A B2B Buyer’s Guide to Miter Bevel Gear: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for miter bevel gear

In the rapidly evolving landscape of global manufacturing, sourcing high-quality miter bevel gears presents a unique challenge for B2B buyers. These specialized gears are essential for applications requiring precise directional changes in motion, making them critical components across various industries, from automotive to robotics. However, navigating the vast array of options, materials, and suppliers can be daunting, especially for international buyers from regions such as Africa, South America, the Middle East, and Europe, including Germany and Saudi Arabia.

This comprehensive guide delves into the intricacies of miter bevel gears, covering essential topics such as types, applications, and supplier vetting processes. We provide insights into the different gear configurations, including straight and spiral miter gears, as well as angular variants that cater to specific shaft angles. Furthermore, the guide explores cost considerations, ensuring that buyers can make informed decisions that align with their budget and operational needs.

By equipping B2B buyers with the necessary knowledge and tools, this guide empowers you to navigate the complexities of sourcing miter bevel gears effectively. With a focus on quality assurance and strategic supplier partnerships, you will be better prepared to enhance your procurement strategy, ensuring reliability and efficiency in your operations.

Understanding miter bevel gear Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Straight Miter Gears | Equal number of teeth, simple design for direction change | General machinery, conveyor systems | Pros: Cost-effective, easy to source. Cons: Limited load capacity. |

| Spiral Miter Gears | Helical tooth design for smoother operation | High-speed applications, robotics | Pros: Quieter operation, higher load capacity. Cons: More expensive than straight gears. |

| Angular Miter Gears | Designed for non-perpendicular shaft angles | Specialized machinery, automotive | Pros: Versatile angle options. Cons: More complex to specify. |

| Hardened Miter Gears | Enhanced durability due to hardening processes | Heavy machinery, industrial equipment | Pros: Increased wear resistance. Cons: Higher initial cost. |

| Plastic Miter Gears | Lightweight, lubrication-free nylon construction | Light-duty applications, toys | Pros: Cost-effective, corrosion-resistant. Cons: Limited load capacity and durability. |

What Are the Key Characteristics of Straight Miter Gears?

Straight miter gears are characterized by their simple design with equal numbers of teeth, allowing for a straightforward change in rotational direction. They are often used in general machinery and conveyor systems where cost-effectiveness is crucial. Buyers should consider their limited load capacity, making them suitable for lighter applications.

How Do Spiral Miter Gears Enhance Performance?

Spiral miter gears feature a helical tooth design that reduces noise and improves efficiency during operation. These gears are ideal for high-speed applications and robotics, where smoother engagement is necessary. While they offer higher load capacities and quieter performance, they come at a higher price point, which buyers must factor into their purchasing decisions.

In What Situations Are Angular Miter Gears Most Beneficial?

Angular miter gears are specifically designed for applications requiring non-perpendicular shaft angles, typically ranging from 45° to 120°. This versatility makes them suitable for specialized machinery and automotive applications. However, their complexity in specification and installation can be a disadvantage for some buyers, necessitating careful planning and consideration.

Why Should You Consider Hardened Miter Gears?

Hardened miter gears undergo specialized processes to enhance their durability and wear resistance, making them ideal for heavy machinery and industrial equipment. While they may have a higher initial cost, their longevity and reduced maintenance needs can lead to cost savings over time. Buyers should evaluate their operational demands to justify this investment.

What Are the Advantages and Limitations of Plastic Miter Gears?

Plastic miter gears, often made from nylon, are lightweight and can operate without lubrication, making them suitable for light-duty applications such as toys or small machinery. They are cost-effective and resistant to corrosion, but their load capacity and overall durability are limited compared to metal options. Buyers must weigh these factors based on their specific application needs.

Key Industrial Applications of miter bevel gear

| Industry/Sector | Specific Application of miter bevel gear | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Conveyor Systems | Efficient direction change and compact design | Material selection (steel, stainless, plastic) and durability |

| Robotics | Robotic Arm Mechanisms | Precision movement and space-saving configurations | Accuracy in gear dimensions and compatibility with existing systems |

| Food Processing | Food Packaging Machinery | Hygiene and rust resistance for safe food handling | Compliance with food safety standards and easy cleaning features |

| Automotive | Differential Gear Systems | Enhanced torque distribution and vehicle performance | Strength, weight, and noise reduction factors |

| Aerospace | Aircraft Control Systems | Reliable directional control in compact spaces | High precision manufacturing and material durability |

How is Miter Bevel Gear Used in Manufacturing Conveyor Systems?

In manufacturing, miter bevel gears are integral to conveyor systems that require a change in direction for material transport. These gears enable efficient operation while maintaining a compact footprint, crucial for optimizing space in production lines. The use of materials such as stainless steel or plastic can enhance durability and reduce maintenance needs. For international buyers, understanding the specific load requirements and environmental conditions (such as humidity or temperature) is vital for selecting the right gear type.

What Role Do Miter Bevel Gears Play in Robotics?

In the robotics sector, miter bevel gears are employed in robotic arm mechanisms to facilitate precise movement and orientation changes. These gears allow for complex motions while conserving space, essential in robotic applications where size constraints are common. Buyers must consider the accuracy of gear dimensions and the need for compatibility with existing robotic systems, ensuring seamless integration and functionality in diverse environments.

How Are Miter Bevel Gears Applied in Food Processing?

In food processing, miter bevel gears are utilized in food packaging machinery to ensure hygienic and efficient operation. The rust-resistant properties of stainless steel gears are particularly beneficial in this industry, where sanitation is paramount. Buyers should prioritize suppliers who adhere to food safety standards and offer easy-to-clean designs, thus ensuring compliance with health regulations while optimizing operational efficiency.

