A B2B Buyer’s Guide to Parts Of Exchanger: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for parts of exchanger

In the dynamic landscape of international trade, sourcing reliable parts for heat exchangers presents a significant challenge for B2B buyers, especially those operating across diverse regions such as Africa, South America, the Middle East, and Europe, including countries like Vietnam and Germany. The complexity of navigating various supplier networks, understanding the specifications of different types of exchangers, and managing costs can lead to costly errors and inefficiencies. This guide on parts of exchangers aims to demystify the procurement process by providing a comprehensive overview of key components, their applications, and the standards that govern their use.

From shell and tube configurations to advanced designs tailored for specific industries, this guide covers the essential types of exchangers, enabling buyers to make informed choices that align with their operational needs. Additionally, we delve into supplier vetting processes, ensuring that buyers can identify trustworthy manufacturers who adhere to quality standards. Understanding the cost implications of different materials and designs is also critical, and this guide offers insights into budgeting effectively for your projects.

By leveraging the information within this guide, international B2B buyers will be empowered to streamline their purchasing decisions, optimize their supply chains, and enhance operational efficiency. With a focus on actionable insights and practical advice, this resource serves as a crucial tool for navigating the global market for parts of exchangers.

Understanding parts of exchanger Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fixed Tubesheet Exchanger | Welded tubesheet; simple design; limited accessibility | Petrochemical processing, HVAC systems | Pros: Cost-effective, easy to manufacture. Cons: Limited cleaning access, potential thermal stress. |

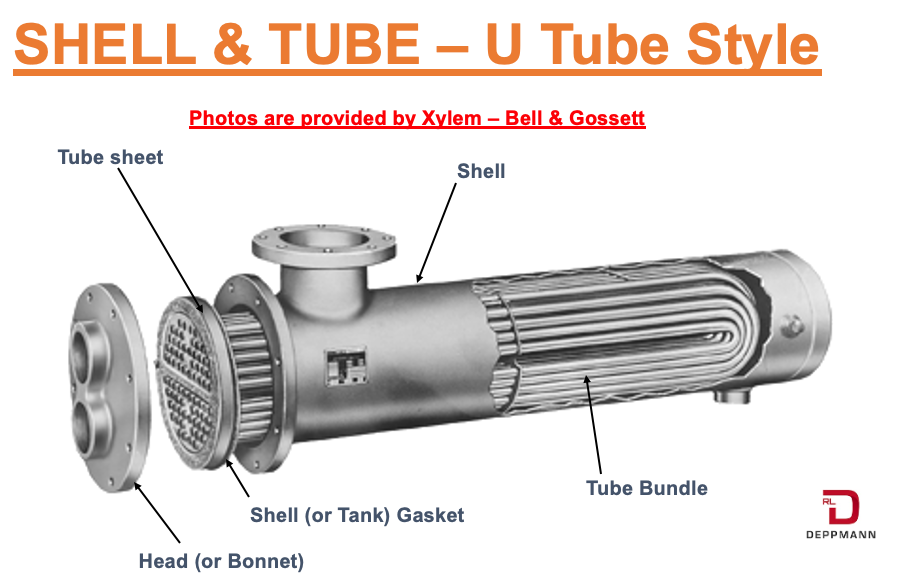

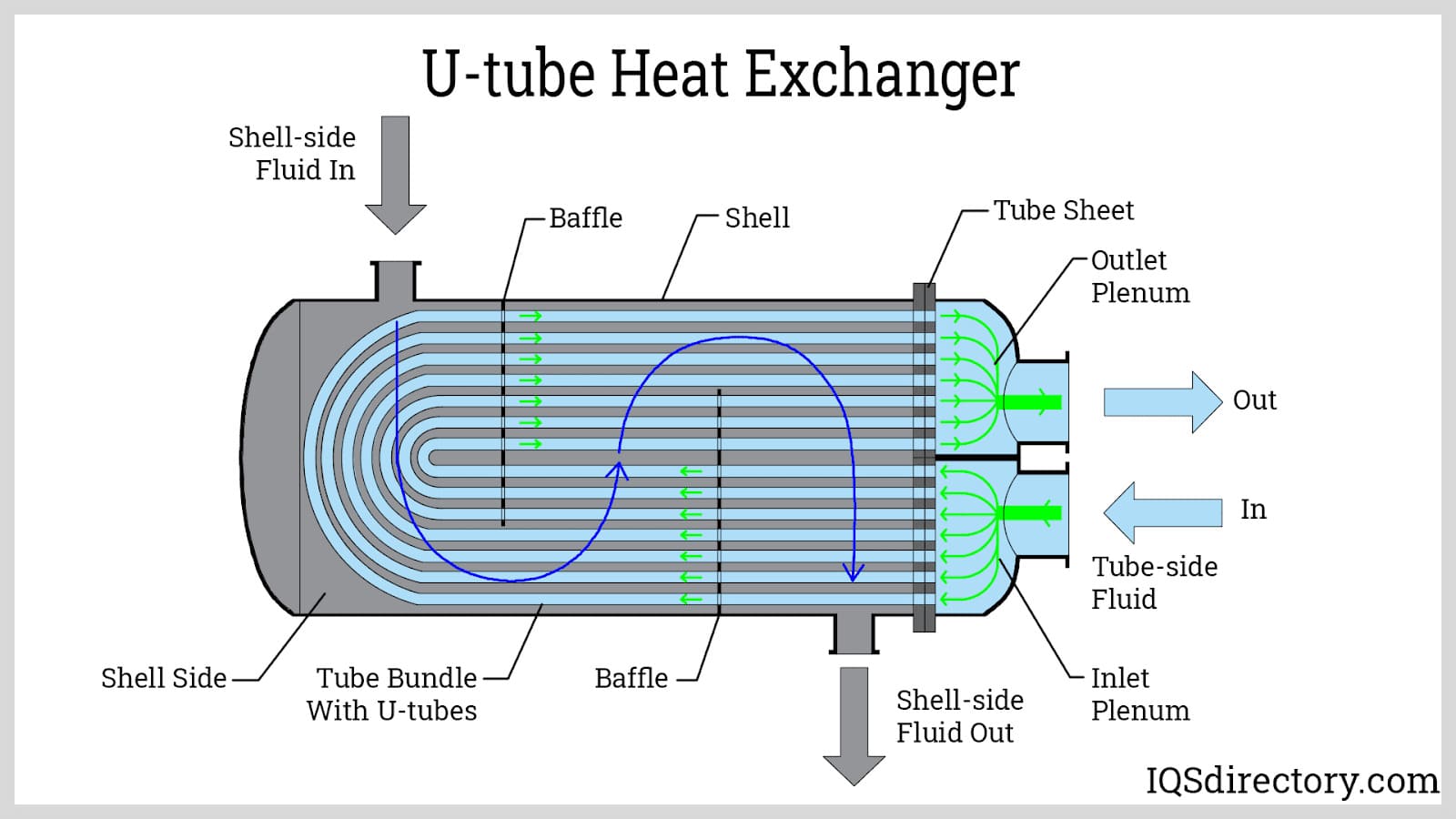

| U-Tube Exchanger | U-shaped tubes; allows for thermal expansion | Power generation, chemical industries | Pros: Facilitates thermal expansion, easy bundle removal. Cons: Difficult internal cleaning, suitable only for clean fluids. |

