A B2B Buyer’s Guide to Pawl Latch: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for pawl latch

In the rapidly evolving landscape of industrial hardware, sourcing reliable pawl latches can present a significant challenge for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe (including key markets like Saudi Arabia and Brazil) seek durable and efficient solutions for securing access panels and enclosures, understanding the nuances of pawl latch options becomes crucial. This guide delves deep into the world of pawl latches, offering insights into various types, applications across diverse industries, and key considerations for supplier vetting and cost analysis.

Navigating the complexities of the global market for pawl latches requires a comprehensive approach. Buyers will benefit from detailed discussions on the material specifications, installation requirements, and the specific advantages of fixed versus adjustable grip options. Additionally, this guide equips decision-makers with actionable strategies to assess quality, ensuring that their chosen products meet stringent international standards.

By arming B2B buyers with the knowledge needed to make informed purchasing decisions, this guide not only simplifies the sourcing process but also enhances operational efficiency. Whether you are involved in manufacturing, automotive, or HVAC industries, understanding pawl latches is essential for optimizing product design and functionality, ultimately leading to a more competitive edge in the marketplace.

Understanding pawl latch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fixed Grip Pawl Latch | Uses a rotating pawl, engages directly with door frame | Automotive, HVAC systems, electronic enclosures | Pros: Versatile, modular design; Cons: Limited adjustment for door thickness. |

| Adjustable Grip Pawl Latch | Features a long shaft for grip length adjustment | Marine, heavy-duty enclosures | Pros: Customizable to various door sizes; Cons: More complex installation. |

| Camloc Pawl Latch | Rotatable actuator with wire-form or solid arm pawls | Industrial panels, display cases | Pros: Easy installation; high clamping force; Cons: May require specific tools for adjustment. |

| Quarter-Turn Pawl Latch | Engages with a 90-degree rotation; compact design | Enclosures for electronics, transportation | Pros: Space-efficient; reliable operation; Cons: Limited grip range. |

| Multi-Point Pawl Latch | Engages at multiple points for enhanced security | Large doors, high-value equipment | Pros: Increased security; ideal for heavy use; Cons: Higher cost and complexity. |

What are the Characteristics of Fixed Grip Pawl Latches?

Fixed grip pawl latches are designed for straightforward applications, featuring a rotating pawl that engages the door frame directly. Commonly used in the automotive and HVAC industries, these latches offer a modular design that allows for compatibility with various offset cams. When purchasing, consider the specific dimensions of your door or panel, as fixed grip latches are not adjustable for thickness. Their reliability and ease of installation make them a popular choice for OEMs seeking cost-effective solutions.

How Do Adjustable Grip Pawl Latches Stand Out?

Adjustable grip pawl latches incorporate a long shaft that allows users to modify the grip length, making them suitable for a wider range of door sizes. These latches are particularly beneficial in marine and heavy-duty applications where door dimensions may vary. While they provide greater flexibility, buyers should be aware that their installation can be more complex due to the additional components. It’s essential to assess the specific requirements of your project to determine if the added versatility justifies the potential increase in installation time.

What are the Advantages of Camloc Pawl Latches?

Camloc pawl latches feature a rotatable actuator that connects to either wire-form or solid arm pawls, allowing for significant clamping force. They are often used in industrial panels and display cases due to their ease of installation and reliability. When considering a Camloc latch, buyers should evaluate the installation tools required and the specific application needs, as these latches excel in environments where quick access and secure closure are paramount. Their adaptability to varying grip ranges makes them a favored choice among product designers.

Why Choose Quarter-Turn Pawl Latches?

Quarter-turn pawl latches operate with a simple 90-degree rotation, making them an efficient choice for compact enclosures, particularly in electronic and transportation applications. Their space-efficient design is a significant advantage in environments where every inch counts. However, the limited grip range can be a drawback for some projects. Buyers should weigh the benefits of their compactness against the specific requirements of their applications to ensure compatibility and performance.

