A B2B Buyer’s Guide to Machine For Cutting Keys: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for machine for cutting keys

In the ever-evolving landscape of global commerce, sourcing high-quality machines for cutting keys poses a significant challenge for B2B buyers. With a myriad of options available, from manual duplicators to advanced electronic code machines, the task can be daunting. This comprehensive guide aims to demystify the key cutting machine market by providing insights into various types, applications, and the critical aspects of supplier vetting. Understanding these elements is vital, especially for international buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Vietnam and Germany, where local market dynamics and regulations can differ substantially.

By delving into the intricacies of key cutting machines, this guide empowers businesses to make informed purchasing decisions. It will cover essential topics such as cost considerations, the latest technological advancements, and the importance of after-sales support. Furthermore, we will explore the diverse applications of key cutting machines, from locksmithing to automotive services, ensuring that buyers can identify solutions tailored to their specific needs. Ultimately, this resource serves as a strategic tool for navigating the complexities of the key cutting machine market, equipping buyers with the knowledge required to enhance their operational efficiency and profitability.

Understanding machine for cutting keys Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Key Duplicator | Operates without electricity, portable, low cost | Small locksmith shops, mobile services | Pros: Affordable, easy to use. Cons: Slower, limited to simpler keys. |

| Semi-Automatic Key Machine | Combines manual operation with automated features | High-volume key cutting, automotive keys | Pros: Faster than manual, versatile. Cons: Higher cost, maintenance needed. |

| Automatic Key Cutting Machine | Fully automated, high precision, programmable | Large-scale operations, key production | Pros: Fast, precise, reduces labor. Cons: Significant investment, complex setup. |

| Code Cutting Machine | Uses code cards for key duplication | Advanced locksmith services, specialty keys | Pros: Accurate, can cut complex keys. Cons: Requires training, higher cost. |

| Tubular Key Cutting Machine | Specialized for tubular keys, compact design | Safe deposit boxes, vending machines | Pros: Efficient for specific keys. Cons: Limited to tubular keys only. |

What Are the Characteristics of Manual Key Duplicators?

Manual key duplicators are basic machines that do not require electricity, making them ideal for small locksmith shops and mobile services. They are typically portable and low-cost, allowing businesses to enter the key cutting market without a significant initial investment. However, their reliance on manual operation means that they are slower than automated machines and are best suited for simpler key types. B2B buyers should consider their customer demand and volume when opting for a manual solution.

How Do Semi-Automatic Key Machines Enhance Efficiency?

Semi-automatic key machines blend manual and automated features, enabling operators to work more efficiently while still maintaining control over the cutting process. These machines are particularly beneficial for high-volume key cutting tasks, such as automotive keys, where speed and versatility are essential. While they are more expensive than manual machines, their ability to handle various key types and increase throughput makes them a valuable investment for businesses looking to expand their services.

Why Choose Automatic Key Cutting Machines for Large Operations?

Automatic key cutting machines offer the highest level of efficiency and precision, making them ideal for large-scale operations. These machines can be programmed to cut a wide range of keys quickly, significantly reducing labor costs and minimizing human error. However, they come with a higher price tag and require a more complex setup and maintenance. B2B buyers should evaluate their production needs and budget constraints when considering an automatic solution.

What Are the Advantages of Using Code Cutting Machines?

Code cutting machines are specialized tools that utilize code cards to replicate keys accurately. They are essential for advanced locksmith services that handle complex key types, providing a level of precision that manual machines cannot achieve. While these machines can be more expensive and require training to operate effectively, their accuracy and ability to work with a variety of key designs make them a worthwhile investment for businesses focused on high-quality service.

How Do Tubular Key Cutting Machines Serve Specific Needs?

Tubular key cutting machines are designed specifically for cutting tubular keys, often used in applications like safe deposit boxes and vending machines. Their compact design allows for easy integration into existing workflows. While they are efficient for their specific purpose, they lack versatility and are limited to tubular key types. Businesses should assess whether the demand for tubular keys justifies the purchase of this specialized equipment.

Key Industrial Applications of machine for cutting keys

| Industry/Sector | Specific Application of Machine for Cutting Keys | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Key duplication for automotive locksmiths | Enables quick service, increases customer satisfaction. | Machine compatibility with various key types and brands. |

| Hospitality | Cutting keys for hotels and resorts | Improves guest experience with efficient key management. | Need for portability and ease of use in high-volume environments. |

| Security Services | Cutting specialized keys for security systems | Enhances security by providing precise key duplication. | Requirement for advanced features like code cutting capabilities. |

| Manufacturing | Production of keys for machinery and equipment | Streamlines operations by ensuring all equipment is accessible. | Durability and reliability of machines in high-volume production. |

| Retail | Key duplication services in retail stores | Attracts customers and increases sales through added services. | Compact size and ease of use for retail environments. |

How Is the Machine for Cutting Keys Used in the Automotive Industry?

In the automotive sector, key cutting machines are essential tools for locksmiths who provide key duplication services. These machines can handle various key types, including transponder keys and laser-cut keys, enabling locksmiths to quickly and efficiently duplicate keys on-site. This capability is crucial for maintaining customer satisfaction, especially in emergencies where quick access is needed. Buyers in this sector should consider machines that offer high precision, compatibility with multiple automotive brands, and advanced features such as code cutting capabilities.

