A B2B Buyer’s Guide to Parts Of A Hose Reel: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for parts of a hose reel

In today’s competitive landscape, sourcing high-quality parts of a hose reel can present significant challenges for international B2B buyers. Whether you’re operating in the vibrant markets of Africa, South America, the Middle East, or Europe, the need for reliable hose reel components is paramount for maintaining operational efficiency and ensuring customer satisfaction. This comprehensive guide addresses the complexities of sourcing these essential components by exploring various types of hose reels, their applications across different industries, and the specific parts that contribute to their functionality.

By delving into the intricacies of supplier vetting processes, cost considerations, and key performance indicators, this guide equips buyers with the knowledge needed to make informed purchasing decisions. We will also highlight the importance of understanding regional differences in supply chains, which can greatly affect availability and pricing.

As you navigate the global market for hose reel parts, this resource aims to empower you to select the best suppliers and products that meet your unique business needs. With actionable insights and strategic guidance, you will be better prepared to enhance your procurement processes, optimize your inventory, and ultimately drive your business success in an increasingly interconnected world.

Understanding parts of a hose reel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Free-Standing Hose Reel | Portable, 360-degree rotation, easy to relocate | Landscaping, gardening, maintenance services | Pros: High mobility, ease of use. Cons: Requires space for storage. |

| Wall-Mounted Hose Reel | Space-saving, 180-degree rotation, fixed installation | Commercial buildings, residential properties | Pros: Saves floor space, convenient access. Cons: Limited reach compared to free-standing models. |

| Hose Reel Carts | Equipped with wheels, available in 2 or 4-wheel designs | Large properties, farms, industrial applications | Pros: High mobility, can transport hoses easily. Cons: May take up more storage space. |

| Portable Hose Reel | Versatile design, can be wall-mounted or free-standing | Small businesses, events, temporary setups | Pros: Flexible use, compact design. Cons: Limited hose capacity. |

| Industrial Hose Reel | Heavy-duty construction, designed for high volume use | Construction, industrial cleaning, firefighting | Pros: Durability, suitable for high-pressure applications. Cons: Higher initial investment. |

What Are the Characteristics of Free-Standing Hose Reels?

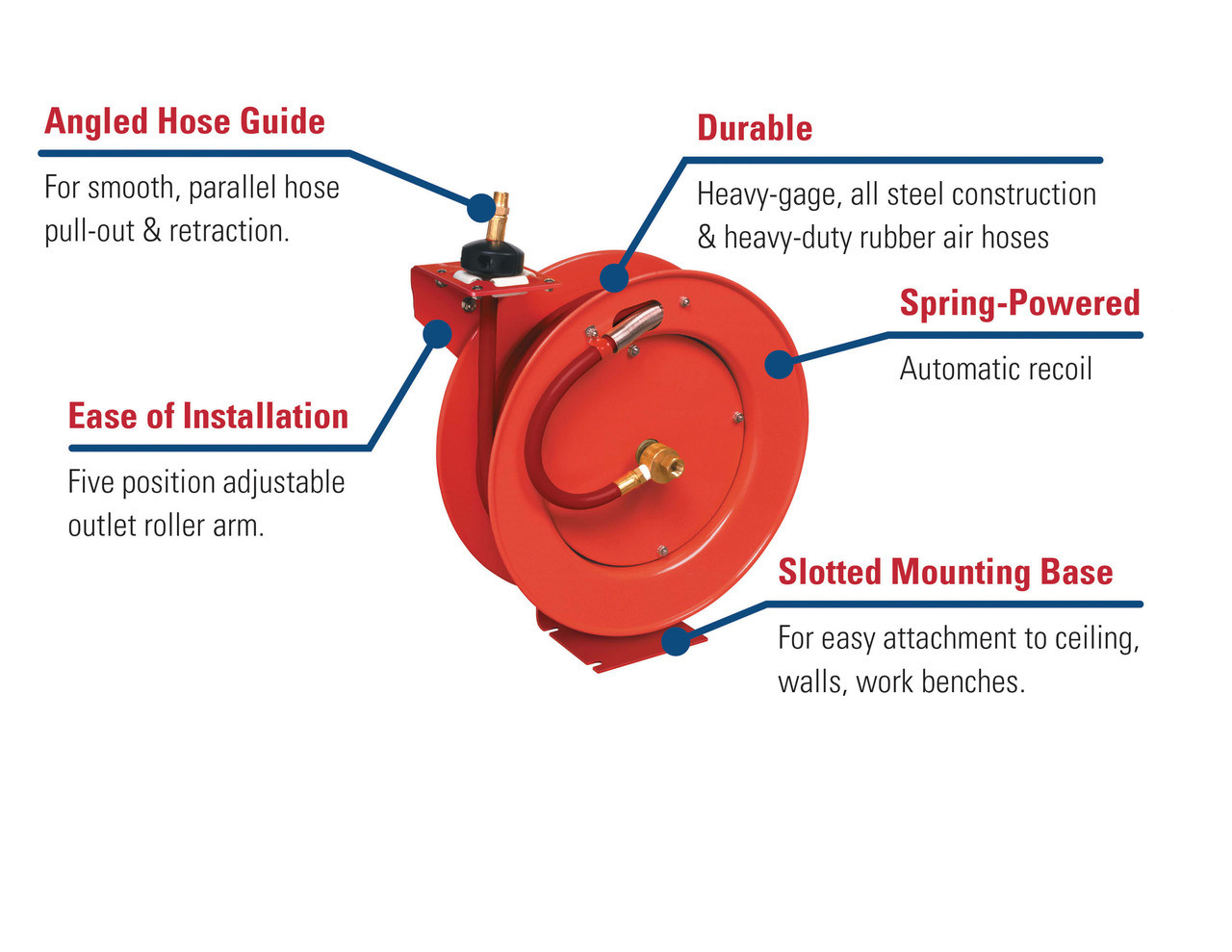

Free-standing hose reels are designed for mobility and convenience, featuring a 360-degree rotation that allows users to easily access their hoses from various angles. These reels are particularly suitable for landscaping and gardening businesses that require frequent hose movement across different areas. When considering a free-standing model, buyers should evaluate the size of the space where the reel will be used and stored, as they require adequate room to operate effectively.

How Do Wall-Mounted Hose Reels Benefit B2B Applications?

Wall-mounted hose reels offer a practical solution for businesses with limited floor space. They provide a 180-degree rotation, making them ideal for commercial buildings and residential properties where space is at a premium. These reels are easy to install and maintain, allowing for quick access to hoses. B2B buyers should consider the installation requirements and the hose length needed, as these factors will influence the reel’s effectiveness in their specific environment.

