A B2B Buyer’s Guide to Pvc Ball Valve Types: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for pvc ball valve types

Navigating the global market for PVC ball valve types presents a unique set of challenges for international B2B buyers. One critical concern is the need for reliable sourcing of high-quality valves that meet specific application requirements. Whether you are managing water treatment facilities, operating in the food and beverage industry, or overseeing landscaping projects, understanding the nuances of PVC ball valves is essential. This guide offers a comprehensive overview of various PVC ball valve types, including True Union, Compact, and 3-Way valves, along with their respective applications, advantages, and limitations.

In the coming sections, we will delve into essential topics such as supplier vetting processes, cost considerations, and regional compliance standards. Buyers from diverse markets—including Nigeria, Brazil, and countries in the Middle East and Europe—will find actionable insights tailored to their specific needs. By equipping you with the knowledge to evaluate and select the right PVC ball valves, this guide empowers you to make informed purchasing decisions that enhance operational efficiency and product reliability. As the demand for durable, corrosion-resistant valves continues to rise globally, understanding these components will be pivotal in ensuring your projects succeed while optimizing costs and resources.

Understanding pvc ball valve types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PVC Compact Ball Valves | Smaller size, lightweight, and easy to install | Landscaping, pools, laboratories | Pros: Cost-effective, space-saving; Cons: Limited flow capacity. |

| PVC True Union Ball Valves | Allows for easy disassembly without removing the entire valve | Water treatment, chemical applications | Pros: Simplifies maintenance; Cons: Slightly higher cost. |

| PVC 3-Way Ball Valves | Can direct flow in multiple directions, offering versatility | HVAC systems, fluid control | Pros: Flexible flow management; Cons: More complex installation. |

| PVC Flanged Ball Valves | Features flanged connections for secure installation | Industrial piping systems, water transport | Pros: Strong connection; Cons: Requires additional space for flanges. |

| PVC Actuated Ball Valves | Equipped with automated actuators for remote operation | Process automation, manufacturing | Pros: Enhances operational efficiency; Cons: Higher initial investment. |

What Are the Characteristics of PVC Compact Ball Valves?

PVC Compact Ball Valves are designed for applications where space is limited. Their lightweight construction and smaller size make them ideal for landscaping, pools, and laboratory environments. They provide a reliable on/off function with a watertight seal, which is crucial in scenarios where leak prevention is paramount. For buyers, the cost-effectiveness and ease of installation are significant advantages; however, they may have limited flow capacity compared to larger valve types.

How Do PVC True Union Ball Valves Simplify Maintenance?

PVC True Union Ball Valves are distinguished by their ability to be disassembled easily without removing the entire valve from the piping system. This feature is particularly beneficial in industrial settings, such as water treatment and chemical applications, where regular maintenance is necessary. Buyers appreciate the ease of repair and maintenance, but the initial purchase price may be higher than standard valves. Investing in true union valves can lead to long-term savings by reducing downtime during maintenance.

Illustrative image related to pvc ball valve types

What Applications Benefit from PVC 3-Way Ball Valves?

PVC 3-Way Ball Valves offer the unique ability to control the direction of fluid flow, making them versatile for various applications, including HVAC systems and fluid control in manufacturing processes. Their design allows for efficient management of flow paths, which can enhance system performance. However, the installation can be more complex than traditional valves, and buyers should consider the technical expertise required for proper installation.

Why Choose PVC Flanged Ball Valves for Industrial Systems?

PVC Flanged Ball Valves are designed with flanged connections that provide a robust and secure installation, making them suitable for industrial piping systems and water transport applications. These valves can handle high-pressure environments and ensure a strong connection, which is essential for maintaining system integrity. While they offer significant advantages in terms of strength and durability, buyers must account for the additional space required for flanged connections in their design considerations.

What Advantages Do PVC Actuated Ball Valves Offer for Automation?

PVC Actuated Ball Valves come equipped with automated actuators, allowing for remote operation, which is increasingly important in process automation and manufacturing settings. These valves significantly enhance operational efficiency by reducing the need for manual intervention. However, they also come with a higher initial investment, making it essential for buyers to evaluate the long-term benefits against upfront costs to determine the best solution for their operational needs.

Key Industrial Applications of pvc ball valve types

| Industry/Sector | Specific Application of PVC Ball Valve Types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Treatment | Flow control in filtration systems | Ensures efficient operation and reduces downtime | Pressure ratings, chemical compatibility, size options |

| Agriculture & Landscaping | Irrigation systems and water management | Optimizes water usage and minimizes waste | Durability, UV resistance, ease of installation |

| Food & Beverage | Process control in beverage production | Maintains hygiene and prevents contamination | Compliance with food safety standards, material certifications |

| Chemical Processing | Mixing and distribution of non-critical chemicals | Reduces corrosion risk and enhances safety | Chemical resistance, valve size, and connection types |

| Laboratory & Research | Fluid transfer and control in experimental setups | Provides precise flow control and reliability | Quality certifications, compatibility with various fluids |

How Are PVC Ball Valve Types Used in Water Treatment?

In water treatment facilities, PVC ball valves play a crucial role in controlling the flow of water through various filtration systems. By enabling quick shut-off capabilities, these valves help maintain system efficiency and reduce the risk of leaks. For international buyers, especially in regions like Africa and the Middle East, it is essential to consider the pressure ratings and chemical compatibility of PVC valves, ensuring they can withstand the specific conditions of local water treatment processes.

What Role Do PVC Ball Valves Play in Agriculture and Landscaping?

PVC ball valves are extensively used in irrigation systems to manage water flow efficiently. Their ability to create a watertight seal allows for precise control over water usage, which is vital in regions prone to drought, such as parts of Brazil and South Africa. Buyers should prioritize durability and UV resistance when sourcing these valves, as they need to withstand outdoor conditions while ensuring long-term functionality in agricultural applications.

