A B2B Buyer’s Guide to Rice Strainer: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for rice strainer

In an increasingly competitive global market, sourcing high-quality rice strainers can pose significant challenges for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. Understanding the nuances of this essential kitchen tool—from material selection to functionality—can be the key to enhancing operational efficiency and customer satisfaction. This guide offers a comprehensive exploration of rice strainers, covering various types, applications, and innovative designs, while also providing insights on supplier vetting and cost considerations.

International buyers will benefit from a detailed examination of the market landscape, including emerging trends that influence purchasing decisions. With a focus on practical applications, this guide empowers businesses to make informed choices that align with their operational needs and customer expectations. Whether you are looking to equip a bustling restaurant in Brazil or a catering service in Saudi Arabia, understanding the diverse offerings available will ensure you select the right rice strainer for your specific requirements.

By leveraging this guide, B2B buyers can navigate the complexities of sourcing rice strainers with confidence, ensuring they procure products that not only meet quality standards but also contribute to the overall success of their culinary operations.

Understanding rice strainer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fine Mesh Strainer | Made from stainless steel; small mesh for fine straining | Restaurants, catering services, food processing | Pros: Excellent for precision; durable. Cons: May clog with small particles. |

| Colander | Generally larger, with wider holes for draining | Food preparation, commercial kitchens | Pros: Versatile; easy to clean. Cons: Not ideal for fine straining. |

| Rice Washing Basket | Specifically designed for rinsing rice | Asian restaurants, catering businesses | Pros: Efficient for rice; prevents breakage. Cons: Limited to rice and grains. |

| Multi-Purpose Strainer | Versatile design for various foods; often collapsible | Food trucks, small eateries, home kitchens | Pros: Space-saving; multifunctional. Cons: May lack durability under heavy use. |

| Noodle Strainer | Deep, fine mesh for draining noodles | Asian cuisine restaurants, pasta shops | Pros: Ideal for high-volume tasks; heat-resistant. Cons: Size can be cumbersome for storage. |

What Are the Characteristics of Fine Mesh Strainers?

Fine mesh strainers are typically crafted from durable stainless steel, featuring a tightly woven mesh that allows for precision straining. They are ideal for draining small particles, making them essential in professional kitchens where clarity in liquids is paramount. B2B buyers should consider the mesh size, as finer meshes are better suited for delicate tasks but may require more cleaning effort. Their durability makes them a worthwhile investment for food processors and catering services.

How Do Colanders Differ from Other Strainers?

Colanders are larger and designed with wider holes, making them perfect for draining pasta, vegetables, and other bulk foods. They offer versatility in food preparation, which is beneficial for commercial kitchens and restaurants. When purchasing, B2B buyers should assess the material (plastic or stainless steel) for durability and ease of cleaning. Colanders are user-friendly but may not perform well for tasks requiring fine straining.

Why Use a Rice Washing Basket?

Rice washing baskets are specifically designed for rinsing rice, featuring a design that prevents grains from slipping through while allowing excess water to drain efficiently. This type of strainer is particularly relevant for businesses specializing in Asian cuisine, where rice is a staple ingredient. Buyers should evaluate the basket’s material and size to match their operational needs, ensuring they can wash rice without damaging the grains.

What Makes Multi-Purpose Strainers Ideal for Small Businesses?

Multi-purpose strainers are designed for versatility, allowing them to handle various foods, from vegetables to pasta. They often feature collapsible designs, making them ideal for small kitchens or food trucks where space is limited. B2B buyers should consider the strainer’s capacity and material, as these factors influence durability and usability in a fast-paced environment. While they are convenient, some may sacrifice strength for multifunctionality.

How Do Noodle Strainers Serve Unique Culinary Needs?

Noodle strainers are characterized by their deep design and fine mesh, specifically made for draining noodles efficiently. They are essential in establishments focusing on Asian cuisine, where noodle dishes are prevalent. Buyers should look for heat-resistant materials to ensure longevity under high-temperature conditions. While they provide excellent functionality, their size may pose storage challenges in smaller kitchen spaces.

Key Industrial Applications of rice strainer

| Industry/Sector | Specific Application of Rice Strainer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Washing and draining rice before processing | Ensures quality control by removing impurities and excess starch | Durability, ease of cleaning, and material safety certifications |

| Restaurant & Catering | Quick straining of rice for meal preparation | Increases efficiency in food prep, saving time and labor costs | Size, ease of use, and ability to withstand high temperatures |

| Retail & Wholesale | Bulk packaging of rice strainers for resale | Expands product offerings and meets diverse customer needs | Cost-effectiveness, variety in design, and market trends |

| Agriculture | Post-harvest processing of rice | Enhances product quality by removing debris and contaminants | Material durability and resistance to environmental factors |

| Domestic Kitchens | Everyday use for rinsing rice and other grains | Facilitates home cooking, promoting healthier meal options | Lightweight design, ease of storage, and aesthetic appeal |

How is a Rice Strainer Used in Food Processing?