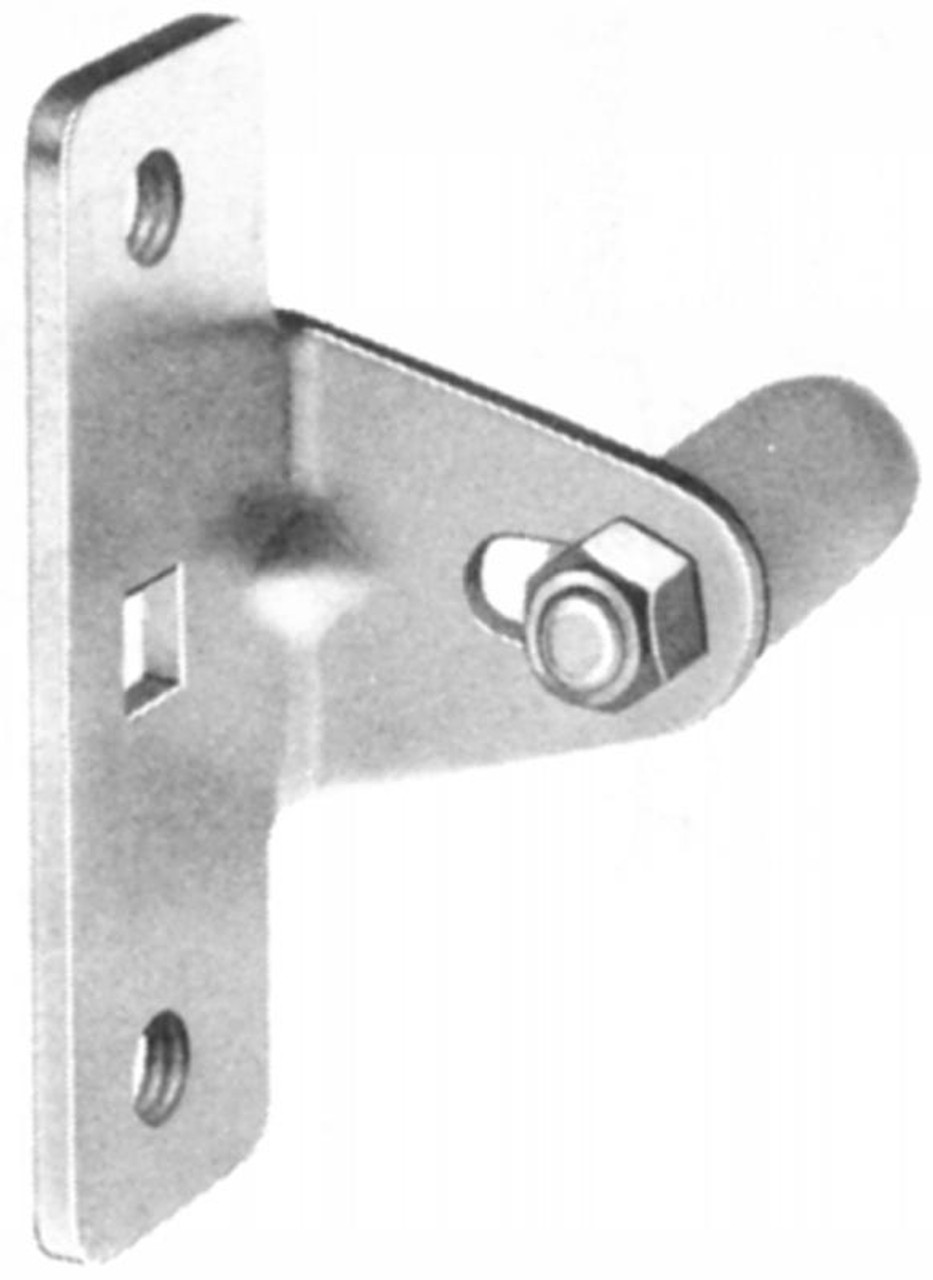

Illustrative image related to pawl latch

What Makes Multi-Point Pawl Latches Ideal for Security?

Multi-point pawl latches engage at multiple points along the door, providing enhanced security for large doors and high-value equipment. These latches are particularly effective in settings where security is a priority, such as in industrial and commercial applications. While they offer superior protection, the complexity and cost associated with multi-point systems can be higher than single-point options. Buyers should consider the balance between security needs and budget constraints when selecting this type of latch for their projects.

Key Industrial Applications of pawl latch

| Industry/Sector | Specific Application of pawl latch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Securing engine compartments and access panels | Enhances vehicle safety and accessibility | Durability in harsh environments, compliance with automotive standards |

| HVAC | Locking access doors on HVAC units | Facilitates maintenance while ensuring security | Compatibility with various door thicknesses and finishes |

| Electronics | Enclosures for electronic equipment | Protects sensitive components from tampering | ESD-safe options and customization for specific dimensions |

| Marine | Securing hatches and storage compartments | Ensures safety and prevents water ingress | Corrosion resistance and reliability in marine conditions |

| Industrial Equipment | Access panels for machinery and equipment | Streamlines maintenance and operational efficiency | Load-bearing capacity and ease of installation |

How Are Pawl Latches Used in the Automotive Industry?

In the automotive sector, pawl latches are commonly employed to secure engine compartments and access panels. These latches provide a reliable locking mechanism that enhances vehicle safety while allowing for easy access during maintenance. Buyers in this industry should prioritize latches that can withstand vibrations and extreme temperatures, ensuring durability and compliance with automotive standards. Sourcing pawl latches with robust materials, such as die-cast zinc or stainless steel, is essential for optimal performance.

What Role Do Pawl Latches Play in HVAC Applications?

In HVAC systems, pawl latches are utilized to lock access doors on various units, including furnaces and air conditioners. This application is critical for facilitating routine maintenance while ensuring that access points remain secure. HVAC manufacturers and service providers should consider the compatibility of pawl latches with different door thicknesses and finishes, as well as their ability to endure fluctuating temperatures and humidity levels. Selecting latches designed for easy installation can significantly reduce labor costs during assembly.

Why Are Pawl Latches Important in Electronics?

Pawl latches are essential for securing enclosures housing sensitive electronic equipment, protecting components from unauthorized access and environmental factors. In the electronics industry, buyers must focus on sourcing ESD-safe pawl latches to prevent damage from electrostatic discharge. Customization options are also crucial, as enclosures often require specific dimensions and features. Ensuring that the pawl latch provides a reliable grip while allowing for easy operation can enhance the overall design and functionality of electronic products.

How Do Pawl Latches Enhance Safety in Marine Applications?

In marine environments, pawl latches are used to secure hatches and storage compartments on boats and vessels. This application is vital for preventing water ingress and ensuring the safety of onboard equipment and personnel. Buyers in the marine industry should prioritize corrosion-resistant materials and reliable locking mechanisms that can withstand the harsh marine environment. Additionally, sourcing latches that are easy to operate, even in challenging conditions, can enhance user experience and safety.

What Benefits Do Pawl Latches Offer for Industrial Equipment?

Pawl latches are frequently used in industrial settings to secure access panels for machinery and equipment. This application streamlines maintenance processes, allowing technicians to quickly access components without compromising safety. When sourcing pawl latches for industrial applications, businesses should consider their load-bearing capacity and ease of installation. Selecting latches that can be adjusted to fit various door sizes and configurations can further enhance operational efficiency and reduce downtime during maintenance activities.

3 Common User Pain Points for ‘pawl latch’ & Their Solutions

Scenario 1: Difficulty in Ensuring Security and Accessibility in Large Vehicles

The Problem:

B2B buyers in the automotive and marine industries often face the challenge of balancing security and accessibility when designing large vehicles, such as buses or boats. They need a latch that can secure doors against unauthorized access while still allowing for quick and easy operation by authorized personnel. This is particularly important in high-traffic environments where doors are frequently opened and closed. A poor choice in latching mechanisms can lead to increased downtime and potential safety hazards.

The Solution:

To address this issue, buyers should consider pawl latches with adjustable grip and padlockable designs. These latches provide a reliable locking mechanism while allowing for easy access. When sourcing pawl latches, look for options that feature multi-point locking systems, which enhance security by distributing the locking force across multiple points of the door. Additionally, select latches that can be operated with different tools or hand grips to accommodate various user needs, ensuring that authorized personnel can quickly access the vehicle without compromising security. Consult manufacturers for customizable options that align with specific project requirements, ensuring both safety and accessibility are prioritized.