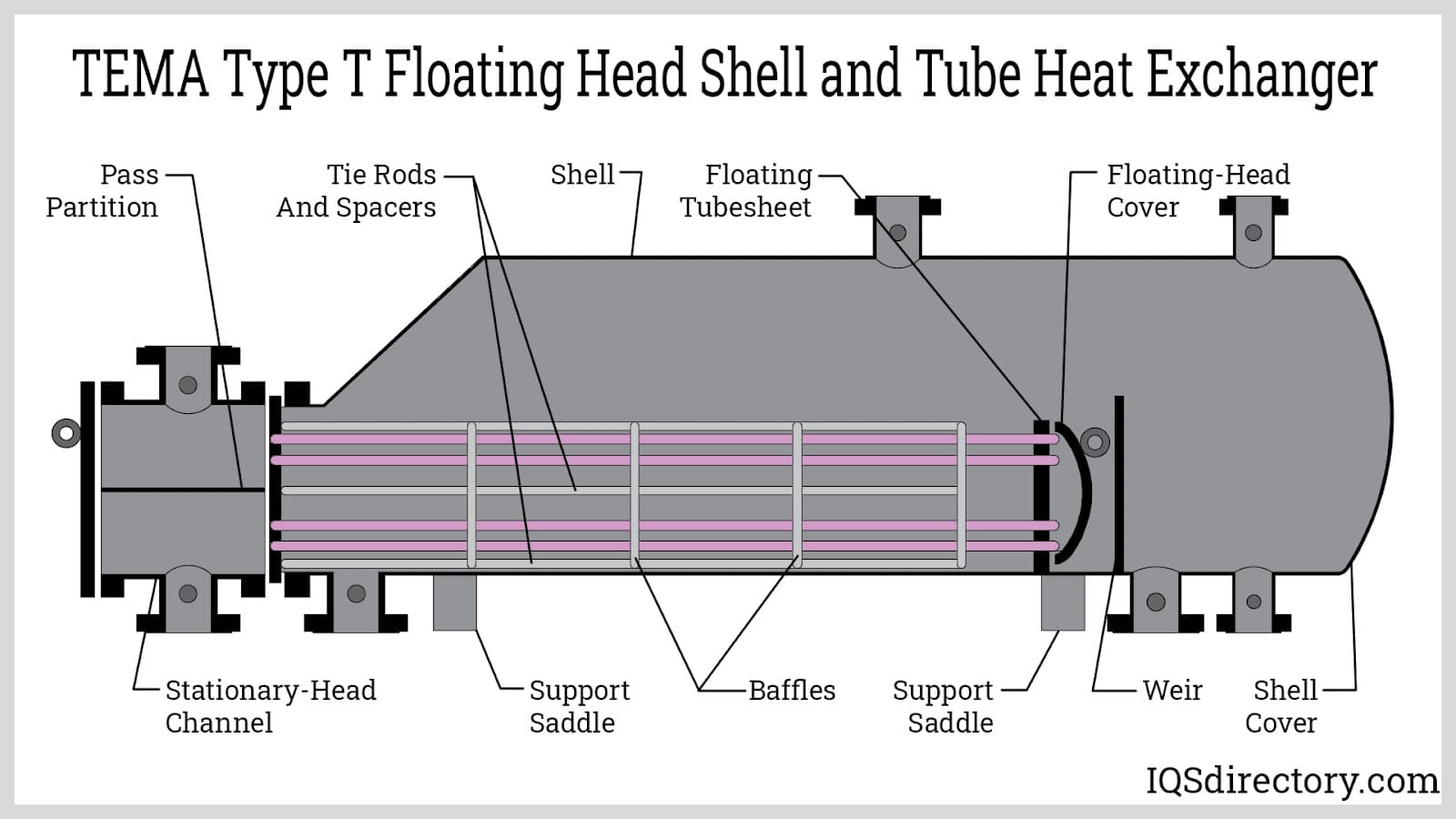

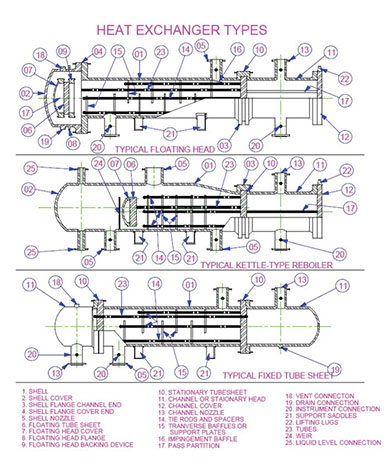

| Floating Head Exchanger | Movable tubesheet; allows for thermal expansion | Oil refineries, large-scale heat recovery systems | Pros: Easy maintenance, accommodates thermal expansion. Cons: More complex design, higher initial cost. |

| Shell and Tube Exchanger | Combination of tubes and shell; versatile design | Food processing, pharmaceutical manufacturing | Pros: High durability, adaptable to various applications. Cons: Requires careful selection to match process conditions. |

| Plate Heat Exchanger | Flat plates for heat exchange; compact design | HVAC, refrigeration, food and beverage processing | Pros: High efficiency, smaller footprint. Cons: Limited pressure handling, potential for fouling. |

What are the Key Characteristics of Fixed Tubesheet Exchangers?

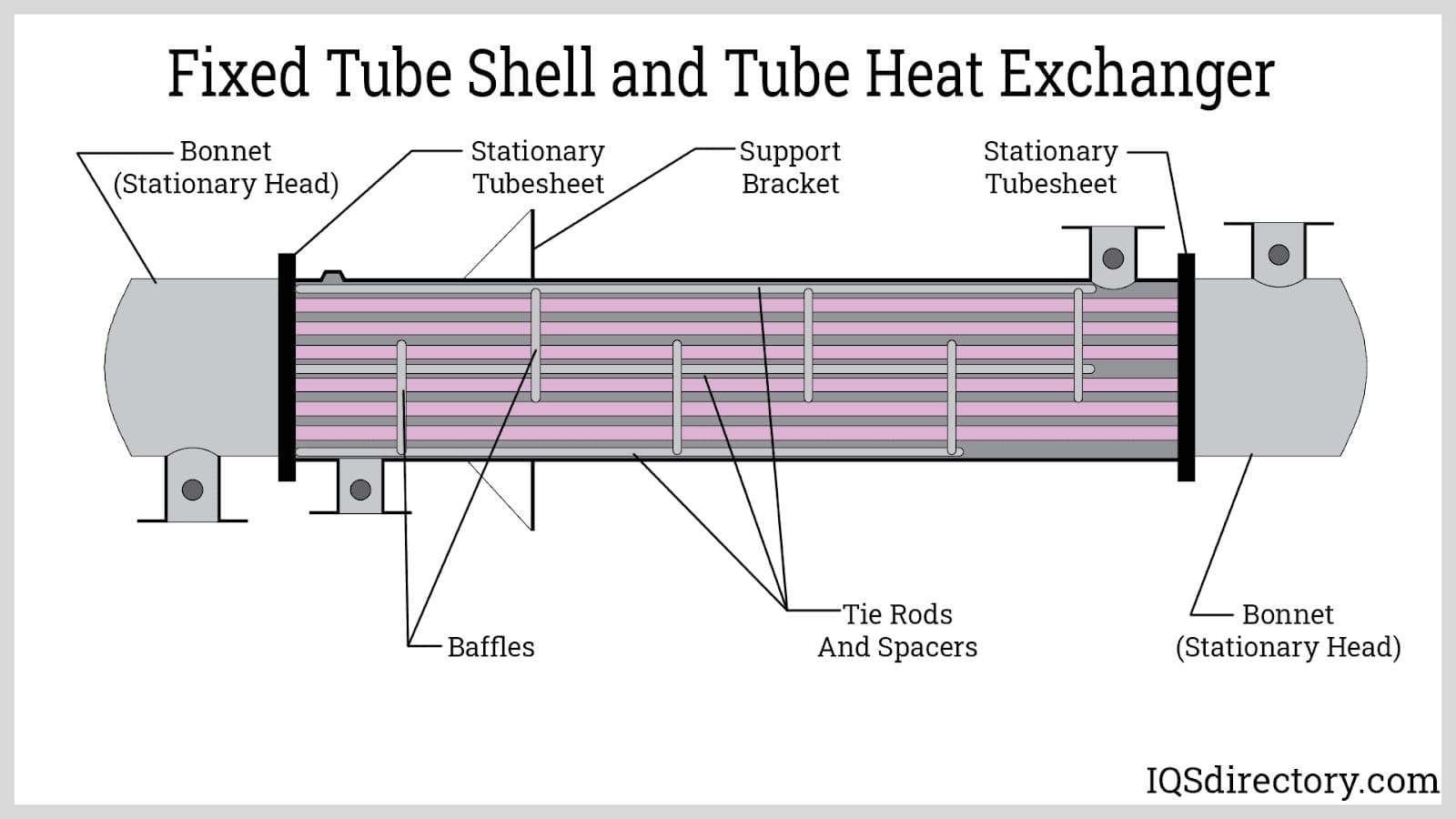

Fixed tubesheet exchangers feature a welded tubesheet that connects directly to the shell, making them a straightforward and economical choice for many industrial applications. They are commonly used in petrochemical processing and HVAC systems due to their simplicity. However, buyers should consider the limited access for cleaning the tubes’ outer surfaces, which can lead to maintenance challenges and potential thermal stress issues if there are significant temperature differentials between the shell and tube materials.

How Do U-Tube Exchangers Facilitate Thermal Expansion?

U-tube exchangers are designed with tubes that bend in a U-shape, allowing for unrestricted thermal expansion. This design is particularly beneficial in power generation and chemical industries, where temperature variations are common. While they offer the advantage of easy bundle removal for cleaning, buyers should note that internal cleaning can be challenging, making them less suitable for applications where the tube side fluids are not consistently clean.

What Makes Floating Head Exchangers Ideal for Rigorous Duties?