In the food processing industry, rice strainers play a crucial role in the washing and draining of rice before it undergoes further processing. This step is essential to ensure that impurities, dust, and excess starch are removed, which can significantly affect the quality of the final product. Buyers in this sector should prioritize strainers that are durable, easy to clean, and made from food-safe materials. Certifications for hygiene and safety are also vital, especially for international buyers in regions like Africa and the Middle East, where food safety regulations can be stringent.

Why are Rice Strainers Essential in Restaurant and Catering Services?

In restaurant and catering environments, efficiency is key. Rice strainers are utilized for quick and effective straining of rice, allowing chefs to prepare meals rapidly without compromising on quality. This application not only saves time but also reduces labor costs. For B2B buyers in this sector, considerations should include the size of the strainer to accommodate varying batch sizes and its ability to withstand high temperatures, as commercial kitchens often operate under rigorous conditions.

What Role do Rice Strainers Play in Retail and Wholesale?

Retailers and wholesalers can capitalize on the demand for rice strainers by offering them in bulk. This application allows businesses to expand their product offerings and cater to a wider range of customer needs. When sourcing rice strainers for resale, businesses should focus on cost-effectiveness and variety in design to attract different market segments. Keeping abreast of market trends and consumer preferences is crucial for optimizing inventory and sales strategies.

How do Rice Strainers Benefit Agriculture?

In agriculture, rice strainers are used during the post-harvest processing phase to enhance the quality of the rice by removing debris and contaminants. This application is critical for ensuring that the rice meets market standards and consumer expectations. Buyers in this sector need to consider the durability of the strainers, as they must withstand various environmental factors. Additionally, sourcing from reputable manufacturers who can provide reliable products is essential for maintaining quality in agricultural practices.

Why are Rice Strainers Important for Domestic Kitchens?

For everyday use, rice strainers are indispensable tools in domestic kitchens, aiding in the rinsing of rice and other grains. They facilitate home cooking by making the preparation process quicker and healthier. B2B buyers targeting the consumer market should look for lightweight designs that are easy to store and have aesthetic appeal to attract customers. Offering a range of colors and styles can also help in appealing to diverse consumer preferences, especially in markets across Europe and South America.

3 Common User Pain Points for ‘rice strainer’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Material for Rice Strainers

The Problem:

B2B buyers, particularly those sourcing kitchen equipment for restaurants or catering services, often face challenges in selecting the right material for rice strainers. With various options available—plastic, stainless steel, and bamboo—each material offers distinct advantages and disadvantages. Buyers may be concerned about durability, heat resistance, and ease of cleaning, which are essential for maintaining hygiene in a commercial kitchen. For example, plastic strainers may warp under high temperatures, while stainless steel options can be heavy and may not be suitable for all types of rice or cooking methods.

The Solution:

To effectively source rice strainers, buyers should conduct a thorough analysis of their specific kitchen needs and workflows. For high-volume kitchens, investing in stainless steel strainers is advisable due to their durability and ability to withstand high temperatures without warping. Buyers should look for options with a fine mesh to prevent rice grains from slipping through while ensuring easy cleaning. Furthermore, providing detailed specifications to suppliers, such as the required size, weight, and mesh type, can help in procuring the right product. Engaging in discussions with suppliers about the best materials for their unique cooking processes will facilitate informed decision-making.

Scenario 2: Inefficiency in Straining and Rinsing Rice

The Problem:

Many businesses encounter inefficiencies in the rice rinsing and straining process, leading to time wastage and decreased kitchen productivity. Traditional methods often involve multiple steps, which can be labor-intensive and slow. Additionally, using strainers that lack a stable design can result in spills and messy workspaces, further complicating the task.

The Solution:

To enhance efficiency, buyers should consider investing in self-standing rice strainers that allow for hands-free operation. These strainers can be placed directly over sinks or pots, facilitating easier rinsing and draining of rice. When selecting a strainer, look for models with ergonomic handles and anti-slip bases for stability. Buyers should also train kitchen staff on the optimal use of these strainers, emphasizing the importance of rinsing rice thoroughly to remove excess starch. Streamlining this process not only saves time but also improves overall kitchen hygiene and food quality.

Scenario 3: Ensuring Consistency in Rice Preparation

The Problem:

Inconsistent rice preparation can be a significant pain point for businesses, especially in restaurants where quality control is paramount. Variations in the rinsing process can lead to differences in texture and taste, ultimately affecting customer satisfaction. B2B buyers may struggle to find strainers that allow for consistent results, particularly when working with different rice types that require unique handling.

The Solution:

To achieve consistency, it is crucial to select rice strainers that are specifically designed for the type of rice being prepared. For instance, fine mesh strainers work well for smaller grains like basmati or jasmine, while larger holes may be suitable for thicker varieties. Buyers should implement standard operating procedures (SOPs) for rice preparation that include specific instructions on how to use the strainers effectively. This could involve training staff on the right rinsing times and techniques to ensure uniform quality across all servings. Additionally, investing in high-quality strainers that are easy to clean will help maintain their effectiveness over time, leading to better consistency in rice preparation.

Strategic Material Selection Guide for rice strainer

What Are the Key Materials Used in Rice Strainers?

When selecting a rice strainer for B2B applications, understanding the materials used is crucial for ensuring product performance, durability, and compliance with international standards. Below, we analyze four common materials—plastic, stainless steel, bamboo, and silicone—highlighting their properties, advantages, disadvantages, and considerations for international buyers.

