms.

-

Total Cost of Ownership (TCO): Assess not just the purchase price but the TCO, which includes maintenance, operational costs, and potential downtime. A lower initial price may lead to higher long-term costs if quality is compromised.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of fluctuating exchange rates, import duties, and shipping costs. Conducting thorough market research can help in anticipating these variables.

-

Leverage Supplier Relationships: Building strong relationships with suppliers can lead to preferential pricing and terms. Regular communication and feedback can also improve service and support.

Disclaimer for Indicative Prices

It is essential to note that prices for shear mixer machines can vary widely based on the factors mentioned above. The costs outlined are indicative and should be confirmed with suppliers for accurate quotations.

Alternatives Analysis: Comparing shear mixer machine With Other Solutions

Understanding Alternatives to Shear Mixer Machines

In the realm of industrial mixing, shear mixer machines are recognized for their efficiency in achieving uniformity and consistency in various applications. However, B2B buyers often explore alternatives that may better suit their specific operational requirements or budget constraints. This section presents a detailed comparison of shear mixer machines against two viable alternatives: Inline Mixers and Batch Mixers.

Comparison Table

| Comparison Aspect | Shear Mixer Machine | Inline Mixer | Batch Mixer |

|---|---|---|---|

| Performance | High shear capability for emulsifying, dispersing, and homogenizing. | Continuous mixing ideal for large-scale operations with consistent flow. | Versatile, good for small to medium batches, but may be slower than shear mixers. |

| Cost | Generally higher initial investment due to advanced technology. | Moderate cost with lower operational costs due to continuous processing. | Lower initial cost, but potential higher labor and energy costs over time. |

| Ease of Implementation | Requires professional installation and calibration. | Often easier to integrate into existing lines with minimal disruption. | Simple setup, but may require more space and labor for loading/unloading. |

| Maintenance | Requires regular maintenance for optimal performance; parts can be costly. | Lower maintenance needs due to fewer moving parts. | Maintenance can be labor-intensive, especially for larger systems. |

| Best Use Case | Ideal for high-viscosity products and when uniformity is critical. | Best for continuous processes in large-scale production environments. | Suitable for diverse formulations and batch processes where flexibility is needed. |

Detailed Breakdown of Alternatives

Inline Mixers

Inline mixers offer continuous mixing capabilities, making them particularly advantageous for operations requiring constant production. They integrate seamlessly into existing production lines, allowing for minimal disruption during setup. The operational costs can be lower due to the elimination of batch processing times. However, they may not achieve the same level of shear as high shear mixers, which could impact the quality of certain emulsions or dispersions. Additionally, the initial investment is moderate, making them an attractive option for companies looking to balance performance and cost.

Batch Mixers

Batch mixers are a well-established solution in many industries, providing flexibility for mixing various formulations. They are generally more affordable upfront compared to shear mixers, making them appealing for smaller operations or startups. However, the slower mixing times and labor-intensive processes can lead to higher operational costs in the long run. Batch mixers may struggle with consistency, especially in larger batches where uniformity is crucial. They are best suited for applications where product variations are common, and the flexibility to switch between different formulations is necessary.

Illustrative image related to shear mixer machine

Conclusion: Choosing the Right Mixing Solution for Your Business

Selecting the right mixing technology is crucial for optimizing production efficiency and product quality. B2B buyers should consider not only the initial investment but also the operational costs, maintenance needs, and specific use cases of each solution. While shear mixer machines provide exceptional performance for high-viscosity applications, inline and batch mixers offer alternatives that may better align with certain production processes. Evaluating the unique requirements of your operation, including production scale, desired quality, and budget constraints, will guide you to the most suitable mixing solution for your business.

Essential Technical Properties and Trade Terminology for shear mixer machine

When considering a shear mixer machine for industrial applications, understanding its technical specifications and common trade terminology is crucial for making informed purchasing decisions. Here’s a breakdown of essential properties and terms that every B2B buyer should be aware of.

What are the Key Technical Specifications of Shear Mixer Machines?

1. Material Grade

The material grade of a shear mixer, typically stainless steel (such as type 316), is vital for durability and resistance to corrosion. This is particularly important in industries like food processing and pharmaceuticals, where hygiene and material integrity are paramount. High-quality materials ensure longevity and reduce the risk of contamination.

