A B2B Buyer’s Guide to Mixing Tank With Agitator: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for mixing tank with agitator

In the fast-evolving landscape of global manufacturing, sourcing the right mixing tank with agitator can be a daunting challenge for international B2B buyers. With diverse applications across industries—from pharmaceuticals to food processing—understanding the various types and specifications is crucial. This guide is designed to assist buyers in navigating the complexities of selecting the optimal mixing tank with agitator, addressing everything from design considerations to operational efficiency.

Throughout this comprehensive resource, we will explore the different configurations available, including clamp mount, flange mount, and top-entry mixers, each tailored for specific operational needs. We will also delve into the critical aspects of supplier vetting, ensuring that you partner with reputable manufacturers who meet international quality standards. Additionally, this guide will provide insights into cost factors, helping you make informed financial decisions that align with your budget and operational goals.

By equipping B2B buyers from Africa, South America, the Middle East, and Europe—particularly in countries like Saudi Arabia and Nigeria—with actionable insights and practical advice, this guide aims to empower you in your purchasing journey. Whether you are scaling operations or optimizing existing processes, understanding the nuances of mixing tanks with agitators will enable you to enhance productivity and ensure quality in your manufacturing endeavors.

Understanding mixing tank with agitator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Clamp Mount Mixer | Portable, easy to install, adjustable height | Small-scale production, lab mixing | Pros: Cost-effective, flexible; Cons: Limited capacity for larger volumes. |

| Flange Mount Mixer | Rigid installation, suitable for sealed tanks | Chemical processing, food production | Pros: Secure attachment, ideal for high-pressure applications; Cons: More complex installation. |

| Top Entry Mixer | Top-mounted design, suitable for large tanks | Heavy-duty industrial mixing | Pros: Efficient for viscous materials; Cons: Requires more space above the tank. |

| High Shear Mixer | Designed for emulsifying and dispersing | Cosmetics, pharmaceuticals, food industry | Pros: High efficiency in particle size reduction; Cons: Higher initial investment. |

| Jacketed Mixing Tank | Insulated design for temperature control | Chemical reactions, food processing | Pros: Maintains temperature for sensitive materials; Cons: Higher maintenance and operational costs. |

What Are the Characteristics and Suitability of Clamp Mount Mixers?

Clamp mount mixers are characterized by their portability and ease of installation, making them ideal for small-scale production and laboratory applications. They can be quickly set up and adjusted to various tank heights, allowing for flexibility in different mixing scenarios. For B2B buyers, these mixers are a cost-effective solution, though they may not be suitable for high-volume mixing due to their limited capacity.

How Do Flange Mount Mixers Stand Out in Industrial Applications?

Flange mount mixers provide a secure attachment to tanks, making them suitable for both sealed and non-sealed applications. Their robust design is especially beneficial in chemical processing and food production, where safety and reliability are paramount. While they offer high stability and can handle high-pressure environments, the installation process can be more complex, which may require additional resources or expertise.

Why Are Top Entry Mixers Preferred for Heavy-Duty Applications?

Top entry mixers are designed for large tanks and are particularly effective for mixing viscous materials. Their top-mounted configuration allows for efficient mixing of heavy substances, making them suitable for industrial applications. However, they do require more vertical space above the tank, which might not be feasible in all facilities. Buyers should consider the operational environment and space limitations when opting for this type.

What Makes High Shear Mixers Essential for Certain Industries?

High shear mixers are specifically engineered for emulsifying and dispersing materials, making them indispensable in industries such as cosmetics, pharmaceuticals, and food production. They excel in achieving a fine particle size, thus enhancing product quality. Despite their efficiency, they come with a higher initial investment, which may be a consideration for budget-conscious buyers.

