A B2B Buyer’s Guide to Polyethylene Bags Manufacturing Process: Price, Quality, and…

Introduction: Navigating the Global Market for polyethylene bags manufacturing process

Navigating the complexities of the polyethylene bags manufacturing process can be a daunting task for international B2B buyers, especially when sourcing high-quality products that meet specific industry needs. As global demand continues to rise across sectors like retail, packaging, and healthcare, understanding the intricacies of poly bag production is crucial. This comprehensive guide delves into various aspects of polyethylene bags, including manufacturing methods, material types, applications, and supplier vetting strategies.

By exploring the blown-film extrusion technique, the differences between low-density and high-density polyethylene, and the latest innovations in bag design, this guide equips buyers from Africa, South America, the Middle East, and Europe—such as Vietnam and Saudi Arabia—with the knowledge needed to make informed purchasing decisions.

With actionable insights on cost considerations and quality standards, you will be empowered to navigate the global market confidently. Whether you are looking to expand your product line or streamline your supply chain, understanding the polyethylene bags manufacturing process is essential for optimizing your operations and enhancing your competitive edge. This guide serves as your trusted resource for maximizing value and ensuring that you partner with reliable suppliers who align with your business goals.

Understanding polyethylene bags manufacturing process Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Blown-Film Extrusion | Produces a continuous tube of plastic; high efficiency | Retail, packaging, food service | Pros: High production speed; customizable sizes. Cons: Initial equipment costs can be high. |

| Cast Film Extrusion | Creates flat films; excellent clarity and strength | Medical supplies, industrial packaging | Pros: Superior optical clarity; good for printing. Cons: Slower production rate compared to blown film. |

| Co-extrusion | Combines multiple materials for enhanced properties | Food packaging, protective liners | Pros: Improved barrier properties; tailored solutions. Cons: Complexity in manufacturing process. |

| Stretch Film Production | Focuses on stretchability and cling | Pallet wrapping, logistics | Pros: Reduces material usage; enhances load stability. Cons: Limited to specific applications. |

| Recycled Polyethylene Bags | Utilizes post-consumer recycled materials | Eco-friendly packaging solutions | Pros: Sustainable; often cost-effective. Cons: Quality may vary based on material source. |

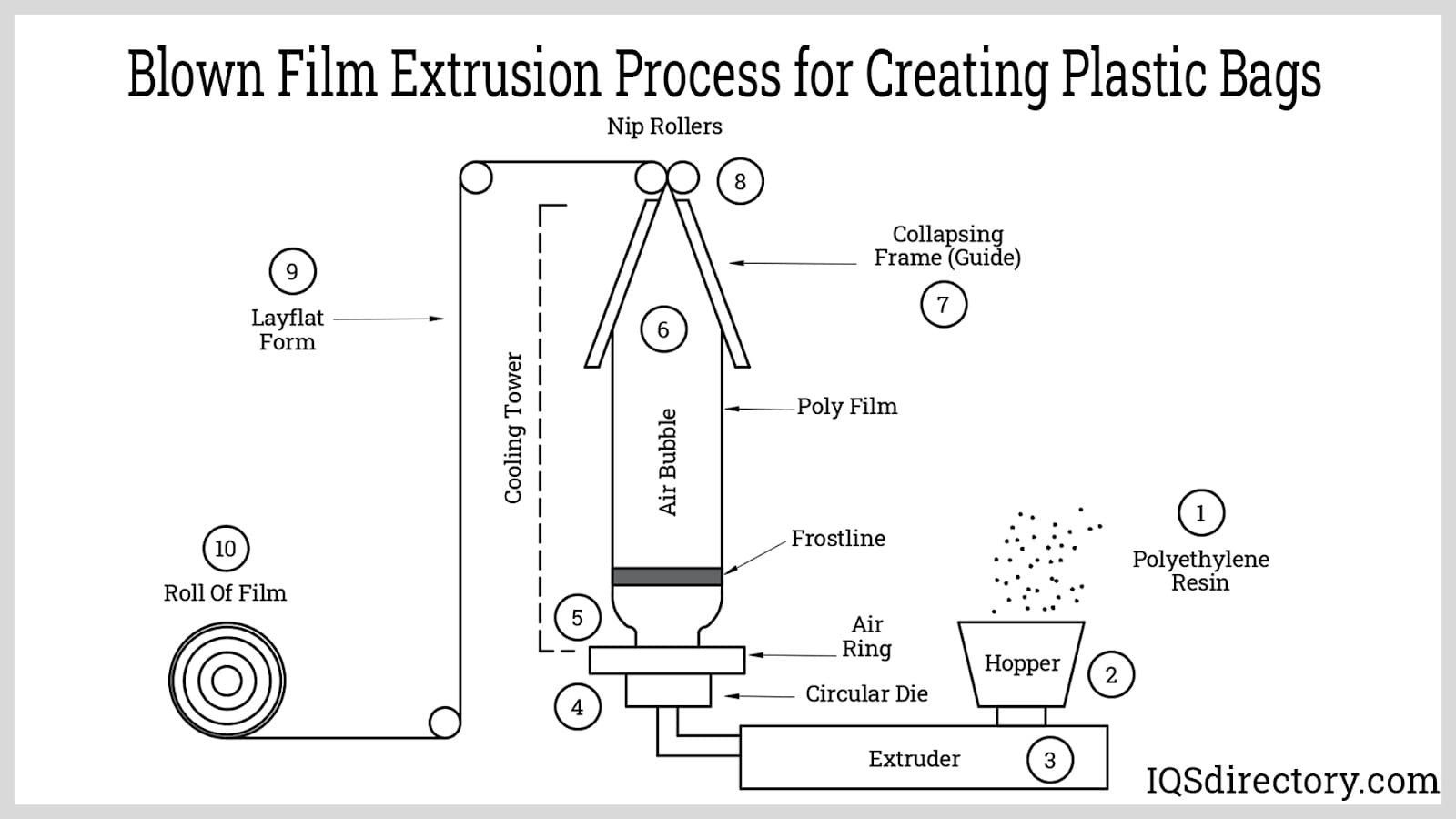

What are the Characteristics of Blown-Film Extrusion in Polyethylene Bag Manufacturing?

Blown-film extrusion is a widely adopted method for producing polyethylene bags. This process involves melting plastic pellets and forming them into a continuous tube, which is then inflated to create a film. The resulting bags are versatile and can be tailored in size and thickness, making them ideal for various applications, including retail and food service. B2B buyers should consider the production speed and customization options when selecting suppliers, as these factors can significantly impact operational efficiency.