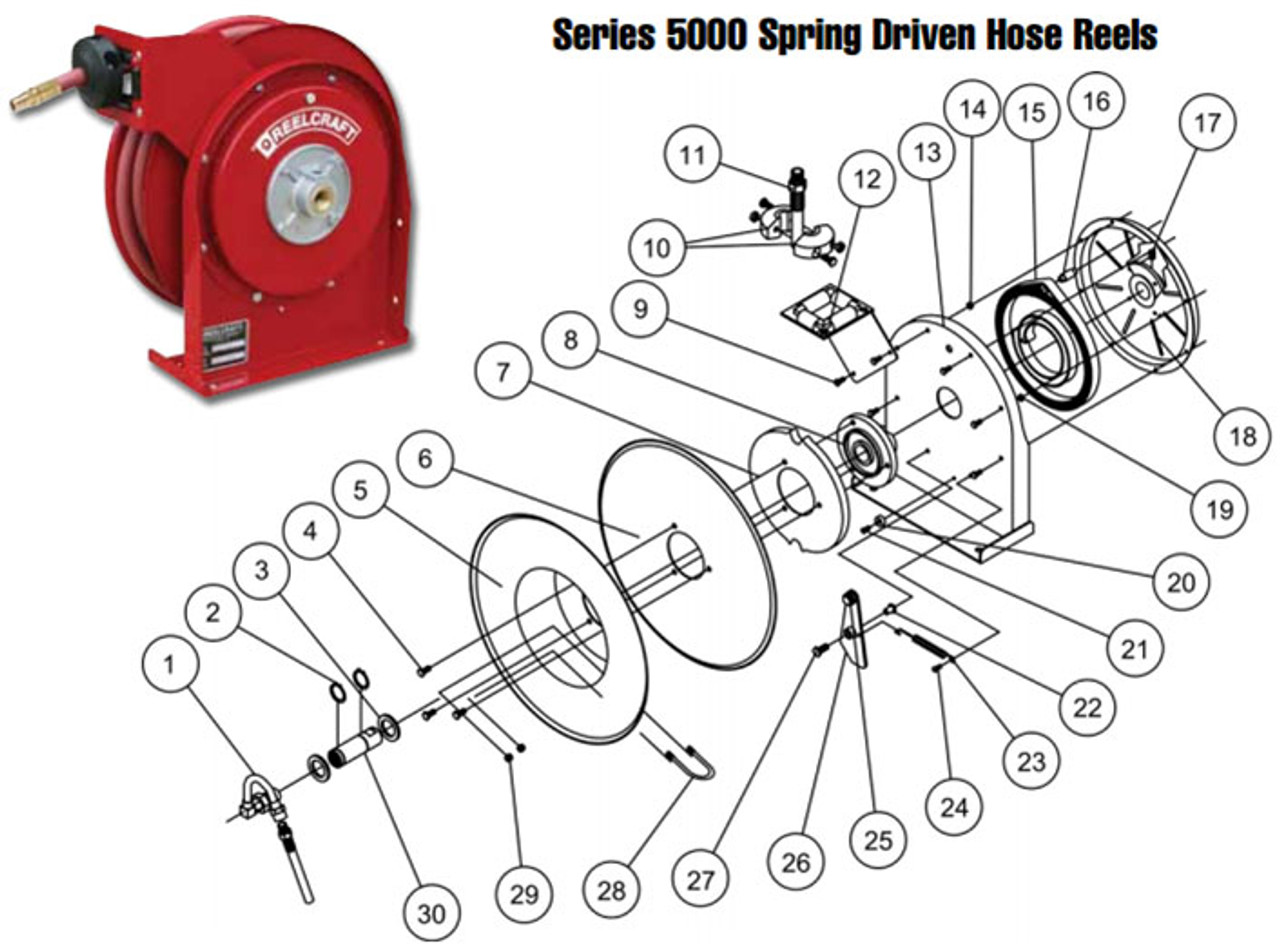

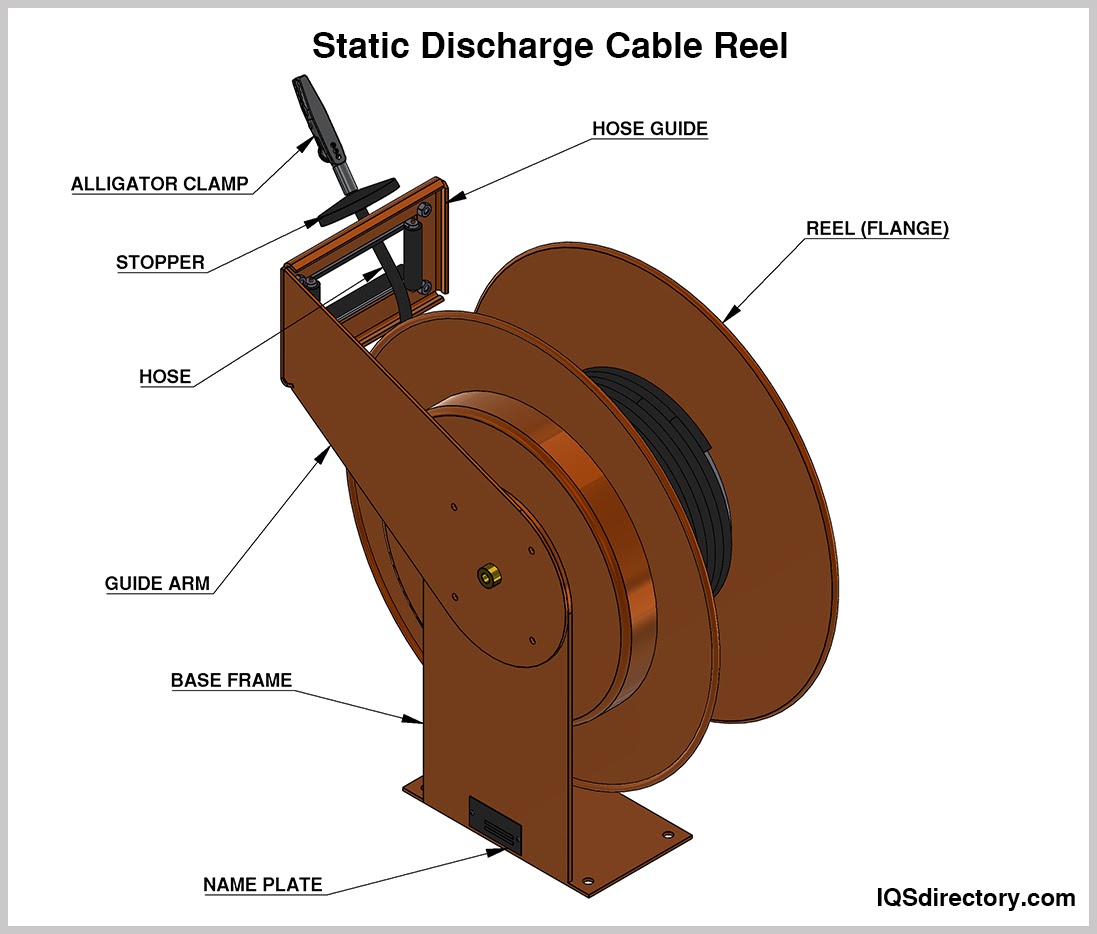

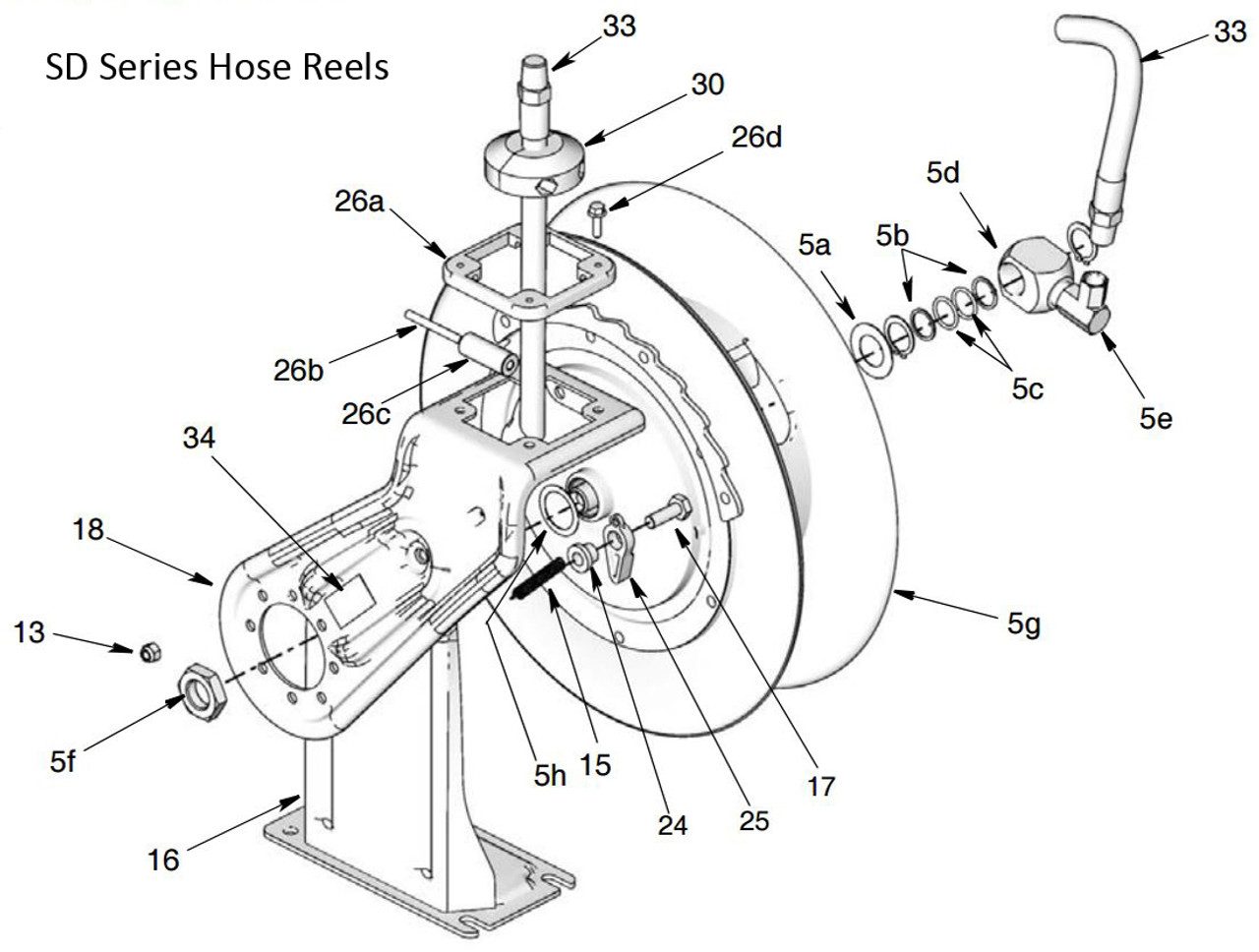

Illustrative image related to parts of a hose reel

What Advantages Do Hose Reel Carts Offer for Large Properties?

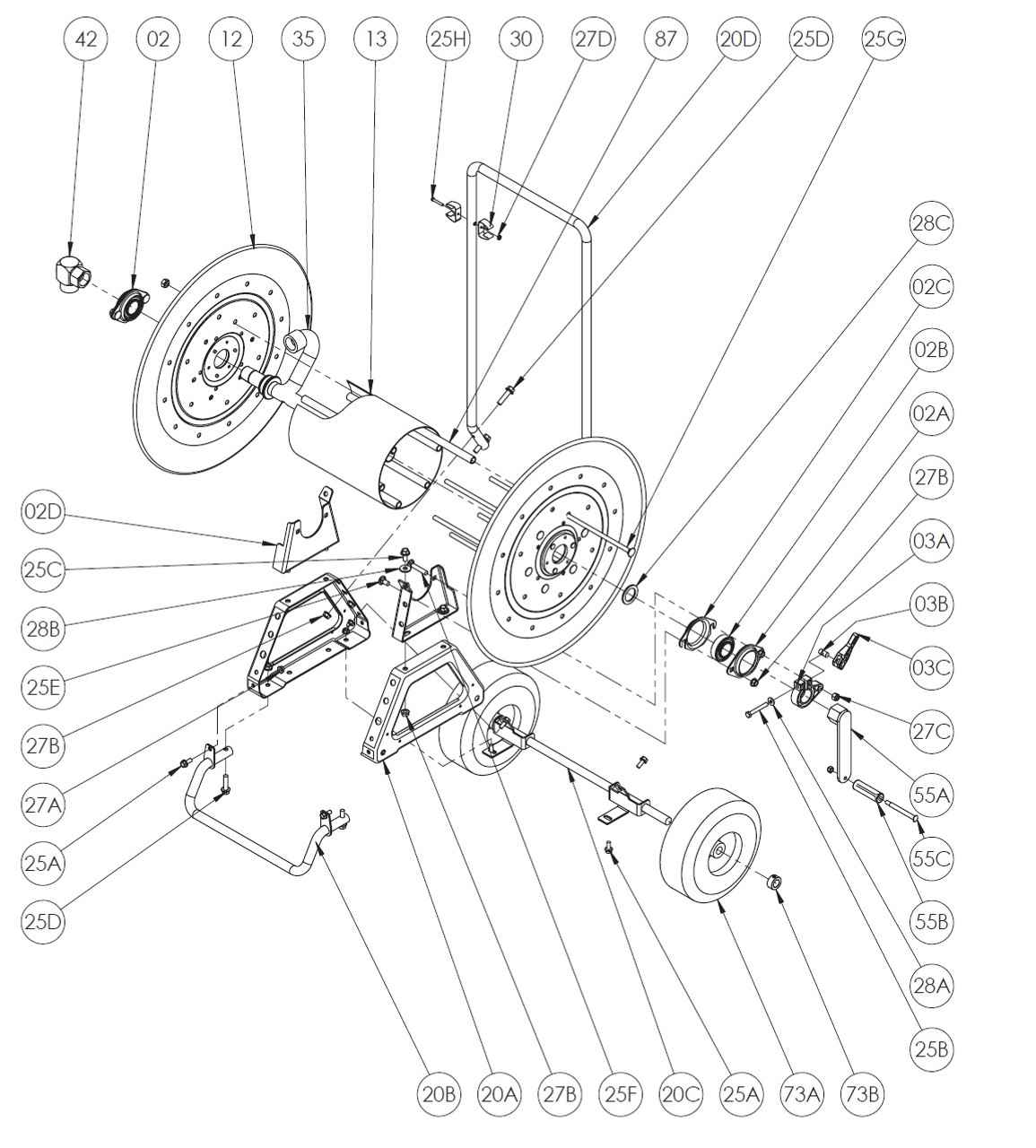

Hose reel carts come equipped with wheels, making them highly mobile and suitable for large properties, farms, and industrial applications. Available in both 2 and 4-wheel designs, these carts allow users to transport hoses effortlessly across expansive areas. When purchasing a hose reel cart, businesses should assess the terrain and storage space available, as these carts can take up more room than stationary options.

Why Choose a Portable Hose Reel for Versatile Use?

Portable hose reels provide a flexible solution for small businesses, events, or temporary setups, as they can be both wall-mounted and used as free-standing units. Their compact design is advantageous for buyers looking for a space-efficient option without sacrificing functionality. When selecting a portable hose reel, consider the hose capacity and intended use to ensure it meets operational needs.