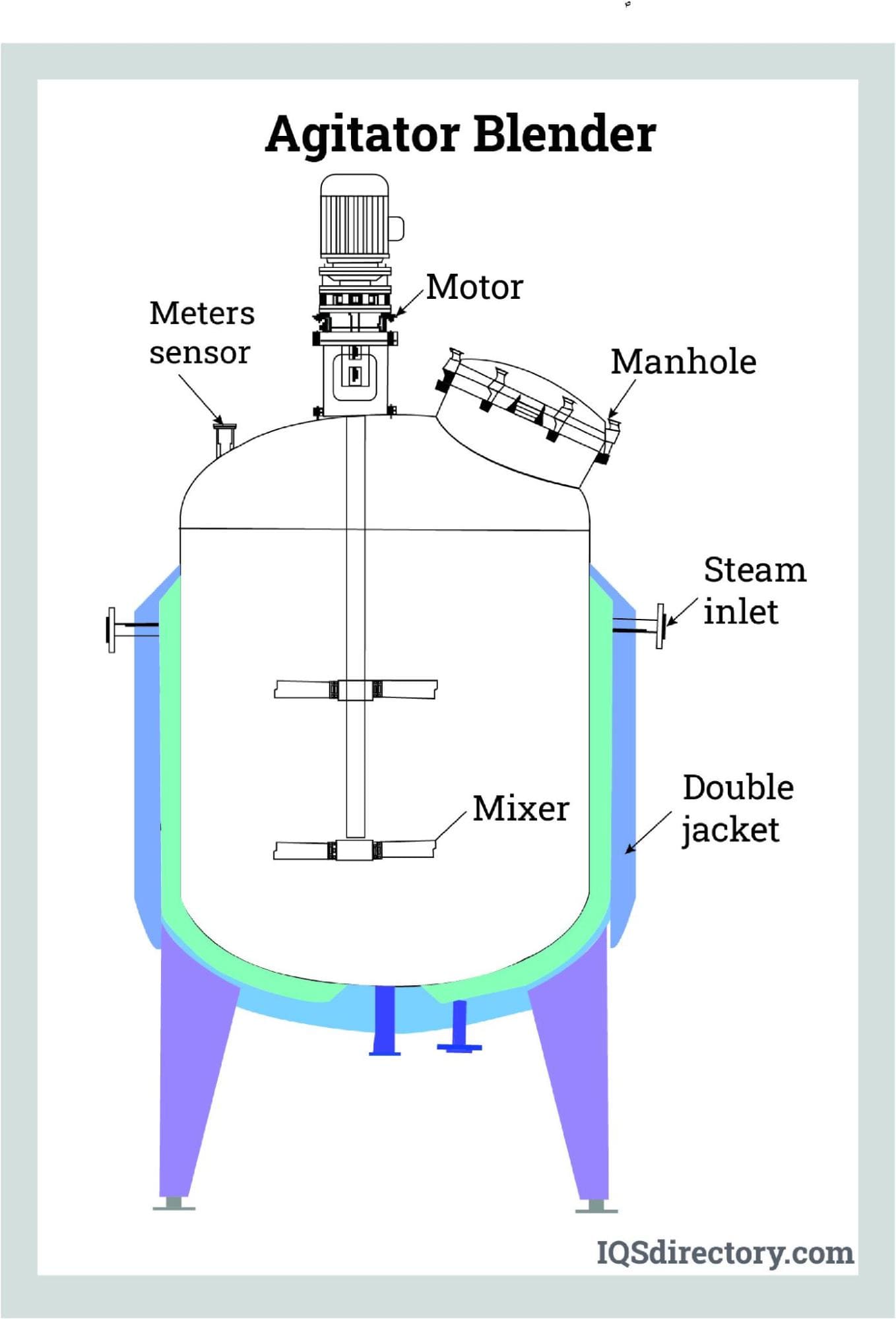

How Do Jacketed Mixing Tanks Enhance Process Control?

Jacketed mixing tanks feature an insulated design that allows for precise temperature control, making them ideal for chemical reactions and food processing applications. This temperature maintenance is crucial for sensitive materials that require specific thermal conditions to prevent degradation. While they enhance operational efficiency, buyers should be aware of the higher maintenance and operational costs associated with these systems.

Key Industrial Applications of mixing tank with agitator

| Industry/Sector | Specific Application of Mixing Tank with Agitator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Homogenization of sauces and dressings | Ensures uniform texture and taste, reducing waste | Compliance with food safety standards, material selection |

| Pharmaceuticals | Preparation of suspensions and emulsions | Enhances bioavailability of active ingredients | GMP compliance, material compatibility, explosion-proof options |

| Chemicals Manufacturing | Mixing of chemical formulations | Improves product consistency and quality | Resistance to corrosive substances, custom tank sizes |

| Cosmetics | Emulsification of creams and lotions | Achieves desired viscosity and stability | FDA regulations, material hygiene, customizable agitator designs |

| Water Treatment | Mixing of coagulants in water purification | Increases efficiency of contaminant removal | Energy efficiency, durability under harsh conditions |

How is a Mixing Tank with Agitator Used in the Food and Beverage Industry?

In the food and beverage sector, mixing tanks with agitators are essential for the homogenization of sauces, dressings, and other liquid products. These tanks ensure that ingredients are uniformly blended, which not only enhances the flavor but also improves the shelf life of the products. For international buyers, particularly in regions like Africa and South America, sourcing equipment that complies with stringent food safety standards is crucial. Additionally, buyers should consider materials that are easy to clean and resistant to contamination.

What Role Do Mixing Tanks with Agitators Play in Pharmaceuticals?

Pharmaceutical companies utilize mixing tanks with agitators for preparing suspensions and emulsions, which are vital for ensuring the bioavailability of active ingredients. These tanks facilitate the precise mixing of compounds, which is critical for maintaining product efficacy. Buyers in the Middle East and Europe must prioritize suppliers that comply with Good Manufacturing Practice (GMP) regulations and offer materials that are compatible with sensitive pharmaceutical ingredients. Explosion-proof options are also important for safety in volatile environments.

How Are Mixing Tanks with Agitators Used in Chemicals Manufacturing?

In chemicals manufacturing, mixing tanks with agitators are used to blend various formulations, ensuring consistent quality and performance of the final products. The ability to customize tank designs to resist corrosive substances is a significant advantage for businesses in this sector. International buyers, especially from regions with diverse industrial needs, should look for suppliers that can provide tailored solutions, including specific agitator types and tank sizes that meet their operational demands.

Why Are Mixing Tanks Important in the Cosmetics Industry?

Cosmetic manufacturers rely on mixing tanks with agitators for the emulsification of creams and lotions, which is essential for achieving the desired texture and stability of products. These tanks help in creating a uniform consistency that enhances the product’s appeal. Buyers from Africa and Europe should ensure compliance with FDA regulations and prioritize sourcing from manufacturers that offer hygiene-compliant materials and customizable agitator designs to meet their specific formulation needs.

How Do Mixing Tanks with Agitators Improve Water Treatment Processes?

In water treatment facilities, mixing tanks with agitators are crucial for the effective mixing of coagulants, which helps in the removal of contaminants from water. Efficient mixing leads to better treatment outcomes and lowers operational costs. Buyers from developing regions, such as Nigeria, should focus on sourcing energy-efficient mixers that are durable enough to withstand harsh conditions. Additionally, they should evaluate suppliers based on their ability to provide equipment that meets local regulatory standards for water safety.

3 Common User Pain Points for ‘mixing tank with agitator’ & Their Solutions

Scenario 1: Inefficient Mixing Leading to Product Inconsistency

The Problem: Many manufacturers face the challenge of inconsistent product quality due to inefficient mixing in their tanks. When the agitator fails to uniformly blend materials, it can lead to variations in viscosity, color, and overall composition. This inconsistency not only compromises product integrity but can also result in increased waste, customer dissatisfaction, and potential regulatory issues, particularly in industries such as food and pharmaceuticals where quality standards are stringent.