What Are the Applications in the Hospitality Industry?

In the hospitality industry, machines for cutting keys are vital for hotels and resorts that require efficient key management systems. These machines allow staff to duplicate keys quickly for guests, enhancing their experience by reducing wait times. Additionally, the ability to create multiple copies of room keys on demand is essential for managing guest turnover. B2B buyers in this sector should prioritize portable machines that are easy to operate and capable of handling high volumes, ensuring that they can meet the demands of busy environments.

How Do Security Services Utilize Key Cutting Machines?

Security services rely on key cutting machines to produce specialized keys for locks and security systems. These machines ensure that duplicates are made with precision, which is critical for maintaining the integrity of security measures. The ability to cut keys accurately helps prevent unauthorized access and enhances overall security. Buyers in this sector should seek machines that can handle a variety of key types and offer advanced features, such as programmable code cutting, to meet diverse security needs.

What Role Does Key Cutting Play in Manufacturing?

In the manufacturing sector, key cutting machines are used to produce keys for various machinery and equipment, ensuring that operations run smoothly. Having the ability to quickly duplicate keys minimizes downtime and ensures that all equipment remains accessible to authorized personnel. B2B buyers should focus on sourcing machines that are durable and reliable, with the capacity to handle high-volume production. This is essential for maintaining efficiency in a fast-paced manufacturing environment.

How Do Retailers Benefit from Key Cutting Machines?

Retailers can enhance their service offerings by providing key duplication services directly to customers. This not only increases foot traffic but also boosts sales by offering an additional convenience. Key cutting machines in retail settings need to be compact and user-friendly to accommodate small workspaces. Retail buyers should consider machines that balance performance with ease of use, ensuring they can serve customers efficiently while maximizing space in their stores.

3 Common User Pain Points for ‘machine for cutting keys’ & Their Solutions

Scenario 1: Managing Key Cutting Machine Downtime

The Problem: For many businesses, especially those in locksmithing and key duplication, unplanned downtime of key cutting machines can lead to significant losses. Whether due to mechanical failure or the need for regular maintenance, downtime not only disrupts workflow but also affects customer satisfaction. A business in South America may find that a critical piece of equipment breaks down during peak hours, resulting in frustrated customers and missed revenue opportunities.

The Solution: To mitigate downtime, B2B buyers should prioritize sourcing high-quality machines with robust warranties and reliable customer support. Investing in machines that feature predictive maintenance technology can also be beneficial; these systems alert users to potential issues before they lead to a breakdown. Moreover, establishing a relationship with a local service provider for rapid repairs and maintenance can minimize the impact of machine failures. Regularly scheduled maintenance checks should be incorporated into the operational calendar to ensure machines remain in optimal condition, thereby enhancing reliability and performance.

Scenario 2: Difficulty in Key Compatibility and Versatility

The Problem: Many buyers struggle with key cutting machines that lack the versatility to handle a wide range of key types, including automotive, residential, and commercial keys. A locksmith in the Middle East may encounter frustration when customers request key duplication for less common key types, but their existing machines cannot accommodate them. This limitation can lead to lost business opportunities and customer dissatisfaction.

The Solution: When selecting a key cutting machine, B2B buyers should focus on models that support a broad spectrum of key types, including dimple keys, tubular keys, and electronic keys. Machines equipped with interchangeable jaws and cutting tools can enhance versatility. Buyers should also consider machines that come with a comprehensive library of key codes and specifications, allowing them to quickly adapt to new key types as they emerge in the market. Partnering with suppliers who offer ongoing training and resources can further empower staff to maximize the capabilities of their equipment.

Scenario 3: The Challenge of Training Staff on New Equipment

The Problem: Implementing new key cutting machines often comes with the challenge of adequately training staff. A European company may invest in a sophisticated automated key cutting machine, but without proper training, employees may struggle to operate it efficiently. This can lead to errors in key duplication, wasted materials, and ultimately, customer dissatisfaction.

The Solution: To address this training challenge, B2B buyers should insist on comprehensive training packages when purchasing new machines. Many manufacturers offer on-site training sessions or webinars as part of the purchase agreement. Additionally, buyers should consider investing in training materials, such as user manuals and video tutorials, which can serve as reference points for employees. Creating a mentorship program where experienced staff can assist newer employees in using the equipment can also foster a culture of continuous learning and improvement. Regular refresher courses can ensure that all team members remain up-to-date with best practices and new features introduced in the machines.

Strategic Material Selection Guide for machine for cutting keys

What Are the Key Materials Used in Key Cutting Machines?

When it comes to selecting materials for machines designed for cutting keys, understanding the properties, advantages, and limitations of each material is essential for international B2B buyers. This analysis focuses on four common materials: steel, aluminum, plastic, and carbide. Each material has unique characteristics that can significantly impact the performance and suitability of key cutting machines.

How Does Steel Perform in Key Cutting Machines?

Steel is widely regarded as the primary material for key cutting machines due to its excellent strength and durability. It typically has a high-temperature rating, making it suitable for operations that generate significant heat during cutting. Steel’s corrosion resistance can vary based on the alloy used, with stainless steel providing superior protection against rust and wear.

Pros: Steel offers high durability and is relatively cost-effective. It can withstand considerable wear and tear, making it ideal for heavy-duty applications.

Cons: While steel is strong, it can be heavier than other materials, potentially complicating portability. Additionally, certain steel grades may require more complex manufacturing processes.