What Makes Industrial Hose Reels Essential for Heavy-Duty Applications?

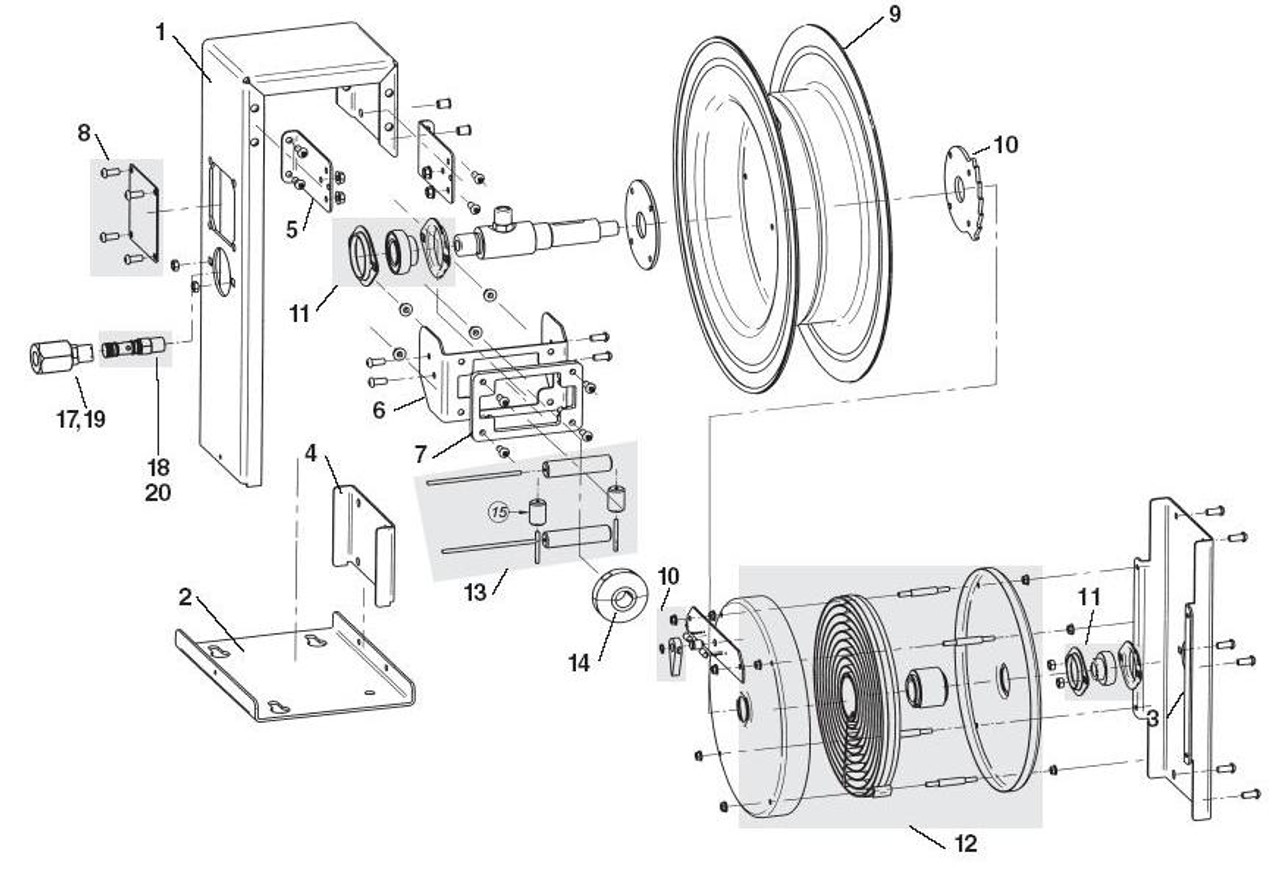

Industrial hose reels are constructed to withstand rigorous use in demanding environments such as construction sites, industrial cleaning, and firefighting. Their heavy-duty design accommodates high-pressure hoses and large volumes of fluid, making them crucial for businesses that require reliability and durability. Prospective buyers should weigh the initial investment against the long-term benefits of durability and efficiency in high-volume applications.

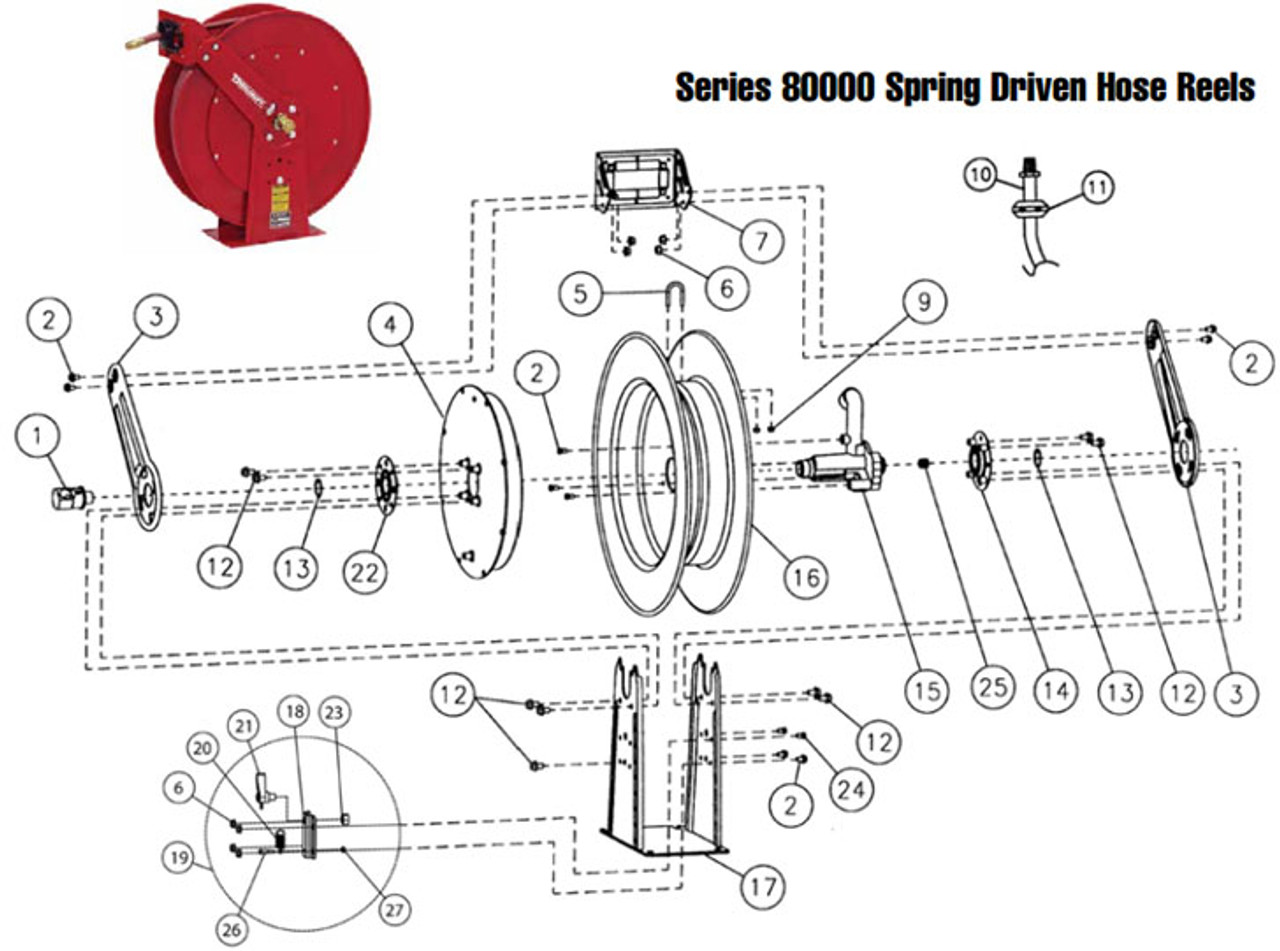

Illustrative image related to parts of a hose reel

Key Industrial Applications of parts of a hose reel

| Industry/Sector | Specific Application of parts of a hose reel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Irrigation systems using hose reels for efficient water distribution | Enhances crop yield through effective water management | Durability in harsh conditions, compatibility with local water systems |

| Construction | Supplying water for dust suppression and equipment cleaning | Reduces downtime and increases safety on construction sites | High-pressure tolerance, ease of mobility, and replacement part availability |

| Landscaping & Gardening | Hose reels for maintenance of green spaces and gardens | Improves operational efficiency and reduces labor costs | Lightweight design, ease of storage, and adaptability to various garden sizes |

| Automotive Services | Hose reels for car washing and maintenance | Streamlines service operations and enhances customer satisfaction | Quality of materials, length of hose, and ease of replacement parts |

| Fire Protection | Hose reels in firefighting equipment for quick access to water | Ensures rapid response in emergencies, enhancing safety | Compliance with safety standards, reliability under pressure, and quick availability of spare parts |

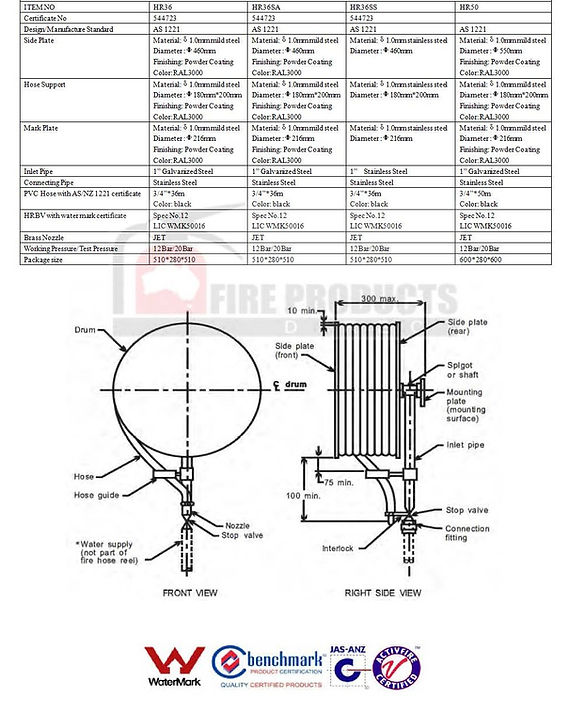

How Are Parts of a Hose Reel Utilized in Agriculture?

In the agricultural sector, hose reels are critical for irrigation systems. They enable the efficient distribution of water across large fields, significantly enhancing crop yield. Parts like the hose adapter and swivel connections ensure that water flows smoothly without leaks, while durable materials withstand harsh environmental conditions. Buyers from regions with extreme weather, such as parts of Africa and South America, must consider the durability and compatibility of these components with local water systems to ensure long-term effectiveness.

What Role Do Hose Reel Parts Play in Construction?

