A B2B Buyer’s Guide to Lost Wax Aluminum: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for lost wax aluminum

In today’s competitive landscape, sourcing high-quality lost wax aluminum can present significant challenges for B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. The intricate process of lost wax casting demands not only a deep understanding of the materials and techniques involved but also careful supplier selection to ensure product reliability and adherence to international standards. This comprehensive guide addresses these key challenges by exploring various types of lost wax aluminum products, their applications across industries, and essential criteria for vetting suppliers.

By delving into the nuances of lost wax aluminum casting, including the latest innovations and cost factors, this guide empowers international B2B buyers to make informed purchasing decisions. Whether you’re looking to enhance your manufacturing capabilities or seeking specialized components for niche applications, understanding the dynamics of the global market is crucial.

Our aim is to equip you with actionable insights and strategic approaches to effectively navigate the complexities of sourcing lost wax aluminum. From identifying reputable suppliers to evaluating pricing structures and understanding market trends, this guide serves as a vital resource for businesses seeking to optimize their procurement processes and drive operational success in an increasingly interconnected world.

Understanding lost wax aluminum Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Lost Wax | Utilizes wax patterns for high-detail casting | Jewelry, sculptures, art pieces | Pros: Excellent detail; versatile material. Cons: Longer production time; higher costs. |

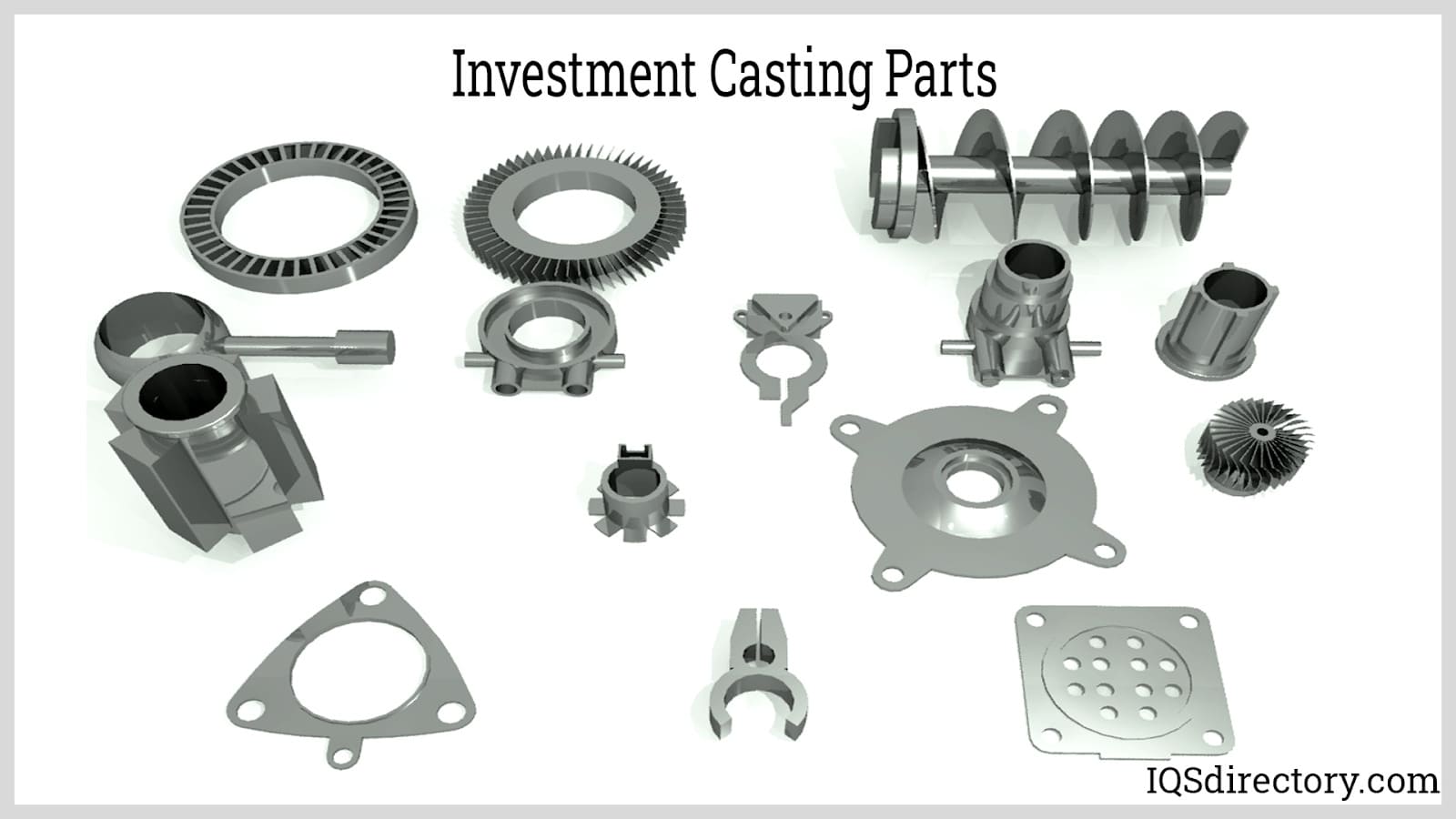

| Investment Casting | Uses metal patterns for durability and precision | Aerospace, automotive components | Pros: High strength; better surface finish. Cons: More complex setup; higher initial costs. |

| Shell Casting | Employs a thin shell of sand and resin for lighter designs | Industrial parts, prototypes | Pros: Lightweight; faster production. Cons: Limited detail; may require post-processing. |

| 3D Printed Wax Patterns | Integrates 3D printing for complex designs | Custom parts, prototypes | Pros: Rapid prototyping; intricate designs. Cons: Higher material costs; potential for lower durability. |

| Refractory Casting | Utilizes refractory materials to withstand higher temps | High-temperature applications | Pros: Suitable for extreme conditions; durable. Cons: Heavier; more costly materials. |

What Are the Characteristics of Traditional Lost Wax Aluminum Casting?

Traditional lost wax aluminum casting is characterized by its use of wax patterns, which are melted away to create the mold. This method is ideal for producing high-detail items such as jewelry and intricate sculptures. B2B buyers should consider the craftsmanship involved, as this technique allows for fine details and smooth finishes. However, the process can be time-consuming and may lead to higher costs, making it essential to balance detail and budget.

