A B2B Buyer’s Guide to Latch Fence: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for latch fence

In today’s interconnected global marketplace, sourcing high-quality latch fences presents unique challenges for international B2B buyers. Whether you’re in Africa, South America, the Middle East, or Europe, the demand for reliable and secure fencing solutions is paramount. Navigating this landscape requires a comprehensive understanding of the various types of latches available, their applications, and the criteria for selecting the right suppliers. This guide will delve into the intricacies of latch fences, including the different styles such as heavy-duty, decorative, and pool safety latches, as well as the materials used—ranging from stainless steel to polymer.

By addressing critical considerations such as supplier vetting, cost analysis, and compliance with regional standards, this guide empowers B2B buyers to make informed purchasing decisions. With insights tailored specifically for markets in Saudi Arabia, Germany, and beyond, we aim to equip you with the knowledge needed to navigate the complexities of sourcing latch fences effectively. From understanding the nuances of latch functionality to evaluating supplier reliability, this guide serves as an essential resource for businesses looking to enhance their fencing solutions while ensuring optimal security and durability.

Prepare to unlock the potential of your sourcing strategy and make confident decisions that align with your operational needs.

Understanding latch fence Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Heavy-Duty Gate Latch | Robust construction, often made from steel or stainless steel | Industrial gates, commercial properties | Pros: High security, durability. Cons: Higher cost, may require professional installation. |

| Gravity Latch | Self-closing mechanism, easy to operate with one hand | Residential fencing, pool areas | Pros: Convenient, minimal maintenance. Cons: May not be suitable for high-security needs. |

| Magnetic Pool Latch | Magnetic closure, child safety features | Pools, child care facilities | Pros: Enhanced safety, easy access. Cons: May require specific installation conditions. |

| Slide Bolt Latch | Horizontal sliding mechanism, often used for double gates | Agricultural gates, large entrances | Pros: Simple design, cost-effective. Cons: Less secure against tampering. |

| Key-Locking Latch | Incorporates a lock for added security | High-security areas, commercial properties | Pros: Enhanced security, customizable. Cons: Requires key management, potential for lock failure. |

What Are the Key Characteristics of Heavy-Duty Gate Latches?

Heavy-duty gate latches are designed for durability and security, often constructed from robust materials such as steel or stainless steel. They are suitable for high-traffic areas in industrial and commercial properties, where enhanced security is paramount. When considering a heavy-duty latch, B2B buyers should evaluate the specific security needs of their facilities, ensuring that the latch can withstand environmental factors and frequent use.

How Do Gravity Latches Work and Where Are They Most Suitable?

Gravity latches utilize a self-closing mechanism that allows for easy one-handed operation, making them ideal for residential fencing and pool areas. Their design often incorporates a simple gravity mechanism that ensures the gate closes securely after use. For B2B buyers, the convenience and minimal maintenance requirements are significant advantages, though it is essential to assess whether their security level meets the specific needs of the property.

What Are the Benefits of Using Magnetic Pool Latches?

Magnetic pool latches are engineered with safety in mind, featuring a magnetic closure that ensures the gate remains securely shut, which is particularly beneficial in environments with children. These latches are commonly used in pools and child care facilities. B2B buyers should consider the ease of access and safety features when selecting a magnetic latch, as these factors can significantly enhance the overall safety of the premises.

Why Choose Slide Bolt Latches for Agricultural Gates?

Slide bolt latches are characterized by their straightforward horizontal sliding mechanism, making them a popular choice for agricultural gates and large entrances. Their simplicity and cost-effectiveness are appealing to B2B buyers, especially for applications where security is important but not the highest priority. However, it’s crucial to consider that slide bolt latches may be less secure against tampering compared to more advanced locking mechanisms.

What Are the Advantages of Key-Locking Latches?

Key-locking latches provide a higher level of security, making them suitable for high-security areas such as commercial properties. These latches can be customized to meet specific security requirements and are often used in conjunction with other security measures. B2B buyers should weigh the benefits of enhanced security against the need for key management and the potential for lock failure, ensuring that the investment aligns with their security protocols.

Key Industrial Applications of latch fence

| Industry/Sector | Specific Application of latch fence | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Securing livestock enclosures | Protects livestock from predators and theft, ensuring safety | Durability against weather, ease of use, and compatibility with existing fencing systems |

| Construction | Gate access for construction sites | Enhances site security while allowing controlled access | Compliance with local safety regulations and ease of installation |

| Residential Security | Home fencing and pool safety | Increases safety for children and pets, deterring unauthorized access | Aesthetic compatibility with home design and child safety certifications |

| Commercial Facilities | Access control for warehouses and storage units | Prevents unauthorized entry, protecting valuable inventory | Heavy-duty options for high-traffic areas and lockable mechanisms |

| Municipal Applications | Public park access gates | Ensures public safety while managing access to facilities | Weather-resistant materials and ease of maintenance for longevity |

How is ‘latch fence’ used in agriculture to enhance livestock security?

In the agricultural sector, latch fences are crucial for securing livestock enclosures. These latches prevent unauthorized access and protect animals from predators, thereby ensuring their safety. Farmers often require durable, weather-resistant materials due to varying climates, particularly in regions like Africa and South America. Additionally, ease of use is essential for quick access during daily operations. Buyers should consider latches that offer robust locking mechanisms to enhance security while being user-friendly for farm staff.

What role do latch fences play in construction site security?

Latch fences are widely used in the construction industry to secure access points on job sites. They provide a balance between security and accessibility, allowing contractors to control who enters and exits the site. This is especially important in regions like the Middle East, where construction sites may be vulnerable to theft. Buyers should prioritize latches that comply with local safety regulations and can withstand heavy use, ensuring they can be installed quickly and efficiently to minimize downtime.

How do latch fences enhance residential security and safety?

