A B2B Buyer’s Guide to Mixer Ribbon: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for mixer ribbon

In the fast-evolving landscape of industrial manufacturing, sourcing the right mixer ribbon can present a formidable challenge for international B2B buyers. Whether you’re in the agricultural sector in Africa, the pharmaceutical industry in Europe, or the food processing market in South America, the need for efficient and reliable mixing solutions is paramount. This comprehensive guide explores the myriad types of ribbon blenders, their diverse applications, and the critical factors to consider when selecting the ideal equipment for your specific needs.

From understanding the technical specifications to evaluating supplier credibility, this guide is designed to empower B2B buyers with actionable insights that streamline the procurement process. We delve into cost considerations, maintenance requirements, and the latest innovations in ribbon blender technology, ensuring that you are well-equipped to make informed decisions.

As businesses across the Middle East and beyond strive for operational excellence, the right mixer ribbon can significantly enhance production efficiency and product quality. By leveraging the knowledge shared in this guide, you can confidently navigate the global market, optimize your supply chain, and ultimately drive your business forward in a competitive landscape.

Understanding mixer ribbon Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Ribbon Blender | U-shaped trough, dual helical ribbons for axial and radial mixing | Food processing, pharmaceuticals, chemicals, plastics | Pros: Versatile, efficient mixing; Cons: Limited to batch processes |

| Vacuum Ribbon Blender | Designed for operation under vacuum to minimize oxidation | Sensitive materials, pharmaceuticals, specialty chemicals | Pros: Preserves material integrity; Cons: Higher initial cost |

| Sanitary Ribbon Blender | Constructed with FDA-compliant materials for hygiene | Food, cosmetics, pharmaceuticals | Pros: Easy to clean, meets strict hygiene standards; Cons: Costly |

| High-Shear Ribbon Blender | Integrated high-speed choppers for particle size reduction | Powder coatings, fine chemicals, food applications | Pros: Enhanced mixing efficiency; Cons: More complex maintenance |

| Paddle Blender | Paddle-shaped agitators for more gentle mixing | Delicate materials, dough, slurries | Pros: Reduces shear; Cons: Slower mixing process |