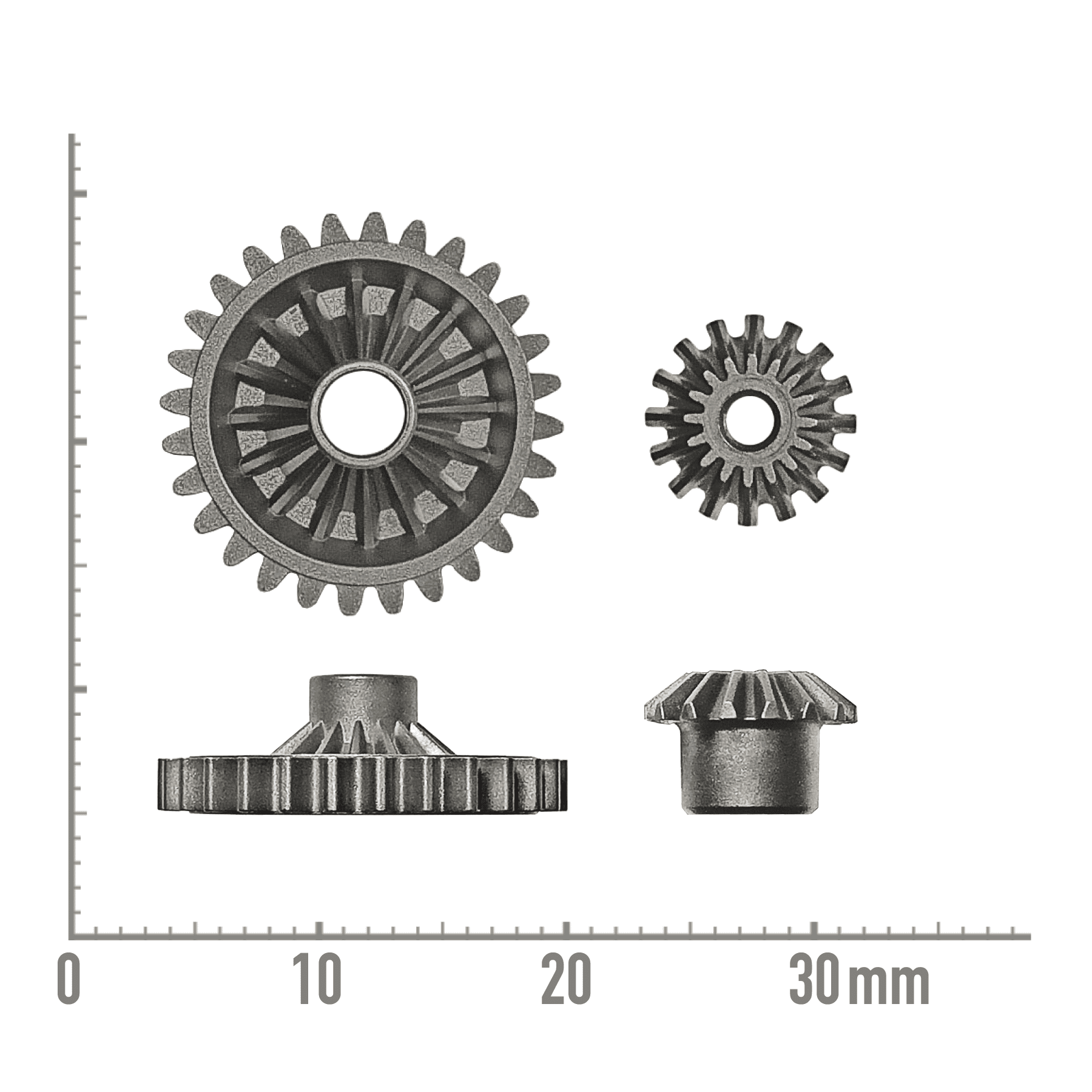

Illustrative image related to miter bevel gear

Why Are Miter Bevel Gears Important in Automotive Applications?

Miter bevel gears are crucial components in automotive differential gear systems, where they facilitate the distribution of torque to wheels during turns. This functionality enhances vehicle performance and stability, particularly in modern vehicles requiring advanced drive systems. When sourcing these gears, international buyers should focus on strength, weight, and noise reduction characteristics, as these factors directly influence vehicle efficiency and user experience.

How Do Miter Bevel Gears Benefit Aerospace Control Systems?

In the aerospace industry, miter bevel gears are vital for aircraft control systems, allowing for reliable directional control in compact configurations. Their ability to handle high precision and significant loads makes them suitable for critical applications in aviation. Buyers from regions with stringent aerospace standards should seek manufacturers who specialize in high-precision gear production, ensuring that the gears meet the rigorous demands of flight safety and performance.

3 Common User Pain Points for ‘miter bevel gear’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Miter Bevel Gear Type

The Problem:

B2B buyers often encounter challenges in selecting the appropriate type of miter bevel gear for their specific application. Given the various options—straight cut, spiral cut, and angular miter gears—making an informed choice can be daunting. This complexity is further exacerbated by the need to consider factors such as load capacity, speed requirements, and installation space. Buyers may worry about making costly mistakes that could lead to operational inefficiencies or equipment failure, particularly in industries like manufacturing and automotive, where precision is critical.

The Solution:

To effectively navigate the selection process, B2B buyers should start by conducting a thorough assessment of their application requirements. This includes understanding the torque, speed, and direction of rotation needed. Utilizing a gear selection guide can help clarify the differences between gear types, including their advantages and limitations. Additionally, collaborating with gear manufacturers who offer customization options can ensure the selected miter bevel gear meets specific operational needs. Buyers should also consider utilizing CAD software to visualize how different gears will fit into their system, providing clarity before making a purchase.

Scenario 2: Managing Noise and Vibration Issues with Miter Bevel Gears

The Problem:

Excessive noise and vibration from miter bevel gears can be a significant issue for B2B buyers, especially in environments where equipment operates continuously or is located near workspaces. This problem can arise from improper gear alignment, inadequate lubrication, or the inherent design of the gears themselves. Not only do these issues affect the efficiency and longevity of the equipment, but they can also lead to worker dissatisfaction and potential regulatory compliance concerns regarding noise levels.

The Solution:

To mitigate noise and vibration, buyers should prioritize the purchase of high-quality miter bevel gears designed with noise reduction features, such as ground teeth for improved tooth engagement and smooth operation. Implementing regular maintenance schedules that include lubrication and alignment checks can also help reduce operational noise. Additionally, utilizing vibration monitoring technologies can provide real-time feedback on the performance of the gears, enabling proactive adjustments before issues escalate. Investing in gears made from materials specifically engineered to dampen sound can further enhance operational tranquility.