In residential settings, latch fences serve as a barrier for home and pool areas, significantly enhancing safety for children and pets. These latches deter unauthorized access, providing peace of mind for homeowners. In European markets like Germany, aesthetic compatibility with home designs is a key consideration for buyers, alongside functionality. It’s also important to look for products that meet child safety certifications, ensuring compliance with local safety standards.

Why are latch fences important for commercial facilities?

For commercial facilities, latch fences are vital for access control, particularly in warehouses and storage units. They prevent unauthorized entry and protect valuable inventory, which is critical for businesses operating in competitive markets. In regions like South America, where theft can be a concern, heavy-duty latches with robust locking mechanisms are essential. Buyers should consider the latch’s durability and ability to withstand high-traffic usage to ensure long-term effectiveness.

How do latch fences contribute to municipal applications in public parks?

Latch fences are commonly used in municipal applications, such as managing access to public parks. They ensure public safety while controlling entry points, allowing municipalities to manage crowds and maintain facilities effectively. In the Middle East, where outdoor public spaces are significant, weather-resistant materials are critical for longevity. Municipal buyers should prioritize latches that require minimal maintenance and can withstand harsh environmental conditions, ensuring they remain functional and secure over time.

3 Common User Pain Points for ‘latch fence’ & Their Solutions

Scenario 1: Difficulty Ensuring Security with Latch Fences

The Problem: Many B2B buyers, particularly those in industries requiring secure perimeters (like agriculture or construction), face challenges in ensuring that their latch fences provide adequate security. Standard latches may not withstand tampering or adverse weather conditions, leading to potential breaches that could compromise valuable assets or safety. For instance, a construction site without secure latches can lead to theft of equipment or unauthorized access, resulting in financial losses and project delays.

The Solution: To address security concerns, buyers should invest in heavy-duty gate latches specifically designed for high-security applications. Latches made from materials like stainless steel or zinc-coated steel offer enhanced durability and resistance to tampering. It’s essential to evaluate options that include key-lockable features or electronic access systems, which provide an additional layer of protection. Furthermore, proper installation is critical; engaging a professional who understands the specific requirements of the latch fence system can ensure that it meets industry standards. Regular maintenance checks should also be scheduled to inspect and replace any worn-out components, thus maintaining the security integrity of the latch fence.

Scenario 2: Inconsistent Performance in Diverse Weather Conditions

The Problem: B2B buyers operating in regions with extreme weather, such as heavy rainfall or intense heat, often struggle with the performance of latch fences. For example, wooden latches may swell or warp in humid conditions, leading to functionality issues, while metal latches can rust or corrode. These problems not only hinder the effectiveness of the latch but can also lead to costly repairs and replacements, impacting operational efficiency.

The Solution: To combat weather-related issues, buyers should consider latches made from weather-resistant materials like polymer or marine-grade stainless steel, which can withstand harsh conditions without degrading. Additionally, opting for latches with protective coatings can further enhance longevity. It is also advisable to conduct an environmental assessment of the site prior to installation. This assessment will help in selecting the right materials and latch types suited for specific climatic conditions. Implementing a regular maintenance schedule, including cleaning and lubrication, can also prevent operational issues and extend the lifespan of latch components.

