A B2B Buyer’s Guide to Nema Plug Chart Twist Lock: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for nema plug chart twist lock

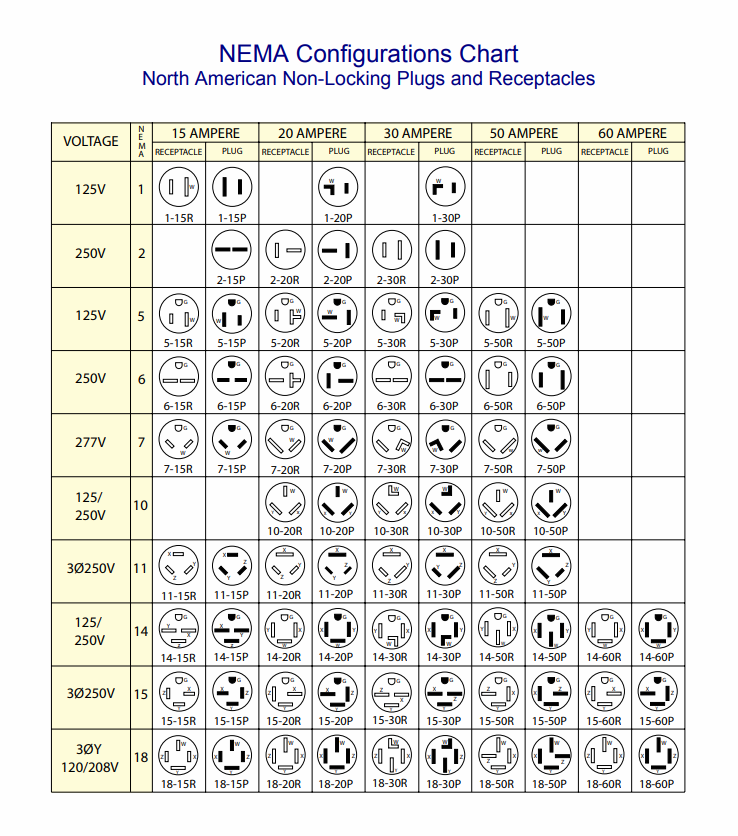

In today’s rapidly evolving global market, sourcing reliable NEMA plug chart twist lock solutions can pose significant challenges for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. With various configurations, voltage ratings, and amperage specifications, the complexity can be overwhelming. This guide aims to simplify the process by providing a comprehensive overview of the different types of twist lock plugs and their applications across diverse industries, from construction to manufacturing and beyond.

Buyers will gain insights into essential considerations such as compatibility, safety standards, and regional regulations that impact purchasing decisions. We will also explore supplier vetting strategies to ensure quality and reliability, as well as factors influencing cost, allowing for informed negotiations. By equipping B2B buyers with this knowledge, we empower them to make strategic choices that enhance operational efficiency and safety.

Navigating the intricacies of NEMA twist lock plugs is no small feat, but with this guide, buyers can confidently approach their sourcing needs. Whether you are in Vietnam, Saudi Arabia, or elsewhere, understanding the nuances of these electrical connections will ultimately lead to better purchasing outcomes and a more robust supply chain.

