A B2B Buyer’s Guide to Pm Review: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for pm review

In the rapidly evolving landscape of powder metallurgy, international B2B buyers face the challenge of sourcing high-quality metal powders and related technologies that meet their unique operational needs. Understanding how to navigate the global market for powder metallurgy is crucial for companies seeking to enhance product performance and maintain a competitive edge. This guide delves into the various types of metal powders, their applications across industries such as automotive, aerospace, and medical, and offers insights into effective supplier vetting processes.

By exploring critical factors such as cost considerations, production methods, and sustainability practices, this comprehensive resource empowers buyers from Africa, South America, the Middle East, and Europe—including key markets like Germany and Saudi Arabia—to make informed purchasing decisions. It highlights emerging trends, such as the shift towards environmentally sustainable practices and innovative production technologies like Hot Isostatic Pressing (HIP).

With detailed market analysis and actionable insights, this guide serves as a strategic tool for decision-makers aiming to optimize their procurement strategies in the powder metallurgy sector. Whether you are looking to enhance supply chain resilience or adopt the latest advancements in metal powder technology, this resource equips you with the knowledge necessary to navigate the complexities of the global market successfully.

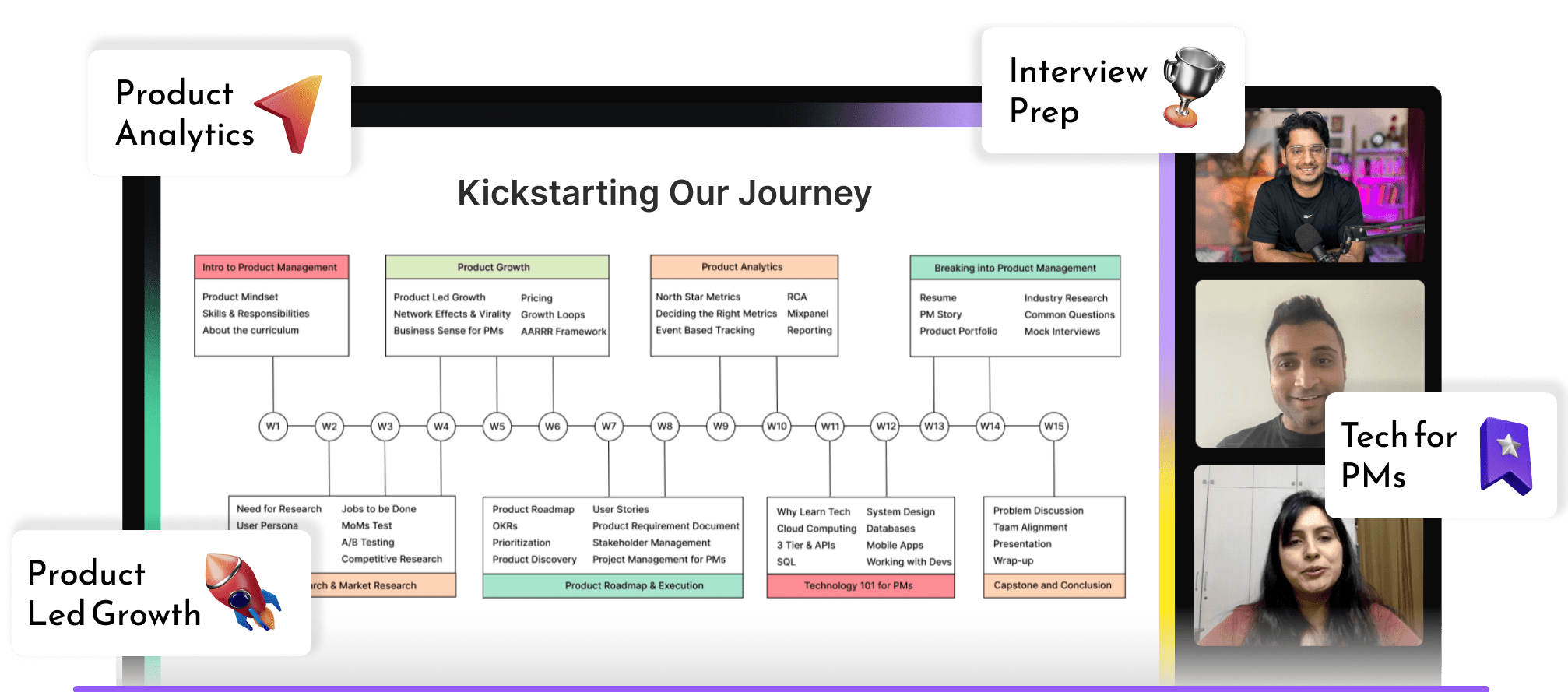

Understanding pm review Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Technical Review | Focuses on detailed analysis of PM processes and technologies. | R&D, process optimization, quality assurance. | Pros: In-depth insights; Cons: Time-consuming. |

| Market Review | Examines market trends, competitive landscape, and forecasts. | Strategic planning, investment decisions. | Pros: Informs strategy; Cons: May lack technical depth. |

| Product Review | Evaluates specific PM products or materials for performance. | Product development, supplier selection. | Pros: Directly applicable; Cons: Limited scope. |

| Sustainability Review | Assesses environmental impact and sustainability practices. | Compliance, CSR initiatives, supply chain. | Pros: Enhances brand reputation; Cons: May require additional resources. |

| Application Review | Explores specific use cases and applications of PM technology. | Custom solutions, niche markets. | Pros: Tailored insights; Cons: May be too specialized. |

What Are the Characteristics of Technical Reviews in PM?

Technical reviews are comprehensive evaluations that delve into the intricacies of powder metallurgy processes and technologies. These reviews are particularly valuable for B2B buyers involved in research and development or quality assurance, as they provide detailed insights into the latest advancements, methodologies, and best practices. Buyers should consider the depth of analysis and the expertise of the reviewers, as a thorough technical review can significantly influence product development and optimization efforts.

How Do Market Reviews Aid Strategic Planning?

Market reviews focus on analyzing current trends, competitive dynamics, and future forecasts within the powder metallurgy sector. These reviews are essential for B2B buyers engaged in strategic planning and investment decisions, as they help identify market opportunities and potential threats. When evaluating market reviews, buyers should assess the credibility of the data sources and the relevance of the insights to their specific industry context, as this information can shape long-term business strategies.

