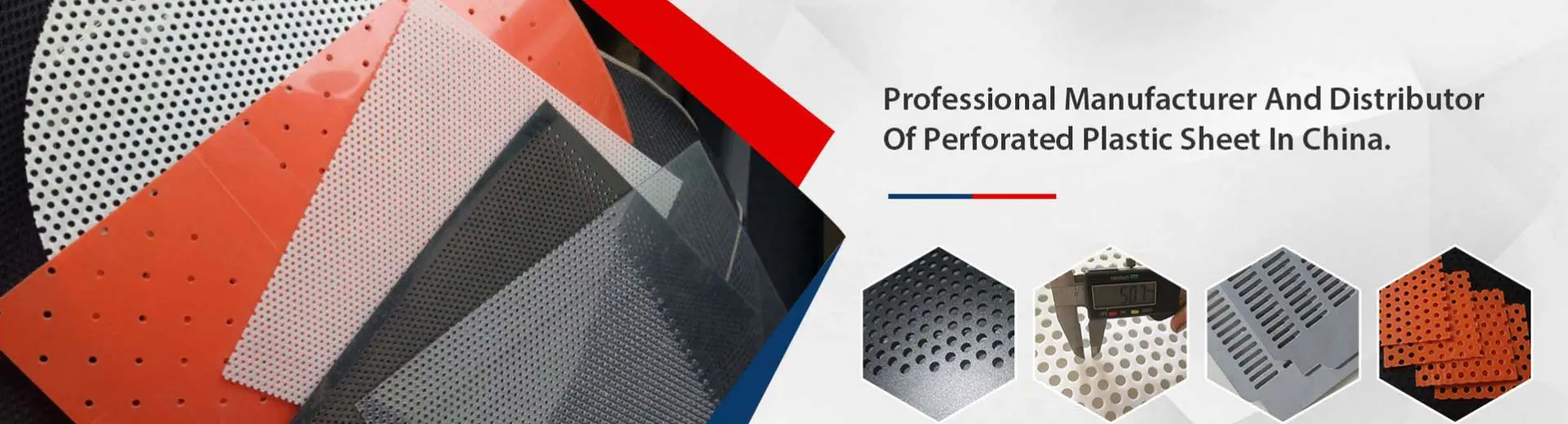

A B2B Buyer’s Guide to Perforated Plastic Sheet Material: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for perforated plastic sheet material

In an increasingly interconnected world, sourcing the right perforated plastic sheet material can present significant challenges for B2B buyers. Whether you’re a manufacturer in Africa, a construction firm in South America, or a supplier in Europe, the need for high-quality, versatile perforated plastic sheets is undeniable. These materials not only offer superior performance compared to traditional options, but they also provide unique design flexibility that caters to a multitude of applications—from food processing and automotive to architecture and logistics.

This comprehensive guide serves as an essential resource for international B2B buyers navigating the complexities of the perforated plastic sheet market. Inside, you’ll find detailed insights into various types of perforated sheets, including their geometric configurations and material compositions. We will explore their extensive applications across diverse industries, while also addressing critical factors such as supplier vetting processes, cost considerations, and customization options.

By leveraging the knowledge contained in this guide, you will be empowered to make informed purchasing decisions that align with your operational needs and budgetary constraints. With a focus on global markets—including emerging regions in Africa and South America, as well as established markets in Europe and the Middle East—you will discover how to effectively source perforated plastic sheets that enhance your product offerings and operational efficiency.

Understanding perforated plastic sheet material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Polypropylene | Lightweight, high chemical resistance, customizable | Acoustical panels, decorative elements, sunshades | Pros: Low weight, excellent moisture resistance. Cons: Limited temperature resistance. |

| PVC | Cost-effective, good rigidity, available in various colors | Construction, signage, industrial applications | Pros: Affordable, versatile. Cons: Less durable under extreme conditions. |

| Polycarbonate | High impact resistance, UV stability | Safety barriers, greenhouse glazing, industrial enclosures | Pros: Durable, excellent light transmission. Cons: Higher cost compared to other plastics. |

| HDPE | High strength-to-density ratio, chemical resistance | Agriculture, water management, packaging | Pros: Long-lasting, resistant to environmental stress. Cons: Limited aesthetic options. |

| PETG | Clarity, easy to thermoform, good impact resistance | Medical applications, retail displays, food packaging | Pros: Excellent clarity, recyclable. Cons: Moderate chemical resistance compared to other plastics. |

What are the Characteristics and Suitability of Polypropylene Perforated Sheets?

Polypropylene perforated sheets are notable for their lightweight nature and high resistance to chemicals, making them ideal for various applications, including acoustical panels and decorative elements. Their customizable perforation patterns allow for versatility in design, enabling businesses to tailor products to specific project requirements. When considering polypropylene, buyers should note its limitations in temperature resistance, which may restrict its use in high-heat environments.

How Does PVC Stand Out in Perforated Plastic Sheets?

PVC (Polyvinyl Chloride) is a popular choice for perforated sheets due to its cost-effectiveness and good rigidity. It is available in a range of colors, making it suitable for signage and construction applications. While PVC provides an economical solution, buyers should be aware of its potential drawbacks, such as reduced durability under extreme environmental conditions, which may lead to concerns in long-term applications.

Why Choose Polycarbonate for Perforated Applications?

Polycarbonate perforated sheets are recognized for their high impact resistance and UV stability, making them an excellent choice for safety barriers and greenhouse glazing. Their ability to transmit light while maintaining structural integrity is a significant advantage in various industrial applications. However, buyers should consider that polycarbonate sheets tend to have a higher cost compared to other plastic options, which may influence budget considerations.

