A B2B Buyer’s Guide to Manufacture Name Wch.Cnc: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for manufacture name wch.cnc

In an increasingly competitive global landscape, sourcing high-quality manufacturing solutions such as those offered by wch.cnc presents both opportunities and challenges for international B2B buyers. The complexities of navigating varying standards, supplier reliability, and cost structures can make the procurement process daunting, particularly for businesses in regions like Africa, South America, the Middle East, and Europe. This guide aims to demystify the landscape of CNC manufacturing by providing a comprehensive overview of the types of products available, their applications across diverse industries, and practical strategies for vetting suppliers.

Within these pages, you will find detailed insights on the various machinery and components that wch.cnc specializes in, from CNC machine tools to industrial robots, as well as essential factors to consider when evaluating suppliers. We will also explore cost considerations and the importance of quality certifications, enabling you to make informed decisions that align with your business needs. By equipping you with the knowledge to navigate this complex market, this guide empowers B2B buyers to not only streamline their purchasing processes but also to forge successful partnerships that drive growth and innovation. Whether you are in Brazil, Germany, or beyond, understanding the nuances of sourcing from wch.cnc can significantly enhance your competitive edge in the global marketplace.

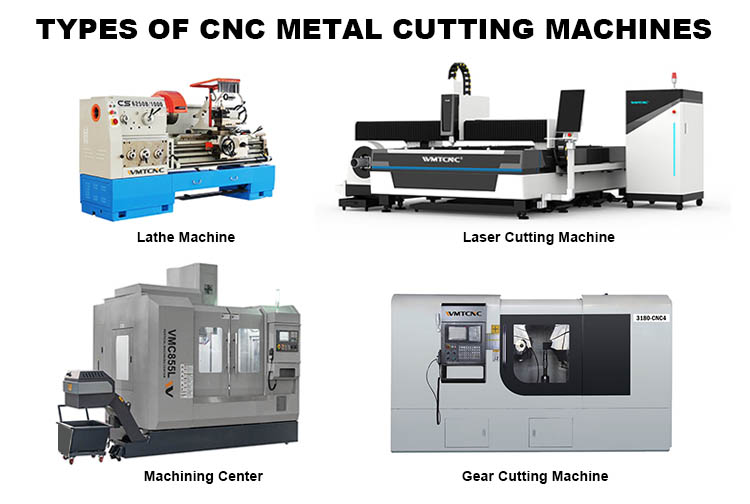

Understanding manufacture name wch.cnc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Machining Centers | High precision, multi-axis capabilities | Aerospace, automotive, medical device production | Pros: High accuracy, versatile. Cons: Higher initial investment. |

| CNC Lathes | Rotational machining, ideal for cylindrical parts | Manufacturing shafts, bushings, and fittings | Pros: Efficient for round parts. Cons: Limited to rotational shapes. |

| CNC Milling Machines | Flat surfaces, complex geometries, and drilling | Metalworking, mold making, and prototyping | Pros: Versatile for various shapes. Cons: Requires skilled operators. |

| CNC Plasma Cutters | Uses plasma to cut metals, fast and efficient | Sheet metal fabrication, automotive components | Pros: Quick cutting, cost-effective. Cons: Limited material thickness. |

| CNC Laser Cutters | High precision laser cutting, minimal material waste | Electronics, signage, and intricate designs | Pros: High accuracy, clean cuts. Cons: Higher operational costs. |

What Are the Characteristics of CNC Machining Centers and Their B2B Suitability?

CNC Machining Centers are distinguished by their ability to perform multiple machining operations within a single setup. This includes milling, drilling, and tapping, making them ideal for complex parts that require high precision. Industries such as aerospace and medical device manufacturing benefit significantly from these machines due to their accuracy and flexibility. When considering a CNC Machining Center, buyers should evaluate their production volume needs and the complexity of parts to ensure the investment aligns with their operational goals.

How Do CNC Lathes Serve Specific Manufacturing Needs?

CNC Lathes specialize in the production of cylindrical parts, utilizing rotational motion to shape materials. They are particularly effective for manufacturing items like shafts, bushings, and fittings. Their efficiency in producing round components makes them indispensable in industries such as automotive and aerospace. Buyers should consider the lathe’s capabilities in terms of size, speed, and material compatibility to match their specific production requirements.

Illustrative image related to manufacture name wch.cnc

What Makes CNC Milling Machines Versatile for Various Applications?

CNC Milling Machines are known for their ability to create complex geometries and flat surfaces. They can handle a wide range of materials, making them suitable for diverse applications, including mold making and metalworking. The versatility of CNC milling allows manufacturers to produce everything from simple parts to intricate designs. Buyers should assess their specific needs for precision and material types, as well as the skill level of operators, to maximize the benefits of CNC milling.

Why Are CNC Plasma Cutters Popular in Sheet Metal Fabrication?

CNC Plasma Cutters are favored for their speed and efficiency in cutting metal sheets. They are particularly useful in industries that require quick turnaround times, such as automotive and construction. While they offer cost-effective solutions for cutting, buyers should note that plasma cutters are best suited for specific material thicknesses and may not provide the same level of detail as laser cutting machines. Evaluating the types of materials and thicknesses required for production is crucial for making an informed purchase.

How Do CNC Laser Cutters Excel in Precision and Efficiency?