What Should Buyers Consider About Product Reviews?

Product reviews assess the performance, quality, and suitability of specific powder metallurgy products or materials. They are crucial for B2B buyers involved in product development and supplier selection, as they provide direct comparisons and evaluations. Buyers should prioritize reviews that include empirical data and user testimonials, ensuring that the products meet their operational requirements and performance standards. However, it’s important to note that product reviews may have a narrower focus and may not cover broader industry trends.

Why Are Sustainability Reviews Important for B2B Buyers?

Sustainability reviews evaluate the environmental impact and sustainability practices associated with powder metallurgy processes. These reviews are increasingly relevant for B2B buyers focused on compliance, corporate social responsibility (CSR), and supply chain sustainability. Buyers should consider the methodologies used in these reviews, as they can reveal opportunities for improving environmental performance and enhancing brand reputation. However, conducting sustainability assessments may require additional resources and expertise.

How Do Application Reviews Provide Tailored Insights?

Application reviews explore specific use cases and applications of powder metallurgy technology, offering tailored insights for niche markets. These reviews are particularly beneficial for B2B buyers seeking custom solutions or innovative applications of PM technology. When considering application reviews, buyers should evaluate the relevance of the case studies presented and the applicability of the findings to their own operational challenges. However, the specialized nature of these reviews may limit their generalizability across broader applications.

Key Industrial Applications of pm review

| Industry/Sector | Specific Application of pm review | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Qualification of titanium powder for cold spray | Enhanced performance and durability in aerospace components | Certification requirements, material purity, and sourcing reliability |

| Automotive | Production of high-performance NdFeB magnets | Improved efficiency and reduced weight in electric vehicles | Supply chain sustainability, rare earth sourcing, and cost-effectiveness |

| Energy Storage | Utilization of iron powder in LFP battery production | Cost-effective, safe, and long-lasting energy solutions | Material compatibility, production scalability, and supplier certifications |

| Medical Devices | Development of advanced medical implants using PM | Biocompatibility and precision in complex geometries | Regulatory compliance, material traceability, and supplier expertise |

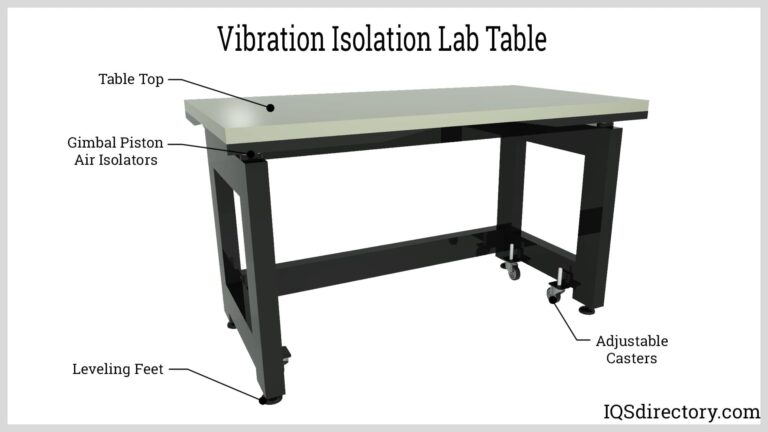

| Industrial Equipment | Manufacturing of defect-free components via HIP | Increased reliability and reduced maintenance costs | Equipment reliability, production capacity, and technology integration |

How is ‘pm review’ Used in Aerospace Applications?

In the aerospace sector, ‘pm review’ plays a crucial role in the qualification of titanium powders for cold spray applications. This process enhances the performance and durability of critical components such as turbine blades and structural parts. International buyers must consider certification requirements and ensure the material’s purity to meet stringent safety standards. Additionally, sourcing reliability is essential to maintain production timelines and quality assurance.

Illustrative image related to pm review

What are the Benefits of ‘pm review’ in Automotive Magnet Production?

The automotive industry increasingly relies on ‘pm review’ for the production of high-performance NdFeB magnets, which are vital for electric vehicles. These magnets contribute to improved efficiency and reduced weight, leading to better vehicle performance. For international buyers, key sourcing considerations include supply chain sustainability, the availability of rare earth materials, and cost-effectiveness, particularly in regions where these resources may be limited or costly.

How Does ‘pm review’ Enhance Energy Storage Solutions?

In the energy storage sector, ‘pm review’ provides significant insights into the use of iron powder in lithium iron phosphate (LFP) batteries. This chemistry is becoming the dominant choice for electric vehicles due to its safety and cost-effectiveness. Buyers need to consider material compatibility with existing production processes, scalability of supply, and supplier certifications to ensure consistent quality and performance.

Why is ‘pm review’ Important for Medical Devices?

The medical device industry benefits from ‘pm review’ through the development of advanced medical implants using powder metallurgy techniques. These methods allow for biocompatibility and precision in creating complex geometries essential for implants. For international buyers, regulatory compliance and material traceability are paramount, alongside the expertise of suppliers in navigating the complex landscape of medical device manufacturing.

What Role Does ‘pm review’ Play in Industrial Equipment Manufacturing?

In the industrial equipment sector, ‘pm review’ is instrumental in manufacturing defect-free components using Hot Isostatic Pressing (HIP) technology. This process increases the reliability of components, leading to reduced maintenance costs and improved operational efficiency. Buyers should focus on the reliability of equipment, production capacity, and how well the technology integrates with their existing manufacturing processes to maximize the benefits of this application.

Illustrative image related to pm review

3 Common User Pain Points for ‘pm review’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Metal Powders

The Problem: B2B buyers in industries relying on powder metallurgy often struggle to find reliable suppliers of high-quality metal powders. This issue can lead to production delays, increased costs, and ultimately, a compromised end product. Buyers may face challenges in verifying the quality and specifications of powders, especially when dealing with international suppliers from diverse regions like Africa and South America. The lack of standardized quality assurance can further complicate the decision-making process.

The Solution: To overcome this challenge, buyers should leverage platforms that specialize in metal powder sourcing, such as industry-specific trade shows or online marketplaces dedicated to powder metallurgy. Engaging with suppliers that have a proven track record and certifications can provide assurance regarding the quality of the materials. It’s essential to request detailed technical data sheets (TDS) and certificates of analysis (CoA) for each batch, ensuring that the powders meet the necessary specifications for their applications. Additionally, establishing a direct line of communication with suppliers can facilitate a clearer understanding of quality control processes and help build trust.

