A B2B Buyer’s Guide to Metal Spinning For Bulk Handling: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for metal spinning for bulk handling

Navigating the complexities of sourcing metal spinning solutions for bulk handling can be daunting for international B2B buyers. As industries around the globe seek efficient methods to transport and manage particulate solids, understanding the nuances of metal spinning becomes crucial. This guide delves into the diverse applications of metal spinning in bulk handling, covering essential topics such as types of spun parts, supplier vetting processes, cost considerations, and quality assurance measures.

B2B buyers from regions like Africa, South America, the Middle East, and Europe—including emerging markets such as Nigeria and Saudi Arabia—will find this resource invaluable in making informed purchasing decisions. The intricacies of sourcing high-quality spun metal components—such as cones, hoppers, and funnels—can significantly impact operational efficiency and cost-effectiveness. By providing comprehensive insights into supplier capabilities and industry standards, this guide empowers buyers to select the right partners and products that align with their unique operational needs.

As you navigate the global market for metal spinning in bulk handling, this guide serves as your trusted companion, ensuring you are equipped with the knowledge to optimize your procurement strategy and enhance your competitive edge. Whether you are exploring custom solutions or evaluating potential suppliers, the information herein will facilitate informed decisions that drive success in your business operations.

Understanding metal spinning for bulk handling Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Spun Cones | Conical shapes, often customized for specific needs | Bulk solid handling, food industry, pneumatic conveying | Pros: Lightweight, customizable; Cons: May require specialized tooling. |

| Spun Hoppers | Large containers with a wide opening for easy loading | Plastics, agriculture, mining | Pros: Efficient material handling; Cons: Limited to specific bulk materials. |

| Spun Rings | Circular profiles used in various applications | Machinery, conveyors, storage tanks | Pros: Strong structural integrity; Cons: May have longer lead times. |

| Spun Funnels | Tapered designs for directing flow | Food processing, chemical industries | Pros: Improved flow efficiency; Cons: Complexity in design may increase costs. |

| Spun Tank Heads | Dome-shaped, used to seal containers | Storage tanks, pressure vessels | Pros: High strength, can withstand pressure; Cons: Requires precise specifications. |

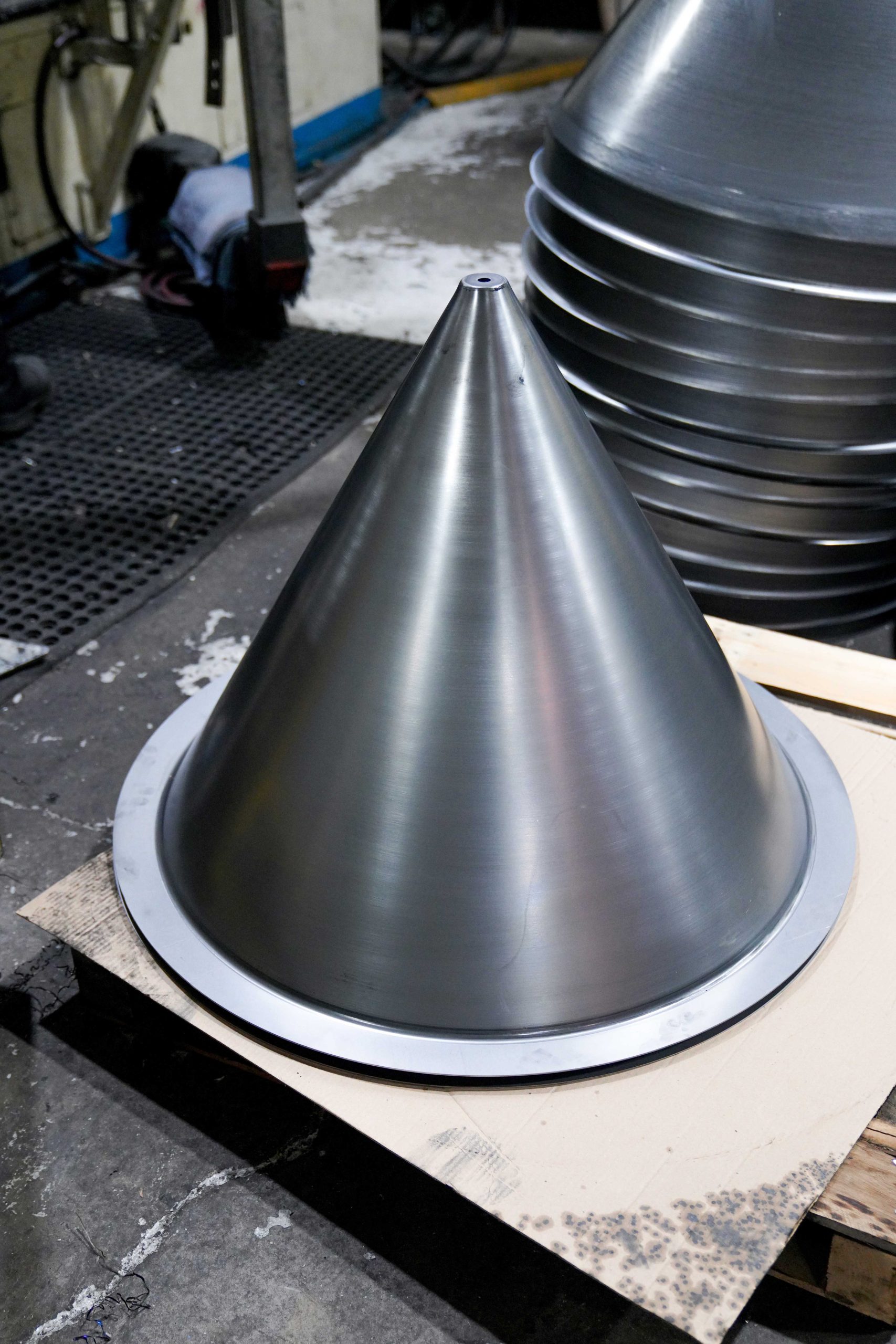

What Are the Key Characteristics of Spun Cones in Bulk Handling?

Spun cones are primarily characterized by their conical shape, which allows for efficient flow and handling of bulk materials. They are commonly used in industries such as food processing and pneumatic conveying, where they facilitate the movement of granular substances. When considering spun cones for purchase, businesses should evaluate customization options, as specific dimensions may be required to fit existing systems. Additionally, the weight and material choice can impact transportation and installation costs.

How Do Spun Hoppers Enhance Bulk Material Handling?

Spun hoppers are designed as large containers with wide openings, making them ideal for loading and unloading bulk materials like grains or plastics. Their robust construction ensures durability during the handling process. When selecting spun hoppers, B2B buyers should consider the material compatibility with the substances being handled and the hopper’s capacity to meet operational needs. Customization for specific applications can also enhance efficiency but may require a longer lead time.

In What Applications Are Spun Rings Most Commonly Used?

Spun rings are circular profiles that provide strong structural integrity, making them suitable for various applications including machinery and conveyor systems. Their design allows for easy integration into existing setups. Buyers should focus on the material properties and load-bearing capacities when considering spun rings. The lead time for manufacturing can vary, so planning ahead is crucial for ensuring timely project completion.