The Solution: To address this issue, buyers should consider investing in advanced mixing technologies that offer precise speed control and optimized agitator designs. For example, variable frequency drive (VFD) systems can be implemented to adjust the speed of the agitator based on the specific properties of the materials being mixed. Furthermore, selecting a mixing tank with a suitable agitator type, such as a high-shear mixer or a hydrofoil mixer, can enhance the efficiency of the mixing process. Collaborating with suppliers who offer custom solutions tailored to specific production requirements can also ensure that the mixing equipment meets the unique needs of the application.

Scenario 2: Equipment Downtime Due to Maintenance Issues

The Problem: Frequent breakdowns and maintenance requirements can severely disrupt production schedules, particularly in industries that rely on continuous mixing processes. B2B buyers often encounter unexpected failures of mixing tanks and agitators, leading to costly downtime and delays in fulfilling orders. This situation can be exacerbated in regions with limited access to replacement parts or technical support, making it imperative for businesses to have reliable equipment.

Illustrative image related to mixing tank with agitator

The Solution: To mitigate downtime, companies should prioritize sourcing mixing tanks with a focus on durability and ease of maintenance. Selecting equipment made from high-quality materials such as stainless steel can enhance longevity and resistance to corrosion, reducing the frequency of repairs. Additionally, integrating predictive maintenance technologies, such as sensors that monitor equipment performance in real-time, can help identify potential issues before they lead to failures. Establishing a strong relationship with a local supplier who can provide timely maintenance support and spare parts can further reduce the risk of prolonged equipment downtime.

Scenario 3: Compliance with Regulatory Standards

The Problem: B2B buyers in sectors such as food processing, pharmaceuticals, and chemicals often face the daunting task of ensuring that their mixing operations comply with various regulatory standards. Non-compliance can result in hefty fines, product recalls, and damage to brand reputation. Buyers may struggle with understanding the specific requirements for their equipment, especially when regulations vary significantly across different countries and regions.

The Solution: To navigate these complexities, it is essential for buyers to engage with suppliers who are knowledgeable about the regulatory landscape specific to their industry. When sourcing mixing tanks with agitators, companies should ensure that the equipment meets applicable certifications, such as FDA compliance for food processing or ASME standards for pressure vessels. Conducting thorough research and consulting with industry experts can help identify the necessary documentation and specifications required for compliance. Additionally, incorporating features like easy-to-clean designs and traceability options can simplify the compliance process and enhance operational efficiency. Regular training and updates on regulatory changes for staff members involved in mixing operations can further ensure adherence to standards.

Illustrative image related to mixing tank with agitator

Strategic Material Selection Guide for mixing tank with agitator

When selecting materials for mixing tanks with agitators, it is crucial to consider the specific properties and performance requirements of each material. Below, we analyze four common materials used in the construction of mixing tanks, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe.

What are the Key Properties of Stainless Steel for Mixing Tanks?

Stainless steel is a popular choice for mixing tanks due to its excellent corrosion resistance and mechanical strength. It typically has a temperature rating of up to 800°F (427°C) and can withstand high pressures, making it suitable for a variety of mixing applications. The most commonly used grades include 304 and 316 stainless steel, with the latter offering enhanced corrosion resistance, particularly against chlorides.

Pros: Stainless steel is durable, easy to clean, and non-reactive, making it ideal for food and pharmaceutical applications. It also complies with various international standards, such as ASTM and DIN.

Illustrative image related to mixing tank with agitator

Cons: The primary drawback is its cost, as stainless steel is more expensive than other materials like carbon steel or plastic. Additionally, it can be susceptible to pitting in aggressive environments.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive chemicals, making it a versatile option for diverse industries.

How Does Carbon Steel Compare for Mixing Tanks?

Carbon steel is another common material used for mixing tanks, especially in applications where cost is a significant consideration. It has a lower temperature rating, typically around 400°F (204°C), and is more prone to corrosion compared to stainless steel.

Pros: The main advantage of carbon steel is its affordability and strength, making it suitable for large-scale operations where budget constraints exist.

Cons: Carbon steel requires protective coatings to enhance corrosion resistance, which can add to maintenance costs. It is less suitable for applications involving aggressive chemicals.

Impact on Application: Carbon steel is best suited for non-corrosive media and applications where the tank is not exposed to extreme conditions.

What are the Benefits of Polypropylene in Mixing Tanks?

Polypropylene is a thermoplastic polymer that offers excellent chemical resistance and is lightweight compared to metals. It can withstand temperatures up to 200°F (93°C) and is often used in applications involving acids and bases.

Pros: The primary benefits of polypropylene include its low cost, ease of fabrication, and resistance to a wide range of chemicals. It is also non-corrosive, making it suitable for various industrial applications.

Cons: However, polypropylene has a lower temperature and pressure tolerance than metals, limiting its use in high-temperature applications. It may also degrade under UV exposure unless treated.

Illustrative image related to mixing tank with agitator

Impact on Application: Polypropylene is ideal for mixing tanks used in chemical processing where aggressive media are present, but it may not be suitable for high-temperature applications.

How Do Glass-Lined Tanks Perform in Mixing Applications?

Glass-lined steel tanks combine the durability of steel with the non-reactive properties of glass. They are typically rated for temperatures up to 400°F (204°C) and are highly resistant to corrosion.

Pros: The glass lining provides a smooth surface that is easy to clean and prevents contamination, making it ideal for food and pharmaceutical applications.

Cons: The main limitation is the fragility of the glass lining, which can chip or crack under impact. Additionally, these tanks can be more expensive than their all-steel counterparts.

Impact on Application: Glass-lined tanks are particularly suitable for sensitive media, including food products and pharmaceuticals, where contamination must be avoided.

Illustrative image related to mixing tank with agitator

Summary Table of Material Selection for Mixing Tanks

| Material | Typical Use Case for mixing tank with agitator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food and pharmaceutical industries | Excellent corrosion resistance | Higher cost, susceptible to pitting | High |

| Carbon Steel | General industrial applications | Cost-effective and strong | Requires coatings for corrosion resistance | Low |

| Polypropylene | Chemical processing applications | Lightweight, excellent chemical resistance | Limited temperature tolerance | Med |

| Glass-Lined Steel | Food and pharmaceutical industries | Non-reactive, easy to clean | Fragile lining, higher cost | High |

In conclusion, the selection of material for mixing tanks with agitators is critical and should be based on specific application requirements, including the type of media being mixed, environmental conditions, and budget constraints. International B2B buyers must also consider compliance with local standards and regulations to ensure the selected materials meet their operational needs.