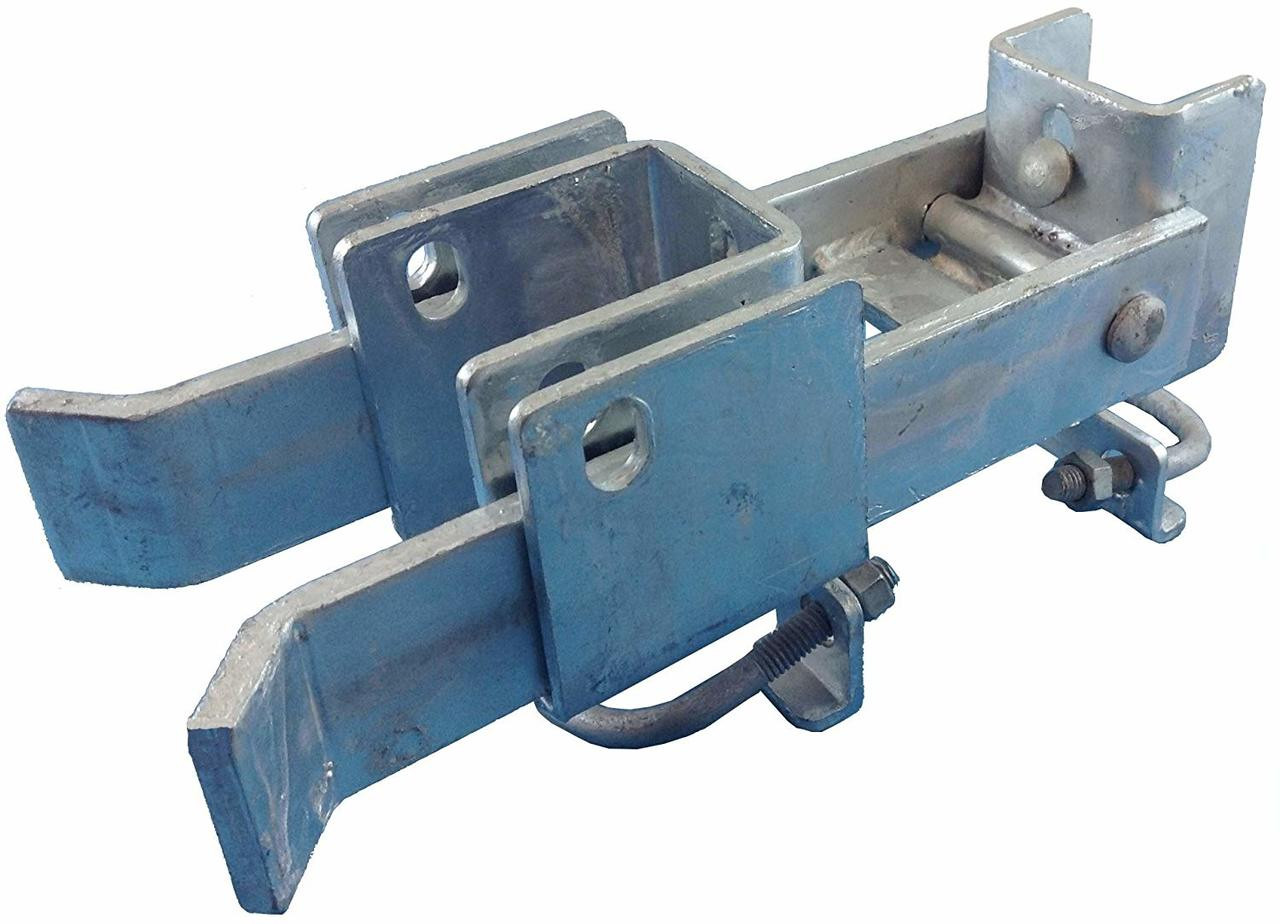

Illustrative image related to latch fence

Scenario 3: Challenges with Compatibility and Sizing of Latch Fences

The Problem: A frequent pain point for B2B buyers is the compatibility of latches with existing fence structures. In many cases, businesses may have varying fence designs (such as chain link, wooden, or vinyl), leading to confusion over which latches are appropriate. Mismatched sizes and types can result in ineffective security and functionality, causing frustration and potential safety hazards.

The Solution: To mitigate compatibility issues, buyers should conduct thorough assessments of their existing fence structures before purchasing latches. This includes measuring the dimensions of the posts and gates and considering the type of fence material. Many manufacturers provide detailed specifications and compatibility charts to assist buyers in making informed decisions. Additionally, investing in adjustable latches or those designed for multiple applications can provide flexibility and ease of installation. Establishing a relationship with a reliable supplier who can offer guidance based on specific needs can also streamline the procurement process, ensuring that all components work seamlessly together.

Strategic Material Selection Guide for latch fence

What Are the Key Properties of Common Materials Used in Latch Fences?

When selecting materials for latch fences, it is essential to consider their properties to ensure optimal performance and longevity. Here, we analyze four common materials: steel, aluminum, plastic, and stainless steel.

How Does Steel Perform as a Material for Latch Fences?

Steel is a widely used material for latch fences due to its strength and durability. It typically has a high tensile strength and can withstand significant pressure and impact, making it suitable for heavy-duty applications. However, steel is prone to corrosion unless treated or coated, which can affect its longevity in harsh environments.

Pros: Steel offers excellent durability and is cost-effective for large-scale applications. It can be easily manufactured into various shapes and sizes, making it versatile for different latch designs.

Cons: The susceptibility to rust and corrosion can be a significant drawback, especially in humid or coastal regions. Additionally, the weight of steel can complicate installation and handling.

Impact on Application: Steel latches are ideal for environments requiring robust security, such as industrial sites or agricultural settings. However, they may require regular maintenance, including painting or galvanizing, to prevent rust.

Considerations for International Buyers: Compliance with international standards such as ASTM for the U.S. and DIN for Germany is crucial. Buyers should also consider local climate conditions that may affect the choice of steel.

What Advantages Does Aluminum Offer for Latch Fences?

Aluminum is increasingly popular for latch fences due to its lightweight and corrosion-resistant properties. It does not rust, making it suitable for outdoor applications in various climates. Aluminum can also be anodized or painted to enhance its aesthetic appeal.

Pros: Its lightweight nature simplifies installation and reduces shipping costs. Aluminum is also resistant to corrosion, making it ideal for coastal areas.

Illustrative image related to latch fence

Cons: While strong, aluminum is not as durable as steel and may not be suitable for high-security applications. It can also be more expensive than steel, depending on the alloy used.

Impact on Application: Aluminum latches are ideal for residential and decorative applications where aesthetics are important, such as in gardens or parks.

Considerations for International Buyers: Buyers should ensure that the aluminum used meets local standards for strength and corrosion resistance, particularly in regions with high humidity or saline environments.

How Does Plastic Compare as a Material for Latch Fences?

Plastic, particularly high-density polyethylene (HDPE) or polyvinyl chloride (PVC), is used for latch fences primarily for its resistance to weathering and low maintenance requirements. Plastic latches are often lightweight and can be molded into complex shapes.

Pros: Plastic is highly resistant to corrosion, rust, and UV radiation, making it suitable for various environmental conditions. It is also cost-effective and easy to install.

Cons: Plastic lacks the strength and durability of metal options, making it less suitable for high-security applications. It can also become brittle over time, particularly in extreme temperatures.

Impact on Application: Plastic latches are ideal for residential settings, pool gates, and temporary fencing where security is less of a concern.

Considerations for International Buyers: Compliance with environmental regulations regarding plastic use is essential, particularly in Europe where regulations are stringent.

What Role Does Stainless Steel Play in Latch Fence Applications?

Stainless steel combines the strength of steel with corrosion resistance, making it an excellent choice for latch fences in various environments. It is particularly suitable for applications where hygiene is a concern, such as in food processing or healthcare facilities.

Pros: Stainless steel is durable, resistant to rust, and requires minimal maintenance. It can withstand extreme temperatures and is suitable for both indoor and outdoor applications.

Illustrative image related to latch fence

Cons: The primary drawback is its cost, as stainless steel is generally more expensive than other materials. Additionally, it can be more challenging to work with due to its hardness.

Impact on Application: Stainless steel latches are ideal for high-security applications and environments where cleanliness is paramount.

