A B2B Buyer’s Guide to Mercedes Benz Steering Wheel: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for mercedes benz steering wheel

In the competitive landscape of the automotive industry, sourcing high-quality Mercedes-Benz steering wheels presents a unique challenge for international B2B buyers. With the steering wheel being the primary interface between the driver and the vehicle, ensuring both functionality and aesthetic appeal is crucial for maintaining the luxury brand’s reputation. This guide serves as a comprehensive resource, detailing the various types of steering wheels available, their applications, and the importance of genuine parts versus aftermarket alternatives.

Navigating the complexities of supplier vetting, understanding cost implications, and recognizing the wear patterns that necessitate replacement are just a few critical areas covered within this guide. By addressing these key aspects, we empower B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including markets like Nigeria and Saudi Arabia—to make informed purchasing decisions.

This resource not only elucidates the essential factors to consider when sourcing steering wheels but also highlights the advantages of working with reputable suppliers who provide genuine Mercedes-Benz components. Armed with the insights from this guide, buyers can enhance their procurement strategies, ensuring they select steering wheels that meet both performance and luxury standards.

Understanding mercedes benz steering wheel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Steering Wheel | Basic functionality, often made of plastic, minimal controls | Entry-level vehicles, fleet management | Pros: Cost-effective; Cons: Lacks advanced features. |

| Multifunction Steering Wheel | Integrated controls for audio, navigation, and phone connectivity | Luxury models, corporate fleets | Pros: Enhanced functionality; Cons: Higher replacement costs. |

| Performance Steering Wheel | Sportier design, often with a thicker grip and racing aesthetics | Performance vehicles, motorsport applications | Pros: Improved handling; Cons: May not suit all drivers. |

| Custom Steering Wheel | Tailored designs and materials, often featuring unique grips | High-end luxury cars, personalization markets | Pros: Unique aesthetics; Cons: Higher price and longer lead times. |

| Heated Steering Wheel | Integrated heating elements for comfort in cold weather | Regions with cold climates, luxury markets | Pros: Enhanced comfort; Cons: More complex installation. |

What Are the Key Characteristics of Standard Steering Wheels?

Standard steering wheels are primarily functional, designed for basic vehicle operation. They typically feature a simple design, often constructed from durable plastic or rubber. These wheels are ideal for entry-level vehicles and fleet management applications, where cost efficiency is paramount. Buyers should consider the longevity and replacement costs, as standard wheels may wear out faster due to their basic materials and lack of advanced features.

How Do Multifunction Steering Wheels Enhance Driving Experience?

Multifunction steering wheels incorporate controls for audio systems, navigation, and phone connectivity, enhancing the overall driving experience. These wheels are prevalent in luxury models and corporate fleets, where driver convenience and safety are priorities. When considering a purchase, B2B buyers should evaluate the compatibility with vehicle systems and the potential for increased driver satisfaction, despite the higher replacement costs associated with these advanced features.

What Makes Performance Steering Wheels Ideal for Sporty Vehicles?

Performance steering wheels are designed with a focus on aesthetics and grip, often featuring a thicker rim and a sporty design. These wheels are suited for performance vehicles and motorsport applications, providing drivers with improved handling and control. B2B buyers in the automotive performance sector should assess the specific needs of their clientele, as these wheels may not be suitable for all drivers and can come at a premium price.

Illustrative image related to mercedes benz steering wheel

Why Choose Custom Steering Wheels for Luxury Vehicles?

Custom steering wheels offer tailored designs and materials, appealing to buyers looking for uniqueness and personalization in their vehicles. These wheels are commonly used in high-end luxury cars and personalization markets. While they provide an exceptional aesthetic appeal, buyers must be prepared for higher prices and longer lead times associated with custom orders. Evaluating the target market’s preferences is crucial for B2B buyers considering this option.

How Do Heated Steering Wheels Benefit Drivers in Cold Climates?

Heated steering wheels come equipped with integrated heating elements, providing comfort during cold weather conditions. They are particularly beneficial in regions with harsh winters and are often found in luxury vehicles. B2B buyers should weigh the added comfort against the complexity of installation and potential maintenance issues that may arise from the heating elements. This feature can significantly enhance the appeal of vehicles in colder markets.

Key Industrial Applications of mercedes benz steering wheel

| Industry/Sector | Specific Application of Mercedes-Benz Steering Wheel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Integration in luxury vehicle production | Enhances vehicle ergonomics and driver experience | Authenticity of parts, compliance with safety standards |

| Fleet Management | Replacement for high-end corporate fleets | Maintains brand image and ensures driver comfort | Availability of genuine parts, warranty options |

| Automotive Restoration | Customization for vintage and luxury car restorations | Increases vehicle value and aesthetic appeal | Sourcing from reputable vendors, quality assurance |

| Motorsports | Performance upgrades in racing vehicles | Enhances driver control and vehicle responsiveness | Material specifications, weight considerations |

| Aftermarket Retail | Sales of custom and remanufactured steering wheels | Expands product offerings and customer satisfaction | Market trends, compatibility with various models |

How is the Mercedes-Benz Steering Wheel Used in Automotive Manufacturing?

In the automotive manufacturing sector, Mercedes-Benz steering wheels are integral to the assembly of luxury vehicles. They serve not just as functional components but also as a key aspect of the vehicle’s aesthetic and ergonomic design. By utilizing genuine steering wheels, manufacturers ensure that the vehicles meet high safety and performance standards, which is crucial for maintaining brand integrity. Buyers in this sector should prioritize sourcing authentic parts to guarantee compatibility and compliance with regulatory requirements, especially when operating in regions with stringent automotive regulations.

