A B2B Buyer’s Guide to Melamine Floor Tile: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for melamine floor tile

In today’s competitive landscape, B2B buyers face the challenge of sourcing melamine floor tiles that not only meet aesthetic demands but also provide durability and cost-effectiveness. As this flooring option gains traction globally, understanding the nuances of melamine floor tiles—from their construction to their applications—is essential for making informed purchasing decisions. This comprehensive guide delves into various types of melamine tiles, their versatile uses in both commercial and residential settings, and the key factors to consider when evaluating suppliers.

Buyers in regions such as Africa, South America, the Middle East, and Europe, including markets like Saudi Arabia and Nigeria, will find valuable insights tailored to their unique needs. By exploring the intricacies of melamine flooring, including installation techniques, maintenance requirements, and pricing structures, this guide equips you with the knowledge to navigate the global market effectively. Additionally, it provides actionable strategies for vetting suppliers and understanding industry standards, ensuring that you choose the right products for your projects.

With a focus on empowering B2B buyers, this guide serves as a vital resource, enabling you to make strategic purchasing decisions that align with your business goals and market demands. Whether you’re looking to enhance the aesthetic appeal of a space or ensure long-lasting performance in high-traffic areas, understanding melamine floor tiles can be a game-changer for your business.

Understanding melamine floor tile Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Melamine Tiles | Made from melamine-saturated paper; resembles wood aesthetics. | Residential and commercial flooring | Pros: Cost-effective, durable. Cons: Limited design options. |

| High-Pressure Melamine Tiles | Enhanced durability; easy installation; lightweight compared to ceramic. | Retail spaces, offices, and schools | Pros: High stain resistance, easy maintenance. Cons: May require specific installation tools. |

| Waterproof Melamine Tiles | Water-resistant surface; ideal for moisture-prone areas. | Bathrooms, kitchens, and basements | Pros: Excellent for wet environments. Cons: Higher cost than standard options. |

| Acoustic Melamine Tiles | Designed to reduce noise; thicker construction. | Multi-family housing, hotels | Pros: Sound absorption capabilities. Cons: Heavier and may increase shipping costs. |

| Decorative Melamine Tiles | Variety of textures and patterns; can mimic stone or ceramic. | High-end retail, showrooms | Pros: Aesthetic appeal, versatile designs. Cons: Typically more expensive. |

What are the Characteristics of Standard Melamine Tiles?

Standard melamine tiles are constructed using melamine resin-impregnated paper, which is then fused to a substrate like particle board. Their primary appeal lies in their ability to mimic the look of natural wood while being more affordable. These tiles are suitable for both residential and commercial applications, making them a versatile choice for B2B buyers. However, while they offer durability and cost-effectiveness, the design options can be somewhat limited compared to more specialized products.

How Do High-Pressure Melamine Tiles Stand Out?

High-pressure melamine tiles are engineered for enhanced durability and ease of installation. Weighing significantly less than traditional ceramic tiles, they reduce transportation and installation costs, making them ideal for retail spaces, offices, and educational institutions. Their high resistance to stains and ease of maintenance make them particularly appealing for high-traffic areas. However, buyers should consider the potential need for specific installation tools, which could add to upfront costs.

Why Choose Waterproof Melamine Tiles for Moisture-Prone Areas?

Waterproof melamine tiles feature a water-resistant surface, making them perfect for environments like bathrooms, kitchens, and basements where moisture is prevalent. These tiles provide peace of mind against water damage and mold, which is a significant consideration for B2B buyers in construction and renovation sectors. While they tend to be more expensive than standard options, the investment is often justified by their longevity and performance in wet conditions.

What Advantages Do Acoustic Melamine Tiles Offer?

Acoustic melamine tiles are specifically designed to minimize noise, making them an excellent choice for multi-family housing, hotels, and other environments where sound control is critical. Their thicker construction aids in sound absorption, providing a quieter atmosphere for occupants. While they can increase shipping costs due to their weight, the benefits of enhanced acoustic performance often outweigh these downsides for businesses focused on creating comfortable living and working spaces.

How Do Decorative Melamine Tiles Enhance Aesthetic Appeal?

Decorative melamine tiles offer a wide range of textures and patterns, allowing for creative design solutions that can mimic materials like stone or ceramic. These tiles are particularly suited for high-end retail environments and showrooms where aesthetics play a crucial role in customer engagement. While they typically come at a higher price point, the investment can significantly enhance the visual appeal of a space, making them a worthwhile consideration for B2B buyers looking to elevate their projects.

Key Industrial Applications of melamine floor tile

| Industry/Sector | Specific Application of melamine floor tile | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Flooring for retail spaces, such as showrooms and stores | Enhances aesthetic appeal while being durable and cost-effective | Ensure designs align with branding; check for high foot traffic durability |

| Hospitality | Flooring in hotels and restaurants | Provides a stylish, easy-to-maintain surface that withstands heavy use | Look for water and stain resistance; consider installation time and costs |

| Education | Flooring in schools and universities | Offers a safe, durable, and easy-to-clean environment for students | Prioritize safety certifications; assess acoustic properties for classrooms |

| Healthcare | Flooring in clinics and hospitals | Ensures hygiene and ease of maintenance while being durable against spills | Verify antimicrobial properties; consider ease of installation in sensitive environments |

| Residential | Flooring in apartments and homes | Combines aesthetic appeal with affordability and durability | Evaluate design options; check for ease of maintenance and installation requirements |

How is Melamine Floor Tile Used in Retail Spaces?