Floating head exchangers feature a tubesheet that is not welded but allows for movement, accommodating thermal expansion effectively. This design is ideal for oil refineries and large-scale heat recovery systems where maintenance and cleaning are critical. While they provide significant operational flexibility, buyers should be aware that floating head exchangers are more complex and typically come with a higher initial cost, which could impact budget considerations.

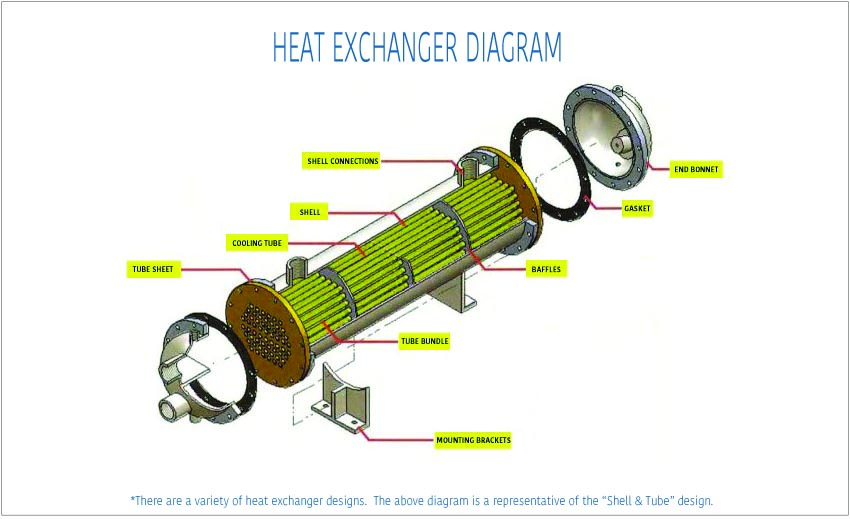

Why are Shell and Tube Exchangers Popular in Various Industries?

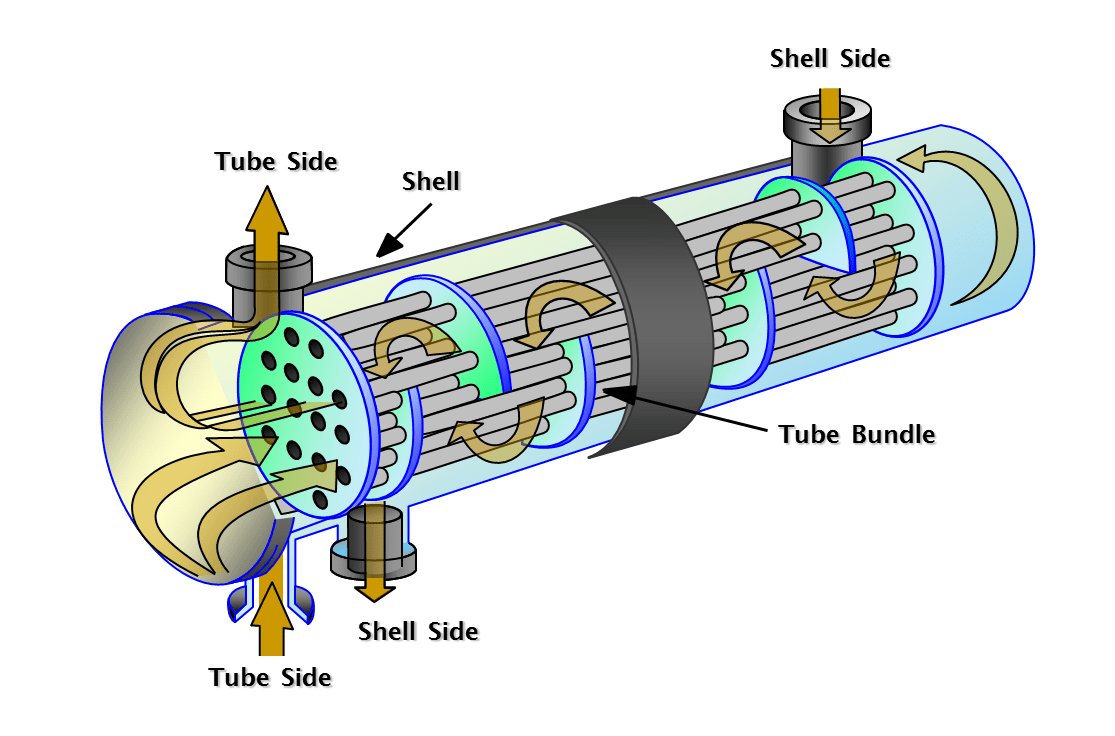

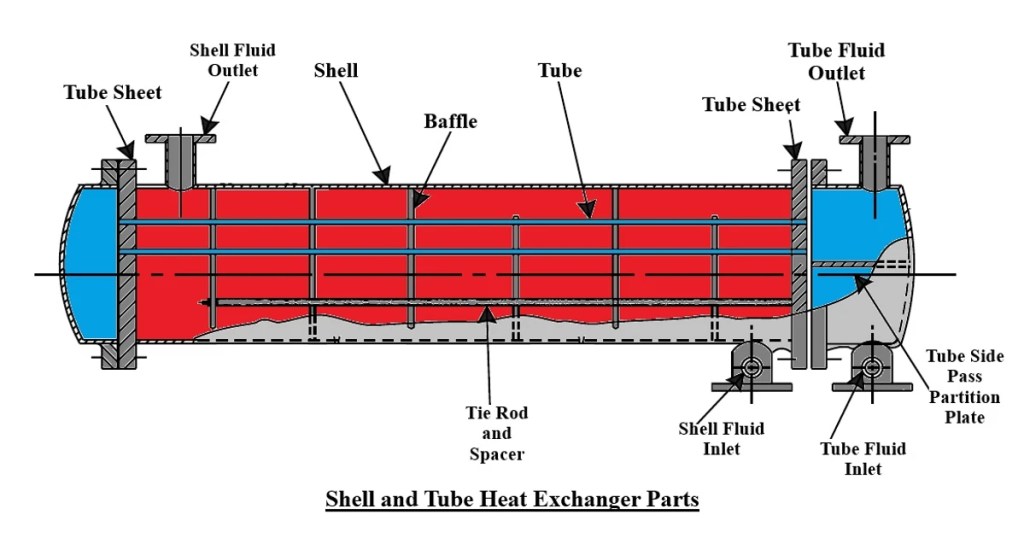

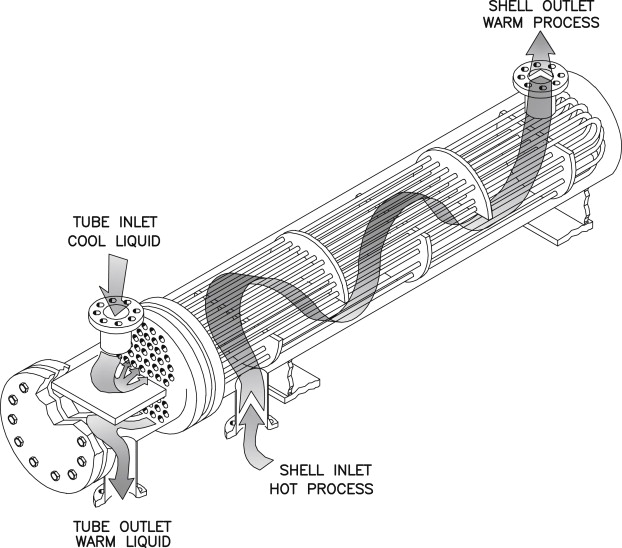

Shell and tube exchangers combine tubes with a cylindrical shell, making them one of the most versatile designs available. They are widely used in food processing and pharmaceutical manufacturing due to their robustness and adaptability to different heat exchange processes. However, selecting the right materials and configurations is crucial to ensure compatibility with specific process conditions, which can add complexity to the purchasing decision.

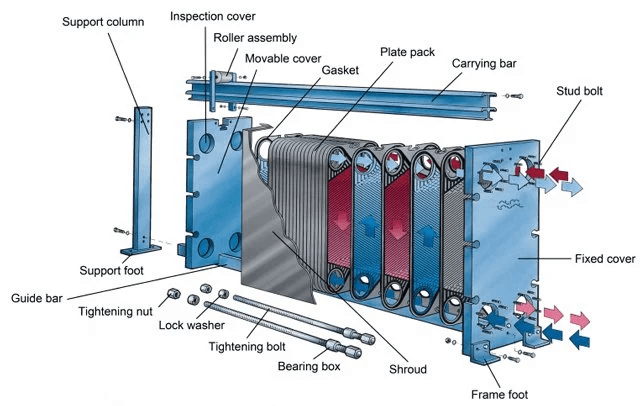

What are the Advantages and Limitations of Plate Heat Exchangers?

