A B2B Buyer’s Guide to Pvc Wall Panels 4X8: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for pvc wall panels 4×8

In today’s dynamic marketplace, sourcing high-quality PVC wall panels 4×8 can be a daunting challenge for international B2B buyers. With a plethora of options available, businesses often struggle to identify products that not only meet aesthetic requirements but also comply with safety and durability standards. This comprehensive guide serves as a vital resource for discerning buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Brazil and Nigeria. By exploring various types of PVC wall panels, their applications, and the intricacies of supplier vetting, this guide empowers businesses to make informed purchasing decisions.

Throughout this guide, you will discover the diverse range of PVC wall panel options available in the market, from luxurious textured designs to practical waterproof solutions suitable for high-humidity environments. We will delve into the essential considerations for selecting the right panels for your specific needs, including installation ease, cost-effectiveness, and maintenance requirements. Additionally, we’ll provide insights on how to effectively evaluate suppliers, ensuring that you partner with reputable manufacturers who adhere to international quality standards.

Ultimately, this guide aims to equip B2B buyers with the knowledge and tools necessary to navigate the global market for PVC wall panels, enabling you to enhance your projects with premium materials while optimizing your procurement process.

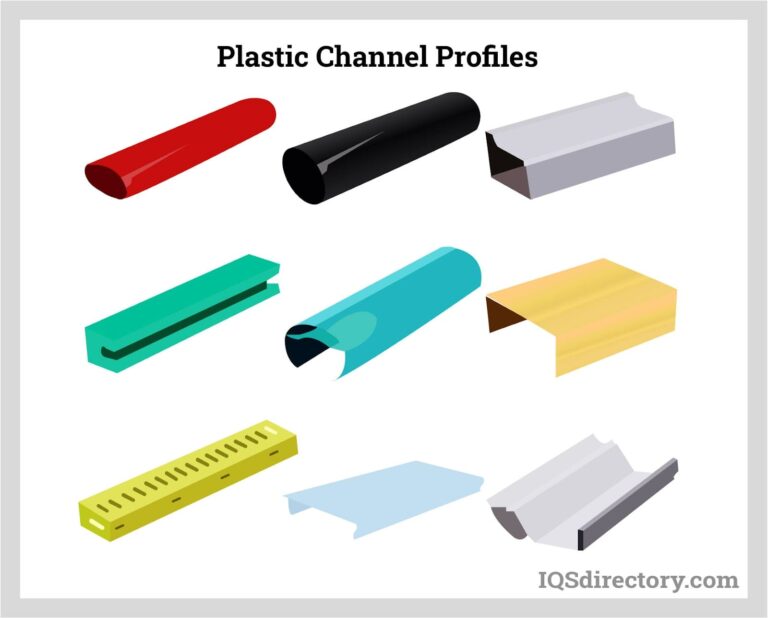

Understanding pvc wall panels 4×8 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard PVC Panels | Lightweight, waterproof, easy to install, and available in various colors and finishes. | Commercial interiors, residential spaces, and renovations. | Pros: Cost-effective, versatile design options. Cons: May not provide high-end aesthetics. |

| 3D Textured PVC Panels | Features raised patterns and textures for enhanced visual appeal. | Retail displays, restaurants, and luxury interiors. | Pros: Eye-catching designs, adds dimension to spaces. Cons: Higher cost and more complex installation. |

| Marble Finish PVC Panels | Mimics the appearance of marble, often UV-protected and fire-resistant. | High-end residential, hotels, and spas. | Pros: Luxurious look at a lower cost, durable. Cons: Limited color options compared to standard panels. |

| Acoustic PVC Panels | Designed to reduce sound transmission; often used in commercial settings. | Offices, conference rooms, and theaters. | Pros: Enhances sound quality, improves privacy. Cons: Typically more expensive than standard panels. |

| Waterproof PVC Panels | Specifically engineered to withstand moisture, ideal for wet environments. | Bathrooms, kitchens, and pool areas. | Pros: Excellent for humid conditions, easy maintenance. Cons: May have a limited aesthetic appeal compared to decorative options. |

What Are the Characteristics of Standard PVC Panels?

Standard PVC panels are a popular choice due to their lightweight nature and ease of installation. They come in a variety of colors and finishes, making them suitable for diverse applications, from commercial interiors to residential renovations. B2B buyers often appreciate their cost-effectiveness and versatility, although they may lack the high-end aesthetic appeal of more decorative options. When purchasing, consider the panel thickness and finish to ensure it meets the project’s design and durability requirements.

How Do 3D Textured PVC Panels Enhance Interior Spaces?

3D textured PVC panels are designed to add a unique visual dimension to interiors. Their raised patterns can create striking focal points, making them ideal for retail displays and upscale restaurant environments. While they offer a more luxurious appearance, B2B buyers should be aware that installation can be more complex and the price point is typically higher. It’s essential to assess the installation environment and desired aesthetic to ensure alignment with brand identity.

Why Choose Marble Finish PVC Panels for High-End Applications?

Marble finish PVC panels provide the luxurious look of marble without the associated costs. These panels are UV-protected and fire-resistant, making them suitable for high-end residential projects, hotels, and spas. B2B buyers should consider their durability and ease of maintenance when selecting these panels, as they can withstand wear and tear while retaining their aesthetic appeal. However, the color options may be more limited compared to standard panels, which could affect design flexibility.

What Advantages Do Acoustic PVC Panels Offer in Commercial Settings?

Acoustic PVC panels are specially designed to minimize sound transmission, making them an excellent choice for offices, conference rooms, and theaters. Their ability to enhance sound quality and improve privacy is highly valued in commercial environments. B2B buyers should weigh the benefits of noise reduction against the typically higher cost compared to standard panels. Consider the specific acoustic requirements of the space when selecting these panels.

In What Scenarios Are Waterproof PVC Panels Essential?

