A B2B Buyer’s Guide to Lab Benchtop: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for lab benchtop

In today’s global market, sourcing the right lab benchtop solutions can be a daunting task for B2B buyers, especially when considering factors like durability, functionality, and compliance with local regulations. As laboratories in Africa, South America, the Middle East, and Europe continue to expand, the demand for high-quality, versatile lab furniture has surged. This comprehensive guide serves as your essential resource for navigating the complexities of lab benchtop procurement, helping you identify the best types, applications, and materials to suit your specific needs.

Within this guide, you will discover a wide array of lab benchtop options, from basic work tables to advanced, customizable solutions that cater to diverse scientific disciplines. We delve into critical aspects of supplier vetting, ensuring you choose partners who meet international standards for quality and safety. Additionally, we provide insights into cost considerations and budget management, empowering you to make informed purchasing decisions that align with your operational goals.

By equipping you with the knowledge to assess product specifications, market trends, and supplier capabilities, this guide aims to streamline your sourcing process, ensuring you select the ideal lab benchtop that enhances productivity and meets regulatory requirements. Whether you are setting up a new laboratory or upgrading existing facilities, our insights will help you navigate the global market with confidence.

Understanding lab benchtop Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Steel Workbench | Durable, corrosion-resistant, often with adjustable heights | Industrial labs, manufacturing | Pros: High load capacity, sturdy; Cons: May be heavy and less mobile. |

| Phenolic Resin Table | Chemical-resistant surface, ideal for harsh environments | Chemical labs, research facilities | Pros: Resistant to spills, easy to clean; Cons: Can be expensive compared to basic options. |

| Mobile Lab Worktable | Lightweight, equipped with casters for easy movement | Educational institutions, fieldwork | Pros: Flexibility in workspace arrangement; Cons: Stability may be compromised on uneven surfaces. |

| Adjustable Height Workbench | Height can be modified for ergonomic use | Medical labs, testing facilities | Pros: Customizable for user comfort; Cons: Mechanism may require maintenance over time. |

| ESD Laminate Top Workbench | Designed to prevent electrostatic discharge, often used in electronics labs | Electronics assembly, cleanrooms | Pros: Protects sensitive components; Cons: Limited to specific applications. |

What are the Key Characteristics of Steel Workbenches?

Steel workbenches are known for their robust construction and high load-bearing capacity, making them suitable for heavy-duty applications in industrial and manufacturing environments. They often feature a durable, corrosion-resistant finish and may come with adjustable heights to accommodate various tasks. Buyers should consider the weight and stability of these benches, especially if they need to be moved frequently.

How Do Phenolic Resin Tables Stand Out in Laboratory Settings?

Phenolic resin tables are engineered for chemical resistance, which makes them ideal for labs dealing with hazardous materials. Their surfaces are easy to clean and maintain, ensuring longevity even in rigorous conditions. B2B buyers should assess their specific chemical handling needs and the potential for spills when considering this option, as the initial investment may be higher than standard tables.

Why Choose Mobile Lab Worktables for Flexibility?

Mobile lab worktables provide the advantage of mobility, allowing users to reconfigure their workspace easily. This is particularly beneficial in educational settings or fieldwork, where adaptability is crucial. However, buyers must evaluate the stability of these tables, especially when placed on uneven surfaces, as this can affect their functionality.

What are the Benefits of Adjustable Height Workbenches?

Adjustable height workbenches are designed to promote ergonomic use by allowing users to modify the height according to their needs. This feature is particularly valuable in medical labs and testing facilities where multiple users interact with the same workspace. Buyers should consider the ease of adjustment and the durability of the mechanism, as these factors can influence long-term satisfaction.

How Do ESD Laminate Top Workbenches Protect Sensitive Equipment?

ESD laminate top workbenches are specifically designed to dissipate static electricity, making them essential in electronics assembly and cleanroom environments. They help protect sensitive components from electrostatic discharge, which can cause damage. Buyers should ensure that their application requires ESD protection and consider the potential trade-offs in terms of versatility compared to other workbench types.