In-depth Look: Manufacturing Processes and Quality Assurance for mixing tank with agitator

What Are the Key Stages in the Manufacturing Process of Mixing Tanks with Agitators?

The manufacturing process for mixing tanks with agitators involves several critical stages, each designed to ensure that the final product meets the high standards required for industrial applications. Here’s a breakdown of the main stages:

1. Material Preparation

The first step in manufacturing mixing tanks is the selection and preparation of materials. Common materials include stainless steel, carbon steel, and various alloys, chosen for their corrosion resistance and mechanical strength. The selected materials undergo rigorous quality checks to ensure they meet industry specifications. Suppliers often use certified materials to ensure compliance with international standards.

2. Forming Techniques

Once the materials are prepared, they are subjected to forming processes. These may include:

- Cutting: Sheets of metal are cut to the required dimensions using laser cutting or plasma cutting technologies for precision.

- Bending: The cut sheets are then bent into shape using hydraulic presses or bending machines, forming the body of the tank.

- Welding: After shaping, components are welded together. Techniques such as TIG (Tungsten Inert Gas) welding or MIG (Metal Inert Gas) welding are commonly employed to ensure strong, durable joints.

3. Assembly of Components

Following the forming stage, the next step is assembling the agitator and tank components. This involves:

- Installation of Agitators: Depending on the design, agitators may be mounted at the top, bottom, or side of the tank. The choice of agitator—whether direct drive or gear-driven—affects the mixing efficiency and is selected based on the application.

- Integration of Accessories: Additional components such as baffles, sight glasses, and temperature sensors are added to enhance functionality.

4. Finishing Processes

The final stage involves finishing processes to enhance durability and aesthetics:

- Surface Treatment: Tanks may undergo treatments such as polishing, passivation, or coating to improve corrosion resistance and cleanliness.

- Quality Inspection: Before leaving the manufacturing facility, tanks are subjected to a thorough inspection to ensure they meet specified standards.

How is Quality Assurance Implemented in the Manufacturing of Mixing Tanks?

Quality assurance (QA) is critical in the manufacturing of mixing tanks with agitators, ensuring that the products not only meet customer expectations but also adhere to international standards. Here’s an overview of how QA is typically implemented:

International Standards and Certifications

Manufacturers often adhere to various international standards to ensure quality, including:

- ISO 9001: This standard focuses on quality management systems and ensures that processes are in place for consistent quality.

- CE Marking: For products sold in the European market, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For tanks used in the oil and gas industry, American Petroleum Institute (API) standards provide guidelines for safety and quality.

Key Quality Control Checkpoints

Quality control (QC) checkpoints are established throughout the manufacturing process:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Inspections are conducted at various stages of the manufacturing process to identify defects early.

- Final Quality Control (FQC): The completed tanks undergo comprehensive testing, including pressure tests, leak tests, and performance evaluations.

What Testing Methods Are Commonly Used for Mixing Tanks?

To ensure the reliability and safety of mixing tanks, several testing methods are commonly employed:

- Hydrostatic Testing: This method checks for leaks by filling the tank with water and applying pressure.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or dye penetrant testing assess the integrity of welds and materials without damaging them.

- Performance Testing: The functionality of the agitator is evaluated under operational conditions to ensure it meets the required mixing specifications.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should take proactive steps to verify the quality control processes of potential suppliers. Here are some actionable strategies:

Conducting Supplier Audits

Buyers should perform regular audits of suppliers’ manufacturing facilities. This allows for an in-depth evaluation of production processes, adherence to quality standards, and overall operational efficiency.

Requesting Quality Assurance Documentation

Buyers should ask suppliers for documentation related to their quality assurance processes, including:

Illustrative image related to mixing tank with agitator

- Certificates of Compliance: Proof that products meet required standards.

- Test Reports: Results from any testing conducted on the products.

- Quality Control Procedures: Detailed descriptions of QC checkpoints and methodologies.

Utilizing Third-Party Inspections

Engaging third-party inspection agencies can provide an unbiased assessment of supplier capabilities. These agencies can conduct audits and inspections, offering valuable insights into the supplier’s manufacturing practices and quality control measures.

What Nuances Should International Buyers Consider Regarding Quality Control?

International buyers, especially those from regions like Africa, South America, the Middle East, and Europe, need to be aware of specific nuances in quality control:

- Regional Standards: Buyers should familiarize themselves with the local regulations and standards that may differ from international norms. Understanding these can help ensure compliance and avoid delays.

- Logistical Considerations: The transportation of mixing tanks can affect quality. Buyers should ensure that suppliers have robust packaging and handling procedures to prevent damage during transit.

- Cultural and Communication Differences: Effective communication is key in international transactions. Buyers should establish clear lines of communication with suppliers to address any quality concerns that may arise during the manufacturing process.

By understanding the manufacturing processes and quality assurance measures in place, B2B buyers can make informed decisions when sourcing mixing tanks with agitators, ensuring they select suppliers who meet their quality expectations.

Illustrative image related to mixing tank with agitator

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mixing tank with agitator’

In the global market, sourcing a mixing tank with an agitator requires careful planning and consideration. This guide provides a structured checklist to help B2B buyers navigate the procurement process efficiently, ensuring that they select the right equipment for their specific operational needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, outline the technical requirements for your mixing tank and agitator. Consider factors such as tank size, material (e.g., stainless steel for corrosion resistance), and mixing capacity. Clearly defined specifications will streamline your search and ensure that suppliers understand your exact needs.

Step 2: Assess Your Mixing Application

Understanding the specific application for the mixing tank is crucial. Different processes, such as blending, emulsifying, or dispersing, require different types of agitation and tank designs. Identify the properties of the materials you will be mixing, including viscosity and temperature, to ensure compatibility with the tank and agitator type.