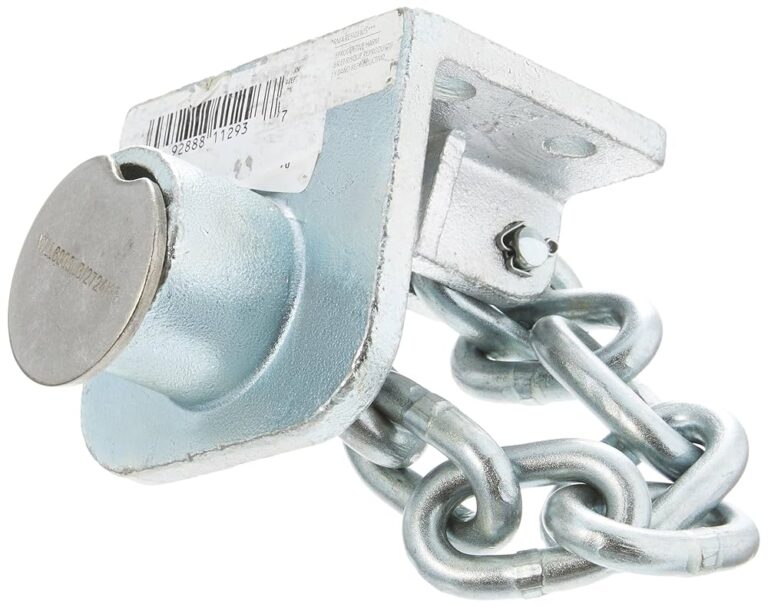

Illustrative image related to pawl latch

Scenario 2: Challenges with Varying Door Frame Thickness

The Problem:

In industries such as HVAC and electronic enclosures, buyers often encounter doors with varying thicknesses that require specific latching solutions. Using a one-size-fits-all approach can lead to inadequate sealing, resulting in potential energy loss or exposure to contaminants. Furthermore, improper fitment can lead to wear and tear on the latch mechanism, increasing maintenance costs and project delays.

The Solution:

To mitigate this pain point, it’s essential to specify pawl latches with adjustable grip lengths. These latches can adapt to different door frame dimensions, ensuring a snug fit that maintains the integrity of the enclosure. When selecting pawl latches, inquire about models that offer interchangeable cam options, which can be tailored to the thickness of the door. Additionally, conduct thorough measurements of the door and frame prior to purchase to ensure compatibility. This proactive approach not only enhances the durability of the latch but also reduces the frequency of replacements and maintenance.

Scenario 3: Quality Assurance in International Supply Chains

The Problem:

B2B buyers sourcing pawl latches from international suppliers may face concerns about quality control and compliance with local standards. Variability in manufacturing processes can lead to inconsistent product quality, resulting in latches that fail under operational stress. This inconsistency can jeopardize the safety of equipment and lead to costly recalls or repairs.

Illustrative image related to pawl latch

The Solution:

To ensure quality assurance, buyers should prioritize suppliers with ISO 9001 certification and a proven track record in the industry. When evaluating potential vendors, request documentation of their quality management practices and certifications to ensure compliance with international standards. It’s also beneficial to ask for product samples before placing large orders, allowing for a thorough inspection of the latch’s material and construction. Establishing a strong relationship with suppliers who understand the specific requirements of your industry can further enhance quality assurance, ensuring that the pawl latches you choose will perform reliably in your applications. Regularly reviewing supplier performance and product feedback can help maintain high standards throughout the supply chain.

Strategic Material Selection Guide for pawl latch

What Are the Key Materials for Pawl Latches in Industrial Applications?

When selecting pawl latches for industrial applications, the choice of material significantly impacts performance, durability, and cost. Here, we analyze four common materials used in the production of pawl latches: die-cast zinc, stainless steel, plastic, and neoprene foam. Each material has unique properties that cater to specific application requirements.

How Does Die-Cast Zinc Perform in Pawl Latch Applications?

Die-cast zinc is a popular choice for pawl latches due to its excellent strength-to-weight ratio and corrosion resistance. It can withstand moderate temperatures and pressures, making it suitable for various environments, including automotive and HVAC applications. The material is also relatively easy to manufacture, allowing for cost-effective production.

Pros:

– High durability and strength

– Cost-effective manufacturing process

– Good corrosion resistance

Cons:

– Limited high-temperature performance

– May not be suitable for highly corrosive environments

Impact on Application:

Die-cast zinc pawl latches are ideal for applications where moderate environmental conditions prevail. However, they may not be suitable for outdoor applications in coastal areas due to potential corrosion from saltwater.

Considerations for International Buyers:

Buyers in regions such as the Middle East and Africa should ensure compliance with local corrosion standards. Familiarity with ASTM and DIN standards can assist in selecting the right grade of die-cast zinc for specific applications.

What Advantages Does Stainless Steel Offer for Pawl Latches?

Stainless steel is renowned for its exceptional corrosion resistance and strength, making it an ideal material for pawl latches used in harsh environments. It can handle high temperatures and is suitable for applications in marine, food processing, and chemical industries.

Pros:

– Outstanding corrosion resistance

– High-temperature and pressure tolerance

– Long lifespan in demanding environments

Illustrative image related to pawl latch

Cons:

– Higher manufacturing costs compared to other materials

– More complex machining processes

Impact on Application:

Stainless steel pawl latches are perfect for applications requiring durability and reliability in extreme conditions, such as marine environments or chemical processing plants.

Considerations for International Buyers:

International buyers should verify compliance with local and international standards, such as JIS for Japan and EN for Europe, to ensure the selected stainless steel grade meets specific application requirements.

How Do Plastic Pawl Latches Compare in Terms of Cost and Performance?

Plastic pawl latches are lightweight and cost-effective, making them suitable for applications where weight is a concern, such as in electronic enclosures and lightweight vehicles. They offer decent resistance to corrosion and are available in various colors and finishes.

Illustrative image related to pawl latch

Pros:

– Low manufacturing costs

– Lightweight and easy to install

– Good for non-heavy-duty applications

Cons:

– Limited temperature and pressure resistance

– Less durable than metal options

Impact on Application:

Plastic pawl latches are best suited for applications that do not require heavy-duty performance, such as securing access panels in electronic devices.