What Role Does the Mercedes-Benz Steering Wheel Play in Fleet Management?

For fleet management companies operating high-end corporate vehicles, the Mercedes-Benz steering wheel is a vital component for maintaining a premium driving experience. These steering wheels enhance comfort and control, which can significantly impact driver satisfaction and productivity. When sourcing these components, businesses should consider the availability of genuine parts and the warranty options provided by suppliers, as these factors can influence the long-term maintenance costs and operational efficiency of their fleets.

How is the Mercedes-Benz Steering Wheel Relevant to Automotive Restoration?

In the automotive restoration industry, particularly for vintage and luxury vehicles, the Mercedes-Benz steering wheel is often replaced or customized to enhance both functionality and aesthetic appeal. A well-preserved steering wheel can increase a vehicle’s value significantly, making it an essential consideration for restorers. Buyers in this sector should focus on sourcing from reputable vendors who can guarantee the quality and authenticity of the steering wheels, ensuring that they meet the specific requirements of vintage models.

Why is the Mercedes-Benz Steering Wheel Important in Motorsports?

In motorsports, the Mercedes-Benz steering wheel is crucial for performance-driven applications. Custom steering wheels are designed to provide enhanced grip and control, allowing drivers to respond quickly to dynamic racing conditions. Businesses involved in motorsports should pay attention to the material specifications and weight considerations when sourcing these components, as they can directly affect vehicle performance and driver safety.

How Does the Aftermarket Retail Sector Utilize Mercedes-Benz Steering Wheels?

The aftermarket retail sector sees significant demand for both custom and remanufactured Mercedes-Benz steering wheels. Retailers can capitalize on this trend by offering a diverse range of options that cater to various customer preferences, from luxury to performance upgrades. To succeed in this market, businesses should stay informed about market trends and ensure compatibility with a wide array of vehicle models, providing customers with reliable solutions that enhance their driving experience.

3 Common User Pain Points for ‘mercedes benz steering wheel’ & Their Solutions

Scenario 1: Sourcing Genuine Parts Amid Market Saturation

The Problem: B2B buyers often struggle with sourcing genuine Mercedes-Benz steering wheels due to the prevalence of counterfeit parts in the market. This issue is particularly prevalent in regions like Africa and South America, where the temptation to opt for cheaper, non-genuine options can lead to significant long-term problems. Counterfeit parts not only fail to meet the strict safety and performance standards of genuine components but can also lead to liability issues if they cause accidents or malfunctions. Buyers face the challenge of ensuring they are getting authentic products to maintain the integrity of their fleet.

Illustrative image related to mercedes benz steering wheel

The Solution: To combat this issue, B2B buyers should establish relationships with authorized Mercedes-Benz dealers and verified parts suppliers. Conduct thorough research to confirm that the supplier has a solid reputation and a proven track record of providing genuine parts. Additionally, consider leveraging online platforms that specialize in genuine parts, such as the official Mercedes-Benz parts website. These platforms often provide detailed information about the part specifications and compatibility, ensuring that the buyer receives the correct steering wheel for their specific model. Regularly attending industry trade shows or networking events can also provide insights into reputable suppliers and emerging market trends, enabling buyers to make informed decisions.

Scenario 2: Managing Wear and Tear in High-Usage Vehicles

The Problem: In the automotive industry, particularly among fleets that utilize Mercedes-Benz vehicles for transportation or logistics, steering wheels endure substantial wear and tear. Factors such as constant hand contact, environmental exposure, and the high mileage associated with commercial use can lead to rapid degradation of the steering wheel’s materials. This not only affects the aesthetic appeal but also compromises functionality, leading to increased maintenance costs and potential safety issues.

The Solution: To effectively manage wear and tear, B2B buyers should implement a proactive maintenance strategy that includes regular inspections of the steering wheels. Establish a routine to check for signs of wear, such as cracking or fading, and schedule replacements before they become a safety hazard. When sourcing replacement steering wheels, prioritize genuine Mercedes-Benz components that offer the same quality and ergonomic design as the originals. Additionally, consider investing in protective covers or coatings that can shield the steering wheel from environmental factors, thus extending its lifespan. Training drivers on proper handling and care of the steering wheel can also reduce wear significantly.

Scenario 3: Ensuring Compatibility with Advanced Technology Features

The Problem: As Mercedes-Benz vehicles evolve, steering wheels are increasingly integrated with advanced technology features such as driver assistance systems, Bluetooth connectivity, and multimedia controls. B2B buyers face the challenge of ensuring that any replacement steering wheel maintains compatibility with these complex systems. Mismatched components can lead to functionality issues, affecting the vehicle’s performance and the overall driving experience.

Illustrative image related to mercedes benz steering wheel

The Solution: To ensure compatibility, buyers should work closely with Mercedes-Benz technical support or authorized service centers when selecting replacement steering wheels. It is crucial to reference the vehicle’s VIN (Vehicle Identification Number) to verify that the replacement part meets the specific requirements of the vehicle model. Additionally, buyers should prioritize genuine parts that are designed to integrate seamlessly with existing technology. Utilizing diagnostic tools during installation can help verify that all functions of the steering wheel, including electronic controls, operate correctly. Offering training to mechanics on the latest technology features can also enhance the installation process and ensure optimal performance.

Strategic Material Selection Guide for mercedes benz steering wheel

What Are the Key Materials Used in Mercedes-Benz Steering Wheels?

Mercedes-Benz steering wheels are crafted from a variety of materials, each offering unique properties that cater to performance, aesthetics, and durability. Understanding these materials can help international B2B buyers make informed decisions based on their specific market requirements.