How Does Cast Film Extrusion Differ from Other Methods?

Cast film extrusion is characterized by its ability to produce flat films with exceptional clarity and strength. This method is particularly suitable for applications requiring high-quality printing, such as medical supplies and industrial packaging. While it offers superior optical properties, the production rate is generally slower compared to blown-film extrusion. Buyers should assess their specific needs for clarity and printability against the potential trade-offs in production speed.

What Advantages Does Co-extrusion Provide for Polyethylene Bags?

Co-extrusion combines multiple layers of materials to enhance the properties of polyethylene bags. This method allows for the creation of bags with improved barrier characteristics, making them suitable for food packaging and protective liners. While co-extrusion provides tailored solutions that can meet specific performance requirements, the complexity of the manufacturing process may lead to higher costs. B2B buyers should evaluate their packaging needs against the benefits of enhanced durability and protection.

Illustrative image related to polyethylene bags manufacturing process

Why is Stretch Film Production Important for Logistics?

Stretch film production focuses on creating polyethylene films that are highly stretchable and clingy, making them essential for pallet wrapping and logistics. This method reduces material usage while enhancing load stability during transportation. While the benefits of stretch films are clear, buyers should be aware that their applications are somewhat limited compared to other types of polyethylene bags. Understanding the specific needs of their logistics operations will help businesses make informed purchasing decisions.

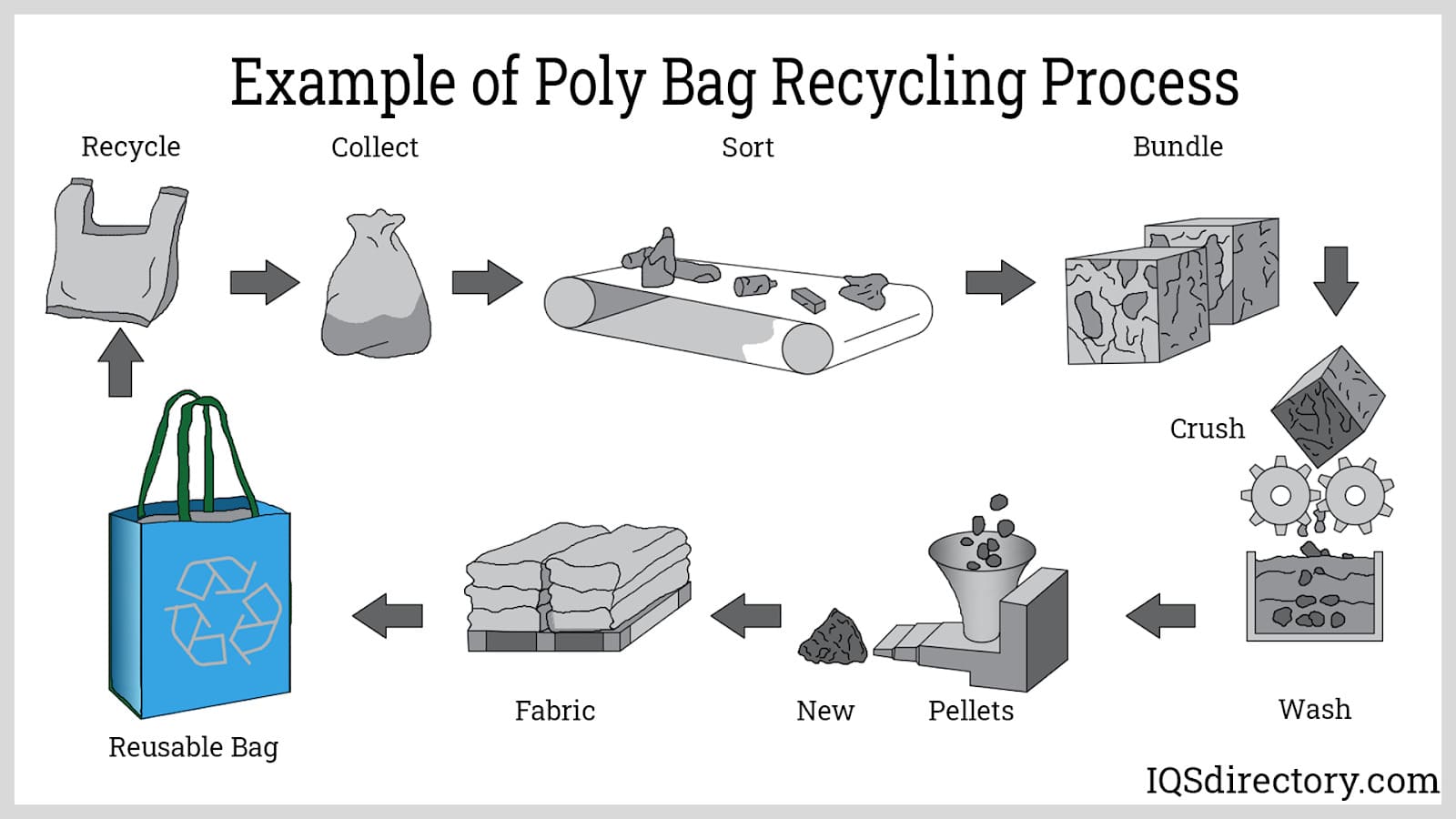

How Do Recycled Polyethylene Bags Support Sustainability Goals?

Recycled polyethylene bags utilize post-consumer materials, promoting sustainability in packaging solutions. These bags are increasingly popular among businesses looking to reduce their environmental impact. They often come at a lower cost, but the quality can vary based on the source of the recycled materials. B2B buyers should consider the balance between sustainability and quality, ensuring that their choice aligns with both their environmental goals and operational requirements.

Key Industrial Applications of polyethylene bags manufacturing process

| Industry/Sector | Specific Application of polyethylene bags manufacturing process | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Custom shopping bags | Enhances brand visibility and customer experience | Consider bag strength, print quality, and eco-friendly materials. |

| Food and Beverage | Food packaging bags | Ensures product freshness and compliance with safety standards | Ensure food-grade materials and certifications for safety compliance. |

| Healthcare | Medical supply bags | Protects sensitive items and maintains sterility | Focus on high-quality, puncture-resistant materials and certifications. |

| Agriculture | Produce bags | Supports efficient handling and transportation of agricultural goods | Evaluate durability and resistance to environmental factors. |

| E-commerce | Shipping and mailer bags | Reduces shipping costs and enhances customer satisfaction | Assess customization options and ability to handle various products. |

What Are the Key Applications of Polyethylene Bags in the Retail Sector?