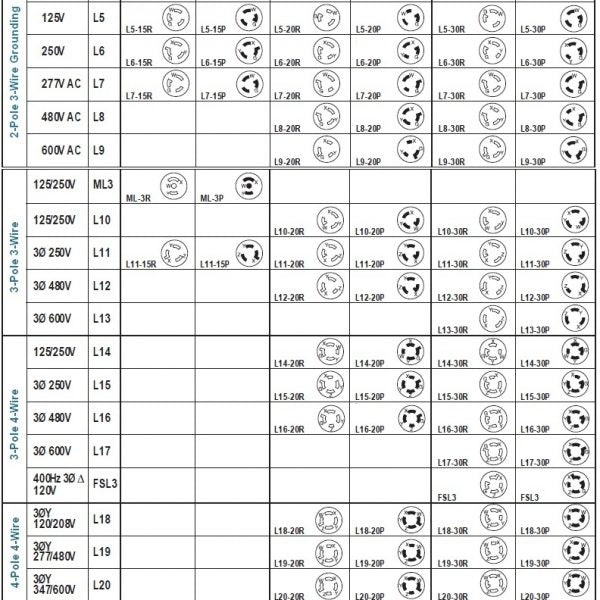

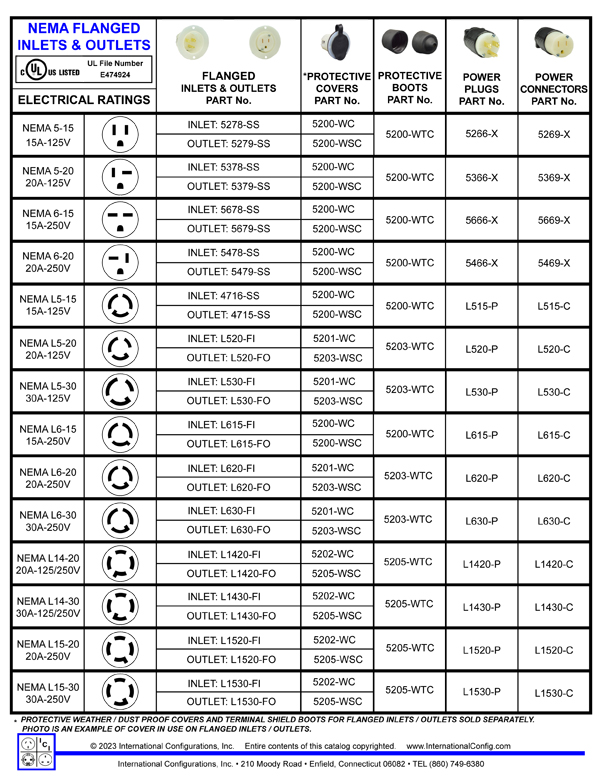

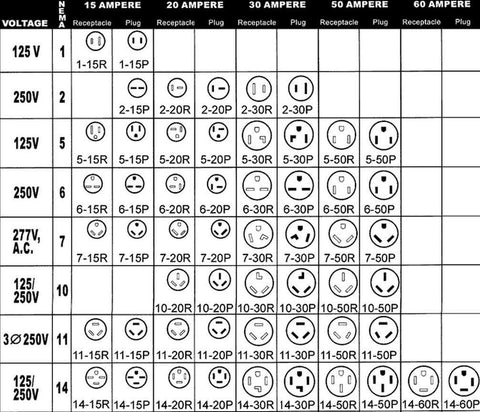

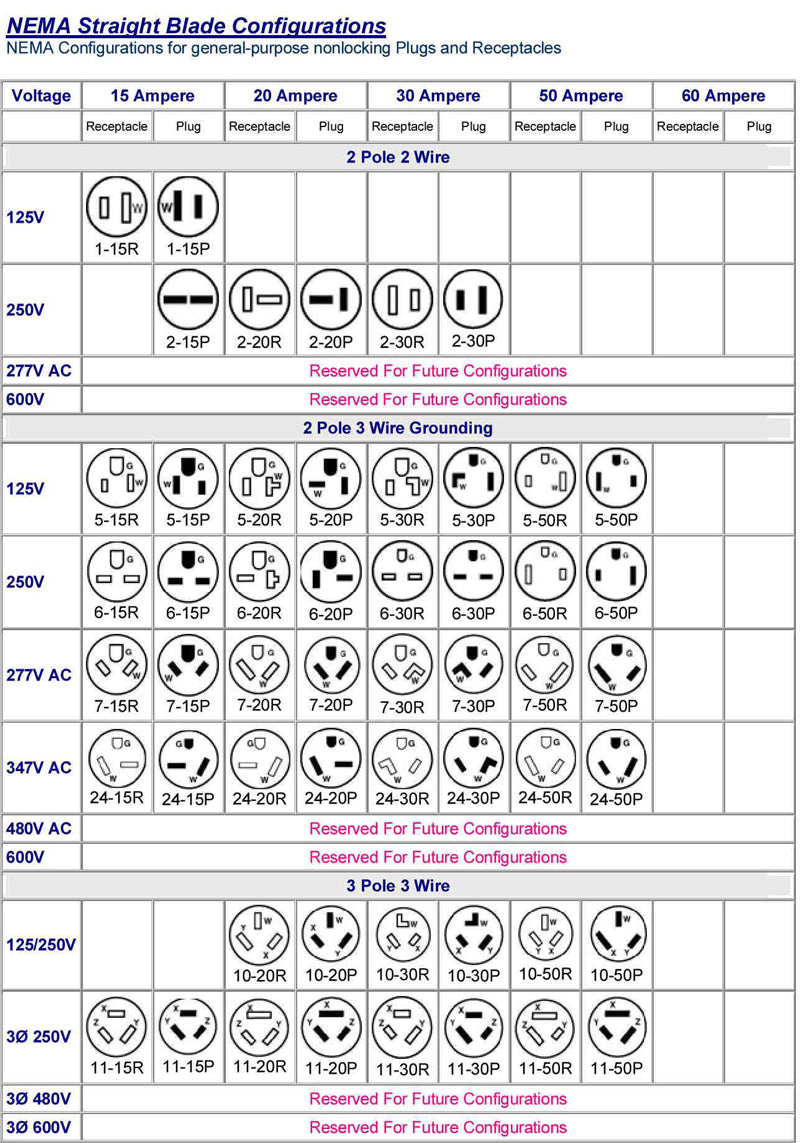

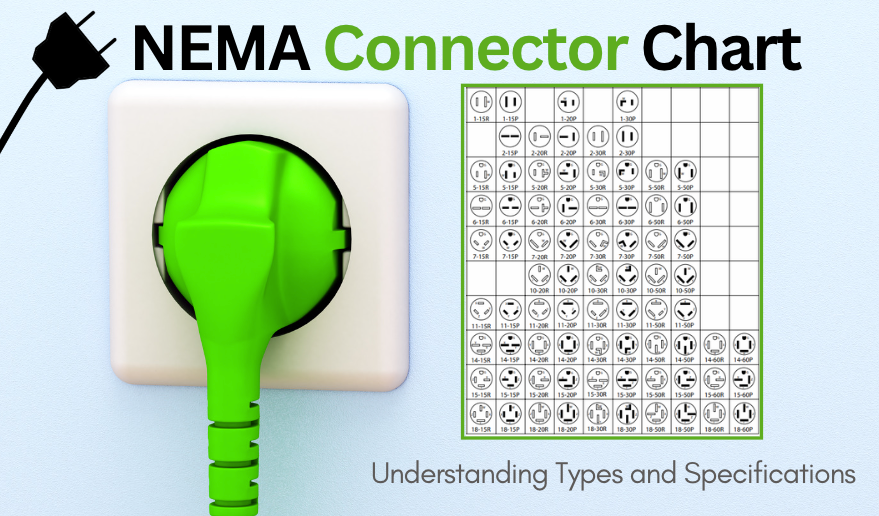

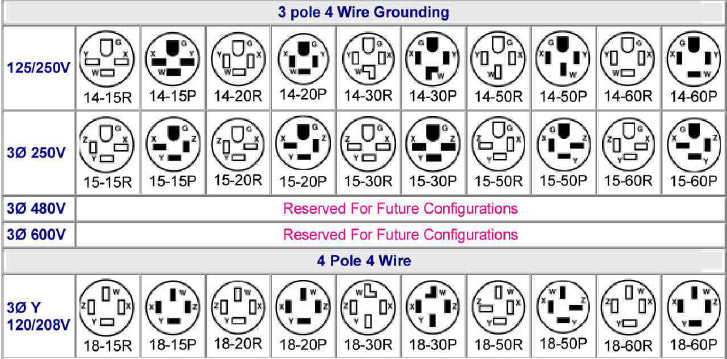

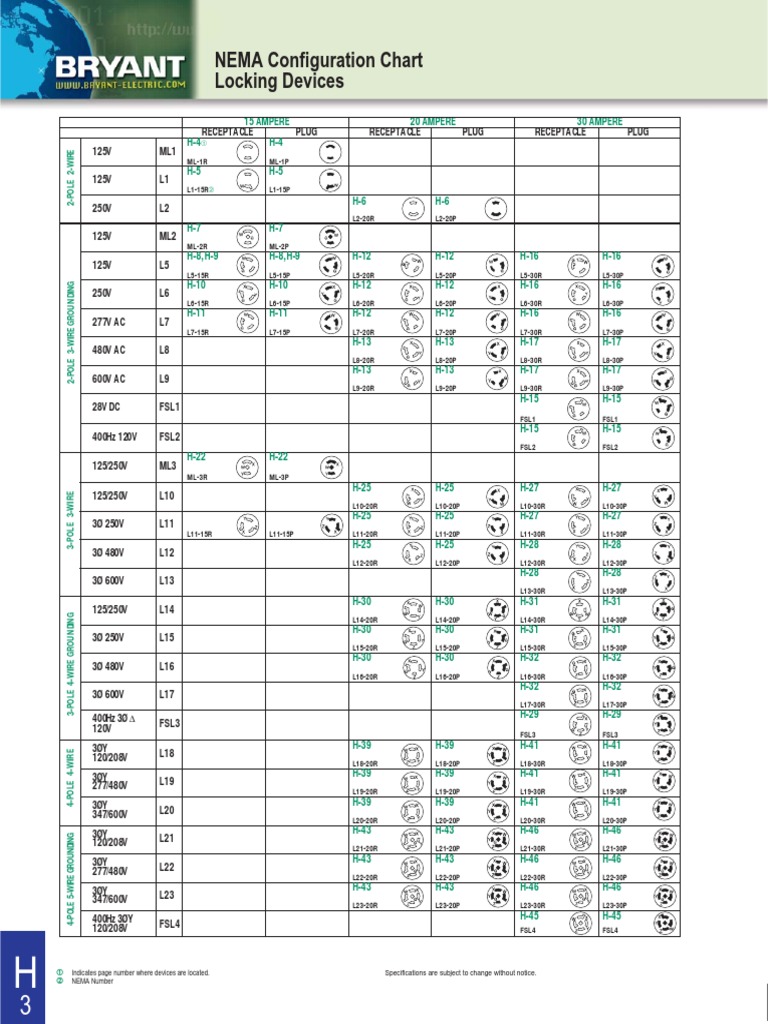

Understanding nema plug chart twist lock Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| NEMA L5-15 | 125V AC, 15 amps, 3 wires, 2 poles | General-purpose electrical equipment | Pros: Versatile, widely available. Cons: Limited to lower amperage applications. |

| NEMA L6-20 | 250V AC, 20 amps, 3 wires, 2 poles | Industrial machinery, HVAC systems | Pros: Higher voltage capacity. Cons: Requires compatible infrastructure. |

| NEMA L14-50 | 125/250V AC, 50 amps, 4 wires, 3 poles | Heavy machinery, commercial power needs | Pros: High amperage, versatile. Cons: Bulkier, may require more space for installation. |

| NEMA L8-30 | 480V AC, 30 amps, 3 wires, 2 poles | High-power industrial applications | Pros: Suitable for heavy-duty use. Cons: Limited availability in some regions. |

| NEMA L23-60 | 3ØY 347/600V AC, 60 amps, 5 wires, 4 poles | Large-scale industrial systems | Pros: High capacity for three-phase systems. Cons: Complexity in installation and compatibility. |

What are the Characteristics of NEMA L5-15 Plugs?

The NEMA L5-15 plug is a common choice for general-purpose electrical equipment, rated for 125V AC and 15 amps. It features three wires and two poles, making it suitable for a variety of applications in both commercial and residential settings. Its wide availability and versatility make it a go-to option for B2B buyers seeking reliable power connections. However, it is limited to lower amperage applications, which may not meet the needs of heavy machinery.