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. In shear mixers, precise tolerances are essential for maintaining consistent product quality. High tolerance levels allow for efficient mixing, minimizing the risk of agglomerates or incomplete emulsions, which can significantly affect product performance.

3. Motor Power and Speed Range

Motor power, often measured in horsepower (HP), and speed range (RPM) are critical for determining the mixer’s effectiveness. A higher motor power enables the machine to handle more viscous materials, while a variable speed control allows for flexibility in processing different formulations. This adaptability is crucial for businesses that require versatility in their production lines.

4. Batch Capacity

Batch capacity indicates the volume of material that can be processed in one cycle. Understanding the required batch size helps businesses choose a mixer that fits their production needs without incurring unnecessary downtime or inefficiencies. Selecting the right batch capacity can enhance operational efficiency and reduce production costs.

5. Energy Efficiency

Energy efficiency is becoming increasingly important in the manufacturing sector. A shear mixer that operates efficiently can lead to significant cost savings over time, particularly in energy-intensive industries. This not only impacts the bottom line but also aligns with sustainability goals, making it a critical consideration for modern businesses.

6. Safety Features

Safety features, such as emergency shut-off mechanisms and explosion-proof designs, are essential for protecting operators and equipment. Ensuring that a shear mixer complies with safety standards can help mitigate risks associated with high-speed operations, particularly in volatile environments.

What are the Common Trade Terms Related to Shear Mixer Machines?

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of shear mixers, understanding OEM relationships is important for buyers looking to ensure compatibility and quality of replacement parts or upgrades.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it affects inventory management and cash flow. Buyers should be aware of MOQs to negotiate better deals and ensure they are purchasing the right amount of equipment for their production needs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for a specific product or service. For shear mixers, submitting an RFQ can help buyers compare offers from different manufacturers, ensuring they receive competitive pricing and favorable terms.

4. Incoterms (International Commercial Terms)

Incoterms are international commercial terms that define the responsibilities of buyers and sellers regarding shipping and delivery. Understanding these terms is essential for international transactions, as they clarify who bears the risk and costs at various stages of the shipping process.

5. Lead Time

Lead time is the period between the initiation of an order and its completion. In the context of shear mixers, understanding lead times helps buyers plan their production schedules effectively. Longer lead times can impact operational efficiency, so it’s important to factor this into purchasing decisions.

6. Calibration

Calibration refers to the process of configuring an instrument to provide a result for a sample within an acceptable range. For shear mixers, proper calibration ensures accurate mixing and product quality. Buyers should ensure that their equipment can be easily calibrated or comes with calibration services to maintain optimal performance.

By familiarizing themselves with these technical specifications and trade terms, B2B buyers can make more informed decisions when selecting shear mixer machines, ensuring they meet their operational needs and enhance productivity.

Navigating Market Dynamics and Sourcing Trends in the shear mixer machine Sector

What Are the Key Trends Shaping the Shear Mixer Machine Market?

The shear mixer machine market is witnessing significant growth driven by several global factors. With the rise of automation and Industry 4.0, manufacturers are increasingly adopting high-shear mixing technology to enhance production efficiency and product quality. In regions such as Africa, South America, the Middle East, and Europe, there is a growing demand for versatile and scalable mixing solutions that can cater to diverse applications, from food and beverage to pharmaceuticals and cosmetics.

Emerging technologies, including IoT-enabled mixers and advanced process controls, are transforming how businesses approach mixing processes. These innovations allow for real-time monitoring and adjustments, leading to improved consistency and reduced waste. Additionally, international B2B buyers are seeking suppliers who can provide customization options to meet specific production needs, thereby enhancing their competitive advantage in local markets.

Another notable trend is the increasing focus on sustainability. Companies are prioritizing energy-efficient machines and sourcing practices that minimize environmental impact. As manufacturers strive for greener production methods, high-shear mixers that reduce processing times and energy consumption are becoming more attractive. This shift towards eco-friendly practices is particularly relevant for buyers in regions with stringent environmental regulations.

How Are Sustainability and Ethical Sourcing Impacting the Shear Mixer Machine Sector?