Considerations for International Buyers: Buyers should verify that the stainless steel meets relevant standards, such as ASTM or ISO, to ensure quality and durability.

Summary Table of Material Selection for Latch Fences

| Material | Typical Use Case for latch fence | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Industrial and agricultural sites | High strength and durability | Prone to corrosion | Medium |

| Aluminum | Residential and decorative fences | Lightweight and corrosion-resistant | Less durable than steel | Medium |

| Plastic | Residential and pool gates | Low maintenance and cost-effective | Less strength and durability | Low |

| Stainless Steel | High-security and hygiene-sensitive areas | Corrosion-resistant and durable | Higher cost | High |

This analysis provides a comprehensive overview of the materials suitable for latch fences, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for latch fence

What Are the Main Stages of Manufacturing Latch Fences?

The manufacturing process for latch fences involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial for producing high-quality products that meet the demands of B2B buyers.

-

Material Preparation: The first step involves selecting high-grade materials suitable for outdoor use, such as galvanized steel, stainless steel, aluminum, and polymer composites. These materials are prepared through cutting, bending, and sometimes pre-treating to enhance corrosion resistance. Quality assurance starts here; suppliers should verify the material’s specifications through certificates of compliance.

-

Forming: The next stage is forming, where materials are shaped into specific components using techniques like stamping, extrusion, or casting. Advanced machinery, such as CNC machines and hydraulic presses, are commonly employed to ensure precision. This stage requires adherence to strict tolerances to ensure that components fit together correctly during assembly.

-

Assembly: After forming, components are assembled into the final latch products. This process may involve welding, riveting, or screwing parts together. Automated assembly lines are increasingly used to enhance efficiency and consistency. Manual assembly checks are also crucial, as skilled workers can identify potential defects that machines may overlook.

-

Finishing: The finishing stage includes surface treatments such as painting, powder coating, or electroplating to enhance aesthetics and durability. These processes not only improve the visual appeal but also provide additional protection against the elements. Quality checks at this stage often include adhesion tests and visual inspections to ensure the finish meets specified standards.

How Is Quality Control Implemented in Latch Fence Manufacturing?

Quality control (QC) is integral to ensuring that latch fences meet international standards and customer specifications. The QC process typically follows several recognized standards, including ISO 9001, which focuses on quality management systems, and CE marking for compliance with EU safety standards.

-

International Standards: Adhering to ISO 9001 ensures that manufacturers implement a systematic approach to quality management, which includes continuous improvement and customer satisfaction. For European markets, CE marking is essential, indicating that products meet safety, health, and environmental protection standards.

-

Industry-Specific Standards: Depending on the application, additional certifications may be relevant. For example, API (American Petroleum Institute) standards may apply if the latch is used in oil and gas applications. Buyers should verify that their suppliers have the necessary certifications for their specific industry requirements.

-

Quality Checkpoints: Quality control involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial stage checks the quality of raw materials before they are used in production. Suppliers should provide certificates of analysis and compliance for materials.

– In-Process Quality Control (IPQC): During manufacturing, random sampling and inspections are conducted to ensure processes adhere to quality standards. This may include measuring dimensions and testing for defects.

– Final Quality Control (FQC): After assembly and finishing, a comprehensive inspection is performed. This includes functional testing of latches to ensure they operate correctly and durability tests to evaluate resistance to wear and environmental conditions.

What Testing Methods Are Commonly Used in Latch Fence Quality Assurance?

Testing methods for latch fences vary based on the materials and intended use but generally include:

- Mechanical Testing: This assesses the strength and durability of latch components. Common tests include tensile strength, shear strength, and fatigue testing to simulate long-term use.

- Corrosion Resistance Testing: Latch fences are often exposed to harsh environmental conditions. Salt spray tests and humidity tests are conducted to evaluate how well the finishes protect against corrosion.

- Functional Testing: Each latch is tested for proper operation, ensuring it can withstand repeated use without failure. This may include opening and closing cycles and testing locking mechanisms.

- Safety Compliance Testing: For products intended for specific applications, such as pool safety latches, additional tests may be required to ensure compliance with safety regulations.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must ensure that their suppliers adhere to rigorous quality control processes. Here are effective strategies for verification:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes and quality control measures firsthand. Audits should focus on production facilities, equipment, and adherence to quality standards.

-

Review of Quality Control Reports: Suppliers should provide regular quality control reports that detail inspection results, non-conformance issues, and corrective actions taken. This transparency fosters trust and helps buyers understand the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging independent third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control processes. These agencies can perform audits and testing, delivering objective reports that help buyers make informed decisions.

-

Certification Verification: Buyers should verify that suppliers hold relevant certifications by checking with certifying bodies. This ensures that the supplier meets international and industry-specific standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate various quality control nuances:

-

Regional Standards and Regulations: Different regions may have unique quality standards and regulations. Buyers should familiarize themselves with local requirements to ensure compliance.

-

Language and Communication Barriers: When dealing with international suppliers, language differences can complicate quality assurance processes. Clear communication is essential, and having bilingual representatives can facilitate this.

-

Cultural Differences in Business Practices: Understanding the cultural context of suppliers can impact negotiations and quality expectations. For example, some cultures may prioritize relationships over contractual obligations, influencing how quality control is perceived.

-

Logistics and Supply Chain Considerations: International shipping can introduce additional risks to product quality. Buyers should consider how transportation methods and storage conditions may affect the integrity of latch fences during transit.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing latch fences, ensuring they receive products that meet their needs and expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘latch fence’

Introduction

Navigating the procurement of latch fences can be a complex task, especially for B2B buyers operating across diverse international markets. This guide provides a step-by-step checklist to streamline your sourcing process, ensuring that you secure quality products that meet your specific requirements.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for your latch fence. This includes dimensions, materials (such as steel, aluminum, or plastic), and any necessary locking mechanisms. Clearly defined specifications will help you communicate your needs to potential suppliers and ensure that the products you receive meet your operational standards.