In retail environments, melamine floor tiles are utilized to create visually appealing showrooms and store layouts. These tiles mimic the look of natural materials, enhancing the aesthetic appeal without the associated costs. Their durability is crucial in high-traffic areas, where wear and tear from foot traffic can be significant. B2B buyers in retail should focus on sourcing tiles that align with their brand image while ensuring they can withstand the demands of a bustling shopping environment.

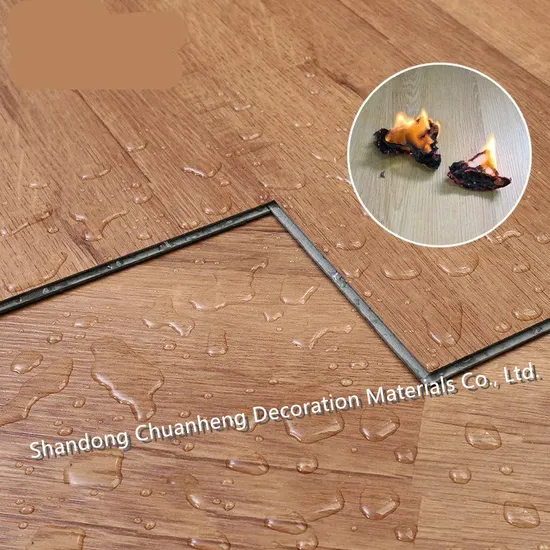

Illustrative image related to melamine floor tile

What are the Benefits of Melamine Floor Tile in Hospitality?

In the hospitality sector, melamine floor tiles are favored for their stylish appearance and ease of maintenance. Hotels and restaurants benefit from the combination of aesthetic appeal and functionality, as these tiles are resistant to stains and spills, crucial in dining and guest areas. Buyers should consider the ease of installation and the need for water-resistant options to maintain hygiene and comfort for guests.

Why Choose Melamine Floor Tile for Educational Institutions?

Educational institutions often utilize melamine floor tiles for classrooms, hallways, and libraries. These tiles provide a safe, durable surface that is easy to clean, promoting a healthy learning environment. Buyers from schools and universities should prioritize sourcing tiles that meet safety standards and consider acoustic properties to minimize noise in learning spaces.

How Does Melamine Floor Tile Enhance Healthcare Facilities?

In healthcare settings, melamine floor tiles are used extensively due to their hygienic properties and ease of maintenance. Clinics and hospitals require flooring that can withstand spills and heavy foot traffic while being easy to clean. B2B buyers should look for tiles with antimicrobial properties and ensure they are compliant with health regulations, as the cleanliness of a facility is paramount in this sector.

What Makes Melamine Floor Tile Ideal for Residential Use?

For residential applications, melamine floor tiles offer homeowners an affordable solution that does not compromise on style or durability. These tiles are ideal for various living spaces, providing a warm and inviting atmosphere while being easy to maintain. Buyers should assess the design options available and consider the ease of installation, especially for DIY projects, to maximize value and aesthetic appeal in their homes.

3 Common User Pain Points for ‘melamine floor tile’ & Their Solutions

Scenario 1: Difficulty in Installation and Maintenance of Melamine Floor Tile

The Problem: Many B2B buyers, especially those in regions with less skilled labor, face significant challenges when it comes to the installation and maintenance of melamine floor tiles. Misalignment during installation can lead to unsightly gaps or uneven surfaces, which not only diminishes the aesthetic appeal but can also affect the durability of the flooring. Moreover, maintaining these tiles can be daunting for businesses lacking the right cleaning protocols, leading to premature wear and a reduced lifespan.

Illustrative image related to melamine floor tile

The Solution: To mitigate installation challenges, it is crucial to partner with suppliers who provide comprehensive installation guides and training resources. Buyers should seek suppliers that offer pre-installation consultations to assess site conditions and recommend appropriate installation methods. Additionally, investing in high-quality tools and ensuring that the installation team is well-trained in the specifics of melamine flooring will significantly reduce errors. For maintenance, buyers should adopt a straightforward cleaning regimen, utilizing non-abrasive cleaners that effectively remove dirt without damaging the surface. Regular training sessions for staff on proper cleaning techniques can prolong the life of the flooring and keep it looking new.

Scenario 2: Concerns About Durability in High-Traffic Areas

The Problem: In commercial settings, especially in high-traffic areas like retail spaces and offices, durability is a primary concern for B2B buyers considering melamine floor tiles. Many businesses worry that these tiles, while affordable, may not withstand the wear and tear from heavy foot traffic, leading to costly replacements and disruptions.