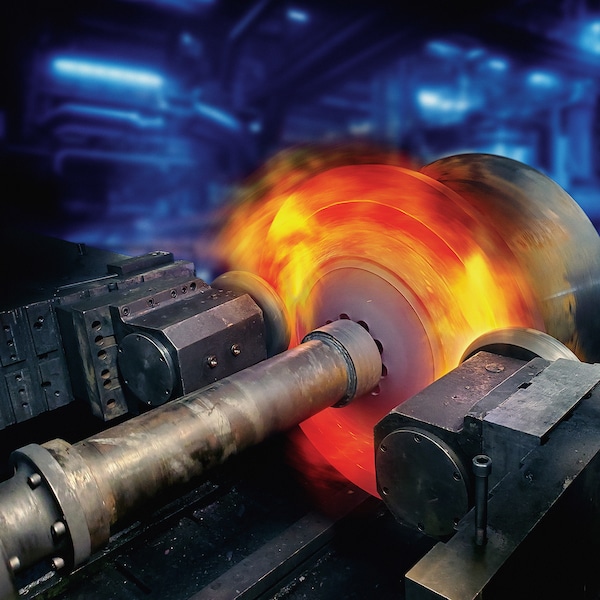

Illustrative image related to metal spinning for bulk handling

Why Are Spun Funnels Important for Flow Management?

Spun funnels feature tapered designs that optimize the flow of materials, making them essential in industries such as food processing and chemicals. The design aids in directing bulk materials efficiently, reducing waste and improving overall processing times. When purchasing spun funnels, businesses should consider the complexity of the design, as this can affect costs. Additionally, the compatibility of materials with the substances being processed is vital for ensuring safety and compliance.

What Advantages Do Spun Tank Heads Offer for Storage Solutions?

Spun tank heads are dome-shaped components used to seal storage tanks, providing high strength and the ability to withstand significant pressure. They are critical in applications like pressure vessels and storage tanks. Buyers should pay attention to the specifications required for their particular applications, as precise dimensions and material choices will influence performance. While spun tank heads offer excellent durability, they may also entail higher production costs due to the need for precision engineering.

Key Industrial Applications of metal spinning for bulk handling

| Industry/Sector | Specific Application of metal spinning for bulk handling | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Stainless steel hoppers and funnels | Ensures hygiene and durability; meets food safety standards | Material certification, surface finish, and tolerance levels |

| Agriculture | Metal spun cones for grain handling | Enhances efficiency in loading/unloading operations | Customization capabilities, weight tolerance, and material type |

| Plastics Manufacturing | Hoppers for bulk plastic materials | Reduces material waste and improves handling efficiency | Resistance to corrosion, size specifications, and design flexibility |

| Mining and Minerals | Spun metal containers for ore transport | Provides robust solutions for heavy-duty applications | Strength and durability, custom sizes, and compliance with industry standards |

| Chemical Processing | Funnels for chemical transfer | Ensures safe and efficient material handling | Chemical resistance of materials, design specifications, and quality assurance |

How is Metal Spinning Used in the Food Processing Industry?

In the food processing sector, metal spinning is critical for producing stainless steel hoppers and funnels that facilitate the transport of raw materials. These components must adhere to strict hygiene and safety regulations, ensuring that they do not contaminate food products. Buyers from regions like Europe and the Middle East should prioritize suppliers who can provide certified materials and demonstrate compliance with food safety standards, focusing on the required surface finishes and precise tolerances.

Illustrative image related to metal spinning for bulk handling

What Role Does Metal Spinning Play in Agriculture?

Metal spun cones are essential in the agricultural industry for efficient grain handling. They are designed to optimize the loading and unloading of bulk grains, reducing spillage and waste. For international buyers, particularly in Africa and South America, selecting manufacturers who offer customization options and can meet specific weight tolerances is crucial. Durability against environmental factors is also a key consideration to ensure long-term performance.

Why is Metal Spinning Important for Plastics Manufacturing?

In plastics manufacturing, metal spinning is employed to create hoppers that handle bulk plastic materials. These hoppers enhance operational efficiency by minimizing material waste during the transfer process. Buyers should focus on sourcing metal components that are resistant to corrosion and can be customized to fit specific production lines. Understanding design flexibility and weight specifications will ensure that the hoppers meet the unique needs of their operations.

How Does Metal Spinning Benefit the Mining and Minerals Sector?

The mining and minerals industry relies on robust spun metal containers for transporting ores and other heavy materials. These containers are engineered to withstand the rigors of heavy-duty applications, providing a reliable solution for material handling. Buyers from mineral-rich regions should seek suppliers who can deliver custom sizes and demonstrate compliance with industry standards, ensuring that the containers meet the necessary strength and durability requirements.

What Are the Advantages of Metal Spinning in Chemical Processing?

Metal spinning is crucial in the chemical processing sector for producing funnels that facilitate the safe transfer of chemicals. These components must be designed with materials that are resistant to chemical corrosion to ensure safe handling. For international buyers, particularly in the Middle East, it is essential to consider the chemical resistance properties of materials and to verify quality assurance processes to ensure compliance with safety regulations.

3 Common User Pain Points for ‘metal spinning for bulk handling’ & Their Solutions

Scenario 1: Challenges with Material Selection for Metal Spinning Parts

The Problem:

B2B buyers often face difficulties in selecting the appropriate materials for metal spun parts used in bulk handling applications. The wrong choice can lead to structural failures, increased costs, and inefficiencies in operations. For instance, a buyer may choose aluminum for a heavy-duty application, only to find that it lacks the necessary strength and durability. This misstep can not only delay production but also compromise safety and operational integrity.

Illustrative image related to metal spinning for bulk handling

The Solution:

To mitigate these issues, buyers should conduct thorough evaluations of the material properties relative to their specific applications. Engage with suppliers who can provide detailed insights into the characteristics of materials like stainless steel, aluminum, and other alloys. Create a checklist that includes factors such as weight, strength, corrosion resistance, and cost-effectiveness. Additionally, consider conducting material testing under real-world conditions to validate your choices before full-scale production. By collaborating closely with manufacturers, you can ensure that the selected materials align with the demands of your bulk handling processes.

Scenario 2: Inconsistent Quality in Metal Spun Products

The Problem:

Inconsistent quality in metal spun products is a significant pain point for buyers, particularly those who rely on precision parts for bulk handling. Variability in thickness, surface finish, and tolerances can lead to assembly issues and operational disruptions. A buyer might receive a batch of parts that are not uniform, resulting in wasted time and resources as they try to rectify the situation or source replacements.

The Solution:

To address quality concerns, buyers should establish clear quality standards and specifications with their suppliers before placing orders. It’s beneficial to implement a robust quality control process that includes regular inspections and testing of parts upon receipt. Consider requesting prototypes or samples before committing to large orders, allowing you to assess the quality and make adjustments as necessary. Building a long-term relationship with a reputable metal spinning supplier who understands your quality requirements can also enhance consistency and reliability in the products you receive.

Illustrative image related to metal spinning for bulk handling

Scenario 3: Long Lead Times Affecting Production Schedules

The Problem:

Long lead times for metal spun parts can severely disrupt production schedules, especially in industries where time-to-market is critical. Buyers may find themselves waiting weeks or even months for essential components, impacting their ability to meet client demands or launch new products. This can result in lost sales opportunities and damage to customer relationships.