Scenario 2: Navigating Regulatory Compliance and Standards

The Problem: Buyers often encounter confusion regarding the regulatory standards and compliance requirements for the use of metal powders in their products. Different regions, particularly in Europe and the Middle East, may have varying regulations that can impact the legality and safety of using certain materials. This complexity can lead to costly mistakes, such as non-compliance fines or product recalls.

Illustrative image related to pm review

The Solution: To effectively navigate these regulatory landscapes, B2B buyers should invest time in understanding the specific compliance requirements pertinent to their industry and region. Collaborating with legal experts or consultants who specialize in metallurgical regulations can provide invaluable insights. Additionally, utilizing resources such as the European Powder Metallurgy Association (EPMA) can help buyers stay informed about changing regulations and best practices. Establishing relationships with suppliers who are knowledgeable about these regulations can also streamline the compliance process. Regular training sessions for procurement teams on the latest regulations can further mitigate risks associated with non-compliance.

Scenario 3: Ensuring Sustainable Practices in Powder Metallurgy

The Problem: As sustainability becomes a critical focus across industries, B2B buyers face pressure to source materials that adhere to environmentally friendly practices. However, identifying suppliers committed to sustainable production methods can be challenging, particularly in regions where such practices are not yet the norm. This can lead to ethical dilemmas and impact brand reputation.

The Solution: Buyers should prioritize sourcing from suppliers who openly communicate their sustainability initiatives and certifications. Conducting thorough research on suppliers’ practices, such as energy consumption, waste management, and the use of recycled materials, is crucial. Attending industry events focused on sustainability in powder metallurgy, like the Euro PM Congress, can help buyers connect with innovative suppliers leading the charge in sustainable practices. Implementing a supplier evaluation scorecard that includes sustainability criteria can also aid in making informed decisions. Additionally, collaborating with suppliers to develop tailored solutions that enhance sustainability in their supply chain can foster long-term partnerships and improve overall environmental impact.

Strategic Material Selection Guide for pm review

What Are the Key Properties of Common Materials Used in Powder Metallurgy?

In the realm of powder metallurgy (PM), the selection of materials is crucial for achieving desired product performance and longevity. Here, we analyze four common materials: titanium, stainless steel, iron, and nickel-based alloys, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Titanium Perform in Powder Metallurgy Applications?

Titanium, particularly commercially pure titanium (CP-Ti), is renowned for its high strength-to-weight ratio and excellent corrosion resistance, making it ideal for aerospace and medical applications. It can withstand high temperatures and pressures, which is critical for components exposed to extreme environments.

Illustrative image related to pm review

Pros: Titanium’s durability and biocompatibility make it suitable for demanding applications, such as implants and aerospace parts. Its lightweight nature contributes to fuel efficiency in transportation.

Cons: The cost of titanium powder is relatively high, and its manufacturing process can be complex, requiring specialized equipment and techniques. This can lead to higher overall production costs.

Impact on Application: Titanium’s compatibility with various media, including saline solutions, enhances its appeal in medical applications. However, its high cost may limit its use in more budget-sensitive projects.

Considerations for International Buyers: Compliance with international standards, such as ASTM and ISO, is essential. Buyers from regions like Europe and the Middle East should be aware of specific regulations regarding titanium usage in medical and aerospace sectors.

What Are the Advantages of Stainless Steel in Powder Metallurgy?

Stainless steel is a versatile material widely used in PM due to its excellent corrosion resistance and mechanical properties. It can withstand high temperatures and is often used in applications requiring durability and aesthetic appeal.

Pros: Stainless steel is relatively cost-effective compared to titanium and offers good machinability. Its resistance to oxidation makes it suitable for harsh environments.

Illustrative image related to pm review

Cons: While it has good strength, stainless steel may not perform as well as titanium in extreme conditions. Additionally, certain grades can be more susceptible to stress corrosion cracking.

Impact on Application: Stainless steel’s compatibility with various environments, including food and chemical processing, makes it a popular choice. However, its weight may be a disadvantage in applications where weight reduction is critical.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM A276 or DIN 1.4301. Understanding regional preferences for specific grades can also influence purchasing decisions.

Illustrative image related to pm review

How Do Iron Powders Fit into Powder Metallurgy Applications?

Iron powders are fundamental in PM, especially for producing parts in automotive and industrial applications. They are known for their good magnetic properties and are often used in the manufacture of components like gears and bearings.

Pros: Iron powders are generally low-cost and widely available. They can be easily processed into various shapes and sizes, making them suitable for mass production.

Cons: Iron is prone to corrosion, which can limit its application in harsh environments unless treated or alloyed. Additionally, the mechanical properties may not match those of more advanced materials like titanium or nickel alloys.

Impact on Application: Iron powders are compatible with a wide range of applications, but their susceptibility to rust may necessitate additional coatings or treatments.

Considerations for International Buyers: Buyers should be aware of regional standards such as JIS for Japan or ASTM for the U.S. market. Understanding local market demands for iron-based products can also inform sourcing strategies.

Illustrative image related to pm review

What Role Do Nickel-Based Alloys Play in Powder Metallurgy?

Nickel-based alloys are known for their exceptional strength and resistance to heat and corrosion, making them suitable for high-performance applications in aerospace and chemical processing.

Pros: These alloys maintain their mechanical properties at high temperatures, making them ideal for turbine components and chemical reactors. Their resistance to oxidation and corrosion is also a significant advantage.

Cons: The cost of nickel-based alloys can be high, and their processing may require more complex techniques compared to other materials. This can lead to increased manufacturing times and costs.

Illustrative image related to pm review

Impact on Application: Nickel alloys are often used in environments where other materials would fail, such as in chemical plants or aerospace applications. Their durability can justify the higher cost in critical applications.

Considerations for International Buyers: Compliance with industry standards is crucial, especially in regulated sectors like aerospace. Buyers should also consider the geopolitical implications of sourcing nickel, particularly from regions with export restrictions.