How Does Investment Casting Differ from Other Methods?

Investment casting is notable for its use of metal patterns instead of wax, which allows for greater durability and precision. This method is commonly employed in industries like aerospace and automotive, where component strength is crucial. Buyers in these sectors should weigh the benefits of high strength and superior surface finishes against the complexity of setup and higher initial costs. The investment in this method often leads to long-term savings through reduced failures and maintenance.

What Are the Advantages of Shell Casting?

Shell casting is recognized for its lightweight design, achieved through a thin shell made of sand and resin. This technique is particularly useful for industrial parts and prototypes where weight is a concern. B2B buyers may find shell casting appealing due to its faster production times compared to traditional methods. However, it is important to note that the level of detail may be limited, and post-processing might be required to achieve the desired finish.

Why Consider 3D Printed Wax Patterns for Custom Parts?

3D printed wax patterns are revolutionizing the lost wax aluminum casting process by enabling the creation of complex designs that would be difficult to achieve through traditional means. This method is particularly advantageous for custom parts and prototypes, allowing for rapid prototyping and intricate detailing. Buyers should consider the trade-off of potentially higher material costs and the possibility of reduced durability when opting for this innovative approach.

Illustrative image related to lost wax aluminum

In What Scenarios Is Refractory Casting Most Beneficial?

Refractory casting employs specialized materials designed to withstand high temperatures, making it suitable for applications in extreme conditions. Industries requiring high-temperature components will find this method particularly beneficial. While it offers durability and resistance to thermal shock, buyers should be aware of the heavier weight and higher costs associated with refractory materials. Understanding the specific application requirements is crucial to making informed purchasing decisions in this area.

Key Industrial Applications of lost wax aluminum

| Industry/Sector | Specific Application of lost wax aluminum | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision components for aircraft engines | High strength-to-weight ratio, improved fuel efficiency | Certification for aerospace standards, material traceability |

| Automotive | Custom engine parts and prototypes | Enhanced performance, reduced weight, design flexibility | Supplier reliability, production scalability, quality control |

| Medical Devices | Surgical instruments and implants | Biocompatibility, precision engineering for safety | Compliance with health regulations, material certifications |

| Art and Design | Artistic sculptures and functional art | Unique designs, high detail, and surface finish | Expertise in custom design, ability to handle complex shapes |

| Marine Engineering | Components for ships and submarines | Corrosion resistance, lightweight solutions | Material durability, resistance to harsh environments |

How Is Lost Wax Aluminum Utilized in Aerospace Applications?

In the aerospace industry, lost wax aluminum is employed to create precision components, such as turbine blades and engine casings. The method allows for intricate designs that enhance aerodynamics and reduce weight, leading to improved fuel efficiency. Buyers in this sector must ensure that suppliers adhere to stringent aerospace standards and can provide detailed material traceability to guarantee quality and safety.

What Are the Automotive Applications of Lost Wax Aluminum?

Automotive manufacturers leverage lost wax aluminum for producing custom engine parts and prototypes. This casting technique enables the creation of lightweight components that enhance vehicle performance and fuel efficiency. For international buyers, especially in regions like Brazil and Germany, it’s crucial to evaluate suppliers based on their production scalability and quality control processes to meet the high demands of the automotive market.

Why Is Lost Wax Aluminum Important for Medical Devices?

In the medical sector, lost wax aluminum is used to manufacture surgical instruments and implants that require high precision and biocompatibility. This method ensures that the final products meet strict health regulations, thus ensuring patient safety. Buyers must prioritize sourcing from manufacturers who can provide certifications and demonstrate compliance with relevant medical standards, especially in international markets.

How Does Lost Wax Aluminum Benefit Art and Design?

Artists and designers utilize lost wax aluminum to create unique sculptures and functional art pieces that demand high detail and exceptional surface finishes. The versatility of this casting method allows for the realization of complex shapes that traditional methods cannot achieve. Buyers looking to source these products should seek suppliers with a strong design expertise and a proven track record in handling custom requests.

Illustrative image related to lost wax aluminum

What Role Does Lost Wax Aluminum Play in Marine Engineering?

In marine engineering, lost wax aluminum is critical for producing components used in ships and submarines, where corrosion resistance and lightweight properties are essential. This application helps improve vessel performance and longevity in harsh marine environments. Buyers in this sector should consider the durability of materials and the supplier’s experience in delivering components that can withstand extreme conditions.

3 Common User Pain Points for ‘lost wax aluminum’ & Their Solutions

Scenario 1: Inconsistent Quality in Castings

The Problem: B2B buyers often face challenges with inconsistent quality in their lost wax aluminum castings. Variability in surface finish, dimensional accuracy, and internal defects such as porosity can lead to increased rejection rates and wasted resources. This inconsistency often arises from factors such as improper mold preparation, insufficient burnout of the wax pattern, or variability in the casting environment. For businesses relying on these castings for critical components, this can result in significant delays and increased costs.

The Solution: To ensure consistent quality, it is crucial to standardize the mold preparation process. Buyers should invest in high-quality refractory materials that enhance the strength and thermal stability of the mold, reducing the likelihood of defects. Additionally, implementing a thorough quality control protocol during the burnout process is essential. This includes verifying that the wax is completely removed from the mold before pouring aluminum. Utilizing advanced monitoring systems that track temperature and humidity in the casting environment can also help maintain optimal conditions. Training personnel on best practices for mold preparation and burnout will further minimize variability, leading to higher quality castings.

Scenario 2: Safety Concerns During Casting Processes

The Problem: Safety is a paramount concern in the aluminum casting process, particularly in lost wax casting, which involves handling molten metal and hazardous materials. B2B buyers may struggle with ensuring a safe working environment, especially in regions where safety regulations may not be as strictly enforced. Inadequate safety measures can lead to severe accidents, resulting in injuries, legal liabilities, and downtime, ultimately affecting production schedules and company reputation.

The Solution: Companies must prioritize safety by implementing comprehensive training programs for all personnel involved in the casting process. This training should cover the proper use of personal protective equipment (PPE), safe handling of molten aluminum, and emergency response protocols. Investing in high-quality PPE such as heat-resistant gloves, face shields, and protective clothing is essential. Furthermore, establishing a robust safety culture by conducting regular safety audits and drills can help reinforce safe practices. Buyers should also consider sourcing casting equipment that incorporates safety features, such as automatic shut-off systems and fume extraction units, to mitigate risks associated with high-temperature operations.