How Does Leather Perform as a Steering Wheel Material?

Leather is a premium choice for steering wheels, particularly in luxury models. Its key properties include excellent tactile feedback and aesthetic appeal, making it a favored option for enhancing the driving experience. Leather also exhibits good temperature resistance, maintaining comfort in both hot and cold environments.

Illustrative image related to mercedes benz steering wheel

Pros:

– Offers a luxurious feel and appearance.

– Provides a non-slip surface, enhancing grip.

– Durable against wear and tear when properly maintained.

Cons:

– Requires regular conditioning to prevent cracking.

– Susceptible to damage from UV exposure, leading to fading.

– Higher cost compared to synthetic alternatives.

For international buyers, especially in regions like Africa and the Middle East, the climate can significantly impact leather’s longevity. Buyers should ensure that the leather used meets local standards for UV resistance and durability.

What Role Does Plastic Play in Steering Wheel Manufacturing?

Plastic, particularly high-quality polymers, is commonly used in steering wheel construction due to its versatility and cost-effectiveness. It can be molded into complex shapes, allowing for ergonomic designs that enhance user comfort.

Illustrative image related to mercedes benz steering wheel

Pros:

– Lightweight and easy to manufacture.

– Resistant to corrosion and moisture.

– Cost-effective, making it suitable for mass production.

Cons:

– May not provide the same premium feel as leather.

– Prone to scratching and surface wear over time.

– Can become brittle in extreme temperatures.

For buyers in Europe and South America, compliance with safety standards such as DIN or ASTM is crucial. Ensuring that the plastic used is of high quality can mitigate issues related to brittleness and wear.

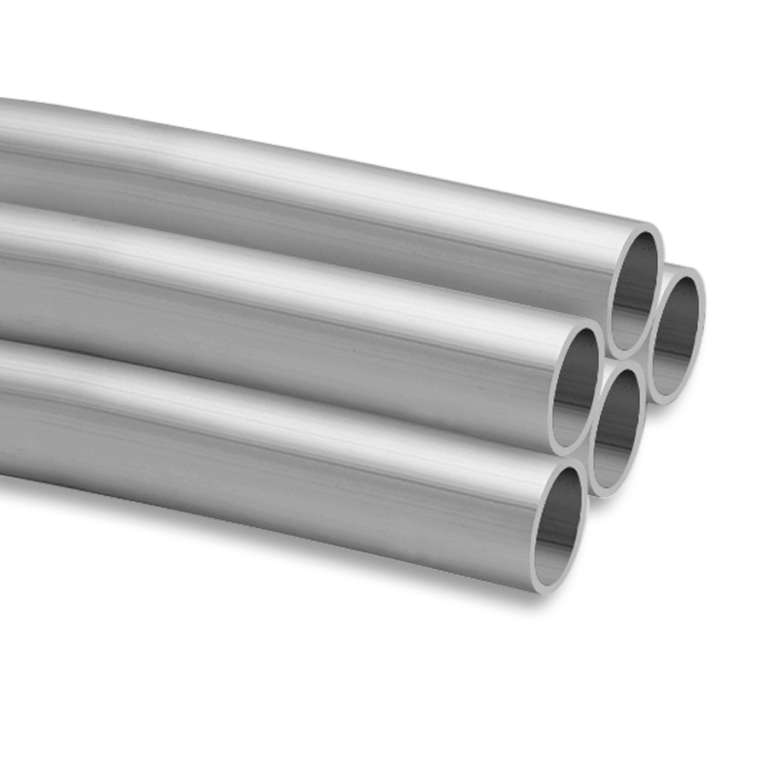

How Do Metals Enhance Steering Wheel Functionality?

Metals, particularly aluminum and steel, are often used in the internal structures of steering wheels. These materials provide strength and stability, essential for the safe operation of steering mechanisms.

Pros:

– High strength-to-weight ratio, enhancing durability.

– Excellent resistance to deformation under stress.

– Can be finished in various ways for aesthetic appeal.

Cons:

– Heavier than plastic or composite materials.

– Can corrode if not properly treated or coated.

– Higher manufacturing complexity and cost.

Illustrative image related to mercedes benz steering wheel

For buyers in regions such as Nigeria and Saudi Arabia, understanding the corrosion resistance of metals is essential due to varying environmental conditions. Ensuring compliance with local standards for metal treatment can prevent premature failure.

What About Composite Materials in Steering Wheel Design?

Composite materials, often a blend of plastics and fibers, are increasingly used in steering wheel design. They offer a balance of weight, strength, and aesthetic flexibility.

Pros:

– Lightweight and strong, improving fuel efficiency in vehicles.

– Can be designed to meet specific aesthetic requirements.

– Resistant to moisture and UV damage.

Cons:

– More expensive than traditional materials.

– Manufacturing processes can be complex.

– May require specialized recycling processes.

International buyers should consider the sustainability of composite materials, especially in Europe, where environmental regulations are stringent. Ensuring that composites meet local recycling standards can enhance marketability.

Illustrative image related to mercedes benz steering wheel

Summary Table of Material Properties

| Material | Typical Use Case for mercedes benz steering wheel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Premium steering wheels in luxury models | Luxurious feel and excellent grip | Requires maintenance; UV susceptible | High |

| Plastic | Standard steering wheels in various models | Lightweight and cost-effective | Prone to scratching; may wear over time | Low |

| Metal | Structural components in steering mechanisms | High strength and durability | Heavier; potential corrosion issues | Medium |

| Composite | Innovative designs for modern steering wheels | Lightweight and customizable | Higher cost; complex manufacturing | High |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed choices that align with their regional requirements and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for mercedes benz steering wheel

What Are the Key Stages in the Manufacturing Process of Mercedes-Benz Steering Wheels?