How Does Plastic Perform as a Material for Rice Strainers?

Plastic is a widely used material for rice strainers, particularly in consumer-grade products. It is lightweight and resistant to moisture, making it suitable for various kitchen tasks.

- Key Properties: Plastic strainers can withstand temperatures up to 100°C (212°F) but may warp at higher temperatures. They are generally resistant to corrosion and do not rust.

- Pros & Cons: While plastic strainers are cost-effective and lightweight, they may not offer the same durability as metal options. They can be prone to scratches and discoloration over time, which may affect their aesthetic appeal.

- Impact on Application: Plastic strainers are suitable for rinsing rice, vegetables, and fruits but may not be ideal for high-temperature applications like boiling pasta.

- International Considerations: Buyers should ensure compliance with food safety regulations such as FDA or EU standards for food contact materials. Additionally, the recyclability of plastic may be a concern in regions focusing on sustainability.

What Advantages Does Stainless Steel Offer for Rice Strainers?

Stainless steel is often favored for its durability and resistance to high temperatures, making it a popular choice for both commercial and residential kitchens.

- Key Properties: Stainless steel strainers can withstand temperatures exceeding 200°C (392°F) and are resistant to corrosion, rust, and staining.

- Pros & Cons: They are highly durable and can last for many years, but they tend to be heavier and more expensive than plastic options. Manufacturing complexity can also increase costs due to the need for specialized equipment.

- Impact on Application: Stainless steel strainers are ideal for high-temperature applications and can handle boiling water, making them versatile for various culinary tasks.

- International Considerations: B2B buyers should look for compliance with ASTM and DIN standards for food-grade stainless steel. Countries in Europe and the Middle East may have specific regulations regarding the use of metals in food preparation.

How Does Bamboo Compare as a Material for Rice Strainers?

Bamboo is an eco-friendly alternative that has gained popularity for its sustainability and unique aesthetic.

- Key Properties: Bamboo strainers are lightweight and naturally resistant to moisture, but they are not as heat-resistant as metal options and can warp or crack under high temperatures.

- Pros & Cons: The primary advantage of bamboo is its sustainability and natural look, appealing to eco-conscious consumers. However, they may require more maintenance and are less durable than plastic or stainless steel.

- Impact on Application: Bamboo strainers are suitable for rinsing rice and vegetables but should not be used for boiling or high-heat applications.

- International Considerations: Buyers should verify that bamboo products meet international standards for sustainability and food safety. Certifications like FSC (Forest Stewardship Council) can enhance marketability in eco-friendly markets.

What Role Does Silicone Play in Rice Strainer Applications?

Silicone is a modern material that combines flexibility with heat resistance, making it an attractive option for various kitchen tools.

- Key Properties: Silicone strainers can withstand temperatures ranging from -40°C to 230°C (-40°F to 446°F), making them versatile for various cooking methods.

- Pros & Cons: They are flexible, easy to clean, and resistant to staining and odors. However, silicone can be more expensive than plastic and may not offer the same structural integrity as metal options.

- Impact on Application: Silicone strainers are ideal for both rinsing and steaming, making them suitable for diverse culinary applications.

- International Considerations: Buyers should ensure that silicone products comply with FDA and EU food safety standards. The perception of silicone as a premium material may also influence pricing strategies in different markets.

Summary of Material Selection for Rice Strainers

| Material | Typical Use Case for rice strainer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Rinsing rice, vegetables, and fruits | Lightweight and cost-effective | Less durable, prone to scratches | Low |

| Stainless Steel | Boiling and high-temperature tasks | Highly durable and heat-resistant | Heavier and more expensive | High |

| Bamboo | Rinsing rice and vegetables | Eco-friendly and sustainable | Less durable, requires maintenance | Medium |

| Silicone | Rinsing, steaming, and versatile use | Flexible and heat-resistant | More expensive, less structural integrity | Medium |

This comprehensive analysis should aid international B2B buyers in making informed decisions regarding material selection for rice strainers, ensuring they choose products that meet their specific operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for rice strainer

What Are the Key Stages in the Manufacturing Process of Rice Strainers?

The manufacturing of rice strainers involves several critical stages that ensure the final product meets the required quality and functionality standards. Understanding these stages can help B2B buyers select suppliers who adhere to best practices.

Material Preparation: Which Materials Are Commonly Used?

The first step in the manufacturing process is material preparation. Rice strainers are typically made from various materials, including:

- Stainless Steel: Known for its durability and resistance to corrosion, stainless steel is a popular choice for high-quality strainers. It can withstand high temperatures, making it ideal for kitchen use.

- Plastic: Lightweight and often more cost-effective, plastic strainers are easier to handle but may not be suitable for high-temperature applications.

- Bamboo: Eco-friendly and often used in traditional designs, bamboo strainers offer a unique aesthetic but may have limitations in durability compared to metal options.

Each material requires specific handling and processing techniques to ensure it meets the desired specifications.