Impact on Application: Steel is compatible with various cutting media, including metal and plastic key blanks, and can handle the pressures involved in high-volume cutting operations.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM for steel quality. In regions like Europe, adherence to DIN standards is crucial for material specifications.

What Advantages Does Aluminum Offer for Key Cutting Machines?

Aluminum is another popular choice for key cutting machines, particularly in portable models. Its lightweight nature makes it easy to transport, and it generally has good resistance to corrosion, especially when anodized.

Pros: The primary advantage of aluminum is its lightweight property, which enhances portability and ease of use. It also offers good thermal conductivity, which can help dissipate heat during operation.

Cons: Aluminum is less durable than steel, making it less suitable for heavy-duty applications. It may also be more expensive than some steel options.

Impact on Application: Aluminum is best suited for light to medium-duty key cutting tasks, particularly in mobile applications where weight is a concern.

Considerations for International Buyers: Buyers should look for aluminum that meets international standards for quality and performance. Compliance with JIS standards in Asia and ASTM in the U.S. can ensure product reliability.

Why Is Plastic Used in Key Cutting Machines?

Plastic materials are often used in the construction of key cutting machines, particularly for components that do not require high strength. They are lightweight and can be molded into complex shapes.

Pros: The primary advantage of plastic is its low cost and versatility in design. It is also resistant to corrosion and can be produced in various colors and finishes.

Cons: Plastic lacks the strength and durability of metals, making it unsuitable for high-stress applications. It may also degrade over time when exposed to certain chemicals or extreme temperatures.

Impact on Application: Plastic components are typically used in non-load-bearing parts of key cutting machines, such as housings and grips.

Considerations for International Buyers: Buyers should ensure that the plastic used complies with relevant safety and quality standards, particularly in regions with strict regulations.

How Does Carbide Enhance Key Cutting Machine Performance?

Carbide is a high-performance material often used for cutting tools within key cutting machines. It offers exceptional hardness and wear resistance, making it ideal for precision cutting.

Pros: Carbide tools maintain their sharpness longer than steel, reducing the frequency of replacements. This translates to lower operational costs over time.

Cons: Carbide is more expensive than other materials, and its brittleness can lead to chipping if not handled properly.

Impact on Application: Carbide is particularly effective for cutting hard materials, ensuring high precision and quality in key duplication.

Considerations for International Buyers: Buyers should verify that carbide tools meet international quality standards, such as ISO certifications, to ensure reliability and performance.

Summary Table of Material Selection for Key Cutting Machines

| Material | Typical Use Case for machine for cutting keys | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty key cutting machines | High durability and strength | Heavier, may require complex manufacturing | Medium |

| Aluminum | Portable key cutting machines | Lightweight and easy to transport | Less durable than steel | Medium |

| Plastic | Non-load-bearing components | Low cost and versatile design | Lacks strength, may degrade over time | Low |

| Carbide | Cutting tools for precision tasks | Exceptional hardness and wear resistance | Expensive and brittle | High |

This strategic material selection guide provides B2B buyers with a comprehensive overview of the materials used in key cutting machines, enabling informed purchasing decisions that align with operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for machine for cutting keys

What Are the Main Stages in the Manufacturing Process of Key Cutting Machines?

The manufacturing process for key cutting machines involves several critical stages that ensure the final product meets the necessary performance and durability standards. Understanding these stages is vital for B2B buyers looking to source reliable equipment.

Material Preparation: What Materials Are Used and Why?

The initial stage involves selecting the right materials, typically high-grade metals like steel or aluminum, which provide strength and durability. Manufacturers often utilize CNC (Computer Numerical Control) machines to precisely cut and shape these materials into components such as frames, cutting heads, and jaws. The choice of materials directly impacts the machine’s longevity and cutting precision, making this stage crucial for producing high-quality key cutting machines.

Forming: How Are Components Shaped and Assembled?

Once the materials are prepared, they undergo forming processes such as machining, stamping, and bending. These processes create the various components of the key cutting machine. For instance, cutting blades are often produced using specialized grinding techniques to ensure sharpness and precision. After forming, components are typically subjected to heat treatment to enhance their hardness and resistance to wear.

Assembly: What Techniques Are Used to Ensure Precision?

The assembly stage requires meticulous attention to detail. Technicians assemble components using fixtures and jigs that ensure each part is placed accurately. This often involves both manual labor and automated systems, depending on the complexity of the machine. For instance, electronic key cutting machines may require integration with software and programming tools, adding another layer of complexity to the assembly process.

Finishing: How Is the Final Product Prepared for Market?

The final stage in manufacturing involves finishing processes, which may include surface treatments like anodizing or powder coating. These treatments not only enhance the aesthetic appeal of the machines but also protect against corrosion and wear. Quality control checks are performed at this stage to ensure that all machines meet the specified standards before they are packaged for shipment.

What Quality Assurance Processes Are Implemented in Key Cutting Machine Manufacturing?

Quality assurance is paramount in the production of key cutting machines, particularly for B2B buyers who require reliability and performance. Various international and industry-specific standards guide these processes.

Which International Standards Should Buyers Be Aware Of?

ISO 9001 is one of the most recognized quality management standards worldwide. It outlines the criteria for a quality management system and emphasizes customer satisfaction through consistent quality. Compliance with ISO 9001 indicates that the manufacturer has a robust quality management system in place.