The Solution: To address durability concerns, buyers should focus on selecting melamine floor tiles with a higher AC rating, indicating greater resistance to wear. Tiles rated AC4 or higher are recommended for commercial environments as they are designed to handle medium to heavy foot traffic. Additionally, incorporating mats at entry points can help mitigate dirt and moisture from being tracked onto the flooring. Regular inspections and timely maintenance, such as resealing or surface treatments, will also extend the life of the tiles and ensure they maintain their appearance and structural integrity over time.

Illustrative image related to melamine floor tile

Scenario 3: Limited Design Options and Customization

The Problem: Many B2B buyers, particularly in design-sensitive industries, often find that the available melamine floor tile options do not align with their branding or aesthetic goals. A limited selection can hinder their ability to create unique and appealing environments that resonate with their target audience.

The Solution: To overcome this challenge, buyers should actively seek suppliers that offer customizable melamine floor tiles. Many manufacturers can create tiles in various colors, textures, and patterns to meet specific design requirements. Engaging with designers or architects during the planning phase can also help in selecting tiles that enhance the overall aesthetic while adhering to functional needs. Furthermore, consider using a combination of different tile styles to create visually interesting layouts. Leveraging digital tools that allow for virtual design previews can also assist buyers in visualizing how different tiles will look in their spaces before making a final decision.

Strategic Material Selection Guide for melamine floor tile

What Are the Key Materials Used in Melamine Floor Tile Production?

When selecting materials for melamine floor tiles, it’s essential to consider the core components that contribute to their performance, durability, and overall suitability for various applications. Below, we analyze three common materials used in the production of melamine floor tiles: melamine resin, particle board, and decorative paper.

How Does Melamine Resin Contribute to Tile Performance?

Melamine resin is a thermosetting plastic that provides the surface layer for melamine floor tiles. It is known for its high resistance to heat, moisture, and chemicals, making it ideal for flooring applications. The resin’s thermal stability allows it to withstand temperature fluctuations without warping or degrading.

Pros: The primary advantages of melamine resin include its excellent durability, scratch resistance, and ease of cleaning. It also provides a high-quality finish that mimics natural materials, enhancing aesthetic appeal.

Cons: However, melamine resin can be sensitive to prolonged exposure to direct sunlight, which may lead to fading. Additionally, while it is moisture-resistant, it is not entirely waterproof, which could be a concern in areas with high humidity.

Impact on Application: Melamine resin is compatible with various flooring environments, including residential and commercial spaces. Its aesthetic versatility allows it to cater to diverse design preferences, making it a popular choice in international markets.

What Role Does Particle Board Play in Melamine Floor Tile Construction?

Particle board serves as the substrate for melamine floor tiles, providing structural integrity. It is created by compressing wood particles and adhesives under heat and pressure, resulting in a lightweight yet sturdy material.

Pros: Particle board is cost-effective and easy to manufacture, making it a popular choice for flooring products. It also provides good sound insulation and thermal properties.

Cons: The primary drawback is that particle board is less durable than other substrates, such as plywood or medium-density fiberboard (MDF). It may also be susceptible to moisture damage if not adequately sealed.

Illustrative image related to melamine floor tile

Impact on Application: For international buyers, particularly in regions with high humidity like parts of Africa and South America, it is crucial to ensure that the particle board used is treated for moisture resistance to prevent long-term damage.

How Does Decorative Paper Enhance the Aesthetic of Melamine Tiles?

Decorative paper is printed with designs and patterns that are then impregnated with melamine resin. This layer is what gives melamine tiles their appealing look, resembling wood, stone, or other natural materials.

Pros: The use of decorative paper allows for a wide range of design options, making it easy to match various interior styles. It is also relatively inexpensive compared to natural materials.

Cons: The main limitation is that decorative paper can be less resistant to heavy wear and tear, especially in high-traffic areas. Over time, it may show signs of wear, such as scratches or fading.

Illustrative image related to melamine floor tile

Impact on Application: Buyers in competitive markets like Europe may prioritize decorative options that offer both durability and aesthetic appeal. Ensuring compliance with local design trends can enhance marketability.

Summary Table of Material Selection for Melamine Floor Tile

| Material | Typical Use Case for melamine floor tile | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Melamine Resin | Surface layer for residential/commercial tiles | High durability and scratch resistance | Sensitive to UV exposure | Medium |

| Particle Board | Substrate for melamine tiles | Cost-effective and lightweight | Less durable, susceptible to moisture | Low |

| Decorative Paper | Aesthetic layer for various designs | Wide design options, cost-effective | Less resistant to wear in high traffic | Low |

This strategic analysis of materials used in melamine floor tiles provides B2B buyers with insights into performance, cost, and application considerations. Understanding these factors can aid in making informed purchasing decisions tailored to specific regional needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for melamine floor tile

What Are the Main Stages in the Manufacturing Process of Melamine Floor Tiles?

The manufacturing of melamine floor tiles involves several critical stages, each contributing to the final product’s quality, durability, and appeal. The process typically consists of material preparation, forming, assembly, and finishing.