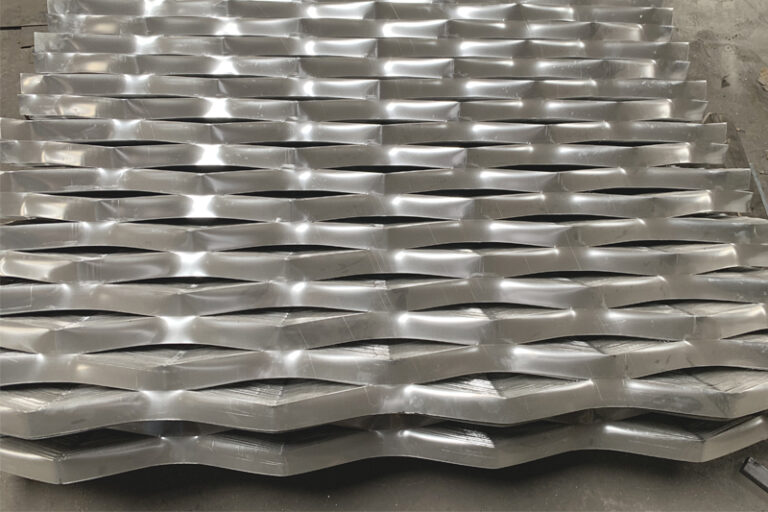

Forming: How Are Rice Strainers Shaped?

After materials are prepared, the next stage is forming. This involves shaping the materials into the desired strainer form. Common techniques include:

- Stamping: For metal strainers, stamping machines cut and shape sheets of metal into the required designs. This process ensures uniformity and precision.

- Injection Molding: For plastic strainers, injection molding is a common technique where heated plastic is injected into a mold to create the desired shape.

- Handcrafting: In some cases, particularly with bamboo or artisanal products, skilled craftsmen may shape the strainers by hand, allowing for unique designs but potentially leading to variations in quality.

Assembly: What Happens During the Assembly Process?

Once the components are formed, they undergo assembly. This stage typically includes:

- Joining Components: For multi-part strainers, components such as handles or grips are attached using welding, riveting, or adhesive bonding.

- Quality Checks: During assembly, initial quality checks (often referred to as In-Process Quality Control, or IPQC) are conducted to ensure that parts fit correctly and function as intended.

Finishing: What Are the Final Touches Applied?

The finishing stage focuses on enhancing the product’s appearance and functionality. Key processes include:

- Surface Treatment: This may involve polishing, coating, or painting to improve aesthetics and resistance to rust or scratches.

- Final Quality Control: Before packaging, strainers undergo Final Quality Control (FQC) to ensure they meet all specifications and standards.

How Is Quality Assurance Implemented in Rice Strainer Manufacturing?

Quality assurance is paramount in the manufacturing of rice strainers to ensure they meet international standards and buyer expectations. Below are the key components of quality assurance relevant to B2B buyers.

What Are the International Standards for Quality Control?

Many manufacturers adhere to international standards to assure quality. Key standards include:

- ISO 9001: This standard outlines requirements for a quality management system and focuses on consistent quality in products and services.

- CE Marking: Particularly important for products sold in Europe, CE marking indicates that the product meets EU safety, health, and environmental requirements.

Understanding these certifications can help buyers identify reputable suppliers.

What QC Checkpoints Should Buyers Be Aware Of?

Quality control is typically implemented at various checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): This involves regular inspections during the manufacturing process to catch defects early.

- Final Quality Control (FQC): Once production is complete, a final inspection is conducted to ensure all products meet quality standards before shipping.

What Testing Methods Are Commonly Used for Rice Strainers?

Different testing methods are employed to verify the quality and durability of rice strainers, including:

- Load Testing: Assessing the strainers’ ability to hold weight without deforming.

- Temperature Resistance Testing: Ensuring that materials can withstand high temperatures without degrading.

- Corrosion Resistance Testing: Particularly for metal strainers, this testing ensures that the material can resist rust and corrosion over time.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying the quality control processes of potential suppliers is crucial. Here are actionable strategies:

What Audits and Reports Should Buyers Request?

- Supplier Audits: Conducting or requesting third-party audits can provide insight into a manufacturer’s quality assurance processes.

- Quality Reports: Requesting detailed quality control reports can help buyers understand the supplier’s testing methodologies and results.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can provide an unbiased review of the manufacturing processes and quality control measures in place. This can be particularly beneficial when sourcing from international suppliers in regions such as Africa, South America, and the Middle East, where local regulations and standards may vary significantly.

What Are the QC and Certification Nuances for International Buyers?

B2B buyers from different regions should be aware of specific nuances related to quality control and certification:

- Regional Standards: Different countries may have unique standards and regulations that must be adhered to. Understanding these can prevent compliance issues.

- Cultural Considerations: Supplier interactions may vary culturally; building relationships can be as important as formal inspections.

By understanding the manufacturing processes and quality assurance protocols for rice strainers, B2B buyers can make informed decisions, ensuring they source high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rice strainer’

Introduction

In the competitive landscape of international trade, sourcing the right rice strainer is essential for businesses in the food service and culinary sectors. This guide provides a step-by-step checklist designed for B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. By following these steps, buyers can ensure they select the best products to meet their operational needs while maximizing value.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in sourcing a rice strainer. Consider factors such as size, material (e.g., stainless steel, plastic, bamboo), and design features (e.g., fine mesh, self-standing). These specifications will guide your search and help you communicate effectively with suppliers.