In the retail industry, polyethylene bags serve as custom shopping bags that enhance brand visibility. Retailers can utilize these bags to create a memorable customer experience while promoting their brand. The manufacturing process allows for customization in size, thickness, and print quality, enabling businesses to cater to specific branding requirements. International buyers should consider sourcing bags that are robust enough to handle the weight of products while also being visually appealing.

How Are Polyethylene Bags Used in Food and Beverage Packaging?

The food and beverage industry relies on polyethylene bags for packaging that ensures product freshness and safety. These bags are designed to meet stringent safety standards, making them ideal for transporting perishable items. The manufacturing process focuses on using food-grade materials that comply with health regulations, which is crucial for international buyers. Sourcing considerations should include certifications that guarantee the bags are safe for food contact and resistant to punctures and tears.

What Role Do Polyethylene Bags Play in Healthcare Applications?

In healthcare, polyethylene bags are vital for packaging medical supplies, ensuring that sensitive items are protected and maintained in sterile conditions. The manufacturing process emphasizes the use of high-quality, puncture-resistant materials to safeguard against contamination. For B2B buyers in the healthcare sector, sourcing bags with specific certifications, such as ISO standards for medical packaging, is essential to ensure compliance with industry regulations and safety protocols.

How Are Polyethylene Bags Beneficial for Agriculture?

Agricultural applications of polyethylene bags include produce bags that facilitate the efficient handling and transportation of fruits and vegetables. The manufacturing process allows for the creation of durable bags that can withstand environmental factors, such as moisture and temperature fluctuations. Buyers in the agriculture sector should prioritize sourcing bags that are not only strong but also eco-friendly, as sustainability is becoming increasingly important in global markets.

What Advantages Do Polyethylene Bags Offer for E-commerce Shipping?

In the e-commerce sector, polyethylene bags are widely used as shipping and mailer bags, providing a cost-effective solution for packaging products for delivery. The lightweight nature of these bags reduces shipping costs while enhancing customer satisfaction through reliable and secure delivery. International buyers should consider customization options, such as branding and size variations, to meet diverse shipping needs and ensure the bags can accommodate various product types effectively.

3 Common User Pain Points for ‘polyethylene bags manufacturing process’ & Their Solutions

Scenario 1: Inconsistent Quality of Polyethylene Bags

The Problem: A common issue faced by B2B buyers is the inconsistency in the quality of polyethylene bags received from suppliers. This inconsistency can lead to significant operational disruptions. For instance, a packaging company might receive bags that vary in thickness, strength, or sealing quality. Such fluctuations can result in product damage during transportation, increased waste due to non-conforming products, and ultimately harm the company’s reputation if clients receive inferior packaging.

Illustrative image related to polyethylene bags manufacturing process

The Solution: To mitigate these quality issues, it is crucial to establish a stringent supplier selection process. Buyers should look for manufacturers with ISO certifications and a proven track record of quality control. Requesting samples before placing bulk orders is essential; this allows buyers to assess the quality firsthand. Implementing a system of regular audits and quality checks on incoming shipments can also help ensure that the polyethylene bags meet the required specifications consistently. Additionally, collaborating closely with suppliers to understand their production processes and quality control measures can lead to more reliable outcomes.

Scenario 2: Environmental Concerns and Regulatory Compliance

The Problem: Increasingly, companies are facing pressure to comply with environmental regulations regarding plastic usage. Buyers may find themselves in a predicament where the polyethylene bags they source do not align with sustainability goals or local legislation, particularly in regions like Europe, where regulations on single-use plastics are stringent. This not only risks legal repercussions but can also alienate environmentally-conscious customers.

The Solution: B2B buyers should prioritize sourcing from manufacturers who offer biodegradable or recyclable polyethylene bags. Engaging with suppliers who can provide detailed information about the environmental impact of their products is vital. Buyers can also look for certifications that demonstrate compliance with eco-friendly standards. Establishing a clear line of communication with suppliers to ensure that they are up-to-date with regulatory changes can help in making informed purchasing decisions. Furthermore, incorporating a sustainability audit into the supplier evaluation process can ensure that the chosen suppliers align with the company’s environmental goals.

Scenario 3: Supply Chain Disruptions and Lead Times

The Problem: Another significant pain point for B2B buyers in the polyethylene bags manufacturing process is the unpredictability of supply chain disruptions. Factors such as raw material shortages, transportation delays, or geopolitical issues can lead to increased lead times, which in turn can affect production schedules and customer satisfaction. A sudden inability to source polyethylene bags can halt operations, especially for businesses that rely on just-in-time inventory practices.

Illustrative image related to polyethylene bags manufacturing process

The Solution: To combat supply chain vulnerabilities, buyers should diversify their supplier base to avoid dependency on a single source. Establishing relationships with multiple manufacturers across different regions can create a buffer against localized disruptions. Buyers should also engage in proactive planning by forecasting demand and placing orders well in advance. Implementing an inventory management system that allows for real-time tracking of stock levels can help identify potential shortages early. Additionally, maintaining open lines of communication with suppliers about their capabilities and challenges can provide insights that help in developing contingency plans, ensuring a more resilient supply chain.

Strategic Material Selection Guide for polyethylene bags manufacturing process

What Are the Key Materials Used in Polyethylene Bags Manufacturing?

In the manufacturing of polyethylene bags, the selection of materials is crucial for ensuring product performance, compliance, and cost-effectiveness. Below, we analyze four common materials used in this process, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