CNC Laser Cutters provide high precision and clean cuts, making them ideal for applications requiring intricate designs, such as electronics and signage. Their ability to minimize material waste while maintaining accuracy makes them an attractive option for manufacturers focused on quality and efficiency. However, buyers should be aware of the higher operational costs associated with laser cutting and ensure that their production needs justify the investment. Consideration of the types of materials and the complexity of cuts required will aid in selecting the right CNC laser cutter for their operations.

Illustrative image related to manufacture name wch.cnc

Key Industrial Applications of manufacture name wch.cnc

| Industry/Sector | Specific Application of manufacture name wch.cnc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Precision CNC Machining for Engine Components | High accuracy and reduced lead times for production | Quality certifications, material specifications, and delivery timelines |

| Aerospace | Manufacturing of Aircraft Structural Parts | Lightweight, durable components that meet strict safety standards | Compliance with aerospace regulations, traceability of materials, and advanced machining capabilities |

| Medical Devices | Production of Surgical Instruments and Implants | Enhanced precision for improved patient outcomes | Biocompatibility of materials, sterilization processes, and regulatory compliance |

| Electronics | Custom CNC Parts for Circuit Boards and Enclosures | Fast prototyping and scalability for diverse designs | Flexibility in production volumes, lead times, and design iterations |

| Industrial Equipment | Fabrication of Machine Tool Components | Increased efficiency and performance of machinery | Durability of materials, compatibility with existing systems, and after-sales support |

How is ‘manufacture name wch.cnc’ Used in the Automotive Industry?

In the automotive sector, ‘manufacture name wch.cnc’ excels in precision CNC machining for engine components, such as crankshafts and camshafts. These components require high accuracy to ensure optimal performance and fuel efficiency. International buyers, particularly from regions like Africa and South America, need to consider quality certifications and material specifications to ensure compliance with industry standards. Additionally, reduced lead times allow for faster production cycles, which is crucial in a competitive market.

What Role Does ‘manufacture name wch.cnc’ Play in Aerospace Manufacturing?

In aerospace manufacturing, ‘manufacture name wch.cnc’ is pivotal for producing lightweight yet durable structural parts that adhere to stringent safety standards. Components like fuselage frames and wing structures benefit from advanced machining techniques that ensure precision and reliability. Buyers from Europe, especially Germany, must focus on sourcing manufacturers that comply with aerospace regulations and can provide traceability of materials. The ability to meet these requirements enhances safety and performance in flight operations.

How is ‘manufacture name wch.cnc’ Applied in Medical Device Production?

For the medical device industry, ‘manufacture name wch.cnc’ is utilized in the production of surgical instruments and implants that require exceptional precision. The enhanced accuracy directly contributes to improved patient outcomes, making it essential for manufacturers to deliver high-quality products. Buyers in this sector must prioritize biocompatibility of materials and adherence to sterilization processes, alongside regulatory compliance, to ensure safety and efficacy in medical applications.

What Benefits Does ‘manufacture name wch.cnc’ Provide for Electronics?

In the electronics industry, ‘manufacture name wch.cnc’ supports the rapid production of custom parts for circuit boards and enclosures. The ability to quickly prototype and scale production allows businesses to innovate and adapt to market demands efficiently. International buyers should consider the flexibility of production volumes and lead times when sourcing CNC services, as these factors can significantly affect their time-to-market and overall competitiveness.

How Does ‘manufacture name wch.cnc’ Enhance Industrial Equipment Manufacturing?

‘Manufacture name wch.cnc’ plays a critical role in fabricating machine tool components that enhance the efficiency and performance of various industrial machinery. The durability of materials used in these components ensures longevity and reliability under demanding conditions. Buyers should evaluate compatibility with existing systems and the availability of after-sales support to maximize their investment and operational efficiency in industrial applications.

3 Common User Pain Points for ‘manufacture name wch.cnc’ & Their Solutions

Scenario 1: Navigating Supply Chain Disruptions in CNC Machining

The Problem: In today’s global market, many B2B buyers face the challenge of supply chain disruptions that can lead to delays in receiving essential CNC machined components. Buyers in regions like Africa or South America may experience additional hurdles due to logistical issues, regulatory complexities, and varying levels of infrastructure. These challenges can result in production bottlenecks, increased costs, and ultimately affect their ability to meet customer demands on time.

The Solution: To mitigate these disruptions, it is vital to establish strong relationships with multiple suppliers, including ‘manufacture name wch.cnc’. Buyers should conduct thorough research to identify reliable suppliers with proven track records of timely delivery. Implementing a diversified sourcing strategy can help cushion against potential delays. Additionally, leveraging technology such as supply chain management software can provide real-time visibility into order statuses and logistics, enabling better planning and proactive communication with stakeholders. It is also beneficial to maintain a buffer inventory of critical components to ensure smooth production operations even during unexpected supply chain challenges.

Scenario 2: Quality Assurance and Compliance Concerns

The Problem: B2B buyers often grapple with the challenge of ensuring that the CNC machined parts they receive meet strict quality and compliance standards. In industries such as aerospace and automotive, any deviation from specifications can result in severe consequences, including safety risks and costly recalls. Buyers may find it difficult to assess the quality assurance processes of suppliers like ‘manufacture name wch.cnc’, especially when sourcing from international markets with different regulatory frameworks.