Step 3: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers. Look for companies with a solid track record in manufacturing mixing tanks and agitators. Pay attention to their industry experience, customer reviews, and case studies relevant to your sector. A well-regarded supplier will often provide insights into the latest technologies and innovations in mixing equipment.

Step 4: Verify Supplier Certifications and Compliance

Ensure that potential suppliers adhere to relevant industry standards and certifications. This may include ISO certifications, CE marking, or compliance with local regulations. Certifications not only indicate quality assurance but also demonstrate that the supplier is committed to safety and environmental standards, which is particularly important in regions with stringent regulations.

Step 5: Request Customization Options

Many applications require tailored solutions. Inquire about the supplier’s ability to customize mixing tanks and agitators to fit your specific requirements. This may include adjustments in size, material, agitator type, or additional features such as heating or cooling jackets. Customization can significantly enhance the efficiency and effectiveness of your mixing process.

Step 6: Evaluate Pricing and Delivery Terms

Once you have shortlisted suppliers, request detailed quotes that include pricing, delivery timelines, and payment terms. Compare the total cost of ownership, which encompasses installation, maintenance, and operational costs, not just the initial purchase price. Clear delivery terms are essential to ensure that your production schedules are not disrupted.

Step 7: Conduct Factory Visits or Virtual Inspections

If possible, arrange visits to the manufacturing facilities or request virtual tours. Observing the production process can provide valuable insights into the quality control measures and manufacturing practices employed by the supplier. This step can help build confidence in your chosen supplier and ensure that they meet your quality standards.

By following this checklist, B2B buyers can approach the procurement of mixing tanks with agitators strategically, ensuring that they make informed decisions that align with their operational needs and standards.

Comprehensive Cost and Pricing Analysis for mixing tank with agitator Sourcing

What Are the Key Cost Components of Mixing Tanks with Agitators?

When sourcing mixing tanks with agitators, understanding the cost structure is crucial for effective budgeting. The primary cost components include:

-

Materials: The choice of materials significantly affects pricing. Stainless steel is commonly preferred for its durability and resistance to corrosion, while carbon steel is often more economical but may require additional coatings for protection. Specialty materials like high-grade alloys can further increase costs.

-

Labor: Skilled labor is essential in the assembly and customization of mixing tanks. Labor costs can vary based on the complexity of the design and the location of manufacturing. Regions with higher labor costs will naturally push up the overall price.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, facility costs, and equipment maintenance. Efficient manufacturing processes can help minimize these expenses.

-

Tooling: Custom tooling for specialized designs or large-scale production can lead to increased initial costs. However, investing in quality tooling can reduce long-term production costs and improve efficiency.

-

Quality Control (QC): Ensuring that mixing tanks meet industry standards requires a robust QC process, which adds to the overall cost. Buyers should consider the certifications and testing procedures that suppliers adhere to, as these can influence the price.

-

Logistics: Shipping costs can vary widely based on the location of the supplier and the destination. Factors like the size and weight of the tanks, as well as the chosen shipping method, will impact logistics costs.

-

Margin: Supplier margins vary by company and market conditions. Understanding the margin expectations of suppliers can aid in negotiations.

What Influences Pricing for Mixing Tanks with Agitators?

Several factors can affect the pricing of mixing tanks with agitators, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for bulk pricing discounts. Buyers should assess their needs to determine if they can benefit from economies of scale.

-

Specifications and Customization: Custom designs tailored to specific processes can incur additional costs. Buyers should clarify their requirements upfront to receive accurate quotes.

-

Material Quality and Certifications: Higher quality materials and industry certifications can lead to increased costs but may be essential for compliance with regulations in certain industries.

-

Supplier Factors: The reputation and reliability of suppliers play a significant role in pricing. Established suppliers may charge a premium for their proven track record, while newer or less-known companies may offer more competitive rates.

-

Incoterms: The terms of shipping and delivery can greatly influence total costs. Buyers should negotiate Incoterms that minimize their logistical burdens and costs, particularly for international shipments.

How Can Buyers Optimize Costs When Sourcing Mixing Tanks?

To achieve cost efficiency in sourcing mixing tanks with agitators, buyers should consider the following strategies:

Illustrative image related to mixing tank with agitator

-

Negotiate Effectively: Understanding the cost breakdown can empower buyers during negotiations. Highlighting potential long-term partnerships can also encourage suppliers to offer better pricing.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operation, and potential downtime costs. Investing in higher quality tanks may yield savings in the long run.

-

Be Aware of Pricing Nuances in International Markets: Different regions may have varying pricing structures due to local economic conditions, tariffs, and regulations. For buyers from Africa, South America, the Middle East, and Europe, understanding these factors can help in making informed decisions.

-

Request Multiple Quotes: Engaging multiple suppliers can help identify competitive pricing and ensure that the buyer has a comprehensive view of the market.

Conclusion

Sourcing mixing tanks with agitators involves navigating a complex landscape of costs and pricing influencers. By understanding these elements and applying strategic sourcing techniques, international B2B buyers can optimize their investments and ensure they receive value for their purchases. Always remember that indicative prices may vary based on the specifics of each transaction, and thorough due diligence is essential.

Alternatives Analysis: Comparing mixing tank with agitator With Other Solutions

Exploring Alternatives to Mixing Tanks with Agitators

In industrial settings, the choice of mixing technology can significantly impact efficiency, product quality, and operational costs. While mixing tanks with agitators are popular for their versatility and effectiveness, various alternative solutions exist that may better suit specific applications or constraints. This analysis will compare mixing tanks with agitators against two alternative technologies: inline mixers and batch mixers.