Illustrative image related to pvc ball valve types

Why Are PVC Ball Valves Important in the Food and Beverage Industry?

In the food and beverage sector, PVC ball valves are critical for process control, ensuring that liquids flow smoothly and hygienically through production lines. These valves help prevent contamination, which is paramount in maintaining food safety standards. B2B buyers should look for valves that comply with relevant food safety certifications, as well as those made from materials that are resistant to cleaning chemicals and high temperatures to ensure compliance with industry regulations.

How Do PVC Ball Valves Enhance Chemical Processing?

In chemical processing, PVC ball valves are utilized for mixing and distributing non-critical chemicals, offering a solution that minimizes corrosion risks compared to metal alternatives. Their high-pressure resistance is particularly beneficial in systems that handle aggressive fluids. Buyers in this sector must assess the chemical resistance of the valves, ensuring they are suitable for the specific chemicals being handled, as well as the necessary valve sizes and connection types for seamless integration into existing systems.

What Benefits Do PVC Ball Valves Offer in Laboratory Settings?

In laboratories, PVC ball valves are essential for fluid transfer and control during experiments. Their precision and reliability make them ideal for critical applications where accurate flow rates are necessary. For international buyers, particularly in Europe and South America, sourcing valves that meet quality certifications and are compatible with various fluids is vital to ensure safety and compliance in laboratory environments.

3 Common User Pain Points for ‘pvc ball valve types’ & Their Solutions

Scenario 1: Difficulty in Achieving a Watertight Seal

The Problem:

Many B2B buyers in industries such as landscaping, water treatment, and food processing face the challenge of ensuring a watertight seal when using PVC ball valves. A compromised seal can lead to leaks, which not only result in wastage of resources but also potential damage to surrounding infrastructure and materials. This issue often arises from improper installation, poor valve selection, or wear and tear over time, creating frustration and unexpected maintenance costs.

Illustrative image related to pvc ball valve types

The Solution:

To avoid issues with sealing, it’s crucial to choose the right type of PVC ball valve based on the specific application. For example, true union ball valves are highly recommended due to their design, which allows for easy replacement and maintenance without removing the entire valve from the pipeline. When sourcing these valves, ensure that they are made from high-quality PVC materials designed for durability and resistance to chemical corrosion. During installation, always follow the manufacturer’s guidelines, ensuring that the valve is properly aligned and that seals and gaskets are in good condition. Regular maintenance checks can also help identify any wear and replace seals proactively, minimizing downtime and leaks.

Scenario 2: Incompatibility with Chemicals

The Problem:

B2B buyers in chemical processing industries often struggle with selecting PVC ball valves that can withstand the specific chemicals they are using. Many standard PVC valves may not be compatible with certain aggressive chemicals, leading to degradation, leaks, or complete valve failure. This scenario not only disrupts operations but can also pose safety hazards for workers and the environment.

The Solution:

To effectively address this issue, buyers should conduct a thorough compatibility analysis of the chemicals involved in their processes. Opt for PVC ball valves specifically designed with enhanced chemical resistance, such as those featuring Viton or EPDM seals, which provide better durability against harsh substances. When sourcing these valves, consult with suppliers who can provide detailed chemical compatibility charts and recommendations based on the specific application. Additionally, implementing a testing phase with a small batch of valves can ensure that they perform adequately under real operational conditions before full-scale deployment.

Illustrative image related to pvc ball valve types

Scenario 3: Pressure Drop Concerns

The Problem:

A common pain point for B2B buyers in industries such as water treatment and food processing is experiencing significant pressure drops when using PVC ball valves. These drops can hinder efficient operations, affect product quality, and lead to increased energy costs. Often, the design of the valve or the size in relation to the pipeline can contribute to this issue, leaving buyers frustrated and seeking alternatives.

The Solution:

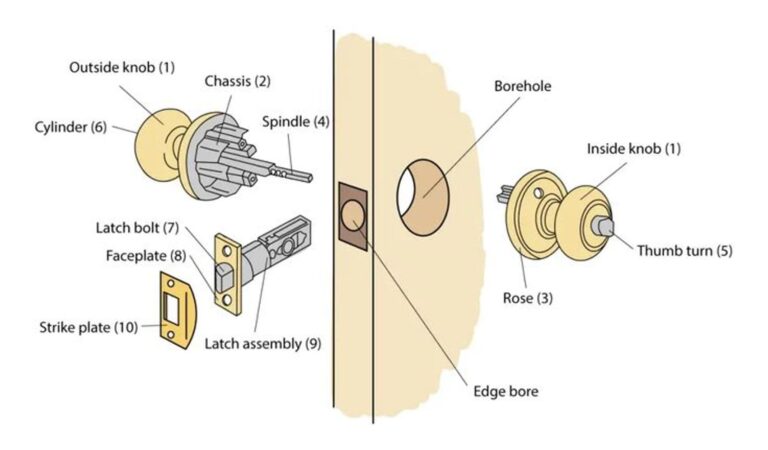

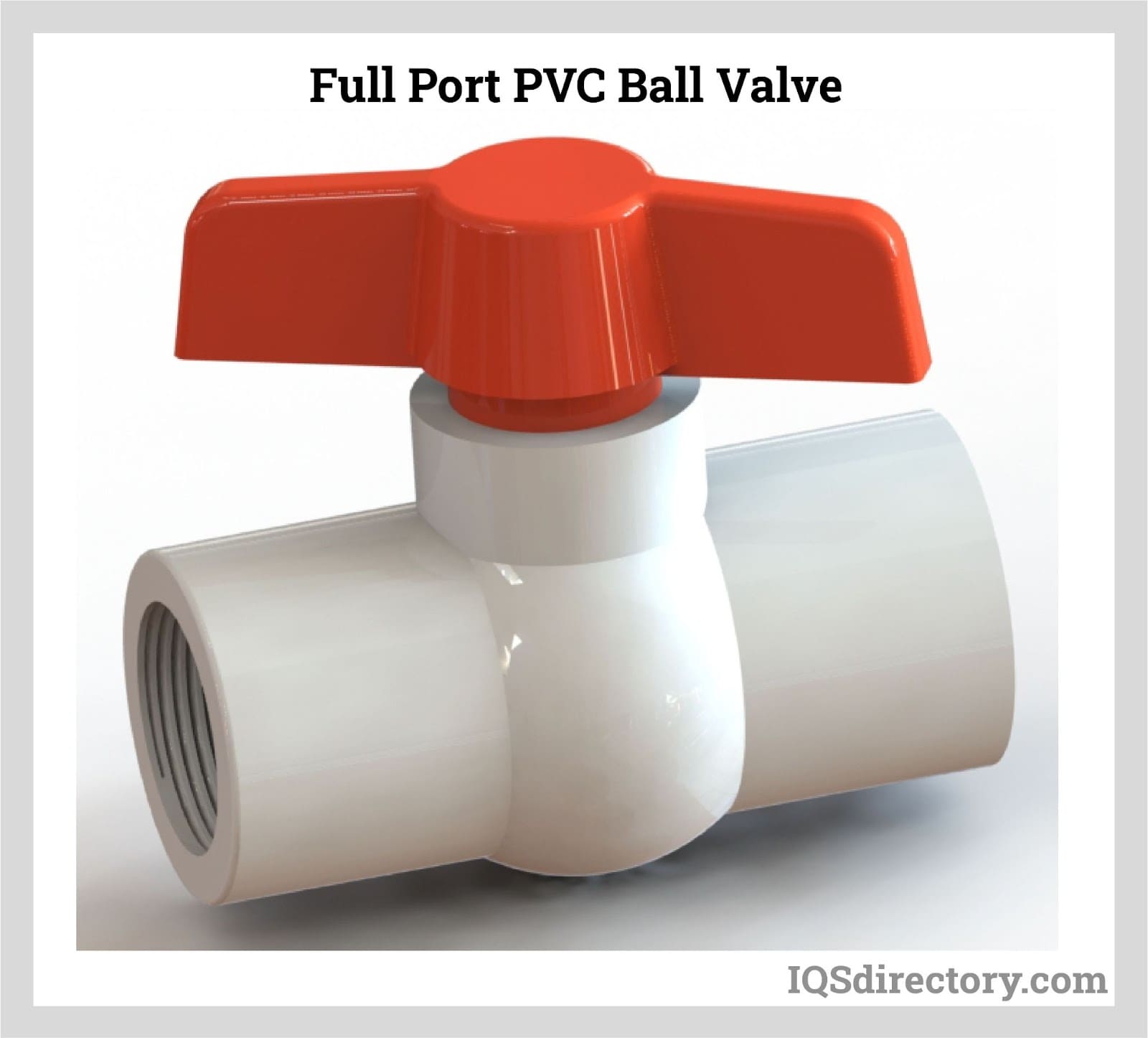

To mitigate pressure drop issues, it’s essential to choose the right size and type of PVC ball valve that matches the system requirements. Select valves that feature a full-port design, as these have openings that are the same diameter as the pipeline, allowing for minimal flow restriction. When evaluating options, consider conducting a flow analysis to understand how different valve types will affect overall system performance. Additionally, ensure that the installation is optimized for flow, avoiding any unnecessary bends or restrictions in the piping that could exacerbate pressure loss. Regularly reviewing system performance and making adjustments as needed can also help maintain optimal pressure levels throughout operations.

Strategic Material Selection Guide for pvc ball valve types

What Are the Key Properties of PVC Ball Valves?

PVC (Polyvinyl Chloride) is the most common material used for ball valves due to its unique properties. It offers excellent corrosion resistance, making it suitable for a variety of applications, including water treatment, chemical processing, and landscaping. PVC ball valves typically operate effectively within a temperature range of -20°C to 60°C (-4°F to 140°F) and can handle pressures up to 150 psi, depending on the design and size.

What Are the Advantages and Disadvantages of PVC for Ball Valves?

Advantages: PVC is lightweight, easy to install, and requires minimal maintenance. Its resistance to rust and corrosion makes it ideal for outdoor applications and environments where exposure to moisture is common. Moreover, PVC is cost-effective, which is a significant consideration for international buyers looking to optimize budgets.

Disadvantages: The primary limitation of PVC is its susceptibility to UV degradation, which can lead to brittleness over time if used in direct sunlight without protective measures. Additionally, while PVC is suitable for many chemicals, it may not be compatible with certain solvents and high-temperature applications.

How Does CPVC Compare for PVC Ball Valve Applications?

Chlorinated Polyvinyl Chloride (CPVC) is another popular choice for ball valves, particularly in applications requiring higher temperature resistance. CPVC can handle temperatures up to 93°C (200°F) and is also resistant to a wider range of chemicals compared to standard PVC.

Advantages: The main advantage of CPVC is its ability to withstand higher temperatures and its compatibility with aggressive chemicals, making it suitable for industrial applications.

Disadvantages: However, CPVC is more expensive than PVC, which could be a drawback for buyers with strict budget constraints. Its installation may also require more specialized tools and techniques.

What Role Does PP (Polypropylene) Play in Ball Valve Selection?