In addition to ISO standards, certifications like CE (Conformité Européenne) for products sold in Europe, and API (American Petroleum Institute) standards for machines used in industrial settings, further ensure that products meet safety and performance regulations. B2B buyers should inquire about these certifications when evaluating suppliers.

What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) is integrated into various stages of the manufacturing process, typically divided into three main checkpoints:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials and components upon arrival at the manufacturing facility. Suppliers must provide documentation proving compliance with specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are conducted to ensure that each stage of production meets quality standards. This includes monitoring the precision of machining operations and the integrity of assembly.

-

Final Quality Control (FQC): Once assembly is complete, final inspections are performed. This includes functional testing of the machines to ensure they operate as intended. Any non-conformities are documented, and corrective actions are taken.

What Common Testing Methods Are Used to Ensure Product Quality?

To ensure that key cutting machines meet performance and safety standards, manufacturers employ various testing methods:

-

Functional Testing: Machines are tested for their operational capabilities, including speed, accuracy, and ease of use. This often involves cutting various key blanks and assessing the results.

-

Durability Testing: This involves subjecting machines to rigorous operational conditions to evaluate their durability and wear over time. This may include extended periods of continuous operation.

-

Safety Testing: Compliance with safety regulations is verified through rigorous testing of electrical components and mechanical safety features.

How Can B2B Buyers Verify Supplier Quality Assurance?

B2B buyers must take proactive steps to ensure they are partnering with manufacturers that maintain high-quality standards. Here are some actionable strategies:

What Should Buyers Look for in Supplier Audits and Reports?

Conducting supplier audits is an effective way to assess quality assurance practices. Buyers should request to see recent audit reports, which should include information on compliance with ISO standards and any certifications held by the manufacturer.

How Can Third-Party Inspections Enhance Buyer Confidence?

Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing processes and quality control measures. These inspections can occur at various stages of production, offering reassurance regarding the quality of the final product.

What Are the Quality Control Nuances for International Buyers?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is crucial. Different regions may have specific regulations or standards that must be adhered to, affecting importation and usage of key cutting machines.

Buyers should familiarize themselves with local regulations and ensure that their suppliers are compliant. Additionally, language barriers and cultural differences can impact communication regarding quality expectations. Establishing clear lines of communication with suppliers and understanding local market conditions can help mitigate these challenges.

Conclusion: How Can Buyers Make Informed Decisions?

In conclusion, understanding the manufacturing processes and quality assurance practices in the production of key cutting machines is essential for B2B buyers. By familiarizing themselves with the main stages of manufacturing, relevant quality standards, and effective verification strategies, buyers can make informed decisions that lead to successful partnerships with reliable suppliers. This knowledge ultimately contributes to the procurement of high-quality machines that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘machine for cutting keys’

Introduction

This practical sourcing guide is designed to assist B2B buyers in the procurement process of key cutting machines. Whether you’re a locksmith, a hardware retailer, or a distributor, understanding the nuances of selecting the right equipment is critical. This checklist will ensure you make informed decisions, balancing quality, functionality, and cost-effectiveness.

Step 1: Define Your Technical Specifications

Before engaging suppliers, clearly outline your technical requirements. Consider the types of keys you will be cutting—automotive, residential, or commercial—and the volume of keys you expect to handle.

– Key Types: Identify whether you need a machine for standard keys, dimple keys, or tubular keys.

– Production Capacity: Assess the frequency and volume of key duplication to determine the machine’s operational speed and efficiency.

Step 2: Research Available Technologies

Explore the various technologies available in key cutting machines, such as manual, semi-automatic, and fully automatic systems. Each type comes with its advantages and operational complexities.

– Manual vs. Automatic: Manual machines may be more cost-effective but require skilled operators, while automatic machines offer higher efficiency and precision.

– Advanced Features: Look for machines with built-in code readers or programmable settings for greater versatility.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers to ensure they can meet your needs. Request company profiles, case studies, and references from clients in similar sectors or regions.

– Supplier Experience: Consider how long the supplier has been in the market and their specialization in key cutting machinery.

– Reputation and Reviews: Check online reviews and testimonials to gauge customer satisfaction and reliability.

Step 4: Request Product Demonstrations

Whenever possible, arrange for live demonstrations of the key cutting machines you’re considering. This allows you to assess functionality and ease of use firsthand.

– Hands-On Evaluation: Pay attention to the machine’s setup time, cutting speed, and the quality of the finished keys.

– Technical Support: Inquire about training and support options available post-purchase to ensure your staff can operate the machinery efficiently.

Step 5: Assess After-Sales Support and Warranty

An effective after-sales support system is crucial for minimizing downtime. Ensure the supplier offers comprehensive support options, including warranty terms and access to replacement parts.

– Warranty Coverage: Understand what is covered under warranty and the duration, as this can significantly impact your long-term costs.

– Availability of Spare Parts: Confirm the supplier’s ability to provide spare parts and maintenance services promptly.

Step 6: Compare Pricing and Payment Terms

Collect quotes from multiple suppliers and carefully analyze pricing structures. Consider not only the upfront costs but also the total cost of ownership, including maintenance and operational costs.

– Transparent Pricing: Ensure all costs are clearly outlined to avoid unexpected expenses.