1. Material Preparation

The first stage is the preparation of materials, primarily involving melamine resin and decorative paper. The resin is produced through the polymerization of melamine and formaldehyde, resulting in a durable and chemically resistant compound. This resin is then mixed with pigments to achieve the desired color and finish. Meanwhile, decorative paper, often printed with wood grain or stone patterns, is saturated with the melamine resin to enhance its strength and aesthetic appeal.

2. Forming

Once the materials are ready, the forming process begins. The saturated decorative paper is layered with a core material, usually high-density fiberboard (HDF) or particle board, which provides structural integrity. The layers are subjected to high pressure and temperature in a hydraulic press, allowing the resin to cure and bond the layers together. This process not only solidifies the tile but also enhances its water, scratch, and stain resistance.

3. Assembly

After forming, the tiles are cut into specified sizes and shapes. This stage may include adding features such as beveled edges or tongue-and-groove systems, which facilitate easier installation. The tiles are then inspected for defects and sorted based on quality, ensuring only the best products proceed to the next stage.

4. Finishing

Finishing involves applying a wear layer, typically another layer of melamine resin, which enhances durability and provides additional protection against scratches and stains. This layer is cured under UV light or heat, ensuring a robust, long-lasting finish. Finally, the tiles undergo a final inspection and are packaged for shipment.

How Is Quality Assurance Implemented in Melamine Floor Tile Manufacturing?

Quality assurance (QA) is integral to the manufacturing of melamine floor tiles, ensuring that products meet international and industry-specific standards. This encompasses various quality checkpoints and testing methods throughout the production process.

Relevant International Standards for Melamine Floor Tile Quality

B2B buyers should be aware of the key international standards that govern the quality of melamine floor tiles. ISO 9001, which outlines the requirements for a quality management system, is crucial for ensuring consistent quality and customer satisfaction. Additionally, products may need to comply with CE marking standards, particularly for the European market, ensuring they meet health, safety, and environmental protection requirements.

What Are the Key Quality Control Checkpoints?

Quality control in melamine floor tile manufacturing typically includes several checkpoints:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival at the facility. Suppliers are evaluated based on the quality of their materials, ensuring that only the best inputs are used in production.

-

In-Process Quality Control (IPQC): During manufacturing, various parameters such as temperature, pressure, and resin saturation levels are monitored. This real-time oversight helps identify and rectify issues before they affect the final product.

-

Final Quality Control (FQC): After finishing, each tile undergoes a thorough inspection for defects, including scratches, color consistency, and dimensional accuracy. Tiles that do not meet quality standards are either reworked or discarded.

What Common Testing Methods Are Used in Melamine Floor Tile Quality Assurance?

To ensure the durability and performance of melamine floor tiles, several common testing methods are employed:

-

Water Resistance Testing: Tiles are subjected to water exposure to evaluate their resistance to moisture, a critical factor for installations in areas prone to spills or humidity.

-

Scratch and Abrasion Testing: This assesses the tile’s surface durability. Tiles are tested against standardized abrasives to determine how well they withstand wear over time.

-

Stain Resistance Testing: Various substances, including oil and ink, are applied to the tile surface to evaluate how easily stains can be cleaned off.

-

Impact Resistance Testing: This measures the tile’s ability to withstand heavy impacts, simulating conditions in high-traffic areas.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should prioritize verifying supplier quality control practices to ensure they receive high-quality products. Here are some actionable steps to consider:

-

Conduct Audits: Regular audits of manufacturing facilities can provide insights into the supplier’s adherence to quality standards. Buyers should request audit reports to assess the effectiveness of the supplier’s quality management system.

-

Review Quality Assurance Documentation: Suppliers should provide documentation outlining their quality control processes, including IQC, IPQC, and FQC procedures. This transparency is vital for establishing trust.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality practices. These inspectors can conduct checks at various stages of production and ensure compliance with international standards.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control and certification is crucial. Buyers should be aware of:

Illustrative image related to melamine floor tile

-

Regional Compliance Requirements: Different regions may have specific regulations regarding materials and safety standards. Understanding these can prevent compliance issues and facilitate smoother import processes.

-

Certification Validity: Verify the validity of any certifications presented by suppliers. Certifications should be current and relevant to the specific products being purchased.

-

Cultural and Communication Considerations: Language barriers and cultural differences may affect the clarity of quality assurance processes. Buyers should ensure effective communication with suppliers to align expectations and avoid misunderstandings.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance protocols for melamine floor tiles is essential for B2B buyers. By focusing on material preparation, forming, assembly, and finishing stages, alongside robust quality control measures, buyers can ensure they partner with reliable suppliers that deliver high-quality products suited to their market needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘melamine floor tile’

To assist B2B buyers in sourcing melamine floor tiles effectively, this guide provides a step-by-step checklist to ensure you make informed decisions. Understanding the nuances of melamine flooring and the procurement process can lead to better purchasing outcomes, especially when catering to diverse markets across Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital to ensure the melamine floor tiles meet your project requirements. Consider factors such as durability, water resistance, aesthetic appearance, and texture. Specifics like AC ratings for wear resistance and size variations can significantly impact the suitability of tiles for different environments.