Illustrative image related to nema plug chart twist lock

How Does NEMA L6-20 Differ for Industrial Use?

NEMA L6-20 plugs are designed for more demanding environments, operating at 250V AC with a capacity of 20 amps. They are commonly used in industrial machinery and HVAC systems, where higher voltage and amperage are necessary. While they provide a robust solution for powering equipment, buyers must ensure their infrastructure can support this type of plug, as compatibility issues may arise with older systems.

What Makes NEMA L14-50 Ideal for Heavy Machinery?

The NEMA L14-50 plug is rated for both 125/250V AC and 50 amps, making it a preferred choice for heavy machinery and commercial power needs. This plug’s four-wire configuration allows for versatile applications, accommodating various equipment types. While its high amperage capacity is a significant advantage, buyers should consider the physical space required for installation, as these plugs tend to be bulkier than their lower-rated counterparts.

Why Choose NEMA L8-30 for High-Power Applications?

The NEMA L8-30 plug, rated at 480V AC and 30 amps, is well-suited for high-power industrial applications. Its design allows for the efficient transfer of electricity to heavy-duty equipment, making it a reliable choice for manufacturers and large-scale operations. However, its limited availability in some regions may pose challenges for international buyers, necessitating a thorough search for compatible suppliers.

Illustrative image related to nema plug chart twist lock

How Does NEMA L23-60 Support Large-Scale Industrial Systems?

The NEMA L23-60 plug is engineered for large-scale industrial systems, featuring a rating of 3ØY 347/600V AC and 60 amps. Its five-wire configuration supports three-phase systems, which are crucial for heavy industrial machinery. While this plug offers high capacity and efficiency, the complexity of installation and the need for compatible infrastructure can be a barrier for some businesses. Buyers should evaluate their operational needs and existing electrical systems before making a purchase.

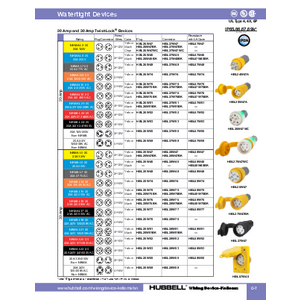

Key Industrial Applications of nema plug chart twist lock

| Industry/Sector | Specific Application of nema plug chart twist lock | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Temporary power distribution for site equipment | Ensures reliable power supply for heavy machinery and tools | Compliance with local electrical standards and safety regulations |

| Entertainment & Events | Powering lighting and sound equipment at venues | Provides secure and stable connections for high-load equipment | Availability of various NEMA configurations for different power needs |

| Manufacturing | Connecting machinery in assembly lines | Enhances operational efficiency and reduces downtime | Durability and compatibility with existing equipment standards |

| Oil & Gas | Powering drilling rigs and equipment in remote locations | Facilitates safe and efficient operations in harsh environments | Resistance to environmental factors and high amperage ratings |

| Agriculture | Electrical supply for irrigation systems | Supports efficient water management and crop production | Weatherproof designs and compliance with agricultural standards |

How is ‘NEMA Plug Chart Twist Lock’ Used in Construction?

In the construction industry, NEMA twist lock plugs are essential for establishing temporary power distribution systems at job sites. These plugs ensure a secure connection for heavy machinery and tools, which is crucial for maintaining productivity. The robust design of twist lock plugs minimizes the risk of accidental disconnection, especially in high-traffic environments. Buyers must consider local electrical codes and safety regulations when sourcing these plugs to ensure compliance and operational safety.

What Role Does ‘NEMA Plug Chart Twist Lock’ Play in Entertainment & Events?

In the entertainment sector, NEMA twist lock plugs are widely utilized to power lighting and sound equipment at events and venues. Their secure locking mechanism prevents accidental disconnections, ensuring that high-load equipment operates smoothly throughout performances. This reliability is vital for event success, as power interruptions can lead to significant financial losses. Buyers should look for plugs that offer various configurations to meet the diverse power requirements of different equipment.

How Does ‘NEMA Plug Chart Twist Lock’ Enhance Manufacturing Operations?

Manufacturers use NEMA twist lock plugs to connect machinery on assembly lines, enhancing operational efficiency. These plugs provide a stable electrical connection, which is critical for minimizing downtime caused by power disruptions. Additionally, their durability ensures they can withstand the rigors of a manufacturing environment. When sourcing, businesses should prioritize plugs that meet industry standards for compatibility with existing machinery to streamline integration.

Why is ‘NEMA Plug Chart Twist Lock’ Important in Oil & Gas Operations?

In the oil and gas industry, NEMA twist lock plugs are critical for powering drilling rigs and equipment located in remote areas. These plugs are designed to handle high amperage and provide reliable connections, essential for operations in harsh conditions. The safety and efficiency of drilling operations depend on the reliability of electrical connections. Buyers should focus on sourcing plugs that are resistant to environmental factors and meet the demanding standards of the oil and gas sector.

Illustrative image related to nema plug chart twist lock

How is ‘NEMA Plug Chart Twist Lock’ Utilized in Agriculture?

Agricultural operations often rely on NEMA twist lock plugs for powering irrigation systems and other electrical equipment. These plugs facilitate efficient water management, which is vital for crop production and sustainability. The secure connection ensures that irrigation systems operate without interruptions, which can be detrimental to crop health. Buyers should consider weatherproof designs and compliance with agricultural standards to ensure longevity and reliability in outdoor applications.

3 Common User Pain Points for ‘nema plug chart twist lock’ & Their Solutions

Scenario 1: Sourcing the Correct NEMA Plug Configuration

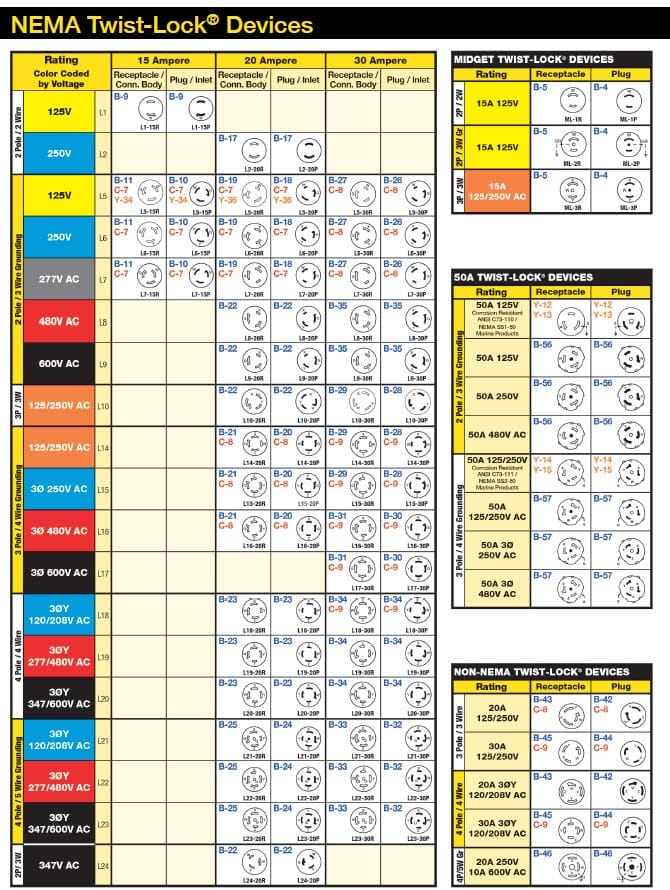

The Problem: In the diverse markets of Africa and South America, many B2B buyers encounter challenges in sourcing the correct NEMA plug configuration for their specific electrical applications. The variety of NEMA twist lock configurations—ranging from L1-15 to L23-60—can be overwhelming. Buyers may find themselves confused about which configuration matches their voltage and amperage needs, leading to potential errors in ordering and costly project delays. This is particularly problematic when dealing with equipment requiring specific power ratings, as mismatched plugs can result in equipment failure or safety hazards.