Plate heat exchangers utilize a series of thin plates to facilitate heat transfer, offering a compact design that is well-suited for applications like HVAC and food processing. They are known for their high efficiency and smaller footprint compared to traditional exchangers. However, buyers should consider their limitations in handling high pressures and the potential for fouling, which may necessitate more frequent maintenance and cleaning efforts.

Illustrative image related to parts of exchanger

Key Industrial Applications of parts of exchanger

| Industry/Sector | Specific Application of parts of exchanger | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Heat exchange in crude oil refining | Enhances energy efficiency and reduces operational costs | Material grade, pressure ratings, and compliance with TEMA standards |

| Chemical Processing | Cooling and heating in chemical reactors | Improves product quality and process reliability | Corrosion resistance, customization options, and lead times |

| Power Generation | Feedwater heating in steam power plants | Increases thermal efficiency and lowers fuel consumption | Design flexibility, maintenance access, and thermal performance |

| Food & Beverage | Pasteurization and temperature control in processing | Ensures product safety and extends shelf life | Hygiene standards, material certifications, and ease of cleaning |

| HVAC Systems | Heating and cooling in large commercial buildings | Optimizes energy use and enhances occupant comfort | Energy efficiency ratings, compatibility with existing systems, and service support |

How Are Parts of Exchangers Used in the Oil & Gas Industry?

In the oil and gas sector, parts of exchangers are critical in crude oil refining processes, where they facilitate heat exchange between various fluids. This application enhances energy efficiency by recovering and reusing heat, ultimately reducing operational costs. Buyers in this industry must consider material grades that can withstand high temperatures and pressures, as well as compliance with the Tubular Exchanger Manufacturers Association (TEMA) standards to ensure safety and reliability.

What Role Do Exchanger Parts Play in Chemical Processing?

In chemical processing, parts of exchangers are utilized in cooling and heating applications within reactors. This ensures optimal reaction conditions, improving product quality and process reliability. Buyers should focus on sourcing exchangers made from corrosion-resistant materials, as they often deal with aggressive chemicals. Customization options for specific process requirements and reasonable lead times are also essential factors for international buyers, particularly in regions with diverse chemical applications.

How Are Parts of Exchangers Beneficial in Power Generation?

In power generation, particularly within steam power plants, parts of exchangers are employed for feedwater heating. This process enhances thermal efficiency, leading to reduced fuel consumption and lower operational costs. When sourcing these components, buyers should prioritize designs that allow for easy maintenance access and superior thermal performance. Additionally, understanding the specific heat transfer requirements of their systems can help ensure that the right exchanger design is selected.

What Importance Do Exchanger Parts Have in the Food & Beverage Sector?

In the food and beverage industry, parts of exchangers are essential for processes like pasteurization and temperature control. They help ensure product safety and extend shelf life by maintaining precise temperature conditions. Buyers in this sector must adhere to stringent hygiene standards and seek materials that comply with food safety regulations. Certifications and ease of cleaning are key considerations to ensure that the heat exchangers meet industry-specific requirements.

How Do Parts of Exchangers Optimize HVAC Systems?

Parts of exchangers are integral to heating and cooling systems in large commercial buildings, optimizing energy use and enhancing occupant comfort. By facilitating effective heat transfer, these components help maintain a consistent indoor climate while minimizing energy costs. Buyers should evaluate energy efficiency ratings and compatibility with existing HVAC systems during sourcing. Additionally, robust service support is crucial to address maintenance needs and ensure long-term operational efficiency.

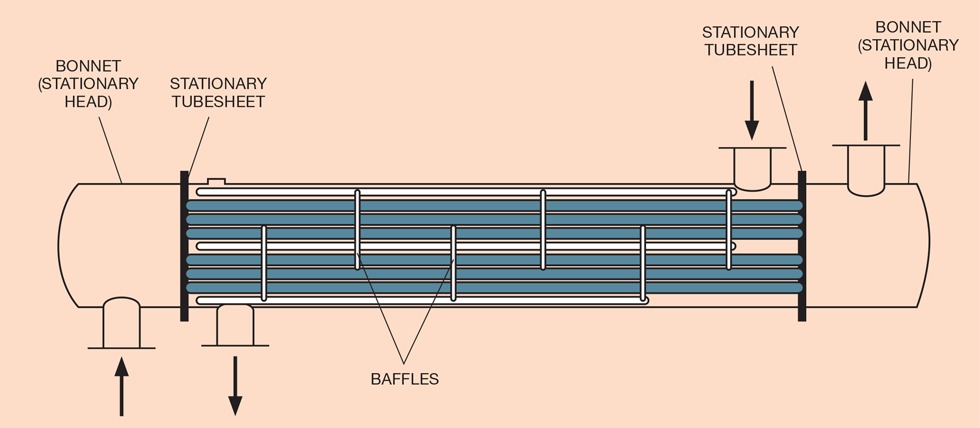

Illustrative image related to parts of exchanger

3 Common User Pain Points for ‘parts of exchanger’ & Their Solutions

Scenario 1: Challenges in Sourcing High-Quality Tube Sheets

The Problem:

B2B buyers often face difficulties when sourcing tube sheets for shell and tube heat exchangers. The challenge is compounded by the need for specific material grades that can withstand high pressures and corrosive environments. Many suppliers may not meet the stringent quality standards required, leading to potential operational failures and costly downtime. Buyers may also struggle with understanding the differences between fixed tubesheet, U-tube, and floating head designs, making it difficult to choose the right option for their application.

The Solution:

To effectively source high-quality tube sheets, buyers should prioritize suppliers who specialize in ASME and TEMA-compliant products. Conduct thorough research to identify manufacturers with a proven track record in producing tube sheets that meet specific pressure and temperature requirements. Request material certifications and performance data to ensure that the products can withstand the intended operational conditions. Additionally, engage in direct discussions with technical representatives from suppliers to clarify design specifications and material choices, ensuring that they align with the unique needs of your heat exchanger system. By establishing strong relationships with reputable manufacturers, buyers can secure the necessary components while also receiving ongoing support for future projects.

Scenario 2: Ensuring Compatibility Between Heat Exchanger Components

The Problem:

Another common pain point is the compatibility of various heat exchanger components, especially when working with a mix of older and newer systems. Buyers often encounter issues when replacing parts like baffles or rods, as different designs and materials may not fit or function properly together. This can lead to inefficiencies, increased maintenance costs, and even system failures if not addressed.

The Solution:

To mitigate compatibility issues, B2B buyers should conduct a comprehensive assessment of their existing heat exchanger systems before sourcing replacement parts. Utilize detailed schematics and documentation from the original equipment manufacturers (OEMs) to identify the specific dimensions and material specifications required for each component. When sourcing new parts, prioritize suppliers who offer customizable solutions, allowing for tailored components that fit seamlessly into existing systems. Additionally, consider working with engineering consultants to evaluate the overall design and compatibility of the entire heat exchanger assembly. This proactive approach ensures that all components work harmoniously, reducing the risk of operational failures and enhancing system efficiency.

Scenario 3: Managing Maintenance and Downtime for Exchanger Parts

The Problem:

B2B buyers often face significant downtime during maintenance periods, particularly when dealing with heat exchanger parts that require specialized knowledge and tools for repairs or replacements. This downtime not only affects production schedules but also leads to financial losses. Furthermore, the lack of readily available spare parts can exacerbate the situation, leaving companies scrambling to find replacements at critical times.

The Solution:

To effectively manage maintenance and minimize downtime, buyers should adopt a proactive maintenance strategy that includes keeping an inventory of critical spare parts. Conduct a thorough analysis of the heat exchanger system to identify components that are most prone to wear and failure. Establish a relationship with suppliers for expedited shipping of spare parts, ensuring that they can respond quickly to urgent requests. Additionally, consider implementing a preventive maintenance schedule that includes regular inspections and servicing of heat exchanger parts. Training in-house maintenance personnel on best practices for heat exchanger upkeep can further reduce reliance on external technicians, leading to faster repairs and lower costs. By being prepared and proactive, companies can significantly decrease downtime and maintain operational efficiency.

Strategic Material Selection Guide for parts of exchanger

What Are the Key Properties of Common Materials Used in Exchanger Parts?

When selecting materials for parts of heat exchangers, it is essential to consider properties such as temperature and pressure ratings, corrosion resistance, and mechanical strength. The most common materials used include carbon steel, stainless steel, copper alloys, and titanium. Each material offers distinct advantages and disadvantages that can significantly impact the performance and longevity of the heat exchanger in various applications.