Illustrative image related to lost wax aluminum

Scenario 3: High Costs of Material and Production

The Problem: High material costs and production expenses can be significant pain points for businesses utilizing lost wax aluminum casting. Fluctuations in raw material prices, coupled with the need for precise casting techniques, can strain budgets and erode profit margins. Additionally, the cost of labor and energy consumption during the casting process can further escalate overall expenses, making it challenging for companies to remain competitive in the market.

The Solution: To combat rising costs, B2B buyers should explore bulk purchasing agreements with suppliers to secure better pricing on aluminum and casting materials. Engaging in long-term partnerships with reliable suppliers can also facilitate more predictable pricing structures. Additionally, optimizing the casting process can lead to reduced waste and lower energy consumption. Implementing lean manufacturing principles, such as minimizing the number of steps in the casting process and recycling scrap aluminum, can significantly enhance operational efficiency. Furthermore, investing in energy-efficient equipment and automation can reduce labor costs and improve production speed, ultimately leading to a more cost-effective casting operation.

Strategic Material Selection Guide for lost wax aluminum

What Are the Key Materials for Lost Wax Aluminum Casting?

When selecting materials for lost wax aluminum casting, several options are commonly utilized, each with distinct properties and implications for performance. Below, we analyze four prevalent materials relevant to this process: wax, plaster, refractory materials, and metal alloys.

How Does Wax Influence Lost Wax Aluminum Casting?

Wax is the primary material used to create the initial model in lost wax casting. It is favored for its ease of shaping and melting properties.

Key Properties: Wax has a low melting point, typically around 60-70°C, which allows for easy removal during the burnout phase.

Pros & Cons: The primary advantage of wax is its ability to reproduce intricate details, making it ideal for complex designs. However, it can be susceptible to deformation under high temperatures, and its cost can vary based on the type of wax used.

Impact on Application: Wax compatibility is critical for the casting process; it must withstand the heat during the burnout without leaving residues.

Considerations for International Buyers: Compliance with local safety standards regarding wax materials is essential. For instance, buyers in Europe may need to adhere to REACH regulations, while those in South America might have different environmental considerations.

Illustrative image related to lost wax aluminum

What Role Does Plaster Play in the Molding Process?

Plaster is often used to create the mold around the wax model.

Key Properties: Plaster is known for its excellent detail reproduction and can withstand moderate temperatures.

Pros & Cons: The advantages of plaster include its affordability and ease of use. However, it may not hold up well under extreme temperatures, leading to cracking during the burnout process.

Impact on Application: The temperature rating of plaster is crucial, as it must endure the high heat of molten aluminum without compromising the mold’s integrity.

Considerations for International Buyers: Different regions may have specific standards for plaster materials, such as ASTM or DIN. Buyers should ensure that the plaster meets local regulations to avoid compliance issues.

Illustrative image related to lost wax aluminum

Why Are Refractory Materials Important in Lost Wax Aluminum Casting?

Refractory materials are used to reinforce plaster molds, enhancing their heat resistance.

Key Properties: Refractory materials can withstand temperatures exceeding 1,000°C, making them suitable for high-temperature applications.

Pros & Cons: The primary advantage is their ability to maintain structural integrity under extreme heat. However, they can be more expensive and may require specialized handling during the mixing and application process.

Impact on Application: The choice of refractory material can significantly affect the quality of the final aluminum cast, particularly in terms of surface finish and detail retention.

Illustrative image related to lost wax aluminum

Considerations for International Buyers: Buyers should be aware of local sourcing options for refractory materials and any required certifications to ensure compliance with industry standards.

How Do Metal Alloys Affect the Final Product?

Various aluminum alloys can be used in the casting process, each offering different properties.

Key Properties: Aluminum alloys, such as 6061 and 356, provide varying levels of strength, corrosion resistance, and workability.

Pros & Cons: The advantages of aluminum alloys include their lightweight nature and excellent corrosion resistance. However, some alloys may be more expensive and require specific casting techniques to achieve optimal results.

Impact on Application: The choice of alloy directly influences the mechanical properties of the final product, affecting its suitability for specific applications like automotive or aerospace components.

Considerations for International Buyers: Understanding regional preferences for specific aluminum alloys is crucial. For instance, European buyers may prefer alloys that meet EN standards, while buyers in the Middle East might look for alloys that perform well in high-temperature environments.

Summary Table of Material Selection for Lost Wax Aluminum Casting

| Material | Typical Use Case for lost wax aluminum | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wax | Model creation | Excellent detail reproduction | Susceptible to deformation | Medium |

| Plaster | Mold creation | Affordable and easy to use | May crack under high temperatures | Low |

| Refractory Materials | Mold reinforcement | High-temperature resistance | More expensive and requires expertise | High |

| Metal Alloys | Final casting | Lightweight and corrosion-resistant | Some alloys are costly and complex | Medium to High |

This strategic material selection guide provides essential insights for international B2B buyers engaged in lost wax aluminum casting, ensuring informed decisions that align with regional standards and application requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for lost wax aluminum