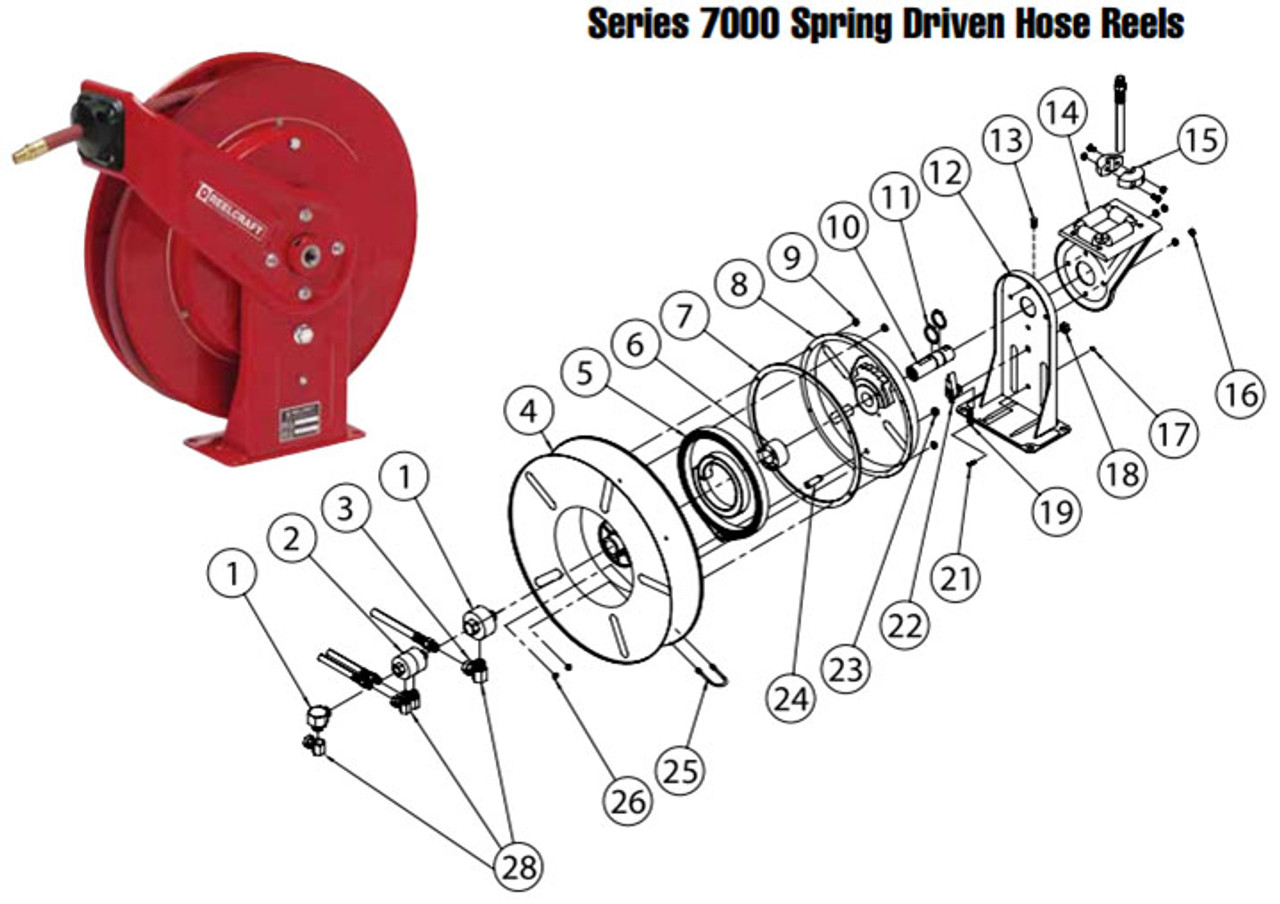

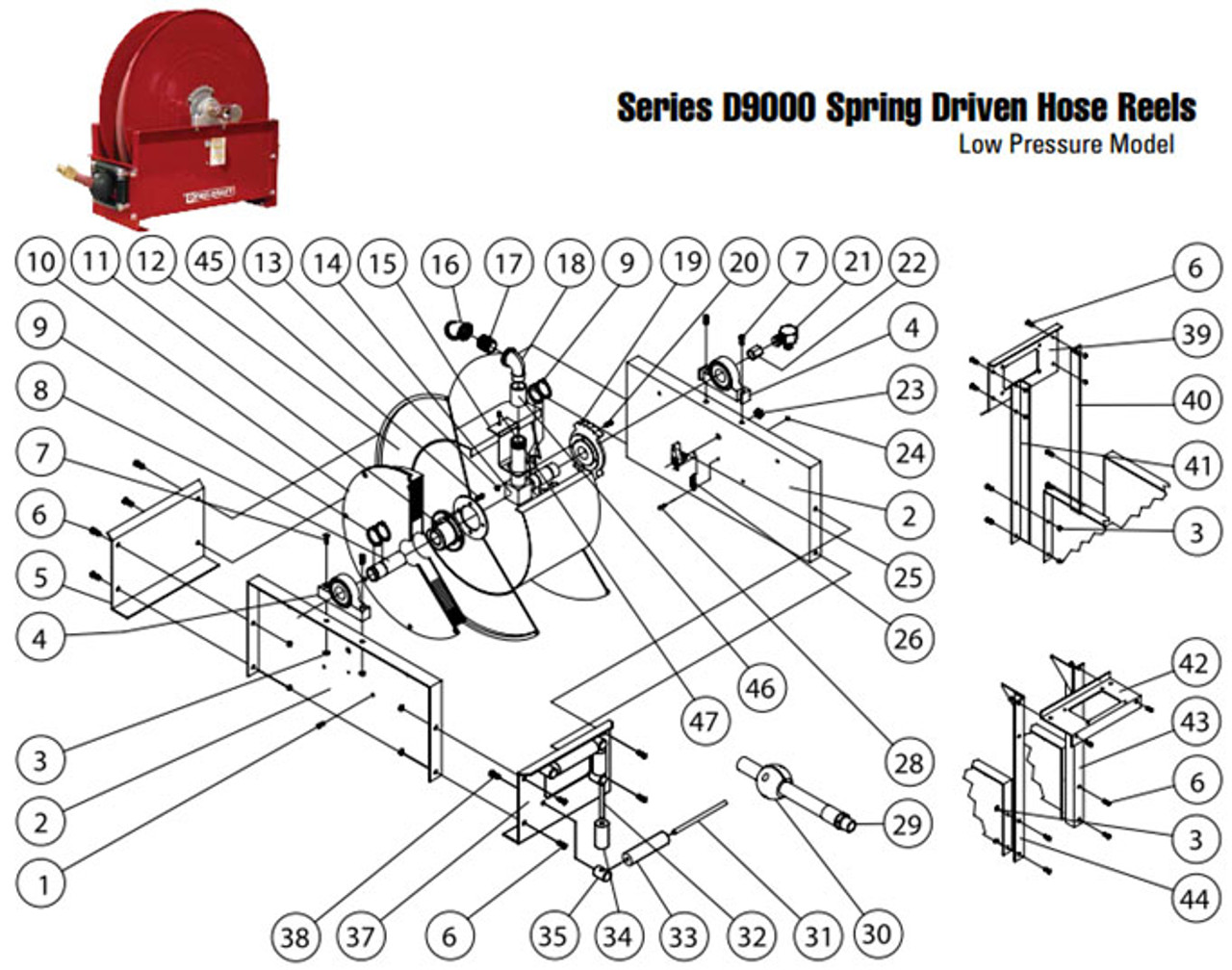

In construction, hose reels are employed for various applications, including dust suppression and equipment cleaning. The reliability of parts such as the reel locking pin and bearing assembly is vital to maintaining operational efficiency and ensuring safety on job sites. The ability to withstand high-pressure water is crucial in this sector. Buyers should prioritize sourcing from reputable manufacturers who offer high-quality parts to minimize the risk of downtime and enhance productivity.

How Are Hose Reel Parts Essential for Landscaping and Gardening?

For landscaping and gardening, hose reels simplify the maintenance of green spaces. They allow for easy access to water, making it more efficient to care for plants and lawns. Components such as drum plates and metal frames provide stability and ease of use. Buyers in Europe and the Middle East should look for lightweight designs that can be easily stored and transported, as well as adaptable models that fit various garden sizes and watering needs.

In What Ways Do Hose Reel Parts Benefit Automotive Services?

In automotive services, hose reels are crucial for car washing and maintenance operations. They streamline the process, allowing technicians to wash vehicles quickly and efficiently, which enhances customer satisfaction. Parts like the hose crank assembly and swivel seals ensure that hoses are retracted and extended smoothly. Buyers should focus on the quality of materials used in these parts, as well as the availability of replacements, to ensure ongoing service efficiency.

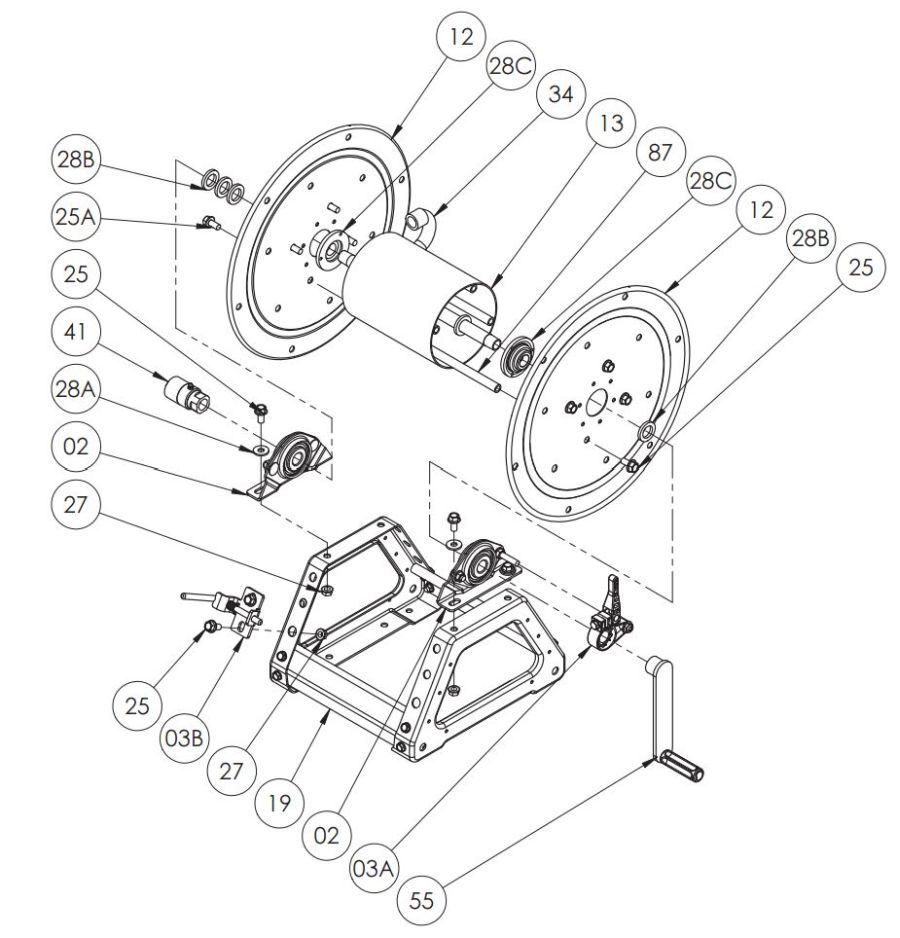

Illustrative image related to parts of a hose reel

Why Are Hose Reel Parts Important in Fire Protection?