Waterproof PVC panels are engineered to withstand moisture, making them ideal for use in bathrooms, kitchens, and pool areas. Their resistance to humidity and ease of maintenance make them a practical choice for environments prone to dampness. B2B buyers should focus on product specifications to ensure they meet the necessary durability standards. While these panels excel in functionality, they may not offer the same aesthetic appeal as decorative alternatives, so careful selection is crucial based on project needs.

Key Industrial Applications of pvc wall panels 4×8

| Industry/Sector | Specific Application of pvc wall panels 4×8 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Interior wall cladding in hotels and resorts | Enhances aesthetic appeal while providing moisture resistance | Look for fireproof and waterproof options; ensure easy installation |

| Healthcare | Wall coverings in hospitals and clinics | Promotes hygiene and easy cleaning, vital in medical environments | Verify antimicrobial properties; compliance with health regulations |

| Retail | Store displays and interior branding | Durable and customizable, aiding in brand identity | Consider design versatility; ensure availability in bulk sizes |

| Food and Beverage | Wall panels in kitchens and food processing areas | Resists moisture and stains, ensuring a clean environment | Ensure panels meet food safety standards; check for easy maintenance |

| Residential | Home renovations, particularly in bathrooms and kitchens | Affordable luxury finish with high durability | Look for aesthetic options; consider regional design preferences |

How Are PVC Wall Panels 4×8 Used in the Hospitality Sector?

In the hospitality sector, PVC wall panels 4×8 are frequently utilized for interior wall cladding in hotels and resorts. Their waterproof and fire-resistant properties make them ideal for high-traffic areas, ensuring durability and safety. Additionally, these panels enhance the aesthetic appeal of spaces, allowing businesses to create a luxurious ambiance without significant investment. International buyers should prioritize sourcing panels that comply with local safety regulations and are easy to install, minimizing downtime during renovations.

What Role Do PVC Wall Panels Play in Healthcare Facilities?

PVC wall panels 4×8 are essential in healthcare settings, providing wall coverings in hospitals and clinics. Their ability to resist moisture and facilitate easy cleaning is crucial in maintaining hygiene standards. The panels can be installed in patient rooms, waiting areas, and surgical suites, contributing to a sterile environment. Buyers from the healthcare sector should ensure that the panels possess antimicrobial properties and comply with strict health regulations to safeguard patient safety.

How Can Retailers Benefit from PVC Wall Panels 4×8?

In retail environments, PVC wall panels 4×8 are used for store displays and interior branding. Their durability and customization options allow retailers to create visually appealing spaces that align with their brand identity. The panels can withstand wear and tear, making them a cost-effective solution for high-traffic areas. Retail buyers should focus on design versatility and the ability to source in bulk, ensuring that their store aesthetics remain fresh and engaging.

Why Are PVC Wall Panels Important in Food and Beverage Industries?

For the food and beverage industry, PVC wall panels 4×8 are commonly installed in kitchens and food processing areas. Their resistance to moisture and stains helps maintain a clean environment, which is critical for food safety. Additionally, these panels can be easily cleaned, reducing the risk of contamination. Buyers in this sector must verify that the panels meet food safety standards and are designed for easy maintenance, ensuring compliance with health regulations.

How Are PVC Wall Panels Used in Residential Renovations?

In residential applications, PVC wall panels 4×8 are increasingly popular for home renovations, particularly in bathrooms and kitchens. They offer an affordable yet luxurious finish, enhancing the aesthetic of living spaces while providing durability against moisture and stains. Homeowners and contractors should look for panels that align with regional design preferences and offer easy installation options, making renovations more efficient and less disruptive.

3 Common User Pain Points for ‘pvc wall panels 4×8’ & Their Solutions

Scenario 1: Navigating Quality Concerns with PVC Wall Panels

The Problem: In many international markets, especially in regions like Africa and South America, B2B buyers often face challenges in ensuring the quality of PVC wall panels. Buyers may encounter products that do not meet expected standards, leading to issues such as discoloration, warping, or inadequate fire resistance. These quality discrepancies can result in costly project delays and damage to reputation when the final installation fails to meet client expectations.