Key Industrial Applications of lab benchtop

| Industry/Sector | Specific Application of lab benchtop | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pharmaceuticals | Drug formulation and testing | Ensures precision and compliance with regulatory standards | Material durability, chemical resistance, and workspace safety |

| Food and Beverage | Quality control and testing | Maintains product safety and quality assurance | Easy-to-clean surfaces, compliance with health regulations |

| Education and Research | Scientific experiments and student labs | Fosters hands-on learning and innovation | Adjustable height options and multi-station configurations |

| Environmental Testing | Sample analysis for pollution and waste | Supports sustainability and environmental compliance | Corrosion resistance and mobility for field testing |

| Biotechnology | Genetic research and sample preparation | Enhances research efficiency and accuracy | Customization for specific lab needs and adherence to biosafety standards |

How Are Lab Benchtops Used in Pharmaceuticals?

In the pharmaceutical industry, lab benchtops are crucial for drug formulation and testing. They provide a stable, clean environment for handling chemicals and conducting experiments. The need for precision and compliance with stringent regulatory standards makes it essential for buyers to consider materials that are chemically resistant and durable. International buyers, particularly from Africa and the Middle East, should also ensure that the benchtops meet local safety regulations and can withstand rigorous cleaning protocols.

What Role Do Lab Benchtops Play in Quality Control for Food and Beverage?

Lab benchtops in the food and beverage sector are vital for quality control and testing of products. They enable consistent monitoring of ingredients and finished goods, ensuring safety and quality assurance. Buyers must prioritize surfaces that are easy to clean and resistant to contamination to comply with health regulations. For businesses in South America and Europe, sourcing equipment that meets both local and international food safety standards is critical.

Why Are Lab Benchtops Important in Education and Research?

In educational institutions and research facilities, lab benchtops facilitate scientific experiments and student labs. They promote hands-on learning and innovation by providing flexible workspaces. Adjustable height options and multi-station configurations are particularly beneficial for accommodating different lab activities. For international buyers, especially in Europe and Asia, it’s essential to select lab furniture that meets ergonomic standards to enhance the learning experience.

How Do Lab Benchtops Contribute to Environmental Testing?

In environmental testing, lab benchtops are essential for analyzing samples related to pollution and waste. They support sustainability efforts by ensuring accurate data collection and analysis. Buyers should focus on sourcing benchtops with corrosion-resistant materials that can withstand exposure to various chemicals. For buyers in developing regions, such as parts of Africa, ensuring that the benchtops are mobile can facilitate field testing, enhancing overall efficiency.

What Are the Specific Needs for Biotechnology Lab Benchtops?

In biotechnology, lab benchtops are used for genetic research and sample preparation. They enhance research efficiency and accuracy by providing a controlled environment for sensitive experiments. Buyers should consider customization options to meet specific lab needs, as well as compliance with biosafety standards. For international buyers, particularly from regions with emerging biotech sectors, it is crucial to source lab furniture that can adapt to evolving research requirements.

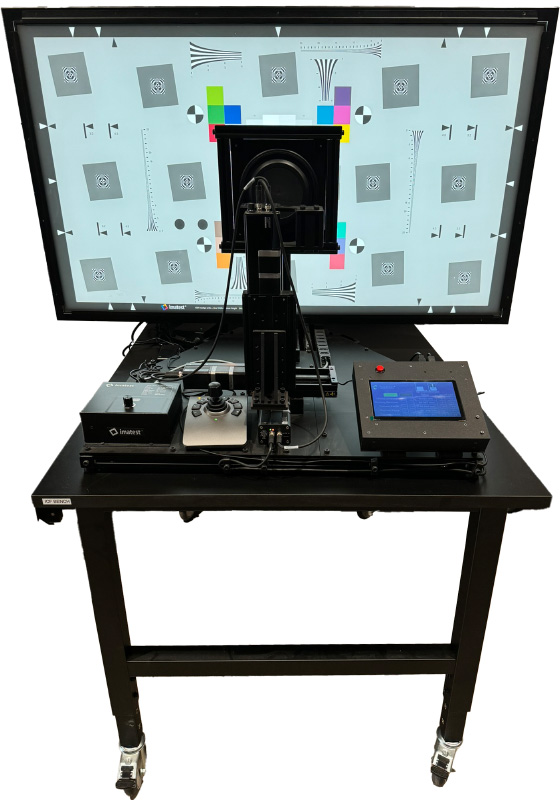

Illustrative image related to lab benchtop

3 Common User Pain Points for ‘lab benchtop’ & Their Solutions

Scenario 1: Inadequate Space Utilization in Laboratories

The Problem: B2B buyers often face challenges in optimizing limited laboratory space when selecting lab benchtops. Many laboratories, especially in emerging markets, have constrained square footage, making it essential to maximize every inch. Buyers may struggle with choosing the right configuration and dimensions of benchtops that not only fit their space but also accommodate the equipment and workflows needed for their specific applications. This can lead to inefficient use of space, cluttered work areas, and potential safety hazards.