Scenario 3: Ensuring Compatibility with Existing Equipment

The Problem:

Compatibility between miter bevel gears and existing machinery is often a source of frustration for B2B buyers. This challenge can stem from variations in gear dimensions, tooth profiles, and mounting configurations. When new gears do not mesh properly with existing components, it can lead to costly downtime and the need for additional modifications or replacements. Buyers may feel overwhelmed by the prospect of re-engineering their systems to accommodate new gear types.

The Solution:

To ensure compatibility, buyers should gather detailed specifications of their current equipment, including gear ratios, shaft diameters, and mounting styles. Engaging with suppliers who provide comprehensive technical support can be invaluable; these experts can assist in identifying suitable miter bevel gears that align with existing systems. Additionally, buyers should consider suppliers who offer prototype or trial options, allowing them to test gear compatibility before making a bulk purchase. Clear communication with manufacturers about specific compatibility needs will lead to more tailored solutions, minimizing the risk of operational disruptions.

Strategic Material Selection Guide for miter bevel gear

What are the Key Properties of Common Materials for Miter Bevel Gears?

When selecting materials for miter bevel gears, understanding the properties and suitability of each option is crucial for optimizing performance and ensuring longevity in various applications. Below, we analyze four common materials used in the production of miter bevel gears: Steel, Stainless Steel, Plastic, and Sintered Metal.

How Does Steel Compare for Miter Bevel Gears?

Steel, particularly grades like S45C and SCM415, is widely used for miter bevel gears due to its excellent strength and durability. Steel gears can typically withstand high loads and exhibit good wear resistance, making them suitable for heavy-duty applications. However, they may be prone to corrosion if not properly treated, which can limit their use in harsh environments.

Pros: High strength, good wear resistance, cost-effective for mass production.

Cons: Susceptible to corrosion, requires surface treatments for enhanced durability.

Impact on Application: Suitable for high-load applications; however, not ideal for corrosive environments without protective coatings.

Considerations for International Buyers: Compliance with standards like ASTM and DIN is essential, especially in regions like Europe where quality assurance is critical.

What Advantages Does Stainless Steel Offer for Miter Bevel Gears?

Stainless steel, particularly SUS303, is favored for applications requiring corrosion resistance, such as in food processing or marine environments. Its resistance to rust and staining makes it an ideal choice for industries where hygiene is paramount. However, stainless steel gears can be more expensive and may not offer the same load-bearing capacity as carbon steel.

Pros: Excellent corrosion resistance, suitable for hygiene-sensitive applications.

Cons: Higher cost, lower load capacity compared to carbon steel.

Impact on Application: Ideal for food machinery and environments exposed to moisture.

Considerations for International Buyers: Buyers in regions with strict food safety regulations (e.g., Germany) will find stainless steel an essential choice.

How Do Plastic Miter Bevel Gears Perform?

Plastic materials, such as nylon (MC901), are increasingly used for miter bevel gears in applications where weight reduction and lubrication-free operation are beneficial. These gears are lightweight and can operate quietly, making them suitable for consumer products and light machinery. However, they may not withstand high loads or extreme temperatures.

Pros: Lightweight, low friction, no lubrication needed, cost-effective.

Cons: Limited load capacity and temperature resistance.

Impact on Application: Best suited for light-duty applications and environments where lubrication is impractical.

Considerations for International Buyers: Cost-effective for mass production, but compliance with environmental regulations regarding plastic waste may be necessary in certain regions.

What Role Does Sintered Metal Play in Miter Bevel Gear Production?

Sintered metal gears are produced through a process that allows for mass production at a lower cost. They are typically used in applications where lightweight components are required, but they can lack the strength and durability of forged or machined gears. Sintered gears are often employed in consumer electronics and automotive applications.

Pros: Cost-effective for high-volume production, lightweight.

Cons: Lower strength and wear resistance compared to traditional materials.

Impact on Application: Suitable for applications where weight is a concern but not ideal for high-stress environments.

Considerations for International Buyers: Buyers should consider the specific application requirements and local manufacturing capabilities when selecting sintered products.

Summary of Material Selection for Miter Bevel Gears

| Material | Typical Use Case for miter bevel gear | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty machinery | High strength and durability | Prone to corrosion | Medium |

| Stainless Steel | Food processing, marine applications | Excellent corrosion resistance | Higher cost, lower load capacity | High |

| Plastic | Consumer products, light machinery | Lightweight, lubrication-free | Limited load capacity and durability | Low |

| Sintered Metal | Consumer electronics, automotive | Cost-effective for mass production | Lower strength and wear resistance | Low |

This strategic material selection guide provides a comprehensive overview for B2B buyers looking to make informed decisions regarding miter bevel gears. Understanding the properties, advantages, and limitations of each material will help in selecting the right gear for specific applications, ensuring optimal performance and longevity.

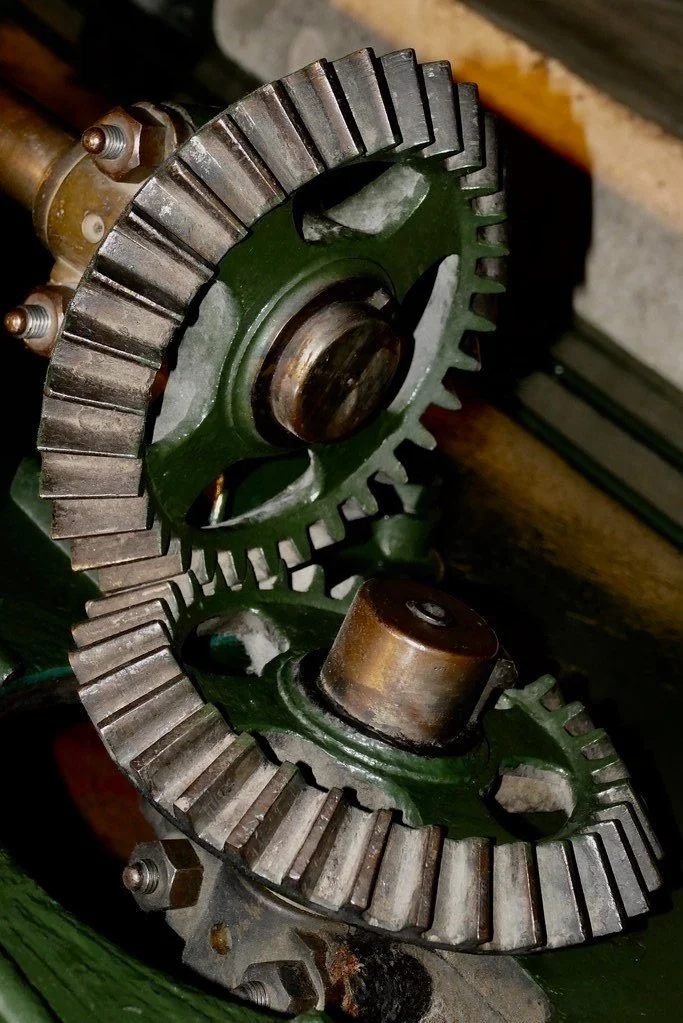

Illustrative image related to miter bevel gear

In-depth Look: Manufacturing Processes and Quality Assurance for miter bevel gear

What Are the Key Stages in the Manufacturing Process of Miter Bevel Gears?