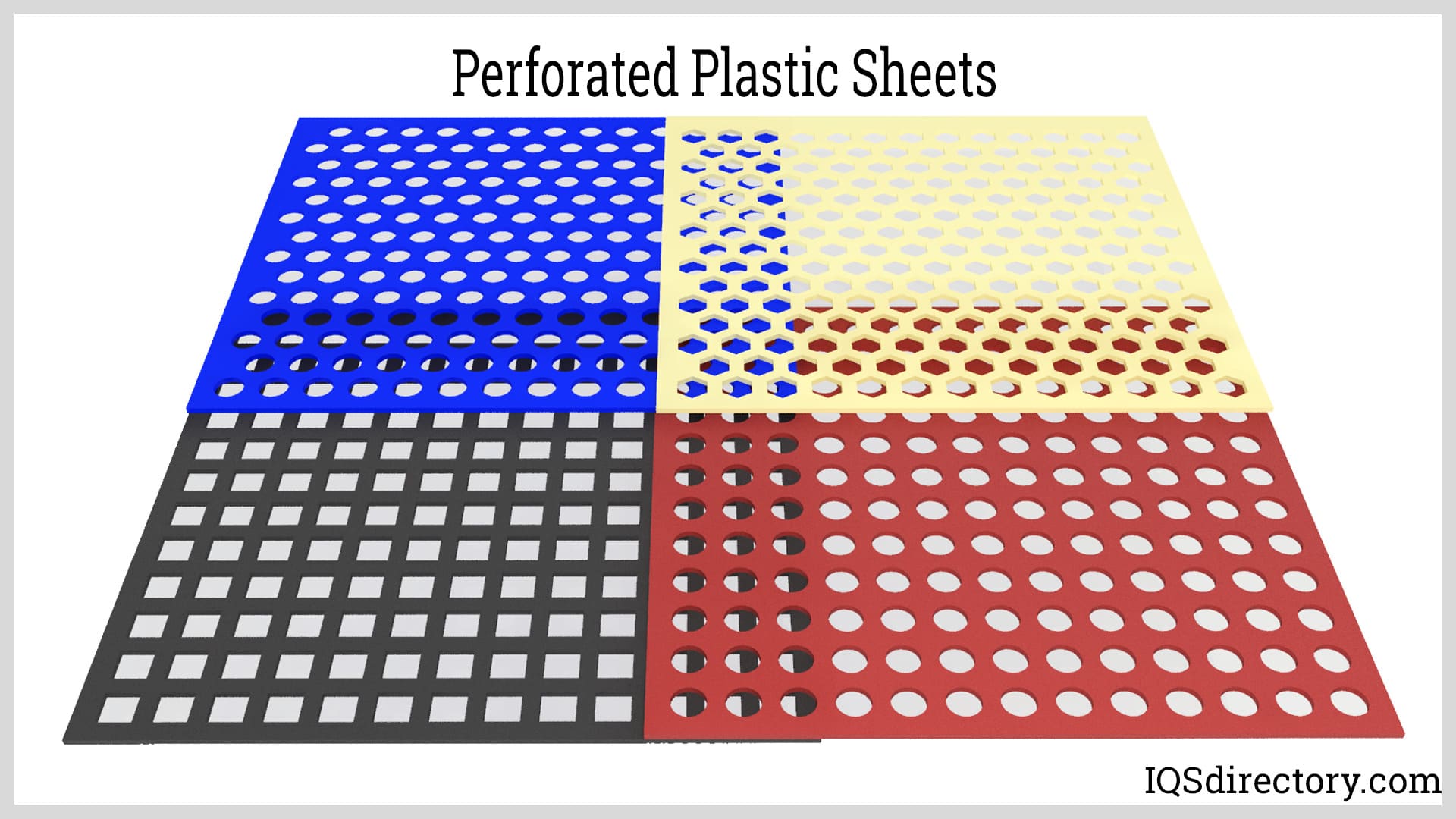

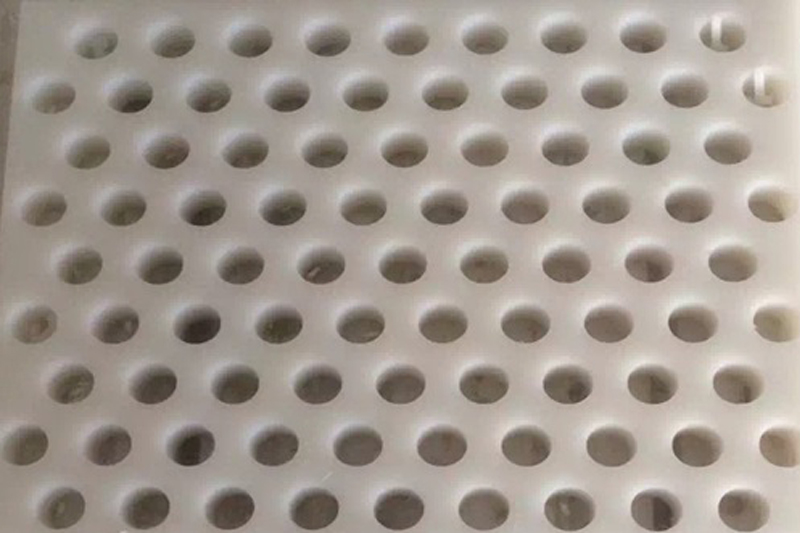

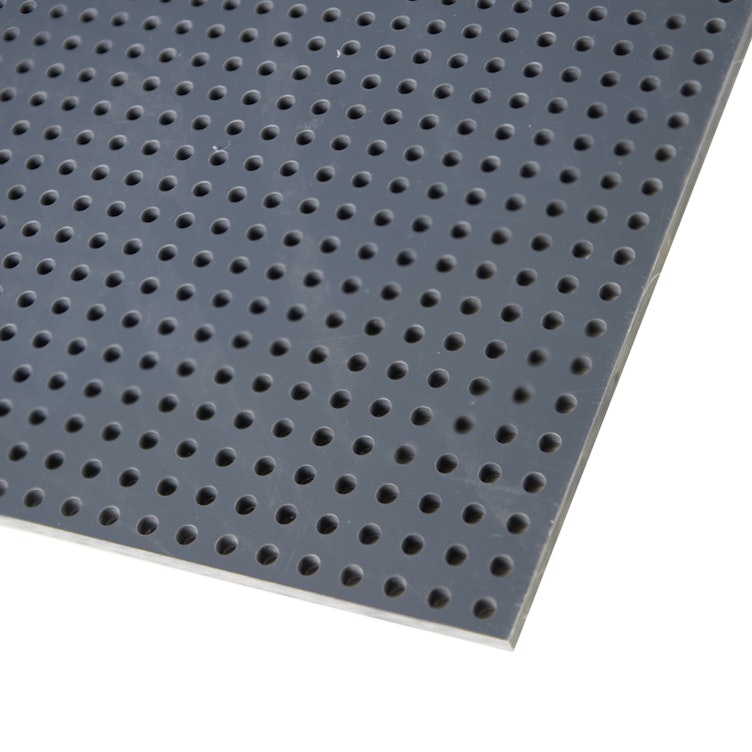

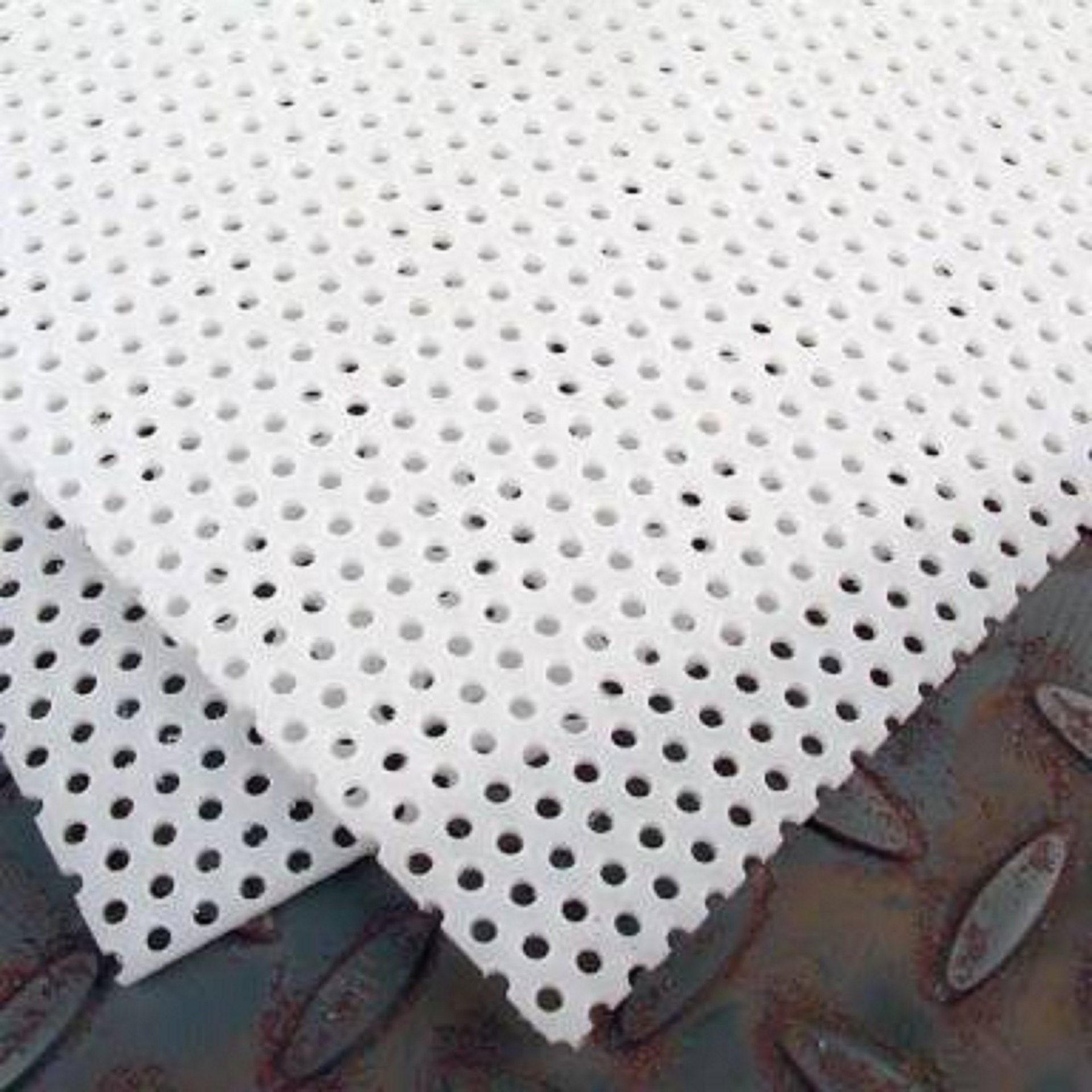

Illustrative image related to perforated plastic sheet material

What Advantages Does HDPE Offer in Perforated Plastic Sheets?

High-Density Polyethylene (HDPE) is favored for its impressive strength-to-density ratio and chemical resistance, making it suitable for agricultural applications and water management systems. Its durability ensures a long service life, even in challenging environmental conditions. Nonetheless, buyers may find HDPE’s aesthetic options limited, which could be a consideration for applications requiring visual appeal.

How Does PETG Compare in Perforated Plastic Options?

PETG (Polyethylene Terephthalate Glycol) is characterized by its clarity and ease of thermoforming, making it ideal for medical applications and retail displays. Its good impact resistance further enhances its suitability for food packaging. However, while PETG is recyclable, its moderate chemical resistance compared to other plastics may limit its use in certain industrial applications. Buyers should weigh these factors against their specific needs when considering PETG.

Key Industrial Applications of perforated plastic sheet material

| Industry/Sector | Specific Application of perforated plastic sheet material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Used as filtration screens in processing equipment | Ensures hygiene and compliance with safety standards | Material must be food-grade and resistant to chemicals |

| Construction | Architectural elements like sunshades and facades | Enhances aesthetic appeal while allowing airflow | Custom perforation patterns and durability in outdoor conditions |

| Agriculture | Used for plant nursery trays and ventilation systems | Promotes healthy plant growth through optimal airflow | Lightweight and UV-resistant materials are essential |

| Automotive | Components in air intake systems and sound insulation | Reduces weight and enhances fuel efficiency | High-temperature resistance and mechanical stability required |

| Chemical Industry | Tanks and filtration systems for chemical processing | Corrosion resistance improves longevity of equipment | Compatibility with specific chemicals is crucial |

How is Perforated Plastic Sheet Material Used in Food Processing?

In the food processing sector, perforated plastic sheets serve as essential filtration screens in various processing equipment. They ensure that contaminants are filtered out while allowing liquids and gases to pass through. This application is critical for maintaining hygiene and compliance with food safety standards. Buyers must prioritize materials that are food-grade, resistant to chemicals, and capable of withstanding high temperatures to ensure safety and durability throughout the processing lifecycle.

What Role Does Perforated Plastic Play in Construction?

In the construction industry, perforated plastic sheets are increasingly used in architectural applications such as sunshades and decorative facades. These sheets provide an aesthetic appeal while allowing for ventilation and light diffusion, making them ideal for both new builds and renovations. When sourcing these materials, businesses should consider custom perforation patterns that meet design specifications and ensure the material’s durability against weather conditions.