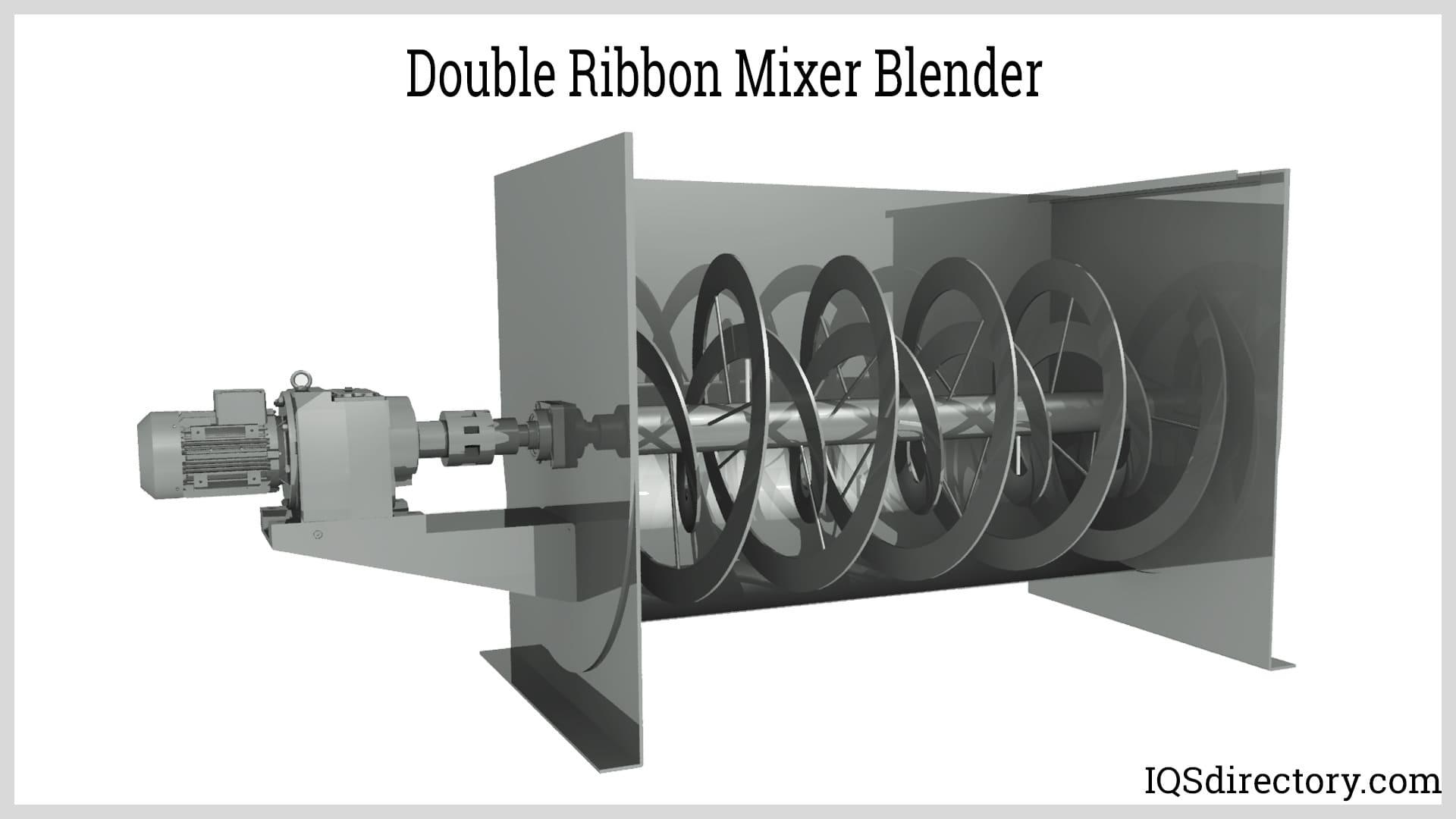

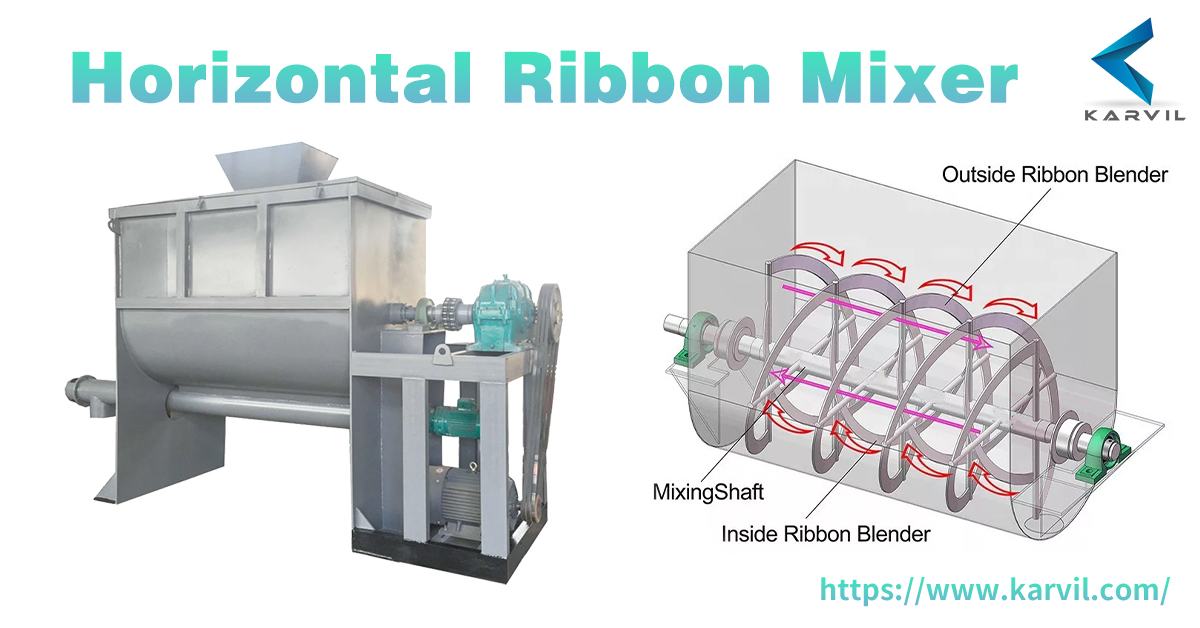

What Are the Characteristics of Standard Ribbon Blenders?

Standard ribbon blenders feature a U-shaped trough and dual helical ribbons that facilitate both axial and radial mixing. This design is particularly effective for blending bulk solids like powders and granules across various industries, including food processing, pharmaceuticals, and chemicals. When considering a purchase, B2B buyers should evaluate the capacity needs, as these blenders range from small to large sizes. While they are versatile and efficient, their batch processing nature may not suit continuous production environments.

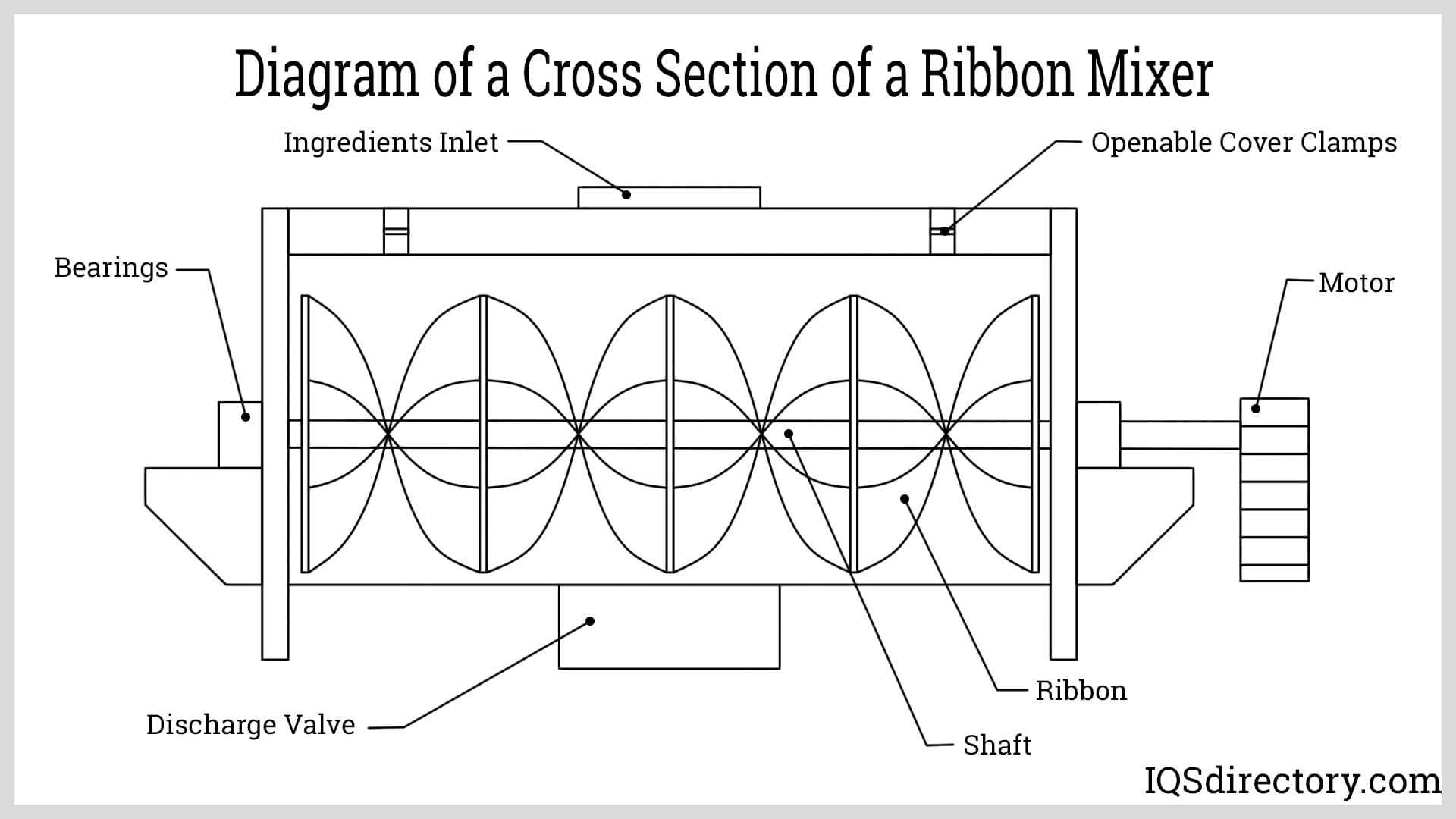

Illustrative image related to mixer ribbon

Why Choose a Vacuum Ribbon Blender?

Vacuum ribbon blenders are specifically engineered to operate under vacuum conditions, which significantly reduces the risk of oxidation and contamination. This makes them ideal for sensitive materials, such as pharmaceuticals and specialty chemicals, where product integrity is paramount. Buyers should consider the operational costs and benefits of maintaining a vacuum environment. While these blenders can be more expensive initially, the protection they offer to sensitive ingredients can justify the investment.