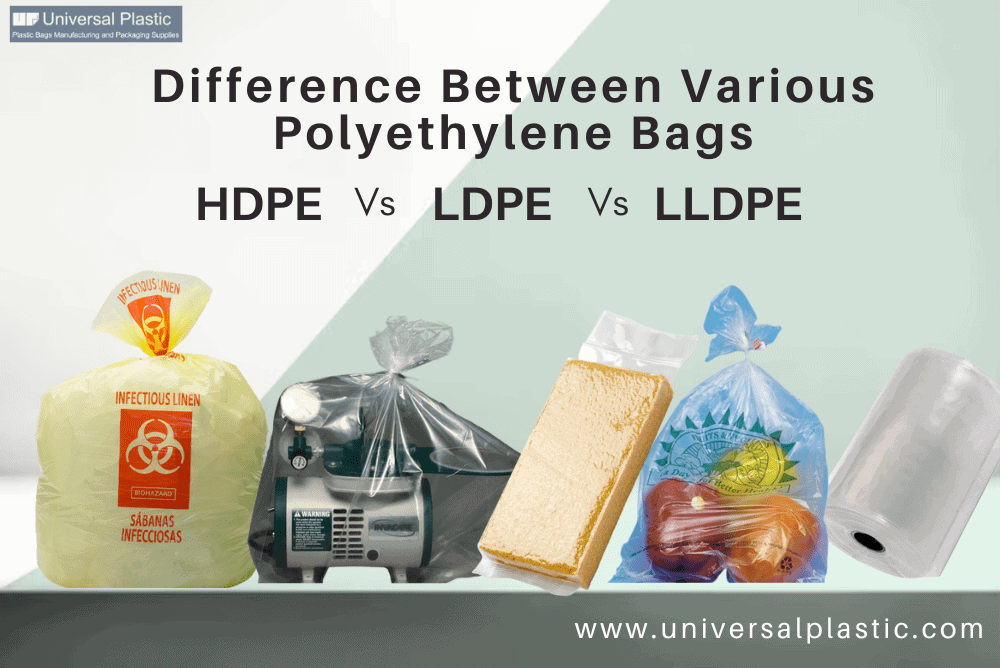

1. Low-Density Polyethylene (LDPE)

Key Properties:

LDPE is characterized by its low density, high flexibility, and excellent impact resistance. It typically operates well at temperatures ranging from -50°C to 80°C, making it suitable for various applications.

Pros & Cons:

LDPE is known for its durability and resistance to moisture, which makes it ideal for packaging food and other sensitive products. However, it has a lower tensile strength compared to other polyethylene types, which may limit its use in heavy-duty applications. Additionally, the manufacturing process for LDPE is relatively straightforward, though it can be more expensive than HDPE.

Impact on Application:

LDPE bags are often used in retail and grocery sectors due to their lightweight nature and flexibility. They are particularly effective for carrying items that require some level of protection from moisture.

Considerations for International Buyers:

Buyers in regions like Africa and South America should ensure compliance with local regulations regarding food safety and environmental impact. Standards such as ASTM D1709 for impact resistance are relevant.

2. High-Density Polyethylene (HDPE)

Key Properties:

HDPE has a higher density than LDPE, providing greater strength and rigidity. It can withstand temperatures from -40°C to 60°C and is resistant to many chemicals, making it suitable for various industrial applications.

Illustrative image related to polyethylene bags manufacturing process

Pros & Cons:

The primary advantage of HDPE is its strength, which allows for the production of thicker bags that can carry heavier loads. However, it is less flexible than LDPE, which may limit its use in applications requiring flexibility. The manufacturing process is more complex, which can lead to higher costs.

Impact on Application:

HDPE bags are commonly used for packaging bulk items, such as agricultural products and industrial goods, due to their robustness. They are also preferred for their recyclability, appealing to environmentally conscious buyers.

Considerations for International Buyers:

In Europe and the Middle East, compliance with recycling standards and environmental regulations is essential. Buyers should look for suppliers who adhere to ISO 14001 for environmental management.

Illustrative image related to polyethylene bags manufacturing process

3. Linear Low-Density Polyethylene (LLDPE)

Key Properties:

LLDPE combines properties of both LDPE and HDPE, offering enhanced tensile strength and puncture resistance. It maintains flexibility while being more durable than LDPE.

Pros & Cons:

LLDPE is versatile and can be used in a variety of applications, from agricultural films to heavy-duty bags. Its production process is more complex than LDPE, which can increase costs. However, its durability often justifies the expense.

Impact on Application:

LLDPE is particularly suited for applications that require a balance of flexibility and strength, such as stretch films and heavy-duty bags for industrial use.

Considerations for International Buyers:

Buyers should ensure that LLDPE products meet specific regional standards, such as JIS K 6768 in Japan, which governs the quality of plastic materials.

4. Recycled Polyethylene (rPE)

Key Properties:

Recycled polyethylene is derived from post-consumer or post-industrial plastic waste. Its properties can vary based on the source material but generally offer similar performance characteristics to virgin polyethylene.

Pros & Cons:

The key advantage of rPE is its reduced environmental impact, making it an attractive option for sustainability-focused businesses. However, variability in quality can be a concern, and it may not always meet the same performance standards as virgin materials.

Impact on Application:

rPE is increasingly used in applications where sustainability is a priority, such as eco-friendly packaging solutions. Its use can enhance a company’s green credentials.

Considerations for International Buyers:

In regions like Europe, buyers must ensure compliance with stringent recycling regulations and standards, such as the EU Plastics Strategy, which promotes the use of recycled materials.

Summary Table of Material Selection for Polyethylene Bags Manufacturing

| Material | Typical Use Case for polyethylene bags manufacturing process | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Low-Density Polyethylene (LDPE) | Retail and grocery bags | Excellent flexibility and moisture resistance | Lower tensile strength | Medium |

| High-Density Polyethylene (HDPE) | Bulk packaging for industrial goods | High strength and rigidity | Less flexibility | Medium-High |

| Linear Low-Density Polyethylene (LLDPE) | Stretch films and heavy-duty bags | Balanced flexibility and strength | Higher production complexity | Medium-High |

| Recycled Polyethylene (rPE) | Eco-friendly packaging solutions | Reduced environmental impact | Variable quality | Medium |

This strategic material selection guide provides B2B buyers with critical insights to make informed decisions regarding the manufacturing of polyethylene bags, ensuring they choose the right materials for their specific applications and compliance needs.

In-depth Look: Manufacturing Processes and Quality Assurance for polyethylene bags manufacturing process

What Are the Main Stages of the Polyethylene Bags Manufacturing Process?

The manufacturing process for polyethylene bags is intricate and consists of several key stages, each critical to ensuring product quality and efficiency. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: How Are Raw Materials for Polyethylene Bags Processed?

The foundation of polyethylene bag manufacturing begins with the preparation of raw materials. Polyethylene is derived from refined oil or natural gas, which undergoes a complex extraction process. After extraction, the hydrocarbons are transported to refineries where they are separated into various densities to isolate pure polyethylene chains. This process produces resin pellets that serve as the primary raw material for bag production.

Before the manufacturing process starts, these resin pellets are rigorously checked for quality. Buyers should ensure that suppliers use high-grade polyethylene, as the quality of the resin directly impacts the durability and functionality of the final bags.