The Solution:

To reduce lead times, establish clear communication channels with your suppliers regarding your project timelines and urgency. Consider sourcing from manufacturers with advanced capabilities, such as automated production processes or those who maintain a stock of commonly used parts. Implementing a just-in-time inventory system can also help manage lead times by ensuring that parts are produced and delivered precisely when needed. Furthermore, collaborating with suppliers on forecasting demand can help them plan their production schedules better, thereby improving overall delivery performance.

Strategic Material Selection Guide for metal spinning for bulk handling

What Materials Are Commonly Used in Metal Spinning for Bulk Handling?

When selecting materials for metal spinning applications in bulk handling, it’s essential to consider properties that impact performance, durability, and cost. Here, we analyze four common materials—stainless steel, aluminum, cold-rolled steel, and brass—focusing on their key properties, advantages and disadvantages, and specific considerations for international B2B buyers.

Illustrative image related to metal spinning for bulk handling

How Does Stainless Steel Perform in Metal Spinning for Bulk Handling?

Stainless steel is renowned for its excellent corrosion resistance and durability, making it suitable for various bulk handling applications, especially in food processing and chemical industries. It can withstand high temperatures and pressures, which is crucial for transporting hot or pressurized materials.

Pros: Stainless steel’s durability ensures a long lifespan, reducing the frequency of replacements. Its resistance to rust and staining makes it ideal for environments where hygiene is critical.

Cons: The primary drawback is its higher cost compared to other materials, which may impact budget-sensitive projects. Additionally, the manufacturing complexity can increase production time.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive substances, making it a versatile choice for diverse bulk handling needs.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial, particularly in regions like Europe and the Middle East, where stringent regulations exist. Buyers should also consider local sourcing options to reduce costs.

Illustrative image related to metal spinning for bulk handling

What Are the Benefits of Using Aluminum in Metal Spinning for Bulk Handling?

Aluminum is lightweight and offers good corrosion resistance, making it a popular choice for applications requiring reduced weight without sacrificing strength. It is particularly beneficial in pneumatic conveying systems due to its lower mass.

Pros: The lightweight nature of aluminum allows for easier handling and transportation. It also has a lower cost compared to stainless steel, making it an attractive option for budget-conscious projects.

Cons: Aluminum has a lower temperature and pressure rating than stainless steel, which may limit its use in high-stress environments. Additionally, it can be less durable in abrasive applications.

Impact on Application: Aluminum is suitable for non-corrosive media and is often used in applications where weight is a critical factor, such as in the agricultural sector.

Considerations for International Buyers: Buyers should ensure that aluminum parts meet relevant standards for strength and corrosion resistance. In regions like Africa and South America, understanding local preferences for aluminum versus steel can influence purchasing decisions.

Why Choose Cold-Rolled Steel for Metal Spinning in Bulk Handling?

Cold-rolled steel is a cost-effective option for metal spinning, offering good strength and durability. It is often used for applications that do not require the corrosion resistance of stainless steel.

Pros: This material is generally less expensive and easier to work with, allowing for quicker production times. It is suitable for applications where aesthetic finish is not a primary concern.

Cons: Cold-rolled steel is susceptible to rust and corrosion, necessitating protective coatings in humid or corrosive environments. Its weight can also be a disadvantage in applications where lightweight materials are preferred.

Impact on Application: Cold-rolled steel is ideal for dry bulk materials and applications where cost is a significant factor.

Considerations for International Buyers: Buyers should consider local environmental conditions that may affect the longevity of cold-rolled steel products. Compliance with local standards is also essential to ensure product suitability.

What Role Does Brass Play in Metal Spinning for Bulk Handling Applications?

Brass is often used in applications requiring good machinability and corrosion resistance, particularly in environments involving moisture. Its aesthetic appeal also makes it a choice for visible components.

Pros: Brass has excellent corrosion resistance and is easy to machine, allowing for intricate designs. Its antimicrobial properties make it suitable for food handling applications.

Cons: Brass is generally more expensive than cold-rolled steel and may not be as strong as stainless steel in high-stress applications.

Impact on Application: Brass is ideal for components that require both functionality and aesthetic appeal, such as fittings and connectors in bulk handling systems.

Illustrative image related to metal spinning for bulk handling

Considerations for International Buyers: Brass components should meet relevant international standards, particularly in food and beverage applications. Buyers should also be aware of local sourcing options to mitigate costs.

Summary Table of Material Selection for Metal Spinning in Bulk Handling

| Material | Typical Use Case for Metal Spinning for Bulk Handling | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, chemical transport | Excellent corrosion resistance and durability | Higher cost and manufacturing complexity | High |

| Aluminum | Pneumatic conveying, agricultural applications | Lightweight and cost-effective | Lower temperature rating and durability | Medium |

| Cold-Rolled Steel | Dry bulk materials, general applications | Cost-effective and easy to work with | Susceptible to rust, heavier weight | Low |

| Brass | Fittings and connectors in bulk handling systems | Good machinability and corrosion resistance | More expensive and lower strength than steel | Medium |

By carefully considering these materials and their properties, international B2B buyers can make informed decisions that align with their specific bulk handling needs.

In-depth Look: Manufacturing Processes and Quality Assurance for metal spinning for bulk handling