– Flexible Payment Options: Look for suppliers offering favorable payment terms that align with your cash flow needs.

Step 7: Finalize Your Purchase Agreement

Once you’ve selected a supplier, ensure that all terms and conditions are clearly documented in a purchase agreement. This should include delivery timelines, payment schedules, and any service agreements.

– Clarity in Terms: A well-defined agreement helps mitigate risks and ensures accountability on both sides.

– Negotiation: Don’t hesitate to negotiate terms that better suit your operational needs, such as bulk purchase discounts or extended warranties.

By following this checklist, you can streamline your procurement process and ensure that your investment in key cutting machines meets your business needs effectively.

Comprehensive Cost and Pricing Analysis for machine for cutting keys Sourcing

What Are the Key Cost Components for Key Cutting Machines?

When evaluating the cost structure of key cutting machines, several components come into play:

-

Materials: The quality of materials used directly influences the durability and performance of key cutting machines. High-grade steel for blades, durable plastics for housing, and electronic components for automation contribute significantly to the cost.

-

Labor: Labor costs encompass both skilled assembly workers and the personnel involved in research and development. The complexity of the machine, whether manual or automatic, affects the labor investment required during manufacturing.

-

Manufacturing Overhead: This includes utilities, facility costs, and equipment depreciation. Efficient manufacturing processes can help keep these costs down, but they can vary significantly depending on the location of production.

-

Tooling: Specialized tools for precision cutting and assembly are necessary for producing high-quality machines. The initial investment in tooling can be substantial, particularly for custom or specialized machines.

-

Quality Control (QC): Implementing rigorous QC processes ensures that each machine meets performance standards. This aspect can increase costs but is essential for maintaining reliability and customer satisfaction.

-

Logistics: Shipping and handling costs can vary based on the destination and shipping methods. For international buyers, factors like customs duties and taxes also play a role in the total logistics cost.

-

Margin: Manufacturers typically add a profit margin on top of the total cost structure, which can vary based on market demand and competitive positioning.

How Do Price Influencers Affect Key Cutting Machine Costs?

Several factors can influence the pricing of key cutting machines:

-

Volume/MOQ: Purchasing in bulk can significantly reduce the per-unit cost. Manufacturers often offer discounts for higher minimum order quantities (MOQs).

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should clearly define their requirements to avoid unnecessary expenses.

-

Materials: The choice of materials can lead to significant price variations. Higher-quality materials may come at a premium, but they often result in machines with better longevity and efficiency.

-

Quality and Certifications: Machines that comply with international quality standards or possess specific certifications (like ISO) may carry a higher price tag. These certifications can be crucial for buyers in regulated markets.

-

Supplier Factors: The reputation, reliability, and location of the supplier can impact pricing. Established suppliers may offer better warranties and support, justifying a higher price.

-

Incoterms: Understanding Incoterms is crucial for international buyers. These terms define the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs, affecting the overall cost.

What Tips Can Help Buyers Negotiate Better Prices?

B2B buyers can adopt several strategies to enhance their purchasing experience:

-

Negotiation: Always engage in negotiation. Suppliers may have flexibility in pricing, especially for larger orders or long-term contracts.

-

Cost-Efficiency Analysis: Assess the total cost of ownership (TCO), which includes purchase price, maintenance, operational costs, and potential downtime. A lower upfront cost may not always translate to better value in the long run.

-

Understanding Pricing Nuances: Different regions may have varying pricing structures due to local market conditions, labor costs, and material availability. For buyers from Africa, South America, the Middle East, and Europe, it’s important to consider these factors when comparing suppliers.

-

Request Multiple Quotes: Obtaining quotes from various suppliers can provide leverage in negotiations and help ensure competitive pricing.

-

Evaluate Post-Sale Support: Consider the level of customer service and support offered post-purchase. Suppliers that provide robust after-sales service may justify a higher initial price.

Conclusion

When sourcing key cutting machines, understanding the cost structure, price influencers, and effective negotiation strategies can lead to more informed purchasing decisions. By considering these elements, international B2B buyers can optimize their investments and ensure they acquire machines that meet their operational needs. Prices may vary significantly based on the aforementioned factors, so it is crucial to conduct thorough research and analysis.

Alternatives Analysis: Comparing machine for cutting keys With Other Solutions

Exploring Alternatives to Key Cutting Machines for B2B Buyers

In the locksmithing and key duplication industry, choosing the right tools is crucial for efficiency and effectiveness. While machines for cutting keys are widely recognized for their precision and speed, there are alternative solutions that may better suit specific business needs. This analysis compares key cutting machines against two viable alternatives: manual key duplicators and electronic key programming tools.

Comparison Table

| Comparison Aspect | Machine For Cutting Keys | Manual Key Duplicator | Electronic Key Programming Tools |

|---|---|---|---|

| Performance | High precision and speed | Moderate precision, slower than machines | Very high precision for specific keys |

| Cost | $500 – $10,250 | $200 – $800 | $1,000 – $5,000 |

| Ease of Implementation | Requires training and setup | Easy to use with minimal training | Requires technical knowledge |

| Maintenance | Regular maintenance needed | Low maintenance | Moderate maintenance and updates needed |

| Best Use Case | High-volume key duplication | Low to moderate volume, portable needs | Automotive keys and specialized keys |

What Are the Advantages and Disadvantages of Manual Key Duplicators?