- Size Requirements: Determine the capacity needed for your operations, whether for small restaurants or large commercial kitchens.

- Material Considerations: Assess durability and resistance to corrosion, especially for high-volume use.

Step 2: Research Market Trends

Understanding current market trends can provide insights into popular products and innovative designs. Analyze competitors and market leaders to identify features that enhance usability and efficiency.

- Consumer Preferences: Investigate which types of strainers are preferred in your target markets, such as eco-friendly materials or ergonomic designs.

- Technological Advances: Look for products that incorporate modern technology, such as heat resistance or easy-clean features.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is crucial. Request company profiles, catalogs, and references from buyers in similar industries or regions. This step ensures you partner with reputable manufacturers.

- Certification Verification: Check for relevant certifications (e.g., ISO, HACCP) to ensure product quality and safety standards.

- Supplier Experience: Consider how long the supplier has been in the industry and their track record with international buyers.

Step 4: Request Samples

Always request product samples before making a bulk purchase. This allows you to assess the quality and performance of the rice strainer firsthand, ensuring it meets your specifications.

- Quality Assessment: Evaluate the durability, ease of use, and effectiveness of the strainer during testing.

- Fit for Purpose: Ensure the sample aligns with your intended use, whether for commercial kitchens or home applications.

Step 5: Compare Pricing and Terms

Once you’ve identified potential suppliers and evaluated samples, compare pricing and terms. Look beyond the initial cost; consider shipping, payment terms, and after-sales support.

- Total Cost of Ownership: Factor in maintenance and durability to gauge long-term value.

- Negotiation Opportunities: Engage in discussions to find mutually beneficial terms, especially for large orders.

Step 6: Finalize Your Order

After selecting the best supplier and confirming terms, finalize your order. Ensure all specifications and agreements are documented to avoid misunderstandings.

- Clear Documentation: Draft a purchase order that outlines all agreed-upon terms, including delivery schedules and warranty conditions.

- Communication Protocol: Establish clear lines of communication for updates and potential issues during fulfillment.

Step 7: Monitor Delivery and Quality Control

Upon receiving your order, conduct a thorough inspection of the products. Quality control is vital to ensure that the strainers meet your specifications and standards.

- Quality Check: Inspect for any damages or discrepancies against your order.

- Supplier Feedback: Provide feedback to the supplier, which can foster a better relationship for future transactions.

By following this checklist, B2B buyers can effectively navigate the sourcing process for rice strainers, ensuring they select high-quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for rice strainer Sourcing

What Are the Key Cost Components in Rice Strainer Manufacturing?

When sourcing rice strainers, understanding the cost structure is crucial for effective budgeting and procurement. The primary cost components include:

-

Materials: The choice of materials significantly impacts cost. Common options include plastic, stainless steel, and bamboo. Stainless steel is often favored for its durability and resistance to corrosion, but it comes at a higher price point compared to plastic.

-

Labor: Labor costs vary by region, influenced by local wage standards and the complexity of the manufacturing process. In regions with higher labor costs, such as Europe, manufacturers may use automation to offset expenses.

-

Manufacturing Overhead: This includes utilities, rent, and equipment maintenance. Efficient production processes can help minimize overhead costs, allowing suppliers to offer competitive pricing.

-

Tooling: Custom tooling for unique designs or specifications can incur significant upfront costs. However, these costs can be amortized over larger production runs, reducing the overall unit cost.

-

Quality Control (QC): Implementing robust quality control measures is essential, especially for products used in food preparation. The costs associated with QC processes can vary based on the complexity of the product and the required certifications.

-

Logistics: Shipping costs are influenced by the origin of the product, transportation method, and destination. International shipping can add significant costs, especially for bulk orders.

-

Margin: Supplier profit margins will vary based on market competition, brand reputation, and product differentiation. Understanding these margins is essential for negotiation.

How Do Price Influencers Affect Rice Strainer Sourcing?

Several factors can influence the pricing of rice strainers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should consider their demand forecasts to negotiate favorable pricing based on volume.

-

Specifications and Customization: Custom designs or additional features (e.g., ergonomic handles, specific mesh sizes) can lead to higher costs. Buyers should clearly define their requirements to avoid unexpected price increases.

-

Materials and Quality Certifications: Strainers made from higher-quality materials or those that meet specific safety and health certifications (e.g., FDA-approved) will command higher prices. Buyers must assess the necessity of these certifications based on their target market.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with proven track records may charge a premium, but they often provide better assurance of quality and service.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for cost management. Terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) can significantly influence the total landed cost of goods.

What Are Effective Buyer Tips for Cost-Efficient Rice Strainer Procurement?

To maximize value and minimize costs when sourcing rice strainers, consider the following strategies:

-

Negotiation: Engage in open discussions with suppliers about pricing, especially when placing large orders. Highlighting long-term relationships can often lead to better terms.