Comparison Table

| Comparison Aspect | Mixing Tank With Agitator | Inline Mixer | Batch Mixer |

|---|---|---|---|

| Performance | High, suitable for various viscosities | High, continuous mixing, ideal for low-viscosity fluids | Moderate, effective for discrete batches |

| Cost | Moderate to high initial investment | Moderate, depending on design | Generally lower initial investment |

| Ease of Implementation | Requires setup and calibration | Quick installation, minimal setup | Moderate, requires proper batch sizing |

| Maintenance | Regular maintenance required | Low maintenance, less wear | Moderate, depends on batch frequency |

| Best Use Case | Large-scale production with diverse materials | Continuous processes, low-viscosity applications | Small to medium production runs, varying formulations |

Detailed Breakdown of Alternatives

What Are Inline Mixers and Their Advantages?

Inline mixers are designed for continuous mixing applications, where fluid flows through the mixer without the need for a tank. This technology is particularly effective for low-viscosity fluids such as water and solvents. The advantages of inline mixers include their compact size, ease of integration into existing pipelines, and lower maintenance needs due to fewer moving parts. However, they may not perform as well with highly viscous materials or larger particle sizes, limiting their versatility compared to mixing tanks with agitators.

Illustrative image related to mixing tank with agitator

How Do Batch Mixers Function and What Are Their Benefits?

Batch mixers operate by mixing discrete quantities of materials in a tank or container. This method is particularly useful for products that require specific formulations or for industries where production runs vary in size. Batch mixers tend to have lower initial costs and can be simpler to operate, making them ideal for smaller businesses or applications with fluctuating demands. However, they may lead to longer production times and increased labor costs per unit compared to continuous mixing solutions.

Conclusion: How to Choose the Right Mixing Solution for Your Needs

When selecting the appropriate mixing technology, B2B buyers should carefully assess their specific operational requirements, including the nature of the materials to be mixed, production volumes, and budget constraints. Mixing tanks with agitators offer versatility and high performance for various applications, while inline and batch mixers present viable alternatives depending on the context. Understanding the pros and cons of each option will empower buyers to make informed decisions that align with their operational goals and enhance overall efficiency.

Essential Technical Properties and Trade Terminology for mixing tank with agitator

What are the Essential Technical Properties of a Mixing Tank with Agitator?

When evaluating mixing tanks with agitators, several technical properties are critical for ensuring optimal performance and compatibility with industrial applications. Understanding these specifications can help B2B buyers make informed decisions.

1. Material Grade

The material used for mixing tanks typically includes stainless steel, carbon steel, or specialized alloys. Stainless steel is preferred for its corrosion resistance and durability, making it ideal for food, pharmaceutical, and chemical industries. Carbon steel, while cost-effective, may require additional coatings for protection against corrosive substances. Selecting the appropriate material grade is vital for ensuring longevity and compliance with industry standards.

2. Tank Capacity

Tank capacity, measured in gallons or liters, indicates the volume of liquid the tank can hold. Capacities can range from small IBC (Intermediate Bulk Container) sizes of 30 gallons to large tanks exceeding 10,000 gallons. The right capacity depends on production needs, batch sizes, and available space. Choosing a tank that aligns with operational requirements prevents inefficiencies and ensures adequate supply during production cycles.

Illustrative image related to mixing tank with agitator

3. Agitator Type and Power

Agitators can be classified into various types, including direct drive, gear drive, and pneumatic systems, with power ratings usually expressed in horsepower (HP). The choice of agitator type affects mixing efficiency and energy consumption. For example, a high-shear agitator is optimal for emulsifying or dispersing materials, while a low-shear agitator is suitable for blending delicate products. Understanding the power requirements and mixing dynamics is essential for achieving desired product consistency.

4. Mounting Design

Mounting design options include clamp mount, flange mount, and top-entry configurations. Each design serves different tank types and operational needs. For instance, clamp mounts are often used for portable tanks, while flange mounts are common in larger, stationary setups. The right mounting design enhances stability and accessibility during maintenance, significantly impacting operational efficiency.

5. Temperature Control Features

For processes requiring specific temperature ranges, features such as jacketed tanks or integrated heating/cooling systems are crucial. These systems help maintain optimal temperatures for mixing sensitive materials. Understanding the thermal management needs is vital for industries like food processing, where temperature control can affect product quality and safety.

Illustrative image related to mixing tank with agitator

What are Common Trade Terminologies in Mixing Tank Procurement?

Familiarity with industry jargon can facilitate smoother negotiations and procurement processes. Here are key terms relevant to mixing tanks with agitators.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that may be marketed under another company’s brand name. In the context of mixing tanks, sourcing from OEMs ensures high-quality standards and compatibility with existing systems. Buyers should consider OEM partnerships for reliable equipment and parts.

2. MOQ (Minimum Order Quantity)

MOQ denotes the minimum number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers, particularly in regions with limited suppliers. Aligning purchase quantities with MOQ can lead to cost savings and optimized inventory management.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. It outlines specifications, quantities, and terms for potential purchases. Crafting a detailed RFQ helps ensure that suppliers provide accurate quotes, allowing buyers to compare options effectively.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping and delivery. Familiarity with these terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is essential for international transactions, impacting total landed costs and risk management.

5. Lead Time

Lead time is the period between placing an order and receiving the product. For mixing tanks, lead times can vary based on customization and manufacturing schedules. Understanding lead times is crucial for production planning and avoiding delays in operations.

By grasping these technical properties and trade terminologies, B2B buyers can enhance their procurement strategies, ensuring they select the right mixing tanks with agitators for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the mixing tank with agitator Sector

What Are the Key Trends and Market Dynamics Influencing the Mixing Tank with Agitator Sector?

The mixing tank with agitator sector is witnessing significant transformation driven by several global factors. Increasing demand for efficient and high-quality mixing processes across industries such as food and beverage, pharmaceuticals, and chemicals is propelling market growth. In regions like Africa, South America, the Middle East, and Europe, buyers are increasingly looking for customizable solutions that cater to specific operational needs. Additionally, the rise of automation and smart technology is reshaping sourcing strategies, with many manufacturers integrating IoT capabilities into their mixing equipment for enhanced monitoring and control.