Why are Perforated Plastic Sheets Important in Agriculture?

Perforated plastic sheets find significant utility in agriculture, particularly in plant nursery trays and ventilation systems. By allowing optimal airflow, these sheets promote healthy plant growth and reduce moisture accumulation, which can lead to mold and other plant diseases. Buyers in this sector should focus on lightweight, UV-resistant materials that can withstand outdoor conditions while ensuring the longevity of the trays and systems they are used in.

How Does Perforated Plastic Enhance Automotive Applications?

In the automotive industry, perforated plastic sheets are utilized in components such as air intake systems and sound insulation panels. The lightweight nature of these materials contributes to overall vehicle weight reduction, enhancing fuel efficiency. Buyers must ensure that the selected perforated sheets possess high-temperature resistance and mechanical stability, as these factors are crucial for maintaining performance under varying operational conditions.

What Benefits Do Perforated Plastic Sheets Offer in the Chemical Industry?

Within the chemical industry, perforated plastic sheets are employed in tanks and filtration systems to manage various chemical processes. Their corrosion resistance is a significant advantage, as it extends the longevity of equipment and reduces maintenance costs. When sourcing for this application, businesses should confirm the compatibility of the material with specific chemicals to prevent degradation and ensure safe operation.

3 Common User Pain Points for ‘perforated plastic sheet material’ & Their Solutions

Scenario 1: Navigating Customization Needs for Specific Applications

The Problem: Many B2B buyers in industries such as food processing or automotive face challenges when sourcing perforated plastic sheets that meet their precise specifications. The need for specific perforation patterns, dimensions, and material properties can lead to frustration, especially when suppliers offer limited options or generic products that do not align with the buyer’s applications. This can result in delays in production and increased costs due to the need for modifications or replacements.

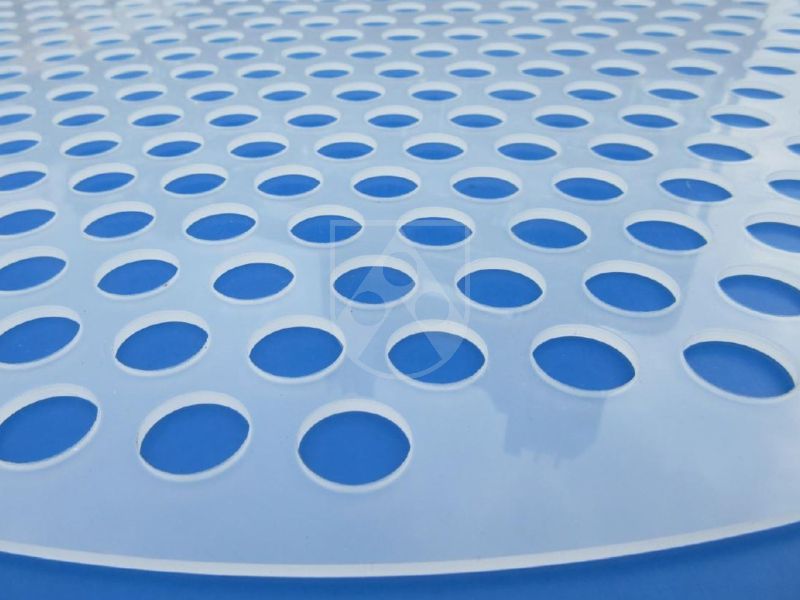

Illustrative image related to perforated plastic sheet material

The Solution: To effectively address these customization needs, buyers should seek suppliers that offer tailored solutions. Begin by clearly defining your requirements, including the size, shape, and perforation pattern needed for your application. Engage with manufacturers that specialize in perforated plastic sheets, such as those with experience in your specific industry. Request samples to evaluate material properties like weight, durability, and resistance to chemicals or UV exposure. By establishing a strong dialogue with your supplier and utilizing their expertise, you can ensure that the perforated sheets you source will perfectly fit your operational needs, ultimately streamlining your production process.