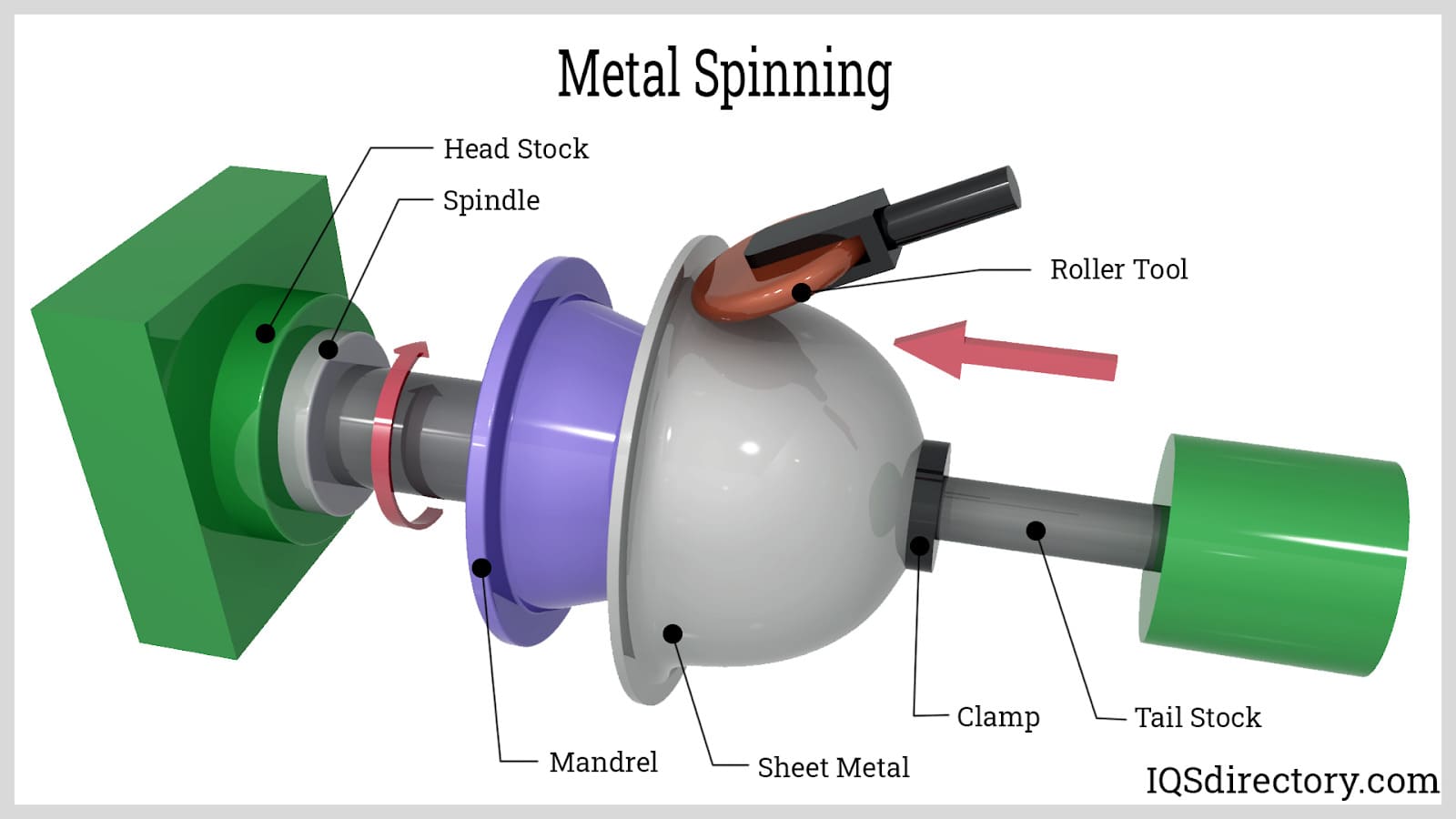

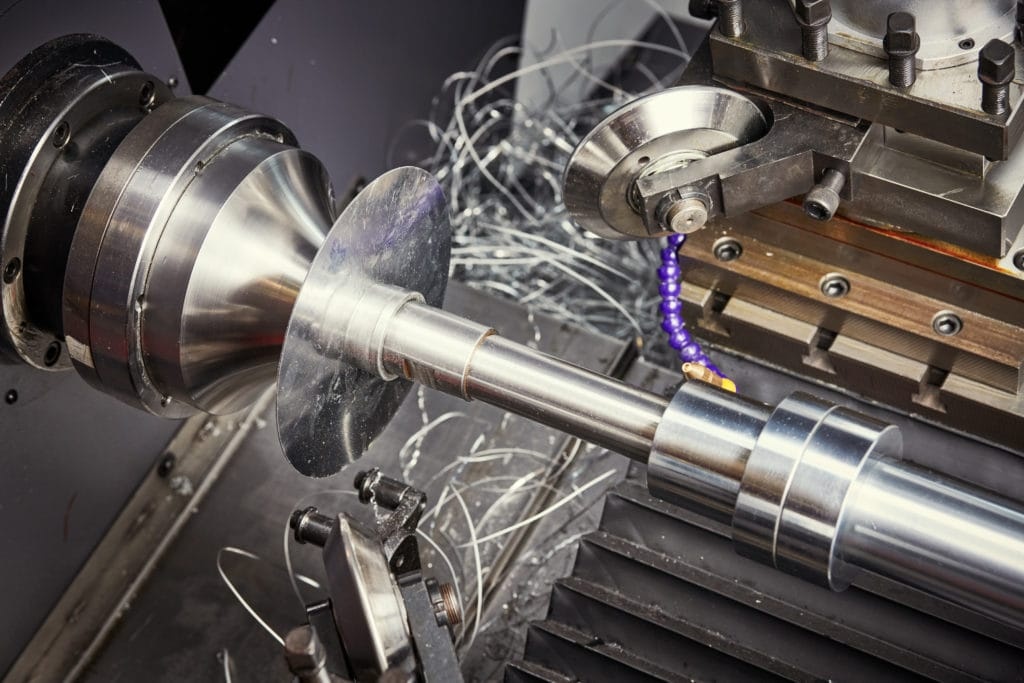

What Are the Typical Manufacturing Processes for Metal Spinning in Bulk Handling?