Hose reels are integral to firefighting equipment, providing quick access to water in emergencies. The reliability of components, such as swivel seals and reel retaining rings, is essential for ensuring that the equipment functions correctly under pressure. International buyers, especially in regions prone to wildfires, must ensure that the parts comply with safety standards and can withstand extreme conditions, making sourcing from established manufacturers a priority.

3 Common User Pain Points for ‘parts of a hose reel’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Replacement Parts

The Problem:

B2B buyers often face significant challenges when sourcing high-quality replacement parts for hose reels. Many suppliers may offer a wide range of parts, but inconsistencies in quality can lead to premature failures or incompatibility with existing equipment. This issue is particularly pronounced in regions where supply chains may be disrupted or where local vendors may not stock the specific parts needed, leading to extended downtimes and increased operational costs.

The Solution:

To mitigate this problem, buyers should establish relationships with reputable suppliers who specialize in hose reel parts and have a proven track record of quality. Conducting thorough research online can help identify trusted manufacturers and distributors that provide detailed specifications and warranties for their products. It is advisable to request samples or small orders to evaluate the quality before committing to larger purchases. Additionally, leveraging platforms that consolidate multiple suppliers can provide a broader selection and facilitate comparisons, ensuring that buyers obtain the best possible components for their hose reels.

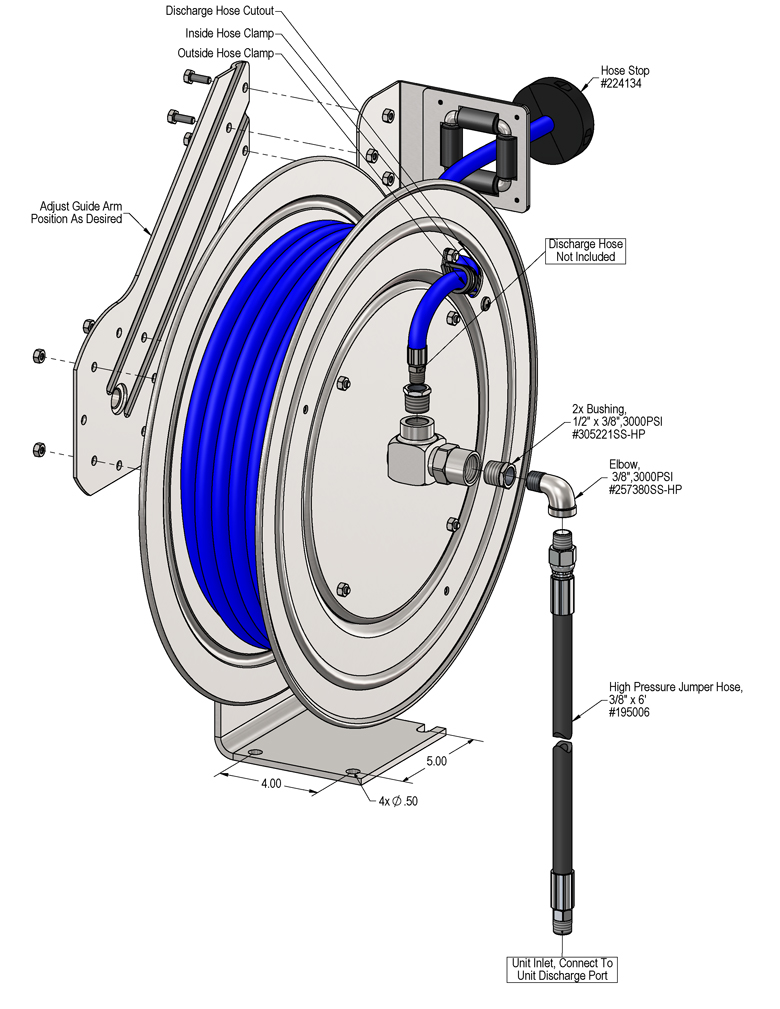

Illustrative image related to parts of a hose reel

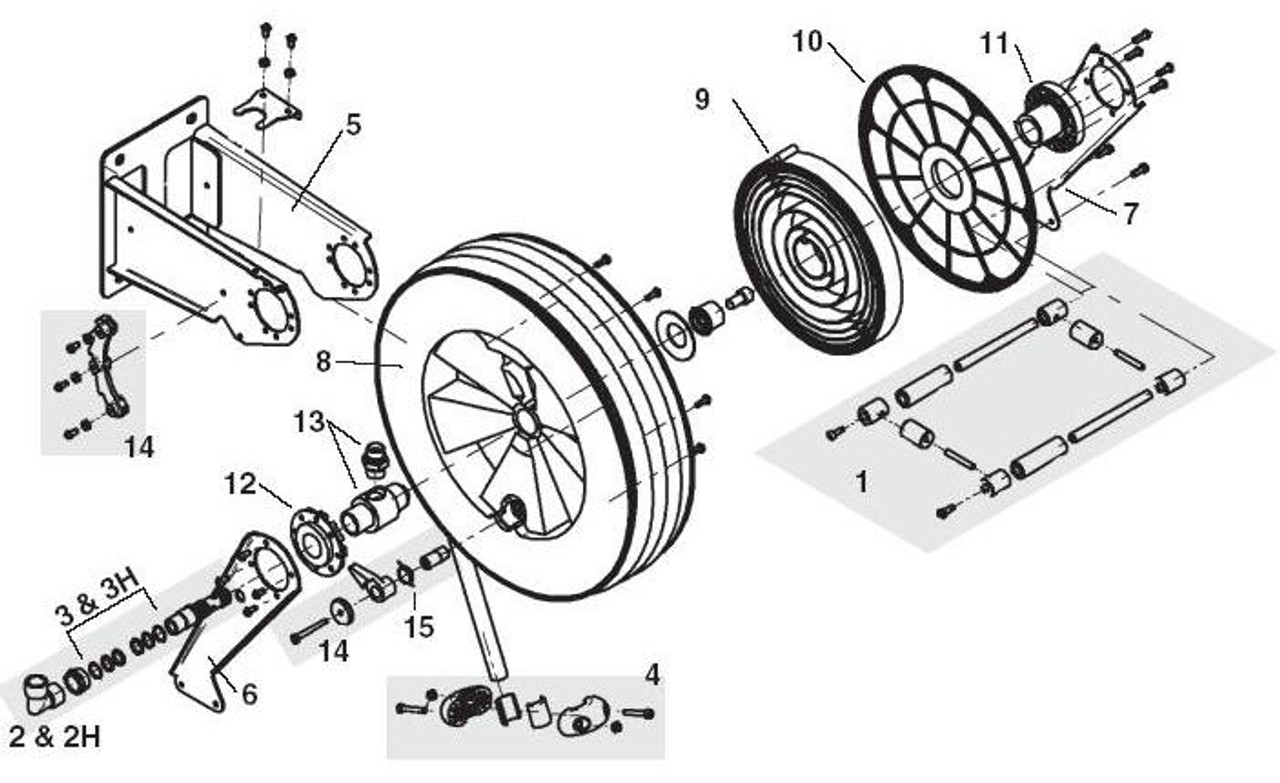

Scenario 2: Misalignment of Parts with Hose Reel Specifications

The Problem:

Another common issue faced by B2B buyers is the misalignment of replacement parts with their specific hose reel models. Different manufacturers may have varying designs and specifications for similar components, leading to frustration when parts do not fit or operate as expected. This can occur during routine maintenance or when a part needs replacing after a failure, resulting in delays and potentially halting operations.

The Solution:

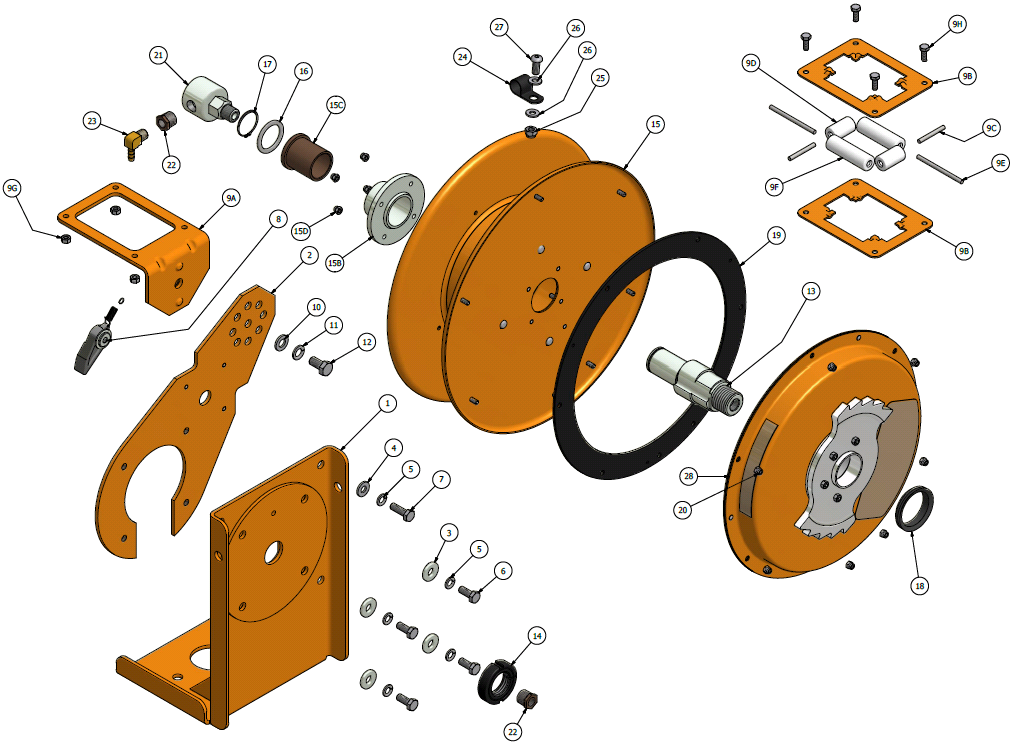

To avoid misalignment, it is crucial for buyers to maintain accurate records of their hose reel models, including serial numbers and specifications. When sourcing parts, they should refer to the manufacturer’s catalogs or websites, which often provide detailed diagrams and compatibility information. Buyers can also benefit from consulting with technical support teams from the suppliers to ensure they are ordering the correct components. Additionally, investing in an inventory management system that tracks parts and their specifications can streamline future orders and reduce the risk of errors.