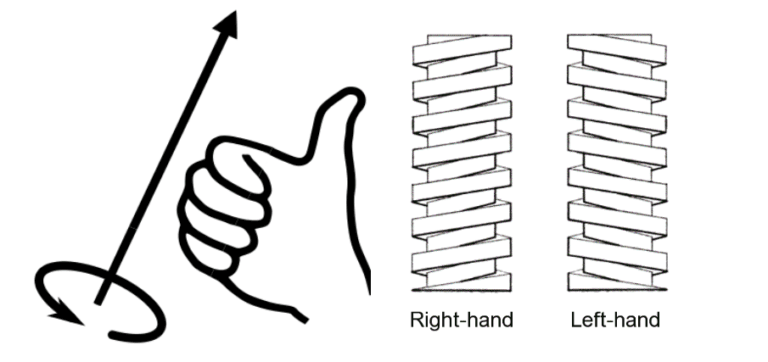

Forming: What Techniques Are Used in the Film Extrusion Process?

Once the raw materials are ready, the next phase is forming the polyethylene into a usable product. The most common method is blown-film extrusion, which involves several steps:

- Melting: Polyethylene pellets are heated until they become molten.

- Extrusion: The molten plastic is pushed through a circular die to form a continuous tube.

- Bubble Formation: Air is introduced to inflate the tube into a bubble, which is then stretched to the desired thickness.

- Cooling: As the bubble rises, it cools and is flattened before being wound onto rolls.

These rolls can be further processed to create various types of polyethylene bags, including single-wound sheeting and tubing. The precision of this process is vital; any inconsistencies can lead to defects in the final product. B2B buyers should inquire about the equipment used, as modern machines with servo drive motors can significantly enhance production accuracy.

Assembly: How Are Polyethylene Bags Made from Rolls of Film?

The assembly phase involves converting the rolls of polyethylene film into bags. This includes:

- Cutting: The film is cut to the desired size, with options for gussets to enhance capacity.

- Sealing: Heat sealing is applied to ensure strong bonds at the base of the bags.

- Customization: Features such as handles or printed logos can be added during this stage, enhancing both functionality and branding.

Efficiency in this stage is crucial, as advanced automation systems can process a high volume of bags rapidly. B2B buyers should seek suppliers who invest in these technologies to ensure timely delivery and consistent quality.

Finishing: What Are the Final Touches Before Polyethylene Bags Are Packaged?

The finishing stage includes several optional processes that can enhance the bag’s durability and aesthetic appeal. These may involve:

- Corona Treatment: This improves the film’s printability and adhesion properties.

- Additional Coatings: UV inhibitors or anti-block agents may be added to enhance performance.

- Quality Testing: Before packaging, bags are often subjected to tests for strength, thickness, and print quality.

Buyers should verify whether suppliers have a dedicated finishing process that aligns with international quality standards.

What Quality Assurance Measures Are Essential for Polyethylene Bag Manufacturing?

Quality assurance (QA) is a fundamental component of the polyethylene bag manufacturing process. Buyers should understand the various standards and checkpoints that ensure product quality.

Which International Standards Should B2B Buyers Look For?

Many manufacturers adhere to international quality management standards, with ISO 9001:2015 being one of the most recognized. This standard emphasizes a process-based approach to quality management, ensuring that manufacturers consistently meet customer and regulatory requirements.

Additionally, industry-specific certifications such as CE marking for products sold in the European market or API standards for packaging in the petroleum sector can further assure buyers of compliance with safety and quality benchmarks.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during production to catch defects early.

- Final Quality Control (FQC): A comprehensive evaluation of finished products before packaging.

These checkpoints are critical for maintaining high standards and minimizing waste. B2B buyers should inquire about the QC processes employed by potential suppliers.

How Can Buyers Verify Supplier Quality Control Procedures?

To ensure that a supplier adheres to high-quality standards, B2B buyers can utilize several methods:

- Audits: Conducting regular audits of suppliers can provide insights into their manufacturing practices and adherence to quality standards.

- Quality Reports: Requesting detailed QC reports can help buyers understand the frequency and results of inspections performed.

- Third-Party Inspections: Engaging independent inspectors to evaluate the manufacturing process can add an extra layer of assurance.

Buyers from regions such as Africa, South America, the Middle East, and Europe should pay particular attention to the nuances of QC certifications, as these can vary significantly by region.

What Are the Key Considerations for International B2B Buyers?

International buyers must navigate various complexities when sourcing polyethylene bags. Understanding regional regulations, quality certifications, and environmental standards is essential. For example, buyers in Europe may need to ensure compliance with the EU Plastics Directive, which emphasizes sustainability and recyclability.

Moreover, considering the environmental impact of polyethylene production is increasingly important. Suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials or implementing waste reduction strategies, may provide a competitive advantage.

In conclusion, understanding the manufacturing processes and quality assurance measures for polyethylene bags can empower B2B buyers to make informed decisions. By prioritizing suppliers who adhere to international standards and employing robust quality control measures, businesses can secure high-quality products that meet their needs while fostering sustainable practices.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘polyethylene bags manufacturing process’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers interested in procuring polyethylene bags through a reliable manufacturing process. Understanding the critical steps involved in sourcing can enhance product quality, optimize supply chains, and ensure compliance with industry standards.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the polyethylene bags you require. This includes dimensions, thickness (measured in mils), and type of polyethylene (LDPE or HDPE) based on your application needs. Providing detailed specifications helps suppliers deliver products that meet your expectations, reducing the risk of errors and enhancing satisfaction.

Step 2: Research Potential Manufacturers

Conduct thorough research to identify reputable manufacturers specializing in polyethylene bags. Focus on their production capabilities, technologies used (such as blown-film extrusion), and the variety of products they offer. A well-established manufacturer will have a track record of consistent quality and efficiency, which is essential for meeting your production demands.

Step 3: Verify Supplier Certifications

Before finalizing a supplier, ensure they possess relevant certifications, such as ISO 9001 for quality management and FSSC 22000 for food safety, if applicable. Certifications indicate adherence to industry standards and can significantly affect the reliability of your supply chain. Ask for documentation to confirm their certifications and check for any compliance history.

Step 4: Evaluate Manufacturing Processes

Examine the manufacturing processes used by potential suppliers. Inquire about their blown-film extrusion techniques, quality control measures, and waste management practices. Understanding their processes can help you assess the efficiency and sustainability of their operations, which is crucial for long-term partnerships.

Step 5: Request Samples and Quality Assurance

Always request samples of the polyethylene bags to evaluate their quality firsthand. Assess factors such as durability, flexibility, and print quality (if branding is required). Additionally, discuss their quality assurance processes to ensure that they can consistently meet your specifications throughout production.