Step 2: Research Market Trends and Pricing

Understanding current market trends and pricing will help you set a budget and identify competitive offers. Research the latest designs and innovations in melamine flooring, such as eco-friendly options or enhanced stain resistance features. This knowledge will also equip you to negotiate better terms with suppliers.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is essential. Request detailed company profiles, including their manufacturing capabilities, quality control processes, and client testimonials. Additionally, consider their experience in your target regions, as local market knowledge can influence supply chain efficiency.

- Check Certifications: Ensure the suppliers adhere to international quality standards (ISO, CE) and environmental regulations.

- Request Samples: Obtain product samples to assess quality firsthand, focusing on aspects like texture and finish.

Step 4: Assess Logistics and Shipping Options

Logistics play a crucial role in the procurement process, especially for international transactions. Evaluate shipping methods, lead times, and associated costs. Consider suppliers that offer efficient delivery options to minimize downtime and ensure timely project completion.

- Discuss Incoterms: Clarify terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) to understand cost responsibilities.

- Review Packaging Standards: Ensure the packaging is robust enough to prevent damage during transit.

Step 5: Negotiate Terms and Conditions

Effective negotiation can lead to more favorable terms, impacting your overall costs. Discuss payment terms, bulk order discounts, and warranty provisions. Be transparent about your purchasing intentions and seek flexible arrangements that suit both parties.

- Explore Financing Options: Some suppliers may offer financing solutions or payment plans, which can ease cash flow concerns.

- Confirm After-Sales Support: Establish what support is available post-purchase, including installation guidance and maintenance recommendations.

Step 6: Finalize the Purchase Agreement

Once satisfied with the supplier’s terms, finalize the purchase agreement. Ensure all specifications, pricing, and delivery timelines are clearly documented. This contract serves as a legal safeguard for both parties and minimizes the risk of misunderstandings.

Step 7: Plan for Installation and Maintenance

Proper planning for installation and ongoing maintenance is crucial for maximizing the longevity of your melamine floor tiles. Ensure you have qualified personnel for installation and understand the maintenance requirements to keep the flooring in optimal condition.

- Educate Your Team: Provide training on care procedures, including cleaning and avoiding damaging chemicals.

- Establish a Maintenance Schedule: Regular inspections can prevent issues before they arise, extending the lifespan of your flooring investment.

By following this checklist, B2B buyers can navigate the complexities of sourcing melamine floor tiles with greater confidence and effectiveness, ultimately leading to successful procurement outcomes.

Comprehensive Cost and Pricing Analysis for melamine floor tile Sourcing

What Are the Key Cost Components in Melamine Floor Tile Sourcing?

When sourcing melamine floor tiles, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

Illustrative image related to melamine floor tile

-

Materials: The core of melamine floor tiles is the melamine resin and the substrate, usually particle board. The prices of these materials can fluctuate based on global supply and demand, as well as local market conditions. In regions like Africa and South America, sourcing locally may mitigate some material costs.

-

Labor: Labor costs vary significantly across different regions. For instance, labor in countries within Africa may be less expensive compared to Europe. However, the skill level of labor can affect the quality of the manufacturing process.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help keep these costs low.

-

Tooling: Initial tooling costs can be high, particularly for customized designs. Buyers should be aware that specific patterns or sizes may require unique molds, which can raise the upfront investment.

-

Quality Control (QC): Ensuring that the tiles meet specified quality standards is crucial. Quality control processes can add to the overall cost but are necessary to avoid defects and maintain customer satisfaction.

-

Logistics: Shipping and handling are significant cost factors, especially for international transactions. Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can influence total logistics costs, depending on who bears responsibility for shipping.

-

Margin: Supplier margins can vary based on competition, demand, and market positioning. Understanding typical margins in your target market can help negotiate better pricing.

What Influences Pricing for Melamine Floor Tiles?

Several factors can influence the pricing of melamine floor tiles:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often provide better pricing for larger orders. Buyers should consider their inventory needs and potential storage costs when negotiating MOQs.

-

Specifications and Customization: Customized designs or unique specifications can significantly increase costs. Buyers should balance the desire for customization with budget constraints.

-

Materials and Quality Certifications: Higher quality materials or certifications can increase costs but may provide better durability and customer satisfaction in the long run. Buyers should weigh the benefits of certified products against their budget.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge a premium for their products, but this often comes with better service and support.

-

Incoterms: Understanding shipping terms and conditions is crucial. Different Incoterms can lead to variations in cost responsibility, impacting the total landed cost of the product.

What Tips Can Help Buyers Negotiate Better Pricing?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to cost savings:

-

Leverage Volume: If feasible, combine orders across different projects to meet MOQ requirements, thereby securing bulk discounts.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also installation, maintenance, and potential replacement costs. A higher upfront investment may yield savings in the long run if the product is more durable.

-

Negotiate Payment Terms: Flexible payment terms can improve cash flow. Discuss options such as net payment terms or installment payments to ease financial pressure.

-

Understand Local Market Conditions: Familiarize yourself with local pricing trends and supplier dynamics in your region. This knowledge can enhance negotiation leverage.