Summary Table of Material Selection for PM Review

| Material | Typical Use Case for pm review | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Aerospace components, medical implants | High strength-to-weight ratio, corrosion resistance | High cost, complex manufacturing | High |

| Stainless Steel | Food processing, automotive parts | Cost-effective, good machinability | Less effective in extreme conditions | Medium |

| Iron | Gears, bearings in automotive | Low-cost, widely available | Prone to corrosion | Low |

| Nickel-Based Alloys | Aerospace turbines, chemical reactors | Exceptional strength, heat resistance | High cost, complex processing | High |

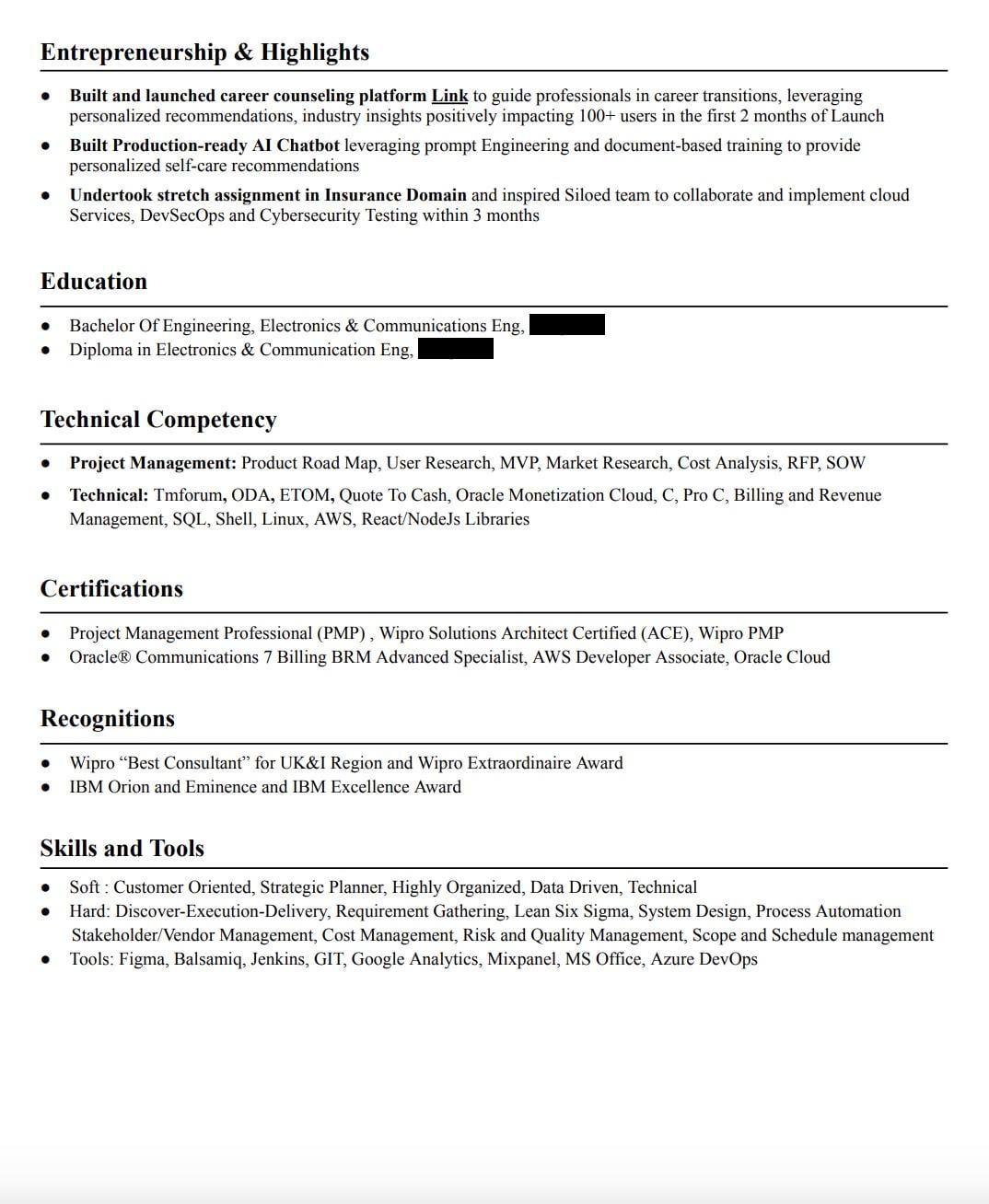

In-depth Look: Manufacturing Processes and Quality Assurance for pm review

What Are the Main Stages of Manufacturing Processes in Powder Metallurgy?

The manufacturing process in powder metallurgy (PM) consists of several critical stages: material preparation, forming, assembly, and finishing. Each stage is essential to ensure the production of high-quality components.

Material Preparation

The first stage involves sourcing and preparing the metal powders, which can be derived from various methods such as atomization, chemical reduction, or milling. This stage is crucial as the properties of the powders—such as particle size, shape, and distribution—directly affect the final product’s performance.

Once sourced, the powders undergo characterization, which includes analysis of their flowability, density, and purity. This data helps in selecting the right powder for specific applications, ensuring optimal performance in subsequent processes.

How Is Forming Conducted in Powder Metallurgy?

Forming is the next stage, where the prepared powders are compacted into desired shapes. The most common techniques include:

- Uniaxial Pressing: Powders are compacted in a single direction using a mechanical or hydraulic press.

- Isostatic Pressing: This method applies pressure uniformly from all directions, resulting in a more uniform density.

- Injection Molding: Here, powders are mixed with a binder and injected into molds, allowing for complex shapes.

The choice of forming technique depends on factors such as the desired geometry and production volume. Ensuring the right pressure and temperature during this stage is vital for achieving the necessary density and strength.

What Happens During the Assembly and Finishing Stages?

After forming, components may require assembly, especially if they consist of multiple parts. Assembly processes can involve techniques like welding, brazing, or fastening. This stage is critical for ensuring that all parts fit accurately and function as intended.

The finishing stage includes processes such as sintering, which involves heating the compacted powder to a temperature below its melting point to bond the particles. Other finishing processes may include machining, surface treatment, or coating to enhance properties such as corrosion resistance or aesthetics.

What Quality Assurance Measures Are Essential in Powder Metallurgy?