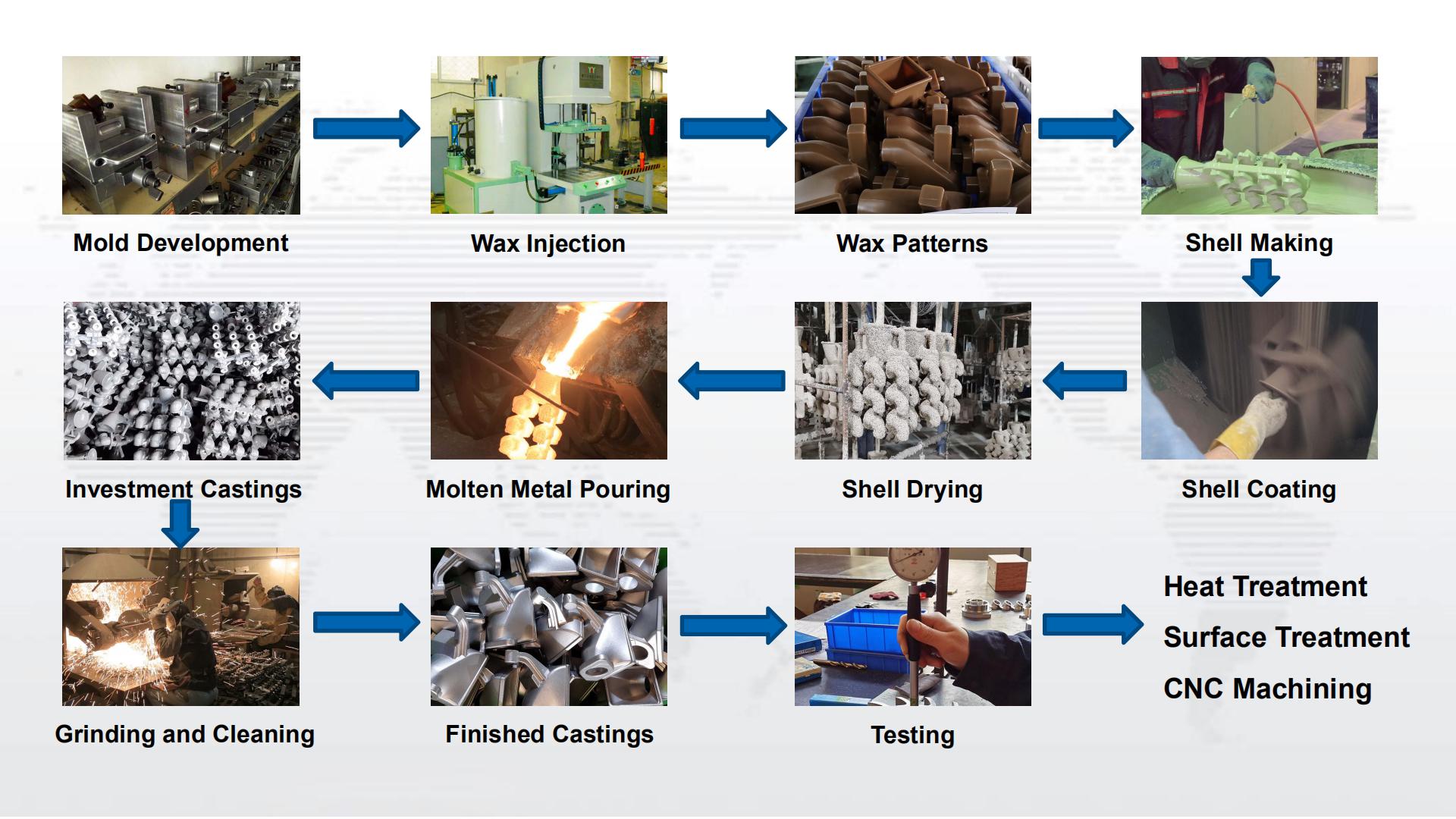

What Are the Key Stages in the Lost Wax Aluminum Manufacturing Process?

The lost wax casting process for aluminum involves several critical stages that ensure high-quality finished products. Understanding these stages can help B2B buyers assess the capabilities of their suppliers.

1. Material Preparation

The first stage involves selecting the appropriate materials, primarily the wax for the original model and aluminum for the final product. Wax models are usually created using injection molding or 3D printing, allowing for intricate designs. It’s essential that the wax is of high quality to ensure a precise mold.

Once the wax model is prepared, it is coated with a mixture of plaster and refractory materials. This coating serves as the mold that will withstand the high temperatures of molten aluminum. The mixture must be carefully blended to achieve the right consistency and strength.

2. Forming the Mold

After the wax model is coated and dried, the next step is the burnout process. This involves heating the coated model in a furnace to melt the wax out of the mold, leaving a cavity that will receive the molten aluminum. Proper temperature control is crucial during this stage to prevent damage to the mold.

The mold is then preheated to ensure that the molten aluminum does not cool too quickly upon contact, which can lead to defects. This preheating step is critical for achieving high-quality castings with minimal porosity and surface imperfections.

3. Pouring and Solidification

In this stage, the molten aluminum is poured into the preheated mold. The pouring process must be executed with precision to avoid turbulence, which can introduce air bubbles into the cast. Once poured, the aluminum needs time to solidify, which can vary based on the complexity of the part and the ambient temperature.

After solidification, the mold is carefully removed, and any remaining plaster is cleaned off. This step can include submerging the casting in water to help with the removal of the mold material.

4. Finishing Operations

The final stage involves finishing processes such as machining, sanding, or polishing to achieve the desired surface finish and dimensional accuracy. This may also include treatments like anodizing or powder coating for added durability and aesthetic appeal.

Illustrative image related to lost wax aluminum

Quality assurance during this stage is vital, as finishing operations can affect both the appearance and functionality of the final product.

How Do Quality Assurance Practices Support Lost Wax Aluminum Manufacturing?

Quality assurance (QA) is essential in ensuring that lost wax aluminum products meet both industry standards and customer expectations.

International Standards and Certifications

B2B buyers should be aware of international quality standards such as ISO 9001, which emphasizes effective quality management systems. Certifications like CE marking for products sold in the European market and API standards for oil and gas equipment can also be relevant depending on the industry. Suppliers should provide documentation of these certifications to verify compliance.

Illustrative image related to lost wax aluminum

What Are the Key QC Checkpoints in the Lost Wax Process?

Quality control (QC) checkpoints play a crucial role throughout the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials (wax and aluminum) to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): At various stages of the production process, inspections are conducted to monitor mold integrity, the burnout process, and the pouring of aluminum. This helps catch issues early.

-

Final Quality Control (FQC): Once the casting is complete, final inspections are performed. This includes dimensional checks, surface quality assessments, and mechanical property testing to ensure the product meets specifications.

What Testing Methods Are Commonly Used in Lost Wax Aluminum QC?

Testing methods for lost wax aluminum castings include:

-

Dimensional Inspection: Using calipers and gauges to verify that the finished part adheres to specified tolerances.

-

Non-Destructive Testing (NDT): Techniques like ultrasonic testing and X-ray inspection can detect internal defects without damaging the product.

-

Mechanical Testing: This includes tensile tests and hardness tests to ensure the material properties meet required specifications.