Illustrative image related to manufacture name wch.cnc

The Solution: To address these concerns, buyers should prioritize suppliers who provide detailed documentation regarding their quality assurance processes and compliance certifications. It is advisable to request samples and conduct rigorous testing to validate the quality of the parts before placing larger orders. Establishing a set of clear quality metrics and performance indicators can facilitate better evaluation of suppliers. Additionally, maintaining open lines of communication with ‘manufacture name wch.cnc’ can ensure any quality issues are quickly identified and resolved. Implementing a robust quality management system within the buyer’s organization will also help in monitoring supplier performance and ensuring compliance with industry standards.

Scenario 3: Technical Support and Customization Limitations

The Problem: Many B2B buyers encounter challenges when seeking technical support for CNC machines or when attempting to customize products to meet specific project requirements. Buyers may feel overwhelmed by the technical jargon and processes, leading to frustration when trying to communicate their needs effectively to manufacturers like ‘manufacture name wch.cnc’. This lack of support can lead to misalignment between the buyer’s expectations and the final product, resulting in wasted resources and time.

The Solution: To overcome these limitations, buyers should actively seek suppliers that offer comprehensive technical support and consultation services. Engaging directly with ‘manufacture name wch.cnc’ to discuss project specifications and customization options can help clarify any uncertainties. Utilizing detailed design specifications and prototypes can facilitate better communication of requirements. Additionally, buyers should explore training opportunities offered by suppliers to enhance their understanding of CNC technology and capabilities, which can empower them to make informed decisions and foster a more collaborative relationship with the manufacturer. Establishing a feedback loop during the design and production phases can also ensure that the final products align closely with the buyer’s expectations.

Strategic Material Selection Guide for manufacture name wch.cnc

What Are the Key Properties of Aluminum for CNC Machining?

Aluminum is a widely used material in CNC machining due to its favorable properties. It has excellent strength-to-weight ratio, making it ideal for applications requiring lightweight components without sacrificing durability. Aluminum also exhibits good thermal and electrical conductivity, which is beneficial in applications like heat sinks and electrical housings. Its corrosion resistance, particularly when anodized, enhances its longevity in various environments.

However, aluminum can be more expensive than some alternatives, and its machining complexity increases with higher grades. Its suitability for high-pressure applications is limited, so understanding the specific requirements of the application is crucial for buyers.

How Does Steel Compare as a Material for CNC Machining?

Steel is another prevalent material in CNC machining, known for its high tensile strength and versatility. It comes in various grades, allowing for tailored applications ranging from structural components to intricate machine parts. Steel’s durability makes it suitable for high-stress environments, and it can withstand elevated temperatures, making it a preferred choice for automotive and aerospace industries.

On the downside, steel can be heavier than aluminum, which may not be ideal for all applications. The cost of high-grade steel can also be significant, and its machining process may require more advanced tooling and longer cycle times. Buyers must consider the balance between strength, weight, and cost when selecting steel for their projects.

What Are the Benefits and Limitations of Plastic Materials in CNC Machining?

Plastics, such as polycarbonate and nylon, are increasingly popular in CNC machining due to their lightweight nature and resistance to corrosion. They are ideal for applications in industries like consumer electronics, automotive, and medical devices where weight savings and chemical resistance are paramount. Plastics can also be more cost-effective compared to metals, particularly for low-volume production.

However, plastics generally have lower strength and temperature resistance compared to metals, which can limit their applications. They may also be more susceptible to wear and tear over time. International buyers should be aware of material certifications and compliance with standards like RoHS, especially in regions with stringent regulations.

How Does Titanium Stand Out in CNC Machining Applications?

Titanium is renowned for its exceptional strength, low density, and corrosion resistance, making it a premium choice for high-performance applications, particularly in the aerospace and medical sectors. Its ability to withstand extreme temperatures and aggressive environments enhances its appeal for specialized components.

The primary drawback of titanium is its high cost and machining complexity. The tooling required for titanium is often more advanced and expensive, leading to higher overall production costs. Buyers must evaluate whether the performance benefits justify the investment, especially in regions with budget constraints.

Summary Table of Material Selection for CNC Machining

| Material | Typical Use Case for manufacture name wch.cnc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components, automotive parts | Lightweight with good strength-to-weight ratio | Higher cost and machining complexity | Medium |

| Steel | Structural components, machine parts | High tensile strength and versatility | Heavier and more expensive for high grades | Medium to High |

| Plastic | Consumer electronics, medical devices | Cost-effective and lightweight | Lower strength and temperature resistance | Low |

| Titanium | Aerospace, medical implants | Exceptional strength and corrosion resistance | High cost and complex machining | High |

This strategic material selection guide provides insights into the properties, advantages, and limitations of common materials used in CNC machining. By understanding these factors, international B2B buyers can make informed decisions that align with their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for manufacture name wch.cnc

What Are the Key Stages of Manufacturing Processes at WCH.CNC?

WCH.CNC employs a comprehensive manufacturing process that ensures precision and quality at every stage. The main stages include material preparation, forming, assembly, and finishing, each utilizing advanced techniques tailored to the needs of B2B clients.

Illustrative image related to manufacture name wch.cnc

How Is Material Prepared for CNC Machining?

The manufacturing journey begins with meticulous material preparation. WCH.CNC sources high-quality raw materials, including various metals and polymers, ensuring they meet industry specifications. This stage involves selecting materials based on the specific properties required for the final product, such as strength, durability, and corrosion resistance.

Once the materials are selected, they undergo cutting and shaping to suit the design specifications. The pre-processing may include processes like shearing, sawing, or laser cutting, which help in reducing waste and optimizing the material usage.