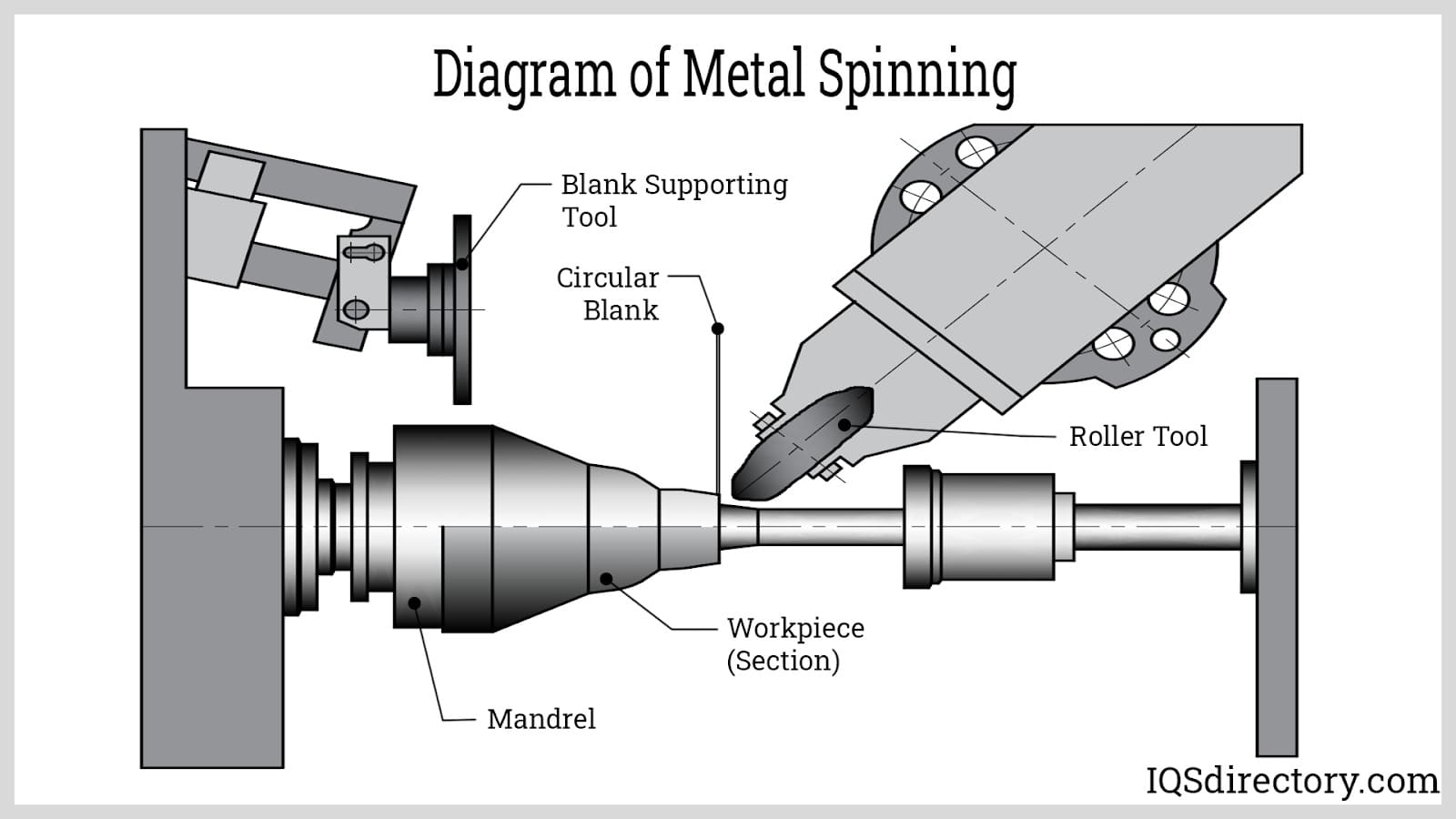

Metal spinning is a versatile manufacturing process that transforms flat metal sheets into complex shapes, particularly useful in bulk handling applications. The primary stages in the metal spinning process include material preparation, forming, assembly, and finishing. Each stage is essential for ensuring the final product meets the stringent demands of bulk handling industries.

Illustrative image related to metal spinning for bulk handling

How Is Material Prepared for Metal Spinning?

The first step in the metal spinning process is material preparation. This involves selecting the right type of metal based on the application’s requirements. Common materials include stainless steel, aluminum, and brass, each chosen for their unique properties such as corrosion resistance and weight. The metal sheets are cut to the required dimensions, and surface treatments may be applied to enhance properties like adhesion for further processes.

What Techniques Are Used in the Forming Stage?

The forming stage is where the metal sheets are spun around a mandrel to achieve the desired shape. This process can be done manually or with the aid of CNC (Computer Numerical Control) machines, which allow for greater precision and consistency. Techniques such as deep drawing, where the metal is drawn into a shape using hydraulic or mechanical force, and beading, which adds stability and functionality to edges, are frequently employed. The choice of technique often depends on the complexity of the part being produced and the volume required.

How Is Assembly Done in Metal Spinning?

In many cases, metal spinning does not require extensive assembly, as the spun parts can often be produced as single-piece components. However, when multiple parts are involved, assembly processes such as welding or riveting may be necessary. During assembly, attention must be paid to alignment and fit to ensure that the final product functions as intended. This is particularly crucial in bulk handling applications where precision can impact efficiency and safety.

Illustrative image related to metal spinning for bulk handling

What Finishing Techniques Are Commonly Used?

Finishing processes are vital for enhancing both the aesthetic and functional qualities of the spun metal parts. Techniques may include polishing, which creates a smooth surface, and coating, which can add corrosion resistance or improve appearance. Each finishing method is chosen based on the end-use of the product and the specific requirements of the industry, such as compliance with food safety regulations in the food handling sector.

How Is Quality Assurance Ensured in Metal Spinning for Bulk Handling?

Quality assurance (QA) in metal spinning is critical to guarantee that products meet industry standards and client specifications. For international B2B buyers, understanding the QA processes can provide confidence in the reliability of their suppliers.

What International Standards Should B2B Buyers Be Aware Of?

ISO 9001 is a widely recognized international standard that outlines the requirements for a quality management system. Suppliers in the metal spinning industry often seek ISO 9001 certification to demonstrate their commitment to quality. Additionally, industry-specific certifications such as CE marking for safety and compliance, and API standards for products used in the petroleum and natural gas industries, may also be relevant depending on the application.

What Are the Key Quality Control Checkpoints in Metal Spinning?

Quality control (QC) involves several checkpoints throughout the manufacturing process to ensure that products meet established standards. These checkpoints typically include:

-

Incoming Quality Control (IQC): This is the first line of defense, where raw materials are inspected for defects before they enter the production process. Ensuring high-quality materials helps prevent issues later in the manufacturing stages.

-

In-Process Quality Control (IPQC): During the manufacturing process, samples may be taken at various stages to monitor the quality of the parts being produced. This can include checking dimensions and surface finishes to ensure they meet specifications.

-

Final Quality Control (FQC): Once the product is complete, a final inspection is performed. This includes measuring critical dimensions, checking surface finishes, and conducting functional tests if necessary.

What Testing Methods Are Commonly Used in Quality Assurance?

Various testing methods are employed to assess the quality of spun metal parts. Common techniques include dimensional inspection using calipers and micrometers, non-destructive testing (NDT) methods such as ultrasonic testing to check for internal flaws, and surface roughness testing to ensure finishes meet requirements. Depending on the application, functional testing may also be performed to verify that the parts perform as intended under operational conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are several strategies:

-

Supplier Audits: Conducting on-site audits can provide insights into a supplier’s manufacturing practices and quality control measures. This allows buyers to assess whether the supplier adheres to international standards and internal quality protocols.

-

Requesting Quality Reports: Buyers should request documentation that details the supplier’s quality control procedures, including results from IQC, IPQC, and FQC inspections. These reports can provide transparency and confidence in the supplier’s capabilities.

-

Utilizing Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality assurance processes. These inspections can cover everything from raw material quality to final product checks, ensuring compliance with both local and international standards.

What Are the QC/Cert Nuances for International B2B Buyers?

Understanding the nuances of quality control and certification can be particularly important for international buyers. Regulations may vary by region, and products that meet standards in one country may not necessarily comply in another. Buyers should familiarize themselves with the specific certifications required in their target markets and ensure that their suppliers are compliant. This can help avoid costly delays and rejections during customs clearance or regulatory inspections.

In conclusion, the manufacturing processes and quality assurance measures in metal spinning for bulk handling are intricate and critical for ensuring product reliability and compliance. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ultimately leading to better outcomes for their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metal spinning for bulk handling’

Introduction

Sourcing metal spinning services for bulk handling applications requires careful consideration and strategic planning. This guide provides a practical step-by-step checklist to help B2B buyers navigate the complexities of procurement. By following these steps, you can ensure that you select the right supplier to meet your technical specifications and operational needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for your metal spun parts, including dimensions, tolerances, and material types. This step is crucial as it establishes the foundation for your procurement process. Be specific about the applications, such as whether the parts will be used for hoppers, funnels, or other bulk handling equipment.

Illustrative image related to metal spinning for bulk handling

- Material Considerations: Determine whether you need stainless steel, aluminum, or other materials based on factors like corrosion resistance and weight.

- Design Complexity: Identify the geometric shapes and features required, as this will influence manufacturing methods.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers with a strong reputation in the metal spinning industry, particularly those experienced in bulk handling applications. This step is important to ensure that you partner with reliable manufacturers who can meet your needs.

- Industry Experience: Look for suppliers that have a proven track record in the bulk handling sector.

- Client Testimonials: Review customer feedback and case studies to gauge satisfaction levels and service quality.

Step 3: Evaluate Supplier Capabilities

Assess the technical capabilities of potential suppliers to ensure they can meet your specific requirements. This evaluation is critical in determining whether a supplier can deliver high-quality products consistently.