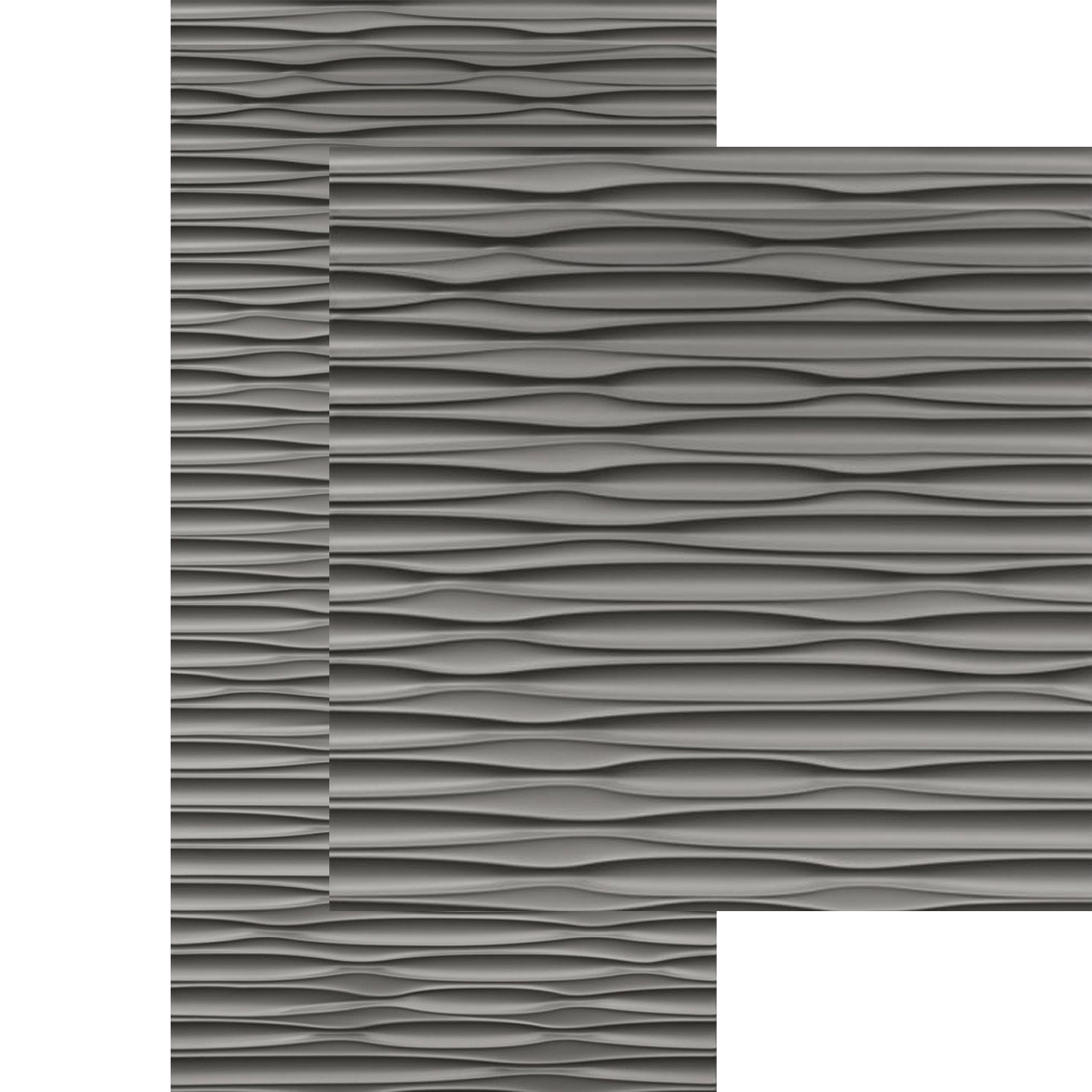

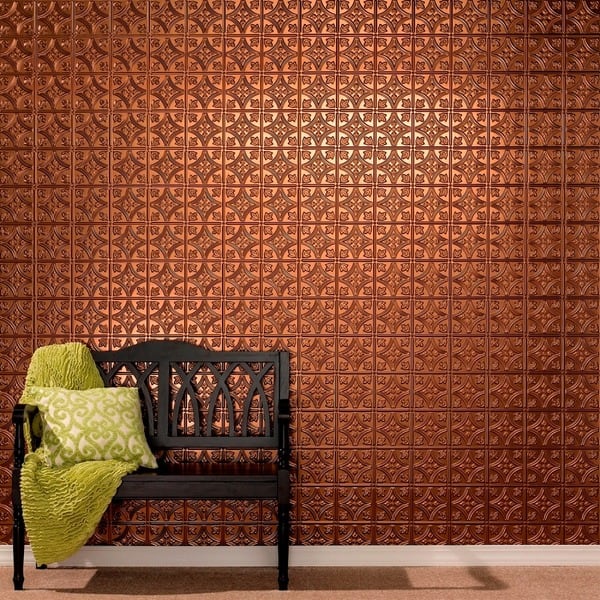

Illustrative image related to pvc wall panels 4×8

The Solution: To mitigate quality concerns, B2B buyers should prioritize sourcing from reputable manufacturers with a proven track record. Conducting thorough due diligence is essential; this includes requesting product certifications that verify compliance with international standards for fire resistance and waterproofing. Establishing direct communication with suppliers can also facilitate better understanding of the product specifications and manufacturing processes. Additionally, consider ordering samples before committing to bulk purchases, allowing for firsthand assessment of texture, durability, and overall aesthetics. Engaging with suppliers who offer robust warranties can further assure buyers of product quality and performance.

Scenario 2: Overcoming Installation Challenges for PVC Wall Panels

The Problem: Many B2B buyers, especially those new to using PVC wall panels, encounter installation challenges that can complicate projects. These challenges may include difficulties in alignment, securing panels properly, or ensuring a seamless finish. Such issues can lead to increased labor costs and extended project timelines, ultimately affecting the profitability of the project.

The Solution: To streamline the installation process, buyers should invest in training for their installation teams. This can include workshops or instructional videos provided by the manufacturer, detailing best practices for installing 4×8 PVC wall panels. Additionally, utilizing the right tools and adhesives specifically designed for PVC can make a significant difference in achieving a professional finish. Buyers should also consider choosing panels that feature interlocking designs or those that come with clear installation guides, as these can simplify the process and reduce the likelihood of errors. Implementing a pilot project with a smaller area can also serve as a practical trial run to hone installation techniques before larger-scale applications.

Scenario 3: Addressing Design Limitations with PVC Wall Panels

The Problem: B2B buyers often seek aesthetically pleasing solutions for their clients, but they may find that standard PVC wall panels lack the desired design flexibility. In regions where unique architectural styles are prevalent, the limited color and texture options can stifle creativity and fail to meet client expectations, leading to dissatisfaction and potential loss of business.

Illustrative image related to pvc wall panels 4×8

The Solution: Buyers should explore suppliers that offer customizable options for PVC wall panels. Many manufacturers now provide a variety of textures, colors, and finishes that cater to diverse design preferences. Additionally, consider collaborating with interior designers to create bespoke designs that can be translated into panel form. Utilizing advanced printing technologies can also allow for the incorporation of custom graphics or patterns on the panels, making them more visually appealing. By presenting clients with a wider range of options, buyers can enhance their service offering, ultimately leading to increased satisfaction and repeat business. Engaging in trend research can also provide insights into popular styles and colors, ensuring that the offerings are aligned with current market demands.

Strategic Material Selection Guide for pvc wall panels 4×8

What Are the Key Materials for PVC Wall Panels 4×8?