-

Surface Quality Assessment: Visual inspections and surface roughness measurements help ensure the aesthetic and functional quality of the product.

How Can B2B Buyers Verify Supplier Quality Assurance?

To ensure that suppliers maintain high standards of quality assurance, B2B buyers should consider the following strategies:

-

Supplier Audits: Conducting regular audits of suppliers’ facilities can help verify their compliance with quality management systems and manufacturing processes.

-

Requesting Quality Reports: Suppliers should provide detailed reports on their QC processes, including inspection results and testing outcomes.

-

Third-Party Inspections: Engaging third-party inspection services can provide an objective assessment of the supplier’s quality practices and product quality.

What Are the Nuances of QC and Certification for International B2B Buyers?

International buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of the nuances in quality certification and compliance. Different regions may have varying requirements for certifications and standards, which can affect market entry.

Additionally, buyers should consider the reliability of suppliers in their region. This includes understanding local regulations and how they impact manufacturing practices. Ensuring that suppliers can navigate these complexities is crucial for maintaining quality and compliance in global supply chains.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing lost wax aluminum products, ensuring they meet their specific needs and expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lost wax aluminum’

In the competitive landscape of B2B procurement, sourcing lost wax aluminum requires a structured approach to ensure quality and reliability. This guide provides a step-by-step checklist to help international buyers navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial to ensure that the lost wax aluminum meets your project requirements. Consider factors such as dimensions, tolerances, surface finish, and alloy composition. Detailed specifications help suppliers understand your needs and reduce the risk of receiving unsuitable products.

- Example specifications: Weight tolerance, dimensional accuracy, and surface roughness.

- Documentation: Ensure that you have technical drawings and material data sheets ready for suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers with a proven track record in lost wax aluminum casting. Utilize online platforms, industry forums, and trade shows to gather information about potential partners. The goal is to compile a list of suppliers who specialize in your specific requirements.

- Key resources: Industry directories, LinkedIn, and professional associations.

- Evaluation criteria: Look for experience, reputation, and previous projects.

Step 3: Evaluate Supplier Certifications

Before proceeding, it’s essential to verify that suppliers hold the necessary certifications and comply with international standards. Certifications such as ISO 9001 for quality management systems demonstrate a commitment to quality and reliability.

Illustrative image related to lost wax aluminum

- Types of certifications to check: ISO 9001, ISO 14001 (environmental management), and specific industry-related certifications.

- Importance: Certification ensures that the supplier adheres to best practices and regulatory requirements.

Step 4: Request Samples for Quality Assessment

Before finalizing your supplier, request samples of their lost wax aluminum products. This step allows you to assess the quality, finish, and suitability of the materials for your applications.

- What to look for: Surface finish, dimensional accuracy, and structural integrity.

- Feedback loop: Provide constructive feedback to the supplier to gauge their responsiveness and willingness to make adjustments.

Step 5: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Understanding the total cost of ownership, including shipping and customs duties, is vital for accurate budgeting.

- Negotiation tips: Be clear about your budget constraints and timelines.

- Consideration: Discuss potential volume discounts or long-term partnership terms.

Step 6: Establish a Communication Plan

Effective communication is key to a successful procurement process. Establish a clear plan for regular updates, reporting, and issue resolution throughout the project lifecycle.

- Communication channels: Decide whether to use email, phone calls, or project management tools for updates.

- Frequency: Set expectations for how often you will check in on progress and address any concerns.

Step 7: Confirm Logistics and Delivery Details

Finally, finalize logistics regarding shipping and delivery. Ensure that you have a clear understanding of lead times, shipping methods, and responsibilities for customs clearance.

Illustrative image related to lost wax aluminum

- Logistics considerations: Factor in shipping costs and timelines when planning your project schedule.

- Responsibility: Clarify who will handle customs and import duties to avoid unexpected delays.

By following this checklist, B2B buyers can streamline the sourcing process for lost wax aluminum, ensuring that they secure high-quality materials that meet their project requirements.

Comprehensive Cost and Pricing Analysis for lost wax aluminum Sourcing

When sourcing lost wax aluminum, understanding the comprehensive cost structure is crucial for B2B buyers. Each cost component plays a significant role in determining the overall price, which can vary based on various influencing factors.

What Are the Key Cost Components in Lost Wax Aluminum Sourcing?

-

Materials: The primary materials involved in the lost wax aluminum casting process include aluminum alloys, wax or thermoplastic patterns, and refractory materials for molds. The choice of aluminum alloy can significantly impact costs, with high-performance alloys generally priced higher.

-

Labor: Skilled labor is essential for both the design and the casting processes. Labor costs can vary widely based on the region, with countries in Europe typically facing higher wage expectations compared to regions in Africa or South America. Additionally, the complexity of the project may require specialized skills, which can further elevate labor costs.

-

Manufacturing Overhead: This includes the costs associated with the facilities, utilities, equipment maintenance, and indirect labor. Overhead can be a substantial portion of the total cost, particularly if advanced machinery is used for precision casting.

-

Tooling: Tooling costs involve the creation of molds and dies necessary for the casting process. These costs can be significant, especially for custom designs, as they often require high-quality materials and precision engineering.

-

Quality Control (QC): Ensuring that the final product meets industry standards and buyer specifications is paramount. QC costs can include testing, inspections, and certifications, which can add to the overall price. Buyers should consider suppliers that offer comprehensive QC processes to minimize risks.

-

Logistics: Transportation and shipping costs are critical, especially for international buyers. Factors such as the distance from the supplier, shipping methods, and Incoterms will influence logistics expenses. Understanding these can help in budgeting effectively.

-

Margin: Suppliers will add a profit margin on top of their costs, which can vary based on market demand, competition, and the supplier’s positioning strategy.

What Influences Pricing in Lost Wax Aluminum Sourcing?

-

Volume and Minimum Order Quantity (MOQ): Suppliers often have different pricing tiers based on order volume. Larger orders can lead to significant discounts, while smaller quantities may incur higher per-unit costs.

-

Specifications and Customization: Custom designs or specific material requirements can increase costs due to the need for specialized tooling and labor. It’s essential to communicate clearly with suppliers to understand how these factors will influence pricing.