- Manufacturing Processes: Inquire about the technology and processes used, such as CNC spinning and finishing techniques.

- Quality Control Measures: Understand the quality assurance practices in place, including testing and inspection protocols.

Step 4: Request and Compare Quotes

Once you have shortlisted potential suppliers, request detailed quotes that outline pricing, lead times, and payment terms. Comparing these quotes will help you make informed decisions based on cost-effectiveness and value.

- Cost Breakdown: Ensure that quotes include a breakdown of costs associated with materials, labor, and any additional services.

- Lead Time Expectations: Clarify production timelines to align with your project schedules.

Step 5: Verify Certifications and Compliance

Ensure that the suppliers you consider have the necessary certifications and comply with industry standards. This step is vital for ensuring that the products meet safety and quality regulations.

- ISO Certifications: Check for ISO 9001 or other relevant certifications that demonstrate commitment to quality management.

- Material Compliance: Verify that materials used comply with relevant industry regulations, especially for food handling applications.

Step 6: Conduct On-Site Visits or Virtual Tours

If feasible, visit the manufacturing facilities of potential suppliers or request a virtual tour. This allows you to assess their operations firsthand and gauge their capabilities more accurately.

Illustrative image related to metal spinning for bulk handling

- Facility Inspection: Evaluate the cleanliness, organization, and technological advancements within the facility.

- Staff Expertise: Observe the skill level of the workforce and inquire about training programs.

Step 7: Establish Communication Channels

Finally, ensure that clear communication channels are established with your chosen supplier. Open lines of communication facilitate smooth collaboration and allow for quick resolution of any issues that may arise during production.

- Point of Contact: Identify a dedicated account manager or liaison for your project.

- Regular Updates: Agree on a schedule for progress updates to keep all stakeholders informed throughout the manufacturing process.

By following this checklist, you can streamline your sourcing process for metal spinning services in bulk handling applications, ultimately leading to successful procurement outcomes.

Comprehensive Cost and Pricing Analysis for metal spinning for bulk handling Sourcing

What Are the Key Cost Components in Metal Spinning for Bulk Handling?

When sourcing metal spinning solutions for bulk handling, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of metal significantly influences cost. Common materials like stainless steel, aluminum, and galvanized steel vary in price. Stainless steel, while more expensive, offers superior corrosion resistance, which may justify its cost in specific applications.

-

Labor: Labor costs are impacted by the complexity of the part design and the level of automation in the manufacturing process. Skilled labor is essential for custom metal spinning, and the labor market in the supplier’s location can affect pricing.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility costs. High-quality manufacturers often invest in advanced machinery, which can increase overhead but also enhance production efficiency and quality.

-

Tooling: Tooling costs can be significant, especially for custom parts. This includes the creation of molds and dies specific to the project. Initial tooling investments can be amortized over larger production volumes, making it essential to consider the anticipated order size.

-

Quality Control (QC): Implementing rigorous QC processes ensures product integrity but adds to costs. Buyers should inquire about the QC measures suppliers employ, as this can directly impact the overall cost through reduced defects and rework.

-

Logistics: Shipping and handling costs vary based on distance, weight, and volume. International buyers should consider import duties and taxes, which can significantly affect the total cost.

-

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. Understanding the market rates for similar products can provide leverage during negotiations.

How Do Price Influencers Affect Metal Spinning Costs?

Several factors influence the pricing of metal spinning services, particularly for bulk handling applications:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their needs while maximizing cost-efficiency.

-

Specifications and Customization: Highly customized parts require additional design and manufacturing efforts, impacting the price. Clear specifications can help suppliers provide accurate quotes and avoid unexpected costs.

-

Materials and Quality Certifications: The choice of materials and the requirement for quality certifications (e.g., ISO, ASTM) can influence costs. Suppliers with certifications may charge a premium, but this often reflects higher reliability and product performance.

-

Supplier Factors: The supplier’s location, reputation, and market position can affect pricing. Established suppliers with a track record of quality may command higher prices, but they also reduce risks associated with defects and delays.

-

Incoterms: Understanding Incoterms is vital for international transactions. Different terms can shift responsibilities and costs between buyers and suppliers, impacting the overall pricing structure.

What Are the Best Buyer Tips for Negotiating Metal Spinning Prices?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider these tips for effective sourcing:

-

Negotiation: Engage suppliers early in the process and communicate your needs clearly. Be prepared to discuss volume commitments, which can leverage better pricing.

-

Cost-Efficiency: Assess the Total Cost of Ownership (TCO), not just the upfront costs. Consider factors such as durability, maintenance, and potential savings from fewer defects.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and their potential impact on pricing. Additionally, consider the total landed cost, including shipping, tariffs, and local taxes, when comparing suppliers across different regions.

-

Request Indicative Prices: Suppliers may provide indicative prices that can serve as a baseline for negotiations. However, always clarify that final prices will depend on specific details of the order.

In conclusion, understanding the comprehensive cost structure and price influencers in metal spinning for bulk handling is essential for B2B buyers. Armed with this knowledge, buyers can make informed decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing metal spinning for bulk handling With Other Solutions

Exploring Alternatives to Metal Spinning for Bulk Handling Solutions

In the dynamic landscape of bulk handling, businesses often seek alternatives to metal spinning for their manufacturing needs. Understanding these alternatives allows B2B buyers to make informed decisions based on performance, cost, and specific application requirements. Below, we compare metal spinning with other viable methods: deep drawing and metal stamping.

| Comparison Aspect | Metal Spinning For Bulk Handling | Deep Drawing | Metal Stamping |

|---|---|---|---|

| Performance | High precision for complex shapes | Excellent for large volumes | Fast production of flat parts |

| Cost | Moderate initial investment | Higher setup costs for tooling | Lower per-unit costs at scale |

| Ease of Implementation | Requires skilled operators | Moderate complexity in setup | Simple with automated lines |

| Maintenance | Low maintenance; durable parts | Moderate; tooling wear issues | Low; requires regular checks |

| Best Use Case | Custom shapes and small batches | High-volume, uniform parts | High-speed production of standard shapes |

What Are the Advantages and Disadvantages of Deep Drawing?

Deep drawing is a metal forming process that uses a hydraulic press to transform flat metal sheets into three-dimensional shapes. This method excels in producing parts with consistent geometry and high precision, making it ideal for large volumes. However, the initial costs for tooling can be significant, which may deter smaller operations or custom projects. Additionally, while deep drawing offers excellent material utilization, it is less flexible for custom designs compared to metal spinning.

Illustrative image related to metal spinning for bulk handling

How Does Metal Stamping Compare to Metal Spinning?

Metal stamping involves the use of dies to cut and shape metal sheets into desired forms. It is particularly advantageous for high-volume production runs where speed and efficiency are paramount. The cost per unit decreases significantly at larger scales, making it a cost-effective solution for standardized parts. However, metal stamping is not as versatile for complex or custom shapes, as it typically requires multiple processes or additional tooling. This limitation can lead to higher costs if custom designs are needed.

Conclusion: Which Bulk Handling Solution is Right for Your Business?