How Does Carbon Steel Perform in Heat Exchanger Applications?

Carbon steel is widely used for shell and tube heat exchangers due to its excellent mechanical properties and cost-effectiveness. It can withstand high pressures and temperatures, making it suitable for many industrial applications. However, carbon steel has limited corrosion resistance, especially in acidic or saline environments, which may lead to premature failure in certain applications.

Pros: Durable and economical, carbon steel is easy to fabricate and weld. It is ideal for applications involving non-corrosive fluids.

Illustrative image related to parts of exchanger

Cons: Susceptible to corrosion, particularly in harsh environments, which may necessitate protective coatings or linings, adding to maintenance costs.

Impact on Application: Best suited for applications involving water or non-corrosive oils. Not recommended for aggressive chemical processes.

What Are the Advantages of Using Stainless Steel in Heat Exchangers?

Stainless steel, particularly grades 304 and 316, is favored for its superior corrosion resistance and strength. This material can handle high temperatures and pressures, making it versatile for various applications, including food processing and chemical manufacturing.

Pros: Excellent resistance to corrosion, high durability, and aesthetic appeal. Stainless steel can be easily cleaned and sanitized, making it ideal for hygienic applications.

Cons: Higher cost compared to carbon steel and more complex manufacturing processes due to its hardness.

Illustrative image related to parts of exchanger

Impact on Application: Suitable for applications involving aggressive chemicals or high-purity requirements. Compliance with standards such as ASTM A240 is crucial for international buyers.

How Do Copper Alloys Enhance Heat Transfer in Exchanger Parts?

Copper and its alloys (such as copper-nickel) are known for their exceptional thermal conductivity, making them ideal for heat exchanger applications where efficient heat transfer is critical. Copper is also resistant to corrosion in seawater, which makes it popular in marine applications.

Pros: High thermal conductivity leads to improved efficiency. Copper alloys also exhibit good resistance to biofouling.

Cons: Copper is more expensive than carbon steel and can be susceptible to corrosion in certain environments, such as those containing ammonia.

Impact on Application: Best used in applications requiring rapid heat transfer, such as in HVAC systems or marine environments. Buyers should ensure compliance with relevant standards like ASTM B122.

Illustrative image related to parts of exchanger

What Makes Titanium a Preferred Choice for Specialized Applications?

Titanium is a premium material known for its outstanding corrosion resistance and strength-to-weight ratio. It can withstand extreme temperatures and is inert to many chemicals, making it suitable for highly corrosive environments.

Pros: Exceptional durability and resistance to corrosion, particularly in aggressive media. Lightweight, which can reduce overall system weight.

Cons: Significantly higher cost and complexity in manufacturing processes, including welding.

Impact on Application: Ideal for applications in chemical processing and offshore oil and gas industries. International buyers must consider compliance with standards such as ASTM B348 and ASTM B265.

Summary of Material Selection for Parts of Exchanger

| Material | Typical Use Case for parts of exchanger | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General industrial applications | Durable and economical | Susceptible to corrosion | Low |

| Stainless Steel | Food processing, chemical manufacturing | Excellent corrosion resistance | Higher cost and complex fabrication | Med |

| Copper Alloys | Marine applications, HVAC systems | High thermal conductivity | More expensive and can corrode in ammonia | Med |

| Titanium | Chemical processing, offshore oil and gas | Outstanding corrosion resistance | High cost and complex manufacturing | High |

This strategic material selection guide provides insights into the properties, advantages, and limitations of various materials used in heat exchangers, aiding international B2B buyers in making informed decisions tailored to their specific applications and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for parts of exchanger

What Are the Key Stages in the Manufacturing Process of Heat Exchanger Parts?

The manufacturing process for parts of a shell and tube heat exchanger involves several critical stages, each designed to ensure the final product meets the stringent requirements for performance and durability. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Heat Exchanger Components?

Material preparation is the first step in the manufacturing process. It begins with selecting the appropriate materials based on the application requirements. Common materials include carbon steel, stainless steel, titanium, and copper alloys.

Once selected, the materials undergo rigorous testing for mechanical properties and chemical composition to ensure they meet industry standards. After passing the initial quality checks, the materials are cut to size using techniques such as plasma cutting or laser cutting. This precision is crucial, as it affects the integrity of the final assembly.

What Forming Techniques Are Used in the Production of Heat Exchanger Parts?

The forming stage involves shaping the prepared materials into specific components. For the shell, manufacturers typically employ rolling techniques to create cylindrical shapes from flat plates. The thickness of the shell is determined based on the pressure and temperature requirements of the application.

Illustrative image related to parts of exchanger

For the tubes, manufacturers may utilize processes like extrusion or cold drawing to create seamless tubes or roll-forming for welded tubes. Tubes can also be enhanced with fins to increase surface area for heat transfer, which is achieved through mechanical attachment or welding.

How Are Heat Exchanger Parts Assembled?

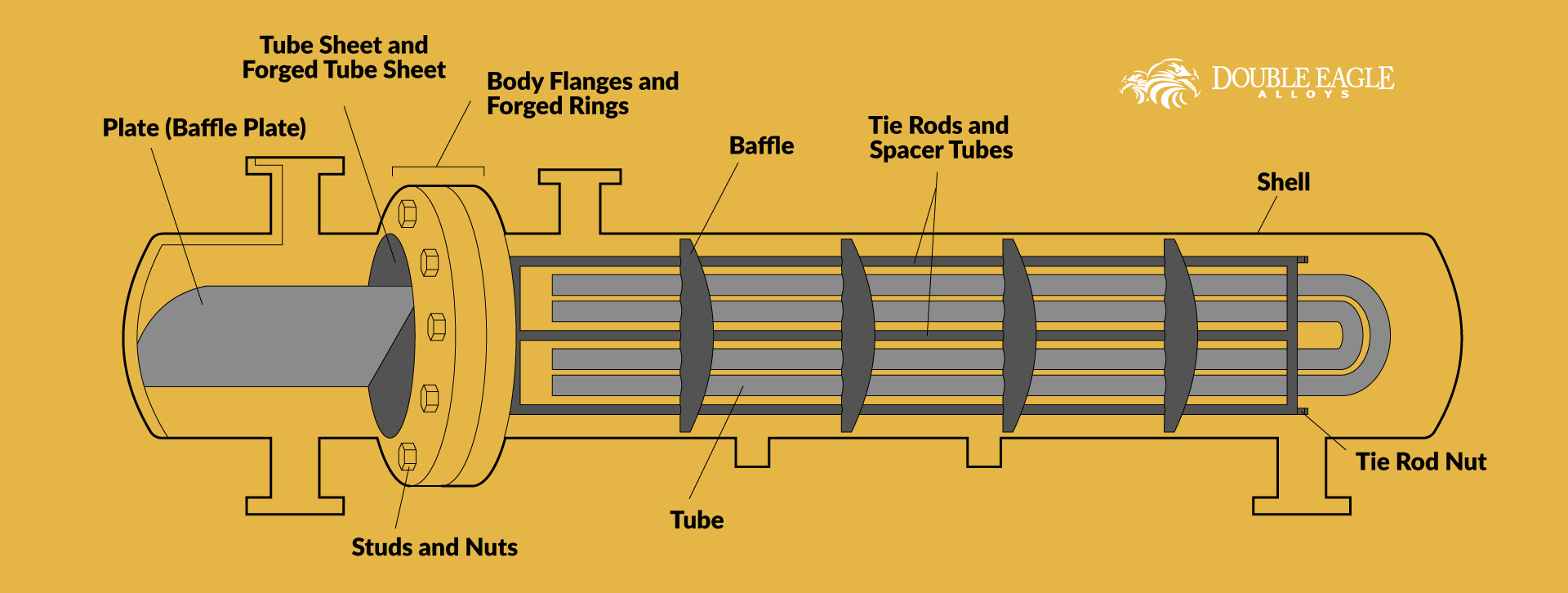

Assembly is a critical phase where all components come together. The tube sheets are first positioned, and the tubes are inserted into pre-drilled holes. This assembly is often secured through welding, which must be done with precision to prevent leaks.

Baffles are installed next to provide structural support and direct fluid flow, followed by rods and spacers that maintain the correct spacing between the baffles. This stage also includes the installation of channels or heads, which contain the fluid for the tube side and dictate the flow path through the exchanger.

Illustrative image related to parts of exchanger

What Finishing Processes Are Necessary for Heat Exchanger Components?

Finishing processes enhance the durability and performance of heat exchanger parts. Common techniques include surface treatment, such as sandblasting or pickling, to remove impurities and improve corrosion resistance.