Emerging trends include a focus on compact and portable mixing solutions, especially in regions with limited space. Clamp mount and portable mixers are gaining traction due to their flexibility and ease of use. Moreover, buyers are increasingly favoring suppliers that offer comprehensive support services, including installation and maintenance, to ensure optimal performance and longevity of their mixing equipment.

Illustrative image related to mixing tank with agitator

Another noteworthy trend is the growing emphasis on energy efficiency and productivity. Companies are seeking mixers that not only deliver superior performance but also reduce energy consumption. This shift is not only cost-effective but aligns with global sustainability goals, making it an attractive proposition for international buyers.

How Is Sustainability Shaping Sourcing Strategies in the Mixing Tank with Agitator Industry?

Sustainability is becoming a cornerstone of procurement strategies in the mixing tank with agitator sector. Companies are increasingly aware of the environmental impact of their operations and are seeking to partner with suppliers that prioritize ethical sourcing and sustainable practices. This includes the use of eco-friendly materials in the manufacturing of mixing tanks and agitators, as well as adherence to green certifications, such as ISO 14001, which focuses on effective environmental management systems.

The importance of ethical supply chains cannot be overstated. Buyers are keen to ensure that their suppliers engage in responsible sourcing practices, reducing waste and minimizing carbon footprints. This trend is particularly pronounced in regions such as Europe, where regulatory standards around sustainability are becoming more stringent. As a result, suppliers that can demonstrate a commitment to sustainability are likely to gain a competitive edge in the marketplace.

Moreover, the integration of renewable energy sources in the operation of mixing equipment is gaining traction. By investing in energy-efficient mixers that utilize solar or wind power, companies can significantly reduce their operational costs while contributing positively to the environment.

What Is the Historical Context of Mixing Tanks with Agitators in B2B Markets?

The evolution of mixing tanks with agitators can be traced back to the early industrial era when the need for efficient mixing processes became paramount. Initially, mixing was a manual process, which proved to be labor-intensive and inconsistent. With advancements in technology, the introduction of mechanical agitators revolutionized the industry, enabling more uniform mixing at a larger scale.

By the mid-20th century, the advent of electric motors and sophisticated control systems further enhanced the capabilities of mixing tanks. This evolution allowed for greater customization and precision in mixing processes, catering to the diverse needs of various industries. Today, the sector continues to innovate, with a strong focus on automation, smart technology integration, and sustainability, reflecting the dynamic demands of global B2B markets.

Frequently Asked Questions (FAQs) for B2B Buyers of mixing tank with agitator

-

How do I solve issues with mixing consistency in my process?

To address mixing consistency, first evaluate the design of your mixing tank and the type of agitator used. Ensure that the agitator is appropriately sized and configured for the specific viscosity and density of your materials. Adjusting the speed settings and using variable frequency drives (VFD) can also enhance mixing efficiency. If problems persist, consider consulting with a mixing equipment supplier to customize the agitator design or to explore additional options like high-shear mixers for more complex applications. -

What is the best mixing tank configuration for my industry?

The ideal mixing tank configuration largely depends on your specific industry requirements. For example, food and beverage industries benefit from stainless steel tanks with sanitary designs, while chemical processing may require specialized materials resistant to corrosion. Additionally, consider factors such as batch size, mixing speed, and the need for temperature control. Consulting with manufacturers who can provide tailored solutions based on your operational needs is highly recommended. -

What customization options are available for mixing tanks and agitators?

Most manufacturers offer extensive customization options, including material selection (e.g., stainless steel, carbon steel), tank size, and agitator type (e.g., paddle, turbine). You can also request features such as heating jackets, insulation, or specific mounting styles to suit your operational setup. When discussing your needs with suppliers, provide detailed specifications and any unique requirements to ensure the final product meets your expectations. -

What are the minimum order quantities (MOQ) for mixing tanks?

Minimum order quantities can vary significantly by supplier and the complexity of the equipment. Typically, manufacturers may have a MOQ ranging from one unit for standard models to larger quantities for custom-built tanks. It’s essential to communicate with potential suppliers to understand their policies and to negotiate terms that suit your purchasing capabilities, especially if you are sourcing for multiple locations. -

What payment terms should I expect when purchasing mixing tanks?

Payment terms can differ based on the supplier’s policies and your location. Common arrangements include upfront deposits (20-50%) with the balance due upon completion or prior to shipping. For international transactions, consider the implications of currency exchange and possible tariffs. Establishing clear payment terms early in negotiations can help prevent misunderstandings and ensure a smooth transaction. -

How can I vet international suppliers for mixing tanks?

To vet international suppliers, start by researching their reputation through customer reviews, industry references, and case studies. Look for certifications such as ISO 9001, which indicates quality management practices. Additionally, consider visiting their manufacturing facility if feasible, or request a virtual tour. Engaging in direct communication about your specific needs and assessing their responsiveness can also provide insights into their reliability and customer service. -

What are the logistics considerations for importing mixing tanks?

Logistics for importing mixing tanks involve several key factors, including shipping methods, customs clearance, and delivery timelines. Ensure that you work with freight forwarders experienced in handling industrial equipment to navigate the complexities of international shipping. Additionally, confirm that the supplier provides all necessary documentation, such as invoices and certificates of origin, to facilitate smooth customs processing. -

What quality assurance practices should I look for in mixing tank suppliers?

Quality assurance practices vary by supplier, but reputable manufacturers will typically have robust quality control processes in place. Look for suppliers who conduct thorough inspections at various stages of production, including material quality checks and final testing of the mixing tanks. Request documentation of their quality assurance protocols and certifications, which can provide assurance of their commitment to delivering high-quality equipment.

Top 9 Mixing Tank With Agitator Manufacturers & Suppliers List

1. INDCO – All Tank Mixers

Domain: indco.com

Registered: 1996 (29 years)

Introduction: All Tank Mixers – Industrial Mixers | INDCO

Key Product Details:

– Types of Mixers: Clamp mount mixers, Top mount mixers, Plate mount mixers, ANSI flange mixers, Tri-clamp mixers, Heavy duty mixers, Sanitary mixers, IBC tote mixers, Drum mixers, Pail mixers, Lab mixers, Handheld mixers, Closed container mixers.