When selecting materials for PVC wall panels, particularly in the 4×8 size, various factors such as durability, cost, and application suitability come into play. The following analysis of common materials will aid international B2B buyers in making informed decisions.

1. Standard PVC

Key Properties:

Standard PVC (polyvinyl chloride) is lightweight, offers good tensile strength, and is resistant to moisture and chemicals. It performs well in a temperature range of -20°C to 60°C, making it suitable for various climates.

Pros & Cons:

The advantages of standard PVC include its affordability and ease of installation, making it a popular choice for residential and commercial applications. However, it may not be as durable as other materials under extreme conditions, and prolonged exposure to UV light can lead to discoloration.

Impact on Application:

Standard PVC panels are ideal for indoor applications such as bathrooms and kitchens due to their waterproof nature. They are compatible with a variety of adhesives and can be painted or printed on, enhancing their aesthetic appeal.

Considerations for International Buyers:

Buyers in regions like Africa and South America should ensure that the PVC panels comply with local building codes and standards, such as ASTM or DIN. Additionally, they should consider the availability of installation services, as DIY installation may not be feasible in all areas.

2. WPC (Wood Plastic Composite)

Key Properties:

WPC combines wood fibers with plastic, offering enhanced durability and resistance to moisture and pests. It performs well in temperatures ranging from -30°C to 70°C, making it suitable for diverse environments.

Pros & Cons:

WPC panels are highly durable and provide a natural wood-like appearance, appealing to buyers looking for aesthetic value. However, they tend to be more expensive than standard PVC and may require specialized tools for installation, increasing manufacturing complexity.

Impact on Application:

WPC panels are well-suited for both indoor and outdoor applications, including commercial spaces that demand high durability. Their compatibility with various finishes allows for customization to meet specific design needs.

Illustrative image related to pvc wall panels 4×8

Considerations for International Buyers:

In regions like the Middle East, where humidity can be high, WPC panels’ resistance to moisture is a significant advantage. Buyers should verify compliance with environmental standards, especially concerning the sourcing of wood fibers.

3. Fire-Retardant PVC

Key Properties:

Fire-retardant PVC is treated with additives that enhance its fire-resistance properties. It typically meets fire safety standards such as ASTM E84, making it suitable for applications where fire safety is a concern.

Pros & Cons:

The primary advantage of fire-retardant PVC is its safety features, making it ideal for commercial spaces and public buildings. However, it is generally more expensive than standard PVC and may have a more limited aesthetic appeal due to its specific formulations.

Impact on Application:

These panels are particularly suitable for areas requiring strict fire safety compliance, such as hospitals and schools. They can be easily integrated into existing designs, providing a balance between safety and aesthetics.

Considerations for International Buyers:

In Europe, compliance with the EN 13501 standard for fire classification is crucial. Buyers should ensure that the panels meet local regulations and consider the potential for higher shipping costs due to the weight of fire-retardant materials.

4. Textured PVC

Key Properties:

Textured PVC panels feature surface designs that enhance visual appeal while maintaining the core properties of standard PVC. They are lightweight and easy to clean, making them suitable for various applications.

Pros & Cons:

Textured PVC offers aesthetic versatility and can mimic the appearance of more expensive materials like wood or stone. The downside is that the manufacturing process can be more complex, leading to higher costs.

Impact on Application:

These panels are ideal for decorative applications in residential and commercial spaces, including accent walls and feature areas. Their easy maintenance makes them suitable for high-traffic areas.

Considerations for International Buyers:

In regions like Brazil, where design trends may favor unique aesthetics, textured PVC can meet consumer demands. Buyers should assess local market preferences and ensure compliance with aesthetic standards.

Summary Table of Material Selection for PVC Wall Panels 4×8

| Material | Typical Use Case for PVC Wall Panels 4×8 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Standard PVC | Indoor applications like kitchens and bathrooms | Affordable and easy to install | Less durable under extreme conditions | Low |

| WPC (Wood Plastic Composite) | Indoor and outdoor applications, commercial spaces | Highly durable with a natural appearance | More expensive and requires specialized tools | Med |

| Fire-Retardant PVC | Public buildings, hospitals, schools | Enhanced fire safety features | Higher cost and limited aesthetic options | High |

| Textured PVC | Decorative applications, accent walls | Aesthetic versatility and easy maintenance | More complex manufacturing process | Med |

This guide provides a comprehensive overview of materials for PVC wall panels, enabling B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for pvc wall panels 4×8

What Are the Key Manufacturing Processes for PVC Wall Panels 4×8?

Manufacturing PVC wall panels involves a systematic approach that ensures quality, durability, and aesthetic appeal. The main stages of production include material preparation, forming, assembly, and finishing.

Illustrative image related to pvc wall panels 4×8

How Is Material Prepared for PVC Wall Panels?

The manufacturing process begins with the careful selection and preparation of raw materials. PVC resin, along with various additives like stabilizers, plasticizers, and pigments, is sourced from reputable suppliers. These materials are then blended in specific proportions to achieve the desired characteristics such as flexibility, strength, and color.

Once the materials are mixed, they undergo a compounding process where they are heated and homogenized. This step ensures that all components are evenly distributed, creating a consistent base for the panels. After compounding, the material is cooled and granulated into pellets, which are easier to handle in subsequent stages.

What Techniques Are Used for Forming PVC Wall Panels?

The next step is the forming process, where the granulated PVC is transformed into sheets. This is typically achieved through extrusion or compression molding.

-

Extrusion: In this technique, the granulated PVC is fed into an extruder, where it is melted and forced through a die to create continuous sheets of the desired thickness, usually around 3mm for 4×8 panels. This method allows for high efficiency and the production of uniform sheets.

-

Compression Molding: Alternatively, compression molding involves placing the PVC material into a mold and applying heat and pressure to shape it. While this method is less common for wall panels, it can be used for specialized designs or textures.

How Are PVC Wall Panels Assembled and Finished?