Step 6: Discuss Lead Times and Minimum Order Quantities (MOQs)

Communicate your timeline and volume requirements to potential suppliers. Understanding lead times and MOQs is critical for planning your inventory and production schedules. Ensure that the supplier can accommodate your needs, especially if you have fluctuating demand or specific project deadlines.

Step 7: Negotiate Terms and Conditions

Finally, negotiate pricing, payment terms, and delivery conditions. Ensure that all agreements are documented clearly to avoid misunderstandings. Consider discussing long-term contracts or bulk order discounts, which can enhance your purchasing power and establish a stable supply relationship.

Illustrative image related to polyethylene bags manufacturing process

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing polyethylene bags, ensuring they partner with reliable suppliers that meet their unique needs.

Comprehensive Cost and Pricing Analysis for polyethylene bags manufacturing process Sourcing

What Are the Key Cost Components in Polyethylene Bags Manufacturing?

The manufacturing process for polyethylene bags involves several critical cost components that buyers should understand to make informed sourcing decisions. The primary costs include:

-

Materials: The cost of polyethylene resin, which is derived from refined oil or natural gas, is a significant factor. Prices fluctuate based on global oil markets and demand for polyethylene, so it’s essential to monitor these trends.

-

Labor: Labor costs vary by region and can significantly impact the overall cost of production. Skilled labor is required for operating advanced machinery, especially in regions with higher wage rates.

-

Manufacturing Overhead: This includes utilities, maintenance of equipment, and facility costs. Efficient manufacturing processes and modern equipment can help minimize these overheads.

-

Tooling: Initial setup costs for molds and cutting tools can be substantial, particularly for custom bag designs. Investing in high-quality tooling can enhance production efficiency and bag quality.

-

Quality Control (QC): Ensuring that bags meet quality standards incurs additional costs. This can include testing for strength, durability, and compliance with industry regulations, which is especially important in markets with strict quality requirements.

-

Logistics: Transportation costs for raw materials and finished products play a critical role, particularly for international buyers. Factors such as shipping distances, modes of transport, and local customs regulations can affect overall logistics expenses.

-

Margin: Suppliers typically apply a margin to cover their operational costs and profit. Understanding the margin expectations of suppliers can help buyers negotiate better pricing.

What Influences Pricing in Polyethylene Bags Manufacturing?

Several factors influence the pricing of polyethylene bags, which international B2B buyers must consider:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to reduced per-unit costs. Suppliers are more willing to negotiate favorable terms with buyers who commit to higher volumes.

-

Specifications and Customization: Custom features such as sizes, thicknesses, colors, and printing can significantly affect costs. Standard products are typically more cost-effective than customized solutions.

-

Material Quality and Certifications: Higher-quality resins and certifications (like ISO or food safety standards) can increase costs but may be necessary depending on the application of the bags.

-

Supplier Factors: The reputation, reliability, and production capabilities of the supplier can influence pricing. Established suppliers may charge a premium for their quality and service.

-

Incoterms: Understanding shipping terms (like FOB, CIF, or DDP) is crucial as these terms dictate who bears the shipping costs and risks at various stages of the supply chain, affecting the total landed cost.

How Can Buyers Optimize Their Sourcing Strategy?

To maximize cost efficiency and ensure value in sourcing polyethylene bags, buyers can follow these tips:

-

Negotiate Effectively: Engage in discussions about volume discounts and flexible payment terms. Suppliers may be willing to offer better pricing for long-term contracts.

-

Consider Total Cost of Ownership (TCO): Look beyond initial purchase prices. TCO includes all costs associated with the product, including logistics, storage, and disposal, which can vary significantly based on the supplier’s efficiency.

-

Understand Pricing Nuances for International Transactions: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import tariffs, and local regulations that can affect pricing. Building relationships with local suppliers can mitigate some of these risks.

-

Evaluate Supplier Capabilities: Assess potential suppliers based on their production capacity, technology, and quality control processes. This can help ensure that they can meet your needs without compromising quality.

-

Stay Informed on Market Trends: Regularly monitor resin prices and market demand. This knowledge can empower buyers to time their purchases strategically and negotiate better terms.

Disclaimer on Indicative Prices

Prices for polyethylene bags can vary widely based on the above factors and market conditions. It is advisable for buyers to obtain quotes from multiple suppliers and consider all cost components to make informed purchasing decisions.

Alternatives Analysis: Comparing polyethylene bags manufacturing process With Other Solutions

Exploring Alternatives to Polyethylene Bags Manufacturing Process

In the quest for effective packaging solutions, it is essential to consider various alternatives to the polyethylene bags manufacturing process. Polyethylene bags are widely used due to their versatility and cost-effectiveness, but other options may offer unique advantages depending on the specific needs of a business. Here, we compare the polyethylene bags manufacturing process with two viable alternatives: biodegradable bags and paper bags.

Comparison Table

| Comparison Aspect | Polyethylene Bags Manufacturing Process | Biodegradable Bags | Paper Bags |

|---|---|---|---|

| Performance | High durability and moisture resistance | Decomposes in soil; less durable | Good strength; limited moisture resistance |

| Cost | Generally low-cost | Moderate to high cost | Moderate cost; varies with quality |

| Ease of Implementation | Established process; widely available | Requires specialized materials | Simple production process |

| Maintenance | Low maintenance; automated systems | May require specific storage | Low maintenance; recyclable |

| Best Use Case | Retail, food packaging, industrial use | Eco-conscious markets, compostable products | Retail, gift packaging, eco-friendly initiatives |

In-Depth Analysis of Alternatives

Biodegradable Bags

Biodegradable bags are designed to break down naturally in the environment, making them a popular choice for eco-conscious businesses. They are typically made from materials such as starch or PLA (polylactic acid). The primary advantage of biodegradable bags is their reduced environmental impact, appealing to brands looking to enhance their sustainability credentials. However, they may not offer the same durability as polyethylene bags, making them less suitable for heavy-duty applications. Additionally, the production costs can be higher, which may deter some businesses from adopting them.

Paper Bags

Paper bags serve as a traditional alternative to plastic, favored for their recyclable nature and aesthetic appeal. They are particularly effective for retail environments where branding and presentation are important. Paper bags can provide adequate strength for most consumer goods, but they may not be as moisture-resistant as polyethylene bags, potentially limiting their use for wet or perishable products. The cost of paper bags can vary significantly based on quality and customization options, and while they are generally easy to produce, the supply chain for raw materials may be less established than for polyethylene.