Manual key duplicators, such as the HPC Mini Speedex, offer a cost-effective solution for locksmiths focusing on lower volumes of key duplication. Their simplicity allows for easy operation, making them suitable for businesses with limited technical skills. However, the trade-off is reduced speed and precision compared to automated machines. Manual machines require a skilled operator to ensure accuracy, which can lead to inconsistencies if not handled correctly.

How Do Electronic Key Programming Tools Compare to Traditional Machines?

Electronic key programming tools, like those offered by ILCO, represent a modern approach to key duplication, especially for automotive applications. These tools can program keys that require electronic synchronization, providing high precision and versatility. However, they come at a higher price point and necessitate a certain level of technical expertise to operate effectively. Moreover, the reliance on software updates and compatibility with various car models can add complexity to their usage.

Conclusion: How Should B2B Buyers Choose the Right Key Cutting Solution?

When selecting the right key cutting solution, B2B buyers should consider their specific operational needs, budget constraints, and the expected volume of key duplication. If high volume and efficiency are priorities, investing in a machine for cutting keys might be the best choice. However, for businesses that handle lower volumes or require the flexibility to duplicate specialized keys, manual duplicators or electronic programming tools may offer the necessary functionality without the need for significant investment. Ultimately, the right choice will depend on the specific requirements of the business and the key types they most frequently work with.

Essential Technical Properties and Trade Terminology for machine for cutting keys

What Are the Key Technical Properties of Key Cutting Machines?

When selecting a machine for cutting keys, understanding critical specifications is essential for ensuring operational efficiency and product quality. Here are some key technical properties to consider:

-

Material Grade

The material used in the construction of key cutting machines significantly affects their durability and performance. Machines made from high-grade steel or aluminum are preferred as they offer better resistance to wear and tear. This is crucial for B2B buyers in industries where machines are subjected to heavy use, ensuring longevity and reducing replacement costs. -

Tolerance Levels

Tolerance refers to the permissible limit of variation in a physical dimension. In key cutting, precise tolerances are vital for ensuring that keys fit perfectly into locks. Machines that can achieve tighter tolerances lead to improved key functionality and customer satisfaction. For international buyers, understanding tolerance levels helps in assessing the compatibility of machines with various key types and lock systems. -

Cutting Speed and Power

The cutting speed, often measured in revolutions per minute (RPM), indicates how quickly a machine can produce a key. Higher RPM values generally lead to increased productivity. Power ratings, typically measured in watts or horsepower, indicate the machine’s capability to handle different materials. Buyers should consider their production needs to choose a machine that balances speed and power. -

Type of Cutting Mechanism

Key cutting machines can feature various cutting mechanisms such as manual, semi-automatic, or fully automatic systems. Each type has distinct advantages; for instance, automatic machines offer higher efficiency and consistency, while manual machines may be more cost-effective for lower volumes. Understanding the operational demands can help buyers select the most suitable machine type. -

Jaw Configuration

The design of the jaws, which hold the key blank during cutting, can affect the machine’s versatility. Machines with 4-way jaws can accommodate a wider variety of key shapes, from standard to double-sided keys. For businesses serving diverse markets, a machine with adaptable jaw configurations can lead to enhanced service offerings. -

Deburring Options

Deburring refers to the process of removing sharp edges from cut keys. Machines equipped with built-in deburring features can streamline operations by eliminating the need for separate tools. This is particularly beneficial for businesses focused on efficiency and quality control.

What Common Trade Terms Should Buyers Know in the Key Cutting Machine Industry?

Understanding trade terminology is vital for effective communication and negotiation in B2B transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the context of key cutting machines, it’s essential for buyers to identify OEMs to ensure they are purchasing reliable and reputable machines. -

MOQ (Minimum Order Quantity)

This term indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to determine whether a supplier’s offerings align with their budget and inventory needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for price estimates on specific products or services. It’s a vital step in the procurement process, allowing buyers to compare options and negotiate better terms. -

Incoterms

International Commercial Terms (Incoterms) define the responsibilities of buyers and sellers in international trade. Understanding these terms helps buyers manage shipping costs, insurance, and risk during the transportation of key cutting machines. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. For businesses that rely on timely deliveries, understanding lead times can help in planning and inventory management. -

Warranty and Support

Warranty terms specify the manufacturer’s commitment to repair or replace defective products. Buyers should evaluate warranty conditions and available customer support to ensure they are making a sound investment.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when sourcing key cutting machines, ultimately leading to improved operations and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the machine for cutting keys Sector

What Are the Key Trends Influencing the Global Machine for Cutting Keys Market?

The global machine for cutting keys market is driven by several factors, including the increasing demand for security solutions and advancements in key-cutting technology. As urbanization progresses in regions like Africa and South America, the need for reliable locksmith services is on the rise. This trend is particularly pronounced in urban centers where residential and commercial security is paramount. Moreover, the integration of digital technology into key-cutting machines, such as programmable systems that streamline the cutting process, is becoming increasingly popular. This shift not only enhances efficiency but also reduces human error, appealing to businesses that prioritize operational precision.

Additionally, international buyers are increasingly interested in semi-automatic and automatic key machines due to their ability to handle diverse key types, from standard cylinder keys to more complex automotive keys. Markets in Europe, particularly Germany, are leading the charge in adopting advanced machines that offer versatility and user-friendly interfaces. The growth of e-commerce platforms has also transformed sourcing dynamics, enabling buyers to access a broader range of products and suppliers globally. This trend is especially beneficial for B2B buyers in emerging markets who seek competitive pricing and reliable supply chains.