What Sets Sanitary Ribbon Blenders Apart?

Sanitary ribbon blenders are constructed from materials that comply with FDA regulations, ensuring they meet stringent hygiene standards. These blenders are essential in industries like food production and cosmetics, where cleanliness is critical. When purchasing, B2B buyers should prioritize features that enhance ease of cleaning and maintenance. Although the upfront costs may be higher, the long-term savings from reduced downtime and compliance with health standards can be significant.

How Do High-Shear Ribbon Blenders Enhance Mixing?

High-shear ribbon blenders incorporate high-speed choppers within their design, enabling them to achieve finer particle sizes and more homogeneous mixtures. This feature is particularly beneficial in applications like powder coatings and fine chemicals, where uniformity is crucial. Buyers should assess the specific mixing requirements of their products and consider the complexity of maintenance, as these blenders may require more frequent servicing due to their intricate components.

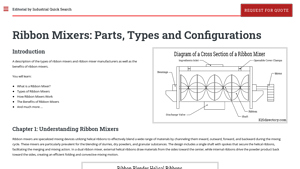

Illustrative image related to mixer ribbon

In What Scenarios Are Paddle Blenders Most Effective?

Paddle blenders utilize paddle-shaped agitators that provide a gentler mixing action, making them suitable for delicate materials such as dough and slurries. Their design minimizes shear, which is essential for preserving the integrity of sensitive mixtures. B2B buyers should consider the trade-off between mixing speed and material safety when selecting this type. While paddle blenders may operate slower than standard ribbon blenders, their ability to handle fragile materials can be a crucial advantage in specific applications.

Key Industrial Applications of mixer ribbon

| Industry/Sector | Specific Application of mixer ribbon | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Mixing dry ingredients for spice blends and seasonings | Ensures uniformity and consistency in flavor profiles | Food-grade materials, compliance with safety standards |

| Pharmaceuticals | Blending active ingredients in tablet production | Enhances product efficacy and stability | Sanitary design, precise mixing capabilities |

| Chemical Manufacturing | Mixing powders for polymer or resin production | Improves product homogeneity and reduces waste | Customization options, durability under harsh conditions |

| Agriculture | Preparing fertilizer blends | Optimizes nutrient distribution for better crop yields | Resistance to corrosive materials, bulk handling design |

| Cosmetics and Personal Care | Combining cosmetic powders and liquids | Achieves desired texture and consistency | Sanitary construction, ease of cleaning and maintenance |

How is Mixer Ribbon Used in the Food and Beverage Sector?

In the food and beverage industry, mixer ribbons are commonly employed to blend dry ingredients, such as spices and seasonings. This application ensures a uniform distribution of flavors, which is crucial for product consistency and quality. Buyers in this sector must prioritize food-grade materials and ensure that mixers comply with safety standards, particularly in regions like Africa and South America where regulations may vary significantly.

What Role Does Mixer Ribbon Play in Pharmaceuticals?

In pharmaceutical manufacturing, mixer ribbons are vital for blending active ingredients in tablet production. The precise mixing capabilities of these blenders enhance product efficacy and stability, which is essential for meeting regulatory standards. International buyers should focus on sanitary designs that prevent contamination, as well as the ability to accommodate various batch sizes, especially in markets like Europe and the Middle East.

How is Mixer Ribbon Utilized in Chemical Manufacturing?

Mixer ribbons are extensively used in chemical manufacturing for blending powders, particularly in the production of polymers and resins. This application ensures improved product homogeneity and minimizes waste, which is critical for operational efficiency. Buyers should consider customization options, such as materials resistant to harsh chemicals, to meet the specific requirements of their production processes.

What Benefits Does Mixer Ribbon Offer in Agriculture?

In agriculture, mixer ribbons are used to prepare blends of fertilizers, ensuring optimal nutrient distribution. This application can significantly enhance crop yields, making it a valuable tool for agricultural businesses. When sourcing, buyers should look for designs that can withstand corrosive materials and facilitate bulk handling, especially in emerging markets across Africa and South America.

Illustrative image related to mixer ribbon

How is Mixer Ribbon Important in Cosmetics and Personal Care?

In the cosmetics and personal care industry, mixer ribbons are essential for combining powders and liquids to achieve the desired texture and consistency in products. This application is crucial for product quality and consumer satisfaction. Buyers should prioritize sanitary construction and ease of cleaning, as these factors are vital for compliance with industry standards, particularly in regions like Europe and the Middle East where hygiene regulations are stringent.

3 Common User Pain Points for ‘mixer ribbon’ & Their Solutions

Scenario 1: Inconsistent Mixing Results Impacting Product Quality

The Problem: B2B buyers in industries such as food production or pharmaceuticals often face challenges with inconsistent mixing results when using ribbon mixers. This inconsistency can lead to product quality issues, such as uneven distribution of ingredients, which is critical for compliance with health regulations and maintaining customer satisfaction. Buyers may find that their ribbon blenders do not achieve the desired homogeneity, resulting in batch variations that can compromise the integrity of the final product.

The Solution: To address this issue, it is essential to properly evaluate the specifications and features of the ribbon blender before purchasing. Buyers should prioritize models equipped with advanced mixing capabilities, such as variable frequency drives that allow precise control over mixing speeds. Additionally, ensuring that the ribbon blender has a high-quality agitator design, such as dual ribbons for improved material movement, can enhance mixing efficiency. Implementing regular maintenance schedules and calibration checks on the equipment can also prevent inconsistencies in the mixing process, ultimately leading to higher product quality and customer satisfaction.

Scenario 2: Operational Downtime Due to Equipment Failures

The Problem: Operational downtime caused by equipment failures is a significant concern for B2B buyers, particularly in industries with tight production schedules. Ribbon blenders, if not properly maintained or if built with lower-quality components, may experience frequent breakdowns. This not only disrupts production but also incurs additional costs for repairs and lost revenue due to halted operations.

The Solution: To mitigate the risk of equipment failure, buyers should invest in ribbon blenders from reputable manufacturers known for their durability and reliability. Look for models that utilize gearmotor drives instead of belt-driven systems, as they offer better performance and lower maintenance needs. It’s also advisable to integrate predictive maintenance technologies, such as condition monitoring sensors, which can provide real-time insights into the equipment’s health. This proactive approach allows companies to schedule maintenance before failures occur, ensuring that production runs smoothly and efficiently, ultimately reducing downtime.