Polypropylene (PP) is another material option for ball valves, particularly in applications involving corrosive substances. PP ball valves can operate effectively at temperatures up to 100°C (212°F) and are known for their excellent chemical resistance.

Advantages: The chemical resistance of PP makes it ideal for industries such as pharmaceuticals and food processing, where contamination must be avoided. Additionally, PP is lightweight and easy to handle.

Disadvantages: On the downside, PP is less rigid than PVC and CPVC, which can lead to deformation under high pressure or temperature. This material may also be more expensive, impacting overall project costs.

What Are the Considerations for International B2B Buyers?

When selecting materials for PVC ball valves, international buyers, especially from regions like Africa, South America, the Middle East, and Europe, must consider compliance with local standards such as ASTM, DIN, and JIS. Understanding the specific requirements for chemical compatibility and environmental conditions is crucial. Additionally, factors such as availability, shipping costs, and supplier reliability can significantly impact procurement decisions.

Summary Table of Material Properties for PVC Ball Valves

| Material | Typical Use Case for pvc ball valve types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Water treatment, landscaping | Cost-effective, lightweight | Susceptible to UV degradation | Low |

| CPVC | Industrial applications, high temperatures | Higher temperature resistance | More expensive, requires specialized installation | Medium |

| PP | Pharmaceuticals, food processing | Excellent chemical resistance | Less rigid, potential deformation | Medium |

| PVDF | Chemical processing, aggressive environments | Superior chemical resistance | Higher cost, limited availability | High |

This analysis should guide international B2B buyers in selecting the most suitable materials for their PVC ball valve needs, ensuring optimal performance and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for pvc ball valve types

What Are the Main Stages in the Manufacturing Process of PVC Ball Valves?

The manufacturing process of PVC ball valves involves several critical stages that ensure the valves meet industry standards and customer requirements.

Material Preparation

The first step in the manufacturing process is material preparation, where high-quality PVC resin is sourced. The resin is typically subjected to rigorous quality checks to ensure it meets specific standards for durability, chemical resistance, and pressure handling. In addition to PVC, other materials such as EPDM or Viton may be used for seals, depending on the application requirements. Suppliers often utilize advanced material testing methods, including spectroscopy and tensile testing, to verify the integrity of the raw materials before moving forward.

Forming Techniques

Once the materials are prepared, the next stage is forming. This typically involves processes such as injection molding or extrusion. Injection molding is particularly common for creating complex shapes and sizes of ball valves. During this stage, the PVC resin is heated until molten and then injected into molds that shape the valve components, including the body, ball, and seals. Extrusion is another technique used for producing long, uniform sections of valve bodies. The choice of forming technique can impact the valve’s performance characteristics, including pressure resistance and flow efficiency.

Assembly Processes

After forming, the individual components are assembled. This stage includes fitting the ball inside the valve body and attaching any necessary seals. True union ball valves, for instance, allow for easy maintenance and repair by enabling the removal of the valve’s carrier without disconnecting the entire system. Automated assembly lines are often employed to enhance precision and reduce human error during this stage. Quality control checkpoints are integrated into the assembly process to ensure that each valve meets stringent design specifications.

Finishing Techniques

The final stage in manufacturing PVC ball valves is finishing. This includes surface treatments such as cleaning, polishing, and applying any necessary coatings to enhance chemical resistance or provide additional protection against environmental factors. Finishing techniques can also include the addition of markings or labels to meet regulatory requirements. Proper finishing is crucial as it can significantly affect the valve’s longevity and performance in various applications.

How Is Quality Assurance Implemented in PVC Ball Valve Manufacturing?

Quality assurance (QA) in the manufacturing of PVC ball valves is vital to ensure that the final products meet international standards and customer specifications.

What International Standards Are Relevant for PVC Ball Valve Quality Control?

Manufacturers often adhere to international quality standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with ISO standards indicates that the manufacturer consistently provides products that meet customer and regulatory requirements. Additionally, industry-specific certifications such as CE marking for compliance with European safety standards and API standards for the oil and gas industry further enhance product credibility.

What Are the Key Quality Control Checkpoints in PVC Ball Valve Manufacturing?

Quality control is embedded at various stages of the manufacturing process. The main checkpoints typically include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): During the manufacturing process, random samples are taken to check for dimensional accuracy and material integrity. This is crucial to identify defects early in the production cycle.

- Final Quality Control (FQC): After assembly, each valve undergoes a thorough inspection, which may include pressure testing, leak testing, and dimensional checks to ensure they function correctly before shipment.

What Testing Methods Are Commonly Used in PVC Ball Valve Quality Assurance?

Testing methods employed in the quality assurance of PVC ball valves include:

- Hydrostatic Testing: This method assesses the valve’s ability to withstand high-pressure conditions without leaking.

- Leak Testing: Valves are subjected to various methods to ensure they provide a watertight seal in both open and closed positions.

- Dimensional Inspection: Precision measuring tools are used to ensure that all components conform to specified tolerances.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must ensure that their suppliers maintain rigorous quality control processes. Here are several ways to verify supplier quality:

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request access to quality assurance reports and audit results from their suppliers. Regular internal audits and third-party inspections can serve as credible evidence of a supplier’s commitment to maintaining high-quality standards. Buyers should also inquire about the frequency of these audits and any corrective actions taken in response to identified issues.

Are There Nuances in Quality Control for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of the specific regulations and standards that apply to their respective markets. For instance, compliance with local regulations may differ from international standards, necessitating additional certifications or testing. Understanding these nuances can help buyers mitigate risks and ensure product compliance.