The manufacturing process for miter bevel gears involves several critical stages, ensuring that the final product meets the specific requirements of various applications across industries. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Materials Are Commonly Used for Miter Bevel Gears?

Miter bevel gears are typically produced from high-quality materials such as carbon steel (e.g., S45C, SCM415), stainless steel (e.g., SUS303), and even plastic for lightweight applications. The choice of material affects the gear’s strength, wear resistance, and overall performance.

The preparation phase includes sourcing raw materials that meet international standards, such as JIS (Japanese Industrial Standards) or equivalent standards in Europe and the Americas. Suppliers often perform tests to verify material properties, ensuring that they can withstand the operational demands of their intended applications.

How Are Miter Bevel Gears Formed During Manufacturing?

Once the materials are prepared, the next step is forming, which typically involves various techniques such as cutting, forging, and machining. For miter bevel gears, the most common methods include:

- Gear Cutting: This involves creating the gear teeth profiles using specialized machines. Processes like hobbing and shaping are prevalent for producing straight and spiral miter gears.

- Grinding: After initial cutting, grinding is used to achieve the desired precision and surface finish. This step is crucial for high-performance gears, as it ensures smoother operation and reduced noise.

- Carburizing and Hardening: For gears that require enhanced strength and wear resistance, processes like carburizing are employed. This involves infusing carbon into the gear surface, followed by hardening treatments to improve durability.

What Assembly Techniques Are Used in Miter Bevel Gear Production?

After forming, assembly is a pivotal stage where various components come together. For miter bevel gears, assembly typically involves:

- Pairing Gears: Since miter gears come in pairs, it’s essential to ensure that the right gears are matched. This is particularly important for spiral miter gears, where the direction of twist must be considered.

- Installing Additional Features: Depending on the application, features such as keyways or set screw holes might be added during this stage.

- Final Inspections: Before moving to the finishing stage, a preliminary inspection is often conducted to verify dimensional accuracy and gear alignment.

How Is Finishing Performed on Miter Bevel Gears?

Finishing processes are critical for enhancing the performance and longevity of miter bevel gears. Common finishing techniques include:

- Surface Treatment: This can involve processes such as plating or coating to improve corrosion resistance, especially for gears intended for harsh environments.

- Final Grinding: A last pass of grinding may be performed to achieve tighter tolerances and a superior surface finish. This is particularly vital for gears used in precision applications.

- Quality Inspection: Before the gears are shipped, they undergo thorough inspections to confirm that they meet all specified tolerances and quality standards.

What Are the Key Quality Assurance Standards for Miter Bevel Gears?

Quality assurance is paramount in the manufacturing of miter bevel gears, ensuring that products meet both industry standards and customer expectations. Key international standards include:

- ISO 9001: This standard outlines criteria for a quality management system, emphasizing consistent quality in products and services.

- CE Marking: Particularly relevant for products sold in the European market, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For gears used in the oil and gas sector, adherence to API (American Petroleum Institute) standards is often required.

What Are the QC Checkpoints Throughout the Manufacturing Process?

A robust quality control (QC) system includes several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components to ensure they meet specified requirements before production begins.

- In-Process Quality Control (IPQC): During the manufacturing process, various inspections are conducted to monitor quality at different stages, such as during cutting, grinding, and assembly.

- Final Quality Control (FQC): This is a comprehensive inspection before products leave the facility. It includes dimensional checks, functional testing, and verification against quality standards.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control processes of potential suppliers:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturer’s production processes, QC systems, and adherence to international standards.

- Review of Quality Reports: Buyers should request quality reports that detail inspection results, testing methods, and compliance with standards.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality practices and product reliability.

What QC and Certification Nuances Should International Buyers Consider?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances related to quality control and certification:

- Local Regulations: Different regions may have specific regulations that affect gear manufacturing and certification. Understanding these can help in compliance and market entry.

- Language and Documentation: Ensure that quality assurance documentation is available in a language that all stakeholders understand. This facilitates clear communication and reduces the risk of misunderstandings.

- Cultural Factors: Be aware of cultural differences that may impact negotiations and quality expectations. Building strong relationships with suppliers can lead to better quality outcomes and service.

By understanding the manufacturing processes and quality assurance practices for miter bevel gears, B2B buyers can make more informed decisions, ensuring they select suppliers that meet their quality and operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘miter bevel gear’

Introduction

This practical sourcing guide aims to equip B2B buyers with a systematic checklist for procuring miter bevel gears. Understanding the unique specifications and requirements of these gears is crucial for ensuring operational efficiency and compatibility within your machinery. Following this guide will help you make informed decisions, ultimately leading to successful procurement.