What Forming Techniques Are Utilized in CNC Machining?

The forming stage is where the actual machining occurs. WCH.CNC employs state-of-the-art CNC (Computer Numerical Control) machines, which provide high precision and repeatability. Techniques such as milling, turning, and drilling are commonly used, allowing for intricate designs and complex geometries.

Advanced technology, including 5-axis machining, enables the production of parts with complex shapes that would be challenging to achieve with traditional methods. The integration of CAD/CAM software streamlines the design and programming processes, ensuring that the transition from digital design to physical product is seamless.

How Is Assembly Conducted at WCH.CNC?

Following the forming stage, assembly takes place. This phase may involve the integration of multiple components into a single unit, depending on the product specifications. WCH.CNC utilizes automated assembly lines to enhance efficiency and reduce human error.

Quality checks are embedded within the assembly process to ensure that each component meets the required tolerances and specifications before proceeding to the next stage. This proactive approach minimizes defects and enhances the overall quality of the final product.

What Finishing Techniques Are Employed?

Finishing is the final stage in the manufacturing process at WCH.CNC, where products undergo treatments to enhance their appearance and functionality. Techniques such as anodizing, plating, and powder coating are commonly applied to improve corrosion resistance and aesthetic appeal.

Additionally, surface finishing processes like grinding and polishing are used to achieve the desired surface quality. This attention to detail not only enhances the product’s performance but also aligns with the aesthetic requirements of B2B clients.

What Quality Assurance Standards Does WCH.CNC Adhere To?

Quality assurance is integral to WCH.CNC’s manufacturing philosophy. The company adheres to several international standards, including ISO 9001, which emphasizes a systematic approach to quality management. This certification ensures that WCH.CNC maintains consistent quality across its processes and products.

How Are Quality Control Checkpoints Established?

WCH.CNC implements a robust quality control (QC) framework that includes multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials upon arrival. Materials that do not meet established standards are rejected or sent back to the supplier.

-

In-Process Quality Control (IPQC): During production, continuous monitoring is conducted to ensure compliance with specifications. This may involve real-time inspections and adjustments to the machining process.

-

Final Quality Control (FQC): Before products are shipped, a thorough final inspection is performed. This includes dimensional checks, functional tests, and surface inspections to confirm that the product meets all quality standards.

What Testing Methods Are Commonly Used?

WCH.CNC employs a range of testing methods to validate product quality. Common techniques include:

-

Dimensional Inspection: Using precision measuring tools such as calipers and CMM (Coordinate Measuring Machines) to ensure parts are manufactured within specified tolerances.

-

Functional Testing: Evaluating the performance of the product under simulated operational conditions to ensure it meets functional requirements.

-

Non-Destructive Testing (NDT): Techniques like ultrasonic testing and dye penetrant inspection are used to detect internal and surface defects without damaging the product.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are actionable steps to ensure robust QC:

-

Conduct Audits: Schedule on-site audits to assess the manufacturing processes and quality control systems in place. This hands-on evaluation can provide insights into the operational standards of WCH.CNC.

-

Request Quality Reports: Ask for detailed quality assurance reports, including metrics on defect rates, compliance with international standards, and results from recent inspections or audits.

-

Engage Third-Party Inspectors: Consider hiring third-party inspection services to perform independent quality checks. This adds an extra layer of assurance and credibility to the supplier’s claims.

What Are the Quality Certification Nuances for International B2B Buyers?

When engaging with international suppliers like WCH.CNC, understanding quality certification nuances is vital. Different regions have varying standards and regulations that may affect product acceptance in local markets.

Illustrative image related to manufacture name wch.cnc

For instance, products destined for the European market may require CE marking to indicate compliance with safety and environmental standards. Similarly, buyers in the Middle East might look for compliance with specific local regulations.

B2B buyers should thoroughly research and communicate their quality and compliance requirements during the procurement process to ensure that WCH.CNC can meet these standards effectively.

Conclusion

WCH.CNC’s commitment to quality and precision throughout its manufacturing processes positions it as a reliable partner for international B2B buyers. By understanding the key stages of manufacturing, quality assurance standards, and verification methods, buyers can make informed decisions that align with their operational needs and market requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘manufacture name wch.cnc’

Introduction

This sourcing guide is designed for B2B buyers seeking to procure products from ‘manufacture name wch.cnc’. It outlines a systematic approach to ensure that you select the right supplier, understand your needs, and establish a successful partnership. By following these steps, you can streamline your procurement process and enhance your supply chain efficiency.

Illustrative image related to manufacture name wch.cnc

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the products you need. This step is crucial as it sets the foundation for your sourcing process. Be specific about dimensions, materials, tolerances, and any industry standards that must be met.

- Considerations: Include details about the production volume, delivery timelines, and any customization needs to ensure the supplier can meet your expectations.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in CNC machining. This step is essential to ensure that you are considering reputable manufacturers who can deliver quality products.

- Where to Look: Utilize industry-specific directories, trade shows, and online platforms that list CNC manufacturers. Pay attention to customer reviews and ratings to gauge their reliability.

Step 3: Evaluate Supplier Capabilities

Assess each potential supplier’s manufacturing capabilities and technology. This evaluation is vital to determine if they can meet your specific needs.