Illustrative image related to mixer ribbon

Scenario 3: Safety Concerns with Dust and Fume Emissions

The Problem: Safety in the workplace is a paramount concern for B2B buyers, especially in industries like chemicals and food processing where dust and fume emissions can pose significant health risks. Poorly designed ribbon blenders can exacerbate these issues, leading to not only regulatory compliance risks but also jeopardizing worker safety. Buyers may struggle to find equipment that balances effective mixing with safe operation.

The Solution: To enhance workplace safety, buyers should select ribbon blenders that come equipped with features aimed at minimizing dust and fume emissions. Look for models that include dust-tight discharge valves and safety covers that prevent the escape of particulates. Additionally, consider blenders that offer vacuum capabilities to contain dust during operation. Implementing proper training for operators on best practices for using the equipment can further reduce risks. Regularly reviewing and updating safety protocols and conducting audits on equipment performance can ensure compliance with safety regulations while promoting a safer working environment. By prioritizing safety features in the selection process, buyers can protect their workforce and maintain operational integrity.

Strategic Material Selection Guide for mixer ribbon

What Are the Key Properties of Common Materials Used in Mixer Ribbons?

When selecting materials for mixer ribbons, it is crucial to consider their properties, as these directly impact performance, durability, and application suitability. Below are analyses of four common materials used in the construction of mixer ribbons, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Illustrative image related to mixer ribbon

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, durability, and ability to withstand high temperatures and pressures. Typically, grades like 304 and 316 are used, with 316 offering superior resistance to chlorides and acids.

Pros & Cons:

The primary advantage of stainless steel is its longevity and minimal maintenance needs, making it suitable for various applications, including food processing and pharmaceuticals. However, it can be more expensive than other materials and may require specialized manufacturing processes, which can increase lead times.

Impact on Application:

Stainless steel is compatible with a wide range of media, including corrosive substances. Its non-reactive nature makes it ideal for applications where contamination must be avoided.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM A240 for stainless steel. Different regions may have specific preferences; for instance, European buyers often favor EN standards.

Illustrative image related to mixer ribbon

2. Carbon Steel

Key Properties:

Carbon steel is characterized by its strength and toughness, with a higher yield strength compared to stainless steel. However, it lacks corrosion resistance unless treated with coatings.

Pros & Cons:

The main advantage of carbon steel is its cost-effectiveness, making it an attractive option for large-scale operations. However, its susceptibility to rust and corrosion can limit its applications, particularly in humid or corrosive environments.

Impact on Application:

Carbon steel is suitable for dry bulk materials but may not be ideal for wet or corrosive applications. Proper coating or treatment is necessary to enhance its durability.

Considerations for International Buyers:

Buyers in regions with high humidity or corrosive environments, such as parts of Africa and South America, should consider the long-term costs associated with maintenance and potential failures due to corrosion.

3. Hastelloy

Key Properties:

Hastelloy is a high-performance alloy known for its exceptional resistance to corrosion and high-temperature environments. It can withstand extreme conditions, making it suitable for various industrial applications.

Pros & Cons:

The key advantage of Hastelloy is its ability to perform in harsh environments, significantly reducing the risk of failure. However, it is one of the most expensive materials available, which may not be feasible for all budgets.

Impact on Application:

Hastelloy is ideal for mixing highly corrosive chemicals or in applications where extreme temperatures are present, such as in the chemical and petrochemical industries.

Considerations for International Buyers:

International buyers must consider the availability and sourcing of Hastelloy, as it may not be as widely available in all regions. Compliance with industry-specific standards is also critical.

4. Polypropylene

Key Properties:

Polypropylene is a thermoplastic polymer known for its chemical resistance, lightweight nature, and ease of fabrication. It can handle moderate temperatures but is not suitable for high-pressure applications.

Pros & Cons:

The main advantage of polypropylene is its low cost and versatility, making it suitable for various applications. However, it has lower mechanical strength and temperature resistance compared to metals, which may limit its use in demanding environments.

Impact on Application:

Polypropylene is suitable for mixing non-corrosive materials and is often used in the food industry due to its FDA compliance. However, it may not perform well with high-temperature or high-pressure applications.

Considerations for International Buyers:

Buyers should check for compliance with food safety regulations, especially in Europe and North America, where stringent standards are enforced.

Illustrative image related to mixer ribbon

Summary Table of Material Selection for Mixer Ribbons

| Material | Typical Use Case for mixer ribbon | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Carbon Steel | Dry bulk materials | Cost-effective | Susceptible to rust and corrosion | Low |

| Hastelloy | Chemical and petrochemical mixing | Exceptional corrosion resistance | Very high cost | High |

| Polypropylene | Non-corrosive materials | Lightweight and low cost | Limited temperature and pressure tolerance | Medium |

This guide serves as a comprehensive overview for B2B buyers seeking to make informed decisions regarding the material selection for mixer ribbons, considering both performance and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for mixer ribbon

What Are the Main Stages of Manufacturing a Mixer Ribbon?

Manufacturing a mixer ribbon involves several critical stages, each designed to ensure the final product meets the high standards required for effective mixing in various applications. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Mixer Ribbon Manufacturing?

The first stage of the manufacturing process is material preparation. This involves selecting high-quality materials, typically stainless steel or other alloys, to ensure durability and resistance to corrosion. The materials are then cut to size and subjected to pre-treatment processes such as cleaning or surface treatment to remove impurities. This step is essential as it directly impacts the performance and longevity of the mixer ribbon.

What Techniques Are Used in Forming Mixer Ribbon Components?

Forming is the next stage, where the prepared materials are shaped into the necessary components of the mixer ribbon. Common techniques include welding, machining, and stamping. For instance, the helical blades, or ribbons, are often fabricated through precision machining to achieve the required dimensions and tolerances. Advanced CNC (Computer Numerical Control) machining is frequently utilized to ensure accuracy, particularly in high-volume production runs. This stage is crucial for ensuring that the components fit together seamlessly during assembly.

How Are Mixer Ribbon Components Assembled?

The assembly stage involves bringing together the various components, including the trough, agitator, and motor. This process typically follows a systematic approach, where components are first inspected for defects before assembly. Proper alignment and secure fastening are critical, as any misalignment can lead to operational inefficiencies or equipment failure. Depending on the design, assembly may also include integrating features such as heating/cooling jackets or vacuum systems.

What Finishing Techniques Are Applied to Mixer Ribbons?