Scenario 2: Overcoming Material Limitations for Harsh Environments

The Problem: Buyers in sectors such as chemical processing or oil and gas often encounter the limitation of traditional materials when exposed to harsh environments. Perforated plastic sheets may not have the necessary resistance to chemicals or extreme temperatures, leading to rapid degradation, safety hazards, and increased operational downtime.

The Solution: To overcome these material limitations, it’s crucial to understand the specific environmental conditions your perforated plastic sheets will face. Collaborate with suppliers who offer a diverse range of thermoplastic materials designed to withstand such challenges, including those with high chemical resistance and temperature tolerances. For instance, materials like Polystone® or specialized PVC can provide enhanced durability. When ordering, specify the environmental factors, such as chemical exposure and temperature fluctuations, to ensure that the selected material is adequately suited for your application. This proactive approach will enhance the longevity and reliability of your perforated sheets, thus minimizing maintenance costs and operational disruptions.

Illustrative image related to perforated plastic sheet material

Scenario 3: Managing Inventory and Supply Chain Efficiency

The Problem: B2B buyers often struggle with inventory management and supply chain efficiency, particularly when dealing with multiple suppliers for various types of perforated plastic sheets. This fragmentation can lead to inconsistencies in quality, delivery delays, and increased administrative burdens when tracking orders.

The Solution: To streamline inventory management, consider consolidating your supplier base by choosing manufacturers that can provide a comprehensive range of perforated plastic sheets tailored to different applications. This not only simplifies the ordering process but also ensures consistent quality across your materials. Implement a centralized inventory management system that tracks the usage and stock levels of perforated sheets, allowing for timely reordering before stock runs low. Additionally, negotiate with suppliers for bulk purchasing agreements or just-in-time delivery schedules to enhance supply chain efficiency. By strategically managing your supply chain and supplier relationships, you can reduce costs, improve lead times, and maintain operational continuity across your projects.

Strategic Material Selection Guide for perforated plastic sheet material

What Are the Key Properties of Common Materials for Perforated Plastic Sheets?

When selecting perforated plastic sheet materials for diverse applications, understanding the properties and performance characteristics of each material is crucial. Here, we analyze four common materials: Polypropylene, PVC, Polycarbonate, and HDPE, focusing on their suitability for various industrial applications.

How Does Polypropylene Perform in Perforated Plastic Applications?

Polypropylene (PP) is a thermoplastic known for its lightweight and high impact resistance. It typically withstands temperatures up to 100°C and exhibits excellent chemical resistance, making it suitable for applications in the food processing and chemical industries.

Pros: Polypropylene is cost-effective, has low moisture absorption, and is resistant to many solvents. Its flexibility allows for various perforation designs, enhancing its usability in different applications.

Cons: However, it has a lower temperature tolerance compared to other materials and can become brittle under UV exposure unless treated.

Impact on Application: PP is ideal for environments where weight is a concern, such as in automotive or packaging applications. Its compatibility with food-grade standards makes it a top choice for food processing.

Considerations for International Buyers: Buyers in regions like Europe and the Middle East should ensure compliance with food safety standards, such as FDA and EU regulations, when using PP in food-related applications.

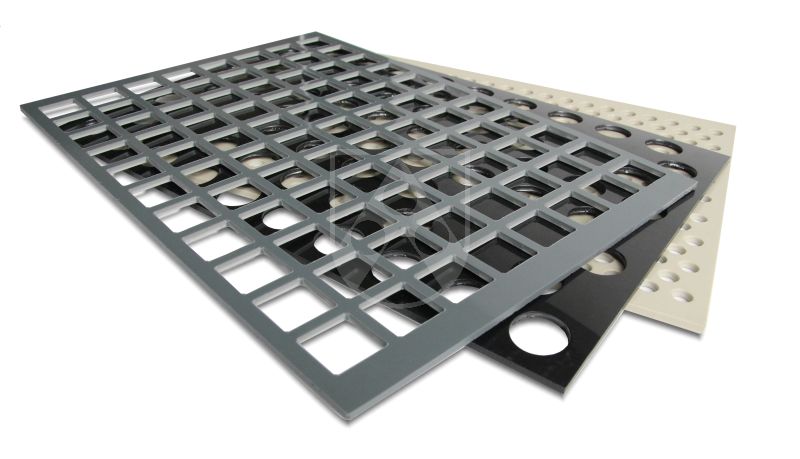

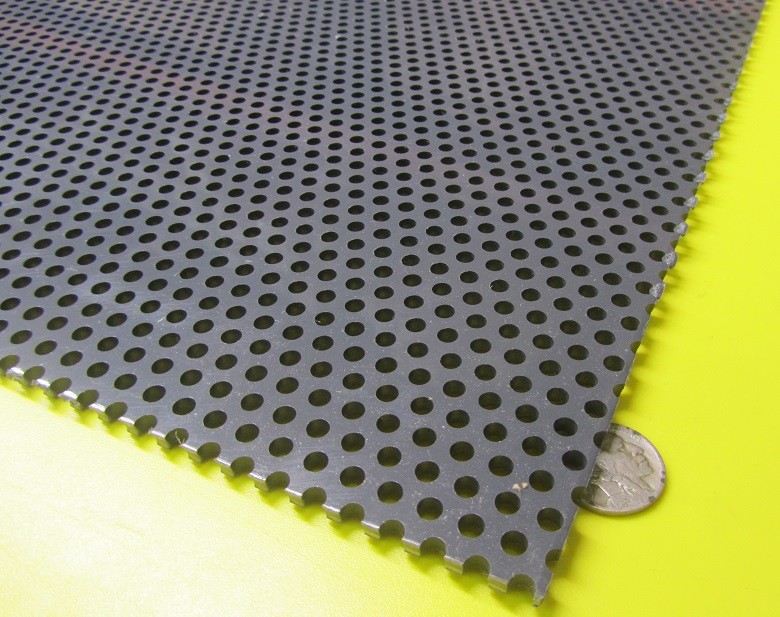

Illustrative image related to perforated plastic sheet material

What Are the Advantages of PVC for Perforated Sheets?

Polyvinyl Chloride (PVC) is another popular choice for perforated sheets, known for its durability and versatility. It can withstand temperatures up to 60°C and is highly resistant to corrosion and chemicals, making it suitable for various industrial applications.

Pros: PVC is affordable and offers good mechanical strength. It is also easy to fabricate, allowing for custom perforation patterns.

Cons: Its lower heat resistance and potential for environmental stress cracking can limit its use in high-temperature applications.

Illustrative image related to perforated plastic sheet material

Impact on Application: PVC is commonly used in construction, automotive, and electrical applications due to its excellent insulating properties.

Considerations for International Buyers: Buyers should be aware of the environmental regulations surrounding PVC, particularly in Europe, where there are stringent guidelines on the use of certain additives.

Why Choose Polycarbonate for Perforated Sheets?

Polycarbonate (PC) is a high-performance thermoplastic known for its exceptional strength and impact resistance, withstanding temperatures up to 120°C. It is transparent, allowing for applications that require light transmission.

Illustrative image related to perforated plastic sheet material

Pros: Polycarbonate is highly durable, UV-resistant, and offers excellent dimensional stability, making it suitable for outdoor applications.

Cons: The higher cost of polycarbonate compared to other plastics can be a limiting factor for some projects, and it may require specialized fabrication techniques.

Impact on Application: PC is ideal for applications in the construction and automotive industries, where strength and clarity are essential.

Considerations for International Buyers: Buyers should ensure compliance with safety standards, especially in regions like Germany, where building regulations are strict.