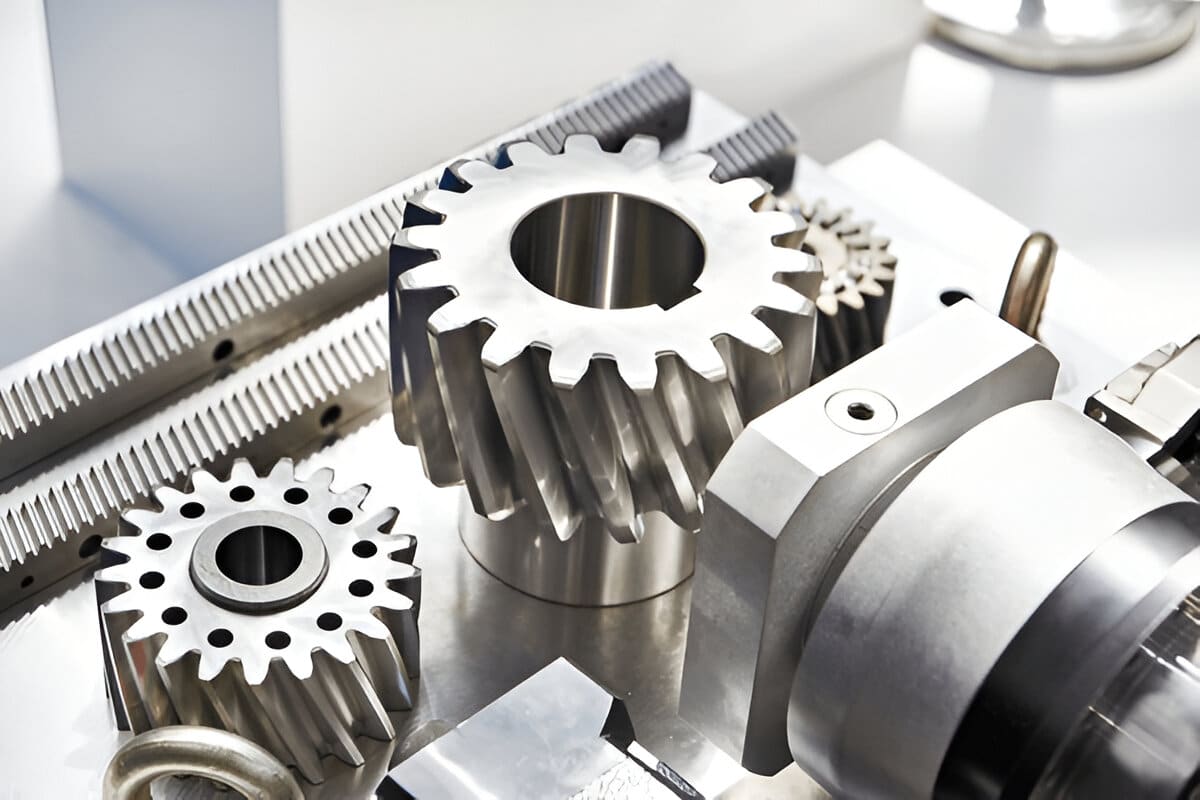

Illustrative image related to miter bevel gear

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for the miter bevel gears you need. Consider factors such as gear type (straight or spiral), tooth count, material (e.g., steel, stainless steel, plastic), and module size. A well-defined specification helps streamline the selection process and ensures that the gears will meet your operational needs.

- Key Points to Specify:

- Gear angle (90 degrees or other)

- Load and torque requirements

Step 2: Identify Application Requirements

Understanding the application in which the miter bevel gears will be used is essential. Different applications may require specific features such as corrosion resistance, high-speed capabilities, or noise reduction. Identifying these needs will guide your selection process and help you choose the most suitable product.

- Considerations:

- Environmental conditions (humidity, temperature)

- Load characteristics (static or dynamic loads)

Step 3: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of miter bevel gears. Look for manufacturers with a strong reputation, particularly those who specialize in gear production. Supplier reputation can significantly impact the quality and reliability of the products you receive.

- What to Look For:

- Industry certifications (ISO, JIS)

- Client testimonials and case studies

Step 4: Evaluate Product Quality and Testing Standards

Before making a purchase, assess the quality of the gears offered by potential suppliers. Inquire about the testing standards they adhere to and request documentation that verifies product quality. High-quality gears can enhance performance and longevity, reducing the risk of failure.

- Quality Indicators:

- Material certifications

- Testing reports (e.g., fatigue testing, wear resistance)

Step 5: Request Samples and Technical Drawings

It is prudent to request samples and technical drawings of the miter bevel gears you are considering. This allows you to evaluate the physical characteristics and compatibility with your systems before committing to a larger order. Additionally, reviewing technical drawings can help ensure that the gears meet your precise specifications.

- Important Aspects:

- Review tooth profiles and dimensions

- Ensure compatibility with existing machinery

Step 6: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in negotiations regarding pricing and terms of sale. Consider factors such as bulk order discounts, payment terms, and delivery schedules. Effective negotiation can lead to cost savings and a more favorable procurement agreement.

- Key Negotiation Points:

- Minimum order quantities

- Warranty and return policies

Step 7: Finalize Your Order and Monitor Delivery

After agreeing on terms, finalize your order and establish a clear timeline for delivery. Monitor the process to ensure that the gears are manufactured and shipped according to the agreed schedule. Maintaining communication with the supplier during this phase can help address any potential issues promptly.

- Delivery Monitoring:

- Confirm shipping dates

- Set up checkpoints for quality assurance upon receipt

Following this comprehensive checklist will empower you to make strategic decisions when sourcing miter bevel gears, ensuring that your procurement process is efficient and effective.

Comprehensive Cost and Pricing Analysis for miter bevel gear Sourcing

When sourcing miter bevel gears, international B2B buyers need to understand the comprehensive cost structure and pricing dynamics involved. This analysis will delve into the various cost components, price influencers, and practical tips to enhance procurement efficiency.

What Are the Key Cost Components for Miter Bevel Gears?

-

Materials: The choice of materials significantly impacts the cost of miter bevel gears. Common materials include carbon steel (e.g., S45C, SCM415), stainless steel (SUS303), and various plastics. Higher-grade materials offer better performance and durability but can elevate costs. Buyers should assess material requirements based on application needs.

-

Labor: Labor costs are influenced by the complexity of the gear production process. Automated manufacturing can reduce labor costs, while custom or intricate designs may require specialized craftsmanship, increasing labor expenses.

-

Manufacturing Overhead: This encompasses expenses related to factory operations, including utilities, equipment maintenance, and depreciation. Efficient manufacturing processes can help mitigate these costs, but they still contribute to the overall pricing.

-

Tooling: Tooling costs relate to the initial investment in molds and dies necessary for producing specific gear types. For custom gears, the tooling cost can be substantial, impacting the overall price, particularly for low-volume orders.

-

Quality Control (QC): Ensuring the gears meet quality standards involves additional costs for testing and inspection. Certifications such as ISO or specific industry standards can enhance product reliability but may also increase pricing.