Quality assurance (QA) is a vital component of the manufacturing process, especially in industries such as aerospace, automotive, and medical, where precision and reliability are paramount.

Which International Standards Should Be Considered?

International standards like ISO 9001 provide a framework for quality management systems, ensuring that products meet customer and regulatory requirements. Additionally, industry-specific standards such as CE marking for the European market or API specifications for the oil and gas industry may also apply, depending on the application of the PM products.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints should be established throughout the manufacturing process to ensure compliance with these standards. Common QC checkpoints include:

Illustrative image related to pm review

- Incoming Quality Control (IQC): This involves inspecting raw materials and powders upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the manufacturing process, periodic checks on parameters like pressure, temperature, and density are conducted to ensure the process remains within defined limits.

- Final Quality Control (FQC): After the finishing stage, final inspections and testing, including dimensional checks and mechanical property assessments, are carried out before the product is shipped.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential.

What Auditing and Reporting Practices Should Be Followed?

Buyers should request and review quality management system documentation, including:

- Quality Assurance Plans: Outline the processes and procedures in place to maintain quality.

- Audit Reports: Third-party audits can provide an unbiased assessment of a supplier’s compliance with international and industry standards.

- Certificates of Compliance: Documentation confirming that products meet required specifications and standards.

Are There Nuances in QC/Certification for International Buyers?

When sourcing from international suppliers, buyers should be aware of nuances in quality assurance and certification requirements. Different countries may have varying standards, which can impact product acceptance in specific markets. For example, CE marking is mandatory for products sold in the European Union, while other regions may have different regulatory requirements.

What Testing Methods Are Commonly Used in Quality Control?

Several testing methods are commonly employed to ensure the quality of PM products:

- Mechanical Testing: This includes tensile tests, hardness tests, and fatigue testing to evaluate the material properties.

- Non-destructive Testing (NDT): Techniques like X-ray or ultrasonic testing are used to detect internal defects without damaging the product.

- Chemical Analysis: To ensure the composition of the powders meets specifications, chemical analysis methods such as spectroscopy may be employed.

Conclusion

Understanding the manufacturing processes and quality assurance measures in powder metallurgy is crucial for B2B buyers. By focusing on the main stages of manufacturing, adhering to international standards, and implementing robust quality control practices, buyers can ensure they source high-quality products that meet their specific needs. As the global market continues to evolve, maintaining a keen awareness of these processes will empower buyers to make informed decisions and foster successful partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pm review’

Introduction

In the competitive landscape of powder metallurgy (PM) sourcing, having a structured approach is essential for B2B buyers. This checklist will guide you through the critical steps needed to effectively procure materials and services related to PM. By following these actionable steps, you can ensure a successful sourcing experience, ultimately leading to improved product quality and cost efficiency.

Illustrative image related to pm review

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it is vital to have a clear understanding of your technical requirements. This includes defining the types of metal powders, particle sizes, and specific applications you intend to target. Precise specifications will help you communicate effectively with suppliers and ensure that the materials meet your production needs.

- Consider the intended use of the metal powders in your applications (e.g., automotive, aerospace).

- Document any industry standards or certifications that your materials must comply with.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in the types of metal powders you require. Utilize industry publications, trade shows, and online platforms to gather information about various companies and their product offerings. A well-informed selection process can lead to better partnerships.

- Look for suppliers with a proven track record and positive reviews from other B2B buyers.

- Pay attention to their geographical location, as this can affect shipping costs and lead times.

Step 3: Evaluate Supplier Capabilities

Before committing to a supplier, assess their capabilities and production processes. This step is crucial to ensure that they can meet your technical specifications consistently. Request detailed information about their manufacturing processes, quality control measures, and research and development capabilities.

Illustrative image related to pm review

- Ask for case studies or examples of previous projects that demonstrate their expertise.

- Verify their production capacity and lead times to ensure they align with your project schedules.

Step 4: Verify Certifications and Compliance

Compliance with industry standards is non-negotiable in the PM sector. Ensure that your potential suppliers possess the necessary certifications (e.g., ISO 9001, ISO 13485) that validate their quality management systems. This step mitigates risks associated with subpar materials and enhances your supply chain integrity.

- Request copies of their certifications and verify their validity.

- Inquire about their adherence to environmental and safety regulations, especially if you operate in regulated industries.

Step 5: Assess Pricing and Payment Terms

Cost is a critical factor in any procurement process. Obtain detailed pricing from your shortlisted suppliers, including bulk discounts, shipping costs, and payment terms. Understanding the total cost of ownership will enable you to make informed financial decisions.

- Compare pricing models and consider total costs, not just unit prices.

- Discuss payment terms and options, such as upfront payments, credit terms, or flexible financing.

Step 6: Conduct Site Visits or Virtual Inspections

If feasible, conduct site visits or arrange for virtual inspections of the supplier’s facilities. This step provides valuable insight into their operational capabilities and quality control practices. Observing their processes firsthand can help build trust and confidence in your supplier relationship.

- Prepare a checklist of critical areas to assess during your visit (e.g., equipment, cleanliness, safety standards).

- Engage with key personnel to gauge their expertise and commitment to quality.

Step 7: Establish Clear Communication Channels

Effective communication is vital for a successful partnership. Establish clear channels of communication with your suppliers, including regular updates and feedback mechanisms. This ensures that any issues can be addressed promptly and fosters a collaborative relationship.

- Use project management tools to track progress and maintain transparency.

- Schedule regular check-ins to discuss performance, quality, and any potential challenges.

By following this step-by-step checklist, B2B buyers can streamline their sourcing process for powder metallurgy and ensure they partner with reliable suppliers that meet their specific needs.

Comprehensive Cost and Pricing Analysis for pm review Sourcing

What Are the Key Cost Components in Powder Metallurgy Sourcing?

In the realm of powder metallurgy (PM), understanding the cost structure is crucial for B2B buyers. Key components that contribute to the overall cost include:

-

Materials: The choice of metal powders significantly influences cost. For instance, high-performance materials like titanium or specialized alloys typically demand higher prices compared to standard steels. Buyers should assess the material requirements meticulously to balance performance and cost.

-

Labor: Skilled labor is essential in the PM process, impacting labor costs. Regions with a well-trained workforce may offer competitive rates, while areas with labor shortages could see inflated costs.