Scenario 3: High Costs Associated with Replacement Parts

The Problem:

Cost is a significant concern for many B2B buyers, particularly when it comes to replacing parts for hose reels. Over time, frequent maintenance and replacement of worn components can accumulate high expenses, especially if parts are sourced from premium suppliers without exploring cost-effective alternatives. This financial strain can impact overall budget allocations and profitability, particularly for small to mid-sized enterprises.

The Solution:

To manage costs effectively, buyers should consider bulk purchasing agreements with suppliers, which can provide significant discounts on replacement parts. Additionally, exploring alternative brands that offer comparable quality at lower prices can also help. Regular maintenance and timely replacements of parts can prevent larger failures, ultimately saving costs in the long run. Implementing a preventive maintenance schedule can minimize wear and tear on components, thus extending their lifespan and reducing the frequency of replacements. Furthermore, buyers can participate in industry forums or groups where they can share experiences and recommendations about suppliers and parts, ensuring they make informed purchasing decisions.

Strategic Material Selection Guide for parts of a hose reel

When selecting materials for the various parts of a hose reel, it is essential to consider their properties, advantages, disadvantages, and suitability for specific applications. The choice of material can significantly influence the performance, durability, and cost-effectiveness of the hose reel, making it crucial for B2B buyers to understand the implications of their selections.

Illustrative image related to parts of a hose reel

What Are the Key Properties of Plastic in Hose Reel Components?

Plastic, particularly high-density polyethylene (HDPE) and polypropylene, is commonly used for various components of hose reels, including the drum plates and side plates. These materials are lightweight, resistant to moisture, and can withstand a range of temperatures.

Pros: Plastics are generally low-cost, easy to mold, and resistant to corrosion, making them suitable for outdoor applications. They are also less likely to rust compared to metal counterparts.

Cons: However, plastics may not withstand high temperatures or heavy mechanical stress as effectively as metals. They can also degrade over time when exposed to UV radiation unless treated.

Impact on Application: Plastic components are ideal for residential hose reels used in gardens or light commercial applications where exposure to water and moderate temperatures is expected.

Considerations for International Buyers: Buyers should ensure that the plastic materials comply with local regulations regarding environmental impact and safety standards. For instance, compliance with ASTM standards for plastic materials may be necessary in certain regions.

How Does Aluminum Compare for Hose Reel Parts?

Aluminum is another popular choice for hose reel components, especially for frames and structural parts. It boasts a high strength-to-weight ratio, excellent corrosion resistance, and the ability to withstand varying temperatures.

Pros: Aluminum is durable and lightweight, making it easy to transport and install. Its corrosion resistance is particularly beneficial in humid or coastal environments.

Cons: The primary drawback is that aluminum can be more expensive than plastic and may require more complex manufacturing processes such as welding or machining.

Illustrative image related to parts of a hose reel

Impact on Application: Aluminum is suitable for both residential and commercial hose reels, particularly in environments where durability and resistance to corrosion are critical.

Considerations for International Buyers: When sourcing aluminum parts, buyers should verify that the material meets international standards such as ASTM or ISO, particularly in regions like Europe where compliance is strictly enforced.

What Role Does Brass Play in Hose Reel Components?

Brass is often used in fittings and connectors due to its excellent corrosion resistance and mechanical properties. It is particularly effective in applications involving water and other fluids.

Illustrative image related to parts of a hose reel

Pros: Brass fittings provide a secure and leak-proof connection, are resistant to rust, and can handle high pressure and temperature variations.

Cons: Brass can be more expensive than plastic and aluminum, and its weight may be a consideration for portable hose reel designs.

Impact on Application: Brass is ideal for high-pressure applications and environments where durability and reliability are paramount, such as in industrial settings.

Illustrative image related to parts of a hose reel

Considerations for International Buyers: Buyers should check for compliance with local plumbing standards and regulations, particularly in regions with stringent quality requirements like the Middle East and Europe.

How Do Steel Components Enhance Hose Reel Durability?

Steel, particularly stainless steel, is used for heavy-duty hose reels and components requiring maximum strength and durability. Stainless steel offers excellent corrosion resistance and can withstand extreme temperatures.

Pros: Steel components are incredibly strong and can handle heavy loads, making them suitable for industrial applications. They also have a long lifespan when properly maintained.

Cons: The main disadvantages are the higher cost and weight compared to other materials. Steel components may also require protective coatings to prevent rust in humid environments.

Impact on Application: Steel is ideal for commercial and industrial hose reels, especially in environments where heavy usage and exposure to harsh conditions are expected.

Considerations for International Buyers: Buyers should ensure that the steel used complies with relevant standards such as ASTM A240 for stainless steel, particularly in regions with specific material requirements.

Illustrative image related to parts of a hose reel

Summary Table of Material Selection for Hose Reel Parts

| Material | Typical Use Case for parts of a hose reel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Drum plates, side plates | Lightweight, corrosion-resistant | Limited temperature tolerance | Low |

| Aluminum | Frames, structural components | High strength-to-weight ratio | Higher cost, complex manufacturing | Medium |

| Brass | Fittings, connectors | Excellent corrosion resistance | Higher cost, heavier weight | Medium |

| Steel | Heavy-duty components | Maximum strength and durability | Heavier, requires protective coating | High |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in hose reel parts, enabling informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for parts of a hose reel

What Are the Main Stages of Manufacturing Hose Reel Parts?

The manufacturing process for hose reel parts involves several critical stages, each essential for ensuring the final product meets quality standards and customer expectations. Understanding these stages helps B2B buyers appreciate the complexities involved and the importance of selecting reputable suppliers.

How Is Material Prepared for Hose Reel Parts?

The first stage in the manufacturing process is material preparation. This typically involves sourcing high-quality raw materials, such as steel, plastic, and rubber, which are essential for creating durable and functional hose reel components. Suppliers often rely on certified material vendors to ensure the quality and consistency of the materials.

Illustrative image related to parts of a hose reel

Once the materials are sourced, they undergo inspection to verify their compliance with required specifications. This may include checking for defects, measuring thickness, and testing tensile strength. After passing inspections, materials are cut and shaped into the required dimensions for further processing.

What Forming Techniques Are Used in Hose Reel Manufacturing?

The forming stage employs various techniques, depending on the material and the specific part being manufactured. Common methods include:

-

Injection Molding: Predominantly used for plastic components, this technique involves injecting molten plastic into a mold, allowing it to cool and solidify into the desired shape. This method is efficient for producing large volumes of identical parts, such as handles and side plates.

-

Stamping and Die-Cutting: For metal parts, stamping processes use dies to cut and shape metal sheets into specific forms, such as drum plates and supports. This method offers precision and is cost-effective for mass production.

-

Machining: Precision machining, including CNC (Computer Numerical Control) machining, is employed for parts requiring high accuracy, such as bearings and swivel mechanisms. This method allows for intricate designs and tight tolerances.

-

Welding and Assembly: After forming, components are often welded together or assembled using fasteners. This stage is crucial for ensuring structural integrity, particularly for parts like metal frames and carts.

What Finishing Techniques Enhance the Quality of Hose Reel Parts?

The finishing stage is vital for enhancing both the aesthetic appeal and functional performance of hose reel parts. Common finishing techniques include:

-

Surface Treatment: Techniques such as powder coating, galvanizing, or anodizing are used to protect metal parts from corrosion and wear. This is especially important for outdoor products exposed to various environmental conditions.

-

Polishing and Painting: For aesthetic components, polishing and painting may be applied to achieve a smooth finish and attractive appearance. This not only enhances the product’s look but also improves its resistance to wear and tear.

What Quality Assurance Practices Are Essential in Hose Reel Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that all parts meet the required standards before they reach the market. Implementing robust QA practices is essential for suppliers to build trust with B2B buyers.

Which International Standards Are Relevant for Hose Reel Parts?

International standards play a crucial role in the quality assurance of hose reel parts. The most relevant standards include:

-

ISO 9001: This standard outlines requirements for a quality management system (QMS) and is crucial for manufacturers aiming for consistent quality. Compliance with ISO 9001 demonstrates a commitment to quality and continuous improvement.

-

CE Marking: For products sold in the European market, CE marking indicates compliance with EU safety, health, and environmental protection standards. This is particularly relevant for hose reel parts that may be used in residential or commercial environments.

-

API Standards: For hose reels used in industrial applications, compliance with American Petroleum Institute (API) standards may be necessary, ensuring that the products can withstand demanding conditions.

What Are the Key Quality Control Checkpoints in Hose Reel Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to monitor and verify quality. Key checkpoints include:

-

Incoming Quality Control (IQC): This initial inspection verifies the quality of raw materials before they enter the production line. Ensuring that materials meet specifications helps prevent defects in the final product.

-

In-Process Quality Control (IPQC): During production, IPQC involves regular checks and tests at various stages. This may include monitoring machinery calibration, inspecting formed parts, and checking assembly accuracy.

-

Final Quality Control (FQC): Before shipment, FQC involves comprehensive testing of the finished hose reel parts. This may include functional testing, dimensional checks, and inspections for surface defects.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those in international markets like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is crucial for ensuring product reliability. Here are actionable steps buyers can take:

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request detailed audits and quality assurance reports from suppliers. These documents should outline:

- Quality Management Systems: Information about ISO certifications and adherence to international standards.

- Inspection Procedures: Details on IQC, IPQC, and FQC procedures, including any specific tests conducted on products.

- Non-Conformance Reports: Documentation of any quality issues that have arisen and how they were addressed.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can provide an additional layer of assurance. These independent organizations can conduct audits and inspections at various stages of production, offering unbiased assessments of the supplier’s quality control processes. Buyers should consider including third-party inspections in their procurement strategy, especially for high-value or mission-critical components.

What Nuances Should International Buyers Consider in Quality Control?

When dealing with international suppliers, buyers must navigate various quality control nuances:

-

Cultural Differences: Different regions may have varying approaches to quality and manufacturing practices. Understanding these cultural nuances can help buyers communicate effectively and set clear expectations.

-

Regulatory Compliance: Buyers should be aware of local regulations and standards that may impact product quality and safety in their markets.

-

Logistical Challenges: International shipping and handling can affect product quality. Buyers should consider suppliers with robust logistics and packaging solutions to minimize damage during transit.

In conclusion, understanding the manufacturing processes and quality assurance practices for hose reel parts is essential for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they procure high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts of a hose reel’

In the competitive landscape of B2B procurement, sourcing the right parts for hose reels requires a structured approach. This guide will help you navigate the essential steps to ensure you acquire quality components that meet your operational needs.

Step 1: Define Your Technical Specifications

Understanding the exact specifications of the hose reel parts you need is fundamental. Consider the type of hose reel (e.g., wall-mounted, free-standing, or portable) and the specific components required, such as drum plates, handles, or swivel seals. Accurate specifications help prevent compatibility issues and ensure that the parts function effectively in your applications.

Step 2: Research Reputable Suppliers

Identifying reliable suppliers is critical for ensuring the quality and availability of parts. Look for suppliers with a proven track record in the industry, focusing on those that specialize in hose reel components. Evaluate their online presence, customer reviews, and any certifications or awards that demonstrate their credibility.