Illustrative image related to perforated plastic sheet material

What Makes HDPE a Viable Option for Perforated Plastic Sheets?

High-Density Polyethylene (HDPE) is known for its high strength-to-density ratio and resistance to impact and chemicals. It typically operates effectively within a temperature range of -40°C to 60°C.

Pros: HDPE is lightweight, cost-effective, and has excellent resistance to moisture and chemicals. It is also recyclable, making it an environmentally friendly option.

Cons: Its lower rigidity compared to other materials may limit its use in applications requiring structural integrity.

Illustrative image related to perforated plastic sheet material

Impact on Application: HDPE is commonly used in agricultural, packaging, and waste management applications due to its chemical resistance and durability.

Considerations for International Buyers: Buyers should consider the recycling capabilities and environmental regulations in their regions, as HDPE is often favored for sustainable practices.

Summary of Material Selection for Perforated Plastic Sheets

| Material | Typical Use Case for perforated plastic sheet material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | Food processing, automotive components | Lightweight and chemical resistant | Lower temperature tolerance | Low |

| PVC | Construction, electrical insulation | Durable and affordable | Environmental stress cracking | Low |

| Polycarbonate | Outdoor applications, safety glazing | High strength and UV resistance | Higher cost | High |

| HDPE | Agricultural applications, packaging | Moisture and chemical resistant | Lower rigidity | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of common perforated plastic sheet materials, facilitating informed decision-making for various industrial applications.

In-depth Look: Manufacturing Processes and Quality Assurance for perforated plastic sheet material

What Are the Main Stages in the Manufacturing Process of Perforated Plastic Sheets?

The manufacturing of perforated plastic sheets involves a series of well-defined stages, each critical to ensuring the final product meets quality and performance standards. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation

The process begins with the selection and preparation of thermoplastic materials. Commonly used plastics include polypropylene, PVC, and various high-performance polymers. These materials are chosen based on their physical properties, such as weight, corrosion resistance, and temperature tolerance. Before processing, the materials may undergo drying to eliminate moisture, ensuring optimal performance during the subsequent stages.

Forming Techniques: How Are Perforations Created?

Once prepared, the plastic sheets are subjected to forming techniques that create the desired perforations. This can be achieved through various methods, including:

- Mechanical Perforation: High-speed presses equipped with custom tooling can punch holes into the sheets. This method allows for a wide range of hole sizes and patterns, accommodating specific design requirements.

- Laser Cutting: For more intricate designs, laser cutting offers precision and flexibility, allowing for complex patterns and shapes. This method is particularly advantageous for prototypes or low-volume production runs.

Assembly and Finishing: What Happens Next?

After the perforation stage, the sheets may require assembly with other components, depending on their intended application. For instance, perforated sheets used in railings or architectural features might be integrated with frames or supports.

Illustrative image related to perforated plastic sheet material

Finishing processes enhance both the aesthetic and functional properties of the sheets. This may include:

- Surface Treatment: Techniques such as coating or polishing can improve scratch resistance and enhance visual appeal.

- Coloring: Custom colors can be added to meet branding or design specifications.

What Quality Assurance Measures Are Commonly Employed?

Quality assurance is a critical aspect of the manufacturing process for perforated plastic sheets, ensuring that the products meet international standards and customer expectations.

Which International Standards Should Buyers Be Aware Of?

B2B buyers should familiarize themselves with relevant international standards, such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards ensures that manufacturers follow consistent processes, leading to high-quality products.

Illustrative image related to perforated plastic sheet material

In addition to ISO standards, industry-specific certifications may be necessary, such as CE marking for products sold in Europe, or API specifications for materials used in the oil and gas sector. These certifications assure buyers that the products meet safety and performance requirements.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral to maintaining product quality throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): At this stage, raw materials are inspected for compliance with specifications before they enter the production process.

- In-Process Quality Control (IPQC): During manufacturing, periodic inspections occur to ensure that the sheets are being produced according to design specifications.

- Final Quality Control (FQC): After production, finished products undergo thorough inspection and testing to confirm they meet all quality standards before shipping.

What Testing Methods Are Commonly Used?

Various testing methods are employed to evaluate the quality and performance of perforated plastic sheets. Common tests include:

- Mechanical Testing: Assessing tensile strength, impact resistance, and elasticity to ensure the material can withstand operational demands.

- Chemical Resistance Testing: Evaluating the material’s ability to resist degradation when exposed to various chemicals, which is crucial for applications in the chemical and food processing industries.

- Thermal Testing: Determining the material’s performance at elevated temperatures, particularly for applications that involve heat exposure.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential for ensuring product reliability. Here are some actionable strategies:

- Conduct Audits: Regular audits of suppliers can help verify their adherence to quality standards and manufacturing processes. This may include on-site visits or third-party audits.

- Request Documentation: Suppliers should provide documentation of their quality management systems, including certification copies, quality control reports, and testing results.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes and product quality before shipment.

What Are the Quality Control Nuances for International Buyers?

International buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, must navigate varying quality expectations and regulatory requirements. Understanding these nuances includes:

- Cultural Differences in Quality Expectations: Different regions may have unique expectations regarding product quality and performance. Buyers should communicate their specific requirements clearly.

- Regulatory Compliance: Each region may have different regulatory requirements affecting product specifications, such as safety standards and environmental regulations. Familiarity with local laws is vital for compliance.

- Logistics and Supply Chain Considerations: International shipping can introduce additional risks, such as damage during transit. Quality assurance measures should extend to the logistics phase, ensuring products arrive in optimal condition.

By understanding the manufacturing processes and quality assurance measures associated with perforated plastic sheet materials, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers who meet their specific needs and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘perforated plastic sheet material’

In the competitive landscape of B2B procurement, sourcing perforated plastic sheet materials requires a strategic approach to ensure quality, cost-effectiveness, and suitability for your specific applications. This guide offers a systematic checklist to help international buyers navigate the complexities of sourcing these versatile materials.

Illustrative image related to perforated plastic sheet material

Step 1: Define Your Technical Specifications

Begin by clearly outlining your technical requirements for the perforated plastic sheets. Consider factors such as size, thickness, hole pattern, and material type (e.g., polypropylene, PVC). This clarity will streamline your search and help suppliers provide accurate quotes and samples that meet your needs.

- Dimensions: Specify the required length, width, and thickness to avoid miscommunication.

- Perforation Patterns: Identify whether you need round, square, or custom-shaped perforations.

Step 2: Identify Your Application Needs

Understanding the specific applications for the perforated plastic sheets is crucial. Different industries, such as food processing, construction, and automotive, have varying requirements regarding durability, chemical resistance, and hygiene standards.

- Industry Requirements: Research industry-specific standards that may apply to your purchase.

- Performance Criteria: Determine if the sheets need to withstand high temperatures or exposure to chemicals.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers to ensure they can meet your specifications and quality standards. Request detailed company profiles, product catalogs, and references from other clients in similar industries.

- Certifications: Look for suppliers with ISO or industry-specific certifications to guarantee quality and compliance.

- Experience: Consider suppliers with a proven track record in your specific application area.

Step 4: Request Samples for Testing

Once you have narrowed down your list of suppliers, request samples of the perforated sheets you are interested in. Testing these samples will allow you to assess their quality, durability, and performance in real-world applications.

- Material Properties: Evaluate aspects like weight, flexibility, and resistance to wear and tear.

- Compatibility: Ensure the samples meet the performance criteria established in your application needs.

Step 5: Review Pricing and Payment Terms

Gather quotes from multiple suppliers to compare pricing structures and payment terms. Look beyond the initial cost; consider factors such as bulk discounts, shipping costs, and payment flexibility.