Illustrative image related to latch fence

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify suppliers who specialize in latch fences. Focus on companies that have a strong presence in your target regions, such as Africa, South America, the Middle East, and Europe. Utilize online directories, trade shows, and industry publications to compile a list of potential vendors.

- Look for suppliers with experience in international shipping and trade regulations.

- Consider their production capacity to meet your order volume.

Step 3: Evaluate Supplier Credentials and Reliability

Before moving forward, it’s essential to vet each supplier for credibility. Request documentation such as business licenses, certifications, and quality assurance processes. This step is vital to ensure you are partnering with reliable suppliers who adhere to industry standards.

- Ask for references from previous clients in similar markets.

- Check for any certifications relevant to your region, such as ISO or CE marking.

Step 4: Request Samples for Quality Assessment

Once you’ve narrowed down your list of suppliers, request samples of their latch fence products. Evaluating samples allows you to assess the quality, durability, and functionality of the latches. This is crucial to avoid issues post-purchase that could lead to costly replacements or repairs.

Illustrative image related to latch fence

- Inspect the materials used and the finish quality.

- Test the locking mechanisms and ease of installation.

Step 5: Compare Pricing and Payment Terms

Gather pricing information from your shortlisted suppliers, ensuring that you compare similar products based on quality and features. Pay attention to payment terms, as favorable conditions can significantly impact your cash flow.

- Look for volume discounts or flexible payment options.

- Consider the total cost of ownership, including shipping and installation costs.

Step 6: Verify Compliance with Local Regulations

It’s imperative to ensure that the latch fences comply with local safety and security regulations in your target market. Non-compliance can lead to legal issues and additional costs down the line.

- Check for any specific regulations regarding fencing materials and locking mechanisms in your region.

- Ensure that the supplier is familiar with and adheres to these regulations.

Step 7: Finalize the Purchase Agreement

Once you’ve selected a supplier, negotiate and finalize the purchase agreement. Ensure that all terms, including delivery schedules, warranties, and service agreements, are clearly outlined. A well-defined contract will protect both parties and ensure a smooth transaction.

- Include clauses for quality control inspections and returns.

- Specify the timeline for delivery and any penalties for delays.

By following this checklist, B2B buyers can streamline their procurement process for latch fences, ensuring a reliable and efficient sourcing experience.

Comprehensive Cost and Pricing Analysis for latch fence Sourcing

Understanding the cost structure and pricing for latch fences is crucial for international B2B buyers, especially in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis delves into the essential components that contribute to the overall pricing of latch fences and offers actionable insights for negotiating and optimizing purchasing decisions.

What Are the Key Cost Components in Latch Fence Manufacturing?

The cost structure of latch fences includes several critical components:

-

Materials: The choice of materials significantly impacts pricing. Common materials include steel, aluminum, and various polymers. High-grade materials or those with special finishes (e.g., galvanized or marine-grade) typically lead to higher costs. Buyers should assess material quality based on their intended use, as this can affect durability and maintenance needs.

-

Labor: Labor costs vary by region and can be influenced by local wage standards. Skilled labor is often required for manufacturing latches, especially for custom or complex designs. Understanding regional labor costs can help buyers gauge where to source their products.

-

Manufacturing Overhead: This encompasses the indirect costs of production, such as utilities, rent, and administrative expenses. These costs are typically factored into the final price and can vary based on the efficiency of the manufacturing process.

-

Tooling: Custom tooling for unique latch designs can increase initial costs. If a buyer opts for custom specifications, the tooling expenses should be factored into the total cost of ownership (TCO).

-

Quality Control (QC): Ensuring that products meet safety and quality standards can add to costs. Suppliers with robust QC processes may charge more, but this investment can reduce returns and enhance product reliability.

-

Logistics: Shipping costs are a significant consideration, especially for international buyers. Factors such as distance, shipping method, and freight charges can vary widely, impacting overall expenses.

-

Margin: Suppliers typically add a profit margin to their costs. Understanding the industry standard margins can help buyers negotiate better deals.

What Influences the Pricing of Latch Fences?

Several factors can influence the pricing of latch fences:

-

Volume/MOQ: Bulk purchases often lead to reduced unit prices. Buyers should consider establishing minimum order quantities (MOQ) to leverage better pricing.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Quality and Certifications: Products that meet specific quality standards or possess certifications (e.g., safety certifications) may command higher prices. These certifications can be crucial for buyers in regulated markets.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while newer suppliers might offer competitive pricing to enter the market.

-

Incoterms: Understanding Incoterms is vital for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can impact the total landed cost.

How Can Buyers Optimize Their Purchasing Strategy for Latch Fences?

For B2B buyers looking to optimize costs, consider the following tips:

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Leverage competitive quotes from multiple suppliers to strengthen your negotiating position.

-

Cost-Efficiency: Evaluate the total cost of ownership rather than just the purchase price. This includes maintenance, potential downtime, and replacement costs over the product’s lifespan.

-

Pricing Nuances for International Buyers: Familiarize yourself with local market conditions and pricing structures in your target region. Be aware of currency fluctuations and tariffs that may affect final costs.

-

Supplier Relationships: Build strong relationships with suppliers to gain insights into pricing trends and potential cost-saving opportunities.

In conclusion, understanding the comprehensive cost structure and pricing influencers for latch fences is essential for B2B buyers. By strategically assessing these factors, buyers can make informed decisions that enhance their purchasing efficiency and overall project success. Remember that prices can vary significantly based on the aforementioned elements, so it’s essential to conduct thorough market research and maintain open lines of communication with suppliers.