Considerations for International Buyers:

Buyers should consider the specific environmental conditions of their regions. For example, high UV exposure in South America may affect the longevity of plastic latches, necessitating UV-resistant materials.

What Role Does Neoprene Foam Play in Pawl Latch Applications?

Neoprene foam is often used as a sealing material in conjunction with pawl latches, providing additional protection against moisture and dust. While not a primary material for the latch itself, it enhances the latch’s performance by ensuring a tight seal.

Pros:

– Excellent sealing properties

– Resistant to moisture and dust

– Flexible and easy to apply

Cons:

– Limited structural strength

– Not suitable as a standalone latch material

Impact on Application:

Neoprene foam is ideal for applications requiring additional sealing, such as in HVAC systems or outdoor enclosures.

Considerations for International Buyers:

International buyers should ensure that the neoprene foam meets local standards for environmental resistance, especially in humid or coastal regions.

Summary Table of Material Selection for Pawl Latches

| Material | Typical Use Case for pawl latch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Die-Cast Zinc | Automotive, HVAC | High durability and strength | Limited high-temperature performance | Medium |

| Stainless Steel | Marine, food processing, chemical | Outstanding corrosion resistance | Higher manufacturing costs | High |

| Plastic | Electronic enclosures, lightweight vehicles | Low manufacturing costs | Limited durability | Low |

| Neoprene Foam | HVAC systems, outdoor enclosures | Excellent sealing properties | Limited structural strength | Low |

This guide provides valuable insights for international B2B buyers in selecting the appropriate material for pawl latches, ensuring optimal performance and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for pawl latch

What Are the Main Stages of Manufacturing Pawl Latches?

The manufacturing of pawl latches involves several key stages, each critical to ensuring that the final product meets the required specifications for quality and performance. The typical stages include material preparation, forming, assembly, and finishing.

Illustrative image related to pawl latch

How Is Material Prepared for Pawl Latch Production?

The first step in the manufacturing process is material preparation, where raw materials such as die-cast zinc, steel, stainless steel, or plastic are sourced. Quality sourcing is essential, as the durability and performance of the pawl latch depend on the material used. Suppliers must ensure that materials meet industry standards and specifications, which may include certifications for corrosion resistance or tensile strength. For instance, stainless steel may require a passivated finish to enhance its corrosion resistance, particularly for applications in marine or outdoor environments.

What Forming Techniques Are Used in Pawl Latch Manufacturing?

Once the materials are prepared, the next stage is forming. This typically involves techniques such as die-casting, machining, or stamping. Die-casting is particularly common for pawl latches made from zinc, as it allows for precise shapes and dimensions. For steel or stainless steel components, processes like stamping and machining are often employed to achieve the necessary tolerances. The forming stage is crucial because any inaccuracies can affect the latch’s functionality, such as its ability to properly engage and disengage from the door frame.

How Are Pawl Latches Assembled?

The assembly process for pawl latches generally involves integrating various components, including the pawl, cam, handle, and housing. This stage may require manual assembly or the use of automated systems, depending on the volume of production. Key considerations during assembly include ensuring that moving parts are correctly aligned and that any necessary adjustments for grip length are properly set. Adjustable grip pawl latches may require additional steps to configure the mechanism that allows for variation in grip length.

What Finishing Processes Are Essential for Pawl Latches?

Finishing is the final stage in the manufacturing process and plays a vital role in both aesthetics and functionality. This may involve processes such as plating, painting, or applying protective coatings. For example, pawl latches may be zinc-plated for added shine and corrosion resistance, while others may receive a powder-coated finish for durability. The choice of finish often depends on the intended application and the environmental conditions the latch will face, such as exposure to moisture or chemicals.

What International Standards Guide Quality Assurance for Pawl Latches?

Quality assurance (QA) is critical in the manufacturing of pawl latches, particularly for B2B buyers who require reliability and safety. International standards such as ISO 9001 are widely recognized and ensure that manufacturers adhere to rigorous quality management practices. Compliance with ISO 9001 indicates that the manufacturer has established processes for continuous improvement and customer satisfaction.

In addition to ISO standards, industry-specific certifications may be necessary. For example, pawl latches used in automotive applications may require compliance with Automotive Product Quality (APQ) standards, while those intended for electronic enclosures may need to meet Underwriters Laboratories (UL) requirements. Buyers should inquire about these certifications to verify the suitability of pawl latches for their specific applications.

What Quality Control Checkpoints Are Common in Pawl Latch Manufacturing?

Quality control (QC) checkpoints are integral to ensuring that pawl latches meet the required specifications throughout the manufacturing process. Key checkpoints typically include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet the necessary specifications and standards.

- In-Process Quality Control (IPQC): During manufacturing, periodic checks are performed at various stages to monitor the quality of the production process. This may include dimensional checks or functional tests of components.

- Final Quality Control (FQC): Once assembly is complete, a thorough inspection is conducted to verify that the finished pawl latches meet all specifications and quality standards before they are packaged for shipment.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

B2B buyers can take several steps to verify the quality assurance practices of suppliers. One effective method is to conduct audits of the manufacturing facilities. These audits allow buyers to assess the implementation of quality management systems, the cleanliness of the production environment, and the adherence to safety standards.

Additionally, requesting QC reports can provide insights into the testing methods employed by the manufacturer. Common testing methods for pawl latches include tensile strength tests, corrosion resistance tests, and functional tests to ensure proper operation. Buyers should also consider third-party inspections, which can offer an unbiased assessment of the manufacturer’s quality assurance practices.

What QC and Certification Nuances Should International Buyers Consider?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding local and international compliance standards is crucial. Variations in regulatory requirements can affect the acceptance of pawl latches in different markets. For instance, products sold in the European Union may need CE marking, indicating compliance with health, safety, and environmental protection standards.

Furthermore, buyers should be aware of any specific regional certifications that may be necessary for their applications. In some cases, additional testing may be required to meet local standards. Engaging with suppliers who are familiar with these nuances can help streamline the procurement process and ensure compliance with all applicable regulations.