The manufacturing of Mercedes-Benz steering wheels involves several intricate stages, each designed to ensure the highest quality and performance standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used?

The process begins with selecting high-quality materials, which often include premium-grade leather, durable plastics, and advanced composites. The selection of materials is crucial as it affects not only the aesthetic appeal but also the durability and functionality of the steering wheel. For example, leather is chosen for its luxurious feel and grip, while high-strength plastics and composites ensure longevity and resistance to wear and tear.

Forming: How Are Steering Wheels Shaped?

Once the materials are prepared, the next step is forming. This involves cutting and molding the materials into the desired shapes and contours. Advanced techniques such as injection molding and CNC machining are commonly employed. Injection molding allows for complex geometries to be created with precision, while CNC machining ensures that components fit perfectly. These methods contribute to the ergonomic design that is characteristic of Mercedes-Benz vehicles, enhancing driver comfort and control.

Assembly: What Are the Key Components Involved?

The assembly phase is critical as it integrates various components of the steering wheel, including the horn mechanism, electronic controls, and airbag systems. Each steering wheel is assembled with meticulous attention to detail, ensuring that all electronic functions operate seamlessly. Automated assembly lines may be utilized to enhance efficiency, but skilled technicians oversee the process to ensure that each unit meets the stringent quality standards set by Mercedes-Benz.

Illustrative image related to mercedes benz steering wheel

Finishing: How Is the Final Product Enhanced?

The finishing stage involves applying surface treatments and coatings that enhance both aesthetics and durability. This may include polishing, painting, or applying protective coatings that resist UV damage and wear. The finishing touches not only provide a luxurious appearance but also ensure that the steering wheel can withstand environmental factors, such as temperature extremes and moisture, which are critical for international markets.

What Quality Assurance Standards Are Applied to Mercedes-Benz Steering Wheels?

Quality assurance is paramount in the manufacturing of steering wheels, especially for a brand like Mercedes-Benz, known for its commitment to excellence. The company adheres to international standards such as ISO 9001, which ensures that quality management systems are in place throughout the manufacturing process.

What Are the Relevant International Standards?

ISO 9001 is a globally recognized standard that focuses on consistent quality management systems. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may apply, particularly in regions like Europe and the Middle East, where compliance with local regulations is crucial. These certifications guarantee that the products meet safety and performance requirements.

What Are the QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process. Incoming Quality Control (IQC) is conducted to inspect raw materials before they enter production. In-Process Quality Control (IPQC) takes place during the manufacturing stages to identify any defects early on. Finally, Final Quality Control (FQC) is performed on the finished products to ensure they meet all specifications and quality standards before they are shipped.

What Testing Methods Are Commonly Used in Quality Assurance?

Common testing methods employed in the quality assurance of steering wheels include tensile testing, fatigue testing, and environmental testing. Tensile testing assesses the strength of materials, while fatigue testing evaluates how the steering wheel performs under repeated use. Environmental testing simulates real-world conditions, ensuring that the steering wheel can withstand extreme temperatures, humidity, and UV exposure.

Illustrative image related to mercedes benz steering wheel

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to source Mercedes-Benz steering wheels should take proactive steps to verify supplier quality control measures. Conducting audits is one effective method. By visiting manufacturing facilities, buyers can assess the processes, equipment, and adherence to quality standards firsthand.

What Documentation Should Buyers Request?

Buyers should request detailed quality control reports that outline testing methods, results, and compliance with international standards. Documentation such as ISO certification, inspection reports, and compliance certificates should be readily available from reputable suppliers. This transparency not only builds trust but also assures buyers of the quality they can expect.

Are There Specific QC/CERT Nuances for International Buyers?

For international buyers, particularly those from regions such as Africa, South America, and the Middle East, understanding local regulations and standards is essential. Different countries may have specific requirements for automotive components, and suppliers should be able to demonstrate compliance with these standards. Engaging with third-party inspection agencies can provide an additional layer of assurance, verifying that the products meet local regulations and quality expectations.

Illustrative image related to mercedes benz steering wheel

Conclusion: Why Is Quality Assurance Essential for Mercedes-Benz Steering Wheels?

Quality assurance is not just a regulatory requirement; it is integral to the reputation of Mercedes-Benz as a luxury automotive manufacturer. By understanding the manufacturing processes and the rigorous quality assurance standards that steering wheels undergo, B2B buyers can make informed decisions when sourcing these essential components. This knowledge allows buyers to ensure that they are investing in products that not only meet but exceed industry standards, ultimately enhancing customer satisfaction and loyalty.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mercedes benz steering wheel’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to procure Mercedes-Benz steering wheels. Given the critical role these components play in vehicle functionality and driver experience, it is essential to approach sourcing with a clear strategy. This checklist will help ensure that you make informed decisions, aligning your procurement processes with quality standards and supplier reliability.

Step 1: Define Your Technical Specifications

Begin by establishing the specific requirements for the Mercedes-Benz steering wheels you need. Consider factors such as model compatibility, material specifications (e.g., leather, plastic), and any integrated technologies (like audio or cruise control functions). This clarity will streamline your search and help you communicate effectively with suppliers.