Finishing is the final manufacturing stage, which includes processes like polishing, coating, and quality inspection. The surfaces of the mixer ribbon are often polished to a specific grit finish to enhance their sanitary properties, particularly for applications in food and pharmaceuticals. Additionally, protective coatings may be applied to enhance resistance to wear and corrosion. It’s also during this stage that the final quality checks are conducted to ensure compliance with international standards.

What Are the Quality Control Measures in Mixer Ribbon Manufacturing?

Quality control (QC) is paramount in the manufacturing of mixer ribbons, ensuring that products meet both international and industry-specific standards. For B2B buyers, understanding these QC processes can aid in selecting reliable suppliers.

Illustrative image related to mixer ribbon

Which International Standards Are Relevant for Mixer Ribbon Quality Control?

Manufacturers often adhere to international quality standards, such as ISO 9001, which outlines criteria for a quality management system. Compliance with ISO standards indicates that a manufacturer has established robust quality management processes. Additionally, industry-specific certifications such as CE (for European markets) and API (for the oil and gas sector) may also be relevant, depending on the application of the mixer ribbon.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control checkpoints are integrated at various stages of the manufacturing process, including:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before they are used in production.

- In-Process Quality Control (IPQC): Conducted during manufacturing, this ensures that processes are functioning correctly and that components meet design specifications.

- Final Quality Control (FQC): This final inspection assesses the finished product against predefined criteria, ensuring it meets customer and regulatory requirements.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify the quality control practices of potential suppliers:

- Conduct Audits: Regular audits of suppliers can help assess their compliance with international standards and internal QC processes.

- Request Quality Reports: Buyers should ask for documented evidence of quality control measures, including test results and certifications.

- Engage Third-party Inspectors: Utilizing independent third-party inspectors can provide an objective assessment of a supplier’s quality assurance practices.

What Testing Methods Are Commonly Used in Quality Control for Mixer Ribbons?

Testing methods play a crucial role in ensuring the performance and reliability of mixer ribbons. Common testing methods include:

- Dimensional Inspection: Verifying that all components meet specified dimensions and tolerances.

- Material Testing: Conducting tensile strength tests and hardness tests to ensure materials can withstand operational stresses.

- Performance Testing: Assessing the mixer ribbon’s ability to perform under simulated operational conditions, including mixing efficiency and consistency.

What Nuances Should International B2B Buyers Be Aware of Regarding Quality Control?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances related to quality control:

- Regulatory Compliance: Different regions may have varying regulatory requirements that manufacturers must comply with, which can impact product certifications.

- Cultural Considerations: Understanding local manufacturing practices and standards can aid in assessing supplier capabilities and reliability.

- Logistics and Supply Chain Risks: Buyers should consider the potential for delays or disruptions in the supply chain, which can affect the timely delivery of quality products.

By being informed about the manufacturing processes and quality assurance measures for mixer ribbons, international B2B buyers can make more educated decisions, ensuring they partner with manufacturers who uphold the highest standards of quality and performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mixer ribbon’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure a mixer ribbon. A well-chosen mixer ribbon can significantly enhance operational efficiency and product quality across various industries, including pharmaceuticals, food processing, and chemical manufacturing. This step-by-step guide will help you navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s essential to clearly outline your technical requirements. Consider factors such as the volume of material to be mixed, the physical properties of the materials (e.g., density, moisture content), and specific mixing needs (e.g., batch size, mixing speed).

– Ensure that your specifications align with industry standards to facilitate smoother communication with suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers that specialize in mixer ribbons. Look for companies with a proven track record in your specific industry or application.

– Use online directories, industry trade shows, and professional networks to compile a list of potential suppliers.

– Pay attention to customer reviews and case studies to gauge their reliability and product performance.

Step 3: Evaluate Supplier Certifications

It’s crucial to verify the certifications and quality standards of potential suppliers. Look for ISO certifications or industry-specific compliance that demonstrate adherence to quality management systems.

– Certifications like FDA approval are particularly important in the food and pharmaceutical sectors, ensuring that the equipment meets safety and quality standards.

Step 4: Request Product Samples and Demonstrations

Before making a final decision, request product samples or demonstrations to assess the mixer ribbon’s performance. This step allows you to evaluate the mixing efficiency, ease of use, and maintenance requirements firsthand.

– Ensure that the samples reflect the actual materials you intend to mix to provide a realistic assessment of the machine’s capabilities.

Step 5: Inquire About Customization Options

Discuss customization options with potential suppliers to ensure the mixer ribbon meets your specific operational needs. Many manufacturers offer customizable features such as different materials, sizes, and additional functionalities like heating or cooling capabilities.

– Customization can enhance performance and efficiency, particularly for unique mixing applications.

Step 6: Assess After-Sales Support and Warranty

Evaluate the after-sales support and warranty offered by suppliers. A reliable supplier should provide comprehensive support, including installation, training, and maintenance services.

– Inquire about warranty terms to protect your investment and ensure that you have recourse in case of equipment failure.

Step 7: Compare Pricing and Total Cost of Ownership

Finally, compare pricing among shortlisted suppliers while considering the total cost of ownership (TCO). The lowest upfront cost may not always be the best option if it leads to higher maintenance or operational costs.

– Analyze factors such as energy efficiency, potential downtime, and parts availability to make an informed financial decision.

By following this checklist, B2B buyers can confidently navigate the procurement process for mixer ribbons, ensuring that they select the best equipment for their operational needs.

Comprehensive Cost and Pricing Analysis for mixer ribbon Sourcing

What Are the Key Cost Components in Sourcing Mixer Ribbon?

When sourcing mixer ribbons, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality stainless steel is often preferred for its durability and resistance to corrosion, but alternatives such as carbon steel may be less expensive. Custom materials or coatings for specific applications can further increase costs.

-

Labor: Labor costs can vary based on geographic location and the complexity of the manufacturing process. Skilled labor is often required for assembly and quality control, influencing the overall labor cost.

-

Manufacturing Overhead: This includes indirect costs such as factory utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help reduce these costs.

-

Tooling: The initial setup for producing mixer ribbons may require specialized tooling, particularly for custom designs. This upfront investment is often amortized over the production run.

-

Quality Control (QC): Rigorous quality assurance processes are essential to ensure the mixer ribbons meet industry standards. The cost of QC can vary based on the level of testing and certification required.

-

Logistics: Transportation, warehousing, and handling of materials add to the total cost. International shipments may incur additional fees such as customs duties and insurance.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. This margin can vary widely depending on the supplier’s market positioning and the competitive landscape.

How Do Price Influencers Affect Mixer Ribbon Costs?

Several factors can influence the pricing of mixer ribbons:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to reduced per-unit costs. Suppliers may offer discounts for bulk purchases, which can significantly lower the overall expense.