-

Logistics: Transportation and shipping costs are critical, especially for international buyers. Factors such as distance, shipping method, and customs duties can significantly affect the final price.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market conditions, competition, and the supplier’s positioning.

What Influences the Price of Miter Bevel Gears?

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing. Larger orders often lead to lower per-unit costs due to economies of scale. Negotiating for bulk purchases can yield significant savings.

-

Specifications and Customization: Custom gears tailored to specific applications will generally cost more than standard products. Buyers should clearly define their requirements to avoid unexpected costs.

-

Material Choices: The selection of materials directly impacts cost. For instance, stainless steel gears will be pricier than their carbon steel counterparts, but may be necessary for corrosion resistance in certain environments.

-

Quality and Certifications: Higher-quality gears that meet stringent certifications usually come at a premium. Buyers should weigh the benefits of these certifications against their budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer competitive pricing to gain market share.

-

Incoterms: Understanding international commercial terms (Incoterms) is crucial for cost estimation. They determine who bears the cost and risk during shipping, impacting the total landed cost for buyers.

How Can Buyers Negotiate for Better Pricing?

-

Conduct Market Research: Buyers should benchmark prices across different suppliers to gain insights into competitive pricing structures.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better negotiation outcomes. Long-term partnerships often result in more favorable terms.

-

Focus on Total Cost of Ownership (TCO): Rather than solely considering the purchase price, evaluate the TCO, which includes maintenance, operational efficiency, and potential downtime. This approach can justify higher upfront costs if long-term savings are evident.

-

Be Flexible with Specifications: If possible, being open to alternative materials or designs can lead to cost savings without compromising functionality.

-

Leverage Volume Discounts: If planning future purchases, communicate anticipated volumes to suppliers to negotiate better rates.

Conclusion

Understanding the cost structure and pricing dynamics of miter bevel gear sourcing is essential for international B2B buyers. By considering the various cost components, price influencers, and implementing strategic negotiation tactics, buyers can optimize their purchasing decisions. Remember that prices can vary widely based on numerous factors, so it is advisable to request indicative prices and quotes tailored to specific needs.

Alternatives Analysis: Comparing miter bevel gear With Other Solutions

Understanding Alternatives to Miter Bevel Gears in Mechanical Applications

In the realm of mechanical engineering, selecting the right gear system is crucial for achieving optimal performance, efficiency, and cost-effectiveness. Miter bevel gears, known for their ability to change the direction of drive without altering speed, are a popular choice. However, several alternative solutions exist, each with its own unique advantages and potential drawbacks. This analysis compares miter bevel gears with two viable alternatives: worm gears and planetary gears, providing insights for B2B buyers considering their options.

Comparison Table

| Comparison Aspect | Miter Bevel Gear | Worm Gear | Planetary Gear |

|---|---|---|---|

| Performance | High efficiency, low backlash | High torque, low speed | High torque density, compact |

| Cost | Moderate cost | Generally lower cost | Higher initial investment |

| Ease of Implementation | Requires precise alignment | Simple installation | Complex assembly |

| Maintenance | Moderate maintenance needs | Low maintenance | Moderate maintenance |

| Best Use Case | Direction change in compact spaces | Heavy load applications | Applications needing high torque and compact design |

Analyzing the Alternatives: Worm Gears and Planetary Gears

Worm Gears

Worm gears consist of a worm (screw) and a worm wheel (gear) and are renowned for their ability to transmit power at right angles. They excel in applications requiring high torque and low speed, making them suitable for heavy machinery and conveyor systems. The main advantage of worm gears is their ability to provide significant speed reduction and increase torque while being relatively compact. However, they can suffer from lower efficiency due to sliding friction, which may lead to higher operational costs in the long run. Additionally, while they typically require less maintenance, their design can limit the direction of load application.

Planetary Gears

Planetary gear systems consist of a central gear (sun gear), surrounded by several gears (planet gears) that revolve around it, along with a stationary outer gear (ring gear). This arrangement allows for compact design and high torque density, making them suitable for applications like automotive transmissions and industrial machinery. The main benefit of planetary gears is their ability to handle high loads while maintaining a small footprint. However, they tend to be more complex to assemble and may require more precise manufacturing processes, which can increase initial costs. Maintenance can also be moderate, particularly if the system operates under high stress.

Conclusion: How to Choose the Right Gear Solution

When selecting between miter bevel gears, worm gears, and planetary gears, B2B buyers must consider their specific application requirements. Miter bevel gears are optimal for applications needing direction change in tight spaces without speed alteration. Conversely, worm gears are ideal for low-speed, high-torque scenarios, while planetary gears suit high-load applications where space is a premium. Evaluating factors such as performance needs, cost constraints, ease of implementation, and maintenance requirements will empower buyers to make informed decisions that align with their operational goals and industry standards.

Essential Technical Properties and Trade Terminology for miter bevel gear

What Are the Key Technical Properties of Miter Bevel Gears?

When considering miter bevel gears, several technical properties are critical for ensuring optimal performance in various applications. Understanding these specifications can help B2B buyers make informed decisions that align with their operational requirements.

1. Material Grade

The material used in miter bevel gears significantly influences their strength, durability, and performance. Common materials include SCM415, S45C, and stainless steel (SUS303). High-grade materials like SCM415 are often carburized for enhanced wear resistance, making them suitable for high-load applications. For B2B buyers, selecting the right material ensures longevity and reduces the risk of failure, which can lead to costly downtime.

2. Tooth Finish

The finish of the gear teeth affects their performance and noise levels during operation. Options include ground teeth and cut (non-ground) finishes. Gears with ground teeth offer superior accuracy and reduced friction, leading to quieter operation and longer lifespan. Buyers should consider tooth finish in relation to their application’s noise tolerance and operational efficiency requirements.

Illustrative image related to miter bevel gear

3. Module Size

The module size of a miter bevel gear refers to the size of the teeth and is crucial for determining compatibility with other gears. Common module sizes range from 0.5 to 10, depending on the specific gear type. Selecting the appropriate module size ensures proper meshing with mating gears, which is essential for smooth operation and efficiency.