Illustrative image related to manufacture name wch.cnc

- What to Check: Look for certifications such as ISO 9001, which indicate quality management systems. Inquire about their machinery, production capacity, and experience with similar projects.

Step 4: Request Samples and Prototypes

Before making a large order, request samples or prototypes of the products. This step allows you to evaluate the quality of the supplier’s work firsthand.

- Importance of Samples: Testing the samples can help identify any potential issues with design or functionality early on, saving you time and resources in the long run.

Step 5: Verify Supplier Certifications

Ensure that the supplier holds relevant certifications and adheres to international quality standards. This verification is crucial for mitigating risks in your supply chain.

- Key Certifications to Look For: ISO certifications, industry-specific compliance (e.g., ASTM for materials), and environmental certifications (e.g., ISO 14001) that demonstrate their commitment to quality and sustainability.

Step 6: Establish Clear Communication Channels

Effective communication is essential for successful sourcing. Set up clear communication protocols to facilitate smooth interactions.

Illustrative image related to manufacture name wch.cnc

- Considerations: Determine preferred communication methods, establish points of contact, and agree on regular updates regarding production status and any potential issues.

Step 7: Negotiate Terms and Finalize Contracts

Once you’ve selected a supplier, negotiate terms that are favorable to both parties. This step is critical to ensure clarity and prevent misunderstandings in the future.

- Important Aspects to Discuss: Payment terms, delivery schedules, warranty conditions, and penalties for non-compliance. Having a well-defined contract protects your interests and fosters a transparent relationship.

By following this step-by-step checklist, B2B buyers can effectively navigate the sourcing process for ‘manufacture name wch.cnc’, ensuring they select a supplier that meets their technical and operational needs while fostering a strong business relationship.

Comprehensive Cost and Pricing Analysis for manufacture name wch.cnc Sourcing

What Are the Key Cost Components in CNC Manufacturing?

When sourcing from manufacture name wch.cnc, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of raw materials significantly affects pricing. High-quality metals or specialized composites will raise costs, while bulk purchasing can lead to discounts.

-

Labor: Labor costs can vary widely based on the location of the manufacturing facility. For instance, countries with lower labor costs may provide a competitive edge, but the skill level and efficiency of the workforce are also critical factors.

-

Manufacturing Overhead: This includes expenses related to utilities, equipment maintenance, and factory operations. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Initial tooling costs can be substantial, especially for custom projects. These costs are typically amortized over the production run, making high-volume orders more cost-effective.

-

Quality Control: Implementing rigorous QC measures ensures product reliability but adds to costs. Certifications such as ISO9001 can also influence pricing, as compliance requires investment in processes and training.

-

Logistics: Shipping costs, including freight and insurance, can vary greatly depending on the destination. Factors like Incoterms (e.g., FOB, CIF) will also impact final pricing.

-

Margin: Finally, manufacturers incorporate a profit margin that reflects their operational costs and market position.

How Do Price Influencers Affect CNC Machining Costs?

Several factors influence pricing in CNC machining, particularly for international buyers.

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should consider negotiating MOQs to optimize pricing.

-

Specifications and Customization: Custom projects often entail higher costs due to the additional engineering time and specialized tooling required. Standardized designs may offer more favorable pricing.

-

Material Quality and Certifications: Premium materials and necessary certifications can drive up costs. Buyers should assess whether the quality justifies the price based on the application requirements.

-

Supplier Factors: The reliability and reputation of the supplier can influence pricing. Established manufacturers may charge more for their proven track record and superior service.

-

Incoterms and Shipping: Understanding Incoterms is vital for international transactions. They define responsibilities for shipping costs, customs clearance, and risk, which can significantly affect the total cost.

What Tips Can Help Buyers Negotiate Better Prices?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider several strategies to enhance cost efficiency:

-

Negotiate Effectively: Open negotiations on pricing, especially for larger orders. Highlighting long-term partnership potential can incentivize suppliers to offer better terms.

-

Consider Total Cost of Ownership (TCO): Evaluate the long-term costs associated with a product, including maintenance, operational efficiency, and potential downtime. A lower initial price may not always lead to the best TCO.

-

Be Aware of Pricing Nuances: Understand the local market conditions, including currency fluctuations and trade tariffs, which can influence pricing. Engaging with local experts or consultants can provide valuable insights.

-

Request Detailed Quotations: Ask suppliers for itemized quotations that break down all cost components. This transparency can help identify areas for negotiation and ensure you’re comparing similar offers.

-

Build Relationships: Cultivating strong relationships with suppliers can lead to better pricing, improved service, and more favorable terms over time.

Disclaimer

Prices and terms mentioned in this analysis are indicative and subject to change based on market conditions, specific project requirements, and negotiations between the buyer and supplier. Always conduct thorough research and seek multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing manufacture name wch.cnc With Other Solutions

Understanding Alternatives in CNC Solutions

In the competitive landscape of CNC machining and manufacturing, selecting the right technology or method can significantly impact efficiency, cost-effectiveness, and product quality. For businesses considering ‘manufacture name wch.cnc’, evaluating viable alternatives is crucial. This analysis will compare ‘manufacture name wch.cnc’ with two notable alternatives—Protolabs and Richconn—to help B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | ‘Manufacture Name Wch.Cnc’ | Protolabs | Richconn |

|---|---|---|---|

| Performance | High precision and speed | Rapid prototyping capabilities | Comprehensive machining services |

| Cost | Moderate to high | Generally higher due to speed | Competitive pricing |

| Ease of Implementation | Requires skilled labor | User-friendly digital interface | Moderate complexity |

| Maintenance | Regular maintenance needed | Minimal due to automated systems | Regular service recommended |

| Best Use Case | Large-scale production | Fast prototyping and short runs | Custom metal parts and assemblies |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Using Protolabs?