In conclusion, understanding the manufacturing processes and quality assurance measures for pawl latches is essential for B2B buyers. By focusing on materials, techniques, and certifications, buyers can make informed decisions that enhance their projects’ reliability and performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pawl latch’

To ensure a successful procurement process for pawl latches, it’s essential to follow a structured approach. This guide provides a practical checklist that will help B2B buyers navigate through the various considerations involved in sourcing pawl latches effectively.

Step 1: Define Your Technical Specifications

Establish clear technical specifications for the pawl latches you require. Consider factors such as the type (fixed or adjustable grip), materials (e.g., zinc, stainless steel, or plastic), and specific dimensions necessary for your application. Having precise specifications helps streamline the selection process and ensures compatibility with your equipment.

Step 2: Identify Application Requirements

Understand the specific applications where the pawl latches will be utilized. Different industries may have unique demands; for instance, automotive applications might require heavy-duty options, while electronics may prioritize a lighter design. Knowing the environment—be it harsh outdoor conditions or controlled indoor settings—will guide your material and design choices.

Step 3: Evaluate Potential Suppliers

Before committing, conduct thorough evaluations of potential suppliers. Request detailed company profiles, product catalogs, and case studies that demonstrate their experience in your industry. Look for references from other buyers, especially those in similar markets like Africa, South America, or the Middle East, to gauge reliability and quality.

Step 4: Verify Supplier Certifications

Ensure that the suppliers you are considering have the necessary certifications, such as ISO 9001 or UL listings. These certifications indicate adherence to quality management standards and safety regulations. A certified supplier is more likely to provide consistent quality and compliance with international standards, which is crucial for minimizing risks in your supply chain.

Step 5: Assess Customization Options

Inquire about customization capabilities if your project requires specific features or finishes for the pawl latches. Many suppliers offer options for tailored designs to fit unique applications or aesthetic requirements. Understanding these options can enhance the functionality and visual appeal of your final product.

Step 6: Request Samples for Testing

Before placing a bulk order, always request samples to evaluate the quality and performance of the pawl latches. Conduct tests to ensure they meet your specifications and perform well under operational conditions. This step can prevent costly mistakes and ensure that the latches will serve their intended purpose effectively.

Step 7: Review Terms of Sale and Return Policies

Finally, closely examine the terms of sale, including pricing, payment terms, and shipping conditions. Additionally, understand the return policy in case the products do not meet your expectations. Clear terms can protect your investment and simplify the procurement process, ensuring a smoother transaction.

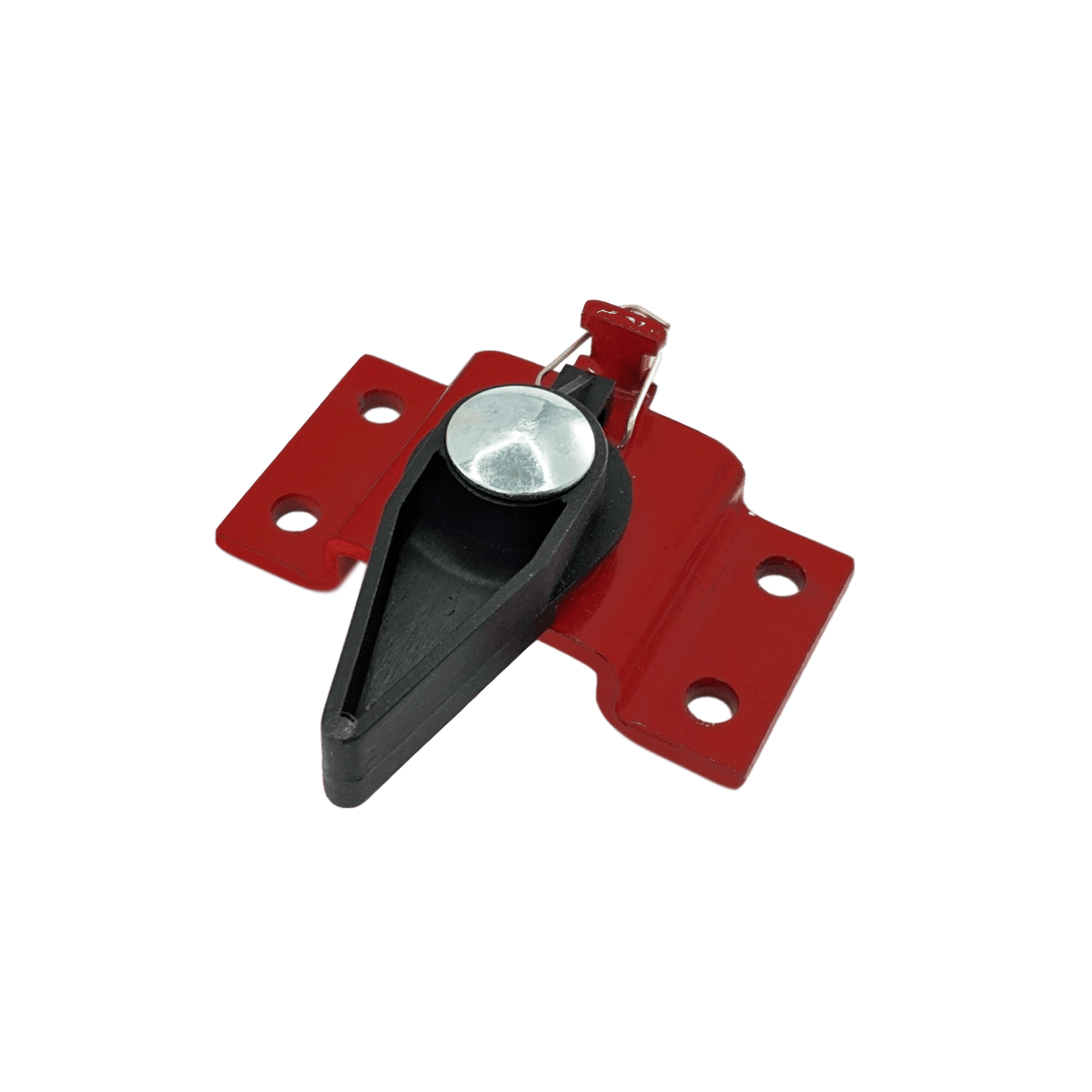

Illustrative image related to pawl latch

By following this checklist, you can streamline your sourcing process for pawl latches and make informed decisions that align with your business needs.