Illustrative image related to pvc ball valve types

Conclusion

The manufacturing processes and quality assurance protocols for PVC ball valves are essential for producing reliable and durable products. By understanding the stages of manufacturing, the importance of quality control, and how to verify supplier compliance, international B2B buyers can make informed decisions when sourcing PVC ball valves for their applications. This knowledge not only enhances procurement strategies but also helps in establishing long-term partnerships with manufacturers committed to quality and excellence.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pvc ball valve types’

To assist international B2B buyers in procuring PVC ball valves effectively, this step-by-step guide outlines key considerations and actions. By following this checklist, you will ensure that your sourcing process is thorough, cost-effective, and aligned with your specific requirements.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical for ensuring that the PVC ball valves meet your operational needs. Consider factors such as size (e.g., diameter), pressure ratings, and chemical compatibility. Documenting these specifications will facilitate discussions with suppliers and prevent misunderstandings later in the procurement process.

Step 2: Identify the Right Type of PVC Ball Valve

Understand the different types of PVC ball valves available, including compact, true union, and three-way valves. Each type serves specific applications, such as water treatment, chemical processing, or irrigation. Knowing the application will help you choose the most suitable valve type, optimizing performance and efficiency.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers that specialize in PVC valves and have a proven track record of reliability and quality in their products.

Illustrative image related to pvc ball valve types

- Check certifications: Ensure that suppliers comply with international standards relevant to your industry, such as ISO certifications or specific regional standards.

Step 4: Assess Product Quality and Durability

Product quality is paramount when sourcing PVC ball valves, as they must withstand various operating conditions. Request samples or detailed product specifications to evaluate materials and construction. Look for features like rust-proofing, pressure resistance, and compatibility with your intended applications.

Step 5: Review Pricing and Payment Terms

Analyze pricing structures from multiple suppliers to identify competitive rates while ensuring quality is not compromised. Inquire about bulk pricing, discounts, and payment terms that align with your budget and financial strategy. Transparent pricing practices help in forecasting costs accurately.

Step 6: Understand Shipping and Delivery Logistics

Discuss shipping options and delivery timelines with potential suppliers. Consider lead times, shipping costs, and the ability to handle customs clearance if you’re sourcing internationally. A reliable supplier should provide clear and efficient logistics solutions to ensure timely delivery.

Step 7: Establish After-Sales Support and Warranty

Inquire about the after-sales support and warranty options offered by suppliers. A good warranty can protect your investment and provide peace of mind, while responsive customer support can assist with any issues that arise post-purchase. Ensure that you understand the terms and conditions of warranties and support services.

By following this checklist, you can streamline your sourcing process for PVC ball valves, ensuring that you select the right products and suppliers that align with your business needs and industry standards.

Comprehensive Cost and Pricing Analysis for pvc ball valve types Sourcing

What Are the Key Cost Components for Sourcing PVC Ball Valve Types?

When sourcing PVC ball valves, understanding the cost structure is crucial for making informed purchasing decisions. The primary components of the cost structure include:

-

Materials: PVC is the primary material used in ball valves due to its durability, resistance to corrosion, and low maintenance requirements. The cost of PVC can fluctuate based on market conditions, affecting the overall price of the valves. Higher-grade materials, such as those with enhanced chemical resistance (like Viton or EPDM seals), can also increase costs.

-

Labor: Manufacturing labor costs vary significantly by region. In regions with lower labor costs, such as parts of Africa and South America, the cost of production may be more competitive, potentially reducing the overall price for buyers.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help minimize these costs, leading to more competitive pricing.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs or larger production runs. Buyers should consider whether the tooling costs are included in the quoted price or charged separately.

-

Quality Control (QC): Ensuring that the valves meet industry standards is critical. QC processes add to the manufacturing costs but are essential for maintaining product reliability, especially in applications involving chemicals or high-pressure systems.

-

Logistics: Shipping costs can vary based on the destination and the chosen Incoterms. International shipping can lead to additional expenses due to tariffs, taxes, and freight charges, which should be factored into the total cost.

-

Margin: Suppliers typically apply a markup to cover their costs and generate profit. Understanding the margin can provide insights into pricing flexibility during negotiations.

What Influences the Pricing of PVC Ball Valves?

Several factors can influence the pricing of PVC ball valves, making it essential for buyers to consider these aspects during procurement:

-

Volume/MOQ: Ordering in bulk often results in lower per-unit costs. Suppliers may have minimum order quantities (MOQ) that can affect pricing, so negotiating larger orders can yield cost savings.

-

Specifications and Customization: Custom valves or those with specific requirements (e.g., size, pressure rating) may incur higher costs due to the additional resources needed for production.

-

Materials and Quality Certifications: Valves made from higher-quality materials or those that meet specific certifications (such as ISO or ANSI standards) will typically command higher prices. Buyers should weigh the benefits of these certifications against their specific needs.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge a premium for their proven quality and service.

-

Incoterms: The chosen Incoterms can significantly impact the total cost, as they dictate who is responsible for shipping, insurance, and tariffs during the transport of goods. Understanding these terms can help buyers avoid unexpected expenses.

How Can Buyers Negotiate and Optimize Costs When Sourcing PVC Ball Valves?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can adopt several strategies to optimize costs:

-

Leverage Negotiation: Engage in discussions with suppliers to negotiate better terms, especially if you have a long-term relationship or are placing a significant order.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but the overall cost of ownership, including maintenance, replacement, and operational efficiency. Investing in higher-quality valves can lead to long-term savings.

-

Understand Pricing Nuances: Be aware of the specific pricing dynamics in your region. Local economic conditions, currency fluctuations, and supply chain disruptions can all affect costs and availability.

-

Build Relationships with Suppliers: Establishing strong relationships with suppliers can lead to preferential pricing, improved service levels, and better access to new products.