-

Manufacturing Overhead: This encompasses utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can mitigate overhead costs, so buyers should inquire about a supplier’s operational efficiencies.

-

Tooling: The initial investment in tooling can be substantial, particularly for custom components. Buyers should consider the longevity and adaptability of tooling when evaluating total costs.

-

Quality Control (QC): Rigorous QC processes ensure that products meet specifications, but they add to costs. Buyers should understand the QC measures in place and how they affect pricing.

-

Logistics: Transportation and warehousing costs vary significantly based on location and supplier. International buyers must factor in shipping costs, tariffs, and potential delays.

-

Margin: Suppliers typically incorporate a profit margin into their pricing. Understanding a supplier’s market position can help buyers gauge the reasonableness of their pricing.

How Do Pricing Influencers Affect PM Review Costs?

Several factors influence the pricing of PM products, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their production needs.

-

Specifications and Customization: Custom specifications can lead to increased costs. Buyers should weigh the benefits of tailored solutions against potential price increases.

-

Material Quality and Certifications: High-quality materials and certifications (e.g., ISO standards) can raise costs but are often essential for critical applications. Buyers should evaluate the importance of these factors in relation to their specific needs.

-

Supplier Factors: The supplier’s location, reputation, and financial stability can influence pricing. Building long-term relationships with reliable suppliers can lead to better pricing and service.

-

Incoterms: Understanding Incoterms is essential for international transactions, as they define responsibilities and costs associated with shipping. Buyers should clarify these terms to avoid unexpected expenses.

What Are the Best Tips for Negotiating PM Pricing?

For buyers, especially those in Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings:

-

Engage in Open Dialogue: Establishing a rapport with suppliers can facilitate better negotiations. Clear communication regarding needs and expectations can lead to more favorable terms.

-

Focus on Total Cost of Ownership (TCO): Rather than solely considering the upfront price, evaluate the TCO, which includes maintenance, operational efficiency, and potential savings over time. This holistic view can justify higher initial costs for quality products.

-

Be Aware of Pricing Nuances: Different regions may experience varying pricing structures due to economic conditions, tariffs, and local supply chains. Buyers should conduct market research to understand these nuances.

-

Leverage Competitive Quotes: Obtaining quotes from multiple suppliers can provide leverage in negotiations. This not only helps in securing better pricing but also provides insights into market standards.

Conclusion

Navigating the cost and pricing landscape in powder metallurgy requires a comprehensive understanding of various components and influencers. By employing strategic negotiation tactics and focusing on long-term value, B2B buyers can optimize their sourcing decisions and achieve favorable outcomes in their procurement processes. Always remember that prices can vary widely, and it’s essential to approach each negotiation with a clear strategy and understanding of the market dynamics.

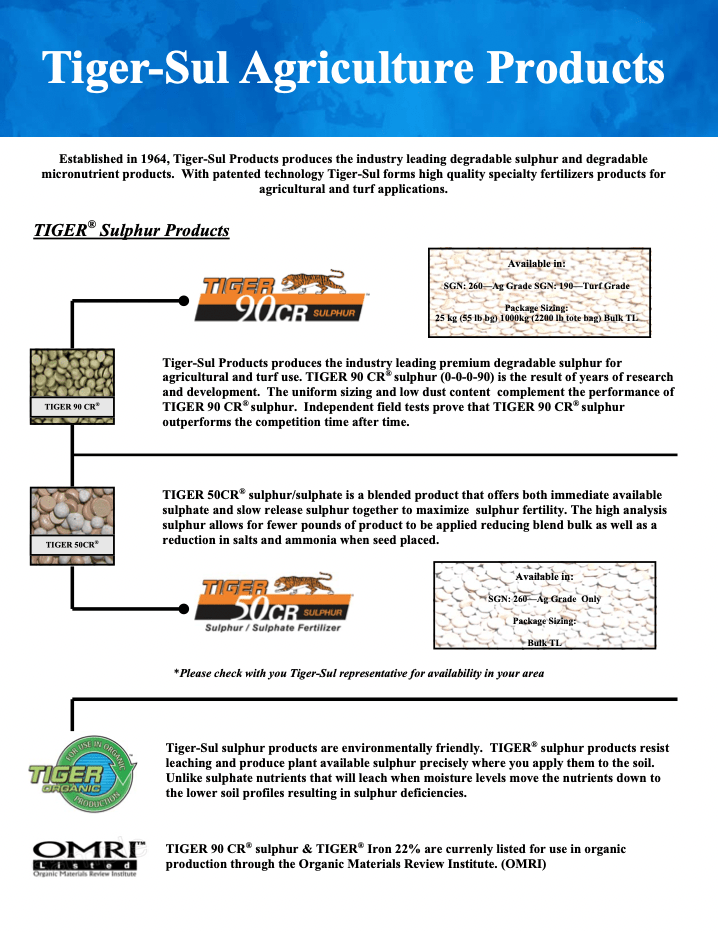

Alternatives Analysis: Comparing pm review With Other Solutions

Introduction to Alternative Solutions for PM Review

In the dynamic landscape of powder metallurgy and metal powder technologies, organizations often seek to evaluate various solutions to optimize their operations. PM Review is a leading source of information in this field, but it is essential to consider other viable alternatives that can complement or even replace its offerings. By comparing PM Review with alternative solutions, B2B buyers can make informed decisions that align with their specific business needs.

Comparison Table

| Comparison Aspect | PM Review | Metal Powder Technology Magazine | Industry Conferences |

|---|---|---|---|

| Performance | Comprehensive news coverage and insights | In-depth technical articles and industry reports | Networking and real-time industry insights |

| Cost | Subscription-based, moderate cost | Subscription-based, similar pricing | Varies based on location and participation fees |

| Ease of Implementation | Easy to access online and offline | Accessible online, requires subscription | Requires planning and travel logistics |

| Maintenance | Regular updates and new editions | Periodic releases, ongoing updates | Event-dependent, infrequent updates |

| Best Use Case | Daily industry news and trends | Technical depth for R&D and innovation | Networking and knowledge exchange for industry trends |

Detailed Breakdown of Alternatives

1. Metal Powder Technology Magazine

Metal Powder Technology Magazine offers a blend of industry news and technical articles that delve into specific topics related to powder metallurgy. Its strengths lie in providing detailed insights into emerging technologies and case studies. However, it may not cover daily news as extensively as PM Review. For organizations focused on deepening their technical knowledge and understanding industry trends, this magazine is a robust alternative. Its subscription model mirrors that of PM Review, making it a familiar option for B2B buyers.