The Solution: To navigate this complexity, B2B buyers should first invest time in understanding the NEMA locking reference chart. This chart provides detailed information about the voltage, amperage, and pin configuration for each plug type. Buyers can leverage this resource by cross-referencing their equipment specifications with the chart to ensure they select the appropriate plug. Additionally, consulting with suppliers who have expertise in NEMA configurations can provide clarity and confidence in decision-making. Establishing a strong relationship with reliable suppliers who can offer technical support and advice can further enhance the buying experience and minimize the risk of errors.

Scenario 2: Ensuring Compatibility with International Standards

The Problem: International B2B buyers often face compatibility issues when sourcing NEMA plugs due to variations in electrical standards across regions. For example, a company based in the Middle East may import equipment designed for North American markets that utilize NEMA plugs, only to discover that the local electrical infrastructure does not support these configurations. This mismatch can lead to costly modifications and delays in project timelines, frustrating buyers who need seamless integration for their operations.

The Solution: To prevent compatibility issues, B2B buyers should conduct thorough research on the electrical standards applicable in their region and ensure that any NEMA plugs sourced align with those requirements. Utilizing international standards organizations’ resources can provide valuable insights into local regulations. Additionally, buyers should consider investing in adapters or converters that can bridge the gap between different plug types. By incorporating flexibility in their sourcing strategy, such as including multi-standard plugs that can accommodate various configurations, companies can streamline their operations and reduce the risks of equipment incompatibility.

Illustrative image related to nema plug chart twist lock

Scenario 3: Understanding Safety and Compliance Regulations

The Problem: Safety is a paramount concern for B2B buyers when it comes to electrical components like NEMA twist locks. Many regions, including Europe and the Middle East, have stringent safety regulations that require compliance with specific standards. Buyers may struggle to ensure that the NEMA plugs they select not only meet operational needs but also adhere to local safety codes. Non-compliance can result in significant legal liabilities, fines, and damage to reputation.

The Solution: To address safety and compliance concerns, buyers should prioritize sourcing NEMA plugs that are certified by recognized safety organizations, such as UL (Underwriters Laboratories) or CE (Conformité Européenne). This certification indicates that the products have undergone rigorous testing for safety and performance. Buyers should also familiarize themselves with local compliance requirements by consulting industry guidelines or engaging with compliance experts. Regular training and updates on safety standards for their teams will empower buyers to make informed decisions and foster a culture of safety within their organizations. By prioritizing compliance, buyers can mitigate risks and enhance the overall reliability of their electrical systems.

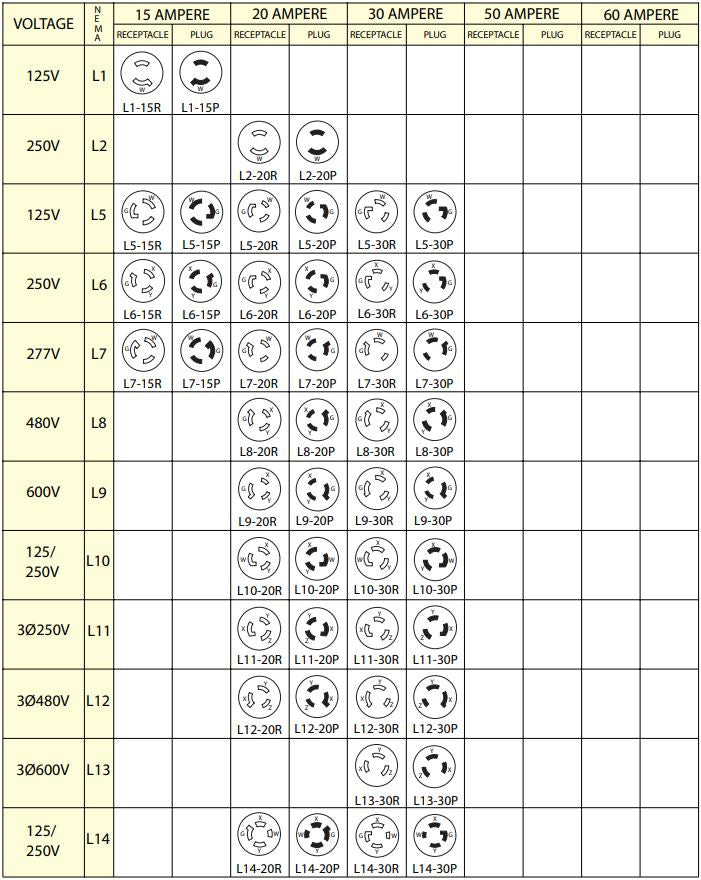

Strategic Material Selection Guide for nema plug chart twist lock

What Materials Are Commonly Used for NEMA Plug Chart Twist Locks?

When selecting materials for NEMA plug chart twist locks, understanding the properties, advantages, and limitations of each material is crucial for ensuring optimal performance and compliance with international standards. Here, we analyze four common materials used in the production of these electrical components.

1. Thermoplastic Elastomers (TPE)

Key Properties: TPEs are known for their flexibility, excellent temperature resistance, and durability. They can withstand temperatures ranging from -40°C to 120°C and exhibit good resistance to UV light and ozone.

Pros & Cons: TPEs are lightweight and cost-effective, making them suitable for mass production. However, they may not offer the same level of mechanical strength as other materials, which could limit their use in high-stress applications.

Illustrative image related to nema plug chart twist lock

Impact on Application: TPEs are compatible with various media, including water and mild chemicals, making them suitable for indoor applications. However, they may not be ideal for environments with harsh chemicals.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local electrical standards, as TPEs may not meet specific industrial requirements in these areas.

2. Polycarbonate (PC)

Key Properties: Polycarbonate is a robust thermoplastic known for its high impact resistance and transparency. It can withstand temperatures up to 135°C and offers excellent dimensional stability.

Illustrative image related to nema plug chart twist lock

Pros & Cons: The durability of polycarbonate makes it suitable for outdoor applications where impact resistance is critical. However, it can be more expensive than other plastics and may require specialized manufacturing processes.

Impact on Application: Polycarbonate is ideal for environments where mechanical stress and temperature fluctuations are prevalent. Its transparency can also be beneficial for applications requiring visual inspection.

Considerations for International Buyers: Compliance with ASTM and DIN standards is essential, particularly in Europe and the Middle East, where safety regulations are stringent.

3. Nylon

Key Properties: Nylon is a strong, lightweight synthetic polymer that offers excellent abrasion resistance and can operate effectively at temperatures up to 120°C. It also has good chemical resistance.

Pros & Cons: The strength and durability of nylon make it suitable for heavy-duty applications. However, it can absorb moisture, which may affect its electrical properties over time.

Impact on Application: Nylon’s chemical resistance makes it suitable for various applications, including those involving oils and fuels. However, its moisture absorption can be a concern in humid environments.

Considerations for International Buyers: Buyers should be aware of the specific grades of nylon that comply with local standards, particularly in regions with high humidity, such as parts of Southeast Asia.

4. Stainless Steel

Key Properties: Stainless steel is known for its high corrosion resistance, strength, and ability to withstand extreme temperatures. It can endure temperatures up to 800°C, depending on the alloy.

Illustrative image related to nema plug chart twist lock

Pros & Cons: The durability and corrosion resistance of stainless steel make it ideal for harsh environments. However, it is heavier and more expensive than plastic alternatives, which may increase shipping costs.

Impact on Application: Stainless steel is suitable for outdoor and industrial applications where exposure to corrosive elements is a concern. Its strength ensures long-term reliability.

Considerations for International Buyers: Compliance with international standards such as JIS and ASTM is crucial for stainless steel components, especially in regions like the Middle East where environmental conditions can be extreme.