Once the panels are formed, they undergo an assembly process. This may involve cutting the sheets to size, typically 4×8 feet, and adding features such as grooves or interlocking edges for easy installation. At this stage, additional components, such as edge trims or corner pieces, may also be produced.

Finishing processes play a crucial role in the final product’s quality. Panels often undergo surface treatment to enhance durability and aesthetics. This can include UV coating to improve resistance to fading, as well as printing or laminating to achieve various textures and colors. The panels are then inspected for visual defects and consistency before being packaged for distribution.

What Quality Assurance Measures Are Commonly Implemented?

Quality assurance is vital in the manufacturing of PVC wall panels, ensuring that products meet international standards and customer expectations. Key quality assurance measures include adherence to relevant standards, implementation of quality checkpoints, and rigorous testing protocols.

Which International Standards Are Relevant for PVC Wall Panels?

For B2B buyers, understanding the international standards that apply to PVC wall panels is essential. Key standards include:

-

ISO 9001: This standard focuses on quality management systems and is applicable to any organization looking to enhance customer satisfaction through effective quality management.

-

CE Marking: In Europe, CE marking indicates that the product meets EU safety, health, and environmental protection requirements. This is particularly important for construction materials.

-

API Standards: For applications in specific industries such as oil and gas, compliance with API standards ensures that materials can withstand harsh conditions.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) is integrated at various stages of the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): This initial inspection assesses the quality of raw materials before production begins. Suppliers must provide documentation proving compliance with relevant standards.

-

In-Process Quality Control (IPQC): During manufacturing, samples are taken at regular intervals to ensure that the production process remains within specified limits. This can include checking dimensions, color consistency, and surface quality.

-

Final Quality Control (FQC): Before packaging, finished panels undergo a comprehensive inspection to verify that they meet all quality specifications. This includes visual inspections and functional tests.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some methods to ensure compliance:

What Should Buyers Look for in Supplier Audits and Reports?

Conducting audits of potential suppliers can provide valuable insights into their manufacturing processes and quality assurance measures. Buyers should request:

-

Quality Management System Documentation: This includes details on how the supplier complies with ISO 9001 and other relevant standards.

-

Inspection Reports: Suppliers should provide records of IQC, IPQC, and FQC, demonstrating their commitment to quality throughout the manufacturing process.

-

Certificates of Compliance: Look for documentation that confirms adherence to industry-specific standards, such as CE marking or API certifications.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can further enhance confidence in a supplier’s quality control. These inspections provide an unbiased evaluation of the manufacturing process and product quality, often resulting in detailed reports that can highlight potential issues before shipment.

What Are the Nuances of Quality Control for International Buyers?

International B2B buyers should be aware of specific nuances that can affect quality control when sourcing PVC wall panels. These may include:

-

Cultural Differences in Quality Expectations: Understanding regional preferences and standards is vital, as they may vary significantly between regions such as Europe and Africa.

-

Logistical Considerations: Ensure that the supplier has robust logistics in place for transporting panels, as damages during shipping can affect perceived quality.

-

Regulatory Compliance: Familiarity with local building codes and regulations in the buyer’s country can help in ensuring that the panels meet necessary safety and performance standards.

In conclusion, the manufacturing and quality assurance processes for PVC wall panels are complex but essential for delivering high-quality products. B2B buyers must engage in thorough due diligence to ensure they select suppliers who meet rigorous standards, ultimately leading to successful projects and satisfied customers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pvc wall panels 4×8’

Introduction

When sourcing PVC wall panels measuring 4×8 feet, it is essential to adopt a structured approach to ensure that you meet both quality and cost-effectiveness. This guide provides a practical checklist to help B2B buyers navigate the procurement process efficiently, ultimately leading to informed purchasing decisions.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the specific requirements for your PVC wall panels. Consider the intended application, such as residential or commercial use, and the environmental conditions they must withstand.

– Key factors to define include:

– Thickness: Ensure the panels can support the intended load and resist damage.

– Finish and texture: Select designs that align with your aesthetic preferences and functional needs.

Step 2: Research Potential Suppliers

Thorough research on potential suppliers is vital to ensure reliability and quality. Identify manufacturers or distributors with a strong reputation in the market.

– Considerations during research:

– Look for suppliers with experience in your region, as they may understand local regulations and market demands better.

– Explore online platforms, trade shows, and industry forums for recommendations.

Step 3: Evaluate Supplier Certifications

Before making a commitment, it is crucial to verify that suppliers possess relevant certifications. This step assures that the products meet international safety and quality standards.

– Certifications to look for include:

– ISO certification: Indicates adherence to quality management practices.

– Fire and safety ratings: Essential for applications in sensitive environments, such as healthcare or hospitality.

Step 4: Request Samples

Requesting samples is a practical way to assess the quality of the PVC wall panels firsthand. It allows you to evaluate the material, finish, and durability before making a bulk purchase.

– What to assess in samples:

– Color consistency and texture: Ensure they meet your design specifications.

– Resistance to water and humidity: Important for applications in kitchens and bathrooms.

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers to understand the pricing landscape. A thorough comparison will help you identify competitive offers while ensuring quality is not compromised.

– Factors to consider in pricing:

– Shipping costs: Understand how these will affect your overall budget.

– Payment terms: Look for flexible payment options that align with your cash flow.

Step 6: Check Reviews and References

Investigate customer feedback and case studies related to the suppliers you are considering. This research can provide valuable insights into their reliability and product performance.

– Focus on:

– Reviews from similar industries: These can highlight specific strengths or weaknesses.

– References from previous clients: Direct insights can enhance your confidence in your supplier choice.

Step 7: Finalize Your Order and Terms

Once you have selected a supplier, finalize your order by clearly outlining all terms and conditions. Ensure that the agreement includes delivery timelines, warranty information, and after-sales support.

– Important elements to confirm:

– Detailed specifications: Ensure everything aligns with your initial requirements.