Comprehensive Cost and Pricing Analysis for pawl latch Sourcing

What Are the Key Cost Components in Pawl Latch Sourcing?

When sourcing pawl latches, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of material significantly impacts the cost. Pawl latches are commonly made from die-cast zinc, stainless steel, or plastic. While zinc latches are cost-effective, stainless steel options offer greater durability and corrosion resistance, justifying a higher price.

-

Labor: Manufacturing labor costs vary by region. In countries with higher labor costs, such as those in Europe, the overall price of pawl latches may reflect these expenses. Conversely, sourcing from regions with lower labor costs can result in savings.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can reduce overhead, allowing suppliers to offer more competitive pricing.

-

Tooling: Custom tooling for specific designs can add to the initial costs. If a buyer requires unique specifications, investing in customized tooling may be necessary, leading to higher upfront costs but potentially lower long-term expenses.

-

Quality Control (QC): Ensuring that pawl latches meet industry standards involves rigorous quality control measures. Suppliers that invest in comprehensive QC processes might charge more, but this often results in better reliability and performance.

-

Logistics: Shipping costs can vary widely based on the supplier’s location, the volume of the order, and the chosen shipping method. International buyers should factor in customs duties and taxes, which can significantly affect the total cost.

-

Margin: Suppliers will add a profit margin to cover their costs and ensure sustainability. This margin can vary based on competition, market demand, and the supplier’s positioning.

How Do Price Influencers Affect Pawl Latch Sourcing?

Several factors can influence the pricing of pawl latches:

-

Volume/MOQ: Larger orders typically qualify for lower unit prices due to economies of scale. Buyers should consider negotiating minimum order quantities (MOQs) to maximize cost efficiency.

-

Specifications and Customization: Custom designs or specific performance requirements can lead to increased costs. Buyers should clearly define their needs to avoid unnecessary expenses.

-

Materials and Quality Certifications: Higher quality materials and certifications (like ISO 9001) often come at a premium. However, these can provide long-term benefits, reducing maintenance costs and increasing product lifespan.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with a history of quality may command higher prices, but they also reduce risk for buyers.

-

Incoterms: Understanding Incoterms is crucial for international transactions. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, directly impacting the total cost.

What Are the Best Practices for Negotiating Pawl Latch Prices?

International B2B buyers should employ several strategies to enhance cost-effectiveness:

-

Negotiate Terms: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Flexibility can lead to better deals.

-

Assess Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the TCO, which includes maintenance, operational costs, and potential downtime. Higher-quality pawl latches may have a higher upfront cost but save money over time.

-

Understand Pricing Nuances: Be aware of regional pricing differences. For instance, suppliers in South America might offer more competitive rates than those in Europe due to lower operational costs.

-

Leverage Relationships: Building long-term relationships with suppliers can lead to favorable pricing and terms. Regular communication and trust can result in better deals and priority service.

Conclusion

Navigating the cost and pricing landscape for pawl latches requires a comprehensive understanding of various influencing factors. By focusing on cost components, price influencers, and negotiation strategies, international buyers can optimize their purchasing decisions, ensuring they receive quality products at competitive prices. Always remember that pricing can fluctuate based on market conditions, so staying informed is key.

Alternatives Analysis: Comparing pawl latch With Other Solutions

Introduction

In the realm of industrial hardware, selecting the right latch is critical for ensuring security, functionality, and cost-effectiveness. While pawl latches are popular for their reliability and ease of use, it is essential to explore alternative solutions that may meet specific project requirements. This section compares pawl latches with two viable alternatives: compression latches and slam latches. Each option presents distinct advantages and challenges, making them suitable for different applications.

| Comparison Aspect | Pawl Latch | Compression Latch | Slam Latch |

|---|---|---|---|

| Performance | Reliable for moderate loads | High compression for secure sealing | Quick, single-action closure |

| Cost | Generally low-cost | Moderate pricing | Cost-effective for high volume |

| Ease of Implementation | Simple installation | Moderate complexity | Easy installation |

| Maintenance | Low maintenance needs | Moderate maintenance | Low maintenance |

| Best Use Case | Electronic enclosures, vehicles | Enclosures requiring sealing | High-traffic areas, quick access |

Detailed Breakdown of Alternatives

What are Compression Latches and Their Advantages?

Compression latches are designed to create a tight seal between two surfaces, making them ideal for applications where moisture or dust ingress is a concern. They provide a higher clamping force than pawl latches, which is essential for environments requiring robust sealing, such as HVAC systems or outdoor enclosures. However, they may require more effort to install and adjust, especially in applications with varying panel thicknesses. Their cost is typically moderate, making them a viable option when high security and sealing are prioritized.

How Do Slam Latches Compare in Terms of Functionality?

Slam latches are engineered for quick, one-handed operation, allowing doors or panels to be closed and latched in a single motion. This feature is particularly advantageous in high-traffic environments, such as service vehicles or industrial facilities, where speed is essential. Slam latches are generally low-cost and easy to install, similar to pawl latches. However, their reliance on gravity for closure can lead to less secure locking in comparison to pawl or compression latches, making them less suitable for applications requiring high security.

Conclusion

When evaluating latching solutions, B2B buyers must consider the specific requirements of their applications. Pawl latches provide a reliable and cost-effective solution for various uses, particularly in vehicle and electronic enclosure applications. Compression latches are preferable for projects demanding a strong seal against environmental factors, while slam latches excel in scenarios where quick access is paramount. Ultimately, assessing performance, cost, ease of implementation, maintenance needs, and the best use case will guide buyers in selecting the most suitable latch for their industrial needs.

Essential Technical Properties and Trade Terminology for pawl latch

What Are the Essential Technical Properties of Pawl Latches?

When selecting pawl latches for industrial applications, understanding key technical specifications is crucial for ensuring optimal performance and compatibility with your specific requirements. Here are some critical properties to consider:

Illustrative image related to pawl latch

1. Material Composition

Pawl latches are typically constructed from materials such as die-cast zinc, stainless steel, or plastic. The choice of material affects durability, corrosion resistance, and overall performance. For example, stainless steel is ideal for outdoor applications where exposure to moisture is a concern, while zinc offers a cost-effective solution for less demanding environments.