-

Cost-Efficiency: Look beyond the initial purchase price. Consider the Total Cost of Ownership (TCO), which includes maintenance, longevity, and potential replacement costs. Investing in higher-quality strainers may yield savings over time.

-

Pricing Nuances for International Buyers: Be aware of regional market trends and local competitors when negotiating prices. Understanding the economic climate in regions like Africa, South America, the Middle East, and Europe can provide leverage in negotiations.

-

Sample Testing: Request samples before committing to large orders. This allows buyers to assess quality and suitability, ensuring that the final products meet expectations.

Disclaimer on Indicative Pricing

Prices for rice strainers can vary widely based on the factors discussed above. The figures observed in market research may serve as a guide but should not be considered fixed. Buyers are encouraged to conduct thorough market analysis and engage directly with suppliers to obtain accurate pricing tailored to their specific needs.

Alternatives Analysis: Comparing rice strainer With Other Solutions

In the competitive landscape of kitchen equipment for food processing, understanding the alternatives to a rice strainer is crucial for B2B buyers. Various solutions exist to achieve similar results, each with its unique advantages and drawbacks. This analysis will compare the rice strainer with two viable alternatives: the colander and the specialized rice washing basket.

Comparison Table

| Comparison Aspect | Rice Strainer | Colander | Rice Washing Basket |

|---|---|---|---|

| Performance | Efficient in removing excess water; specifically designed for rice. | Versatile; suitable for various foods (e.g., pasta, vegetables). | Designed for thorough rinsing and washing of rice; prevents breakage. |

| Cost | Moderate cost (typically $20-$50). | Generally lower cost ($10-$30). | Similar to rice strainers ($15-$40). |

| Ease of Implementation | Simple to use; requires minimal setup. | User-friendly; widely available and easy to use. | Slightly more complex; may require specific techniques for optimal use. |

| Maintenance | Easy to clean; dishwasher safe. | Easy to clean; often dishwasher safe. | Requires careful cleaning to prevent mold; hand wash recommended. |

| Best Use Case | Ideal for specific rice dishes and quick straining. | Best for a variety of foods, especially in bulk cooking. | Perfect for traditional rice washing methods, ensuring quality. |

Detailed Breakdown of Alternatives

Colander

Colanders are versatile kitchen tools that can be used for various foods, making them a valuable asset in any kitchen. They are typically less expensive than specialized rice strainers and are easy to find. However, while they perform well for general straining, they may not be as effective for rice, which can slip through the holes or break. Colanders also lack the specific design features that enhance rice washing, such as finer mesh options.

Rice Washing Basket

Rice washing baskets are designed specifically for washing rice, providing a gentler method that reduces breakage. They allow for thorough rinsing, which is essential for removing excess starch and improving the quality of the rice. While they are generally priced similarly to rice strainers, they may require a bit more technique to use effectively. Maintenance can be slightly more demanding, as they should be cleaned thoroughly to prevent mold growth, especially if used frequently in humid environments.

Conclusion

When selecting the right solution for your kitchen needs, consider factors such as the specific type of food preparation, budget constraints, and maintenance preferences. For B2B buyers in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of each option is essential. If your focus is primarily on rice, investing in a dedicated rice strainer or washing basket may yield the best results in terms of performance and food quality. Conversely, for broader culinary applications, a colander may offer the versatility needed for diverse kitchen operations. Ultimately, the choice should align with your operational goals and the specific demands of your culinary practices.

Essential Technical Properties and Trade Terminology for rice strainer

What Are the Key Technical Properties of Rice Strainers for B2B Buyers?

In the competitive landscape of kitchenware, understanding the essential technical properties of rice strainers is crucial for international B2B buyers. Here are some of the critical specifications to consider:

-

Material Grade

Rice strainers are typically made from materials such as stainless steel, plastic, or bamboo. Stainless steel, particularly of the 18/8 grade, is preferred for its durability, resistance to rust, and ease of cleaning. Plastic strainers, while lightweight and cost-effective, may not withstand high temperatures or prolonged use. The choice of material directly impacts product longevity, safety, and user satisfaction, making it a vital consideration for bulk buyers. -

Mesh Size

The mesh size determines the strainer’s ability to separate fine particles from liquids. A finer mesh is essential for tasks like rinsing rice to avoid grain loss, while a coarser mesh may be adequate for draining pasta. Understanding the mesh specification helps buyers select the right strainer for their specific culinary applications, ensuring efficient food preparation. -

Size and Capacity

Strainers come in various sizes, usually measured in diameter and depth. Capacity is often indicated in liters or quarts. Buyers must consider their intended use—whether for commercial kitchens needing larger capacities or smaller household use. This specification is critical for optimizing storage space and meeting operational demands. -

Ergonomics and Design Features

Features such as handles, stability (self-standing designs), and weight impact usability. Ergonomically designed strainers reduce strain during use, which is particularly important in high-volume environments. Buyers should look for designs that enhance functionality and ease of handling. -

Heat Resistance

Depending on the intended use, heat resistance can be a crucial property. Stainless steel strainers can typically withstand high temperatures, making them suitable for boiling applications. In contrast, plastic strainers may melt or warp under heat. For B2B buyers, selecting heat-resistant products ensures safety and durability in food processing environments. -

Durability and Maintenance

The durability of materials affects both the lifespan of the product and maintenance requirements. Stainless steel options generally offer longer life and require less frequent replacement compared to plastic. Understanding maintenance needs, such as whether a product is dishwasher safe or requires hand washing, helps buyers manage operational costs effectively.