Finally, heat treatment processes may be applied to relieve stresses induced during welding and forming. This ensures that the components are not only strong but also capable of withstanding the demanding conditions they will face in operation.

What Quality Assurance Measures Are Essential for Heat Exchanger Parts?

Quality assurance (QA) is paramount in the manufacturing of heat exchanger components, ensuring that they meet both international and industry-specific standards.

Illustrative image related to parts of exchanger

Which International Standards Apply to Heat Exchanger Manufacturing?

Manufacturers should adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific standards such as the American Petroleum Institute (API) and the European CE marking ensure that products meet safety and performance criteria.

Compliance with these standards is essential, as they guide manufacturers in implementing effective quality management practices throughout the production process.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process. These include:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected to verify compliance with specifications. This may involve testing material properties, dimensions, and chemical composition.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are performed to monitor critical parameters such as welding quality, dimensional accuracy, and surface finish. This helps identify potential issues before they escalate.

-

Final Quality Control (FQC): Once assembly is complete, a thorough inspection is conducted to ensure all components meet design specifications. This often includes non-destructive testing (NDT) methods, such as ultrasonic testing or radiographic inspection, to detect any hidden defects.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers have several avenues to verify the quality control practices of their suppliers.

What Auditing Practices Should Buyers Consider?

Conducting supplier audits is an effective way to assess compliance with quality standards. This involves visiting the manufacturing facility to review processes, inspect documentation, and evaluate the overall quality management system.

Buyers should also request quality assurance reports and certifications to ensure that suppliers adhere to relevant international and industry-specific standards.

How Can Third-Party Inspections Enhance Buyer Confidence?

Engaging third-party inspection agencies can provide an unbiased evaluation of a supplier’s quality control processes. These agencies can conduct independent audits and testing, providing buyers with detailed reports that affirm the quality and reliability of the products.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential.

How Do Regional Standards Impact Quality Assurance?

Different regions may have varying standards and regulations that impact product quality. For example, buyers in Europe must ensure compliance with CE marking regulations, while those in the Middle East may need to adhere to specific local standards.

It’s vital for buyers to communicate their requirements clearly and verify that suppliers can meet these regional standards. This not only ensures compliance but also enhances the reliability and performance of the heat exchanger components.

In conclusion, understanding the manufacturing processes and quality assurance measures for heat exchanger parts is crucial for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they source high-quality components that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts of exchanger’

Introduction

In the complex landscape of industrial equipment procurement, sourcing parts for heat exchangers requires a strategic approach to ensure quality, efficiency, and cost-effectiveness. This guide serves as a comprehensive checklist for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, to facilitate informed decision-making when procuring components for shell and tube heat exchangers.

Illustrative image related to parts of exchanger

Step 1: Define Your Technical Specifications

Start by establishing the precise technical requirements for the heat exchanger parts you need. This includes understanding the operating temperatures, pressures, and the specific fluids involved in your processes.

– Considerations: Determine material compatibility (e.g., stainless steel vs. titanium) based on the corrosiveness of the fluids and thermal conductivities required for optimal performance.

Step 2: Research Industry Standards and Certifications

Familiarize yourself with relevant industry standards, such as those from the Tubular Exchanger Manufacturers Association (TEMA). Ensure that the components comply with these standards for safety and reliability.

– Verification: Look for certifications such as ISO, ASME, or other quality assurance marks that indicate adherence to industry benchmarks.

Step 3: Evaluate Potential Suppliers

Conduct thorough due diligence on potential suppliers to assess their credibility and capacity. Request detailed company profiles, product catalogs, and references from similar industries.

– Key Questions: What is their track record in supplying parts for heat exchangers? Have they worked with companies in your region?

Step 4: Request Samples and Technical Documentation

Before making bulk purchases, request samples of the parts along with technical documentation, including installation guides and maintenance instructions.

– Importance: This allows you to evaluate the quality of the components firsthand and ensures they meet your specifications before committing to larger orders.

Step 5: Assess Lead Times and Delivery Capabilities

Understanding the supplier’s lead times and delivery capabilities is crucial for maintaining your project timelines.

– Considerations: Inquire about their production capacity and any potential delays in sourcing raw materials, especially if your requirements are urgent.

Step 6: Negotiate Terms and Conditions

Once you’ve shortlisted suppliers, engage in negotiations regarding pricing, payment terms, and warranties.

– Points to Address: Ensure that warranties cover defects and provide clarity on the return policies for any defective parts. This helps safeguard your investment.

Step 7: Establish a Quality Control Process

Implement a quality control process to inspect the parts upon delivery. This should include checking for compliance with specifications and identifying any visible defects.

– Actions: Create a checklist based on your original specifications to ensure each component meets your operational needs before integration into your systems.

By following this step-by-step checklist, B2B buyers can streamline the procurement process for heat exchanger parts, ensuring that they invest in high-quality components that enhance operational efficiency and reliability.

Comprehensive Cost and Pricing Analysis for parts of exchanger Sourcing

What Are the Key Cost Components in Sourcing Parts of Exchangers?

When sourcing parts for heat exchangers, a comprehensive understanding of the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The choice of materials significantly influences costs. Common materials like carbon steel are generally less expensive, while specialty alloys such as titanium or stainless steel can escalate costs due to their durability and corrosion resistance. Buyers should assess the specific application requirements to select the most cost-effective material without compromising quality.

-

Labor: Labor costs vary based on the complexity of the parts being manufactured. Skilled labor for precision machining and assembly is often more expensive but necessary for high-quality output. Understanding the labor market in the supplier’s region can provide insights into potential cost variations.

-

Manufacturing Overhead: This encompasses expenses related to facilities, utilities, and equipment maintenance. Efficient manufacturers tend to have lower overhead, which can translate into more competitive pricing for buyers.

-

Tooling: Initial tooling costs can be substantial, particularly for custom parts. However, once tooling is established, the per-unit cost decreases significantly. Buyers should inquire about tooling amortization over production volume to better understand pricing dynamics.

-

Quality Control (QC): QC processes are crucial for ensuring the reliability and performance of heat exchanger parts. Enhanced QC measures can increase costs, but they are often justified by the reduction in defects and failures, leading to a lower Total Cost of Ownership (TCO).

-

Logistics: Shipping costs can vary widely based on distance, weight, and delivery speed. International buyers should consider the implications of Incoterms, which define the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs.

-

Margin: Supplier margins fluctuate based on market conditions, competition, and the supplier’s operational efficiency. Understanding the typical margins in different regions can aid buyers in negotiating more favorable terms.

How Do Volume and Customization Affect Pricing of Exchanger Parts?

Pricing for heat exchanger parts is heavily influenced by order volume and customization requirements. Higher volumes generally lead to lower unit costs due to economies of scale. Suppliers are often willing to negotiate better pricing for bulk orders, which can be advantageous for larger projects.

Customization, on the other hand, can significantly increase costs. Custom specifications may necessitate additional design work, specialized materials, and unique tooling. Buyers should evaluate whether the benefits of customization justify the added expense and consider standard options where feasible.

Illustrative image related to parts of exchanger

What Buyer Tips Can Help Negotiate Better Prices?

-

Negotiate with Data: Utilize market data and comparable quotes to negotiate better terms. Suppliers may be more willing to adjust pricing if they see that a buyer has done their homework.

-

Focus on Total Cost of Ownership (TCO): Consider not only the initial purchase price but also maintenance, operational efficiency, and longevity of the parts. Highlighting TCO in negotiations can lead to more strategic purchasing decisions.

-

Understand Pricing Nuances for International Transactions: International buyers, particularly from regions like Africa, South America, and the Middle East, should be aware of currency fluctuations, tariffs, and import duties. These factors can dramatically affect the total cost and should be factored into budgeting.

-

Explore Multiple Suppliers: Diversifying the supplier base can foster competitive pricing. Having alternative options allows buyers to negotiate better terms and reduces dependence on a single supplier.

-

Assess Quality Certifications: Ensure that suppliers meet relevant industry standards and certifications. Higher quality often equates to a higher price, but it can also mean fewer failures and lower long-term costs.

Conclusion

In summary, understanding the comprehensive cost structure and pricing influences for heat exchanger parts is vital for B2B buyers. By focusing on key cost components, leveraging volume and customization insights, and employing effective negotiation strategies, buyers can achieve more favorable purchasing outcomes. Always remember to consider indicative prices as market conditions can fluctuate, impacting overall sourcing costs.