Conclusion

Navigating the complexities of sourcing PVC ball valves requires a deep understanding of cost components, pricing influencers, and effective negotiation strategies. By taking these factors into account, international buyers can make more informed decisions, ensuring they secure quality products at competitive prices while minimizing long-term costs.

Alternatives Analysis: Comparing pvc ball valve types With Other Solutions

Exploring Alternatives to PVC Ball Valve Types: A Comparative Analysis

In the realm of fluid control systems, PVC ball valves are widely recognized for their durability, efficiency, and cost-effectiveness. However, various alternatives exist that may better suit specific applications or environments. Understanding these alternatives can help B2B buyers make informed decisions when selecting the right solution for their fluid management needs.

Illustrative image related to pvc ball valve types

| Comparison Aspect | PVC Ball Valve Types | Alternative 1 Name: Stainless Steel Ball Valves | Alternative 2 Name: Electric Actuated Valves |

|---|---|---|---|

| Performance | High pressure resistance; watertight seal; minimal pressure drop | Excellent corrosion resistance; suitable for high temperatures | Provides precise control and automation of flow |

| Cost | Generally low-cost; affordable maintenance | Higher initial investment; longer lifespan may offset costs | Higher installation and operational costs due to automation |

| Ease of Implementation | Simple installation; available in various sizes | Moderate installation complexity; may require specialized tools | Complex installation; requires electrical connections |

| Maintenance | Low maintenance; resistant to rust and corrosion | Moderate maintenance; may need periodic checks for leaks | Requires regular maintenance of electronic components |

| Best Use Case | Landscaping, water treatment, chemical applications | Industrial applications, food processing, high-pressure systems | Automation in process control, where precision is critical |

What Are the Advantages and Disadvantages of Stainless Steel Ball Valves?

Stainless steel ball valves offer a robust alternative to PVC options, particularly in environments where corrosion resistance is paramount. They excel in high-temperature applications, making them ideal for industries such as food processing and pharmaceuticals. However, the initial investment is significantly higher than that of PVC ball valves, which may be a deterrent for budget-conscious buyers. Additionally, while stainless steel valves have a longer lifespan, they require more maintenance compared to their PVC counterparts, particularly in aggressive chemical environments.

How Do Electric Actuated Valves Compare in Terms of Control and Automation?

Electric actuated valves provide an advanced solution for fluid control, particularly in systems requiring automation. These valves allow for precise control over flow rates and can be integrated into automated systems for enhanced efficiency. However, the complexity of installation and the need for electrical connections make them less accessible for some applications. Moreover, the operational costs can be higher due to the need for regular maintenance of the electronic components. For companies looking to enhance their process control capabilities, electric actuated valves can be a worthwhile investment, provided the budget allows for it.

Making the Right Choice: How to Select the Best Valve Solution for Your Needs?

When evaluating valve solutions, B2B buyers should consider several factors, including the specific application requirements, budget constraints, and the desired level of control. PVC ball valves are well-suited for low-cost, low-maintenance applications, especially in landscaping and water treatment. Conversely, if the application involves corrosive substances or requires automation, investing in stainless steel or electric actuated valves may provide long-term benefits. Ultimately, understanding the unique demands of each project will guide buyers toward the most suitable valve solution, ensuring operational efficiency and cost-effectiveness.

Essential Technical Properties and Trade Terminology for pvc ball valve types

What Are the Key Technical Properties of PVC Ball Valves?

When selecting PVC ball valves for industrial applications, understanding their technical properties is crucial. Here are some essential specifications that every B2B buyer should consider:

-

Material Grade

PVC ball valves are typically made from high-quality polyvinyl chloride (PVC) that is resistant to rust and corrosion. The material grade affects durability, chemical resistance, and suitability for various applications. For instance, valves made from Schedule 40 PVC are robust for general use, while those made from Schedule 80 PVC provide higher pressure resistance. -

Pressure Rating

The pressure rating of a PVC ball valve indicates the maximum pressure it can withstand while maintaining functionality. This specification is critical for applications involving high-pressure liquids, as failure to meet pressure requirements can lead to leaks or catastrophic failures. Common pressure ratings for PVC valves are between 150 psi to 300 psi, depending on the valve size and configuration. -

Temperature Tolerance

PVC ball valves generally have a temperature tolerance ranging from 0°F to 140°F (-18°C to 60°C). Understanding temperature limits is vital for applications involving hot liquids or environments. Exceeding these limits may compromise the integrity of the valve and lead to operational failures. -

Size and Connection Type

PVC ball valves come in various sizes, typically ranging from ½ inch to 6 inches in diameter. The connection type (socket, threaded, or flanged) is equally important, as it determines how the valve integrates into existing piping systems. Choosing the correct size and connection type ensures optimal flow and minimizes installation challenges. -

Flow Rate

The flow rate, often measured in gallons per minute (GPM), indicates how much liquid can pass through the valve when fully open. This specification is essential for ensuring that the valve meets the demands of specific applications, such as irrigation or chemical processing. A higher flow rate typically means less pressure drop across the valve. -

Seal Type

The type of seal used in a PVC ball valve—such as EPDM or Viton—affects its suitability for various chemicals and temperature ranges. For instance, Viton seals are preferred for applications involving aggressive chemicals, while EPDM is suitable for water and moderate chemical exposure. Selecting the right seal type ensures long-lasting performance and reduces maintenance costs.