How Is Sustainability Shaping the Sourcing of Machines for Cutting Keys?

Sustainability is emerging as a crucial consideration in the procurement of machines for cutting keys. Environmental impact assessments are becoming standard practice as companies look to minimize their carbon footprint. Key manufacturers are increasingly adopting eco-friendly materials and practices, such as utilizing recyclable metals and reducing energy consumption in their production processes. Buyers are encouraged to seek out suppliers who hold green certifications, which indicate adherence to sustainable practices.

Ethical sourcing is another vital aspect, particularly in regions where labor practices can vary significantly. B2B buyers must prioritize suppliers who demonstrate transparency in their supply chains and commit to fair labor practices. This shift not only supports responsible manufacturing but also enhances brand reputation among increasingly environmentally and socially conscious consumers. As a result, companies that prioritize sustainable sourcing are likely to gain a competitive edge, especially in markets where regulatory frameworks are tightening around environmental compliance.

How Has the Machine for Cutting Keys Market Evolved Over Time?

The evolution of machines for cutting keys has been marked by significant technological advancements. Initially, key-cutting was a manual process requiring skilled artisans. However, with the advent of electric machines in the late 20th century, the speed and accuracy of key duplication improved dramatically. As technology progressed, the introduction of computerized and semi-automatic machines further revolutionized the industry, allowing for more complex key designs and greater efficiency.

Today, we see a blend of traditional craftsmanship and modern technology, with machines capable of handling a wide array of key types—from residential to automotive. This evolution reflects the changing demands of the market, as security needs become more sophisticated and diversified. As a result, international B2B buyers must stay informed about these advancements to make educated purchasing decisions that align with their operational needs and market trends.

Frequently Asked Questions (FAQs) for B2B Buyers of machine for cutting keys

-

How do I choose the right key cutting machine for my business needs?

Selecting the ideal key cutting machine depends on several factors including the type of keys you need to cut, your production volume, and your budget. For businesses dealing with high volumes, automatic or semi-automatic machines may be more efficient, while smaller operations might benefit from manual duplicators. Additionally, consider the machine’s compatibility with various key types (e.g., dimple, tubular) and its ease of use and maintenance. Researching product reviews and seeking demonstrations can also aid in making an informed decision. -

What is the best machine for cutting keys in high-demand environments?

For high-demand environments, semi-automatic or fully automatic key cutting machines are recommended. Models like the Silca Speed 044 or the Framon #2 Code Machine offer efficiency and precision, allowing for rapid key duplication. These machines are designed to handle a variety of key types and can operate continuously, which is essential for businesses with a high turnover of customers. Investing in a machine with robust build quality and manufacturer support ensures longevity and reliable performance. -

What should I consider when vetting suppliers for key cutting machines?

When vetting suppliers, consider their reputation, experience in the industry, and the range of machines they offer. Look for suppliers who provide warranties and after-sales support, as this indicates confidence in their products. Verify their compliance with international standards and certifications, particularly if you are importing machines. Additionally, request references or case studies from other customers to gauge satisfaction levels and reliability. -

What is the typical minimum order quantity (MOQ) for key cutting machines?

MOQs for key cutting machines can vary significantly depending on the supplier and machine type. Some suppliers may allow single-unit purchases, particularly for lower-cost manual machines, while others may require bulk orders for higher-end models. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms, especially if you are looking to establish a long-term partnership. -

What payment terms are commonly offered by international suppliers?

Payment terms can differ among suppliers and may include options such as upfront payment, partial payment upon order confirmation, and balance payment before shipping. Some suppliers may also accept letter of credit or trade financing options, which can provide additional security for large transactions. Always clarify payment terms during negotiations and ensure they are documented in the purchase agreement to avoid misunderstandings. -

How can I ensure quality assurance for key cutting machines?

To ensure quality assurance, request detailed product specifications and certifications from the supplier. It’s essential to inquire about the manufacturing processes and quality control measures in place. Many reputable suppliers will provide documentation of testing and compliance with international standards. Additionally, consider ordering samples or demo units to assess quality firsthand before committing to a larger order. -

What logistics considerations should I keep in mind when importing key cutting machines?

When importing key cutting machines, consider shipping costs, import duties, and potential tariffs that may apply in your country. It’s advisable to work with logistics providers who have experience in handling industrial equipment to ensure safe and timely delivery. Additionally, verify the supplier’s shipping policies and lead times to align with your business needs. Ensure that proper documentation is in place to facilitate customs clearance. -

Can key cutting machines be customized for specific business requirements?