Step 3: Verify Supplier Certifications

Before engaging with a supplier, confirm their certifications and compliance with international quality standards. This step is essential, particularly when sourcing from regions with varying regulations. Suppliers with ISO certification or similar endorsements often adhere to rigorous quality control processes, which can reduce the risk of receiving subpar parts.

Step 4: Request Samples or Detailed Product Specifications

Whenever possible, request samples or detailed specifications of the parts you intend to purchase. This allows you to assess the quality and suitability of the components firsthand. Pay attention to materials, dimensions, and finish, as these factors can significantly affect the performance and longevity of the hose reel.

Illustrative image related to parts of a hose reel

Step 5: Evaluate Pricing and Terms of Sale

While cost is an important factor, it should not be the sole criterion for your decision. Compare pricing across multiple suppliers but also consider the total cost of ownership, including shipping, warranties, and potential return policies. Understanding the terms of sale can help you avoid unexpected expenses down the line.

Step 6: Check for After-Sales Support and Warranty

A robust after-sales support system is crucial when dealing with parts procurement. Ensure that the supplier offers adequate support for installation, maintenance, and troubleshooting. Additionally, check the warranty terms on the parts, as a strong warranty can provide peace of mind and protect your investment.

Step 7: Establish a Communication Channel

Once you select a supplier, establish clear lines of communication. This relationship is vital for addressing any issues that may arise during the procurement process. Effective communication can also facilitate future orders and enable you to stay informed about new products or updates in the supplier’s inventory.

Illustrative image related to parts of a hose reel

By following these steps, you can streamline the sourcing process for hose reel parts, ensuring that you make informed decisions that align with your operational requirements and budget constraints.

Comprehensive Cost and Pricing Analysis for parts of a hose reel Sourcing

What Are the Key Cost Components in Hose Reel Parts Sourcing?

When sourcing parts for hose reels, understanding the cost structure is crucial for B2B buyers. The major cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

Materials: The choice of materials significantly influences cost. For example, brass fittings and high-grade plastics typically incur higher costs compared to standard metals or lower-quality plastics. Given the outdoor application of hose reels, durability and resistance to weather conditions are essential, justifying investment in quality materials.

Illustrative image related to parts of a hose reel

Labor: Labor costs vary based on the manufacturing location. Regions with higher labor costs will increase the overall price of components. Additionally, specialized labor for intricate parts can further elevate costs.

Manufacturing Overhead: This includes costs associated with utilities, maintenance, and factory operations. Efficient manufacturing processes can help reduce overhead, which may translate to lower prices for buyers.

Tooling: The initial investment in tooling for manufacturing specific parts can be significant. However, this cost is often amortized over larger production runs, affecting pricing structures.

Illustrative image related to parts of a hose reel

Quality Control: Implementing rigorous QC processes ensures that the parts meet specified standards. This is particularly important for buyers in regulated markets, as non-compliance can lead to costly returns or liabilities.

Logistics: Transportation costs play a vital role, especially for international buyers. Incoterms and freight options can significantly impact the total landed cost of parts.

Margin: Supplier margins can vary widely based on market conditions and competition. Understanding these margins can aid buyers in negotiating better prices.

What Influences Pricing for Hose Reel Parts?

Several factors influence the pricing of hose reel parts, including volume, specifications, material quality, and supplier reliability.

Volume/MOQ: Purchasing in bulk often leads to reduced unit prices. Suppliers may offer discounts for larger orders, making it essential for buyers to assess their needs accurately.

Specifications and Customization: Customized parts typically incur higher costs due to the need for specialized tooling and labor. Buyers should weigh the necessity of customization against the potential for cost savings with standard components.

Materials and Quality Certifications: Higher-grade materials and certifications (such as ISO or CE) can elevate prices but may be necessary for specific applications or markets. Buyers should consider the long-term benefits of investing in higher-quality components.

Supplier Factors: Established suppliers with a reputation for quality may command higher prices, while newer or lesser-known suppliers might offer lower costs but carry risks regarding reliability and service.

Illustrative image related to parts of a hose reel

Incoterms: Understanding Incoterms is critical for international buyers. The choice between FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect pricing and the total cost of ownership.

What Are Essential Negotiation and Cost-Efficiency Tips for Buyers?

Effective negotiation strategies can lead to significant savings. Here are some tips for B2B buyers:

-

Build Relationships: Establishing a rapport with suppliers can lead to better terms and pricing flexibility. Suppliers are often more willing to negotiate with trusted partners.

-

Request Multiple Quotes: Obtaining quotes from various suppliers enables buyers to compare costs and negotiate better deals.

-

Evaluate Total Cost of Ownership (TCO): Consider not only the purchase price but also factors like maintenance, replacement frequency, and potential downtime costs. A lower upfront cost may lead to higher long-term expenses.

-

Leverage Market Insights: Stay informed about market trends and pricing fluctuations. This knowledge can empower buyers during negotiations.

-

Understand Pricing Nuances for International Sourcing: Be mindful of currency fluctuations, tariffs, and import duties, which can affect overall costs. Local suppliers may offer more stable pricing compared to international sources.

Conclusion

Navigating the cost and pricing landscape for hose reel parts requires a strategic approach. By understanding the cost components, pricing influencers, and effective negotiation techniques, B2B buyers can make informed purchasing decisions that align with their operational needs and budget constraints. Remember, while indicative prices are useful for initial planning, thorough supplier discussions are essential for accurate pricing and optimal sourcing strategies.

Alternatives Analysis: Comparing parts of a hose reel With Other Solutions

Understanding Alternatives to Parts of a Hose Reel

When evaluating hose reel solutions, it’s crucial to consider not only the components of traditional hose reels but also alternative systems that can offer similar benefits. Different technologies can provide unique advantages, depending on the specific needs of the business. This analysis compares the essential parts of a hose reel against two viable alternatives: hose reel carts and automatic hose retractors.

Illustrative image related to parts of a hose reel

Comparison Table

| Comparison Aspect | Parts of a Hose Reel | Hose Reel Cart | Automatic Hose Retractor |

|---|---|---|---|

| Performance | Reliable for manual operation | High mobility; good for large areas | Automatic retraction; saves time |

| Cost | Moderate initial cost; variable parts | Generally higher due to wheels and frame | Higher upfront cost; low maintenance |

| Ease of Implementation | Simple setup; requires manual handling | Requires assembly and some space | Easy installation; minimal effort |

| Maintenance | Moderate; parts may wear over time | Moderate; wheels may need replacing | Low; minimal moving parts |

| Best Use Case | Small to medium gardens or properties | Large properties; areas needing mobility | Enclosed spaces; frequent use areas |

Detailed Breakdown of Alternatives

Hose Reel Cart

Hose reel carts are designed for portability and convenience, featuring wheels that allow for easy transportation across larger properties. Their performance excels in situations where flexibility is essential, such as watering gardens spread over vast areas. However, they require more space for storage and typically involve a higher initial investment due to their robust design. Maintenance is manageable but can include the need to replace wheels over time.

Automatic Hose Retractor

Automatic hose retractors offer the convenience of one-touch operation, automatically winding the hose back into its storage unit after use. This technology significantly reduces the time spent on hose management, making it ideal for busy commercial environments or facilities with high watering demands. While the upfront cost is generally higher compared to traditional hose reels, the lower maintenance requirements and efficiency gains can lead to long-term savings. However, the installation process might be more complex and may require professional assistance.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate hose management solution hinges on the specific requirements of your operation. For businesses with limited space or those needing a straightforward and reliable solution, traditional hose reels and their parts may suffice. However, if your operations demand mobility and ease of use across extensive areas, hose reel carts could provide the necessary flexibility. Conversely, for environments where efficiency and minimal manual handling are priorities, automatic hose retractors present a compelling option. Assessing your operational needs, budget constraints, and maintenance capabilities will guide you toward the best choice for your hose management solutions.

Essential Technical Properties and Trade Terminology for parts of a hose reel

What Are the Critical Technical Properties of Hose Reel Parts?

Understanding the technical properties of hose reel components is essential for B2B buyers to ensure they select durable, high-quality products that meet their specific operational needs. Here are several key specifications:

-

Material Grade

Hose reel parts are often made from materials like stainless steel, brass, or high-density polyethylene (HDPE). The material grade affects durability, corrosion resistance, and weight. For instance, stainless steel offers superior corrosion resistance, making it ideal for outdoor or humid environments. Selecting the right material ensures longevity and minimizes replacement costs. -

Tolerance Levels

Tolerance refers to the permissible limit of variation in a physical dimension. For hose reel parts, maintaining precise tolerances is crucial for ensuring that components fit together seamlessly, minimizing wear and tear. In manufacturing, tighter tolerances can lead to increased costs, but they often enhance performance and reliability, particularly in high-use applications. -

Load Capacity

This specification indicates the maximum weight a hose reel can handle without risk of damage or failure. It is vital for B2B buyers to choose a reel that can accommodate the weight of the hose and any additional pressure from water or other fluids. Underestimating load capacity can lead to premature failure and operational downtime. -

Pressure Rating

The pressure rating of hose reel parts indicates the maximum pressure that the components can withstand safely. This is particularly important for applications involving high-pressure water systems. Understanding the pressure requirements of your application ensures that the selected parts can handle operational demands, thus preventing leaks or ruptures. -

Finish and Coating

The finish on hose reel parts can significantly affect their resistance to corrosion and wear. Common finishes include powder coating, electroplating, or anodizing. A high-quality finish not only enhances aesthetic appeal but also contributes to the longevity of the equipment, especially in harsh environmental conditions.

What Common Trade Terms Should B2B Buyers Know About Hose Reel Parts?

Navigating the purchasing process for hose reel components involves understanding specific industry jargon. Here are some common terms you should be familiar with:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts that are used in another company’s end products. For buyers, purchasing OEM parts often means acquiring components that meet the original specifications and quality standards, ensuring compatibility and reliability. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for budget management and inventory planning. B2B buyers should evaluate their needs against the MOQ to avoid excess inventory or stock shortages. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products or services. This process is essential for comparing costs and ensuring that you receive competitive pricing for hose reel parts. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers, as they dictate shipping costs, insurance, and liability, impacting the total cost of acquiring hose reel parts. -

Lead Time

This term refers to the time taken from placing an order to receiving the product. Understanding lead times is important for project planning and inventory management, particularly in industries where downtime can be costly.

By familiarizing yourself with these technical properties and trade terms, you can make informed decisions that align with your operational goals and budgetary constraints, ensuring the reliability and efficiency of your hose reel systems.

Navigating Market Dynamics and Sourcing Trends in the parts of a hose reel Sector

What Are the Current Market Dynamics and Key Trends Affecting Hose Reel Parts?

The global market for hose reel parts is experiencing significant growth, driven by increasing demand for efficient water management solutions across various sectors, including agriculture, landscaping, and industrial applications. In regions like Africa and South America, where agriculture remains a key economic driver, the need for reliable irrigation systems is pushing the demand for durable hose reel components. Similarly, in the Middle East and Europe, the emphasis on water conservation is catalyzing investments in high-quality hose reels and their parts.