Sustainability and ethical sourcing are paramount concerns for international B2B buyers in the shear mixer machine sector. The environmental impact of manufacturing processes is under scrutiny, compelling companies to adopt practices that minimize their carbon footprint. High-shear mixers that utilize energy-efficient motors and reduce processing times are increasingly preferred, as they contribute to lower energy consumption and waste generation.

Moreover, ethical supply chains are becoming a critical factor in the purchasing decisions of B2B buyers. Companies are seeking partners who adhere to responsible sourcing practices, ensuring that raw materials are obtained from environmentally and socially responsible sources. Certifications such as ISO 14001 for environmental management and other green certifications signal a commitment to sustainability, making suppliers more appealing to conscientious buyers.

As consumers demand transparency regarding the environmental impact of products, manufacturers are compelled to showcase their sustainability efforts. Buyers are encouraged to engage with suppliers who can demonstrate a commitment to using eco-friendly materials and processes, thus aligning with the growing consumer preference for sustainable products.

What is the Evolution of Shear Mixer Machines in the B2B Landscape?

The evolution of shear mixer machines can be traced back to the early 20th century when mixing technology began to advance significantly. Initially, mixing processes were labor-intensive and relied heavily on manual labor and basic mechanical devices. However, as industries expanded and the demand for consistent product quality grew, there was a shift towards more sophisticated mixing technologies.

By the mid-20th century, high-shear mixers emerged, revolutionizing the way materials were processed. These machines utilized advanced rotor-stator designs to create intense shear forces, enabling the efficient mixing of viscous materials and the formation of stable emulsions. This innovation significantly improved production efficiency and product quality across various sectors, including food, pharmaceuticals, and cosmetics.

Illustrative image related to shear mixer machine

In recent years, the introduction of digital technologies has further transformed the shear mixer landscape. The integration of automation, IoT, and data analytics into mixing processes has provided manufacturers with unprecedented control over their operations. This evolution not only enhances productivity but also aligns with the industry’s growing emphasis on sustainability and ethical sourcing, ensuring that shear mixer machines remain at the forefront of modern manufacturing solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of shear mixer machine

-

How do I solve mixing inconsistencies in my production?

To address mixing inconsistencies, consider investing in a high shear mixer that is tailored to your specific application. These mixers are designed to provide intense hydraulic shear, ensuring uniformity in emulsions and dispersions. Conducting trials with different rotor/stator configurations can help identify the optimal setup for your materials. Additionally, maintaining consistent operational parameters, such as speed and temperature, will enhance the reliability of your mixing process. Consult with suppliers who offer testing and validation services to find the best solution for your needs. -

What is the best shear mixer for high-viscosity materials?

For high-viscosity materials, a high shear inline mixer is often the best choice. These mixers are engineered to handle thick substances by providing powerful shear forces that effectively break down agglomerates and ensure uniform mixing. Look for models with adjustable speed settings and interchangeable stators, which allow for flexibility in processing different formulations. It’s advisable to request product demonstrations or case studies from suppliers that highlight their mixers’ performance with similar applications. -

How can I evaluate suppliers of shear mixer machines?

When evaluating suppliers, consider their industry experience, customer testimonials, and case studies that demonstrate their mixers’ effectiveness. Look for manufacturers that provide comprehensive support, including installation, training, and maintenance services. Verify their quality assurance processes and compliance with international standards. Additionally, assess their ability to customize solutions based on your specific needs and ensure they have a reliable supply chain for timely delivery. -

What customization options are available for shear mixers?

Most reputable manufacturers offer customization options to tailor mixers to specific applications. This may include modifications to rotor/stator designs, materials of construction, and size variations. Additional features like variable speed controls, temperature monitoring, and integrated data logging can enhance functionality. Discuss your requirements with suppliers to explore available customizations that align with your production goals. -

What are typical minimum order quantities (MOQs) for shear mixers?

Minimum order quantities for shear mixers can vary widely depending on the manufacturer and the complexity of the machine. Some suppliers may offer lower MOQs for standard models, while customized machines might require larger orders. It’s important to clarify MOQs during negotiations and see if the supplier can accommodate your budget and production schedule. Engaging in direct discussions with manufacturers can often lead to more flexible terms. -

What payment terms should I expect when purchasing shear mixers?