2. Industry Conferences

Participating in industry conferences provides a unique opportunity for networking and firsthand exposure to the latest trends and innovations in powder metallurgy. These events foster collaboration and knowledge sharing among professionals and can lead to new partnerships and business opportunities. However, the costs can vary significantly depending on the location and scale of the conference, and they require careful planning and travel arrangements. While conferences do not provide regular updates like PM Review, they offer real-time insights and discussions that can be invaluable for strategic decision-making.

Conclusion: How to Choose the Right Solution

When selecting the most suitable solution for staying informed in the powder metallurgy sector, B2B buyers must assess their specific requirements. If the need is for up-to-date news and trends, PM Review provides a comprehensive and easily accessible platform. For those looking for in-depth technical knowledge, Metal Powder Technology Magazine may be more appropriate. Conversely, if networking and direct engagement with industry experts is a priority, attending industry conferences could be the best choice. Ultimately, the decision should align with the organization’s strategic goals, resources, and the specific insights required to navigate the evolving market landscape effectively.

Essential Technical Properties and Trade Terminology for pm review

What Are the Key Technical Properties in Powder Metallurgy (PM)?

Understanding the essential technical properties of materials used in powder metallurgy is critical for B2B buyers to make informed purchasing decisions. Here are several key specifications that significantly impact the performance and application of PM products:

-

Material Grade:

Material grade refers to the classification of metal powders based on their composition and mechanical properties. Common grades include stainless steel, titanium alloys, and tool steels. For B2B buyers, selecting the right material grade is vital for ensuring compatibility with the intended application, whether it’s for automotive, aerospace, or industrial uses. The right grade can enhance durability and performance while minimizing failure rates. -

Particle Size Distribution (PSD):

PSD describes the range and frequency of particle sizes within a given powder batch. A narrow PSD can lead to better packing density and mechanical properties, while a broad PSD may enhance flowability during processing. Buyers should consider PSD when specifying materials for additive manufacturing or compaction processes, as it can directly influence the final product’s quality and performance. -

Sintering Temperature:

This is the temperature at which powder particles bond to form a solid piece. The chosen sintering temperature affects the mechanical properties of the final product, including density and strength. Understanding the optimal sintering temperature is essential for B2B buyers, as it can impact production efficiency and product characteristics. -

Tensile Strength:

Tensile strength measures a material’s resistance to being pulled apart. It is a critical property that indicates how much load a PM component can withstand before failure. Buyers must evaluate tensile strength to ensure the selected materials meet the performance requirements of their applications, particularly in high-stress environments. -

Porosity:

Porosity refers to the volume fraction of voids within a material. In PM, porosity can influence the mechanical properties, wear resistance, and fatigue strength of components. For B2B buyers, understanding porosity levels is essential, especially when considering applications where structural integrity and performance are paramount.

What Are Common Trade Terms Used in Powder Metallurgy?

Navigating the world of powder metallurgy also requires familiarity with specific industry jargon. Here are several key terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer):

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of PM, OEMs often require custom powder formulations or specific processing capabilities. Understanding OEM relationships is crucial for buyers looking to source specialized components. -

MOQ (Minimum Order Quantity):

MOQ is the smallest quantity of a product that a supplier is willing to sell. For buyers, knowing the MOQ is essential for budgeting and planning inventory, particularly when sourcing specialized or high-cost materials in powder metallurgy. -

RFQ (Request for Quotation):

An RFQ is a document issued by a buyer to solicit pricing and terms from suppliers. This term is especially relevant in PM, where the complexity of materials and processes can lead to varied pricing structures. B2B buyers should leverage RFQs to obtain competitive bids and ensure they are receiving fair market pricing. -

Incoterms:

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping and delivery. Understanding these terms can help B2B buyers navigate logistics and ensure that they are clear on who bears the risks and costs associated with transportation and delivery. -

HIP (Hot Isostatic Pressing):

HIP is a process used to improve the density and mechanical properties of PM components by applying high pressure and temperature. B2B buyers should be aware of HIP as a valuable technique that can enhance product quality and performance, particularly in critical applications like aerospace and medical devices.

By grasping these technical properties and trade terms, B2B buyers can engage more effectively with suppliers, optimize their procurement strategies, and ensure that their material selections align with their operational goals.

Navigating Market Dynamics and Sourcing Trends in the pm review Sector

What Are the Key Market Dynamics and Trends in the Powder Metallurgy Sector?

The global powder metallurgy (PM) sector is experiencing significant growth, driven by advancements in manufacturing technology and increasing demand for high-performance materials across various industries. Notably, the automotive sector’s shift towards electrification is a critical driver, necessitating sustainable and efficient production methods for components like electric vehicle (EV) batteries and magnets. B2B buyers from regions such as Africa, South America, the Middle East, and Europe should note that the integration of additive manufacturing techniques is reshaping sourcing strategies, allowing for more flexible production and reduced waste.

Emerging technologies such as Hot Isostatic Pressing (HIP) are gaining traction, offering solutions to produce defect-free, high-integrity components that are essential in critical applications, including aerospace and medical devices. The recent surge in events like the Euro PM2025 Congress indicates a robust interest in networking and collaboration, which is vital for staying ahead in a rapidly evolving market. Furthermore, the increasing emphasis on localizing supply chains, particularly for critical materials like rare earth elements, reflects a strategic pivot towards resilience in sourcing practices.

How Is Sustainability Reshaping Sourcing Strategies in the PM Industry?

Sustainability has become a paramount concern for B2B buyers in the PM sector. The environmental impact of traditional powder production methods is prompting companies to adopt greener practices. For instance, manufacturers are increasingly focusing on sourcing recycled materials and implementing processes that minimize energy consumption and waste. The shift towards using 100% green nitrogen in additive manufacturing powders, as seen with companies like voestalpine Böhler, exemplifies this trend.