- Total Cost of Ownership: Assess long-term costs, including potential maintenance or replacement expenses.

- Negotiation: Don’t hesitate to negotiate terms to secure the best deal for your organization.

Step 6: Confirm Delivery and Lead Times

Before finalizing your order, confirm the lead times for production and delivery. Understanding the timeline is essential for planning your project and ensuring materials arrive when needed.

- Production Capacity: Inquire about the supplier’s ability to meet your deadlines, especially for large orders.

- Shipping Arrangements: Discuss logistics to avoid unexpected delays or additional costs.

Step 7: Establish a Quality Control Process

Implement a quality control process to ensure the perforated plastic sheets meet your standards upon delivery. This includes inspecting the materials and verifying compliance with your specifications.

- Inspection Criteria: Define what constitutes an acceptable product before it arrives.

- Feedback Loop: Establish a communication channel with the supplier for addressing any quality concerns post-delivery.

By following these steps, you can efficiently navigate the procurement of perforated plastic sheet materials, ensuring that your final choice aligns with your operational needs and business goals.

Comprehensive Cost and Pricing Analysis for perforated plastic sheet material Sourcing

What Are the Key Cost Components in Perforated Plastic Sheet Material Sourcing?

When sourcing perforated plastic sheets, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of plastic significantly affects the overall cost. Common materials include polypropylene, PVC, and various high-performance thermoplastics. Each has different pricing based on availability, quality, and specific attributes (e.g., UV resistance, temperature tolerance).

-

Labor: Labor costs vary by region and the complexity of manufacturing processes. Skilled labor is often required for precision cutting and perforating, particularly for custom designs.

-

Manufacturing Overhead: This encompasses the costs associated with the facility, utilities, and equipment maintenance. Higher efficiency in manufacturing processes can lead to lower overhead costs per unit.

-

Tooling: Custom tooling for perforation patterns can add significant upfront costs. However, for high-volume orders, these costs can be amortized over time, reducing the per-unit price.

-

Quality Control: Ensuring the perforated sheets meet industry standards and specifications incurs costs. Rigorous QC processes are essential, particularly for applications in sectors like food processing and healthcare.

-

Logistics: Shipping costs depend on the destination and volume of the order. International shipments require careful consideration of customs duties and potential tariffs, which can impact overall pricing.

-

Margin: Suppliers will apply a profit margin based on their operational costs and market conditions. This can vary widely depending on the supplier’s positioning and the competitive landscape.

How Do Price Influencers Impact the Cost of Perforated Plastic Sheets?

Several factors can influence the price of perforated plastic sheets, particularly for international buyers:

-

Volume/MOQ: Bulk orders often lead to lower prices per unit. Understanding the minimum order quantities (MOQ) can help buyers negotiate better terms.

-

Specifications and Customization: Custom perforation patterns and dimensions can increase costs. While tailored products can meet specific needs, they often come at a premium.

-

Material Selection: Higher-quality materials may incur additional costs but can provide better performance and longevity, thus affecting the Total Cost of Ownership (TCO).

-

Quality Certifications: Certifications for specific industries (e.g., FDA approval for food applications) can add to the cost but are critical for compliance and market acceptance.

-

Supplier Factors: The reputation, reliability, and geographical location of the supplier can influence pricing. Suppliers in regions with lower operational costs may offer more competitive pricing.

-

Incoterms: Understanding Incoterms is vital for international transactions. They dictate who is responsible for shipping, insurance, and tariffs, directly impacting the final cost.

What Buyer Tips Can Help Optimize Costs When Sourcing Perforated Plastic Sheets?

To ensure cost-efficiency and value in sourcing perforated plastic sheets, international buyers should consider the following strategies:

-

Negotiation: Leverage volume purchasing to negotiate better rates. Building long-term relationships with suppliers can also lead to favorable terms and discounts.

-

Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the product, including maintenance, durability, and potential replacements. A higher upfront cost may be justified by lower TCO.

-

Market Research: Conduct thorough market research to compare prices and suppliers. Understanding regional pricing dynamics can help identify the best value.

-

Quality vs. Cost: Prioritize quality to avoid future costs associated with product failures. Cheaper options may lead to higher expenses in the long run due to replacements or downtime.

-

Consider Local Suppliers: Sourcing from local suppliers can reduce logistics costs and lead times, improving overall efficiency.

Disclaimer for Indicative Prices

Prices for perforated plastic sheets can fluctuate based on market conditions, material availability, and supplier pricing strategies. Buyers should seek quotes from multiple suppliers to obtain accurate pricing tailored to their specific requirements.

Alternatives Analysis: Comparing perforated plastic sheet material With Other Solutions

When evaluating materials for specific applications, it is essential to consider alternatives that may provide similar functionality or performance characteristics. This analysis focuses on comparing perforated plastic sheet material with other viable solutions, such as perforated metal sheets and expanded metal mesh. Each option has unique advantages and drawbacks, making it crucial for B2B buyers to understand these differences to make informed purchasing decisions.

Illustrative image related to perforated plastic sheet material

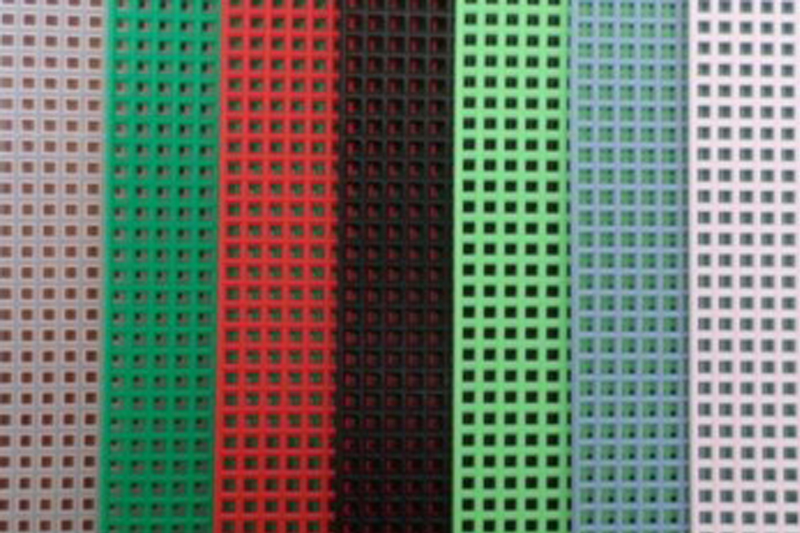

| Comparison Aspect | Perforated Plastic Sheet Material | Perforated Metal Sheets | Expanded Metal Mesh |

|---|---|---|---|

| Performance | Lightweight, corrosion-resistant, customizable perforation designs | High strength, durable, good airflow | Good strength-to-weight ratio, allows for light and air flow |

| Cost | Moderate initial cost, lower lifecycle cost due to durability | Higher initial cost, potential corrosion issues | Cost-effective, but may require additional treatment for corrosion |

| Ease of Implementation | Easy to cut and shape, suitable for various applications | Requires specialized tools for cutting and installation | Can be challenging to fabricate and install |

| Maintenance | Low maintenance, resistant to rot and UV degradation | Moderate maintenance due to potential rust | Moderate maintenance, may require protective coatings |

| Best Use Case | Ideal for applications requiring aesthetic appeal and sound insulation | Suitable for structural applications and environments needing strength | Effective for security applications and lightweight structures |

What Are the Advantages and Disadvantages of Perforated Metal Sheets?