Summary Table of Material Selection for NEMA Plug Chart Twist Locks

| Material | Typical Use Case for nema plug chart twist lock | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic Elastomers (TPE) | Indoor electrical applications | Lightweight and cost-effective | Limited mechanical strength | Low |

| Polycarbonate | Outdoor applications requiring impact resistance | High impact resistance and durability | Higher cost and specialized manufacturing | High |

| Nylon | Heavy-duty industrial applications | Strong and abrasion-resistant | Moisture absorption can affect properties | Medium |

| Stainless Steel | Harsh environments with corrosive elements | Excellent corrosion resistance | Heavier and more expensive | High |

This material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on performance characteristics and regional compliance standards.

Illustrative image related to nema plug chart twist lock

In-depth Look: Manufacturing Processes and Quality Assurance for nema plug chart twist lock

What Are the Key Stages in the Manufacturing Process of NEMA Twist Lock Plugs?

The manufacturing of NEMA twist lock plugs involves several critical stages, each ensuring that the final product meets both functional and safety requirements. The main stages in the manufacturing process include:

1. Material Preparation

The first step in producing NEMA twist lock plugs involves selecting high-quality raw materials. Typically, manufacturers utilize thermoplastics for the housing and copper or brass for the conductors. The materials undergo thorough inspection to ensure they meet specifications regarding conductivity, insulation properties, and durability. This stage may also involve cutting materials into specific dimensions and preparing them for the forming process.

2. Forming

In this stage, the prepared materials are shaped into the desired configurations. For thermoplastics, injection molding is commonly employed. This technique involves melting the plastic and injecting it into molds that shape the plug housing. For metal components, stamping and machining techniques are used to create the pins and blades that fit into the receptacles. The forming process is crucial as it dictates the overall quality and dimensional accuracy of the components.

3. Assembly

Once the individual parts are formed, they are assembled into complete NEMA plugs. This stage typically involves inserting the metal blades into the housing and securing them with screws or rivets. Manufacturers may also integrate additional components, such as strain reliefs or locking mechanisms, to enhance durability and safety. Automated assembly lines are often employed to ensure consistency and efficiency, although some intricate assembly tasks may still require skilled manual labor.

4. Finishing

The final stage of manufacturing includes finishing processes such as surface treatment, cleaning, and labeling. Surface treatments may involve applying coatings to enhance corrosion resistance or aesthetic appeal. After finishing, each plug is cleaned to remove any contaminants from the production process, ensuring that the product is ready for use. Finally, manufacturers label the plugs with relevant specifications, including voltage ratings and compliance marks.

Illustrative image related to nema plug chart twist lock

What Quality Control Measures Are Essential for NEMA Twist Lock Plugs?

Quality control (QC) is a critical component of the manufacturing process for NEMA twist lock plugs. It ensures that products meet safety standards and customer expectations. Here are the key QC measures that manufacturers typically implement:

International Standards Compliance

Manufacturers often adhere to international quality management standards such as ISO 9001. This standard focuses on continuous improvement and customer satisfaction, requiring manufacturers to establish and maintain effective quality management systems. Additionally, compliance with industry-specific certifications, such as CE marking for European markets or UL certification for North American markets, is crucial. These certifications indicate that the products meet specific safety and performance criteria.

Quality Control Checkpoints

Quality control checkpoints are strategically integrated into the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet predetermined specifications before they enter the production line.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, regular checks are performed to monitor the quality of components as they are being produced. This may include dimensional checks, visual inspections, and functional testing.

- Final Quality Control (FQC): Once assembly is complete, each plug undergoes final testing to verify its performance and safety features. This may involve electrical testing, mechanical stress testing, and compliance checks.

Common Testing Methods

Various testing methods are employed to ensure the quality of NEMA twist lock plugs:

- Electrical Testing: This includes tests for continuity, insulation resistance, and dielectric strength to ensure safe operation under load.

- Mechanical Testing: Tests may involve checking the durability of the locking mechanism, resistance to environmental factors, and overall structural integrity.

- Thermal Testing: Plugs are subjected to thermal cycling tests to assess their performance under extreme temperature variations.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential to ensure product reliability and safety. Here are actionable strategies:

Conducting Supplier Audits

One of the most effective methods for verifying QC practices is through supplier audits. Buyers can request on-site inspections to review manufacturing processes, quality control checkpoints, and compliance with international standards. During audits, buyers should evaluate the supplier’s documentation, including quality management certifications, test reports, and inspection records.

Illustrative image related to nema plug chart twist lock

Requesting Quality Control Reports

Buyers can ask suppliers to provide detailed quality control reports that outline testing methodologies, results, and compliance certifications. These reports should indicate how often tests are conducted and the failure rates of products. A transparent QC report can provide valuable insights into the supplier’s commitment to quality.

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can add an extra layer of assurance. Independent inspectors can evaluate the manufacturing process and conduct tests on samples to verify compliance with international standards. This service is particularly beneficial for buyers who may not have the resources to conduct audits themselves.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International buyers must navigate various quality control and certification nuances when sourcing NEMA twist lock plugs. Here are some key considerations:

Regulatory Compliance

Different regions have specific regulatory requirements for electrical products. Buyers should be aware of local regulations regarding electrical safety, environmental impact, and product certifications. For instance, European buyers must ensure that products comply with the EU’s Low Voltage Directive (LVD) and the Restriction of Hazardous Substances (RoHS) directive.

Understanding Certification Marks

Recognizing certification marks is crucial for ensuring product safety. In North America, UL and CSA marks are common, while CE marking is essential for products sold in Europe. Buyers should verify that the certifications are legitimate and current by checking with the relevant certification bodies.

Cultural and Communication Considerations

When dealing with international suppliers, cultural differences may affect communication about quality expectations. Buyers should establish clear lines of communication and ensure that quality standards are explicitly outlined in contracts. This clarity helps prevent misunderstandings and ensures that both parties are aligned on quality expectations.

By understanding the manufacturing processes and quality assurance measures for NEMA twist lock plugs, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers who prioritize quality and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘nema plug chart twist lock’

To successfully procure NEMA plug chart twist lock connectors, B2B buyers must navigate a series of critical steps. This checklist serves as a practical guide to ensure a smooth sourcing process, focusing on technical specifications, supplier evaluation, compliance, and logistical considerations.

Illustrative image related to nema plug chart twist lock

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in the sourcing process. Identify the specific NEMA configurations you need based on voltage, amperage, and the number of poles and wires required. This step is essential to ensure that the products you procure will fit your operational needs without any compatibility issues.

- Voltage Requirements: Ensure you know whether you need plugs for 125V, 250V, or higher voltages.

- Amperage Ratings: Specify the amperage ratings such as 15, 20, 30, or 50 amps to match your equipment.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in NEMA twist lock connectors. Look for companies with a proven track record and experience in international trade, especially if you are sourcing from regions like Africa, South America, or the Middle East.

- Supplier Experience: Prioritize suppliers with years of experience in the industry.

- Product Range: Ensure they offer a wide range of NEMA configurations to meet your diverse needs.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website.

- Certifications: Verify that suppliers have necessary certifications, such as UL or CE, indicating compliance with safety standards.

- Customer Feedback: Look for testimonials or reviews from previous customers to gauge reliability and product quality.

Step 4: Verify Compliance with Regional Standards

Ensure that the NEMA plugs meet the regulatory standards of the countries where they will be used. Compliance with local electrical codes can prevent costly delays or issues after procurement.

- Documentation: Request technical data sheets and compliance certifications specific to your region.

- Local Regulations: Familiarize yourself with any unique requirements in your target market.

Step 5: Request Samples for Testing

Before placing a large order, always request samples of the NEMA twist lock connectors. Testing samples in your own environment allows you to confirm compatibility and functionality.

- Performance Testing: Evaluate the samples under operational conditions to ensure they meet your specifications.

- Quality Assurance: Check for durability and resistance to environmental factors relevant to your operational setting.