4. Hardening Method

The method of hardening impacts the gear’s strength and wear resistance. Common hardening techniques include carburizing and induction hardening. These processes improve the gear’s ability to withstand high stress and reduce wear over time. B2B buyers should assess the expected load conditions of their applications to choose gears with the appropriate hardening treatment.

5. Tolerance Grades

Tolerance grades define the precision of the gear manufacturing process. In Japan, for example, grades range from JIS 0 (highest precision) to JIS 6 (lower precision). Higher tolerance grades are essential for applications requiring tight fit and minimal backlash, which can enhance performance and extend service life. Buyers should evaluate their precision requirements to select gears that meet operational standards.

Illustrative image related to miter bevel gear

What Are Common Trade Terms Used in Miter Bevel Gear Transactions?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B market for miter bevel gears. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of miter bevel gears, OEMs typically provide customized solutions tailored to specific machinery requirements. Understanding OEM relationships can help buyers secure quality products that meet their unique specifications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and cost efficiency. Knowing the MOQ can help in planning purchases and ensuring that orders align with production needs.

3. RFQ (Request for Quotation)

An RFQ is a formal document that buyers send to suppliers to request pricing and terms for specific products. In the context of miter bevel gears, an RFQ can include detailed specifications, such as material grade and tolerance requirements. Properly constructed RFQs facilitate competitive bidding and help buyers obtain the best value.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms is essential for B2B transactions involving miter bevel gears, as they clarify shipping costs, risk management, and delivery obligations, ultimately streamlining the procurement process.

5. Lead Time

Lead time refers to the duration from placing an order to receiving the product. It encompasses manufacturing and shipping times. For businesses relying on miter bevel gears, understanding lead times is critical for scheduling production and minimizing disruptions in operations.

By grasping these technical properties and trade terms, B2B buyers can enhance their procurement strategies, ensuring they select the right miter bevel gears for their applications. This knowledge not only facilitates better communication with suppliers but also optimizes operational efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the miter bevel gear Sector

What Are the Key Trends Shaping the Miter Bevel Gear Market?

The global miter bevel gear market is experiencing a significant transformation driven by several key factors. Firstly, the rising demand for precision-engineered components in industries such as automotive, aerospace, and manufacturing is propelling growth. As these sectors increasingly rely on automation and efficiency, the need for high-quality miter bevel gears that ensure smooth transmission and direction change is paramount.

Moreover, technological advancements are redefining sourcing trends. The integration of Industry 4.0 technologies, including IoT and AI, is enhancing the production processes of miter bevel gears, allowing for better precision and reduced lead times. B2B buyers are increasingly seeking suppliers who leverage these technologies to ensure competitive pricing and superior product quality.

Geographical dynamics also play a crucial role. For international buyers in regions like Africa, South America, the Middle East, and Europe, the focus is shifting toward sourcing from suppliers who can provide not only quality products but also flexibility in customization. In particular, markets such as Germany and Saudi Arabia are seeing a surge in demand for angular miter gears due to their versatility in machinery design.

Illustrative image related to miter bevel gear

Lastly, the trend toward digital procurement platforms is transforming how buyers interact with suppliers. Enhanced transparency, streamlined communication, and improved access to product catalogs are becoming essential features that B2B buyers prioritize when selecting their suppliers.

How Are Sustainability and Ethical Sourcing Influencing the Miter Bevel Gear Sector?

Sustainability has emerged as a critical consideration for B2B buyers in the miter bevel gear sector. The environmental impact of manufacturing processes, particularly concerning energy consumption and waste generation, is under scrutiny. Buyers are increasingly inclined to partner with manufacturers who demonstrate a commitment to sustainable practices, such as utilizing energy-efficient machinery and recycling materials.

Ethical sourcing is equally important, as companies strive to ensure their supply chains are free from exploitation and environmental harm. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming prerequisites for suppliers. Buyers are actively seeking these certifications to ensure that their supply chains align with global sustainability standards.

Furthermore, the availability of ‘green’ materials is becoming a selling point. Manufacturers offering miter bevel gears made from recycled or eco-friendly materials can appeal to environmentally conscious buyers. This not only supports corporate social responsibility initiatives but also enhances brand reputation in a market increasingly driven by consumer awareness of environmental issues.

What Is the Historical Context of Miter Bevel Gears in B2B Markets?

The evolution of miter bevel gears can be traced back to their early applications in woodworking and machinery. Traditionally, these gears were crafted from wood, but the industrial revolution ushered in the use of metals, significantly enhancing their durability and performance. Over time, advancements in metallurgy and gear design have led to the development of various types of miter bevel gears, including straight, spiral, and angular configurations.

As industries evolved, so did the requirements for precision and reliability in gear systems. The introduction of CNC machining and advanced manufacturing technologies in the late 20th century further revolutionized the production of miter bevel gears, enabling the creation of highly specialized components tailored to specific applications. Today, the market reflects a diverse range of options, catering to the growing demands of international B2B buyers seeking efficiency and innovation in their machinery solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of miter bevel gear

-

How do I select the right miter bevel gear for my application?

Choosing the right miter bevel gear involves considering several factors, including the gear’s material, size, and tooth configuration. First, assess the load requirements and operating conditions, such as speed and torque. Next, determine whether you need straight or spiral miter gears based on noise and efficiency considerations. For specific applications, consider angular miter gears for non-perpendicular angles. Collaborating with a reputable manufacturer can provide guidance tailored to your needs and ensure compatibility with your existing systems. -

What is the best material for miter bevel gears in different environments?

The best material for miter bevel gears depends on the operating environment. For high-load applications, steel or carburized materials like SCM415 are ideal due to their strength and wear resistance. In corrosive environments, such as food processing, stainless steel (SUS303) is preferable for its rust resistance. For lightweight applications, plastic miter gears can be effective, particularly in low-load scenarios. Always consider the specific demands of your application to choose the most suitable material. -

What are the minimum order quantities (MOQs) for miter bevel gears?

Minimum order quantities (MOQs) for miter bevel gears can vary significantly between suppliers. Generally, manufacturers may set MOQs based on production costs, material availability, and customization requirements. For standard products, MOQs can range from a few dozen to several hundred pieces. However, if you require customized solutions, the MOQ may be higher. It’s essential to discuss MOQs with your supplier upfront to ensure they align with your procurement strategy. -

How can I ensure the quality of miter bevel gears from suppliers?