Alternatives Analysis: Comparing latch fence With Other Solutions

Exploring Alternative Solutions to Latch Fence Systems

In the world of security and access management, various solutions exist to secure gates and fences. While latch fences are a popular choice due to their reliability and ease of use, understanding alternatives can help B2B buyers make informed decisions that align with their specific operational needs. This section compares latch fences with two viable alternatives: electronic gate locks and traditional padlocks.

Comparison Table

| Comparison Aspect | Latch Fence | Electronic Gate Locks | Traditional Padlocks |

|---|---|---|---|

| Performance | High, with quick access | Very high, offers remote access | Moderate, depends on key management |

| Cost | Moderate, $20 – $100 | High, $150 – $500+ | Low, $5 – $50 |

| Ease of Implementation | Simple installation | Requires wiring/setup | Very easy to install |

| Maintenance | Low, minimal upkeep | Moderate, battery changes required | Low, requires key management |

| Best Use Case | Residential, light commercial | High-security areas, commercial | Low-security areas, temporary needs |

In-Depth Analysis of Alternatives

What Are the Benefits and Drawbacks of Electronic Gate Locks?

Electronic gate locks represent a modern alternative to latch fences, offering advanced security features such as remote access, keypad entry, and integration with smart home systems. Their performance is typically superior, providing enhanced security measures that are appealing for high-risk areas. However, the initial investment is significantly higher, which may deter budget-conscious buyers. Additionally, the installation process can be complex, often requiring professional assistance, and maintenance involves changing batteries or managing electronic components, which can be a drawback for some users.

Illustrative image related to latch fence

How Do Traditional Padlocks Compare to Latch Fences?

Traditional padlocks are a straightforward, cost-effective solution for securing gates, especially in low-security environments. Their simplicity is a significant advantage; they are easy to use and install without requiring any special tools or knowledge. However, they offer limited security features compared to latch fences and electronic locks, making them less suitable for high-security applications. Moreover, they rely heavily on key management, which can lead to issues if keys are lost or stolen.

Making the Right Choice: Which Solution Fits Your Needs?

When deciding between latch fences and their alternatives, consider the specific security requirements, budget constraints, and the intended application. Latch fences are ideal for users seeking a balance of security, ease of use, and cost-effectiveness, particularly in residential or light commercial settings. On the other hand, electronic gate locks are best suited for high-security environments where advanced features are necessary. Traditional padlocks serve well for temporary or low-security needs but may not provide adequate protection in more vulnerable settings. Ultimately, understanding these alternatives will enable B2B buyers to select the most appropriate solution for their unique circumstances.

Essential Technical Properties and Trade Terminology for latch fence

What Are the Key Technical Properties of Latch Fences?

Understanding the technical specifications of latch fences is crucial for international B2B buyers. These specifications not only impact the performance and durability of the products but also influence maintenance costs and overall satisfaction. Here are some critical properties to consider:

Illustrative image related to latch fence

-

Material Grade

Latch fences are commonly made from various materials, including stainless steel, aluminum, and plastic. The material grade affects corrosion resistance, strength, and longevity. For instance, stainless steel (often rated 304 or 316) offers superior rust resistance, making it ideal for outdoor applications in humid or coastal environments. Buyers should prioritize high-grade materials to ensure long-term performance and reduce replacement costs. -

Duty Rating

Duty ratings categorize latches based on their load-bearing capabilities, typically defined as standard, heavy-duty, or extra heavy-duty. Heavy-duty latches are essential for high-traffic areas or gates subjected to frequent use, as they are designed to withstand greater stress. Selecting the appropriate duty rating minimizes the risk of malfunction and enhances safety, especially in commercial applications. -

Finish and Coating

The finish of a latch plays a significant role in its resistance to environmental factors. Common finishes include powder coating, galvanization, and anodizing. A quality finish protects against rust and enhances aesthetic appeal. In regions with extreme weather conditions, investing in a durable finish can extend the product’s lifespan and maintain its functionality. -

Locking Mechanism Type

Latch fences can incorporate various locking mechanisms, such as key-locking, pad-locking, or magnetic latches. The choice of locking mechanism should align with the security requirements of the application. For example, key-locking mechanisms provide higher security for residential properties, while magnetic latches are often used in pool safety applications due to their ease of use. -

Installation Compatibility

Compatibility with existing fence structures is vital when selecting latch fences. Specifications like post size and frame dimensions must match the installation requirements. Buyers should confirm that latches are compatible with the type of gate—be it a single or double gate—and the material of the fence. This ensures a smooth installation process and optimal performance.

What Are Common Trade Terms Related to Latch Fences?

Navigating the world of latch fences also involves understanding industry-specific terminology. Familiarity with these terms can streamline communication and facilitate smoother transactions:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components or products that are sold by another company under its brand name. Buyers should consider OEM products for quality assurance, as they often meet stringent industry standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is critical for budgeting and inventory management, especially for international buyers who may face higher shipping costs for small orders. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. It’s an essential step in the procurement process, enabling buyers to compare offers from multiple suppliers and negotiate better deals. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping responsibilities, risk, and costs associated with transportation. -

Lead Time

This term refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is crucial for planning and inventory management, especially in industries where timing can significantly impact operations. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the product, typically covering defects and performance issues for a specified period. Buyers should assess warranty terms to understand the level of protection they have against potential issues, thus ensuring their investment is safeguarded.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, optimize procurement processes, and enhance their overall operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the latch fence Sector

What Are the Current Market Dynamics and Key Trends in the Latch Fence Sector?

The latch fence sector is witnessing significant transformations driven by various global factors. One of the primary drivers is the growing emphasis on security and safety across residential, commercial, and industrial applications. As urbanization accelerates, particularly in regions like Africa and the Middle East, the demand for robust fencing solutions, including high-quality latches, is on the rise. In addition, the increasing awareness of child safety in residential areas has spurred interest in specialized latches, such as those for pool gates.