Step 2: Research Potential Suppliers

Invest time in identifying reputable suppliers who specialize in Mercedes-Benz parts. Look for suppliers with a proven track record in the automotive industry, especially those that offer genuine or remanufactured parts. Utilize online directories, industry forums, and trade shows to compile a list of potential vendors.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and industry standards compliance. Check if they hold ISO certifications or similar quality assurances, which indicate a commitment to quality control. This step mitigates risks associated with sourcing inferior products and ensures that you receive parts that meet Mercedes-Benz specifications.

Illustrative image related to mercedes benz steering wheel

Step 4: Request Samples or Product Specifications

Once you have narrowed down your options, request samples or detailed product specifications. This allows you to assess the quality and compatibility of the steering wheels firsthand. Pay attention to craftsmanship, material quality, and whether the product meets your defined technical specifications.

Step 5: Check Warranty and Return Policies

Review the warranty and return policies offered by your chosen suppliers. A robust warranty indicates the supplier’s confidence in their product quality, while favorable return policies provide peace of mind should the parts not meet your expectations. Ensure that these policies align with your business needs and risk management strategies.

Step 6: Negotiate Pricing and Terms

When you are satisfied with your potential suppliers, initiate negotiations regarding pricing and payment terms. Be prepared to discuss volume discounts, shipping costs, and payment methods. Establishing favorable terms is crucial for maintaining your profit margins while ensuring a reliable supply chain.

Illustrative image related to mercedes benz steering wheel

Step 7: Establish a Long-term Partnership

Once you finalize a supplier, focus on building a long-term relationship. Regular communication and feedback can enhance collaboration and ensure that your needs are consistently met. This partnership can also lead to better pricing, priority service, and early access to new products, benefitting your overall procurement strategy.

By following these steps, B2B buyers can effectively navigate the sourcing process for Mercedes-Benz steering wheels, ensuring a combination of quality, reliability, and value in their procurement efforts.

Comprehensive Cost and Pricing Analysis for mercedes benz steering wheel Sourcing

What Are the Key Cost Components in Sourcing Mercedes-Benz Steering Wheels?

When sourcing Mercedes-Benz steering wheels, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and supplier margins.

-

Materials: The choice of materials significantly impacts cost. High-quality leather, plastics, and metals used in steering wheel production not only enhance durability but also elevate the price. Premium models may incorporate unique materials, which can lead to higher costs.

-

Labor: Labor costs vary based on the region of production. Countries with lower labor costs may provide a cost advantage, but this must be balanced against quality assurance and manufacturing standards.

-

Manufacturing Overhead: This includes utilities, factory maintenance, and administrative costs. Efficient production processes can help minimize overhead, thereby reducing overall costs.

-

Tooling: Custom tooling for specialized steering wheel designs can be a significant initial investment. However, the cost per unit decreases with higher production volumes, making it essential to consider the economies of scale.

-

Quality Control (QC): Ensuring that each steering wheel meets Mercedes-Benz standards is vital. Rigorous QC processes add to costs but are necessary to maintain brand integrity and customer satisfaction.

-

Logistics: Transportation costs can vary greatly depending on the shipping method, distance, and Incoterms. Buyers should factor in these logistics costs when calculating total expenses.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin varies based on market competition and supplier relationships.

What Price Influencers Should Buyers Consider?

Several factors influence the pricing of Mercedes-Benz steering wheels, making it essential for buyers to understand their implications.

Illustrative image related to mercedes benz steering wheel

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders generally lead to lower per-unit costs, which can be beneficial for bulk buyers.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should assess the need for customization against potential budget constraints.

-

Material Quality and Certifications: Higher quality materials and compliance with industry certifications can raise prices. However, investing in certified components often leads to improved longevity and performance.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge premium prices due to their experience and the assurance of quality.

-

Incoterms: Understanding shipping terms is crucial. FOB (Free on Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid) affect the total landed cost and should be clearly negotiated with suppliers.

What Tips Can Help Buyers Negotiate Better Prices?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, can leverage several strategies to negotiate favorable terms.

-

Conduct Market Research: Understanding prevailing market prices and competitor offerings can give buyers a strong negotiating position.

-

Negotiate Payment Terms: Flexible payment terms can sometimes lead to better pricing. Consider negotiating for extended payment periods or discounts for upfront payments.

-

Evaluate Total Cost of Ownership (TCO): Buyers should look beyond the initial purchase price. TCO includes maintenance, operational costs, and potential resale value. A higher upfront cost may be justified if it leads to lower lifetime costs.

-

Build Long-Term Relationships: Establishing strong relationships with suppliers can lead to better pricing and terms over time. Trust can foster loyalty, leading suppliers to offer preferential pricing.

-

Be Aware of Pricing Nuances: Different regions may have unique pricing structures influenced by local economic conditions, tariffs, or trade agreements. Understanding these nuances can help buyers make informed decisions.

Disclaimer on Indicative Prices

Prices for Mercedes-Benz steering wheels can fluctuate based on market conditions, materials, and supplier factors. It is advisable for buyers to consult with multiple suppliers and obtain quotes to ensure competitive pricing.

Alternatives Analysis: Comparing mercedes benz steering wheel With Other Solutions

Understanding Alternatives for Steering Wheel Solutions

In the automotive industry, particularly for luxury vehicles like those produced by Mercedes-Benz, the steering wheel is not just a functional component; it is a crucial interface that enhances the driving experience. However, various alternatives exist that can provide similar functionality and aesthetics. This analysis will compare the Mercedes-Benz steering wheel with two notable alternatives: custom aftermarket steering wheels and universal steering wheel solutions. Understanding these options will enable B2B buyers to make informed decisions based on their specific needs.