-

Request Samples: Before placing large orders, request samples to assess quality and confirm that the product meets your specifications. This can prevent costly mistakes down the line.

Disclaimer

Prices for melamine floor tiles can vary widely based on market conditions, supplier relationships, and specific project requirements. Always seek multiple quotes and conduct thorough due diligence to ensure competitive pricing.

Alternatives Analysis: Comparing melamine floor tile With Other Solutions

When evaluating flooring solutions for commercial or residential spaces, it’s essential to consider various alternatives to melamine floor tiles. Melamine tiles are known for their affordability, durability, and aesthetic appeal, but there are other options that may better meet specific requirements based on performance, cost, and maintenance needs. Below is a comparative analysis of melamine floor tiles against two viable alternatives: vinyl flooring and ceramic tiles.

| Comparison Aspect | Melamine Floor Tile | Vinyl Flooring | Ceramic Tiles |

|---|---|---|---|

| Performance | Durable, water-resistant, mimics wood | Highly durable, waterproof, versatile | Extremely durable, water-resistant |

| Cost | Generally low-cost | Moderate cost | Higher initial investment |

| Ease of Implementation | Easy to install, lightweight | Simple installation (peel-and-stick or click-lock) | More complex installation, requires skilled labor |

| Maintenance | Low maintenance, no waxing needed | Low maintenance, easy to clean | Requires regular maintenance, prone to chipping |

| Best Use Case | High-traffic commercial areas | Residential, light commercial spaces | High-end residential and commercial areas |

What Are the Key Advantages and Disadvantages of Vinyl Flooring Compared to Melamine?

Vinyl flooring is a popular alternative due to its versatility and ease of installation. It is highly durable and resistant to water, making it suitable for areas prone to moisture, such as kitchens and bathrooms. The peel-and-stick or click-lock installation options significantly reduce labor costs and downtime. However, vinyl can be less aesthetically pleasing than melamine, particularly in high-end applications, and can be susceptible to wear and tear over time, especially in high-traffic environments.

How Do Ceramic Tiles Compare to Melamine in Terms of Performance and Maintenance?

Ceramic tiles are well-regarded for their durability and aesthetic appeal, offering a high-end finish that can elevate the overall look of a space. They are resistant to water and stains, making them ideal for both residential and commercial settings. However, ceramic tiles typically come with a higher initial cost and can be challenging to install, often requiring professional help. Maintenance can also be more demanding, as they may require sealing and are prone to chipping or cracking.

Conclusion: How Can B2B Buyers Select the Right Flooring Solution for Their Needs?

When choosing the right flooring solution, B2B buyers should assess their specific needs, including budget constraints, the intended use of the space, and maintenance capabilities. Melamine floor tiles offer an excellent balance of affordability and aesthetic appeal, making them suitable for many applications, particularly in high-traffic areas. Vinyl flooring provides a cost-effective and easy-to-install option for less demanding environments, while ceramic tiles offer luxury and durability for high-end projects. By understanding the strengths and weaknesses of each alternative, buyers can make informed decisions that align with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for melamine floor tile

What Are the Essential Technical Properties of Melamine Floor Tile?

1. Material Composition

Melamine floor tiles are primarily made from melamine resin, which is a thermosetting plastic. This material is known for its durability and resistance to wear, making it an ideal choice for high-traffic areas. The resin is combined with layers of paper and bonded to a core material, typically particle board. Understanding the material composition is crucial for B2B buyers as it impacts the product’s longevity, maintenance requirements, and overall cost-effectiveness.

2. AC Rating (Abrasion Class)

The AC rating system measures the durability of laminate flooring, with ratings ranging from AC1 (light residential use) to AC5 (heavy commercial use). For melamine floor tiles, an AC3 rating is common for residential heavy traffic, while AC4 is suitable for moderate commercial traffic. Buyers should consider the AC rating based on the intended application to ensure the selected product meets the expected performance standards.

3. Thickness

Melamine floor tiles typically range from 7mm to 12mm in thickness. Thicker tiles often provide better sound insulation and impact resistance, making them preferable for commercial settings or multi-family housing. When sourcing melamine tiles, it is essential for buyers to match the thickness with their specific installation requirements and performance expectations.

4. Water Resistance

Many melamine floor tiles come with enhanced water-resistant properties, making them suitable for areas prone to moisture, such as kitchens and bathrooms. This characteristic is vital for B2B buyers, particularly in regions with high humidity or potential water exposure, as it directly affects the product’s lifespan and maintenance needs.

5. Ease of Installation

Melamine tiles are designed for straightforward installation, often featuring a click-lock system that eliminates the need for adhesives or nails. This not only reduces labor costs but also minimizes downtime during installation. B2B buyers should consider this property when evaluating total project costs, especially for large-scale installations.

Illustrative image related to melamine floor tile

What Are Common Trade Terms Related to Melamine Floor Tile?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are then sold under another brand’s name. In the context of melamine floor tiles, understanding OEM relationships can help buyers ensure product quality and brand reputation, as they may be sourcing from well-established manufacturers.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum quantity of a product that a supplier is willing to sell. For melamine floor tiles, MOQs can vary significantly depending on the supplier and product type. Buyers should be aware of MOQs to manage inventory costs effectively and ensure they are not overcommitting to excess stock.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request a quote from suppliers for specific products or services. Submitting an RFQ for melamine floor tiles can help buyers compare prices, negotiate better terms, and establish relationships with multiple suppliers.