– Return and exchange policies: Understand the process in case of defects or dissatisfaction.

By following this checklist, you can streamline your sourcing process for 4×8 PVC wall panels, ensuring you make informed, strategic decisions that meet your project needs.

Comprehensive Cost and Pricing Analysis for pvc wall panels 4×8 Sourcing

To effectively analyze the costs and pricing associated with sourcing PVC wall panels in the 4×8 size, it is crucial to break down the various components that contribute to the overall cost structure. Understanding these elements can provide significant insights for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in PVC Wall Panel Manufacturing?

-

Materials: The primary cost driver is the raw materials used to manufacture PVC wall panels. High-quality PVC resin, additives for UV protection, and fireproofing agents are critical components that affect pricing. Buyers should be aware that sourcing sustainable materials may incur additional costs but can enhance product appeal.

-

Labor: Labor costs encompass the wages paid to workers involved in the production process, including assembly and quality assurance. Regions with lower labor costs can provide significant savings, but this may also impact the quality and consistency of the product.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can reduce overhead and, consequently, the overall price of the panels.

-

Tooling: Initial tooling costs can be high, particularly for custom designs. Buyers looking for unique specifications should anticipate these costs and negotiate them upfront, as they can significantly influence the final price.

-

Quality Control (QC): Ensuring product quality through rigorous testing and inspections adds to the overall cost. Buyers should inquire about the QC processes employed by suppliers to ensure they align with their standards.

-

Logistics: Shipping and handling costs vary widely based on the distance from the manufacturing site to the buyer’s location. Factors such as shipping method, packaging, and customs duties must be factored into the total cost.

-

Margin: Suppliers typically apply a markup to cover their operational costs and profit. Understanding the competitive landscape can help buyers negotiate better pricing.

What Influences the Pricing of PVC Wall Panels?

Pricing for PVC wall panels can fluctuate based on several factors:

-

Volume/MOQ: Bulk purchases usually lead to lower per-unit costs. Buyers should consider their storage capabilities and demand forecasts when negotiating minimum order quantities (MOQs).

-

Specifications/Customization: Custom designs or specific features (like enhanced fire resistance) can raise prices. Buyers should evaluate the necessity of these features against their budget constraints.

-

Materials: The choice between standard and premium materials will impact costs. Buyers should weigh the benefits of higher-quality materials against budget limitations.

-

Quality and Certifications: Panels that meet international standards (e.g., fire rating, water resistance) may command higher prices but can offer peace of mind and compliance with local regulations.

-

Supplier Factors: The reliability, reputation, and financial health of suppliers can affect pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: Understanding shipping terms (like FOB, CIF) is critical as they dictate who is responsible for shipping costs and risks, thereby impacting the total landed cost.

What Tips Can Help Buyers Achieve Cost-Efficiency?

-

Negotiation: Establishing a strong relationship with suppliers can lead to better pricing and terms. Consider leveraging long-term contracts for price stability.

-

Total Cost of Ownership (TCO): Look beyond initial costs; consider maintenance, replacement, and disposal costs. Investing in higher-quality panels may yield savings over time.

-

Pricing Nuances for International Buyers: Currency fluctuations, tariffs, and trade agreements can significantly impact costs for international buyers. Staying informed about geopolitical factors can aid in strategic sourcing decisions.

-

Disclaimer for Indicative Prices: Pricing for PVC wall panels can vary based on the factors outlined above. The prices mentioned (e.g., $55 to $189.53 for 4×8 panels) are indicative and may not reflect current market conditions. Buyers should conduct thorough market research and obtain quotes from multiple suppliers to ensure competitive pricing.

By understanding these cost components and pricing influencers, B2B buyers can make informed decisions that align with their business goals while optimizing their sourcing strategies for PVC wall panels.

Alternatives Analysis: Comparing pvc wall panels 4×8 With Other Solutions

When considering wall solutions for commercial and residential spaces, PVC wall panels measuring 4×8 feet present a unique blend of functionality and aesthetic appeal. However, it’s essential for B2B buyers to evaluate alternatives that may offer different advantages. This analysis compares PVC wall panels with two viable alternatives: fiberglass reinforced panels (FRP) and traditional drywall.

| Comparison Aspect | PVC Wall Panels 4×8 | Fiberglass Reinforced Panels (FRP) | Traditional Drywall |

|---|---|---|---|

| Performance | Water-resistant, durable, lightweight | Highly resistant to moisture, durable | Good for dry areas, less resistant to moisture |

| Cost | Moderate, typically $55-$65 per panel | Higher initial cost, $80-$100 per panel | Lower cost, around $10-$15 per sheet |

| Ease of Implementation | Easy to install with basic tools | Requires adhesive and special tools | Requires framing and finishing |

| Maintenance | Low maintenance, easy to clean | Low maintenance, easy to clean | Requires painting and repair |

| Best Use Case | Ideal for wet areas like bathrooms and kitchens | Best for commercial kitchens, hospitals, and labs | Suitable for general interior walls |

How Do Fiberglass Reinforced Panels (FRP) Compare to PVC Wall Panels?

Fiberglass reinforced panels are known for their exceptional durability and resistance to moisture, making them ideal for environments that demand sanitary conditions, such as commercial kitchens and healthcare facilities. They are highly resistant to mold and mildew, which can be a significant advantage in humid climates. However, the initial investment is higher than PVC panels, and installation can be more complex, requiring specialized adhesives and tools.

What Are the Advantages of Traditional Drywall Over PVC Wall Panels?

Traditional drywall is often the go-to choice for many contractors due to its low cost and ease of availability. It is suitable for a variety of indoor applications and offers a smooth finish that can be painted or textured. However, drywall is less effective in areas exposed to moisture, as it can deteriorate and develop mold. Additionally, drywall installation can be labor-intensive, requiring framing and finishing work, which can increase overall project costs and timelines.