Making the Right Choice for Your Business

When selecting a packaging solution, B2B buyers must carefully evaluate their specific requirements, including performance, cost, and environmental impact. Polyethylene bags are ideal for businesses prioritizing durability and low cost, while biodegradable bags are suited for those aiming to enhance their sustainability profile. Paper bags may be the best option for businesses focused on branding and customer experience. Ultimately, understanding the unique advantages and limitations of each alternative will empower buyers to make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for polyethylene bags manufacturing process

What Are the Key Technical Properties of Polyethylene Bags?

In the manufacturing of polyethylene bags, understanding the technical specifications is crucial for ensuring product performance and meeting customer requirements. Here are some essential properties to consider:

1. Material Grade: LDPE vs. HDPE

Polyethylene bags are primarily made from two grades of polyethylene: Low-Density Polyethylene (LDPE) and High-Density Polyethylene (HDPE). LDPE is more flexible and transparent, making it ideal for retail bags, while HDPE is stronger and more rigid, suitable for grocery and industrial applications. Choosing the right grade affects the bag’s durability, flexibility, and suitability for specific uses.

2. Thickness (Mil)

The thickness of polyethylene bags is measured in mils (thousandths of an inch). Common thicknesses range from 0.75 to 12 mils, with thicker bags offering greater strength and resistance to tearing. B2B buyers must specify the required thickness based on the intended use, as this impacts both durability and cost.

3. Tolerance

Tolerance refers to the allowable variation in the dimensions of the bags. In the context of polyethylene manufacturing, maintaining tight tolerances ensures consistency in size and functionality. This is particularly important for businesses that require precise fitting of bags for automated packaging systems.

4. UV Resistance

Polyethylene bags can be treated with UV inhibitors to protect contents from sun damage during storage or transport. This property is vital for businesses that ship products over long distances or store them outdoors, ensuring product integrity and reducing spoilage.

5. Seal Strength

The strength of the seals on polyethylene bags is critical for preventing leaks and ensuring product safety. Heat-sealed bags require precise temperature control during the manufacturing process to achieve optimal seal integrity. A strong seal is essential for industries like food packaging, where contamination risks must be minimized.

6. Customization Options

Customization can include adding features such as handles, gussets, or printing. Custom bags can enhance branding and consumer appeal, making them a valuable asset for businesses looking to differentiate themselves in the marketplace.

What Are Common Trade Terms in Polyethylene Bag Manufacturing?

Understanding industry jargon can facilitate smoother transactions and negotiations. Here are key trade terms relevant to polyethylene bags:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of polyethylene bags, an OEM might supply the machinery used in bag production, making it essential for buyers to understand the capabilities of their suppliers.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For polyethylene bags, MOQs can vary significantly based on factors like customization and material. Buyers should clarify MOQs to ensure that their purchasing needs align with supplier capabilities.

Illustrative image related to polyethylene bags manufacturing process

3. RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests price quotes from suppliers for specific products. In the polyethylene bag industry, submitting an RFQ allows businesses to compare prices and terms from different manufacturers, aiding in budget planning and supplier selection.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms is crucial for B2B buyers in the polyethylene bag sector, as they dictate who is responsible for shipping, insurance, and tariffs, ultimately affecting total costs and delivery timelines.

5. Lead Time

Lead time refers to the duration between placing an order and receiving the product. In polyethylene bag manufacturing, lead times can vary based on order size and customization requirements. Buyers should factor lead times into their supply chain planning to avoid disruptions.

Illustrative image related to polyethylene bags manufacturing process

6. Sustainability Certifications

Many polyethylene bag manufacturers pursue sustainability certifications to demonstrate their commitment to environmentally friendly practices. Certifications such as ISO 9001 or FSSC 22000 can reassure buyers about the quality and sustainability of the products, influencing purchasing decisions in a market increasingly focused on eco-friendliness.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and strategic goals in the polyethylene bags market.

Navigating Market Dynamics and Sourcing Trends in the polyethylene bags manufacturing process Sector

What Are the Current Market Dynamics and Key Trends in Polyethylene Bags Manufacturing?

The polyethylene bags manufacturing sector is experiencing significant transformation driven by several global factors. One of the primary drivers is the increasing demand for flexible packaging solutions across various industries, including retail, food service, and e-commerce. As businesses expand into emerging markets in Africa, South America, and the Middle East, they seek cost-effective, versatile packaging options. Furthermore, advancements in manufacturing technology, such as blown-film extrusion and automation, are enhancing production efficiency and enabling rapid customization to meet specific client needs.

Another critical trend is the integration of digital technologies in the sourcing process. B2B buyers are increasingly leveraging e-commerce platforms and digital marketplaces to streamline procurement, allowing for easier comparison of suppliers and products. This shift is particularly relevant for international buyers from regions like Vietnam and Saudi Arabia, who benefit from improved access to a global network of manufacturers. Additionally, the rise of data analytics in supply chain management is helping companies optimize their inventory and logistics, thereby reducing costs and improving service levels.

How Is Sustainability Influencing Sourcing in the Polyethylene Bags Manufacturing Sector?

Sustainability has become a central theme in the polyethylene bags manufacturing process. With growing awareness of environmental issues, B2B buyers are increasingly prioritizing suppliers that adopt sustainable practices. This includes sourcing raw materials responsibly and minimizing waste during production. The use of recycled materials in the manufacturing of polyethylene bags is gaining traction, as is the adoption of biodegradable alternatives.

Moreover, certifications such as ISO 14001 for environmental management and FSSC 22000 for food safety are becoming essential for suppliers looking to attract conscientious buyers. These certifications not only demonstrate a commitment to sustainability but also reassure businesses that their packaging solutions meet international standards. Buyers are encouraged to assess the environmental impact of their supply chains and favor manufacturers who can provide transparency regarding their sourcing practices and waste management strategies.

What Is the Historical Context of Polyethylene Bags Manufacturing Relevant to B2B Buyers?

The production of polyethylene bags has evolved significantly since its inception in the mid-20th century. Initially, the focus was primarily on functionality and cost-effectiveness, with minimal consideration for environmental impact. However, as awareness of plastic pollution grew, the industry began to shift towards more sustainable practices.

Illustrative image related to polyethylene bags manufacturing process

This evolution has led to innovations in production processes, including the introduction of advanced extrusion techniques and the development of eco-friendly materials. For B2B buyers, understanding this historical context is vital, as it highlights the industry’s commitment to adapting to market demands and regulatory pressures. Today, buyers are not just looking for products; they are seeking partners who align with their values and can contribute to their sustainability goals. This ongoing transformation emphasizes the importance of choosing suppliers who are proactive in their approach to environmental responsibility and innovation.