-

Specifications and Customization: Customized mixer ribbons tailored for specific applications can lead to higher costs due to the added complexity in design and manufacturing.

-

Materials: The choice of materials not only affects the initial purchase price but also impacts long-term maintenance and operational costs. Investing in high-quality materials can lead to better performance and durability.

-

Quality and Certifications: Certifications such as ISO or FDA compliance can add to the costs but may be necessary for certain industries, particularly pharmaceuticals and food processing.

-

Supplier Factors: The reputation, reliability, and location of the supplier can influence pricing. Established suppliers may charge more due to their experience and quality assurance processes.

-

Incoterms: The terms of delivery (Incoterms) can affect logistics costs and responsibilities between buyers and sellers. Understanding these terms can help buyers anticipate additional expenses related to shipping and customs.

What Are Some Tips for Buyers to Negotiate Better Prices on Mixer Ribbons?

B2B buyers should consider the following strategies to enhance cost-efficiency and negotiate better prices:

-

Negotiate Terms: Engage suppliers in discussions about pricing, especially for larger orders. Leverage your purchasing power to negotiate favorable terms and discounts.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the TCO, which includes maintenance, operational costs, and the lifespan of the mixer ribbon. A slightly higher upfront cost might result in lower TCO if the product is more durable.

-

Research Suppliers: Conduct thorough research on potential suppliers. Compare quotes, assess their reputation, and check for any hidden costs associated with their products.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, tariffs, and regional market conditions that can affect pricing. Engaging with local representatives can provide insights into the local market.

-

Request Samples: Before finalizing an order, request samples to evaluate quality and performance. This can help avoid costly mistakes down the line.

Conclusion

Sourcing mixer ribbons requires a comprehensive understanding of the cost structure and pricing influencers. By considering these elements and employing strategic negotiation techniques, buyers can optimize their purchasing decisions, ensuring they receive the best value for their investment. Always remember that prices can vary significantly based on a multitude of factors, so it’s advisable to seek multiple quotations and conduct due diligence to ensure a wise procurement choice.

Alternatives Analysis: Comparing mixer ribbon With Other Solutions

Understanding Alternatives in Bulk Mixing Solutions

In the realm of bulk solids processing, selecting the right mixing technology is crucial for optimizing efficiency, performance, and cost-effectiveness. While ribbon blenders are widely recognized for their versatility and effectiveness, several alternative solutions also exist, each with unique advantages and drawbacks. This section will explore how the mixer ribbon compares to two viable alternatives: paddle mixers and high-shear mixers.

Comparison Table

| Comparison Aspect | Mixer Ribbon | Paddle Mixer | High-Shear Mixer |

|---|---|---|---|

| Performance | Efficient for dry powders, good for wet applications | Effective for thick, viscous materials | Excellent for emulsifying and homogenizing |

| Cost | Moderate initial investment; low operating costs | Generally lower initial cost but may require more maintenance | Higher initial investment; higher operating costs |

| Ease of Implementation | Moderate; requires space and setup | Easy to implement in existing setups | Requires specialized installation and training |

| Maintenance | Low maintenance; durable design | Moderate maintenance; wear on paddles | Higher maintenance due to complex parts |

| Best Use Case | Seasonings, pharmaceuticals, agricultural products | Heavy slurries, pastes, and doughs | Cosmetics, food emulsions, and pharmaceuticals |

Detailed Breakdown of Alternatives

Paddle Mixer

Paddle mixers are designed with flat blades that move materials in a circular motion, making them suitable for mixing heavy and viscous substances. One of their primary advantages is their relatively low initial cost, making them an attractive option for businesses with budget constraints. However, they tend to require more frequent maintenance due to wear on the paddles, which can lead to increased operational downtime. Paddle mixers excel in applications such as dough production and slurries, but may not be as effective for lighter powders or granules.

High-Shear Mixer

High-shear mixers utilize high-speed rotors to generate intense shear forces, making them ideal for emulsifying, homogenizing, and dispersing materials. Their performance in creating fine emulsions is unmatched, which is particularly beneficial in industries such as cosmetics and pharmaceuticals. However, the initial investment for high-shear mixers is typically higher than that of ribbon or paddle mixers, and they also incur greater operating costs due to energy consumption and maintenance of complex parts. These mixers require specialized training for operators and may not be suitable for bulk dry powders.

Conclusion: Choosing the Right Mixing Solution for Your Needs

When selecting a mixing solution, B2B buyers must consider their specific application requirements, budget constraints, and operational capabilities. Ribbon blenders offer a versatile, efficient option for a wide range of products, particularly in bulk solids processing. Paddle mixers may be more cost-effective for heavier materials but could involve higher maintenance. High-shear mixers excel in creating emulsions but come with a higher price tag and operational demands. By carefully evaluating these alternatives against their mixing needs, buyers can make informed decisions that enhance productivity and efficiency in their operations.

Essential Technical Properties and Trade Terminology for mixer ribbon

What Are the Critical Technical Properties of a Mixer Ribbon?

Understanding the essential technical properties of a mixer ribbon is vital for B2B buyers, particularly when assessing equipment that meets specific operational requirements. Here are key specifications to consider:

-

Material Grade

The material used in mixer ribbons, typically high-quality stainless steel, is crucial for durability and hygiene. Stainless steel is resistant to corrosion, making it suitable for food, pharmaceutical, and chemical applications. Selecting the right material grade ensures compliance with industry standards and affects the longevity of the equipment. -

Capacity

Mixer ribbons come in various sizes, typically ranging from ½ cubic foot to over 1000 cubic feet. The capacity determines the volume of material that can be processed in a single batch. Understanding capacity is essential for aligning equipment with production needs, ensuring efficiency, and minimizing downtime. -

Power and Drive Type

The type of motor and drive system (e.g., gearmotor vs. belt-driven) significantly impacts the performance and maintenance of the mixer ribbon. Gearmotors provide higher efficiency and reliability, reducing the risk of slippage and wear, which translates to lower operational costs over time. -

Safety Features

Safety is paramount in industrial equipment. Features like OSHA-compliant guards, safety limit switches, and dust-tight discharge valves help minimize risks for operators. Investing in equipment with robust safety measures not only protects personnel but also complies with regulatory standards, reducing liability. -

Mixing Mechanism

The design of the mixing mechanism, including the configuration of ribbons, affects the mixing efficiency. A well-designed ribbon blender facilitates both radial and axial mixing, leading to uniformity in the final product. Understanding the mixing dynamics can help buyers select equipment suited to their specific processing requirements. -

Customizability Options

Many manufacturers offer customization options, such as heating/cooling jackets or vacuum capabilities. This flexibility allows businesses to adapt equipment to unique processes or product characteristics, enhancing overall productivity and efficiency.