Step 6: Negotiate Terms and Pricing

Once you have selected a supplier, engage in negotiations to secure favorable terms and pricing. Clear communication can lead to better deals and potentially long-term partnerships.

- Bulk Discounts: Inquire about discounts for larger orders or long-term contracts.

- Payment Terms: Discuss payment options that can accommodate your cash flow needs.

Step 7: Plan Logistics and Delivery

Finally, develop a comprehensive logistics plan for the delivery of your NEMA plugs. Consider shipping options, delivery timelines, and any customs requirements that may apply.

- Shipping Methods: Evaluate whether air or sea freight is more suitable based on urgency and cost.

- Customs Clearance: Ensure all necessary paperwork is in order to facilitate smooth customs clearance upon arrival.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing NEMA plug chart twist lock connectors, ensuring they make informed decisions that align with their operational requirements.

Comprehensive Cost and Pricing Analysis for nema plug chart twist lock Sourcing

When sourcing NEMA plug chart twist locks, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis will cover the key cost components, price influencers, and provide practical tips for negotiation and procurement strategies.

What Are the Key Cost Components for NEMA Plug Chart Twist Locks?

The cost structure for NEMA plug chart twist locks consists of several components:

-

Materials: The primary materials include high-grade plastics, copper, and other conductive metals. The quality of materials directly impacts the durability and performance of the plugs, influencing overall costs.

-

Labor: Labor costs vary based on the manufacturing location. For example, countries with lower labor costs may offer competitive pricing, but it’s essential to consider the implications for quality and consistency.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, equipment depreciation, and utilities. Efficient manufacturing processes can help reduce these overheads, which in turn can lower prices.

-

Tooling: Custom tooling for specific designs or configurations can be a significant upfront cost. However, these costs can be amortized over larger production runs, thus reducing per-unit costs for bulk orders.

-

Quality Control (QC): Rigorous QC processes are necessary to ensure compliance with safety standards and certifications. These processes incur additional costs but are critical for maintaining product integrity, especially for international markets.

-

Logistics: Shipping and handling costs can vary greatly depending on the destination, shipping method, and volume. Incoterms (International Commercial Terms) will also play a role in determining who bears these costs.

-

Margin: Suppliers typically mark up prices to achieve a profit margin, which can vary based on competition and market demand.

How Do Price Influencers Impact Sourcing Costs?

Several factors influence the pricing of NEMA plugs:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often attract volume discounts, making it more cost-effective for buyers. Suppliers may offer tiered pricing based on order size.

-

Specifications and Customization: Custom designs or specifications will increase costs due to the need for specialized tooling and additional labor. Buyers should evaluate whether standard options meet their needs to avoid unnecessary expenses.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like UL or CE) can lead to increased costs but are essential for safety and reliability, especially in critical applications.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their proven track record and quality assurance processes.

-

Incoterms: Understanding the terms of sale is crucial. For instance, FOB (Free on Board) means the seller covers all costs until the goods are on board the shipping vessel, while CIF (Cost, Insurance, and Freight) includes shipping costs. Buyers should negotiate favorable terms that minimize their financial risk.

What Negotiation Tips Can Help Buyers Achieve Cost Efficiency?

-

Engage in Competitive Bidding: Solicit quotes from multiple suppliers to create competitive pressure, potentially lowering prices.

-

Build Long-Term Relationships: Establishing long-term partnerships with suppliers can lead to better pricing and service, as suppliers may offer loyalty discounts.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the upfront costs but also the long-term implications of maintenance, reliability, and potential downtime. A lower initial price may not always equate to the best value.

-

Negotiate Payment Terms: Flexible payment terms can improve cash flow and overall cost efficiency. Discuss options like extended payment periods or discounts for early payment.

-

Understand Local Market Dynamics: For international buyers, understanding the local market conditions, currency fluctuations, and trade agreements can provide leverage in negotiations.

Conclusion

Sourcing NEMA plug chart twist locks involves navigating a complex landscape of costs and pricing influencers. By understanding these elements, international B2B buyers can make informed decisions that enhance their procurement strategies and ensure they receive the best value for their investments. Always remember that indicative prices may vary based on changing market conditions and supplier negotiations.

Alternatives Analysis: Comparing nema plug chart twist lock With Other Solutions

Introduction to Alternative Solutions for NEMA Plug Chart Twist Lock

In the realm of electrical connections, especially for industrial and commercial applications, NEMA plug chart twist locks are a popular choice due to their reliable locking mechanism and versatility. However, there are alternative solutions available that may suit different operational needs or environments better. Understanding these alternatives can help B2B buyers make informed decisions that align with their specific requirements.

Comparison of NEMA Plug Chart Twist Lock with Alternative Solutions

| Comparison Aspect | NEMA Plug Chart Twist Lock | IEC 60309 (Pin & Sleeve) | Anderson Powerpole Connectors |

|---|---|---|---|

| Performance | High reliability, secure connection | Robust performance, weather-resistant | Excellent for high-current applications |

| Cost | Moderate cost | Higher initial investment | Lower overall cost for bulk applications |

| Ease of Implementation | Simple installation with standard tools | Requires careful installation, may need specialized tools | Easy to install, user-friendly design |

| Maintenance | Low maintenance, durable | Moderate, may need regular checks | Minimal, but contact points may wear over time |

| Best Use Case | General industrial use, portable equipment | Outdoor applications, heavy machinery | High-current DC applications, solar power systems |

Detailed Breakdown of Alternative Solutions

IEC 60309 (Pin & Sleeve) Connectors

IEC 60309 connectors, commonly known as pin and sleeve connectors, offer a robust alternative to NEMA twist locks, especially in outdoor and heavy-duty applications. These connectors are designed to withstand harsh environmental conditions, making them ideal for construction sites or industrial settings exposed to moisture and dust. While they provide excellent durability and safety, the initial investment can be higher compared to NEMA connectors. Installation may also require specialized tools and expertise, which could increase labor costs.

Anderson Powerpole Connectors

Anderson Powerpole connectors are a cost-effective solution for applications requiring high-current DC connections, such as in solar power systems and electric vehicles. Their modular design allows for easy customization and scalability, making them suitable for a range of applications. They are relatively easy to install and maintain, although users must be mindful of potential wear on contact points, which could affect performance over time. Their lower overall cost, especially when purchased in bulk, can make them an attractive option for businesses focused on budget management.

Conclusion: Choosing the Right Electrical Connection Solution

When selecting an electrical connection solution, B2B buyers must consider their specific operational needs, including performance requirements, environmental conditions, and budget constraints. NEMA plug chart twist locks offer a reliable and versatile option for many applications, but alternatives like IEC 60309 and Anderson Powerpole connectors present unique advantages that may better align with particular use cases. Evaluating these factors will enable buyers to make informed decisions that enhance operational efficiency and safety in their respective industries.

Essential Technical Properties and Trade Terminology for nema plug chart twist lock

What Are the Key Technical Properties of NEMA Plug Chart Twist Lock?