Perforated metal sheets are often chosen for their robust strength and durability. They excel in environments that demand high structural integrity, such as construction and industrial applications. However, they come with a higher initial cost and can be prone to corrosion if not properly treated. Maintenance can also be a concern, as rust may develop over time, particularly in humid or corrosive environments. Thus, while they are ideal for strength-centric applications, ongoing maintenance costs should be factored into the decision-making process.

How Does Expanded Metal Mesh Compare in Terms of Functionality?

Expanded metal mesh is another alternative that provides a good balance of strength and weight. It offers excellent airflow and visibility, making it suitable for applications such as security fencing and ventilation systems. However, its fabrication can be more challenging compared to perforated plastic and metal sheets. Additionally, while it is generally cost-effective, it may require protective coatings to prevent corrosion, which can add to the overall expense. Its unique structure allows for effective light and air passage, making it a popular choice for certain architectural applications.

Conclusion: How to Choose the Right Solution for Your Needs?

When selecting a material for your project, it is vital to consider the specific requirements of your application. Perforated plastic sheets offer a lightweight, corrosion-resistant solution with low maintenance needs, making them ideal for aesthetic applications and environments requiring sound insulation. In contrast, perforated metal sheets and expanded metal mesh provide greater strength and durability, suitable for heavy-duty applications but often at a higher cost and maintenance burden. Assessing factors such as performance, cost, ease of implementation, and maintenance will guide B2B buyers in choosing the most appropriate solution for their specific needs.

Essential Technical Properties and Trade Terminology for perforated plastic sheet material

What Are the Key Technical Properties of Perforated Plastic Sheet Material?

Understanding the technical properties of perforated plastic sheet materials is essential for B2B buyers looking for durable, efficient solutions. Here are several critical specifications that should be considered:

-

Material Grade

Perforated plastic sheets are typically made from various thermoplastics, including polypropylene, PVC, and polyethylene. Each material has distinct properties that can affect performance, such as weight, corrosion resistance, and temperature tolerance. Selecting the right material grade ensures that the sheets meet specific application requirements, particularly in industries like food processing, chemical handling, and construction. -

Thickness

The thickness of perforated sheets can range from 2 mm to 8 mm. This specification is crucial as it influences the sheet’s strength, durability, and weight. Thicker sheets generally offer higher mechanical stability and wear resistance, making them suitable for heavy-duty applications. Buyers should assess the thickness required based on the operational demands of their projects. -

Perforation Patterns and Open Area

The design of perforations—whether round, square, or custom—along with the percentage of open area, plays a significant role in airflow, light transmission, and aesthetic appeal. Different industries may require specific perforation patterns to achieve desired functionalities, such as sound attenuation in architectural applications or fluid filtration in industrial uses. -

Temperature Resistance

Depending on the material, perforated plastic sheets can withstand operational temperatures up to 250 °C. This property is vital for applications that involve heat exposure, such as in autoclaves or chemical processing environments. Buyers should confirm the temperature limits of the materials to ensure long-term stability and performance. -

Corrosion Resistance

Many perforated plastics offer superior corrosion resistance compared to metals, making them ideal for use in harsh environments where chemical exposure is a concern. This property is particularly important in industries such as oil and gas, agriculture, and food processing, where longevity and safety are paramount. -

Surface Finish

The surface finish of perforated sheets can be smooth or grained, which affects both aesthetic appeal and functionality. A smooth surface can facilitate easy cleaning and maintenance, while a grained finish can enhance scratch resistance. Choosing the right surface finish can contribute to the overall performance and lifespan of the product.

What Are Common Trade Terms Related to Perforated Plastic Sheets?

Navigating the B2B landscape requires familiarity with specific trade terminology. Here are some essential terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is crucial for buyers looking to integrate perforated plastic sheets into larger systems or machinery. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest amount of product that a supplier is willing to sell. For perforated plastic sheets, knowing the MOQ can help buyers manage inventory costs and ensure they meet production requirements without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to solicit price proposals for specific products or services. This is particularly useful when sourcing perforated plastic sheets, as it allows buyers to compare costs, materials, and delivery timelines from various manufacturers. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers dealing with perforated plastic sheets, as they dictate aspects like shipping responsibilities, insurance, and risk. -

Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. This is a critical factor for businesses needing timely access to perforated sheets for ongoing projects or production schedules. -

Custom Fabrication

This term refers to the process of modifying standard products to meet specific customer requirements. For perforated plastic sheets, custom fabrication can include unique perforation patterns, dimensions, or colors tailored to specific applications, which can significantly enhance functionality and appeal.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that they select the right perforated plastic sheets for their needs while navigating the complexities of international procurement.

Navigating Market Dynamics and Sourcing Trends in the perforated plastic sheet material Sector

What Are the Key Trends Influencing the Perforated Plastic Sheet Material Market?

The perforated plastic sheet material market is witnessing a transformative phase driven by several global factors. Increasing demand for lightweight, corrosion-resistant materials across industries such as construction, food processing, and automotive is reshaping sourcing strategies. International buyers, particularly from Africa, South America, the Middle East, and Europe, are seeking versatile solutions that offer enhanced functionality and customization. Emerging technologies such as computer-assisted design and advanced perforation techniques allow for tailored products, catering to specific application needs.

In addition, the rise of e-commerce and digital procurement platforms is enabling B2B buyers to source these materials more efficiently and transparently. As industries strive for operational efficiency, the ability to order custom perforated sheets directly online is becoming a significant advantage. Moreover, sustainability concerns are prompting buyers to prioritize suppliers who can provide eco-friendly options. The shift towards incorporating recycled materials and minimizing waste in production processes is an emerging trend that aligns with global sustainability goals.

Illustrative image related to perforated plastic sheet material

How Is Sustainability Shaping the Sourcing of Perforated Plastic Sheets?

Sustainability is now a critical consideration for B2B buyers in the perforated plastic sheet material sector. The environmental impact of plastic production and waste has led to an increasing demand for ethically sourced materials. Buyers are encouraged to seek suppliers who offer ‘green’ certifications, which indicate compliance with environmental standards and commitment to sustainable practices.

For instance, materials such as recycled polypropylene and eco-friendly PVC alternatives are gaining traction among buyers looking to reduce their carbon footprint. Furthermore, suppliers that demonstrate transparency in their supply chain and adhere to ethical labor practices are becoming more attractive to international buyers. This focus on ethical sourcing not only helps mitigate environmental impact but also enhances brand reputation and customer loyalty. As the market evolves, integrating sustainability into sourcing strategies will be essential for long-term success.

What Is the Historical Context of Perforated Plastic Sheets in B2B Markets?

The evolution of perforated plastic sheets can be traced back to the early 20th century when advancements in plastic manufacturing began to revolutionize various industries. Initially used primarily for their lightweight and corrosion-resistant properties, these materials have expanded into diverse applications, from acoustical panels in construction to filtration systems in food processing.

Over the decades, technological advancements have facilitated the development of custom perforation patterns and improved material properties, allowing for increased versatility and performance. The introduction of high-performance thermoplastics has further enhanced their applicability across sectors, enabling solutions that withstand extreme conditions and comply with stringent safety standards. Today, the market continues to innovate, integrating advanced manufacturing techniques and sustainable practices to meet the evolving needs of B2B buyers globally.

By understanding these dynamics, international buyers can make informed decisions, ensuring they source the right perforated plastic sheet materials that align with their operational and sustainability objectives.