Illustrative image related to melamine floor tile

4. Incoterms

Incoterms (International Commercial Terms) are a set of predefined commercial terms published by the International Chamber of Commerce that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms is crucial for B2B buyers in the melamine flooring industry, as they dictate who bears the costs and risks during shipping and delivery.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. For melamine floor tiles, lead times can vary based on manufacturing capacity and shipping logistics. Understanding lead times is essential for project planning and ensuring timely delivery to meet construction schedules.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when sourcing melamine floor tiles, ultimately leading to better project outcomes and cost efficiencies.

Navigating Market Dynamics and Sourcing Trends in the melamine floor tile Sector

What Are the Key Market Dynamics and Trends Affecting Melamine Floor Tile Sourcing?

The global melamine floor tile market is experiencing robust growth, driven by increasing urbanization, rising disposable incomes, and a growing preference for cost-effective and durable flooring solutions. In regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Nigeria—demand for melamine floor tiles is surging due to their aesthetic appeal, ease of installation, and low maintenance requirements. The market is witnessing a shift towards products that emulate natural materials, with manufacturers enhancing visual designs to attract discerning buyers.

Emerging B2B technology trends are also reshaping sourcing processes. Digital platforms and e-commerce solutions are streamlining procurement, enabling international buyers to access a wider range of suppliers and products without the constraints of geographical boundaries. Additionally, advancements in manufacturing technology are allowing for improved product quality, with melamine tiles now boasting enhanced resistance to stains and wear, comparable to traditional ceramic options. As companies increasingly prioritize efficiency, innovations like easy-to-install systems are becoming essential features.

Moreover, the trend towards sustainable building materials is gaining traction, prompting buyers to seek out eco-friendly options. This evolution is influencing sourcing strategies, as businesses aim to align with sustainability goals while satisfying consumer demand for environmentally responsible products.

How Is Sustainability Influencing the Melamine Floor Tile Sector?

Sustainability is a critical consideration in the melamine floor tile sector, as environmental concerns continue to gain prominence globally. The production of melamine flooring often involves the use of resins derived from petrochemical sources, raising questions about its ecological impact. Consequently, many manufacturers are now focusing on sustainable sourcing practices and the use of recycled materials to minimize the environmental footprint.

Ethical sourcing is equally important, as B2B buyers increasingly demand transparency in supply chains. Companies that can demonstrate adherence to ethical practices, such as fair labor conditions and responsible sourcing of raw materials, are likely to gain a competitive edge. Certifications such as FSC (Forest Stewardship Council) and other ‘green’ labels are becoming essential for manufacturers looking to appeal to environmentally conscious consumers and businesses.

Investing in sustainable melamine products not only enhances a company’s reputation but also aligns with a growing regulatory landscape that favors eco-friendly building materials. Buyers are encouraged to prioritize suppliers who actively engage in sustainable practices, as this can significantly impact the overall value and longevity of their flooring investments.

Illustrative image related to melamine floor tile

What Is the Historical Context of Melamine Floor Tiles in the B2B Market?

Melamine floor tiles have evolved significantly since their introduction in the mid-20th century. Initially recognized for their affordability and ease of maintenance, they gained popularity in residential and commercial applications alike. The production process has seen considerable advancements, particularly with the integration of high-pressure techniques that enhance the durability and aesthetic qualities of melamine tiles.

Over the decades, the melamine flooring market has adapted to changing consumer preferences, shifting from basic designs to more sophisticated, wood-like finishes that mimic natural materials. This evolution reflects broader trends in the flooring industry, where aesthetics, sustainability, and cost-effectiveness are paramount. As businesses continue to seek innovative solutions that meet modern demands, melamine floor tiles are poised to remain a staple choice in various commercial sectors worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of melamine floor tile

-

How do I choose the right melamine floor tile for my project?

When selecting melamine floor tiles, consider factors such as durability, design aesthetics, and intended use. Look for tiles with high AC ratings (AC3 for residential heavy traffic and AC4 for commercial medium traffic) to ensure they can withstand foot traffic. Evaluate the color and texture that best match your project’s theme, and check for water, stain, and scratch resistance. Additionally, inquire about the installation method and whether the tiles require any special tools or techniques. -

What are the benefits of sourcing melamine floor tiles internationally?

Sourcing melamine floor tiles internationally can provide access to a wider variety of designs and competitive pricing. Many suppliers from regions like Europe and Asia offer innovative products and advanced manufacturing techniques that enhance quality. Furthermore, international partnerships can lead to better negotiation terms and opportunities for bulk purchasing. Consider factors like shipping logistics, customs regulations, and lead times to ensure a smooth procurement process. -

What is the minimum order quantity (MOQ) for melamine floor tiles?