Understanding the technical specifications of NEMA twist lock plugs is crucial for B2B buyers looking to ensure compatibility and safety in electrical connections. Here are several essential properties to consider:

-

Voltage Rating

Voltage rating indicates the maximum voltage the plug can handle. Common ratings include 125V, 250V, and 600V. Selecting the appropriate voltage rating is vital to prevent electrical failures and ensure compliance with local regulations. For international buyers, knowing the voltage standards in your region can help in selecting the right plug. -

Amperage Rating

The amperage rating specifies the maximum current a plug can carry, typically ranging from 15A to 60A for twist lock plugs. This rating is crucial for determining the plug’s suitability for specific applications, particularly in industrial settings where high power is required. Ensuring that the amperage rating aligns with your equipment’s requirements helps avoid overheating and potential hazards. -

Number of Poles and Wires

NEMA plugs can have different configurations, such as 2-pole, 3-pole, or 4-pole designs. The number of wires indicates how many conductors are present for power and ground connections. Understanding these configurations is essential for proper installation and functionality in various electrical systems, especially in complex machinery. -

Material Composition

The materials used in NEMA plugs, often thermoplastic or thermoset materials, affect durability and resistance to environmental factors such as moisture and chemicals. Buyers should consider the environmental conditions in which the plugs will be used. For example, plugs made from high-grade materials may be necessary for outdoor applications or harsh industrial environments. -

Temperature Rating

Each NEMA plug has a temperature rating indicating the maximum ambient temperature it can withstand. This property is particularly relevant in high-temperature environments, as exceeding this limit can lead to insulation failure and increased risk of electrical fires. Selecting plugs with appropriate temperature ratings ensures safety and longevity. -

Locking Mechanism

Twist lock plugs feature a unique locking mechanism that secures the connection, preventing accidental disconnections. This feature is particularly important in applications where a stable power supply is critical. Understanding how the locking mechanism works can help buyers ensure that their electrical systems maintain reliable connections.

What Are Common Trade Terms Related to NEMA Plug Chart Twist Lock?

Familiarity with industry terminology can greatly aid B2B buyers in negotiations and procurement processes. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications ensures compatibility and quality assurance for buyers looking to source plugs for their own products or systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Buyers should be aware of MOQ requirements to plan their purchases effectively and avoid overstocking or stockouts, which can impact operations. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. Crafting a well-defined RFQ can help buyers receive accurate quotes and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping and delivery. Familiarity with these terms helps buyers understand their obligations, such as who is responsible for shipping costs, insurance, and risk during transport. -

Lead Time

Lead time is the period from placing an order to receiving the goods. Understanding lead times helps buyers plan their procurement strategies and manage inventory levels effectively, minimizing disruptions in operations. -

Certification Standards

Certification standards, such as UL (Underwriters Laboratories) or CE (Conformité Européenne), indicate that products meet specific safety and performance criteria. Buyers should look for these certifications to ensure that the plugs comply with safety regulations in their region.

By being aware of these technical properties and trade terms, B2B buyers can make informed decisions when procuring NEMA twist lock plugs, ultimately ensuring compatibility, safety, and efficiency in their electrical systems.

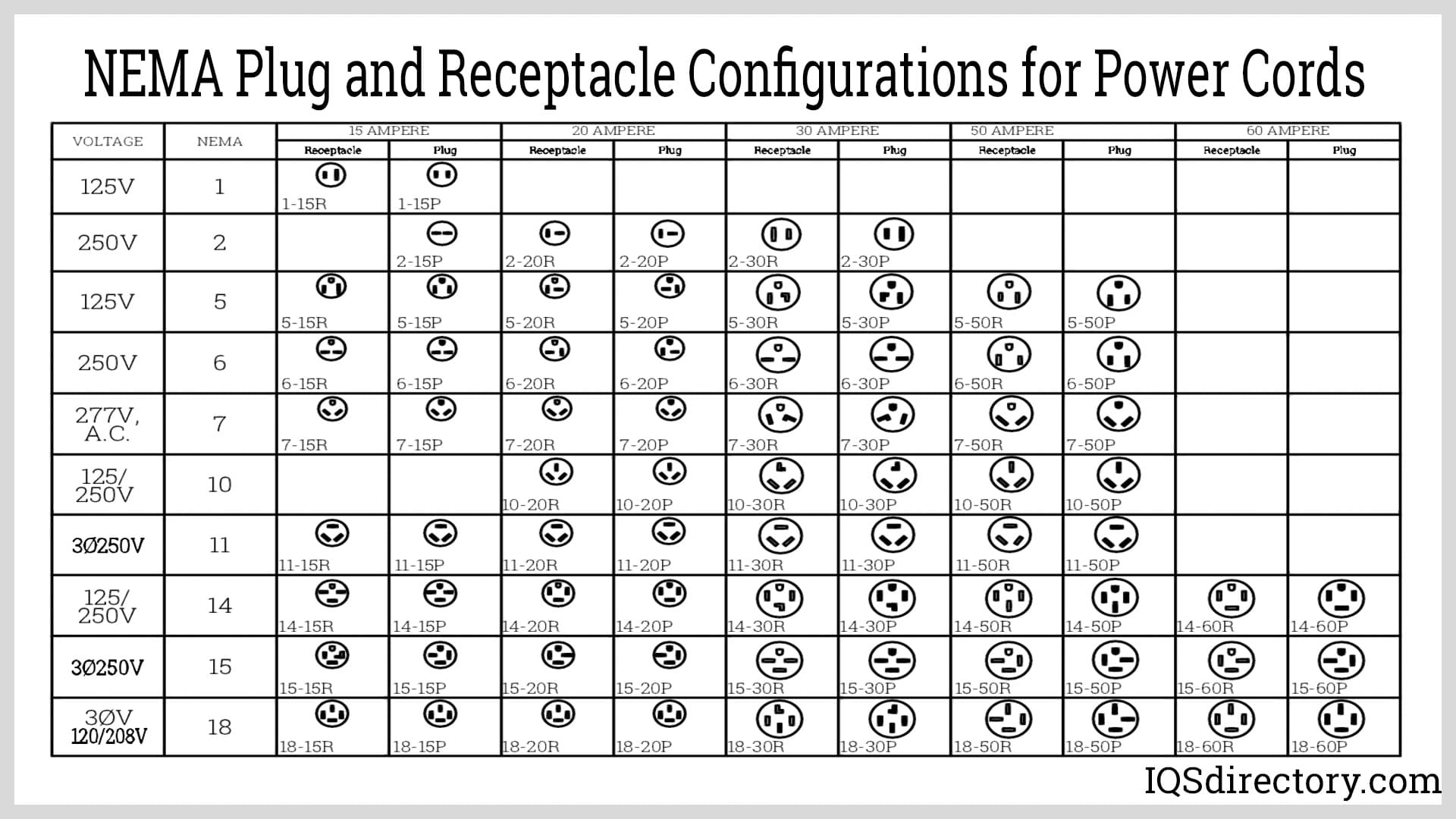

Navigating Market Dynamics and Sourcing Trends in the nema plug chart twist lock Sector

What Are the Key Market Dynamics and Trends in the NEMA Plug Chart Twist Lock Sector?

The NEMA plug chart twist lock sector is witnessing significant growth driven by the rising demand for reliable and secure electrical connections in industrial and commercial applications. Key drivers include the expansion of infrastructure projects across Africa, South America, and the Middle East, coupled with the increasing need for efficient power distribution in Europe and Asia. As countries invest in renewable energy sources, the demand for durable, high-capacity connectors that can withstand varying environmental conditions is on the rise.

Additionally, the integration of smart technology into electrical systems is emerging as a notable trend. This includes the adoption of IoT-enabled devices that facilitate real-time monitoring and management of electrical loads, enhancing operational efficiency. International buyers are increasingly seeking suppliers that offer advanced solutions, including custom configurations that meet specific voltage and amperage requirements. The NEMA L6 and L14 series, for example, are becoming popular due to their versatility in heavy-duty applications.

Furthermore, the COVID-19 pandemic has reshaped sourcing strategies, prompting businesses to diversify their supply chains and reduce dependency on single markets. Buyers are now looking for suppliers with a robust international presence, ensuring a steady flow of products even in times of disruption.

How Is Sustainability Impacting Sourcing Decisions for NEMA Plug Chart Twist Lock Products?

Sustainability is becoming an essential consideration for B2B buyers in the NEMA plug chart twist lock market. The environmental impact of manufacturing processes and materials used in electrical components has garnered significant attention. Buyers are increasingly prioritizing suppliers who adhere to sustainable practices, such as using recyclable materials and minimizing waste during production.