Alternatives Analysis: Comparing parts of exchanger With Other Solutions

Exploring Alternative Solutions to Parts of Exchanger Systems

In the realm of industrial heat transfer, the choice of components and systems can significantly impact efficiency, cost, and operational reliability. While shell and tube heat exchangers are widely recognized for their robustness and versatility, alternative technologies exist that may better suit specific applications or constraints. This analysis compares the traditional parts of exchangers with two viable alternatives: plate heat exchangers and air-cooled heat exchangers.

| Comparison Aspect | Parts Of Exchanger | Plate Heat Exchanger | Air-Cooled Heat Exchanger |

|---|---|---|---|

| Performance | High thermal efficiency; suitable for a wide range of pressures and temperatures. | Excellent heat transfer efficiency in compact design; ideal for low to moderate pressures. | Effective for cooling applications; no need for water, reducing operational costs. |

| Cost | Generally higher initial costs due to material and fabrication; potential for lower lifecycle costs with proper maintenance. | Moderate initial costs; lower operational costs due to reduced energy consumption. | Lower initial cost; operational savings from reduced water usage; however, performance can be affected by ambient temperatures. |

| Ease of Implementation | Installation can be complex due to size and weight; requires careful planning for space and connections. | Easier to install in tight spaces; modular design allows for flexibility. | Simple installation; can be mounted on rooftops or other areas without extensive groundwork. |

| Maintenance | Requires regular maintenance to prevent fouling and corrosion; accessibility can be limited. | Easier to clean and maintain due to removable plates; less prone to fouling. | Generally low maintenance; however, fans may require periodic checks and cleaning. |

| Best Use Case | Ideal for high-temperature and high-pressure applications in petrochemical and power industries. | Best suited for food processing, HVAC, and pharmaceutical industries where space is limited. | Effective for outdoor cooling applications, such as in power plants and industrial refrigeration systems. |

Detailed Breakdown of Alternatives

Plate Heat Exchanger

Plate heat exchangers (PHE) utilize thin plates to transfer heat between fluids. Their compact design allows for a significant surface area in a smaller footprint, making them ideal for applications where space is at a premium. The ease of disassembly for cleaning is a major advantage, as it minimizes downtime. However, they may not be suitable for high-pressure applications, and the initial costs can vary depending on the material and design.

Air-Cooled Heat Exchanger

Air-cooled heat exchangers use ambient air to dissipate heat from process fluids. They are particularly advantageous in areas where water is scarce or expensive, eliminating the need for cooling water. These systems can be easily installed and relocated, making them versatile for outdoor applications. However, their efficiency can be impacted by high ambient temperatures, potentially leading to less effective heat transfer compared to water-cooled systems.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate heat exchanger components or systems hinges on specific operational needs, environmental conditions, and budget constraints. For B2B buyers, it is essential to evaluate the performance, cost, and maintenance requirements of each option in the context of their unique applications. Shell and tube heat exchangers remain a strong choice for high-pressure scenarios, while plate and air-cooled heat exchangers offer distinct advantages in terms of space and resource efficiency. By aligning the chosen solution with operational goals, buyers can optimize performance and achieve cost savings over the lifecycle of their heat transfer systems.

Essential Technical Properties and Trade Terminology for parts of exchanger

What Are the Key Technical Properties of Exchanger Parts?

When considering the procurement of heat exchanger parts, understanding specific technical properties is essential for ensuring compatibility and performance within industrial applications. Here are critical specifications to be aware of:

1. Material Grade

Heat exchangers are typically constructed from various metals and alloys, including carbon steel, stainless steel, copper, and titanium. The choice of material affects corrosion resistance, thermal conductivity, and overall durability. For instance, stainless steel is favored in corrosive environments, while copper is often used for its excellent thermal conductivity. Selecting the appropriate material grade is crucial for operational longevity and compliance with industry standards.

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. In the context of heat exchangers, precise tolerances are vital for ensuring proper fit and function, especially in components like tubes and tube sheets. Tighter tolerances can lead to better thermal efficiency and reduce the risk of leaks. For B2B buyers, understanding tolerance requirements can help prevent costly modifications or replacements down the line.

3. Pressure Rating

Each component of a heat exchanger comes with a specified pressure rating that indicates the maximum pressure it can withstand during operation. This specification is critical for ensuring safety and reliability, particularly in high-pressure applications common in the petrochemical and power industries. Buyers must assess the pressure ratings in relation to their specific operational conditions to avoid catastrophic failures.

4. Flow Arrangement

Understanding the flow arrangement—whether parallel, counterflow, or crossflow—is essential for optimizing heat transfer efficiency. Each arrangement has distinct advantages based on the specific thermal exchange requirements. For instance, counterflow designs typically offer superior efficiency compared to parallel flow configurations. B2B buyers should consider their process needs when selecting the appropriate flow arrangement.

5. Surface Area

The surface area of the heat exchanger components, particularly the tubes, plays a crucial role in determining the efficiency of heat transfer. The larger the surface area, the more effective the heat exchange process. Manufacturers may employ techniques such as finning to enhance the surface area of tubes, thereby improving performance. Understanding these dynamics can help buyers choose parts that meet their efficiency goals.

Illustrative image related to parts of exchanger

What Are Common Trade Terms Used in the Exchanger Industry?

Navigating the procurement process for heat exchanger parts involves familiarizing oneself with industry-specific terminology. Here are several essential terms to understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture components that are used in another company’s end products. In the context of heat exchangers, an OEM may provide specialized parts that meet stringent specifications. Working with reputable OEMs ensures quality and reliability, which is crucial for maintaining operational efficiency.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers, as it impacts inventory management and budgeting. Suppliers may set MOQs based on production costs or inventory levels, making it essential for buyers to align their purchasing strategy accordingly.

Illustrative image related to parts of exchanger

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and availability for specific parts. This document outlines the specifications, quantities, and delivery timelines. Crafting a detailed RFQ can streamline the procurement process, ensuring that buyers receive accurate and competitive quotes from multiple suppliers.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including aspects such as shipping, insurance, and risk. Familiarity with these terms helps B2B buyers navigate cross-border transactions and understand their obligations regarding logistics and costs.

5. TEMA (Tubular Exchanger Manufacturers Association)

TEMA is an organization that establishes standards for the design and construction of shell and tube heat exchangers. Familiarity with TEMA standards helps buyers ensure that the components they procure meet industry benchmarks for safety and performance.

By understanding these key technical properties and trade terms, B2B buyers can make informed decisions when procuring heat exchanger parts, ultimately enhancing operational efficiency and ensuring compliance with industry standards.

Navigating Market Dynamics and Sourcing Trends in the parts of exchanger Sector

What Are the Global Drivers Influencing the Parts of Exchanger Market?

The parts of the exchanger market is currently experiencing dynamic shifts driven by several global factors. First and foremost, the growing demand for energy-efficient solutions across various industries, including petrochemicals and power generation, is propelling the need for advanced heat exchangers. As countries in Africa, South America, the Middle East, and Europe invest in infrastructure and industrialization, the requirement for reliable and efficient heat transfer systems becomes paramount.

Emerging technologies such as IoT and advanced materials science are also reshaping sourcing trends. B2B buyers are increasingly seeking suppliers who can provide smart, integrated solutions that enhance operational efficiency and reduce maintenance costs. Innovations in manufacturing processes, including additive manufacturing and precision engineering, are enabling the creation of high-performance components with reduced lead times.

Additionally, geopolitical tensions and fluctuating raw material prices are influencing sourcing strategies. Buyers are encouraged to diversify their supplier networks to mitigate risks associated with single-source dependencies. This trend is particularly significant in regions like Europe, where regulatory pressures for sustainable practices are heightening the demand for locally sourced materials.

How Are Sustainability and Ethical Sourcing Shaping the Parts of Exchanger Sector?

Sustainability has become a cornerstone of B2B purchasing decisions in the parts of exchanger sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny from regulators and consumers alike. Companies are now prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint through sustainable practices.

Illustrative image related to parts of exchanger

Ethical sourcing is equally critical, with buyers increasingly favoring suppliers who uphold fair labor practices and transparent supply chains. Certifications such as ISO 14001 for environmental management and the Responsible Steel certification are becoming essential credentials that reflect a supplier’s dedication to sustainability.

Furthermore, the use of eco-friendly materials, such as recycled metals and low-impact manufacturing techniques, is gaining traction. Buyers are encouraged to seek out components that not only meet performance standards but also align with their sustainability goals. This shift towards green materials is not only beneficial for the environment but also enhances brand reputation, making it a pivotal factor in procurement strategies.

What Is the Historical Context of the Parts of Exchanger Industry?

The evolution of the parts of exchanger industry dates back to the late 19th century, coinciding with the industrial revolution, which significantly increased the demand for efficient heat transfer solutions. Early designs were simplistic and primarily utilized basic materials, but advancements in metallurgy and engineering led to the development of more sophisticated designs, such as shell and tube heat exchangers.