Protolabs is renowned for its rapid prototyping capabilities, making it an ideal choice for businesses needing quick turnaround times. Its automated systems enable seamless transitions from design to production, significantly reducing lead times. However, this speed comes at a premium, often resulting in higher costs. While Protolabs excels in producing small batches of high-precision parts, it may not be the best fit for large-scale manufacturing due to its pricing structure.

How Does Richconn Compare as an Alternative Solution?

Richconn offers a comprehensive suite of CNC machining services that caters to various industries, including automotive and electronics. With a focus on quality and customization, Richconn provides competitive pricing, making it accessible for businesses looking for cost-effective solutions. The company also emphasizes a skilled workforce and advanced processing technology, but this can lead to longer lead times compared to Protolabs. Regular maintenance is essential to ensure optimal performance, which could require additional resources.

Illustrative image related to manufacture name wch.cnc

Conclusion: How to Choose the Right CNC Solution for Your Business?

Selecting the right CNC solution depends on your specific business needs, including budget constraints, production scale, and required precision. ‘Manufacture name wch.cnc’ may be ideal for companies focused on high-volume production requiring precision. In contrast, Protolabs is better suited for those prioritizing speed and prototyping capabilities, while Richconn serves as a versatile option for custom parts at a competitive price. By carefully assessing these alternatives, B2B buyers can make strategic decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for manufacture name wch.cnc

What Are the Key Technical Properties of WCH.CNC Products?

When considering the procurement of CNC machinery from WCH.CNC, understanding essential technical specifications is crucial. Here are several key properties that significantly impact purchasing decisions:

-

Material Grade

– Material grade refers to the specific classification of the material used in manufacturing CNC machines and components. Common materials include high-grade steel, aluminum alloys, and composites. The choice of material affects durability, weight, and machining precision, making it critical for buyers to assess the performance and longevity of the equipment. -

Tolerance

– Tolerance defines the acceptable range of variation in a manufactured part’s dimensions. For example, a tolerance of ±0.01 mm indicates that the actual size can vary by one-hundredth of a millimeter from the specified dimension. In B2B contexts, tighter tolerances often translate to higher manufacturing costs but are essential for applications demanding precision, such as aerospace and medical devices. -

Spindle Speed

– Spindle speed, measured in revolutions per minute (RPM), indicates how fast the spindle of a CNC machine can rotate. This property is vital for determining the machine’s efficiency and suitability for different materials. Higher speeds can enhance productivity but may require more advanced cooling systems to manage heat generation. -

Axis Configuration

– Axis configuration describes the number of axes on which a CNC machine operates, with common configurations being 3-axis, 4-axis, or 5-axis. More axes allow for more complex machining operations and greater flexibility in part design. Buyers should consider their specific machining needs when evaluating axis configurations. -

Feed Rate

– The feed rate is the speed at which the tool moves through the material, typically measured in millimeters per minute (mm/min). It directly influences machining time and surface finish quality. Understanding the optimal feed rate for different materials is essential for achieving the desired production efficiency and quality.

What Are Common Trade Terms Used in the CNC Industry?

In addition to technical specifications, familiarity with industry jargon is vital for effective communication and negotiation. Here are several commonly used trade terms:

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the CNC sector, buyers often seek OEMs for reliable quality and compatibility with their existing systems. Understanding OEM relationships can help businesses ensure they are sourcing components that meet specific standards. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest amount of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and cash flow. Knowing the MOQ helps businesses plan their purchases more effectively and avoid overstocking or stockouts. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing information for specific products or services. It is an essential step in the procurement process, allowing buyers to compare costs and evaluate potential suppliers. A well-structured RFQ can lead to better pricing and terms. -

Incoterms (International Commercial Terms)

– Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. Understanding Incoterms is vital for international B2B buyers to avoid misunderstandings and ensure smooth transactions. -

Lead Time

– Lead time refers to the time taken from placing an order to receiving the product. It includes manufacturing time and shipping duration. For businesses, understanding lead time is essential for planning production schedules and managing customer expectations.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing CNC machinery from WCH.CNC, ensuring that their operations run efficiently and effectively.

Navigating Market Dynamics and Sourcing Trends in the manufacture name wch.cnc Sector

What Are the Current Dynamics and Key Trends in the Global CNC Sector?

The CNC (Computer Numerical Control) sector is experiencing transformative dynamics driven by technological advancements and shifting buyer preferences. Key global drivers include the increasing demand for precision manufacturing, automation, and the integration of Industry 4.0 technologies. International B2B buyers from regions like Africa, South America, the Middle East, and Europe (particularly Germany and Brazil) are increasingly seeking suppliers that offer advanced capabilities in CNC machining and production flexibility. This shift is propelled by the need for rapid prototyping and customized production runs, allowing companies to remain agile in competitive markets.

Emerging trends in sourcing include the adoption of cloud-based solutions for better collaboration and efficiency, as well as the utilization of AI and machine learning to optimize production processes. Additionally, the rise of additive manufacturing technologies is reshaping traditional CNC machining paradigms, offering opportunities for cost savings and material efficiency. B2B buyers are also prioritizing suppliers who can deliver comprehensive solutions, including post-processing and assembly, to streamline their supply chains.