What Are Common Trade Terms Related to PVC Ball Valves?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some commonly used terms related to PVC ball valves:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces components that are used in another company’s end products. For buyers, knowing the OEM helps ensure the quality and compatibility of the valves with existing systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is vital for buyers to manage inventory levels and cash flow effectively. It can also influence purchasing decisions, especially for smaller businesses. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for price quotes for specific products. This term is crucial for buyers looking to compare costs and negotiate better deals. Providing detailed specifications in an RFQ can lead to more accurate and competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk management, and delivery timelines, ensuring smoother cross-border transactions. -

Lead Time

Lead time refers to the period between placing an order and receiving the goods. Understanding lead times is essential for supply chain management and helps buyers plan their operations effectively to avoid downtime. -

Certification Standards

Certification standards refer to the compliance of PVC ball valves with industry regulations and quality assurance protocols (e.g., ISO, ASTM). These certifications are critical for buyers in regulated industries, as they ensure the products meet safety and quality requirements.

By familiarizing yourself with these technical properties and trade terms, you can make informed decisions when sourcing PVC ball valves, ultimately enhancing operational efficiency and reducing costs.

Navigating Market Dynamics and Sourcing Trends in the pvc ball valve types Sector

What Are the Current Market Dynamics and Key Trends in the PVC Ball Valve Types Sector?

The global market for PVC ball valves is experiencing significant growth, driven by increased demand across various industries such as water treatment, food and beverage, and chemical processing. A key trend is the rising adoption of automation technologies in industrial applications, which enhances the efficiency of fluid control systems. This trend is particularly relevant for international B2B buyers from Africa, South America, the Middle East, and Europe, as automation can lead to improved operational efficiencies and reduced labor costs.

Moreover, the shift towards sustainability is influencing sourcing strategies. Buyers are increasingly seeking suppliers that prioritize eco-friendly materials and processes. In particular, the focus on high-quality, durable PVC ball valves that can withstand harsh environments is expected to dominate the market. Emerging technologies, including IoT-enabled valves, are also gaining traction, allowing for real-time monitoring and control of fluid systems. This is especially beneficial for sectors like agriculture in Africa and water management in Brazil.

Illustrative image related to pvc ball valve types

Another dynamic is the growing importance of regional supply chains. Buyers are looking for local suppliers to minimize logistics costs and lead times. In regions such as the Middle East and Africa, where infrastructure is rapidly developing, the demand for reliable and efficient PVC ball valves is set to increase, thus presenting opportunities for international suppliers to establish a foothold.

How Is Sustainability and Ethical Sourcing Transforming the PVC Ball Valve Types Sector?

Sustainability has become a pivotal factor in the sourcing of PVC ball valves. The environmental impact of manufacturing processes is under scrutiny, prompting buyers to prioritize suppliers who adhere to ethical sourcing practices. This includes the use of recycled materials and the implementation of energy-efficient production methods. Buyers are encouraged to seek out suppliers with certifications such as ISO 14001, which indicates a commitment to environmental management.

Furthermore, the importance of ethical supply chains cannot be overstated. Ensuring that suppliers uphold fair labor practices and adhere to environmental regulations is essential for maintaining corporate responsibility. For B2B buyers, especially in regions like Europe, where regulatory frameworks are stringent, partnering with ethically compliant suppliers can enhance brand reputation and reduce risk.

The trend towards ‘green’ certifications is also gaining momentum. Buyers are increasingly looking for PVC ball valves that are made from materials that meet environmental standards, such as low-VOC (volatile organic compounds) PVC. This not only satisfies regulatory requirements but also appeals to end-users who are becoming more environmentally conscious.

Illustrative image related to pvc ball valve types

What Is the Brief Evolution of PVC Ball Valve Types and Their Relevance Today?

The evolution of PVC ball valves can be traced back to the early 20th century when PVC was first introduced as a viable material for plumbing and industrial applications. Initially, metal valves dominated the market, but the introduction of PVC offered a corrosion-resistant, lightweight, and cost-effective alternative. Over the years, advancements in manufacturing techniques have led to the development of various types of PVC ball valves, including compact, true union, and three-way valves.

Today, the relevance of PVC ball valves is underscored by their versatility and durability, making them suitable for a wide range of applications—from landscaping to industrial fluid control. As industries continue to evolve, PVC ball valves have adapted by incorporating innovative features such as automated control and enhanced sealing mechanisms, ensuring they meet the demands of modern applications. This adaptability positions PVC ball valves as a critical component in many industrial and commercial fluid systems, making them a key focus for international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of pvc ball valve types

-

How do I select the right PVC ball valve for my application?

Selecting the right PVC ball valve involves understanding the specific requirements of your application. Consider factors such as the type of fluid being handled, temperature, pressure ratings, and whether a watertight seal is necessary. Additionally, assess whether you need a true union valve for easy maintenance or a compact design for space constraints. Consulting with your supplier about these parameters can help ensure you choose a valve that meets your operational needs effectively. -

What are the advantages of using PVC ball valves over other materials?

PVC ball valves offer several advantages, including resistance to corrosion, rust, and chemical reactions, making them ideal for various applications, including water treatment and chemical handling. They are lightweight and easy to install, often requiring less support than heavier materials. Their durability ensures a long lifespan, reducing the need for frequent replacements, which can save costs in the long run. -

What is the minimum order quantity (MOQ) for PVC ball valves?

Minimum order quantities can vary significantly among suppliers. Some may offer flexible MOQs for smaller businesses, while others may require bulk orders to ensure cost efficiency. It’s essential to communicate your needs with potential suppliers to find one that accommodates your order size. Additionally, consider the logistics involved in shipping larger quantities, especially if you are sourcing internationally. -

What payment terms should I expect when purchasing PVC ball valves internationally?

Payment terms can differ based on the supplier’s policies and the nature of the transaction. Common options include advance payment, net 30/60 terms, or letters of credit for larger orders. It’s crucial to discuss and negotiate these terms upfront to avoid any misunderstandings. Ensure that the payment method you choose is secure and offers some level of buyer protection, especially for international transactions. -

How can I ensure the quality of PVC ball valves from suppliers?