2. Grip Type: Fixed vs. Adjustable

Fixed grip pawl latches are designed for standard applications, providing a reliable engagement with minimal adjustment. In contrast, adjustable grip pawl latches offer flexibility in accommodating various door thicknesses, making them suitable for diverse applications. This adaptability is particularly beneficial for international buyers who may encounter varying standards across regions.

3. Cam Configuration

The cam mechanism is essential for the latch’s operation. Pawl latches can feature single or multi-point cams, which determine how the latch secures the door. Multi-point cams provide enhanced security by engaging multiple points along the door frame, making them ideal for high-security environments such as electronic enclosures or automotive applications.

4. Finish and Coating

The finish applied to pawl latches, such as zinc plating or passivation, plays a significant role in aesthetics and corrosion resistance. A passivated finish on stainless steel latches can enhance longevity in harsh environments, which is essential for applications in industries like marine or HVAC systems.

5. Operating Mechanism

Pawl latches can be operated using various tools, including keys, screwdrivers, or specialized handles. Understanding the operating mechanism is vital for ensuring ease of use in your application. For instance, a latch that requires a unique tool may not be suitable for environments where quick access is necessary.

6. Weight and Dimensions

The weight and size of the pawl latch should be considered to ensure compatibility with your application. Heavier latches may be more durable but could also add unnecessary weight to portable equipment. Additionally, precise dimensions are critical for ensuring a proper fit within your design specifications.

What Are Common Trade Terms Related to Pawl Latches?

Navigating the procurement process for pawl latches involves familiarizing yourself with industry terminology. Here are several key terms that every B2B buyer should know:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are sold under another company’s brand. Understanding OEM specifications is crucial for ensuring that the pawl latches you procure will meet the quality and compatibility standards of your existing equipment.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps in budgeting and planning your inventory, especially for international transactions where shipping costs can significantly impact overall expenses.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing information for specific products. When dealing with pawl latches, issuing an RFQ ensures that you receive competitive pricing and terms tailored to your needs.

4. Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in shipping agreements. Familiarity with Incoterms is essential for international buyers to understand who bears the risk and cost at various stages of the shipping process.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is critical for project planning, especially in industries with tight deadlines.

6. Certification Standards

Various certification standards, such as ISO or UL listings, indicate that products meet specific quality and safety benchmarks. For international buyers, ensuring that pawl latches comply with relevant certification standards can be vital for regulatory compliance and operational safety.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing pawl latches, ensuring that they select the right products for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the pawl latch Sector

What Are the Current Market Dynamics and Key Trends Influencing the Pawl Latch Sector?

The global pawl latch market is witnessing significant growth driven by the rising demand for durable and secure fastening solutions across various industries, including automotive, electronics, HVAC, and marine applications. In regions such as Africa, South America, the Middle East, and Europe, increasing industrialization and infrastructure development are critical drivers of this demand. Moreover, the shift towards modular and customizable hardware solutions is gaining traction, as manufacturers seek to enhance product design and functionality while reducing costs.

Emerging technologies, such as the integration of smart features and automation in industrial applications, are influencing sourcing trends. International B2B buyers are increasingly looking for pawl latches that can accommodate electronic locking mechanisms or provide better user interaction. Additionally, e-procurement platforms are becoming more prevalent, enabling buyers to streamline their sourcing processes and access a broader range of suppliers. This digital transformation is particularly beneficial for businesses in emerging markets, where access to high-quality components may have been historically limited.

Furthermore, the ongoing emphasis on quality and compliance with international standards is shaping market dynamics. Buyers are increasingly scrutinizing supplier certifications, such as ISO 9001 and UL listings, to ensure they source reliable and safe products. This trend highlights the importance of partnering with manufacturers that prioritize quality assurance and rigorous testing.

How Is Sustainability and Ethical Sourcing Impacting Pawl Latch Procurement?

The environmental impact of manufacturing processes and materials is becoming a focal point for international B2B buyers. As companies strive to enhance their sustainability practices, there is a growing demand for pawl latches made from eco-friendly materials and those produced through sustainable methods. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to reducing their carbon footprint and minimizing waste.

Ethical sourcing is also gaining importance, particularly in regions where supply chain transparency is a concern. B2B buyers are seeking manufacturers who can provide clear information about their sourcing practices, labor conditions, and environmental policies. Certifications such as ISO 14001 for environmental management and adherence to global standards for labor rights are essential factors in the decision-making process.

Incorporating ‘green’ materials, such as recycled metals or biodegradable plastics in the production of pawl latches, is not only beneficial for the environment but can also enhance a company’s brand reputation. As consumers and businesses alike become more environmentally conscious, suppliers that can offer sustainable products are likely to gain a competitive edge in the market.

What Is the Historical Context of Pawl Latch Development Relevant to B2B Buyers?

The development of pawl latches can be traced back to the need for secure yet accessible locking mechanisms in various applications. Initially used in mechanical devices, the design evolved to cater to the growing demands of the automotive and industrial sectors. The introduction of materials like die-cast zinc and stainless steel significantly improved the durability and reliability of these latches, making them suitable for harsher environments.

Over the years, pawl latches have adapted to changing market needs, incorporating features such as adjustable grips and multi-point locking systems to enhance security and usability. This evolution is particularly relevant for B2B buyers who require versatile solutions that can accommodate various door sizes and applications. As technology advances, the integration of electronic components into traditional latch designs is expected to continue, further transforming how these essential hardware components are utilized across industries.

Frequently Asked Questions (FAQs) for B2B Buyers of pawl latch

-

How do I ensure the quality of pawl latches from suppliers?

To ensure the quality of pawl latches, verify that suppliers adhere to international quality standards, such as ISO 9001 certification. Request samples to assess material durability and functionality. Additionally, inquire about their testing procedures and certifications for specific applications, particularly if they cater to industries like automotive or electronics. Establishing a clear communication line with the supplier can help address quality concerns before placing larger orders. -

What is the best material for pawl latches in industrial applications?