Comparison Table

| Comparison Aspect | Mercedes Benz Steering Wheel | Custom Aftermarket Steering Wheel | Universal Steering Wheel Solution |

|---|---|---|---|

| Performance | High precision and durability; integrates with vehicle systems | Varies widely; can offer enhanced grip and aesthetics | Basic functionality; may lack advanced features |

| Cost | Premium pricing ($800 – $1,500) | Moderate pricing ($400 – $1,200) | Budget-friendly ($100 – $300) |

| Ease of Implementation | Requires professional installation; seamless integration | May require adaptation; professional installation recommended | Easy to install; typically a direct fit |

| Maintenance | Low; designed for longevity and minimal wear | Varies; quality affects lifespan and care needed | Generally low; basic materials may wear faster |

| Best Use Case | Luxury vehicles demanding OEM quality | Enthusiasts wanting customization and style | Cost-sensitive buyers needing a functional upgrade |

Pros and Cons of Alternatives

Custom Aftermarket Steering Wheels

Custom aftermarket steering wheels are tailored to meet the aesthetic and functional desires of vehicle owners. They often feature enhanced grips, unique designs, and can be personalized with various materials. However, the performance can vary significantly based on the manufacturer, and compatibility issues may arise, requiring modifications for installation. While they are generally less expensive than genuine Mercedes parts, the potential trade-off in quality and integration must be considered.

Universal Steering Wheel Solutions

Universal steering wheel solutions are designed to fit a wide range of vehicles, making them accessible and cost-effective for many buyers. These wheels are straightforward to install, often requiring minimal tools and time. However, they typically lack the advanced features and precise fit of OEM parts, which may compromise the driving experience in luxury vehicles. Their basic functionality is suitable for budget-conscious buyers, but they may not meet the quality standards expected by those accustomed to high-end vehicles.

Making the Right Choice for Your Needs

When choosing the right steering wheel solution for your business or clientele, consider the specific requirements and expectations of the vehicles involved. For luxury brands like Mercedes-Benz, investing in genuine steering wheels ensures optimal performance, longevity, and integration with vehicle systems. However, if customization or budget constraints are significant factors, exploring aftermarket or universal options may provide a viable alternative. Ultimately, the decision should reflect the balance between quality, cost, and the intended use case, ensuring that the chosen solution aligns with the overarching goals of the business or vehicle fleet.

Essential Technical Properties and Trade Terminology for mercedes benz steering wheel

What Are the Key Technical Properties of Mercedes-Benz Steering Wheels?

Understanding the technical properties of Mercedes-Benz steering wheels is crucial for international B2B buyers. These specifications ensure that the steering wheels meet safety, durability, and aesthetic standards. Here are some essential properties to consider:

-

Material Composition

– Mercedes-Benz steering wheels are typically made from high-quality materials, including leather, polyurethane, and ABS plastic. The choice of material affects not only the tactile feel and aesthetic appeal but also the longevity and resistance to wear and tear. For B2B buyers, sourcing genuine parts ensures compliance with manufacturer specifications, which can be critical for warranty and safety considerations. -

Ergonomic Design

– The ergonomic design of steering wheels enhances driver comfort and control. Features such as contouring and grip texture are engineered to reduce fatigue during long drives. For businesses in automotive sales or service, emphasizing ergonomic benefits can attract clients looking for comfort in luxury vehicles. -

Electrical Specifications

– Steering wheels often integrate electrical components for controls (e.g., audio, cruise control) and safety features (e.g., airbags). Understanding the electrical specifications, such as voltage ratings and compatibility with vehicle systems, is essential for ensuring proper functionality. Buyers must ensure that replacement parts meet the same electrical standards to avoid malfunctions. -

Durability Ratings

– Durability ratings often include resistance to UV exposure, temperature extremes, and chemical wear. A steering wheel must withstand constant use and environmental factors without degrading. B2B buyers should prioritize suppliers that provide durability assessments, ensuring that components will perform reliably over time. -

Compatibility and Fitment

– Proper fitment is critical for steering wheels, as misalignment can lead to safety issues and operational inefficiencies. Buyers should verify part numbers and compatibility with specific Mercedes-Benz models to avoid costly errors. Understanding the fitment specifications can also streamline the procurement process and reduce return rates. -

Finish and Aesthetics

– The finish of a steering wheel—whether matte, glossy, or textured—affects not only the look of the vehicle interior but also the perceived value. For businesses targeting luxury markets, offering steering wheels with premium finishes can enhance product appeal and customer satisfaction.

Which Trade Terms Are Commonly Used in the Mercedes-Benz Steering Wheel Market?

Navigating the B2B landscape requires familiarity with industry jargon. Here are key terms that buyers should understand:

Illustrative image related to mercedes benz steering wheel

-

OEM (Original Equipment Manufacturer)

– OEM parts are components made by the original manufacturer, ensuring compatibility and maintaining the vehicle’s integrity. For buyers, sourcing OEM parts can enhance trust with customers who prioritize quality and reliability. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is vital for businesses to plan inventory and manage cash flow effectively. Buyers should negotiate MOQs that align with their sales projections. -

RFQ (Request for Quotation)

– An RFQ is a formal process where buyers request price estimates from suppliers for specific quantities and specifications. For B2B buyers, issuing RFQs can help compare prices and services, ensuring they secure the best deals. -

Incoterms (International Commercial Terms)

– Incoterms define the responsibilities of buyers and sellers in international trade. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) dictate who bears the costs and risks at various points in the shipping process. Understanding Incoterms is crucial for mitigating risks in cross-border transactions. -

Aftermarket

– The aftermarket refers to parts and accessories not sourced from the original manufacturer. While aftermarket parts can be cost-effective, they may not meet the same quality standards as OEM components. Buyers must weigh the benefits and risks when considering aftermarket options. -

Warranty Period

– This term indicates the duration during which a product is guaranteed against defects. Knowing the warranty period helps buyers assess the value and reliability of parts. Longer warranty periods often correlate with higher quality and can be a selling point in B2B negotiations.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that align with their business objectives and customer needs.