Payment terms for shear mixers can differ based on the supplier’s policies and the size of the order. Common arrangements include a deposit upfront, with the balance due upon delivery or installation. Some suppliers may offer financing options or extended payment plans for larger purchases. Always ensure that payment terms are clearly outlined in the contract to avoid misunderstandings. -

How do I ensure quality assurance for my shear mixer machine?

To ensure quality assurance, request detailed documentation of the manufacturing process, including quality control measures and testing protocols. Look for certifications that demonstrate compliance with international standards, such as ISO or CE. Additionally, inquire about the warranty and after-sales support provided by the supplier. A reputable manufacturer will be transparent about their quality assurance practices and willing to provide references from other satisfied clients. -

What logistics considerations should I keep in mind when importing shear mixers?

When importing shear mixers, it’s crucial to understand shipping logistics, including freight costs, customs duties, and delivery timelines. Partner with a logistics provider experienced in handling industrial machinery to streamline the import process. Ensure that the supplier provides all necessary documentation for customs clearance, such as invoices and certificates of origin. Planning for potential delays and having a clear communication channel with the supplier can mitigate risks associated with international shipping.

Top 4 Shear Mixer Machine Manufacturers & Suppliers List

1. Silverson – High Shear Mixers

Domain: silverson.com

Registered: 1996 (29 years)

Introduction: High Shear Mixers from Silverson include a versatile lineup suitable for various applications from laboratory to production scale. Key products include: 1. **Laboratory Mixers** – Ideal for R&D, capable of mixing, emulsifying, homogenizing, disintegrating, and dissolving. 2. **Batch Mixers** – Designed to reduce mixing times by up to 90%. 3. **In-Line Mixers** – High Viscosity and Ultra Sanitary o…

2. GEA – High Shear Mixers

Domain: gea.com

Registered: 1995 (30 years)

Introduction: GEA offers a range of high shear mixers designed for efficient mixing and high-quality end products. Key products include: 1. GEA BATCH FORMULA® MIN High Shear Mixer – A semi-automatic, compact system for dairy, beverage, plant-based beverage, and liquid food applications. 2. GEA BATCH FORMULA® PRO High Shear Mixer – Available with or without vacuum, optimizing mixing and process times for applica…

3. Dayton – High Shear Mixer Listings

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: High Shear Mixer listings on eBay include various models and specifications. Key details extracted include: 1. Brands: Dayton, various unnamed brands. 2. Conditions: New (1,075 items), Used (82 items). 3. Price Range: Under $900.00, $900.00 to $2,880.00, Over $2,880.00. 4. Features: Mobile carts, emulsifying capabilities, various power ratings (e.g., 15 HP, 300W, 1.5KW), RPM ranges (e.g., 200-1100…

4. Quadro Liquids – High Shear Mixers

Domain: quadroliquids.com

Registered: 2014 (11 years)

Introduction: Industrial High Shear Mixers are versatile and reliable equipment designed for powder dispersion into liquids, liquid mixing, homogenization, and emulsifying. Key features include:

– High shear inline mixers that reduce particle size to submicron levels for consistency and optimal performance.

– Proven to reduce batch times, maximize raw ingredient utilization, decrease energy expenditure, and m…

Strategic Sourcing Conclusion and Outlook for shear mixer machine

In today’s competitive landscape, the strategic sourcing of shear mixer machines is pivotal for businesses aiming to enhance production efficiency and product quality. Buyers should prioritize high-performance mixers that not only reduce mixing times by up to 90% but also ensure consistent results across varying scales of production. Emphasizing the importance of reliability and versatility, companies are encouraged to invest in machinery that can adapt to diverse applications, thus eliminating the need for multiple dedicated devices.

As international markets, particularly in Africa, South America, the Middle East, and Europe, continue to expand, the demand for advanced mixing solutions will only grow. Strategic sourcing not only facilitates access to cutting-edge technology but also fosters partnerships with manufacturers renowned for their innovation and customer support.

Looking ahead, businesses must remain agile and proactive in their sourcing strategies. By leveraging expert insights and proven technologies, organizations can position themselves for sustainable growth and success in the global marketplace. Engage with trusted suppliers today to explore how shear mixer machines can transform your production processes and drive profitability in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.