To ensure quality, conduct thorough research on potential suppliers. Look for certifications such as ISO 9001, which indicates adherence to quality management standards. Request product samples to evaluate the material and construction quality before placing a bulk order. Additionally, consider suppliers who offer warranties or guarantees on their products, as this can provide added assurance regarding quality. -

What shipping options are available for PVC ball valves?

Shipping options for PVC ball valves can include air freight for faster delivery or sea freight for cost-effective bulk shipping. The choice often depends on your urgency and budget. Make sure to discuss logistics with your supplier, including shipping times, packaging methods, and customs clearance processes. Understanding these details can help you plan better for inventory management and reduce potential delays. -

Can PVC ball valves be customized for specific applications?

Many suppliers offer customization options for PVC ball valves, including size, end connections, and additional features such as actuation capabilities. If your application requires specific modifications, communicate these needs to your supplier early in the process. Custom valves may involve longer lead times and additional costs, but they can significantly enhance performance in specialized applications. -

What are the typical applications for PVC ball valves in various industries?

PVC ball valves are commonly used in industries such as water treatment, food and beverage processing, chemical handling, landscaping, and laboratory applications. Their versatility allows them to handle various fluids, including water, mild chemicals, and slurries. When sourcing valves, consider the specific demands of your industry to ensure compliance with any relevant regulations and standards.

Top 8 Pvc Ball Valve Types Manufacturers & Suppliers List

1. PVC Fittings Online – PVC Ball Valves

Domain: pvcfittingsonline.com

Registered: 2011 (14 years)

Introduction: PVC Ball Valves are commonly used in landscaping and allow for quick on/off flow control while creating a watertight seal. They are suitable for applications in pools, laboratories, food and beverage industries, water treatment, life science, and chemical applications. The valves feature a ball that rotates on a 90-degree axis, allowing water to flow freely when in the “on” position and stopping f…

2. Commercial Industrial Supply – PVC Ball Valves

Domain: commercial-industrial-supply.com

Registered: 2009 (16 years)

Introduction: PVC Ball Valves are commonly used in landscaping applications, water treatment, life science, food and beverage industries, measurement and control functions, non-critical chemical applications, pools, and laboratories. The collection includes various types such as PVC 3 Way Ball Valves, PVC Compact Ball Valves, and PVC True Union Ball Valves. Key brands include Asahi/America, Cepex, Flui-PRO Valv…

3. Boshart – PVC Ball Valves

Domain: blog.boshart.com

Registered: 1997 (28 years)

Introduction: PVC ball valves can be divided into three types: Compact, Union, and CPVC. Compact PVC ball valves are molded-in-place, strong, and compact, suitable for water supply applications, available in threaded IPS and slip connections for Schedule 40 & 80 pipe. Union PVC ball valves allow in-line maintenance without disconnecting from the pipe, featuring a handle that acts as a spanner wrench for mainten…

4. Assured Automation – 2-Way and 3-Way Ball Valves

Domain: assuredautomation.com

Registered: 1996 (29 years)

Introduction: This company, Assured Automation – 2-Way and 3-Way Ball Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. 247Garden – PVC Ball Valves

Domain: 247garden.com

Registered: 2012 (13 years)

Introduction: Buy PVC Ball Valves at 247Garden | Durable and Reliable Options. Available sizes include 1/2″, 3/4″, 1″, 1-1/4″, 1-1/2″, 2″, 2-1/2″, 3″, 4″, 5″, 6″, 8″, and 10″. Various types include PVC Shutoff Valves, PVC Flanges, and PVC Male/Female Adapters. Special options include Schedule-80 PVC fittings and plumbing-grade PVC. Free shipping available on select items.

6. Instructables – PVC Ball Valves

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: PVC ball valves are quarter-turn valves that use a hollow, perforated, and pivoting ball to control the flow of water, gas, or other compatible fluids. They are known for their reliability and durability, particularly in corrosive environments. Key applications include plumbing systems, chemical processing, water treatment, and HVAC systems. Advantages include corrosion resistance, cost-effectiven…

7. Valtorc – PVC & CPVC V-Ball Valves

Domain: valtorc.com

Registered: 2001 (24 years)

Introduction: PVC and CPVC V-Ball valves are made from high grade PVC materials available in sizes from 1/2″ – 6″ in NPT (threaded) and flanged connection ends. The angle rotation is up to 90 degrees and the valve body can be rotated 360 degrees for placement. V-Ball valves available between 1/2″ and 6″ in size. High strength industrial PVC valve body. Self lubricated TFE seats. Handle indicates valve open/clos…

8. Flows – Air-Operated PVC Ball Valves

Domain: flows.com

Registered: 1995 (30 years)

Introduction: This company, Flows – Air-Operated PVC Ball Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for pvc ball valve types

In the realm of PVC ball valves, strategic sourcing is paramount for international B2B buyers looking to enhance operational efficiency and reliability. Understanding the various types—such as compact, true union, and 3-way ball valves—enables businesses to select the right solution tailored to specific applications, whether in water treatment, landscaping, or chemical processing. The durability and corrosion resistance of PVC make these valves ideal for both outdoor and industrial environments, ensuring long-lasting performance.

By leveraging strategic sourcing, companies can not only optimize costs but also ensure consistent quality and availability of PVC ball valves. This is particularly vital for markets in Africa, South America, the Middle East, and Europe, where supply chain resilience and product reliability can significantly impact project success.

Illustrative image related to pvc ball valve types

As the demand for sustainable and efficient fluid control solutions continues to rise, now is the time to evaluate your sourcing strategies. Engage with reputable suppliers and explore innovative products that meet your operational needs. By doing so, you can position your business for growth and competitive advantage in the evolving global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.