What Are Common Trade Terms Related to Rice Strainers?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several important terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of rice strainers, buyers may engage with OEMs to create custom products tailored to their branding needs. -

MOQ (Minimum Order Quantity)

MOQ is the minimum number of units that a supplier is willing to sell. Understanding MOQ is vital for buyers to ensure they can meet order requirements without overcommitting resources or inventory. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific quantities and specifications of products. Submitting an RFQ helps buyers gauge market prices and supplier capabilities, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are standardized terms used in international trade to define the responsibilities of buyers and sellers in shipping and logistics. Familiarity with Incoterms helps buyers understand shipping costs, risks, and delivery responsibilities, which is essential for international transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until it is fulfilled. For B2B buyers, understanding lead times is crucial for inventory management and planning, particularly in seasonal markets. -

Certification Standards

These are industry-specific standards that products must meet to be compliant with safety and quality regulations. Buyers should verify that rice strainers meet relevant certifications, such as FDA or CE markings, to ensure product safety and compliance in their target markets.

By comprehensively understanding these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their operational needs and market expectations.

Navigating Market Dynamics and Sourcing Trends in the rice strainer Sector

What Are the Key Market Trends Influencing the Rice Strainer Sector?

The rice strainer market is experiencing significant growth, driven by increasing consumer interest in home cooking and the rising popularity of Asian cuisine worldwide. As a staple in many households, the demand for rice strainers is expanding, particularly in regions such as Africa, South America, the Middle East, and Europe. International B2B buyers should be aware of key trends such as the shift towards multifunctional kitchen tools, where strainers are designed not only for rice but also for pasta, vegetables, and other food items. This versatility appeals to consumers looking for efficient kitchen solutions, enhancing the overall market appeal.

Technological advancements are also shaping the sourcing landscape. The emergence of smart kitchen appliances, including strainers with integrated features like digital timers and automatic monitoring, is becoming increasingly relevant. B2B buyers are encouraged to explore these innovations, as they can offer competitive advantages and align with consumer preferences for convenience. Additionally, the rise of e-commerce platforms is facilitating direct sourcing from manufacturers, enabling buyers to access a broader range of products at competitive prices.

How Is Sustainability Reshaping the Rice Strainer Market?

Sustainability is a crucial consideration for B2B buyers in the rice strainer sector. With growing awareness of environmental issues, consumers are increasingly favoring products that are eco-friendly and ethically sourced. This shift necessitates that international buyers prioritize suppliers who adhere to sustainable practices. Materials such as stainless steel, bamboo, and recycled plastics are gaining traction due to their durability and minimal environmental impact.

Moreover, ethical sourcing is becoming a focal point for brands aiming to build consumer trust. Certifications like Fair Trade and eco-labels not only enhance brand reputation but also cater to the growing segment of environmentally-conscious consumers. B2B buyers should evaluate suppliers based on their commitment to sustainable practices, ensuring that their sourcing decisions align with their corporate social responsibility goals. This focus on sustainability is not just a trend; it’s a strategic imperative for long-term success in the market.

What Is the Historical Context Behind the Rice Strainer’s Development?

The rice strainer has evolved significantly from its traditional roots in Asian cuisine, where it was primarily used for washing and draining rice. Historically, these tools were often handmade from natural materials like bamboo or clay, reflecting local craftsmanship. As culinary practices globalized, the demand for rice strainers expanded, leading to the introduction of modern materials such as stainless steel and high-quality plastics.

Today, rice strainers are integral to diverse cooking styles and are manufactured with a focus on durability, functionality, and design. This evolution reflects broader trends in kitchenware, where efficiency and aesthetics are paramount. For B2B buyers, understanding this historical context can inform product selection and marketing strategies, emphasizing the blend of tradition and innovation that appeals to contemporary consumers.

Frequently Asked Questions (FAQs) for B2B Buyers of rice strainer

-

How do I choose the right rice strainer for my business needs?

Choosing the right rice strainer involves assessing several factors such as material, size, and functionality. Stainless steel strainers are durable and resistant to corrosion, making them ideal for heavy-duty use. Consider the size based on your production volume—larger strainers allow for efficient processing of bulk rice. Additionally, look for features like fine mesh for thorough straining or ergonomic designs for ease of use. Request samples from suppliers to evaluate quality before making a bulk purchase. -

What is the best material for rice strainers in a commercial kitchen?

The best materials for rice strainers in a commercial kitchen are stainless steel and high-quality plastics. Stainless steel is favored for its durability, resistance to heat, and ease of cleaning, making it suitable for high-volume usage. Plastic strainers can be lightweight and cost-effective, but ensure they are made from food-grade materials that can withstand daily wear and tear. For environments with rigorous hygiene standards, stainless steel is often the preferred choice. -

What are the typical minimum order quantities (MOQs) for rice strainers?