When evaluating bulk handling solutions, B2B buyers must consider their specific needs, including production volume, budget, and design complexity. Metal spinning offers unmatched versatility for custom parts but may not be the most cost-effective for high-volume production. Deep drawing is suitable for large runs of uniform parts, while metal stamping shines in high-speed applications with standardized designs. By carefully analyzing these alternatives, businesses can select the most appropriate method to optimize their operations and meet their unique requirements effectively.

Essential Technical Properties and Trade Terminology for metal spinning for bulk handling

What Are the Key Technical Properties of Metal Spinning for Bulk Handling?

When selecting metal spun parts for bulk handling applications, understanding critical technical specifications is essential for making informed purchasing decisions. Here are some of the key properties to consider:

-

Material Grade

– The choice of material, such as stainless steel, aluminum, or galvanized steel, is crucial. Each material offers distinct properties like corrosion resistance, strength, and weight. For instance, stainless steel is preferred in food handling due to its hygienic properties, while aluminum is favored for its lightweight nature in pneumatic conveying systems. Selecting the right material impacts durability and performance in harsh handling environments. -

Tolerance

– Tolerance refers to the allowable deviation from a specified dimension. In metal spinning, tighter tolerances are often required for components that fit into larger assemblies. Understanding tolerance levels ensures that parts will function correctly and fit seamlessly, reducing the risk of costly rework or failure during operations. This is especially important in bulk handling, where precision can influence the efficiency of material transfer. -

Thickness

– The thickness of the spun metal part directly affects its strength and weight. Thicker materials can withstand more stress, making them suitable for heavy-duty applications, while thinner materials may be used for lighter, less demanding tasks. Buyers must evaluate the operational load and environmental conditions to determine the appropriate thickness for their specific needs. -

Surface Finish

– The finish of the metal surface can significantly affect both aesthetics and functionality. For bulk handling applications, finishes can impact the ease of cleaning, resistance to corrosion, and friction properties. A polished finish might be necessary for food-grade applications, while a rougher finish could be acceptable for industrial uses. Ensuring the right surface finish aligns with regulatory requirements and operational needs is vital. -

Forming Process

– Different metal spinning techniques, such as deep drawing or beading, influence the final product’s characteristics. Understanding these processes helps buyers select the most efficient manufacturing methods that align with their production goals and budget constraints. Each method has implications for cost, lead time, and part integrity.

What Are Common Trade Terms in Metal Spinning for Bulk Handling?

Familiarity with industry jargon is crucial for effective communication and negotiation. Here are several essential terms relevant to metal spinning for bulk handling:

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that manufacture products that are then sold under another company’s brand. In the context of metal spinning, OEMs may require custom parts that meet specific design and performance criteria. Understanding the role of OEMs can help buyers navigate supply chains and establish reliable partnerships. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest number of units that a supplier is willing to sell. This term is vital for buyers to understand, as it affects inventory management and budgeting. Suppliers often set MOQs to ensure production efficiency and cost-effectiveness, making it essential for buyers to align their needs with supplier capabilities. -

RFQ (Request for Quotation)

– An RFQ is a formal request sent to suppliers to obtain pricing and terms for specific products. This process allows buyers to compare options and negotiate terms effectively. Providing detailed specifications in an RFQ can lead to more accurate quotes and better supplier relationships. -

Incoterms (International Commercial Terms)

– Incoterms define the responsibilities of buyers and sellers in international shipping. Familiarity with these terms is critical for avoiding misunderstandings related to shipping, insurance, and delivery. Understanding Incoterms helps buyers ensure that they are clear about their obligations and risk exposure throughout the shipping process. -

Lead Time

– Lead time refers to the duration from placing an order to receiving the finished product. Understanding lead times is crucial for project planning and inventory management. Buyers must consider lead times when scheduling production and ensuring timely delivery to avoid disruptions in their operations.

By comprehending these technical properties and trade terms, international B2B buyers can make informed decisions that enhance efficiency and effectiveness in their bulk handling operations.

Illustrative image related to metal spinning for bulk handling

Navigating Market Dynamics and Sourcing Trends in the metal spinning for bulk handling Sector

What Are the Key Market Trends Influencing Metal Spinning for Bulk Handling?

The metal spinning market for bulk handling is experiencing significant transformation driven by various global factors. One of the primary drivers is the increasing demand for efficient and cost-effective material handling solutions, particularly in industries such as agriculture, food processing, and construction. As businesses seek to optimize their operations, there is a notable shift towards automated processes and advanced technologies, including CNC machining and robotic automation. These technologies not only enhance precision but also reduce lead times, making them attractive to international buyers.

Emerging trends also highlight the customization of metal spun products. Buyers are increasingly looking for tailored solutions that cater to specific applications, such as customized hoppers, cones, and funnels designed for unique bulk handling requirements. This trend emphasizes the importance of collaboration between manufacturers and buyers to ensure that products meet exact specifications.

Moreover, sustainability has become a focal point in sourcing strategies. International buyers are increasingly prioritizing suppliers who demonstrate a commitment to environmental responsibility, which includes the use of recycled materials and energy-efficient manufacturing processes. As the market evolves, staying informed about these dynamics will be crucial for B2B buyers aiming to make strategic sourcing decisions.

Illustrative image related to metal spinning for bulk handling

How Is Sustainability Shaping Sourcing Practices in Metal Spinning for Bulk Handling?

Sustainability and ethical sourcing have emerged as critical considerations for B2B buyers in the metal spinning sector. The environmental impact of metal production and disposal is significant, which has prompted many companies to adopt ‘green’ practices. This shift includes the utilization of recycled metals, which not only reduces waste but also minimizes the carbon footprint associated with the mining and processing of new materials.

Buyers are increasingly seeking suppliers who can provide environmentally friendly certifications, such as ISO 14001, which signifies a commitment to effective environmental management systems. Additionally, the use of sustainable materials, such as aluminum and stainless steel, is gaining traction due to their recyclability and durability. B2B buyers are encouraged to engage with suppliers who emphasize transparency in their sourcing practices, ensuring that materials are ethically sourced and produced.

By prioritizing sustainability, companies can not only enhance their brand reputation but also align with regulatory requirements and consumer expectations, particularly in regions where environmental consciousness is paramount. This approach not only benefits the planet but also offers a competitive advantage in a market where sustainability is increasingly valued.

What Is the Historical Context of Metal Spinning in Bulk Handling?

The evolution of metal spinning for bulk handling can be traced back to the early 20th century, where the process was primarily manual and labor-intensive. As industrialization progressed, metal spinning became an essential manufacturing technique for producing lightweight and durable components. The introduction of CNC technology in the late 20th century revolutionized the industry, allowing for greater precision and efficiency.

Over the decades, the bulk handling sector has embraced metal spinning due to its versatility in creating complex shapes, such as cones, funnels, and hoppers, which are vital for transporting granulated materials. This historical context underscores the adaptability of metal spinning in meeting the changing demands of various industries, ultimately shaping the sourcing trends and market dynamics that international buyers face today.

Frequently Asked Questions (FAQs) for B2B Buyers of metal spinning for bulk handling

-

How do I choose the right metal spinning supplier for bulk handling needs?