Illustrative image related to pvc wall panels 4×8

Conclusion: Which Wall Solution Should a B2B Buyer Choose?

When choosing between PVC wall panels, FRP, and traditional drywall, B2B buyers should assess their specific project requirements, including budget, environmental conditions, and aesthetic goals. For high-moisture environments or areas requiring sanitation, FRP may be the superior choice despite its higher cost. Conversely, for budget-conscious projects that do not face moisture challenges, traditional drywall might suffice. However, for those seeking a balance of durability, aesthetic appeal, and ease of maintenance, PVC wall panels measuring 4×8 feet present a compelling option that caters to a broad range of applications.

Essential Technical Properties and Trade Terminology for pvc wall panels 4×8

What Are the Key Technical Properties of PVC Wall Panels 4×8?

When sourcing PVC wall panels, particularly in the 4×8 size, understanding the technical specifications is crucial for making informed purchasing decisions. Here are several critical properties to consider:

-

Material Grade

PVC panels come in various material grades, which indicate their quality and suitability for specific applications. High-grade PVC panels offer superior durability, resistance to moisture, and are less likely to warp or crack. For B2B buyers, selecting the right material grade ensures longevity and reduces replacement costs, especially in high-traffic areas. -

Thickness

The thickness of PVC wall panels typically ranges from 3mm to 10mm. Thicker panels generally provide better insulation and soundproofing, making them ideal for environments like offices, hotels, and residential spaces. Understanding the thickness helps buyers match the product to their specific acoustic and thermal needs. -

Fire Rating

Many PVC wall panels are rated for fire resistance, classified according to standards such as ASTM E-84. A higher fire rating indicates better performance in preventing fire spread. For B2B buyers, especially in commercial sectors, ensuring compliance with fire safety regulations is essential for liability management and insurance considerations. -

Water Resistance

PVC panels are inherently water-resistant, making them suitable for humid environments like bathrooms and kitchens. However, the level of water resistance can vary based on manufacturing processes. Choosing panels with enhanced water-resistant properties can protect against mold and mildew, which is particularly important in tropical climates. -

UV Stability

UV stability refers to a panel’s ability to resist degradation from sunlight exposure. PVC panels designed for outdoor use should have UV protection to prevent fading and brittleness. For buyers in sunny regions, this property is crucial for maintaining aesthetic appeal and extending the lifespan of the installation. -

Ease of Installation

Many PVC wall panels are designed for straightforward installation, often requiring no special tools or skills. This property can significantly reduce labor costs and installation time, making it an attractive option for contractors and builders. Understanding installation requirements can help buyers plan their projects more efficiently.

What Common Trade Terminology Should B2B Buyers Know?

Familiarity with industry jargon is vital for effective communication and negotiation in the procurement process. Here are several key terms relevant to PVC wall panels:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of PVC panels, understanding OEM relationships can help buyers identify quality assurance and product reliability. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of products a supplier is willing to sell. Knowing the MOQ is essential for budget planning and inventory management, especially for businesses looking to minimize overstock or understock situations. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. B2B buyers often use RFQs to compare offers from multiple vendors, ensuring they secure the best deal for their PVC wall panel needs. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms is crucial for B2B transactions, as they clarify shipping costs, risks, and responsibilities, ensuring smoother logistical operations. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. For B2B buyers, understanding lead times is essential for project planning and ensuring that installations can proceed as scheduled without delays. -

Customs Clearance

This term refers to the process of getting goods through customs so they can enter a country. For international buyers, understanding customs clearance procedures is vital to avoid unexpected delays or additional costs when importing PVC wall panels.

By grasping these technical specifications and trade terms, B2B buyers can navigate the procurement of PVC wall panels more effectively, ensuring they make informed decisions that meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the pvc wall panels 4×8 Sector

What Are the Key Market Dynamics and Trends for PVC Wall Panels 4×8?

The global market for PVC wall panels, particularly in the 4×8 size, is experiencing significant growth driven by various factors, including rising demand for cost-effective and aesthetically pleasing interior solutions. Regions such as Africa, South America, the Middle East, and Europe are witnessing a surge in construction and renovation projects, spurring interest in versatile wall paneling options. Notably, the increasing focus on lightweight materials, ease of installation, and low maintenance requirements are pivotal trends influencing purchasing decisions among B2B buyers.

Emerging technologies are also shaping the sourcing landscape, with digital platforms facilitating easier access to suppliers and products. Buyers can leverage online marketplaces to compare prices, product specifications, and reviews, leading to more informed purchasing decisions. Additionally, the advent of augmented reality (AR) tools enables potential buyers to visualize how PVC panels will look in their spaces, enhancing customer engagement and satisfaction.

How Is Sustainability Influencing Sourcing Practices for PVC Wall Panels 4×8?

Sustainability has become a cornerstone of modern B2B sourcing strategies, particularly in the construction and interior design sectors. The environmental impact of materials is a growing concern, prompting buyers to seek out suppliers who prioritize eco-friendly practices. For PVC wall panels, this includes sourcing from manufacturers that utilize recycled materials or those that have adopted cleaner production methods.

Ethical supply chains are equally important, as buyers are increasingly scrutinizing their suppliers’ labor practices and environmental certifications. Certifications such as LEED (Leadership in Energy and Environmental Design) and Green Seal can enhance a product’s appeal, providing assurance that the materials meet rigorous environmental standards. By prioritizing sustainable sourcing, businesses not only fulfill corporate social responsibility (CSR) commitments but also tap into a growing market of eco-conscious consumers.

What Is the Historical Context of PVC Wall Panels in the B2B Market?

The evolution of PVC wall panels can be traced back to the mid-20th century when plastic materials began to gain traction in construction due to their durability and versatility. Initially used primarily in commercial applications, the introduction of advanced manufacturing techniques has broadened their appeal to residential markets. Over the past few decades, innovations in design and technology have transformed PVC wall panels into stylish, functional options that meet diverse aesthetic and practical needs.