Illustrative image related to perforated plastic sheet material

Frequently Asked Questions (FAQs) for B2B Buyers of perforated plastic sheet material

-

1. How do I choose the right type of perforated plastic sheet for my application?

Selecting the appropriate perforated plastic sheet involves considering several factors, including the intended application, environmental conditions, and desired specifications. Assess the load-bearing capacity, chemical resistance, and required aesthetic finish. For instance, polypropylene offers lightweight, corrosion-resistant options ideal for outdoor applications, while PVC is suitable for more structural uses. Collaborating with suppliers who can provide samples and expert recommendations based on your unique needs is advisable to ensure optimal performance. -

2. What customization options are available for perforated plastic sheets?

Customization of perforated plastic sheets can include various hole sizes, shapes, and patterns, as well as specific dimensions to fit your project requirements. Suppliers often offer options for surface finishes, such as smooth or textured surfaces, and can produce sheets in a range of colors. Discuss your specific needs with manufacturers to explore combinations of perforation styles and open areas to achieve the desired functionality and aesthetic appeal for your application. -

3. What are the minimum order quantities (MOQs) for perforated plastic sheets?

Minimum order quantities for perforated plastic sheets can vary significantly by supplier and the complexity of customization. Standard sizes may have lower MOQs, while custom sizes and designs typically require larger orders. It’s essential to communicate your project requirements clearly to suppliers and inquire about their MOQs to find a balance between your budget and production needs. Some suppliers may offer flexibility for smaller orders, particularly for prototyping or initial projects. -

4. How can I ensure quality assurance (QA) when sourcing perforated plastic sheets?

To ensure quality assurance when sourcing perforated plastic sheets, it is crucial to vet suppliers based on their manufacturing processes and certifications. Request product samples to assess material properties and performance. Additionally, inquire about the supplier’s QA protocols, such as testing for mechanical strength, chemical resistance, and dimensional accuracy. Establishing a clear communication channel with your supplier regarding quality expectations and potential inspection processes can help mitigate risks. -

5. What payment terms should I expect when ordering perforated plastic sheets internationally?

Payment terms for international orders of perforated plastic sheets typically range from upfront payment to net 30 or net 60 terms, depending on the supplier’s policies and your negotiation leverage. Established suppliers may offer more favorable terms based on your purchasing history or order volume. Ensure clarity on currency, payment methods, and any applicable fees. Discussing payment terms early in the negotiation process can facilitate smoother transactions and foster a stronger business relationship. -

6. How do logistics and shipping impact my purchase of perforated plastic sheets?

Logistics and shipping play a critical role in the timely delivery of perforated plastic sheets. Factors such as shipping methods, lead times, and customs clearance processes should be considered when planning your order. Collaborate with suppliers who have experience in international shipping to navigate these complexities. Additionally, factor in potential tariffs and duties that may apply to your order, especially when importing to regions like Africa, South America, or the Middle East. -

7. What are the typical applications for perforated plastic sheets across different industries?

Perforated plastic sheets are versatile and find applications in numerous industries, including food processing, construction, automotive, and agriculture. Common uses include ventilation grilles, sound insulation, and decorative elements. Their lightweight nature and corrosion resistance make them suitable for outdoor applications and environments exposed to moisture or chemicals. Understanding the specific needs of your industry will help you select the right materials and designs for optimal performance. -

8. How can I verify the credibility of a supplier for perforated plastic sheets?

Verifying a supplier’s credibility involves researching their reputation, certifications, and customer feedback. Check for industry certifications that demonstrate compliance with quality standards. Request references from previous clients and assess their experience with the supplier. Additionally, consider visiting the supplier’s facility if feasible, or arrange for third-party audits. Establishing a relationship with a supplier who has a proven track record in your target market can significantly enhance your sourcing experience.

Top 8 Perforated Plastic Sheet Material Manufacturers & Suppliers List

1. McMaster – Perforated Plastic Sheets

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Perforated Plastic Sheets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Ametco – Perforated Plastic Solutions

Domain: ametco.com

Registered: 1996 (29 years)

Introduction: Perforated plastic is available in stock sheets or can be custom perforated. It comes in polypropylene (variety of colors) and PVC (dark grey, type 1 – class 1). It is lighter and more corrosive-resistant than perforated steel, suitable for various applications including acoustical wall and ceiling projects, railing systems, sun shades, and decorative design elements. The perforated patterns and o…

3. Roechling – Custom Perforated Plastic Sheets

Domain: roechling.com

Registered: 1998 (27 years)

Introduction: Perforated plastic sheets custom-tailored for various applications with different perforations, shapes, dimensions, and free surfaces. Form options include square sheets (length up to 4 m, width up to 2,500 mm, thickness 2-8 mm) and round sheets (diameters up to 2,500 mm, thickness 2-8 mm). Standard colors are grey and natural, with other colors available upon request. Surface options include both…

4. Professional Plastics – PVC Perforated Sheets

Domain: professionalplastics.com

Registered: 1997 (28 years)

Introduction: PVC Perforated Sheets are available in various sizes and thicknesses. They are lightweight, durable, and resistant to chemicals and moisture. Common applications include ventilation, filtration, and decorative purposes. The sheets can be easily fabricated and are suitable for both indoor and outdoor use.

5. US Plastic – Polypropylene Perforated Sheeting

Domain: usplastic.com

Registered: 1996 (29 years)

Introduction: Polypropylene Perforated Sheeting

– Material: Polypropylene

– Color: Natural

– Features: Rigid, fair impact resistance, very good abrasion resistance, not UV stabilized, excellent corrosion resistance to a wide range of items

– Forming temperature: 310°F to 325°F

– Temperature range: 40°F to 210°F

– FDA standards: Meets

– Cut tolerance: ±1/4″

– Hole tolerance: ±0.005″ (1/16″ thickness); 10% of hol…

6. McNICHOLS – PLASTIPERF™ Perforated Metal

Domain: mcnichols.com

Registered: 1996 (29 years)

Introduction: {“Item Number”:”1P18311648″,”Product Line”:”Perforated Metal”,”Hole Type”:”Round”,”Series Name”:”PLASTIPERF™”,”Series Number”:”1640″,”Primary Material”:”Plastic (PL)”,”Alloy, Grade or Type”:”Polypropylene (POLY)”,”Material Finish”:”Mill Finish”,”Gauge/Thickness”:”16 Gauge (.0598\” Thick)”,”Hole Pattern”:”1/8\” Round on 3/16\” Staggered Centers”,”Hole Size (Diameter)”:”1/8\””,”Hole Centers”:”3/16\”…

7. IQS Directory – Perforated Plastic Sheets

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Perforated plastic sheets are made from various thicknesses of plastic punctured with holes in different shapes and sizes. They exhibit heat, impact, and chemical resistance, are lightweight, and provide insulation for easy installation. Uses include regulating airflow, light distribution, visibility control, and noise reduction. Custom designs can be created using CAD technology. Manufacturing me…

8. Interstate Plastics – Custom Cut Plastic Solutions

Domain: interstateplastics.com

Registered: 1997 (28 years)

Introduction: This company, Interstate Plastics – Custom Cut Plastic Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for perforated plastic sheet material

The strategic sourcing of perforated plastic sheet materials presents a unique opportunity for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. By understanding the diverse applications and advantages of these materials—such as their lightweight nature, corrosion resistance, and customization options—buyers can make informed decisions that align with their project requirements.

Investing in high-quality perforated plastic sheets can lead to enhanced operational efficiency, reduced maintenance costs, and improved product longevity. The ability to customize perforation patterns and dimensions further allows businesses to tailor solutions for specific applications, from construction to food processing.

As markets evolve, the demand for sustainable and versatile materials will only grow. B2B buyers are encouraged to engage with suppliers who offer comprehensive guidance and support, ensuring that the selected materials not only meet current needs but also anticipate future trends.

Now is the time to explore strategic partnerships with leading manufacturers and distributors, tapping into their expertise to secure the best perforated plastic solutions for your business. Embrace the potential of perforated plastic materials and position your company for success in an increasingly competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.