Selecting the right metal spinning supplier involves evaluating their experience, industry reputation, and capabilities. Look for suppliers that specialize in bulk handling applications and have a proven track record of delivering high-quality products. Request samples to assess their manufacturing quality and ensure they meet your specifications. Additionally, consider their capacity for customization and ability to handle large orders to ensure they can meet your operational demands. -

What is the best material for metal spinning parts used in bulk handling?

The best material for metal spinning in bulk handling largely depends on the specific application. Stainless steel is favored for its corrosion resistance and durability, making it ideal for food and agricultural applications. Aluminum is lightweight and cost-effective, suitable for pneumatic conveying. Assess the environmental conditions your parts will face, including exposure to chemicals or extreme temperatures, to determine the most appropriate material for your needs. -

What customization options are available for metal spun parts in bulk handling?

Most metal spinning suppliers offer extensive customization options, allowing you to specify dimensions, shapes, and surface finishes to meet your unique needs. This includes variations in thickness, diameter, and even the addition of features such as beading or edge rolling for enhanced stability. Discuss your project requirements with potential suppliers to explore how they can tailor their offerings to align with your operational requirements. -

What are the typical minimum order quantities (MOQs) for metal spun parts?

Minimum order quantities can vary significantly between suppliers and depend on factors such as the complexity of the part and the production process. Generally, MOQs for metal spun parts in bulk handling can range from a few dozen to several hundred units. It’s advisable to communicate your needs upfront to ensure the supplier can accommodate your order without compromising on quality or delivery timelines. -

How can I ensure quality assurance (QA) in metal spinning products?

To ensure quality assurance, select suppliers that implement stringent QA processes, including material inspections, dimensional checks, and surface finish evaluations. Request documentation of their QA protocols and inquire about certifications such as ISO 9001. Regular communication during the production phase can also help address any potential issues early on, ensuring that the final products meet your specifications and standards. -

What payment terms should I expect when sourcing metal spun parts internationally?

Payment terms for international transactions typically vary by supplier and can include options such as advance payments, letters of credit, or payment upon delivery. It’s crucial to clarify these terms during negotiations to avoid any misunderstandings. Many suppliers may also offer discounts for early payments or bulk orders, so discuss these possibilities to optimize your procurement costs. -

What logistics considerations should I keep in mind when sourcing metal spun parts?

Logistics play a critical role in the timely delivery of metal spun parts. Consider factors such as shipping methods, customs regulations, and lead times when planning your procurement. Work with suppliers who have experience in international shipping and can provide clear timelines and tracking information. Additionally, ensure that the supplier has reliable partnerships with logistics providers to mitigate potential delays. -

How do I handle disputes or issues with a metal spinning supplier?

In the event of a dispute with a supplier, maintaining clear and professional communication is key. Start by discussing your concerns directly with the supplier to seek a resolution. If issues persist, refer to the terms of your contract, which should outline dispute resolution processes. Consider involving a third-party mediator if necessary. Establishing a strong relationship built on transparency and trust from the outset can help prevent disputes and facilitate smoother resolutions.

Top 6 Metal Spinning For Bulk Handling Manufacturers & Suppliers List

1. Toledo Metal Spinning – Conical Hoppers

Domain: toledometalspinning.com

Registered: 1997 (28 years)

Introduction: Toledo Metal Spinning builds a standard line of conical hoppers for bulk handling, primarily used to feed material into other operations. They offer customization for shapes and sizes to meet specific customer needs. The standard hoppers are high quality, economical, and ready to ship. They utilize materials such as Stainless Steels (304, 309, 316), Copper Alloys, and Steel Alloys. Secondary metal…

2. Wenzel Metal Spinning – Custom Metal Spinning Solutions

Domain: wenzelmetalspinning.com

Registered: 1997 (28 years)

Introduction: Wenzel Metal Spinning specializes in custom metal spinning, producing concentric and symmetrical metal parts in production quantities. Key capabilities include CNC metal spinning, press braking, cylinder rolling, shearing, welding services, and laser cutting. Materials used for spinning include various grades of aluminum (1100, 3003, 5052), stainless steel (304, 316, 409, 430), galvanized steel, s…

3. Elemet Group – Precision Metal Spinning

Domain: elemetgroup.com

Registered: 2016 (9 years)

Introduction: Metal spinning, also known as spin forming, is a precision metalworking process that forms flat metal discs into various symmetrical shapes by spinning them around a mandrel. Common shapes produced include conical, dished, domed, cylindrical, flanged, hemispherical, parabolic, semi-elliptical, toroidal, trumpeted, and Venturi shapes. Materials used in metal spinning include steel, stainless steel,…

4. AST – Advanced Metal Spinning Solutions

Domain: astforgetech.com

Registered: 2016 (9 years)

Introduction: AST specializes in advanced metal spinning solutions for the aerospace and space industry, particularly for large rocket components over 80 inches in diameter. Key benefits of their metal spinning process include:

– Strength and Durability: Comparable to forged metals, enhancing hoop strength and durability.

– Material Savings: More efficient material usage than subtractive processes, leading to…

5. Kryton Metals – Precision Metal Fabrication

Domain: krytonmetals.com

Registered: 2010 (15 years)

Introduction: Capabilities: Metal Spinning, Flat Laser Cutting (2D), 5-axis Laser Cutting (3D), Fabrication, Value-Add Services. Materials: Aluminum, Brass, Bronze, Carbon Steel, Copper, Stainless Steel, Corten Steel. Industries Served: Agricultural, Air Movement & Ventilation, Emergency & Signal, Energy, Food, Medical & Scientific. Certifications: ISO 9001:2015 Certified. Company History: Established in 1981, …

6. Metal Spinners – Metal Spinning Services

Domain: metal-spinners.net

Registered: 2001 (24 years)

Introduction: Metal spinning is a cold metalworking process used to shape flat metal discs or tubes (known as blanks) into axially symmetrical parts. It employs either a hand-operated lathe or a CNC lathe. Key services include: Aluminum Spinning, Copper Spinning, Flow Forming, Hydroforming, Shear Spinning, Sheet Metal Spinning, Spin Forming, Spun Aluminum Tank Head, and Titanium Spinning. The process involves a…

Strategic Sourcing Conclusion and Outlook for metal spinning for bulk handling

In conclusion, strategic sourcing in the metal spinning sector for bulk handling offers significant advantages for international B2B buyers. By leveraging high-quality spun metal products, such as cones, funnels, and hoppers, companies can enhance their operational efficiency and ensure durability in the transportation and handling of bulk materials. The ability to customize specifications based on unique project requirements not only reduces costs but also fosters stronger supplier relationships, essential for navigating diverse markets across Africa, South America, the Middle East, and Europe.

Moreover, as industries increasingly prioritize sustainability, sourcing from manufacturers who utilize eco-friendly practices can bolster your brand’s reputation and compliance with global standards. Staying informed about technological advancements in metal spinning processes will further enable businesses to make informed decisions that drive innovation and competitiveness.

Looking ahead, the demand for tailored solutions in bulk handling is set to rise. International buyers should actively engage with suppliers, explore collaborative opportunities, and invest in cutting-edge technologies to future-proof their operations. Embrace the potential of metal spinning today and position your business at the forefront of the evolving global landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to metal spinning for bulk handling

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.