-

Quality and Certifications: Products that require specific quality certifications (e.g., ISO, AS9100) may come at a premium. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: The reliability, reputation, and location of suppliers can influence pricing. Established suppliers with a good track record may charge more due to their quality assurance and consistency.

-

Incoterms: Understanding the chosen Incoterms can significantly affect total costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) determine who bears the shipping costs and risks, impacting the final price.

How Can Buyers Negotiate for Better Pricing?

-

Leverage Volume Discounts: If feasible, consolidating orders can help achieve better pricing. Discussing long-term contracts with suppliers can also lead to favorable terms.

-

Assess Total Cost of Ownership (TCO): Beyond initial costs, consider the long-term implications of sourcing decisions, including maintenance, operational efficiency, and potential failures.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, trade tariffs, and local regulations that may affect pricing. Engaging in thorough market research can provide insights into fair pricing.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better negotiation outcomes and loyalty discounts over time.

Conclusion

In the dynamic landscape of lost wax aluminum sourcing, B2B buyers must navigate a complex web of cost components and pricing influencers. By understanding these elements, buyers can make informed decisions that align with their budgetary constraints while ensuring product quality and reliability.

Alternatives Analysis: Comparing lost wax aluminum With Other Solutions

Exploring Alternative Solutions to Lost Wax Aluminum

When considering manufacturing processes for metal casting, particularly for precision components, it’s essential to evaluate various methods beyond just lost wax aluminum. This analysis compares lost wax aluminum casting against two alternative methods: sand casting and investment casting. Each method has its unique benefits and drawbacks, making them suitable for different applications and industries.

Illustrative image related to lost wax aluminum

| Comparison Aspect | Lost Wax Aluminum | Sand Casting | Investment Casting |

|---|---|---|---|

| Performance | High precision and detail; excellent surface finish | Moderate precision; suitable for large parts | Very high precision; excellent detail and surface finish |

| Cost | Moderate to high due to complexity | Low to moderate; cost-effective for larger quantities | High; suitable for small, complex parts |

| Ease of Implementation | Requires specialized knowledge and equipment | Relatively straightforward; minimal equipment needed | Requires specialized molds and materials |

| Maintenance | Low; molds can be reused | Moderate; molds have a limited lifespan | Low; molds can be reused multiple times |

| Best Use Case | Complex geometries and high-quality finishes | Large, simpler parts; low-cost production | High-precision parts in aerospace, automotive, and medical industries |

What Are the Advantages and Disadvantages of Sand Casting?

Sand casting is a widely used method that involves creating a mold from sand and pouring molten metal into it. Its advantages include lower costs and ease of use, making it ideal for large-scale production runs of simpler parts. However, the precision and surface finish are not as high as those achieved through lost wax aluminum or investment casting. The method is suitable for larger components where intricate details are not critical.

How Does Investment Casting Compare to Lost Wax Aluminum?

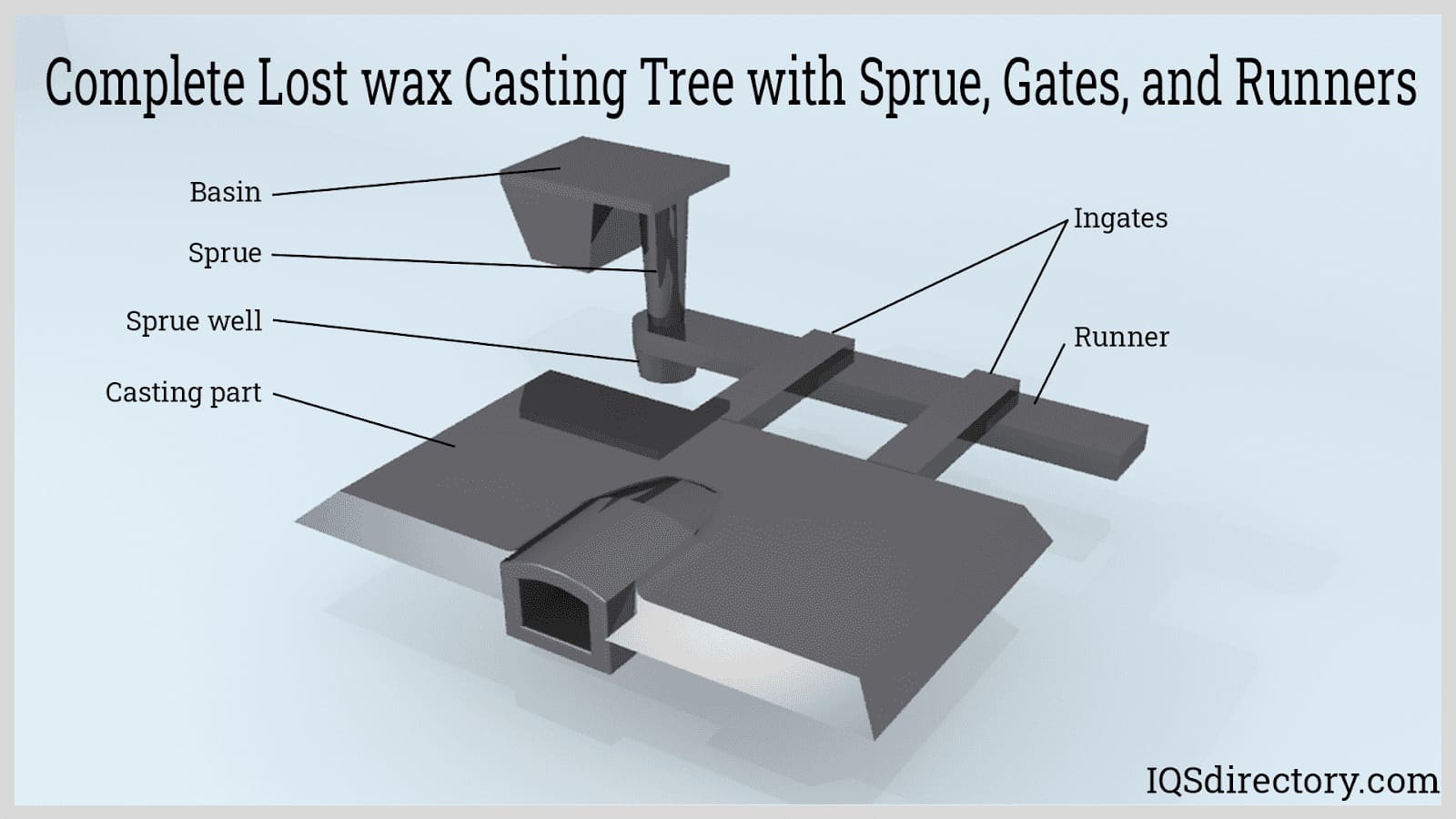

Investment casting, often regarded as a more refined version of lost wax casting, also allows for high precision and complex geometries. The process involves creating a wax pattern, coating it with a ceramic shell, and then melting out the wax. The primary advantage of investment casting is its ability to produce parts with very fine details and excellent surface finishes. However, the initial setup cost is higher, making it less economical for larger parts or lower quantities.