Navigating Market Dynamics and Sourcing Trends in the mercedes benz steering wheel Sector

What Are the Key Trends Influencing the Mercedes-Benz Steering Wheel Market?

The Mercedes-Benz steering wheel sector is witnessing dynamic changes influenced by several global drivers. The increasing demand for luxury vehicles, particularly in emerging markets like Nigeria and Saudi Arabia, is propelling growth. As consumers seek enhanced driving experiences, manufacturers are integrating advanced technologies into steering wheels. Features such as multifunction controls for audio, navigation, and driver assistance systems are becoming standard, highlighting the importance of ergonomics and functionality.

Current B2B sourcing trends reflect a shift towards direct procurement channels. International buyers are increasingly favoring genuine parts sourced directly from manufacturers to ensure quality and compatibility. This trend is further bolstered by the rise of online platforms that facilitate direct sales from manufacturers to B2B buyers. Additionally, the adoption of digital tools for inventory management and procurement is streamlining operations, helping businesses reduce costs and improve efficiency. Companies are also leveraging data analytics to forecast demand and optimize supply chains, ensuring timely availability of parts.

Illustrative image related to mercedes benz steering wheel

Emerging markets are also focusing on customization, with buyers seeking bespoke steering wheel designs that reflect individual preferences. This demand has led to a rise in collaborations between manufacturers and design firms, promoting innovation in aesthetics and functionality. As the market evolves, international buyers must stay informed about these trends to make strategic sourcing decisions that align with consumer expectations and technological advancements.

How Is Sustainability Shaping the Sourcing of Mercedes-Benz Steering Wheels?

Sustainability has become a critical factor in the B2B sourcing of Mercedes-Benz steering wheels. The automotive industry is increasingly under pressure to minimize its environmental impact, prompting manufacturers to adopt greener practices. This shift includes the use of sustainable materials such as bio-based plastics and recycled components in steering wheel production. International buyers are recognizing the importance of sourcing products that align with their sustainability goals, particularly in regions where environmental regulations are tightening.

Ethical sourcing is also gaining prominence, with buyers prioritizing suppliers who maintain transparent supply chains. This approach not only mitigates risks associated with labor practices but also enhances brand reputation. Certifications such as ISO 14001 and adherence to the Global Reporting Initiative (GRI) standards are becoming essential for suppliers aiming to prove their commitment to sustainability.

Furthermore, the demand for “green” products is influencing procurement strategies. Buyers are increasingly looking for steering wheels that are not only high-quality but also come from manufacturers who prioritize environmental stewardship. This trend is not merely a response to regulatory requirements; it reflects a broader shift in consumer preferences towards brands that demonstrate corporate responsibility and sustainability.

What Is the Historical Context of Mercedes-Benz Steering Wheels in B2B?

The history of Mercedes-Benz steering wheels is rooted in the brand’s commitment to luxury and innovation. Since the early 20th century, Mercedes-Benz has been at the forefront of automotive engineering, and the steering wheel has evolved from a simple functional component to a sophisticated interface that enhances the driving experience.

In the 1960s and 70s, steering wheels began to incorporate more advanced features, such as integrated controls for audio and climate settings, reflecting changing consumer expectations for comfort and convenience. The introduction of airbags in the 1980s marked a significant safety advancement, with steering wheels becoming integral to vehicle safety systems.

Today, Mercedes-Benz steering wheels epitomize the blend of luxury, technology, and safety. The evolution of these components has not only influenced design aesthetics but has also set industry standards for functionality and user experience, making them a pivotal element in the ongoing innovation within the automotive sector. As international buyers navigate this landscape, understanding the historical context can provide insights into current trends and future developments in steering wheel design and technology.

Frequently Asked Questions (FAQs) for B2B Buyers of mercedes benz steering wheel

-

How do I identify genuine Mercedes-Benz steering wheels for my business?

To ensure you’re sourcing genuine Mercedes-Benz steering wheels, verify that the supplier is an authorized dealer or directly connected to the manufacturer. Request documentation or certificates proving authenticity. Additionally, inspect product details such as part numbers and material quality, as genuine components will match the original specifications. Establishing relationships with reputable suppliers who have a track record in the industry can also mitigate risks associated with counterfeit products. -

What is the best way to customize Mercedes-Benz steering wheels for my clients?

Customizing Mercedes-Benz steering wheels can enhance client satisfaction and market appeal. Work with manufacturers that offer bespoke services, including material selection, color choices, and additional features like integrated controls. Ensure you gather detailed client specifications and preferences before placing orders. Collaborating with experienced artisans or companies specializing in luxury vehicle interiors can also add value and uniqueness to your offerings. -

What are the minimum order quantities (MOQ) for Mercedes-Benz steering wheels?

Minimum order quantities can vary significantly based on the supplier and the specific product line. Generally, you might encounter MOQs ranging from 10 to 50 units, especially for custom orders. Always clarify MOQs with your supplier to avoid unexpected costs and ensure they align with your purchasing strategy. Smaller businesses may benefit from suppliers willing to negotiate lower MOQs for new partnerships. -

How can I ensure quality assurance for steering wheels sourced internationally?