The minimum order quantity (MOQ) for melamine floor tiles varies by supplier and can range from a few hundred to several thousand square feet. When negotiating with suppliers, clarify the MOQ and discuss potential flexibility based on your project needs. Some manufacturers may offer lower MOQs for first-time buyers or sample orders, allowing you to test their products before committing to larger purchases. -

How can I ensure quality when purchasing melamine floor tiles?

To ensure quality, request product samples before placing a bulk order. Evaluate the finish, texture, and overall appearance of the tiles. Additionally, ask for certifications that demonstrate compliance with international standards (e.g., ISO, CE). It’s advisable to conduct background checks on suppliers, including reviews of their production processes and quality assurance protocols, to ensure they maintain high manufacturing standards. -

What payment terms are typically offered for international purchases of melamine floor tiles?

Payment terms can vary widely among suppliers but often include options such as advance payment, letter of credit, or payment upon delivery. It’s common for suppliers to request a deposit (usually 30% to 50%) upfront, with the balance due before shipment. When negotiating terms, consider your cash flow and the supplier’s reputation. Ensure that the payment method provides adequate protection against fraud or product non-delivery. -

What logistics considerations should I keep in mind when sourcing melamine floor tiles?

Logistics play a crucial role in the procurement of melamine floor tiles. Consider shipping methods (air freight vs. sea freight), delivery timelines, and associated costs. Ensure that your supplier has a reliable logistics partner to handle customs clearance and timely delivery. It’s also wise to factor in potential delays due to seasonal demand or geopolitical issues. Collaborate with your supplier to establish clear shipping schedules and tracking mechanisms. -

Can melamine floor tiles be customized for specific projects?

Yes, many manufacturers offer customization options for melamine floor tiles, including unique colors, patterns, and sizes. Customization can enhance the aesthetic appeal and functionality of your flooring in specific environments. When discussing customization, provide detailed specifications and understand the implications for pricing and lead times. Be prepared for potential minimum order requirements for customized designs. -

What maintenance is required for melamine floor tiles?

Melamine floor tiles are known for their low maintenance requirements. Regular cleaning with a damp mop and a gentle cleaning solution is typically sufficient to keep them looking new. Avoid using abrasive cleaners or wax, as these can damage the surface. Ensure that your cleaning staff is trained on proper care techniques to maintain the tiles’ durability and appearance over time.

Top 5 Melamine Floor Tile Manufacturers & Suppliers List

1. Floor City – Melamine Laminate Flooring

Domain: floorcity.com

Registered: 2002 (23 years)

Introduction: Melamine is a type of laminate flooring made by saturating layers of paper with melamine resin through thermal fusion. It is attached to a particle board and resembles natural wood in color, texture, and patterns. Melamine laminate flooring is affordable, durable, water, scratch, stain, and shatter resistant, making it ideal for high-traffic areas. The boards can be cut into tiles and installed us…

2. アイカ工業 – Melamine Tile

Domain: ipros.com

Registered: 2002 (23 years)

Introduction: Next-generation floor tile “Melamine Tile” by アイカ工業. Features include: high stain resistance against dirt such as heel marks, high-pressure melamine construction that combines strength and ease of installation, surface made of melamine resin for durability comparable to ceramic tiles, weighs one-third of ceramic tiles reducing installation and transportation costs. Additional features: no-wax main…

3. Reddit – Cement Board and Tile Solutions

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 4mm or 6mm cement board, 18mm flat head screws, 9.3mm tiles, 18 or 20mm tile trim

4. Forum – Ceramic Tile Installation Tips

Domain: forum.woodenboat.com

Registered: 1995 (30 years)

Introduction: The discussion revolves around the feasibility of installing ceramic tile over melamine in a shower enclosure. Key considerations include the need to scuff the melamine surface, use proper adhesive, and ensure the underlying structure is sound. Suggestions include potentially removing the melamine to inspect the condition behind it, using a heat gun for removal, and ensuring watertightness with a …

5. Facebook – Melamine Tiles

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Melamine tiles are preferred for their feel, weight, and sound (clink) compared to acrylic tiles.

Strategic Sourcing Conclusion and Outlook for melamine floor tile

In conclusion, the strategic sourcing of melamine floor tiles presents an exceptional opportunity for international B2B buyers seeking quality, durability, and cost-effectiveness. The unique properties of melamine flooring—such as its resemblance to natural wood, resistance to water, scratches, and stains—make it an ideal choice for high-traffic environments across diverse markets in Africa, South America, the Middle East, and Europe.

Understanding the nuances of melamine products, from their manufacturing process to installation advantages, is crucial for making informed purchasing decisions. Buyers should focus on building relationships with reputable suppliers who offer a range of designs and sizes to meet specific project needs, as well as those who emphasize sustainability in their production processes.

Illustrative image related to melamine floor tile

As you look towards the future, consider how investing in melamine floor tiles can not only enhance your projects but also provide long-term value and aesthetic appeal. Explore innovative suppliers and remain agile in your sourcing strategies to capitalize on emerging trends and technologies in the flooring industry. Embrace the opportunity to elevate your offerings and meet the evolving demands of your clients.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.