Emerging B2B technologies are reshaping sourcing strategies. Digital platforms are streamlining procurement processes, allowing international buyers to easily compare products, prices, and suppliers. Innovations in materials, such as stainless steel and polymer composites, are gaining traction due to their durability and resistance to environmental factors. Moreover, suppliers are increasingly offering customizable latch solutions to meet specific regional requirements, thus enhancing buyer engagement.

Another important trend is the focus on automation and smart technologies. The integration of smart locks and electronic latches is becoming prevalent, catering to a tech-savvy customer base. This is particularly relevant for buyers in Europe, where smart home technology is rapidly evolving. Understanding these dynamics can help B2B buyers make informed purchasing decisions that align with market expectations and technological advancements.

How Are Sustainability and Ethical Sourcing Changing the Latch Fence Sector?

Sustainability is becoming a critical consideration for B2B buyers in the latch fence sector. With increased scrutiny on environmental impact, manufacturers are adopting eco-friendly practices and materials. Ethical sourcing is not just a trend but a necessity, as businesses recognize the importance of responsible supply chains. International buyers are encouraged to evaluate suppliers based on their sustainability practices, including waste reduction and energy-efficient manufacturing processes.

The demand for ‘green’ certifications is rising, influencing buyer decisions. Certifications such as LEED (Leadership in Energy and Environmental Design) and FSC (Forest Stewardship Council) ensure that products are sourced sustainably. This is particularly relevant for materials used in latches, where buyers may prefer options made from recycled or sustainably harvested materials. By prioritizing sustainable sourcing, businesses can enhance their brand reputation and appeal to environmentally conscious consumers.

Illustrative image related to latch fence

Furthermore, the focus on sustainability extends to packaging and logistics. Buyers should seek suppliers who minimize packaging waste and utilize eco-friendly materials. This not only reduces environmental impact but also aligns with corporate social responsibility initiatives, enhancing overall business value.

What Is the Evolution of the Latch Fence Sector and Its Relevance for B2B Buyers?

The evolution of the latch fence sector reflects broader trends in construction and security. Historically, latches were simple mechanical devices, primarily made of wood or basic metal. As technology advanced, the demand for more secure and versatile latching mechanisms grew, leading to the development of diverse latch types suited for various applications.

In recent decades, the introduction of materials like stainless steel and advanced polymers has revolutionized latch design, improving durability and resistance to corrosion. The advent of smart technology has further transformed the sector, with electronic latches and keyless entry systems becoming standard in modern fence solutions.

For B2B buyers, understanding this evolution is crucial. It highlights the importance of selecting suppliers who are not only knowledgeable about traditional latch designs but also innovative in integrating new technologies. This historical context informs current purchasing decisions, ensuring buyers invest in products that meet both present and future market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of latch fence

-

How do I solve latch fence compatibility issues with existing gates?

To address compatibility concerns, first, measure the dimensions and specifications of your existing gate, including post size and frame type. Choose latches designed for the specific gate style—swing or sliding—and ensure they match the material, whether wood, vinyl, or metal. Many suppliers offer adjustable options that can accommodate varying post sizes. Additionally, consult with your supplier about custom solutions if your requirements are unique, ensuring a proper fit and functionality for security. -

What is the best latch for securing a fence gate in a high-security area?

For high-security applications, heavy-duty latches with key-locking mechanisms are ideal. Look for options made from durable materials like stainless steel or galvanized steel, which provide resistance against tampering and corrosion. Additionally, consider latches with advanced features, such as alarm systems or electronic access controls, for enhanced security. Brands specializing in commercial-grade products often provide the best solutions tailored for high-risk environments. -

What should I consider when sourcing latch fences internationally?

When sourcing latch fences internationally, assess the supplier’s reputation, product quality, and compliance with international standards. Review certifications and customer feedback to ensure reliability. It’s also crucial to understand the logistics, including shipping costs and timelines, as well as customs regulations in your region. Engaging in clear communication regarding specifications and expectations can help prevent misunderstandings and ensure smooth transactions. -

What are the minimum order quantities (MOQ) for latch fences?

Minimum order quantities can vary significantly by supplier and product type. Typically, MOQs for latch fences range from 50 to 500 units, depending on the material and complexity of the latch. For specialized or custom latches, suppliers may have higher MOQs. It’s advisable to discuss your specific needs with potential suppliers to explore flexibility in order sizes, especially if you’re testing a new market or product line. -

How can I vet suppliers for latch fences effectively?

To vet suppliers, start by checking their business credentials, including registration and certifications. Request references from previous clients, focusing on their experience with similar products. Conduct a factory visit or request third-party inspections to evaluate production quality and capabilities. Additionally, utilize platforms like Alibaba or Global Sources, which often feature verified suppliers, to enhance trust in your sourcing decisions. -

What payment terms are commonly offered for latch fence orders?

Payment terms can vary widely depending on the supplier and your negotiating power. Common terms include a 30% deposit with the balance due before shipment, or net 30 to net 60 days after delivery. Some suppliers may also accept letters of credit or escrow services for larger orders. Always clarify payment terms upfront and ensure they are included in the contract to avoid disputes later. -

What quality assurance measures should I expect from latch fence suppliers?

Reputable suppliers should have established quality assurance (QA) protocols in place. Look for certifications such as ISO 9001, which indicate adherence to international quality standards. Suppliers should provide documentation of their QA processes, including material inspections, testing of products for durability and functionality, and regular audits. Request samples before placing a large order to assess quality firsthand. -

How do I manage logistics and shipping for latch fence imports?