Minimum order quantities (MOQs) for rice strainers can vary significantly based on the manufacturer and the specific product. Generally, MOQs can range from as low as 100 units to several thousand. It’s essential to discuss your needs directly with suppliers, as many are willing to negotiate MOQs, especially for new business relationships. Consider collaborating with other businesses to meet MOQ requirements if necessary. -

What are the payment terms commonly offered by suppliers of rice strainers?

Payment terms vary by supplier, but typical arrangements include options such as advance payment, net 30, or letter of credit. Many suppliers may require a deposit upon order confirmation, with the balance due before shipment. It’s crucial to establish clear payment terms upfront to avoid any misunderstandings. Additionally, inquire about any discounts for early payments or bulk purchases, which can improve cash flow. -

How can I ensure the quality of rice strainers from international suppliers?

To ensure the quality of rice strainers from international suppliers, conduct thorough due diligence. Request product samples to evaluate quality firsthand and review certifications such as ISO or HACCP, which indicate adherence to industry standards. Establish a quality assurance process that includes on-site inspections or third-party quality checks before shipment. Building a strong relationship with your supplier can also facilitate better communication and quality assurance. -

What logistics considerations should I keep in mind when importing rice strainers?

When importing rice strainers, logistics considerations include shipping methods, customs regulations, and lead times. Choose a reliable shipping partner experienced in handling kitchen equipment to ensure timely delivery. Understand the customs duties and taxes applicable in your country to avoid unexpected costs. Additionally, factor in lead times for production and shipping to align with your inventory needs, allowing for flexibility in your supply chain. -

Are there customization options available for rice strainers?

Many suppliers offer customization options for rice strainers, including size, color, and branding. Customization can be particularly beneficial for businesses looking to differentiate their products in the market. Discuss your specific requirements with potential suppliers to explore available options, including any additional costs or lead times associated with custom orders. This can help you create a product that aligns with your brand identity. -

What certifications should I look for when sourcing rice strainers?

When sourcing rice strainers, look for certifications that ensure compliance with food safety and quality standards. Common certifications include FDA approval for food contact materials, CE marking for European markets, and ISO certifications that demonstrate quality management systems. These certifications can provide assurance that the products meet necessary safety regulations, which is critical when operating in diverse international markets. Always request documentation from suppliers to verify these certifications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Rice Strainer Manufacturers & Suppliers List

1. Amazon – Japanese Fine Mesh Sieve

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Japanese rice strainer from Amazon, fine metal sieve, fine mesh sieve, colander.

2. MTC Kitchen – Colanders & Strainers

Domain: mtckitchen.com

Registered: 2012 (13 years)

Introduction: Colanders, Strainers, Sieves & Skimmers

3. eBay – Rice Strainer Products

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Rice strainer products for sale on eBay include various types such as:

– 2pcs Rice Washing Filter Strainer Basket Rice Sieve Fruit Drain Bowl in Pink, priced at $10.70 (was $15.29) with free shipping.

– Original Rice Rinser for measuring, rinsing, draining, and pouring, priced at $9.99 with free shipping.

– PriorityChef Colander, Stainless Steel Kitchen Strainer for washing rice, priced at $10.16 …

4. Food52 – Fine Mesh Colander

Domain: food52.com

Registered: 2009 (16 years)

Introduction: This company, Food52 – Fine Mesh Colander, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Mintra – Home Rice Colander

Domain: mintrausa.com

Registered: 2014 (11 years)

Introduction: Mintra Home Rice Colander – Strainer, Lightweight for kitchen rinsing of pasta, rice, beans, fruit and vegetables. Dimensions: 12inW x 9.75inD x 7inH – 7 Liters/7.2 Quarts. Material: Solid long lasting poly material, reusable, recyclable. Available colors: Yellow, Orange, White, Red, Fuchsia, Teal, Blue, Green, Black. Price: $17.99.

6. College of EMS – Stainless Steel Colander Strainer

Domain: collegeofems.com

Registered: 2015 (10 years)

Introduction: Stainless Steel Colander Strainer Rice Sieve Multifunctional

Strategic Sourcing Conclusion and Outlook for rice strainer

In the evolving landscape of kitchenware, strategic sourcing for rice strainers presents a unique opportunity for international B2B buyers. Key insights reveal a growing demand for durable, high-quality materials such as stainless steel and innovative designs that enhance usability and efficiency. As consumers increasingly prioritize quality and functionality, sourcing partners who offer a diverse range of products—including lightweight plastic and traditional bamboo options—can significantly enhance your product lineup.

Engaging with manufacturers who prioritize sustainability and quality assurance can further differentiate your offerings in competitive markets across Africa, South America, the Middle East, and Europe. By focusing on reliable supply chains and fostering relationships with trusted vendors, businesses can not only optimize costs but also ensure timely delivery of products that meet local consumer preferences.

Looking ahead, the market for rice strainers is poised for growth as culinary trends evolve and consumer awareness of kitchen efficiency increases. International buyers are encouraged to leverage strategic sourcing to capitalize on these trends, ensuring they remain at the forefront of the industry. Start exploring partnerships today to enhance your product offerings and meet the rising demand for quality kitchen tools.