To maintain quality assurance for internationally sourced steering wheels, establish clear quality standards and specifications with your suppliers. Conduct pre-shipment inspections and request samples to evaluate product quality before bulk orders. Utilizing third-party quality control services can also provide an unbiased assessment of the products. Ensure that your suppliers have a solid return policy in case the products do not meet the agreed-upon standards. -

What payment terms should I negotiate with suppliers for steering wheels?

Negotiating payment terms is crucial for maintaining cash flow. Common terms include a deposit upfront (typically 30% to 50%) with the balance due upon delivery or before shipment. Consider using letters of credit or escrow services for larger orders to protect your investment. Ensure that the payment terms are mutually beneficial and clearly documented in the contract to avoid misunderstandings. -

What logistics considerations should I be aware of when importing steering wheels?

When importing steering wheels, consider shipping methods, customs regulations, and potential tariffs specific to your country. Air freight is faster but more expensive than sea freight, which is often more cost-effective for larger shipments. Work with logistics providers experienced in automotive parts to ensure compliance with local regulations and timely delivery. Establishing a reliable supply chain can help mitigate delays and unforeseen costs. -

How can I vet suppliers of Mercedes-Benz steering wheels effectively?

Vetting suppliers involves assessing their credibility, experience, and reliability. Check for industry certifications, customer reviews, and references from previous clients. Conduct site visits if possible or request virtual tours to observe their manufacturing processes. Additionally, consider their responsiveness and communication skills, as these are indicative of their customer service and commitment to quality. -

What trends are influencing the demand for Mercedes-Benz steering wheels in global markets?

Trends such as rising consumer preferences for luxury vehicles and increasing customization options are driving demand for Mercedes-Benz steering wheels. Additionally, sustainability practices are becoming a priority, leading to more interest in eco-friendly materials. Keeping abreast of these trends can help you align your product offerings with market demands, enhancing your competitiveness in regions like Africa, South America, the Middle East, and Europe.

Top 7 Mercedes Benz Steering Wheel Manufacturers & Suppliers List

1. Mercedes-Benz – Steering Wheels & Horns

Domain: mbparts.mbusa.com

Registered: 1996 (29 years)

Introduction: Mercedes-Benz Steering Wheels & Horns: Genuine parts for optimal performance and aesthetic appeal. Steering wheels integrate controls for audio, cruise, phone connectivity, and driver assistance features. Horn mechanism activates warning signals via electrical contacts. Replacement recommended when controls are unresponsive or materials show excessive wear. Luxury models may require attention afte…

2. Mercedes-Benz – AMG Steering Wheel

Domain: usedparts.mercedes-benz.com

Registered: 1994 (31 years)

Introduction: This company, Mercedes-Benz – AMG Steering Wheel, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Exclusive Steering – Custom Mercedes Benz Steering Wheels

Domain: exclusivesteering.com

Registered: 2020 (5 years)

Introduction: This company, Exclusive Steering – Custom Mercedes Benz Steering Wheels, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Mercedes-Benz – Steering Wheels & Horns

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Car & Truck Steering Wheels & Horns for Mercedes-Benz available on eBay. Key categories include: Steering Wheels, Horn Buttons, and various interior parts. Popular models include 190, 220, 300E, A-Class, C-Class, E-Class, G-Class, S-Class, and more. Products range from new, used, and remanufactured items. Brands include OEM, AMG, and aftermarket options. Materials vary from leather, wood, carbon f…

5. Reddit – Steering Wheel Upgrade

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Steering Wheel Upgrade, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Mercedes-Benz – Innovative Steering Wheel Design

Domain: mercedesbenzofwashington.com

Registered: 2022 (3 years)

Introduction: Mercedes-Benz has filed a patent for a new steering wheel design that includes an air duct system to disperse air through air-permeable surfaces. This system allows for both cooling and heating of the air directed towards the driver, similar to a ventilated seat. The airflow can be manually adjusted using controls, enabling targeted air distribution to specific areas, such as the palms or upper bo…

7. Carbon City Customs – 2023 AMG Style Customizable Steering Wheel

Domain: carboncitycustoms.com

Registered: 2021 (4 years)

Introduction: Mercedes-Benz steering wheel upgrades available for various models including AMG styles. Key products include: 1. 2023 AMG Style Customizable Steering Wheel – Sale price: $1,199.99 (Regular price: $1,299.99) 2. 2020 AMG Performance Style Customizable Steering Wheel (Fits 2010+ All Models) – Sale price: $999.99 (Regular price: $1,099.99) 3. 2017 AMG Performance Style Customizable Wheel – Sale price…

Strategic Sourcing Conclusion and Outlook for mercedes benz steering wheel

The importance of strategic sourcing for Mercedes-Benz steering wheels cannot be overstated, particularly for international B2B buyers in regions like Africa, South America, the Middle East, and Europe. Quality steering wheels are essential not only for operational efficiency but also for maintaining the luxury and performance standards that Mercedes-Benz represents. By sourcing genuine parts, businesses can ensure that their vehicles retain the original ergonomic designs and functionality that enhance driver experience and safety.

Investing in high-quality steering wheels contributes to long-term value, reducing the frequency of replacements and potential operational downtime. Understanding the wear patterns and the importance of timely replacements can guide procurement decisions, ensuring that only the best components are integrated into your fleet.

As the automotive landscape evolves, staying ahead with genuine components will be pivotal. We encourage B2B buyers to leverage their purchasing power by establishing relationships with reliable suppliers of Mercedes-Benz parts. This proactive approach not only enhances operational efficiency but also positions your business for sustained growth in a competitive marketplace. Take the next step toward elevating your fleet’s performance and reliability—source strategically today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.