By the mid-20th century, the industry saw significant innovations driven by the petrochemical boom, which necessitated more robust and efficient exchangers capable of withstanding high pressures and temperatures. The introduction of standards by organizations like the Tubular Exchanger Manufacturers Association (TEMA) further formalized design and manufacturing processes, ensuring quality and safety across the industry.

Today, the parts of exchanger sector is characterized by a blend of traditional engineering excellence and cutting-edge technology, reflecting a continuous journey of adaptation to meet the evolving needs of global markets.

Illustrative image related to parts of exchanger

Frequently Asked Questions (FAQs) for B2B Buyers of parts of exchanger

-

How do I choose the right parts for my heat exchanger?

Choosing the right parts for your heat exchanger requires a thorough understanding of your operational requirements. Consider factors such as the type of fluids involved, temperature and pressure conditions, and the specific application (e.g., petrochemical, power generation). Evaluate the material compatibility to avoid corrosion and ensure efficiency. Collaborate with suppliers who can provide detailed specifications and recommendations based on your unique needs to ensure optimal performance and longevity of the heat exchanger. -

What is the best material for heat exchanger parts?

The best material for heat exchanger parts largely depends on the application and environmental conditions. Common materials include carbon steel for general use, stainless steel for corrosion resistance, and titanium for high-temperature applications. For industries dealing with aggressive chemicals, copper-nickel alloys may be ideal. Assess the thermal conductivity, corrosion resistance, and mechanical properties of each material to make an informed decision tailored to your specific requirements. -

What customization options are available for heat exchanger parts?

Customization options for heat exchanger parts can include variations in size, shape, and materials based on specific application needs. Suppliers often offer bespoke solutions, such as different tube lengths, wall thicknesses, and fin configurations to enhance heat transfer efficiency. When seeking customization, provide detailed specifications and performance criteria to your supplier to ensure that the final product meets your operational demands effectively. -

What are the minimum order quantities (MOQ) for heat exchanger parts?

Minimum order quantities for heat exchanger parts vary by supplier and the type of component. Generally, MOQs can range from a few pieces for standard items to larger quantities for custom or specialized parts. It’s essential to communicate your needs with potential suppliers to negotiate favorable terms, especially if you are looking for a smaller quantity or a prototype. Many suppliers may be willing to accommodate smaller orders depending on the overall business relationship. -

How can I verify the credibility of a supplier for heat exchanger parts?

To verify the credibility of a supplier, conduct thorough research, including checking their certifications (e.g., ISO, TEMA), customer reviews, and industry reputation. Request references from previous clients and inquire about their experience with similar projects. Additionally, assess their production capabilities and quality assurance processes to ensure they meet international standards. Establishing clear communication and visiting their facility, if possible, can further enhance trust in the supplier. -

What payment terms should I expect when sourcing heat exchanger parts internationally?

Payment terms for international sourcing of heat exchanger parts can vary significantly. Common terms include upfront payments, partial payments upon order confirmation, and balance upon shipment. Discuss options such as letters of credit or escrow services for larger transactions to mitigate risks. Always ensure that payment terms are clearly outlined in the purchase agreement and consider the implications of exchange rates and transaction fees in your budgeting. -

What quality assurance measures should be in place for heat exchanger parts?

Quality assurance measures should include rigorous testing and inspection protocols to ensure that all parts meet specified standards and performance criteria. Look for suppliers that conduct non-destructive testing, pressure testing, and dimensional inspections. Certifications from recognized bodies (e.g., ASME, API) can provide additional assurance of quality. Establishing a clear quality control agreement with your supplier is crucial to safeguard against defects and ensure the reliability of the components. -

What logistics considerations should I keep in mind when sourcing parts internationally?

When sourcing parts internationally, consider logistics factors such as shipping methods, lead times, and import/export regulations. Assess the cost and reliability of different shipping options, including air freight for expedited needs or sea freight for bulk orders. Familiarize yourself with customs procedures in your country to avoid delays. It’s also wise to discuss packaging solutions with your supplier to ensure that parts arrive in good condition, minimizing the risk of damage during transit.

Top 7 Parts Of Exchanger Manufacturers & Suppliers List

1. Forged Components – Shell and Tube Heat Exchanger Parts

Domain: forgedcomponents.com

Registered: 2000 (25 years)

Introduction: Components of Shell and Tube Heat Exchangers include: 1. Shell – a cylindrical structure made from rolled plate metal or pipe, typically steel, with nozzle inlet and impingement plate. 2. Tubes – seamless or welded tubes, usually 5/8 inch to 1 inch in diameter, may include fins for enhanced heat transfer. 3. Tube Sheets – forged plates with drilled holes for tube insertion and welding. 4. Baffles …

2. Thermopedia – Shell and Tube Heat Exchangers

Domain: thermopedia.com

Registered: 2007 (18 years)

Introduction: Shell and Tube Heat Exchangers are popular for their flexibility in handling a wide range of pressures and temperatures. They consist of a cylindrical shell containing tubes, allowing two fluids to exchange heat. Key components include: 1. Front Header (Stationary Header) – where fluid enters the tubeside. 2. Rear Header – where tubeside fluid exits. 3. Tube Bundle – includes tubes, tube sheets, b…

3. Double Eagle Alloys – Shell and Tube Heat Exchangers

Domain: doubleeaglealloys.com

Registered: 2004 (21 years)

Introduction: Key components of a shell and tube heat exchanger include:

1. Shell: Large pressure vessel housing the tube bundle, directing fluid flow.

2. Tubes: Primary elements for heat transfer, made from high-quality stainless steel or copper.

3. Tube Sheets: Thick metal plates securing the tubes, maintaining structural integrity. Alloys available: C276, 825, 625, 400, 304L, 316L, 321, 347, F53, F51/F60 …

4. Patriot Bolt – Shell and Tube Heat Exchangers

Domain: patriotbolt.com

Registered: 2018 (7 years)

Introduction: Shell and tube heat exchangers are commonly used in oil refineries and large chemical processes, suitable for high temperature and high pressure applications. The design consists of a shell with a bundle of tubes; one fluid runs through the tubes while another medium runs over them for heat transfer. Heat exchangers can be single phase or two phase, with specific temperature inlets and outlets def…

5. Atlas Bronze – Heat Exchanger Parts

Domain: atlasbronze.com

Registered: 1997 (28 years)

Introduction: Heat Exchanger Parts Diagram | Heat Exchanger Schematic. Heat exchangers are devices used to transfer heat between fluids, which may be separated by a solid wall or in direct contact. They are utilized in various industries including space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural gas processing, sewage treatment,…

6. Shell & Tube Heat Exchangers – Key Components Overview

Domain: slideshare.net

Registered: 2006 (19 years)

Introduction: This document provides a comprehensive overview of various components and design considerations in shell and tube heat exchangers, detailing the functions and specifications of the shell, baffles, tube sheets, and other parts. It highlights the importance of factors such as shell diameter, baffle types, tube sizes, and flow velocities in optimizing heat transfer efficiency while managing costs. Ad…

7. SetXInd – Heat Exchangers

Domain: setxind.com

Registered: 2001 (24 years)

Introduction: Heat exchangers are essential equipment in industrial processes, particularly in refineries and processing plants, used for both heating and cooling fluids. Key components include:

1. **Tubes**: Crucial for heat transfer, available as welded or seamless, with standard diameters of 5/8 inch, 3/4 inch, or 1 inch. Innovations include twisted tapes for improved efficiency.

2. **Front and Rear Headers…

Strategic Sourcing Conclusion and Outlook for parts of exchanger

In the competitive landscape of industrial processes, effective strategic sourcing of heat exchanger parts is crucial for maximizing operational efficiency and minimizing costs. Understanding the components of shell and tube heat exchangers—such as tubes, shells, baffles, and tube sheets—enables buyers to make informed decisions when selecting materials and suppliers. By prioritizing quality and compatibility with industry standards, businesses can enhance their reliability and performance in demanding environments.

Moreover, leveraging strategic sourcing allows organizations to build resilient supply chains, fostering partnerships with manufacturers that adhere to international standards. This not only ensures the availability of high-quality components but also mitigates risks associated with supply disruptions.

Looking ahead, international B2B buyers from Africa, South America, the Middle East, and Europe should remain proactive in exploring innovative sourcing strategies and technologies that align with their specific needs. By investing in robust supplier relationships and staying informed about market trends, businesses can position themselves for success in an evolving marketplace. Engage with trusted suppliers today to secure the best solutions for your heat exchanger requirements and drive your operations forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.