Frequently Asked Questions (FAQs) for B2B Buyers of polyethylene bags manufacturing process

-

1. How do I ensure the quality of polyethylene bags from a supplier?

To ensure quality, start by requesting samples to evaluate the material, thickness, and finish. Look for suppliers with relevant certifications like ISO 9001 or FSSC 22000, indicating adherence to quality management and food safety standards. Additionally, consider visiting the manufacturing facility or conducting a third-party audit. Engage in open communication with the supplier about your quality expectations and any specific requirements, such as load-bearing capacity or environmental considerations. -

2. What are the key factors to consider when choosing a polyethylene bag supplier?

When selecting a supplier, evaluate their manufacturing capabilities, production capacity, and experience in your industry. Assess their ability to provide customization options, including size, thickness, and printing. Additionally, inquire about their lead times, minimum order quantities (MOQs), and payment terms. A supplier’s responsiveness and customer service are equally crucial, as they reflect their commitment to supporting your business needs. -

3. What is the typical lead time for producing polyethylene bags?

Lead times can vary significantly based on factors such as order size, customization requirements, and the supplier’s production capacity. Generally, standard orders may take anywhere from 2 to 4 weeks. However, for larger or more complex orders, it might extend to 6 weeks or more. Always confirm lead times with your supplier upfront, as this will help you plan your inventory and logistics effectively. -

4. How can I customize my polyethylene bags to meet specific needs?

Customization options include selecting the bag size, thickness, color, and print design. Most manufacturers can incorporate features like handles, gussets, or resealable closures. Discuss your requirements with the supplier, providing samples or specifications to ensure clarity. Be aware that customization may affect the MOQ and lead time, so plan accordingly to align with your business goals. -

5. What are the common payment terms for international polyethylene bag orders?

Payment terms can vary by supplier but typically include options like upfront payment, 30% deposit with the balance upon delivery, or net 30/60 days. Always clarify payment terms before placing an order to avoid misunderstandings. Using secure payment methods such as letters of credit or escrow services can also protect your investment, especially in international transactions. -

6. How do I handle logistics and shipping for polyethylene bags from international suppliers?

Coordinate logistics by discussing shipping options with your supplier, including freight forwarders and shipping methods. Consider factors such as shipping costs, transit times, and customs duties. Ensure the supplier provides necessary documentation for customs clearance, including invoices and certificates of origin. Familiarize yourself with local import regulations in your country to ensure compliance and avoid delays. -

7. What are the environmental considerations when sourcing polyethylene bags?

When sourcing polyethylene bags, consider suppliers that offer eco-friendly options, such as biodegradable or recyclable materials. Inquire about their manufacturing processes and waste management practices. Additionally, understanding the life cycle of the bags, from production to disposal, can help align your sourcing strategy with sustainability goals, which is increasingly important for consumers and regulatory bodies. -

8. How can I assess the reliability of a polyethylene bag supplier?

To assess reliability, review customer testimonials and case studies to gauge past performance. Check for certifications that indicate industry standards compliance. Engaging in a trial order can also provide insights into their production quality and delivery timelines. Additionally, consider their responsiveness to inquiries and their ability to adapt to your specific needs as indicators of a dependable partnership.

Top 4 Polyethylene Bags Manufacturing Process Manufacturers & Suppliers List

1. Leeline Bags – Polyethylene Solutions

Domain: leelinebags.com

Registered: 2024 (1 years)

Introduction: Polyethylene bags are versatile and serve various sectors including retail, packaging, and medical supplies. They are made from polyethylene, a flexible plastic polymer available in forms such as LDPE (Low-Density Polyethylene) and HDPE (High-Density Polyethylene). The manufacturing process includes several key steps: 1) Raw Material Extraction from refined oil or natural gas, involving drilling a…

2. IQS Directory – Plastic Bags

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Plastic bags are versatile, one-piece containers made from polymer-based materials, primarily polyethylene and polypropylene. They are durable, waterproof, and maintain their form under normal usage. Types of plastic bags vary in density (high-density, low-density, medium, linear) and characteristics (transparency, tensile strength, heat and chemical resistance). The production process involves co…

3. Kete Group – Plastic Bags Manufacturing

Domain: ketegroup.com

Registered: 2010 (15 years)

Introduction: Plastic bags are made from raw polymers derived from natural gas or petroleum, which are transformed into plastic resin pellets through heating and pressure. The manufacturing process involves several steps: 1) Raw Material Transformation, 2) Extrusion Process, 3) Blown Film, 4) Cooling and Setting, 5) Coloring and Additive Mixing, 6) Cutting and Sealing, 7) Printing (optional), and 8) Quality Con…

4. PolyPostal – Polythene Bag Manufacturing

Domain: polypostalpackaging.com

Registered: 2007 (18 years)

Introduction: Manufacturing polythene bags involves 4 stages: (1) Raw Material – Polyethylene (PE), produced from crude oil or natural gas through a process called polymerisation. (2) Film – Granules are blended with coloring agents and extruded into a molten tube, which is biaxially oriented for strength and cooled into layflat tubing. (3) Printing – The film is printed using a flexographic printer, treated fo…

Strategic Sourcing Conclusion and Outlook for polyethylene bags manufacturing process

In the competitive landscape of polyethylene bag manufacturing, strategic sourcing emerges as a vital component for B2B buyers aiming to enhance their supply chain efficiency and product quality. Understanding the intricacies of the manufacturing process—from raw material extraction to the blown-film extrusion and conversion into finished bags—can significantly impact procurement decisions. Buyers should prioritize suppliers who utilize advanced technologies and maintain rigorous quality control to ensure the consistency and durability of their products.

Investing in partnerships with reputable manufacturers can lead to optimized production processes, reduced costs, and enhanced sustainability practices, crucial for meeting the growing demand in diverse sectors. As international markets evolve, particularly in regions like Africa, South America, the Middle East, and Europe, the need for innovative packaging solutions is paramount.

Looking ahead, now is the time for B2B buyers to leverage strategic sourcing to not only secure high-quality polyethylene bags but also to foster long-term partnerships that drive growth and sustainability. By aligning with suppliers who share a commitment to quality and efficiency, businesses can position themselves favorably in an increasingly eco-conscious market. Engage with your suppliers today to explore how strategic sourcing can transform your operations and enhance your competitive edge.

Illustrative image related to polyethylene bags manufacturing process

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.