Many manufacturers offer customization options for key cutting machines, allowing you to tailor features based on your business requirements. Customizations may include modifications for specific key types, software enhancements for automated systems, or additional accessories. Discuss your needs with the supplier during the initial consultation to explore available options and understand any impact on pricing and lead times.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 10 Machine For Cutting Keys Manufacturers & Suppliers List

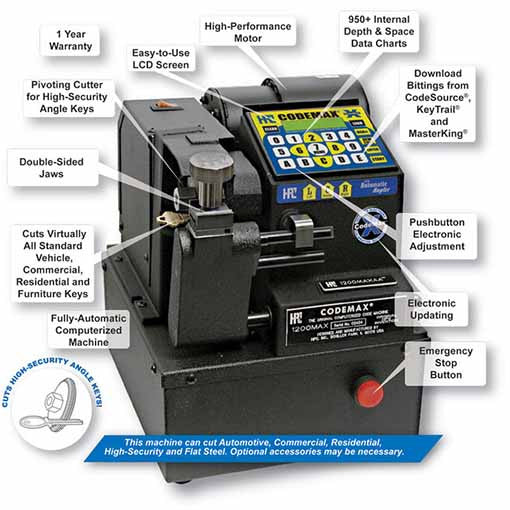

1. LockPicks – Key Cutting Machines

Domain: lockpicks.com

Registered: 1997 (28 years)

Introduction: This company, LockPicks – Key Cutting Machines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Ilco – FLASH 008 SILCA COMPACT KEY DUPLICATOR

Domain: mbausa.com

Registered: 1996 (29 years)

Introduction: {“products”:[{“name”:”FLASH 008 SILCA COMPACT KEY DUPLICATOR”,”brand”:”Ilco”,”msrp”:”$625.65″,”description”:”Lightweight, Compact, Portable mechanical edge cut key duplicator ideal for on-site jobs or limited spaces.”},{“name”:”Framon #2 Code Machine”,”brand”:”Framon”,”msrp”:”$1,949.00″,”description”:”Enables origination of almost any cylinder key in use today, compatible with various standard cyl…

3. Triton – Key Cutter Recommendations

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Key cutter and key programmer recommendations for a new locksmith. Suggested brands include Triton (noted for reliability but considered pricey), and HPC (not recommended due to quality concerns). Mention of the HPC Blitz and 3D Elite as commonly used machines. Discussion on the importance of having a manual backup machine and avoiding machines that require internet or app connectivity.

4. Smallwood Lock – Key Machines & Programmers

Domain: smallwoodlock.com

Registered: 1998 (27 years)

Introduction: This company, Smallwood Lock – Key Machines & Programmers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Keys NOW! – Automated Key Duplication Solutions

Domain: carkeysexpress.com

Registered: 2009 (16 years)

Introduction: Keys NOW! is the world’s first and only fully-automated house and car key duplication machine. It offers two varieties: the KEYS NOW! MACHINE and the KEYS NOW! VENDING MACHINE. The KEYS NOW! MACHINE is designed for retailers who want store associates to assist customers, while the VENDING MACHINE provides a do-it-yourself option for consumers. Both machines cut house keys and car keys, require no …

6. UHS Hardware – Key Cutting Machines

Domain: uhs-hardware.com

Registered: 2016 (9 years)

Introduction: Professional Key Cutting Machines for Locksmiths at UHS Hardware. Collection includes durable and high-precision devices: manual cutters, semi-automatic machines, and fully automatic machines. Designed for duplicating residential, automotive, and commercial keys. Focus on enhancing efficiency and reliability with cutting-edge designs and advanced technology. Suitable for both seasoned professional…

7. Locksmith Keyless – Premium Cutting Machines

Domain: locksmithkeyless.com

Registered: 2015 (10 years)

Introduction: This company, Locksmith Keyless – Premium Cutting Machines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. CLKSupplies – Key Machines

Domain: clksupplies.com

Registered: 2004 (21 years)

Introduction: This company, CLKSupplies – Key Machines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

9. Minute Key – Key Copy Kiosks

Domain: minutekey.com

Registered: 2007 (18 years)

Introduction: Key Copy Kiosks allow users to duplicate keys for home, office, or padlocks quickly and easily. The kiosks are self-service and can copy keys within minutes. Additional services include key fobs and car keys. Locations can be found using a zip code, city, or state.

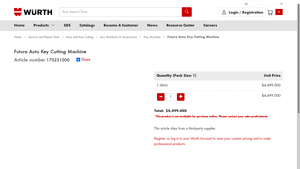

10. Würth – Futura Auto Key Cutting Machine

Domain: wurthusa.com

Registered: 1996 (29 years)

Introduction: Futura Auto Key Cutting Machine

– Article number: 170231000

– Price: $4,499.00

– Quantity: Pack size of 1, Minimum order quantity: 1

– Type: Electronic key cutting machine

– Features:

– One cutting station

– Two interchangeable clamps for duplicating and originating all types of automotive keys (including heavy trucks and motorcycles)

– Database includes keys for gas cap locks, glove boxes, …

Strategic Sourcing Conclusion and Outlook for machine for cutting keys

The landscape of key cutting machinery presents immense opportunities for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Strategic sourcing is essential to leverage these opportunities effectively. By understanding the diverse range of key cutting machines available—from manual duplicators to sophisticated electronic code machines—businesses can select equipment that aligns with their operational needs and budget constraints.

Investing in high-quality key cutting machines not only enhances productivity but also ensures precision and reliability in service delivery. As demand for efficient key duplication and cutting services grows, sourcing from reputable suppliers will be crucial. Buyers should prioritize suppliers who offer comprehensive support, including training and maintenance, to maximize their investment.

Looking ahead, the key cutting industry is poised for growth driven by technological advancements and increasing security needs. Now is the ideal time for international buyers to engage with suppliers, explore innovative solutions, and expand their product offerings. Embrace the future of key cutting by making informed sourcing decisions that position your business for success in a competitive market.