How Is Sustainability and Ethical Sourcing Influencing B2B Decisions in the CNC Sector?

Sustainability is becoming a pivotal factor in the sourcing decisions of international B2B buyers in the CNC sector. With growing awareness of environmental impacts, businesses are increasingly looking for suppliers who demonstrate a commitment to sustainable practices. This includes the adoption of energy-efficient machinery, waste reduction strategies, and responsible sourcing of materials.

Ethical supply chains are paramount, especially for buyers in Europe and North America, where regulatory frameworks are becoming stricter. Certifications such as ISO 14001 for environmental management systems and adherence to standards for ethical labor practices are crucial for building trust with partners. B2B buyers are also interested in sourcing from manufacturers who utilize ‘green’ materials, such as recycled metals or biodegradable composites, aligning their purchasing decisions with broader corporate sustainability goals.

What Is the Historical Context of CNC Manufacturing and Its Relevance Today?

The evolution of CNC manufacturing can be traced back to the 1950s when the first numerical control machines were developed. This marked a significant shift from manual machining to automated processes, enabling higher precision and efficiency in production. Over the decades, advancements in computer technology have further enhanced CNC capabilities, leading to the widespread adoption of CNC machines across various industries, including automotive, aerospace, and electronics.

Illustrative image related to manufacture name wch.cnc

Today, the historical context of CNC manufacturing is significant for B2B buyers. Understanding the foundational technologies and their evolution provides insights into current capabilities and future trends. Buyers can leverage this knowledge to identify suppliers that not only have a robust technological background but also a forward-thinking approach to innovation, ensuring they remain competitive in a rapidly changing marketplace.

In summary, navigating the CNC sector requires an understanding of global market dynamics, a commitment to sustainability, and an appreciation for the historical evolution of manufacturing technologies. These insights will empower B2B buyers to make informed sourcing decisions that align with their operational needs and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of manufacture name wch.cnc

-

How do I ensure quality when sourcing CNC machines from WCH.CNC?

To ensure quality, start by verifying WCH.CNC’s certifications, such as ISO 9001, which indicates adherence to quality management standards. Request samples or conduct a factory audit to assess their production processes and machinery. Additionally, inquire about their quality assurance protocols, including inspection procedures during and after production. Establish clear communication regarding your specifications and expectations to ensure that the final product meets your standards. -

What customization options does WCH.CNC offer for CNC machines?

WCH.CNC typically provides a range of customization options tailored to meet specific industry needs. Buyers can request alterations in design, size, and functionality, including specialized tooling and software compatibility. It is essential to communicate your precise requirements early in the negotiation process to ensure that the customization aligns with your operational goals. Discuss lead times and costs associated with customized solutions to plan your budget effectively. -

What are the minimum order quantities (MOQs) for products from WCH.CNC?

Minimum order quantities (MOQs) can vary based on the type of machinery and customization required. Generally, WCH.CNC may have different MOQs for standard and customized products. It’s advisable to discuss your order size during initial negotiations. If your requirement is below the MOQ, inquire about possible options, such as combining orders with other clients or accessing stock machines that may not have MOQs. -

What payment terms does WCH.CNC offer for international buyers?

WCH.CNC typically provides flexible payment terms, which may include options like upfront deposits followed by balance payments upon delivery or after inspection. Common payment methods include bank transfers, letters of credit, and PayPal, depending on your location and volume of order. It is crucial to clarify payment terms early in discussions to avoid any misunderstandings and ensure smooth transactions. -

How does WCH.CNC handle logistics and shipping for international orders?

WCH.CNC usually partners with reliable logistics providers to facilitate international shipping. They can assist with customs documentation and offer various shipping options, including air freight for faster delivery or sea freight for cost-effective solutions. Make sure to discuss shipping timelines and costs upfront, and confirm whether they provide support for insurance and tracking during transit to mitigate risks. -

What are the common challenges when sourcing CNC machines internationally?

Common challenges include language barriers, varying quality standards, and complex logistics. Additionally, understanding different regulations and compliance requirements in your country is crucial. To mitigate these issues, consider working with a local representative or a sourcing agent familiar with international trade. Establishing clear communication and documentation can also help streamline the process and minimize misunderstandings. -

How can I vet suppliers like WCH.CNC effectively?

To vet suppliers effectively, conduct thorough research on their background, including customer reviews, certifications, and industry reputation. Request references from previous clients and analyze their business practices. Engage in direct communication to gauge responsiveness and willingness to address concerns. If possible, arrange a visit to their manufacturing facility to observe operations firsthand and ensure they meet your quality and service expectations. -

What support does WCH.CNC provide post-purchase?

WCH.CNC typically offers comprehensive post-purchase support, including installation guidance, training, and maintenance services. Inquire about warranty terms and the process for addressing any defects or malfunctions. Effective post-purchase support is crucial for ensuring that your machinery operates optimally and meets your production needs. Establishing a clear line of communication for ongoing support can enhance your overall experience and satisfaction with the purchase.

Top 10 Manufacture Name Wch.Cnc Manufacturers & Suppliers List

1. CNC Machine Manufacturers – Key Players in India

Domain: scribd.com

Registered: 2006 (19 years)

Introduction: This document provides information on 10 leading CNC machine manufacturers in India. The companies featured include: Mori Seiki, Matsuura, Yamazaki Mazak, Toyoda, Hyundai Wia, Haas Automation, Okuma, Yasda, Makino, and Hitachi. It lists their name, location of India office, year established, business sector, and website.