Conclusion: Which Metal Casting Solution Should B2B Buyers Choose?

For B2B buyers, the choice of casting method depends largely on specific project requirements. If precision and surface finish are paramount, lost wax aluminum or investment casting may be the best options, despite higher costs. Conversely, for larger, simpler components where budget constraints are significant, sand casting could be the more pragmatic choice. By carefully assessing the performance, costs, and specific use cases of each method, buyers can make informed decisions that align with their operational needs and financial considerations.

Essential Technical Properties and Trade Terminology for lost wax aluminum

What Are the Key Technical Properties of Lost Wax Aluminum for B2B Buyers?

When considering lost wax aluminum for your production needs, understanding its technical properties is essential. Here are several critical specifications that can significantly impact your procurement decisions:

Illustrative image related to lost wax aluminum

-

Material Grade

Material grades for lost wax aluminum are classified based on their chemical composition and mechanical properties. Common grades include A356 and A380, which are known for their excellent castability and mechanical strength. Selecting the right grade is crucial for ensuring that the final product meets industry standards and performance requirements. -

Dimensional Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. In lost wax casting, tight tolerances (e.g., ±0.5 mm) are often required to ensure that parts fit together seamlessly in assembly applications. Understanding the required tolerances can help you evaluate potential suppliers and avoid costly rework or product failures. -

Surface Finish

The surface finish of lost wax aluminum components can vary significantly, affecting both aesthetics and functionality. Common finishes include sandblasted, polished, or anodized. A proper surface finish can enhance corrosion resistance and improve the part’s overall lifespan, making it a key factor in the selection process. -

Mechanical Properties

Key mechanical properties such as tensile strength, yield strength, and elongation are vital for determining the material’s performance under stress. For instance, A356 aluminum typically offers a tensile strength of around 240 MPa, making it suitable for structural applications. Understanding these properties will help ensure that the material can withstand operational demands. -

Thermal Stability

Thermal stability refers to the material’s ability to maintain its properties under varying temperature conditions. In applications where components will be exposed to extreme heat or cold, it’s essential to consider how lost wax aluminum will perform. A material with high thermal stability will reduce the risk of warping or failure in critical applications.

What Are Common Terms in the Lost Wax Aluminum Industry?

Navigating the lost wax aluminum market requires familiarity with specific jargon. Here are some common terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM produces parts or equipment that may be marketed by another manufacturer. Understanding whether a supplier is an OEM can indicate the quality and reliability of the components you are purchasing, as they often adhere to strict manufacturing standards. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Being aware of MOQs can help you plan your inventory and budget effectively. Suppliers with lower MOQs may be more suitable for smaller projects or testing phases. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. Crafting a detailed RFQ can ensure that you receive accurate quotes, allowing for better comparisons between potential suppliers. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and customs clearance. Familiarity with these terms can help you negotiate better contracts and understand your obligations in the shipping process. -

Lead Time

Lead time refers to the period between placing an order and receiving the goods. Understanding lead times is essential for project planning and inventory management, especially if you are working on tight schedules or in industries with high demand fluctuations. -

Casting Yield

Casting yield is the percentage of usable product obtained from the raw material used in the casting process. A higher yield indicates more efficient use of materials, which can significantly impact your cost-effectiveness and sustainability goals.

By understanding these properties and terms, B2B buyers can make informed decisions regarding lost wax aluminum, ultimately leading to more successful procurement strategies.

Navigating Market Dynamics and Sourcing Trends in the lost wax aluminum Sector

What Are the Current Dynamics and Key Trends in the Lost Wax Aluminum Market?

The lost wax aluminum sector is experiencing significant transformations driven by technological advancements and changing market demands. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly focused on precision engineering and custom solutions, propelling the demand for lost wax casting. The rise of Industry 4.0, characterized by automation and data exchange in manufacturing technologies, is facilitating more efficient production processes. Buyers are also leveraging advanced materials and innovative techniques that enhance the quality and reduce lead times for complex aluminum parts.

Emerging technologies such as 3D printing are reshaping design and prototyping processes, allowing for rapid iterations and improved customization. This trend is particularly relevant in regions like Germany and Brazil, where the automotive and aerospace industries are thriving. These markets are demanding lighter, more durable components, prompting suppliers to adopt lost wax casting methods that offer excellent surface finishes and intricate designs. Additionally, the rise of global trade agreements is making it easier for businesses in these regions to source materials and collaborate on projects, fostering a more interconnected market landscape.

How Are Sustainability and Ethical Sourcing Impacting the Lost Wax Aluminum Sector?

Sustainability and ethical sourcing are becoming paramount concerns for B2B buyers in the lost wax aluminum sector. The environmental impact of aluminum production, particularly in terms of energy consumption and greenhouse gas emissions, has led to a growing demand for greener alternatives. Suppliers are increasingly adopting sustainable practices by using recycled aluminum and employing energy-efficient casting methods. These practices not only reduce the carbon footprint but also appeal to environmentally conscious buyers.

Illustrative image related to lost wax aluminum

Moreover, the importance of ethical supply chains cannot be overstated. B2B buyers are now prioritizing suppliers who demonstrate compliance with international labor standards and environmental regulations. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming essential in supplier selection processes. Buyers are also exploring materials that are certified as eco-friendly, such as those with low environmental impact during production. This shift towards sustainability is not just a trend; it is becoming a core component of corporate responsibility and brand reputation.

What Is the Historical Context of Lost Wax Aluminum Casting for B2B Buyers?