What Common Trade Terms Should B2B Buyers Know About Mixer Ribbons?

Familiarity with industry jargon can significantly streamline communication and purchasing processes. Here are some common terms relevant to mixer ribbons:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reputable sources for high-quality mixer ribbons and components. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for budgeting and inventory management, ensuring that purchasing aligns with operational needs. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price proposals from suppliers. For mixer ribbons, submitting an RFQ allows buyers to compare offers, negotiate terms, and select suppliers based on cost-effectiveness and quality. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, outlining who is responsible for shipping, insurance, and tariffs. Familiarity with these terms helps B2B buyers mitigate risks and understand logistical responsibilities when importing mixer ribbons. -

Batch Processing

This term refers to the method of processing materials in discrete groups or quantities. Understanding batch processing is crucial for buyers as it impacts production scheduling, inventory control, and overall efficiency in manufacturing operations. -

Sanitary Design

This term refers to equipment designed to meet specific cleanliness and safety standards, especially important in food and pharmaceutical industries. Buyers should prioritize sanitary designs to ensure compliance with health regulations and maintain product integrity.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when purchasing mixer ribbons, ensuring they select equipment that meets their operational needs while adhering to industry standards.

Navigating Market Dynamics and Sourcing Trends in the mixer ribbon Sector

What Are the Key Market Trends Influencing the Mixer Ribbon Sector?

The global mixer ribbon market is experiencing significant growth driven by the increasing demand for efficient mixing solutions across various industries, including food and beverage, pharmaceuticals, chemicals, and plastics. The rise of automation in manufacturing processes is a notable trend, with many companies seeking advanced mixing technologies that offer precision and consistency. For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions.

Emerging technologies such as Industry 4.0 and the Internet of Things (IoT) are reshaping the mixer ribbon landscape. These innovations enable real-time monitoring and data analysis, enhancing operational efficiency and reducing downtime. Moreover, as businesses expand their global footprint, there is a growing emphasis on sourcing machinery that complies with international safety and quality standards, such as CE and ISO certifications. Buyers are increasingly prioritizing suppliers who can demonstrate a commitment to quality, reliability, and innovation.

Regional market dynamics also play a vital role. In Europe, stringent regulations regarding product safety and environmental impact drive demand for high-quality, efficient mixing equipment. Conversely, in emerging markets like Vietnam, the focus is on cost-effectiveness and scalability, as businesses aim to optimize production without compromising quality. As such, B2B buyers must navigate these diverse market conditions to identify the most suitable mixer ribbon solutions for their specific needs.

Illustrative image related to mixer ribbon

How Are Sustainability and Ethical Sourcing Changing the Mixer Ribbon Market?

Sustainability is becoming a critical consideration in the sourcing of mixer ribbon machinery. International buyers are increasingly aware of the environmental impact associated with manufacturing processes and are seeking suppliers that prioritize sustainability. This includes the use of eco-friendly materials, energy-efficient designs, and manufacturing practices that minimize waste.

Ethical sourcing is also gaining traction, with businesses looking to establish transparent supply chains that prioritize fair labor practices and responsible sourcing of raw materials. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming essential criteria for B2B buyers when evaluating potential suppliers. These certifications not only ensure compliance with environmental regulations but also demonstrate a supplier’s commitment to sustainability.

In addition, the demand for “green” certifications and materials is on the rise. For example, using stainless steel in the construction of mixer ribbon equipment is not only beneficial for product longevity but also supports a circular economy by being recyclable. As international buyers prioritize sustainability, they will likely choose suppliers who can provide evidence of their environmental initiatives and ethical sourcing practices.

Illustrative image related to mixer ribbon

How Has the Mixer Ribbon Sector Evolved Over Time?

The mixer ribbon sector has undergone significant evolution since its inception, adapting to the changing needs of industries and advancements in technology. Originally designed for simple mixing tasks, modern mixer ribbons now integrate complex functionalities, such as heating, cooling, and vacuum operation, allowing for a wider range of applications.

The introduction of automation and smart technology has further transformed the sector, enabling precise control over mixing processes and facilitating real-time monitoring. This evolution reflects a broader trend in industrial mixing towards increased efficiency, safety, and quality assurance. As businesses continue to seek out innovative solutions, the mixer ribbon sector is positioned to play a critical role in the future of manufacturing across various industries.

Understanding these trends and dynamics is essential for international B2B buyers looking to invest in mixer ribbon technology that meets their operational requirements while aligning with sustainability and ethical sourcing goals.

Frequently Asked Questions (FAQs) for B2B Buyers of mixer ribbon

1. How do I select the right mixer ribbon for my application?

Selecting the right mixer ribbon involves assessing your specific blending needs, such as the type of materials to be mixed, batch size, and desired consistency. Consider the mixer’s capacity, which can range from ½ to 1000 cubic feet, and the specific features required, like vacuum capabilities or heating/cooling jackets. Understanding your industry’s regulations, such as FDA compliance for food applications, is also crucial. Finally, consult with suppliers for expert recommendations based on their experience with similar applications.

Illustrative image related to mixer ribbon

2. What is the best ribbon blender for pharmaceutical applications?

For pharmaceutical applications, a ribbon blender that meets stringent hygiene and safety standards is essential. Look for models constructed from high-quality stainless steel with FDA-compliant finishes to ensure easy cleaning and minimal contamination risk. Features such as vacuum operation, dust-tight discharge valves, and programmable logic controllers (PLC) for batch consistency are also beneficial. Collaborate with suppliers specializing in pharmaceutical equipment to find a model tailored to your specific production requirements.

3. How can I ensure the quality of the mixer ribbon I purchase?

To ensure quality, start by vetting suppliers through their certifications, customer reviews, and industry reputation. Request detailed specifications, including materials used and safety features, and inquire about the manufacturing process. It’s also beneficial to ask for references or case studies from previous clients in your industry. Conducting a factory visit or requesting a sample can further validate the quality of the mixer ribbon before making a bulk purchase.

4. What customization options are available for mixer ribbons?

Customization options for mixer ribbons can include variations in size, materials (such as Hastelloy for corrosive environments), and additional features like heating/cooling jackets, vacuum capabilities, and different agitator designs. Suppliers often offer tailored solutions to meet specific industry needs, such as sanitary finishes for food applications or explosion-proof motors for hazardous environments. Discuss your requirements with potential suppliers to explore the full range of customization possibilities.