Ethical sourcing is not just a trend but a necessity in today’s market landscape. Companies that invest in transparent supply chains and sustainable sourcing practices often experience enhanced brand loyalty and customer trust. For instance, obtaining certifications like ISO 14001 (Environmental Management) and using eco-friendly materials can be pivotal for suppliers looking to stand out. Additionally, buyers are now more informed and demand proof of sustainability efforts, such as lifecycle assessments and carbon footprint reports.

The push for greener solutions has also led to innovations in the design of NEMA plugs, focusing on energy efficiency and reduced environmental impact. Suppliers who can demonstrate their commitment to sustainability through product offerings will likely have a competitive advantage.

How Has the NEMA Plug Chart Twist Lock Sector Evolved Over Time?

The NEMA plug chart twist lock sector has evolved significantly since its inception in the early 20th century. Originally designed for industrial applications, these connectors have adapted over the years to accommodate the growing needs of various sectors, including construction, entertainment, and renewable energy.

The introduction of twist lock technology was revolutionary, providing enhanced safety and reliability compared to traditional plugs. This evolution has paralleled advancements in electrical standards, with NEMA continually updating specifications to meet the demands of modern electrical systems. Today, NEMA connectors are recognized globally, with a wide array of configurations available to cater to different voltage and amperage requirements.

As the market continues to expand, the focus on innovation and adaptability remains crucial, ensuring that the NEMA plug chart twist lock sector can meet the challenges of tomorrow’s electrical needs. International buyers can benefit from this evolution by seeking suppliers who embrace technological advancements and prioritize quality and safety in their product offerings.

Frequently Asked Questions (FAQs) for B2B Buyers of nema plug chart twist lock

-

How do I select the right NEMA plug configuration for my equipment?

Choosing the correct NEMA plug configuration involves assessing the voltage and amperage requirements of your equipment. Start by identifying the power specifications of your devices, including the number of poles and wires needed. Consult the NEMA locking reference chart to match your equipment’s requirements with the appropriate NEMA configuration. Additionally, consider the environment where the plug will be used, as some configurations are better suited for outdoor or industrial applications. -

What is the best NEMA twist lock plug for heavy-duty applications?

For heavy-duty applications, the NEMA L6-50 and L14-50 plugs are excellent choices due to their robust construction and high amperage ratings of 50 amps. These plugs are designed for higher voltage and are suitable for industrial machinery and equipment. Ensure that the selected plug matches the voltage requirements (250V for L6-50 and 125/250V for L14-50) of your application to ensure safety and performance. -

What are the advantages of using twist lock plugs over standard plugs?

Twist lock plugs offer enhanced safety and reliability compared to standard plugs. Their design allows for a secure connection that prevents accidental disconnection, making them ideal for high-demand environments such as construction sites and industrial settings. Additionally, twist lock plugs provide better resistance to environmental factors, reducing the risk of electrical hazards in harsh conditions. -

What factors should I consider when vetting suppliers for NEMA plugs?

When vetting suppliers for NEMA plugs, consider their industry reputation, product quality, and compliance with international standards. Request samples to evaluate the materials and craftsmanship. Additionally, inquire about their manufacturing processes, quality assurance protocols, and certifications (such as ISO). Understanding their logistics capabilities and lead times is also crucial for ensuring timely delivery. -

What are typical minimum order quantities (MOQ) for NEMA plugs?

Minimum order quantities for NEMA plugs can vary significantly based on the supplier and the specific product. Generally, MOQs range from 50 to 500 units for standard configurations. However, for customized or specialized plugs, MOQs might be higher. Always confirm the MOQ with the supplier before placing an order to avoid unexpected costs. -

What payment terms should I expect when sourcing NEMA plugs internationally?

Payment terms for international transactions often include options like advance payment, letter of credit, or payment upon delivery. Many suppliers may require a deposit (20-50%) upfront, with the balance due before shipment or upon receipt. It’s essential to negotiate favorable terms that align with your cash flow while ensuring supplier security. -

How can I ensure quality assurance when purchasing NEMA plugs?

To ensure quality assurance, request certifications from suppliers that demonstrate compliance with relevant safety and performance standards. Conduct factory audits, if possible, to evaluate manufacturing practices. Additionally, establish clear quality control protocols, including inspection processes for received goods, to verify that the products meet your specifications before use. -

What logistics considerations should I be aware of when importing NEMA plugs?

When importing NEMA plugs, consider shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder to navigate international shipping complexities. Ensure that all necessary documentation, such as invoices and certificates of origin, is prepared to facilitate smooth customs clearance. Additionally, account for lead times and plan your inventory levels accordingly to avoid disruptions in your operations.

Top 6 Nema Plug Chart Twist Lock Manufacturers & Suppliers List

1. StayOnline – NEMA Receptacle & Power Cord Solutions

Domain: stayonline.com

Registered: 1996 (29 years)

Introduction: NEMA Receptacle Chart – Twist Lock Receptacle Reference Chart. Product categories include Power Cords, Data Center Power Cords, International Cords, Locking Power Cords, Splitter Power Cords, Hospital Grade Power Cords, IEC 60309 Pin and Sleeve Power Cords, and various plug adapters. Specific NEMA locking power cables listed include NEMA L5-15, L5-20, L5-30, L6-15, L6-20, L6-30, L14-20, L14-30, L1…

2. Elliott Electric – Twist Lock Plug

Domain: elliottelectric.com

Registered: 1997 (28 years)

Introduction: This company, Elliott Electric – Twist Lock Plug, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Quail Electronics – Power Cords

Domain: quail.com

Registered: 1996 (29 years)

Introduction: Quail Electronics Inc. offers a wide range of power cords including North American Power Cords, International Power Cords, IEC/Jumper Power Cords, Hospital Grade Power Cords, High Voltage Power Cords, and Specialty Power Cords. Key product categories include: 1. North American Power Cords: Various configurations such as 2 Conductor, 3 Conductor, Auto-Lock, and different plug types (5-15P, 6-15P, e…

4. Badass Extension Cords – NEMA Twistlock Plugs & Connectors

Domain: badassextensioncords.com

Registered: 2017 (8 years)

Introduction: This company, Badass Extension Cords – NEMA Twistlock Plugs & Connectors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Installation Parts Supply – NEMA L6-20P Twist Lock Plug

Domain: installationpartssupply.com

Registered: 2004 (21 years)

Introduction: NEMA L6-20P 20A, 250V Twist Lock Plug, 2 Pole, 3 Wire, Black/White

6. Americord – NEMA Plug Charts

Domain: americord.com

Registered: 1999 (26 years)

Introduction: NEMA Plug Charts provide configurations for non-locking and locking plugs and receptacles in North America, detailing connector layouts, voltage, and current limits to ensure compatibility and minimize risks. Non-locking configurations include voltage classifications (125V, 250V, 277V, 125/250V) and current capacities (15A, 20A, 30A, 50A, 60A). Common configurations are 5-15 (standard residential)…

Strategic Sourcing Conclusion and Outlook for nema plug chart twist lock

In the evolving landscape of electrical connectivity, the strategic sourcing of NEMA plug chart twist locks presents significant opportunities for B2B buyers across diverse global markets. Understanding the specifications and configurations of various NEMA plugs, such as voltage ratings and amperage capacities, is crucial for ensuring compatibility with regional electrical systems. Buyers must prioritize sourcing from reputable manufacturers that adhere to international safety standards, ensuring reliability and performance in critical applications.

The value of strategic sourcing extends beyond mere procurement; it fosters long-term partnerships that can enhance supply chain resilience and operational efficiency. By leveraging insights from trusted suppliers, businesses can optimize their electrical systems, reduce downtime, and enhance safety measures.

Illustrative image related to nema plug chart twist lock

As markets in Africa, South America, the Middle East, and Europe continue to expand, proactive engagement in sourcing high-quality NEMA twist locks will be essential. Now is the time for international buyers to evaluate their sourcing strategies, considering not only the immediate needs but also future growth and sustainability. By making informed decisions today, companies can position themselves for success in tomorrow’s competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.