The best material for pawl latches largely depends on the specific application. For heavy-duty industrial use, stainless steel or die-cast zinc are ideal due to their strength and corrosion resistance. For lighter applications, plastic or neoprene may suffice. Consider environmental factors such as exposure to moisture or chemicals when selecting the material to ensure longevity and performance. -

Can I customize pawl latches to fit my specific needs?

Yes, many manufacturers offer customization options for pawl latches. You can request modifications in dimensions, materials, finishes, or even functionality, such as adding adjustable grips or specific locking mechanisms. Ensure you discuss your specific requirements with potential suppliers and ask for examples of past custom projects to gauge their capabilities. -

What are the typical minimum order quantities (MOQs) for pawl latches?

Minimum order quantities for pawl latches vary by supplier and can range from a few dozen to several hundred units. Factors influencing MOQs include the complexity of the latch design, customization requirements, and production capabilities. It’s advisable to inquire directly with suppliers about their MOQs and discuss potential flexibility, especially for first-time orders or trial runs. -

What payment terms should I expect when sourcing pawl latches internationally?

Payment terms for international transactions typically include options such as advance payment, letters of credit, or net terms (e.g., 30, 60, or 90 days). It’s crucial to negotiate terms that are mutually beneficial and ensure secure transactions. Additionally, clarify any fees associated with currency conversion or international banking to avoid unexpected costs. -

How can I vet suppliers for pawl latches in international markets?

To vet suppliers, start by researching their reputation through industry reviews and testimonials. Request references from previous clients, particularly those in your region. It’s also prudent to verify their certifications and compliance with international standards. Conducting a site visit or using third-party inspection services can further ensure that the supplier meets your quality and operational expectations. -

What logistics considerations should I keep in mind when importing pawl latches?

When importing pawl latches, consider shipping methods, lead times, and customs regulations specific to your country. Evaluate whether air or sea freight aligns best with your timeline and budget. Additionally, ensure that you understand duties and taxes applicable upon import, as these can impact overall costs. Working with a logistics provider experienced in international trade can streamline the process. -

What are common applications for pawl latches in different industries?

Pawl latches are versatile and used across various industries, including automotive, electronics, marine, and HVAC. In automotive applications, they secure access panels, while in electronics, they protect enclosures. Their robust design makes them suitable for marine environments, and in HVAC systems, they provide reliable access to components. Understanding your industry’s specific needs can guide you in selecting the appropriate pawl latch.

Top 7 Pawl Latch Manufacturers & Suppliers List

1. McMaster – Pawl Latches

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Pawl Latches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Sierra Pacific Engineering – Industrial Pawl Latches

Domain: spep.com

Registered: 1997 (28 years)

Introduction: Industrial Pawl Latches from Sierra Pacific Engineering and Products (SPEP) are designed for Original Equipment Manufacturers (OEM), product designers, and engineers. They are a type of quarter-turn latch that uses a rotating cam (pawl) to engage and disengage a keeper or door frame, providing compression between the door and frame. Common applications include large vehicles (buses, trucks/trailer…

3. Item24 – Ergonomic Door Knob

Domain: item24.com

Registered: 2005 (20 years)

Introduction: This company, Item24 – Ergonomic Door Knob, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

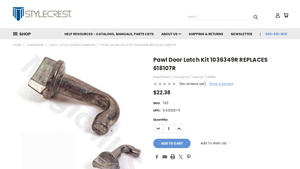

4. MH Parts – Pawl Door Latch Kit 1036349R

Domain: mhparts.net

Registered: 2020 (5 years)

Introduction: Pawl Door Latch Kit 1036349R, replaces 618107R, replaces 606275R & 632330, zinc construction, OEM part for Nordyne, Intertherm or Revolv furnaces, kit includes one latch, fits Miller and Intertherm M1, M3, and M7 series furnaces with a center twist lock, MSRP: $22.38, SKU: 793, UPC: 6.63132E+11.

5. MSC Direct – Dzus Pawl Latch

Domain: mscdirect.com

Registered: 1996 (29 years)

Introduction: Dzus Pawl Latch, used for securing panels and covers, available in various sizes and materials, designed for quick release and easy installation, commonly used in aerospace and automotive applications.

6. Jet-Tek – Pawl Latches H-43

Domain: jet-tek.com

Registered: 2006 (19 years)

Introduction: Pawl Latches H-43 are designed to secure hinged panels with a rotatable actuator connected to a radially projecting pawl. The shaft is mounted through the panel, engaging the frame member. Two pawl styles are available: wire-form (pre-set for desired clamping force) and solid arm type (continuously adjustable). They are easy to install, accommodate a large grip range, and provide a reliable, low i…

7. Nordyne – Miller 618107R Door Latch Pawl

Domain: keithspecialty.com

Registered: 1999 (26 years)

Introduction: {“name”: “Nordyne Miller 618107R door latch pawl”, “price”: “$18.78”, “replaces”: [“606317”, “606317R”, “618107”, “606275”, “606275R”, “632330”, “632330R”], “SKU”: “NR-205”}

Strategic Sourcing Conclusion and Outlook for pawl latch

In the competitive landscape of industrial hardware, pawl latches stand out as a versatile and cost-effective solution for a myriad of applications, from automotive to HVAC systems. By strategically sourcing these components, B2B buyers can not only enhance product reliability but also optimize their supply chain efficiency. The diversity in design—ranging from fixed to adjustable grip options—allows for tailored solutions that meet specific operational requirements, ensuring that businesses maintain the highest standards of quality and functionality.

Moreover, the importance of selecting pawl latches made from durable materials, such as stainless steel or die-cast zinc, cannot be overstated. These choices enhance longevity and performance, crucial for applications subjected to rigorous conditions. As industries evolve, so too does the need for innovative latch solutions that can adapt to changing demands.

Illustrative image related to pawl latch

Looking ahead, international buyers from regions such as Africa, South America, the Middle East, and Europe are encouraged to explore the extensive range of pawl latch offerings. Engaging with suppliers that prioritize quality and customization will pave the way for improved operational efficiencies and product excellence. Take the next step in your sourcing strategy—invest in pawl latches that will secure your projects for years to come.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.