Ethical sourcing is also gaining traction, with buyers seeking suppliers who can demonstrate responsible practices throughout their supply chains. Certifications such as ISO 14001 for environmental management and adherence to responsible sourcing standards are becoming essential in supplier evaluations. This focus not only mitigates environmental impact but also enhances brand reputation, as consumers increasingly favor companies that prioritize sustainability. For international buyers, understanding these trends can inform sourcing decisions, aligning with global sustainability goals while optimizing operational efficiency.

What Is the Historical Context of Powder Metallurgy and Its Relevance Today?

Powder metallurgy has evolved significantly since its inception in the early 20th century, initially focused on producing simple metal parts. Over the decades, technological advancements have expanded its applications, particularly in high-performance sectors. The introduction of innovative techniques such as sintering and advanced compaction methods has enabled the production of complex geometries and high-strength materials, making PM a vital process in industries ranging from automotive to aerospace.

Today, the historical context of PM underscores its adaptability and relevance in meeting modern manufacturing challenges. The sector’s evolution towards sustainability and innovation reflects a broader industry trend towards efficiency and environmental responsibility. As international B2B buyers navigate this landscape, understanding the historical developments in PM can provide valuable insights into current capabilities and future opportunities in sourcing high-quality materials and components.

Illustrative image related to pm review

Frequently Asked Questions (FAQs) for B2B Buyers of pm review

-

How do I ensure quality when sourcing metal powders for my production needs?

To ensure quality when sourcing metal powders, start by vetting potential suppliers through industry certifications such as ISO 9001 or specific quality assurance standards relevant to powder metallurgy. Request sample materials for testing and assess their particle size distribution, purity levels, and flow characteristics. Additionally, inquire about the supplier’s quality control processes, including any third-party testing they employ. Establishing a clear communication channel for ongoing quality checks can also help maintain standards throughout the supply chain. -

What factors should I consider when choosing a supplier for metal powders?

When selecting a supplier for metal powders, consider their industry experience, reputation, and technological capabilities. Evaluate their production capacity and lead times to ensure they can meet your demand. Geographic location is also crucial; suppliers closer to your operation can reduce shipping costs and times. Furthermore, assess their customer service responsiveness and willingness to customize products according to your specifications, as these factors can significantly impact your overall satisfaction. -

What are the minimum order quantities (MOQ) typically required for metal powders?

Minimum order quantities (MOQ) for metal powders can vary significantly depending on the supplier and the specific material. Generally, MOQs can range from a few kilograms to several tons. Smaller suppliers may offer more flexible MOQs, while larger manufacturers might have stricter requirements. It’s essential to discuss your needs upfront and explore possibilities for trial orders if you’re unsure about committing to larger quantities. -

What payment terms are common in international B2B transactions for metal powders?

Common payment terms in international B2B transactions for metal powders often include options like advance payment, letter of credit, or open account terms. Many suppliers may request a partial upfront payment, with the balance due upon delivery or after an agreed-upon period. Ensure to clarify payment methods accepted (e.g., wire transfer, credit card) and any associated fees. It’s advisable to establish clear terms in your contract to prevent misunderstandings later on. -

How do I manage logistics when sourcing metal powders internationally?

Managing logistics for international sourcing of metal powders requires careful planning. Start by understanding the shipping regulations and customs requirements for your country and the supplier’s location. Select a reliable freight forwarder experienced in handling industrial materials, and consider using Incoterms to define responsibilities for shipping costs and risks. Additionally, track shipments closely to ensure timely delivery and address any potential delays proactively. -

Can I customize the metal powders according to my specific needs?

Yes, many suppliers offer customization options for metal powders based on your specific production requirements. This may include adjustments in particle size, composition, or coating treatments. When discussing customization, provide detailed specifications and communicate your application needs clearly. Be aware that customization may affect lead times and pricing, so ensure these factors are accounted for in your planning. -

What quality assurance processes should I expect from a reputable metal powder supplier?

Reputable metal powder suppliers typically implement rigorous quality assurance processes, including in-house testing of material properties such as purity, particle size distribution, and flowability. Look for suppliers who offer certifications and documentation, such as Certificates of Analysis (CoA), to substantiate their claims. Additionally, inquire about their procedures for handling non-conformities and how they ensure consistent quality across batches. -

What are the key trends in the metal powder industry that I should be aware of?

Key trends in the metal powder industry include the increasing demand for sustainable and recyclable materials, driven by the push for green manufacturing practices. Innovations in additive manufacturing and the development of advanced alloys are also shaping the market. Suppliers are focusing on enhancing production efficiency and reducing environmental impact, such as through the use of green technologies in powder production. Staying informed about these trends can help you make strategic sourcing decisions that align with industry advancements.

Top 1 Pm Review Manufacturers & Suppliers List

1. Prime Minister – Jacinda Ardern Documentary

Domain: latimes.com

Registered: 1990 (35 years)

Introduction: Title: Prime Minister

Director: Michelle Walshe, Lindsay Utz

Subject: Jacinda Ardern, former Prime Minister of New Zealand

Genre: Documentary

Running time: 1 hour, 41 minutes

Release date: June 13, 2025

Rating: Not rated

Overview: The documentary chronicles Jacinda Ardern’s five-year administration as New Zealand’s progressive leader and her experience as a new mother. It provides an intimate view…

Strategic Sourcing Conclusion and Outlook for pm review

In the dynamic landscape of powder metallurgy, strategic sourcing emerges as a critical driver of competitive advantage for B2B buyers. As highlighted in our guide, the growing demand for sustainable and innovative materials—such as green metal powders and locally sourced magnets—underscores the importance of establishing robust supplier relationships. Engaging with qualified suppliers not only enhances the supply chain’s resilience but also opens up avenues for collaboration on emerging technologies like additive manufacturing and hot isostatic pressing.

International buyers, particularly from Africa, South America, the Middle East, and Europe, are encouraged to leverage industry events such as the Euro PM Congress and the Formnext Asia Forum. These platforms provide invaluable opportunities for networking, knowledge sharing, and discovering cutting-edge solutions tailored to specific market needs.

As we look ahead, the commitment to sustainability and innovation will shape the future of powder metallurgy. By prioritizing strategic sourcing, you can position your organization at the forefront of industry advancements. Embrace the opportunity to enhance your sourcing strategies today and secure a competitive edge in the evolving marketplace.

Illustrative image related to pm review

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.