To ensure quality, start by vetting potential suppliers through research and reviews. Request certifications such as ISO 9001, which indicates adherence to quality management standards. Ask for samples to evaluate the gear’s performance, accuracy, and finish. Additionally, inquire about their manufacturing processes and quality control measures, including testing protocols for durability and precision. Establishing a clear communication channel with the supplier will also facilitate better quality assurance throughout your order. -

What payment terms should I consider when sourcing miter bevel gears internationally?

Payment terms can vary widely in international trade, typically influenced by the supplier’s policies and the buyer’s creditworthiness. Common terms include upfront payment, partial payment upon order confirmation, and the balance upon delivery. Consider using secure payment methods like letters of credit or escrow services to mitigate risks. Additionally, negotiate favorable terms that allow flexibility based on your cash flow and inventory management practices. Always clarify payment terms in the contract to avoid misunderstandings. -

What are the shipping options for importing miter bevel gears?

Shipping options for importing miter bevel gears typically include air freight and sea freight, with the choice depending on urgency and budget. Air freight is faster but more expensive, suitable for smaller, high-value orders. Sea freight is cost-effective for larger shipments but may take longer. Discuss logistics with your supplier, as they often have established relationships with freight forwarders. Ensure that you understand customs regulations and import duties in your region to avoid unexpected costs. -

Can I customize miter bevel gears to fit my specific requirements?

Yes, many manufacturers offer customization options for miter bevel gears. You can request alterations in gear size, tooth count, material, and finish to suit your application. Discuss your specifications with the supplier during the initial stages of procurement. Be aware that custom orders may come with higher MOQs and longer lead times. It’s advisable to provide detailed drawings or prototypes to facilitate accurate production and ensure that the final product meets your expectations. -

What are the common applications for miter bevel gears in various industries?

Miter bevel gears are widely used across numerous industries due to their ability to change the direction of drive shafts. Common applications include conveyor systems, automotive steering mechanisms, and robotics. In manufacturing, they are often found in machine tools and packaging equipment. Additionally, they are used in the aerospace sector for flight control systems. Understanding the specific demands of your industry will help you choose the appropriate type and configuration of miter bevel gears for optimal performance.

Top 7 Miter Bevel Gear Manufacturers & Suppliers List

1. KHK – Miter Gears

Domain: khkgears.net

Registered: 2015 (10 years)

Introduction: Miter Gears are a type of bevel gear that change transmission direction without altering speed, as they have the same number of teeth. KHK produces angular miter gears with shaft angles from 45 to 120 degrees. Key specifications include:

– Types: Straight tooth and spiral miter gears

– Materials: SCM415, S45C, SUS303, SMF5040, MC901

– Hardening: Curburized, Induction hardened, None

– Tooth fin…

2. KHK Gears – Miter Gears

Domain: khkgears.us

Registered: 2015 (10 years)

Introduction: Miter gears are a special class of bevel gears where the shafts intersect at 90° and the gear ratio is 1:1. KHK stock miter gears are available in two types: spiral and straight tooth. They offer high precision grade for demanding torques and speeds, and commercial grade for economical applications. Types of miter gears include:

1. Ground Spiral Miter Gears (MMSG) – High strength, abrasion-resist…

3. Boston Gear – Miter and Bevel Gears

Domain: bostongear.com

Registered: 1997 (28 years)

Introduction: Boston Gear’s stock miter and bevel gears are designed for efficient power and motion transmission between intersecting shafts at a right angle (90°). Miter gears operate in pairs with identical teeth and diametral pitches, maintaining a 1:1 ratio. Stock bevel gear sets are available with ratios from 1-1/2:1 to 6:1. All gears are manufactured with a 20° pressure angle and comply with AGMA specific…

4. Igus – Bevel Gears

Domain: igus.com

Registered: 1995 (30 years)

Introduction: Bevel gears are conically shaped gears used to transmit power between two shafts at a 90-degree angle. They mesh their teeth together to transfer torque and rotational motion between non-parallel shafts. The gear ratio, determined by the number of teeth on each gear, is crucial for mechanical advantage, affecting speed and torque output. Bevel gears with a 1:1 ratio are known as miter gears. igus …

5. Servocity – MOD 1.5 Bevel Gears

Domain: servocity.com

Registered: 2000 (25 years)

Introduction: Bevel gears are designed to drive a shaft at a 90° angle, available in ratios of 1:1 (miter gears) and 2:1 for speed and torque tuning. Key products include: MOD 1.5 Bevel Gears (2:1 Ratio) – specific tooth profile for compatibility; MOD 1 Miter Gears (1:1 Ratio) – two-piece steel construction with pinch bolts; MOD 1.25 Miter Gears (1:1 Ratio) – high-torque applications, slip-fit on 8mm REX™ shaft…

6. McMaster – Miter Gears & Bevel Gears

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Miter Gears & Bevel Gears, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Reddit – Bevel/Miter vs. Helical Gears

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Bevel/Miter Gears vs. Helical Gears: Bevel/miter gears are commonly used for 90° power transmission, while perpendicular-axis helical gears are less frequently utilized in industry. Helical gears are easier to design in CAD as they are essentially spur gears twisted at a 45° angle. However, manufacturing bevel gears may be cheaper and more efficient. Helical gears can generate greater axial thrust…

Strategic Sourcing Conclusion and Outlook for miter bevel gear

In conclusion, the strategic sourcing of miter bevel gears presents significant opportunities for international B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. Understanding the technical specifications, such as the differences between straight and spiral miter gears, as well as their applications in various industries, is crucial for informed purchasing decisions. By prioritizing quality, such as opting for ground or carburized options, buyers can enhance operational efficiency and longevity in their machinery.

Investing in strategic sourcing not only ensures access to high-performance miter bevel gears but also fosters sustainable supplier relationships, which are vital in today’s competitive landscape. As global supply chains evolve, buyers must remain agile, leveraging local and international resources to optimize their procurement processes.

Looking ahead, we encourage international buyers to stay informed about emerging technologies and market trends within the gear manufacturing sector. Engaging with reliable suppliers and exploring innovative solutions will be key to unlocking the full potential of miter bevel gears in your operations. Take action now to secure the best products that align with your business goals and drive growth in your market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.