Today, PVC wall panels, especially in the 4×8 format, are recognized for their potential to enhance interior spaces while providing moisture resistance, fireproof properties, and ease of installation. This evolution reflects a shift in market demands, where aesthetics, functionality, and sustainability play critical roles in driving B2B purchasing decisions.

Illustrative image related to pvc wall panels 4×8

In conclusion, the PVC wall panels market is characterized by dynamic trends influenced by technology and sustainability, requiring international B2B buyers to remain vigilant in sourcing practices to meet evolving consumer expectations and regulatory standards.

Frequently Asked Questions (FAQs) for B2B Buyers of pvc wall panels 4×8

1. How do I ensure the quality of PVC wall panels before purchasing?

To ensure the quality of PVC wall panels, request product samples from potential suppliers. Assess the panels for durability, color consistency, and finish. Additionally, inquire about certifications, such as fire resistance and waterproof ratings, which indicate compliance with international standards. Establish clear quality control measures, including third-party inspections, to validate the product’s quality before shipment.

2. What is the best way to find reliable suppliers of PVC wall panels?

Finding reliable suppliers involves conducting thorough research. Utilize online B2B marketplaces, industry trade shows, and local business directories. Verify suppliers’ credentials through reviews, ratings, and references from previous clients. Consider engaging with trade associations or chambers of commerce in your region for recommendations on reputable manufacturers.

3. What are the typical minimum order quantities (MOQs) for PVC wall panels?

Minimum order quantities for PVC wall panels can vary significantly among suppliers, typically ranging from 100 to 1,000 square feet. Some suppliers may offer lower MOQs for custom designs or samples. Discuss your project needs directly with suppliers to negotiate favorable terms that align with your purchasing strategy and budget.

4. Can I customize the design and colors of PVC wall panels?

Yes, many manufacturers offer customization options for PVC wall panels, including colors, textures, and sizes. Be prepared to provide detailed specifications and possibly a design mockup. Custom designs may have higher MOQs or lead times, so it’s essential to confirm these details upfront to ensure alignment with your project timelines.

5. What payment terms should I expect when sourcing PVC wall panels internationally?

Payment terms can vary by supplier but generally include options such as upfront deposits (often 30-50%) and the balance upon shipment or delivery. Letters of credit and PayPal may also be available for added security. It’s crucial to clarify payment terms early in negotiations to avoid misunderstandings and ensure a smooth transaction process.

6. How do I handle logistics and shipping for international orders of PVC wall panels?

Coordinate with your supplier to determine the most efficient shipping method, considering factors like cost, speed, and reliability. Work with freight forwarders who specialize in international shipping to manage customs clearance and delivery logistics. Ensure that all shipping documents, including invoices and packing lists, are accurate to prevent delays.

7. What are the best practices for installation of PVC wall panels?

For optimal installation, ensure that the wall surface is smooth, clean, and dry. Most PVC panels can be installed using adhesive or screws, depending on the specific product requirements. Follow the manufacturer’s installation guidelines closely, and consider hiring experienced installers to achieve a professional finish. Proper installation techniques will enhance durability and aesthetics.

8. How do I assess the environmental impact of PVC wall panels?

Assessing the environmental impact involves reviewing the manufacturer’s sustainability practices and certifications. Inquire if the panels are made from recycled materials or are recyclable themselves. Certifications like GreenGuard or LEED can indicate lower emissions and environmental friendliness. Engaging with suppliers who prioritize sustainability can align your projects with eco-friendly initiatives.

Top 3 Pvc Wall Panels 4X8 Manufacturers & Suppliers List

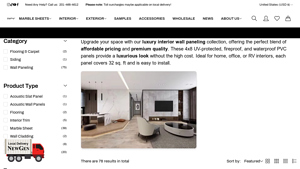

1. New Gen Depot – Luxury Interior Wall Panels

Domain: newgendepot.com

Registered: 2024 (1 years)

Introduction: Luxury Interior Wall Panels – Premium Quality and Waterproof. Available in various styles including PVC Marble Sheets, Acoustic Wall Panels, Bamboo Veneer Panels, and WPC Wall Panels. Sizes include 4×8 ft panels covering 32 sq. ft. Features include UV protection, fireproof, and waterproof materials. Pricing ranges from $30.00 to $86.00 depending on the specific product. Products are available in m…

2. MirroFlex – Glacier PVC Wall Panels

Domain: decorativeceilingtiles.net

Registered: 2007 (18 years)

Introduction: Glacier 4×10 and 4×8 PVC Wall Panels by MirroFlex: Attractive, Affordable Wall Paneling Sheets

3. Farmer Boy – PVC & Polymer Wall Panels

Domain: farmerboyag.com

Registered: 1997 (28 years)

Introduction: PVC, Polymer, & Plastic Wall Panels for sale; Everyday low shipping cost; Most products ship for $14.95.

Strategic Sourcing Conclusion and Outlook for pvc wall panels 4×8

In conclusion, the strategic sourcing of 4×8 PVC wall panels presents a compelling opportunity for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. These panels offer a unique combination of durability, aesthetic appeal, and ease of installation, making them ideal for a wide range of applications, from residential to commercial settings. The competitive pricing and availability of various styles and finishes enhance their attractiveness for businesses seeking cost-effective solutions without compromising on quality.

As the demand for versatile and sustainable building materials continues to rise, leveraging strategic sourcing can ensure that businesses stay ahead of market trends while maximizing profit margins. By partnering with reliable manufacturers and suppliers, buyers can access high-quality products that meet international standards and cater to local preferences.

Looking ahead, it is essential for businesses to remain proactive in exploring innovative designs and technologies within the PVC wall panel market. Embrace this opportunity to enhance your product offerings and respond to evolving customer demands. Connect with trusted suppliers today to position your business for success in the dynamic landscape of interior design and construction.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.