2. CNC Winner – Vertical Machining Centers

Domain: cnc-winner.com

Registered: 2022 (3 years)

Introduction: CNC Vertical Machining Center (VMC A/D/E/L series) with X-axis strokes ranging from 650mm to 2100mm; Drill Tap Center – High Speed & High Efficiency; Bridge Type Machining Center (High-Speed); designed for high-precision and high-performance workpieces; widely used in automotive parts, mold making, 3C parts, medical equipment, and aerospace engineering.

3. BrandCrowd – CNC Business Name Generator

Domain: brandcrowd.com

Registered: 2009 (16 years)

Introduction: CNC Business Name Generator, AI-powered tool, unique and creative CNC business names, options for CNC machining, CNC routing, CNC manufacturing, extensive database of names, professional and innovative branding, logo maker for visual representation, customizable logos, strong brand identity.

4. Yamazaki Mazak – CNC Machines and Control Systems

Domain: prototool.com

Registered: 2004 (21 years)

Introduction: Top 8 Brands of CNC Machines: 1. Yamazaki Mazak (Japan) – Leading global CNC machine producer, established in 1919, offers lathes, turning centers, milling machines, machining centers, laser cutters, FMS, CAD/CAM programs, and control systems. 2. DMG MORI (Germany + Japan) – Joint venture of Demag and Mori Seiki, combines 65 and 143 years of experience, produces vertical/horizontal machining cente…

5. Pavewel Precision CNC Machining – Custom CNC Parts

Domain: wemachining.com

Introduction: Pavewel Precision CNC Machining specializes in custom CNC parts, including metal and plastic parts. Key materials used include 1010, Nitronic 60, 5052-H32, C360 Brass, Titanium, Black Delrin, PPS 30% Glass Filled, Propylux, Radel, and PPSU. The company has a workforce of 200 and operates a 6000 square meter factory equipped with various CNC machines, including 50 CNC milling machines, 20 CNC lathe…

6. Yamazaki Mazak – CNC Lathes

Domain: worldmanufactures.com

Introduction: Top 10 CNC Lathe manufacturers include:

1. Yamazaki Mazak (China) Ltd.

– Address: No. 5131, Jindu Road, Minhang District, Shanghai

– Website: https://www.mazak.com/us-en/

– Overview: Established in 1974, Mazak has multiple production bases globally and focuses on high-quality products and technologies, promoting automation and smarter production.

2. DMG MORI Machine Tools Trading Co., Lt…

7. LightBurn Software – Laser & CNC Control Solution

Domain: forum.lightburnsoftware.com

Registered: 2017 (8 years)

Introduction: LightBurn Software version 0.9.04; Compatible with grbl version 1.1f; Used for controlling grbl laser and CNC machines; Connection issues reported with ‘port opened waiting for response’; Debug logging feature available; Supports USB-SERIAL CH340 interface; User configuration settings for grbl include parameters for step pulse time, idle delay, spindle speed, and travel resolution.

8. Metoree – NC Lathes

Domain: us.metoree.com

Registered: 2020 (5 years)

Introduction: {“overview”:”Numerically Controlled (NC) lathes are computer-controlled machines used for cutting and processing materials like metal and plastic, providing high precision and minimizing operator error.”,”applications”:”Used in metalworking, automotive, medical devices, and general manufacturing for precision parts such as cylinder heads, crankshafts, artificial joints, and electronic components.”…

9. SparkFun – CH340 USB-to-Serial Converter

Domain: learn.sparkfun.com

Registered: 2002 (23 years)

Introduction: CH340 USB-to-Serial converter; variants include CH340G (requires external crystal oscillator) and CH340C (includes built-in crystal oscillator); compatible with multiple operating systems including Windows 7/10, Mac OSX v10.10.5 to v10.14.5, and Linux distributions like Raspbian and Ubuntu; driver installation may be required for some systems; various SparkFun products utilizing CH340 include: Spa…

10. WCH – Interface & Microprocessor Chips

Domain: wch-ic.com

Registered: 2004 (21 years)

Introduction: This company, WCH – Interface & Microprocessor Chips, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for manufacture name wch.cnc

In today’s competitive landscape, strategic sourcing remains a cornerstone for international B2B buyers seeking high-quality CNC machining solutions. The insights gleaned from the operations of manufacture name wch.cnc underscore the importance of leveraging reliable suppliers who not only deliver precision but also innovate through advanced technologies. By focusing on partnerships that prioritize quality, cost-effectiveness, and flexibility, buyers can enhance their supply chain resilience and operational efficiency.

For businesses in Africa, South America, the Middle East, and Europe, the opportunity to engage with wch.cnc represents a pathway to superior manufacturing capabilities. The company’s commitment to excellence and customer-centric solutions positions it as a vital partner in achieving sustainable growth and operational success.

As global markets evolve, it is essential for B2B buyers to remain proactive in their sourcing strategies. Embrace the potential that strategic partnerships offer and consider wch.cnc as a pivotal element in your manufacturing ecosystem. Now is the time to reach out, explore collaborative opportunities, and elevate your production capabilities to meet the demands of an ever-changing marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to manufacture name wch.cnc

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.