Emerging B2B technology trends include the rise of e-commerce platforms that facilitate seamless sourcing and procurement processes. Buyers are increasingly turning to online marketplaces to find replacement parts, benefiting from a wider selection and competitive pricing. Additionally, advancements in inventory management systems are allowing suppliers to optimize stock levels and reduce lead times, enhancing the overall efficiency of the supply chain.

Another trend is the integration of smart technologies into hose reel systems, with IoT-enabled devices providing real-time monitoring and control over water usage. This tech-driven approach not only supports efficient resource management but also aligns with the sustainability goals of many organizations, making it a crucial consideration for international buyers seeking innovative solutions.

How Is Sustainability Shaping Sourcing Decisions in the Hose Reel Parts Market?

Sustainability is becoming a cornerstone of sourcing strategies in the hose reel parts sector. As global awareness of environmental issues rises, B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and sustainable practices. The environmental impact of manufacturing processes and materials used in hose reel parts is under scrutiny, prompting companies to seek out manufacturers who utilize recycled materials and environmentally friendly production methods.

Moreover, certifications such as ISO 14001 for environmental management systems and the use of eco-labels can influence purchasing decisions. Buyers are more likely to partner with suppliers who can provide proof of their commitment to sustainability, which can enhance brand reputation and customer loyalty.

The shift towards ‘green’ materials—such as biodegradable plastics or sustainably sourced metals—is another key trend. These materials not only reduce the ecological footprint but also cater to the growing consumer demand for environmentally responsible products. Consequently, international buyers from regions like Europe, where regulatory frameworks are increasingly stringent regarding environmental impacts, are particularly vigilant about sourcing practices.

What Is the Historical Context of Hose Reel Parts Development?

The evolution of hose reel parts can be traced back to the early days of gardening and agriculture when manual tools were the norm. Initially, hose reels were simple mechanical devices designed to keep hoses organized and easily accessible. Over the decades, advancements in materials science and engineering led to the development of more sophisticated designs that enhanced durability and usability.

In the latter half of the 20th century, the introduction of high-quality plastics and metals revolutionized hose reel manufacturing, making them lighter, more resilient, and easier to transport. The rise of automation and smart technologies in recent years represents the latest chapter in this evolution, allowing for innovations that improve efficiency and water management capabilities.

Understanding this historical context is vital for B2B buyers as it highlights the importance of selecting suppliers who not only provide high-quality parts but also innovate in response to changing market demands and technological advancements.

Frequently Asked Questions (FAQs) for B2B Buyers of parts of a hose reel

-

1. How do I solve common issues with hose reel parts?

To address issues with hose reel parts, begin by identifying the specific problem, such as leaks, difficulty in winding, or damaged components. Inspect the hose adapter, seals, and bearings, as these are frequent culprits. Replacing worn-out parts, ensuring proper lubrication, and maintaining a clean reel can help. If issues persist, consult the manufacturer’s specifications for troubleshooting guidelines, or reach out to your supplier for support. Regular maintenance and timely replacement of components can prevent most common problems. -

2. What is the best type of hose reel for commercial use?

For commercial applications, heavy-duty hose reels designed for high-frequency use are ideal. Consider models with robust metal frames, corrosion-resistant materials, and a capacity suitable for longer hoses. Free-standing or cart-style hose reels offer mobility, while wall-mounted options save space. Evaluate the working environment and hose length to determine the most efficient design. Additionally, look for features such as easy winding mechanisms and quick-connect fittings to enhance usability and efficiency. -

3. What factors should I consider when sourcing hose reel parts internationally?

When sourcing hose reel parts internationally, consider factors such as supplier reliability, quality certifications, and compliance with international standards. Research the supplier’s reputation through reviews and testimonials. Evaluate shipping costs and lead times to ensure timely delivery. Additionally, understand the payment terms and currency exchange implications. It’s beneficial to establish clear communication channels and confirm that the supplier can accommodate your specific needs, including customization and bulk orders. -

4. How can I vet a supplier for hose reel parts?

To vet a supplier for hose reel parts, conduct thorough research to assess their experience and industry standing. Request references from previous clients and check for certifications such as ISO or other relevant quality assurances. Evaluate their product range and the availability of parts for your specific hose reel models. Additionally, initiate contact to gauge their responsiveness and willingness to address your inquiries. A supplier’s transparency regarding pricing, lead times, and returns policy is also crucial for establishing a trustworthy partnership. -

5. Are there minimum order quantities (MOQs) for hose reel parts?

Minimum order quantities (MOQs) for hose reel parts vary by supplier and can depend on the specific part being ordered. Some suppliers may set MOQs to ensure cost-effectiveness, particularly for customized or specialized components. It’s advisable to discuss your requirements directly with potential suppliers to negotiate terms that suit your purchasing needs. Smaller businesses may benefit from suppliers offering flexible MOQs, allowing for lower initial orders while building a relationship. -

6. What payment terms are commonly offered for international B2B transactions?

Common payment terms for international B2B transactions include options such as advance payment, letters of credit, and payment upon delivery. Many suppliers may require a deposit upfront, followed by the balance upon shipment. Some may offer net terms (e.g., net 30 or net 60), allowing buyers to pay within a specified period after receiving the goods. Always clarify payment methods accepted (e.g., wire transfer, credit card) and ensure that terms are documented in the purchase agreement to avoid misunderstandings. -

7. How can I ensure quality assurance (QA) for the parts I purchase?

To ensure quality assurance for hose reel parts, request detailed specifications and certifications from your supplier. Implement a quality control process that includes inspecting parts upon arrival for damage and verifying compliance with your requirements. Establish clear criteria for acceptable quality levels and communicate these to your supplier. Consider conducting periodic audits of the supplier’s production processes or requesting samples before placing large orders to ensure that the components meet your standards. -

8. What logistics considerations should I keep in mind when ordering hose reel parts?

When ordering hose reel parts, logistics considerations include shipping methods, costs, and timelines. Assess whether the supplier offers door-to-door delivery or if you need to arrange for pick-up. Factor in customs duties, import regulations, and potential delays at border crossings, especially when sourcing from outside your region. It’s also wise to confirm the supplier’s packaging standards to prevent damage during transit. Planning for contingencies can help mitigate risks associated with logistics and ensure a smooth procurement process.

Top 6 Parts Of A Hose Reel Manufacturers & Suppliers List

1. Yard Butler – Essential Replacement Parts

Domain: yardbutler.com

Registered: 2002 (23 years)

Introduction: [{‘name’: ‘S-Pipe Replacement Part’, ‘price’: 32.0}, {‘name’: ‘Buna-N Shore O-Ring for S-PIPE’, ‘price’: 12.0}, {‘name’: ‘1.010″ I.D. Nylon Bearing (3 pcs)’, ‘price’: 11.0}, {‘name’: ‘Inlet pipe for HT-2EZ’, ‘price’: 32.0}, {‘name’: ‘ISR-360 Mid Post’, ‘price’: 57.0}, {‘name’: ‘Lock Mechanism’, ‘price’: 20.0}, {‘name’: ‘Leader Hose’, ‘price’: 14.0}, {‘name’: ‘Replacement fittings for SR-360 & SRPB…

2. Access Truck Parts – Hose Reel Parts

Domain: accesstruckparts.com

Registered: 2008 (17 years)

Introduction: Hose Reel Parts for Water Trucks available online at Access Truck Parts. Key products include: 1. Brass Nitrile Seal Swivel – SKU: 294-20288, Price: $79.95 2. Viton™ Seal Swivel – SKU: 294-20288, Price: $79.95 3. Nitrile Swivel Seal Kit – SKU: 294-20288-KIT, Price: $24.95 4. Reel Retaining Ring – SKU: 294-20252, Price: $3.00 5. Bearing Assembly (Rev A) – SKU: 294-8166, Price: $99.95 6. Reel Washer…

3. UnitedBuilt Equipment – Hose Reel Parts

Domain: watertrucks.com

Registered: 1997 (28 years)

Introduction: Hose Reel Parts – UnitedBuilt Equipment. In Stock, Top Quality, Ships in 1 Day! Order by 2PM MST. Product categories include: Adapter Plug, Air Fitting, Air Switch, Airline Anode, Axle Assembly, Ball Bearing, Ball Valve, Beacon Light, Bearing Assembly, Bearing Cap, Blind Flange, Bolt, Brake Knob, Brake Spring, Brake Stud, Brass Fitting, Bulkhead Fitting, Bushing, Butterfly Valve, Camlock, Cannon H…

4. T&S Brass – Hose Reel Parts

Domain: tsbrass.com

Registered: 1996 (29 years)

Introduction: Hose Reel Parts from T&S Brass include various components designed for washdown solutions. Key features include durable construction, compatibility with different hose reel models, and ease of installation. The parts are engineered to withstand harsh environments and provide reliable performance for commercial and industrial applications.

5. Suncast – Hose Reel Replacement Parts

Domain: support.suncast.com

Registered: 1996 (29 years)

Introduction: Suncast Hose Reel Replacement Parts Installation guidance, including video tutorials for removing and installing basic elements. Support available via phone (1-800-846-2345) Monday to Friday, 7:30 AM to 6:00 PM CST.

6. Hannay – Hose Reel Motors & Parts

Domain: northridgefire.com

Registered: 2018 (7 years)

Introduction: Hannay Hose Reel Parts & Accessories include various components such as: 12V DC Flange 2/3 HP Hose Reel Motor ($551.95), 12V DC Flange 1/2 HP Hose Reel Motor ($474.95), HANNAY 9915.0042 1/3HP Motor P56AN227 ($414.95), 24V DC Face Mount 1/3 HP Hose Reel Motor ($343.95), Hannay 9939.0033 FH-3 Roller Set for 24 Series Reel ($175.95), Wildland Mount for MC40 or MC65 Hose Coilers ($157.95), Trailer Hit…

Strategic Sourcing Conclusion and Outlook for parts of a hose reel

As businesses increasingly recognize the importance of efficient resource management, strategic sourcing for hose reel parts emerges as a critical component in optimizing operations. By investing in quality replacement parts, buyers can ensure longevity and reliability in their hose reel systems, reducing downtime and maintenance costs. The diverse range of parts available—from drum plates to swivel seals—allows for tailored solutions that meet specific operational needs, particularly in diverse markets such as Africa, South America, the Middle East, and Europe.

In a competitive landscape, leveraging strategic sourcing not only enhances product quality but also fosters stronger supplier relationships. Buyers are encouraged to prioritize suppliers who offer comprehensive support, including warranties and easy access to replacement parts. This proactive approach not only streamlines procurement but also secures a competitive advantage in the marketplace.

Looking ahead, businesses should stay attuned to emerging trends in hose reel technology and sourcing strategies. By integrating innovative solutions and sustainable practices, international buyers can position themselves for success in an ever-evolving market. Now is the time to assess your sourcing strategies and partner with trusted suppliers to ensure your hose reel systems are equipped for the future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.