Effective logistics management involves planning for shipping methods, timelines, and costs. Determine whether to use air freight for faster delivery or sea freight for cost-efficiency. Work with a freight forwarder experienced in handling international shipments to navigate customs requirements and documentation. Additionally, consider insurance options to protect your investment during transit, and keep clear communication with your supplier regarding shipment schedules and tracking.

Top 7 Latch Fence Manufacturers & Suppliers List

1. Hoover Fence Co. – Gate Latches

Domain: hooverfence.com

Registered: 1996 (29 years)

Introduction: Gate Latches from Hoover Fence Co. include various types such as single gate latches, double gate latches, pool gate latches, and wooden gate latches. They are available in multiple materials including aluminum, steel, polymer, and stainless steel. Key features include options for key locking, pad locking, and mechanical code locks. The latches are suitable for both swinging and sliding gates. Bra…

2. Fence Center – Heavy Duty Gate Latch

Domain: fencecenter.com

Registered: 1999 (26 years)

Introduction: [{‘name’: ‘Gate Latch – Heavy Duty’, ‘price’: ‘$49.00’}, {‘name’: ‘Post Latch – 5×5 Standard 2-Sided Locking’, ‘price’: ‘$69.00’}, {‘name’: ‘Gravity Latch – Two Sided Locking’, ‘price’: ‘$95.00’}, {‘name’: ‘Gravity Latch – Decorative’, ‘price’: ‘$49.00’}, {‘name’: ‘Gravity Latch – One Sided Locking’, ‘price’: ‘$59.00’}, {‘name’: ‘Pool Safety Latch – Locking – Compact’, ‘price’: ‘$99.00’}, {‘name’:…

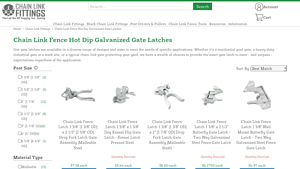

3. Chain Link Fittings – Hot Dip Galvanized Gate Latches

Domain: chainlinkfittings.com

Registered: 2008 (17 years)

Introduction: Chain Link Fence Hot Dip Galvanized Gate Latches available in various designs and sizes for different applications including residential pool gates and industrial gates. Key specifications include:

– Post Sizes: 1 3/8″, 1 5/8″, 2″, 2 1/2″, 3″, 4″, 6 5/8″

– Material Types: Malleable Steel, Nylon, Pressed Steel

– Colors: Black, Galvanized Gray, Galvanized Silver, Aluminum

– Examples of products:…

4. HingeOutlet – BadAss Coded Gate Locks

Domain: hingeoutlet.com

Registered: 2004 (21 years)

Introduction: Gate Locks and Latches for Security and Privacy – HingeOutlet offers a variety of gate locks and latches designed for both security and privacy. Key products include: BadAss Coded Gate Locks, Heavy Duty Bolt On and Weld On Hinges, Double Action Spring Hinges, Drop Bolts, Farm Gate Hinges, Gate Access Controls, Heavy Duty Gate Closers, Locinox Gate Locks, Safety Gate Latches, and various types of m…

5. Signet Fence – Key Products

Domain: signetfence.com

Registered: 2009 (16 years)

Introduction: Key Products: 1. D&D Technologies LokkLatch 3 Plus Gate Latch – Keyed Alike, MSRP: $68.99 2. Dac Industries Sentry Latch – Heavy-Duty Dumpster Gate Latch, MSRP: $64.99 3. Dac Industries 1-3/4″ Adapter Kit for Square Walk Gate Strong Arm Latch w/ Hardware Bags, MSRP: $8.99 4. D&D Technologies MagnaLatch Series 3 Round Post Adapter for Chain Link Gates – Black, MSRP: $26.99 5. D&D Technologies Gate …

6. A Fence – SPRING LATCH ONLY

Domain: afence.com

Registered: 1997 (28 years)

Introduction: {“product_name”: “SPRING LATCH ONLY”, “sku”: “015SL”, “price”: “$8.55”, “stock”: {“Georgetown”: 23, “League City”: 8}, “description”: “Used to latch chainlink gate shut. Requires either a wood mount keeper (015WK) or a 2 3/8\” O.D. pipe post keeper (015PK). Requires 2 self-tapping drill bolts to fasten to gate frame.”, “material”: “Pressed Steel Construction, Galvanized”, “reviews”: {“average_rati…

7. Nationwide Industries – Round Loop Latch

Domain: pennfence.com

Registered: 1999 (26 years)

Introduction: Product Name: Round Loop Latch

Price: $5.00

Availability: In stock

Features:

– Wide selection of hardware for various gate types (vinyl, steel, aluminum, wood, pool)

– Trusted quality from Nationwide Industries

– Innovative design for safe and efficient function

– Complete kits with screws and installation instructions

– Durable hinges sold in pairs for strength and long-lasting performance

– Des…

Strategic Sourcing Conclusion and Outlook for latch fence

As businesses continue to expand globally, the significance of strategic sourcing for latch fences cannot be overstated. By understanding the diverse range of latch products available—from heavy-duty options to locking mechanisms—buyers can make informed decisions that enhance security and operational efficiency. The ability to source high-quality latches tailored to specific regional needs, whether in Africa, South America, the Middle East, or Europe, is crucial for maintaining competitive advantage.

Illustrative image related to latch fence

International buyers should prioritize partnerships with reliable suppliers who offer comprehensive product lines, transparent pricing, and robust support services. This strategic approach not only ensures access to innovative latch solutions but also fosters long-term relationships that can yield better pricing and service terms.

Looking ahead, the demand for advanced gate latch technologies will likely rise, driven by increasing safety regulations and consumer preferences for enhanced security features. Buyers are encouraged to explore emerging trends and innovations in latch technology, ensuring they remain at the forefront of their respective markets. Embrace the opportunity to enhance your sourcing strategy today—invest in quality latch solutions that will safeguard your assets and elevate your business operations for years to come.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to latch fence