– Motor Types: Air, Electric.

– Horsepower Options: 1/4, 1/3, 1/2, 3/4, 1, 1-1/2, 2, 3…

2. Cedarstone Industry – Industrial Mixing Tanks and Mixers

Domain: cedarstoneindustry.com

Registered: 2016 (9 years)

Introduction: Cedarstone Industry offers a range of industrial mixing tanks and mixers, including custom built and standard built options. Key products include:

– Custom Built Mixing Tanks

– Standard Mixing Tanks

– Custom Built Blending Systems

– High Shear Dispersing Tanks

– Inline High Shear Mixers

– In-Line and In-Tank Homogenizers

– High Shear Blending Tanks

– High Shear Microjet Mixers

– IBC Tote Mixers

– …

3. Mixer Direct – Stainless Steel Mixing Tanks

Domain: mixerdirect.com

Registered: 2008 (17 years)

Introduction: Stainless Steel Mixing Tanks available in various sizes: 30 gal, 55 gal, 80 gal, 125 gal, and 200 gal. Each tank comes with a standard hinged lid suitable for industrial mixers. Prices range from $3,015.00 for the 30 gallon tank to $10,066.00 for the 200 gallon tank. Key features include different horsepower options (1/2 HP, 3/4 HP, 1.5 HP), impeller diameters (4.5 in. to 6 in.), and shaft lengths…

4. WM Process – Industrial Mixing Systems

Domain: wmprocess.com

Registered: 2003 (22 years)

Introduction: Key Product Details: 1. Industrial Mixing Systems, Agitators, & Mix Tanks – Custom built to specifications. 2. Types of Mixers: Tri Clamp Mixers, Top Entry Mixers, High Viscosity Mixers, Mag Drive Mixers, Explosion Proof Mixers, Sanitary Mixers, Lab Mixers, C Clamp Mixers, Single Use Mixers, Bottom Entry Mixers, Carboy Mixers, Corrosion Resistant Mixers. 3. Mixing Tanks: Poly (PE) Mixing Tanks, St…

5. Heritage Equipment – Stainless Steel Mixing Tanks

Domain: heritage-equipment.com

Registered: 1998 (27 years)

Introduction: Stainless Steel Mixing Tanks & Blending Tanks from Heritage Equipment

– Sizes: 100 gallons to 5,000 gallons

– Material: High-quality 304 stainless steel (option for 316L stainless steel product contact surface)

– Features:

– Interior Construction: 304 Stainless Steel, #4 finish

– Exterior Construction: 304 Stainless Steel, #2B finish

– Insulation: Polyurethane, minimum 2″ thick

– Agitation…

6. Alfa Laval – Tank Agitators

Domain: alfalaval.us

Registered: 2002 (23 years)

Introduction: Alfa Laval tank agitators maximize mixing efficiency while ensuring optimal flow rates and gentle product treatment. Key features include:

– Versatile designs with customization and mounting options for various hygienic applications.

– Higher mixing efficiency than comparable agitators.

– Unique impeller design for greater energy savings and a smaller carbon footprint.

– Easy installation, operati…

7. Dynamix – Industrial Mixing Tanks and Mixers

Domain: dynamixinc.com

Registered: 1999 (26 years)

Introduction: Dynamix offers a range of industrial mixing tanks and mixers suitable for various applications across multiple industries. Key product details include: 1. **Mixer Types by Volume**: – XLarge Mixers: 100,000 – 1,000,000 Gal – Large Mixers: 10,000 – 100,000 Gal – Medium Mixers: 300 – 10,000 Gal – Small Mixers: 50 – 3,000 Gal 2. **Mixer Types by Tank Type**: – Large Tank Mixers – Medium Tank Mixers -…

8. G&F – Mixing Tanks

Domain: gandf.com

Registered: 1996 (29 years)

Introduction: G&F Mixing Tanks are used to stir or mix fluids in industries such as chemical, food, pharmaceutical, and cosmetic. They are also known as agitators. Key uses include: mixing liquids, promoting chemical reactions, maintaining homogeneous liquid bulk during storage, and increasing heat transfer. An agitator consists of a drive device (motor, gear reducer), a guiding system (shaft with bearings), a …

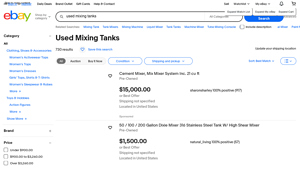

9. Dixie Mixer – Used Mixing Tanks

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Used Mixing Tanks available on eBay, with various options including sizes ranging from 5 gallons to 1,000 liters. Prices range from under $900 to over $46,000. Conditions include new and used items. Popular brands include Dixie Mixer, Readco, and Watson Metal Masters. Features may include stainless steel construction, jacketed tanks, and pneumatic mixers. Many listings offer ‘Best Offer’ options a…

Strategic Sourcing Conclusion and Outlook for mixing tank with agitator

In the competitive landscape of industrial manufacturing, effective strategic sourcing of mixing tanks with agitators is crucial for enhancing operational efficiency and ensuring product quality. Buyers should focus on understanding their specific application needs—whether for small-scale production or large-scale operations—and the mounting options available, such as clamp mount or flange mount mixers. Selecting the right equipment not only improves mixing performance but also reduces maintenance costs and downtime.

As international buyers from regions like Africa, South America, the Middle East, and Europe seek to optimize their processes, prioritizing suppliers who offer customization and quick shipping can provide a significant advantage. Investing in durable materials, such as stainless steel, ensures longevity and compliance with industry standards, especially in sectors like food and pharmaceuticals.

Looking ahead, the demand for innovative mixing solutions will continue to rise. B2B buyers are encouraged to engage with reputable manufacturers and distributors to explore tailored solutions that align with their operational goals. By fostering strong partnerships and leveraging strategic sourcing, companies can enhance their production capabilities and remain competitive in the global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.