5. What are the minimum order quantities (MOQs) for mixer ribbons?

Minimum order quantities (MOQs) for mixer ribbons can vary significantly between manufacturers and depend on the level of customization required. Generally, standard models may have lower MOQs, while customized solutions may require higher quantities to justify production costs. It’s advisable to discuss your needs directly with suppliers to negotiate MOQs that align with your budget and project timelines, especially if you are a smaller business or just starting out.

6. What payment terms should I expect when sourcing mixer ribbons internationally?

Payment terms for international purchases of mixer ribbons can vary widely depending on the supplier and the buyer’s location. Common terms include advance payment, letter of credit, or net payment options (e.g., net 30 or net 60 days). Be prepared to discuss payment security measures, such as escrow services or payment through verified platforms. Always clarify terms in writing to avoid misunderstandings and to ensure compliance with international trade regulations.

7. How can I manage logistics when importing mixer ribbons?

Managing logistics involves coordinating with suppliers, freight forwarders, and customs brokers to ensure smooth transportation of mixer ribbons. Confirm shipping methods (air or sea freight) based on urgency and cost-effectiveness, and be aware of customs regulations in your country. Ensure all necessary documentation is prepared, such as invoices, packing lists, and certificates of origin. Additionally, consider insurance options to protect your investment during transit.

8. What are the common troubleshooting steps for mixer ribbon issues?

Common issues with mixer ribbons may include uneven mixing, excessive wear, or mechanical failures. Start by checking the calibration and settings of the mixer, ensuring it is operating within specified parameters. Inspect the agitator and trough for damage or blockages and verify that all safety features are functioning correctly. Regular maintenance, such as lubrication and cleaning, can prevent many issues. If problems persist, consult the manufacturer’s technical support for specialized troubleshooting advice.

Top 7 Mixer Ribbon Manufacturers & Suppliers List

1. ROSS – Ribbon Blender

Domain: mixers.com

Registered: 1999 (26 years)

Introduction: Ribbon Blender Overview: The ROSS Ribbon Blender is a batch-style mixer designed for bulk solids processing, suitable for a variety of applications including seasonings, beverage mixes, pharmaceuticals, chemicals, plastics, and agricultural powders. It can heat, cool, dry materials under vacuum, coat solid particles with liquids, and mix wet applications like soups and slurries. Features include a…

2. MARSHALLTOWN – Ribbon Mixers

Domain: marshalltown.com

Registered: 1996 (29 years)

Introduction: Ribbon Mixers by MARSHALLTOWN and WAL-BOARD TOOLS, designed for mixing drywall mud, paint, EIFS adhesives, and coatings. Made from high-quality plated steel. MARSHALLTOWN mixers available in lengths of 16 in., 24 in., and 30 in. with widths of 2 in., 3 in., 4 in., and 5 in. Best working speeds are 500-900 RPM. 2″ and 3″ mixers fit a ⅜” or larger speed drill; 4″ and 5″ mixers fit a ½” or larger spe…

3. Ribbon Blenders – Stainless Steel Mixers

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: – Product Type: Ribbon Blenders

– Categories: Ribbon Mixer, Ribbon Blender

– Sizes Available: 2.5 CF, 10 CF, 25 CF, 35 CF, 50 CF, 200L, 215 CF, 268 CF, 300L, 400 CF, 460V

– Material: Stainless Steel (SS304, SUS316)

– Condition: New, Used, Pre-Owned

– Price Range: Under $10,000 to over $160,000

– Features: Food Grade, Pharma Grade, Horizontal, Double Ribbon, Jacketed, Incline Feeding Screws

– Brand…

4. NAC Supply – Tote Ribbon Mixer

Domain: nacsupply.com

Registered: 2006 (19 years)

Introduction: Tote Ribbon Mixer – 52″; 7/16” Hex Shaft; 4.5” Ribbon Diameter; 8” Ribbon Length; 52” Total Length; designed for mixing materials in 275 gal totes; effective for mixing asphalt sealer and similar materials; compatible with power drill; priced at $96.50.

5. Scott Equipment – Industrial Batch Mixers

Domain: scottequipment.com

Registered: 1996 (29 years)

Introduction: Scott Equipment’s Industrial Batch Mixers are designed for accurate mixing of various products, from fine powdered materials to coarse ground ingredients. Key features include:

– Durable construction in mild or stainless steel

– Custom-built to meet specific application requirements

– Complete mix cycles of less than four minutes

– Available designs: ribbon, paddle, or paddle/ribbon combinatio…

6. IQS Directory – Ribbon Mixers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Ribbon mixers are specialized mixing devices utilizing helical ribbons to blend materials by channeling them inward, outward, forward, and backward. They are prevalent for blending slurries, dry powders, and granular substances. Key features include a U-shaped drum that facilitates easy loading, cleaning, and effective mixing. Types of ribbon mixers include single ribbon blenders, double ribbon bl…

7. Ribbon Mixers – Uniform Blending Solutions

Domain: machineryandequipment.com

Registered: 1997 (28 years)

Introduction: Ribbon Mixers designed for thorough blending of powders, granules, and bulk solids in food, chemical, and pharmaceutical operations. Features dual helical ribbons for uniform mixing in batch or continuous processes. Inventory includes models from Scott, Eirich, American Process Systems, Hayes & Stoltz, and Marion Process Solutions. Key models include:

– Mixer, Ribbon, 600 CF, Carbon Steel, Double…

Strategic Sourcing Conclusion and Outlook for mixer ribbon

How Can Strategic Sourcing Enhance Your Mixer Ribbon Procurement?

In conclusion, the strategic sourcing of mixer ribbons is pivotal for businesses seeking to optimize their production processes across diverse industries. By investing in high-quality ribbon blenders, companies can achieve significant improvements in mixing efficiency, product quality, and operational safety. Key factors to consider include the versatility of applications, customization options, and the importance of reliable supplier partnerships.

A well-executed sourcing strategy not only ensures access to cutting-edge technology but also fosters long-term relationships with suppliers who understand the unique demands of international markets. As B2B buyers from Africa, South America, the Middle East, and Europe navigate the complexities of global procurement, prioritizing quality and innovation in their mixer ribbon choices will be crucial for maintaining competitiveness.

Looking ahead, the market for mixer ribbons is poised for growth, driven by advancements in blending technology and increasing demand for customized solutions. We encourage international buyers to leverage this opportunity by evaluating their sourcing strategies and aligning with trusted manufacturers that can deliver tailored solutions. Your next step is to explore reputable suppliers who can meet your specific needs and help you elevate your production capabilities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.