The lost wax casting process, or cire perdue, has its origins in ancient civilizations, where artisans used it for creating intricate jewelry and religious artifacts. Over the centuries, this method has evolved significantly, particularly in the aluminum sector. Initially utilized for small-scale applications, lost wax casting has expanded into various industries, including aerospace, automotive, and art. The technique’s ability to produce complex shapes with high precision has made it invaluable in modern manufacturing.

In recent decades, the global demand for aluminum components has surged, largely driven by the material’s lightweight and corrosion-resistant properties. This evolution is particularly relevant for B2B buyers who require high-performance materials for demanding applications. As the industry continues to innovate, the historical context of lost wax aluminum casting serves as a foundation for understanding its current and future significance in global markets.

Frequently Asked Questions (FAQs) for B2B Buyers of lost wax aluminum

-

How do I ensure quality when sourcing lost wax aluminum?

To ensure quality when sourcing lost wax aluminum, conduct thorough supplier vetting. Request samples to assess material properties and surface finish. Verify certifications such as ISO 9001 or relevant industry standards. Engage in direct communication with suppliers to discuss their manufacturing processes and quality assurance protocols. Consider visiting their facilities if feasible, or utilizing third-party inspection services to conduct quality checks before shipment. Establishing a clear quality agreement upfront can also help mitigate risks. -

What are the typical minimum order quantities (MOQs) for lost wax aluminum parts?

MOQs for lost wax aluminum can vary significantly based on the supplier and complexity of the parts. Generally, MOQs range from 100 to 1,000 units. Smaller orders may be possible, but they often come with higher per-unit costs due to setup and production time. Discuss your specific needs with potential suppliers, as many are willing to accommodate smaller orders for new clients or prototype runs. Negotiating flexible terms can also lead to better pricing and commitment from suppliers. -

What customization options are available for lost wax aluminum castings?

Customization options for lost wax aluminum castings are extensive. You can request modifications in design, dimensions, surface finishes, and even alloy compositions. Many suppliers offer services such as CNC machining, anodizing, and powder coating to enhance functionality and aesthetics. Ensure that you provide detailed specifications and drawings when discussing customization with suppliers. Collaborating closely during the design phase can also help in achieving the desired end product. -

What payment terms should I expect when sourcing lost wax aluminum?

Payment terms for lost wax aluminum sourcing can vary widely among suppliers. Common terms include a 30% upfront deposit with the balance due upon shipment, or net 30/60 days after delivery. It’s crucial to discuss payment options early in negotiations and ensure they align with your financial practices. Using secure payment methods like letters of credit or escrow services can help protect your investment. Be wary of suppliers asking for full payment upfront without a proven track record. -

How can I assess the reliability of a lost wax aluminum supplier?

To assess the reliability of a lost wax aluminum supplier, start by checking their industry experience and client references. Look for online reviews and testimonials from previous customers. Request information about their production capabilities, quality control measures, and delivery timelines. Engaging in direct communication can also provide insights into their responsiveness and customer service. For additional assurance, consider third-party audits or certifications that validate their operational standards. -

What are the common shipping and logistics considerations for lost wax aluminum?

When sourcing lost wax aluminum, consider logistics factors such as shipping costs, lead times, and import regulations. Discuss with suppliers about their shipping methods and whether they provide door-to-door service. Ensure that you understand the incoterms (e.g., FOB, CIF) that dictate responsibility for shipping costs and risks. Additionally, factor in any customs duties or taxes that may apply upon importation to your country, as these can impact overall costs. -

What quality assurance measures should be in place for lost wax aluminum?

Quality assurance measures for lost wax aluminum should include in-process inspections, final quality checks, and adherence to industry standards. Request documentation of the supplier’s quality control processes, including any certifications like ISO 9001. It’s also beneficial to establish inspection criteria and testing methods (such as dimensional accuracy and surface finish assessments) before production begins. Regular communication with suppliers during production can help address potential issues early. -

How do I handle disputes or quality issues with my lost wax aluminum supplier?

To handle disputes or quality issues with a lost wax aluminum supplier, first, maintain open communication to address concerns promptly. Document all correspondence and issues clearly. If possible, arrange a meeting to discuss the matter in detail and seek a resolution. Refer to any contractual agreements regarding quality expectations and remedies for non-conformance. If a resolution cannot be reached, consider mediation or arbitration as a means to resolve the dispute without resorting to legal action.

Top 2 Lost Wax Aluminum Manufacturers & Suppliers List

1. Instructables – Lost Wax Cast an Aluminium Skull

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Project Title: Lost Wax Cast an Aluminium Skull

Author: Bruce_T_NZ

Category: Workshop, Molds & Casting

Safety Note: Use appropriate protective equipment due to high temperatures and potential hazards from molten aluminium and fumes.

Materials Needed:

1. Wax, ABS, or PLA object to cast

2. Candle (for sprue)

3. Plaster of Paris

4. Refractory material (fine sand or calcined flint clay)

5. Tin can (t…

2. Studio Birtane – Lost Wax Aluminum Pendant Lamp

Domain: adorno.design

Registered: 2015 (10 years)

Introduction: Lost #6 – Lost Wax Aluminum Pendant Lamp by Studio Birtane

Price: €690

Usually Ships in: 3 weeks

Country of Origin: Turkey

Strategic Sourcing Conclusion and Outlook for lost wax aluminum

In the evolving landscape of lost wax aluminum casting, strategic sourcing emerges as a crucial element for international B2B buyers. The intricate process of lost wax casting not only provides high-quality aluminum products but also offers flexibility in design, enabling businesses to meet diverse industry needs. By prioritizing suppliers who emphasize quality, sustainability, and innovation, companies can enhance their operational efficiency and reduce costs, ultimately leading to a competitive edge in the market.

B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including Germany and Brazil, should consider establishing partnerships with manufacturers that leverage advanced technologies and sustainable practices. This approach not only ensures superior product quality but also aligns with global trends towards environmental responsibility.

As we look to the future, the demand for lost wax aluminum is expected to rise, driven by sectors such as automotive, aerospace, and consumer goods. Now is the time for businesses to act, evaluating their sourcing strategies to capitalize on emerging opportunities. By investing in strategic sourcing today, organizations can secure a prosperous tomorrow in the dynamic world of lost wax aluminum casting.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.