The Solution: When sourcing lab benchtops, it’s critical to engage in thorough space planning. Begin by conducting a detailed analysis of your laboratory layout, considering both current and future needs. Opt for modular lab benchtops that can be easily reconfigured or expanded as requirements change. Additionally, consider height-adjustable workstations that can accommodate different users and tasks, promoting ergonomic practices and maximizing workspace functionality. Collaborate with suppliers who offer customization options to ensure that the benchtops fit perfectly within your designated area. Utilizing CAD (Computer-Aided Design) software can also help visualize how different configurations will work in your lab before making a purchase.

Scenario 2: Material Durability and Chemical Resistance Concerns

The Problem: Another significant pain point for B2B buyers is the durability and chemical resistance of lab benchtops. Laboratories often work with corrosive chemicals, heavy equipment, and high temperatures, which can quickly degrade inferior materials. Buyers may find themselves frequently replacing benchtops due to wear and tear, leading to increased costs and downtime.

The Solution: Prioritize materials that are specifically designed to withstand the rigors of laboratory environments. When sourcing lab benchtops, consider options made from phenolic resin, stainless steel, or epoxy resin, all known for their durability and chemical resistance. Request detailed specifications and certifications from suppliers to ensure the materials meet industry standards. Additionally, inquire about maintenance requirements and warranties to protect your investment. Implementing a preventive maintenance schedule can also extend the lifespan of your benchtops, helping to minimize the likelihood of needing replacements due to damage.

Scenario 3: Compliance with Safety and Regulatory Standards

The Problem: Compliance with safety and regulatory standards is a pressing concern for buyers of lab benchtops. Different regions and industries have specific regulations regarding material safety, fire resistance, and environmental impact. Buyers may find it challenging to navigate these regulations, risking non-compliance, which can lead to fines or operational shutdowns.

The Solution: To ensure compliance, start by familiarizing yourself with local and international regulations that apply to your laboratory setting. Consult with regulatory bodies or industry experts to understand the necessary standards. When selecting lab benchtops, choose products that are certified by recognized organizations, such as ASTM or ISO. Suppliers should provide documentation that verifies compliance with these standards. Additionally, consider investing in lab benchtops that are designed with safety features, such as rounded edges or integrated storage solutions, which can enhance overall safety in the laboratory environment. Establishing a clear line of communication with suppliers can facilitate understanding of compliance issues, ensuring that your laboratory remains within regulatory guidelines.

Strategic Material Selection Guide for lab benchtop

What Are the Key Properties of Common Lab Benchtop Materials?

When selecting materials for lab benchtops, several factors must be considered to ensure optimal performance and compliance with industry standards. Here, we analyze four commonly used materials: Phenolic Resin, Stainless Steel, Laminate, and Epoxy Resin. Each material has unique properties that influence its suitability for various laboratory applications.

How Does Phenolic Resin Perform in Laboratory Settings?

Phenolic resin is a popular choice for lab benchtops due to its excellent chemical resistance and durability. It can withstand high temperatures (up to 180°C) and is resistant to most acids and bases. This makes it suitable for environments where harsh chemicals are used.

Pros: Phenolic resin is highly durable, easy to clean, and resistant to moisture and stains. Its non-porous surface prevents bacterial growth, making it ideal for sterile environments.

Cons: The main drawback is its relatively high cost compared to other materials. Additionally, while it is durable, it can be prone to chipping if subjected to heavy impacts.

Impact on Application: Phenolic resin is particularly well-suited for chemical laboratories where spills are common. Its compatibility with a wide range of media makes it a versatile choice.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers from regions like Africa and the Middle East should ensure that the material meets local regulations regarding chemical safety.

What Advantages Does Stainless Steel Offer for Lab Benchtops?

Stainless steel is renowned for its strength and resistance to corrosion, making it a staple in laboratory settings. It can handle high temperatures and is easy to sterilize, which is crucial in environments where hygiene is paramount.

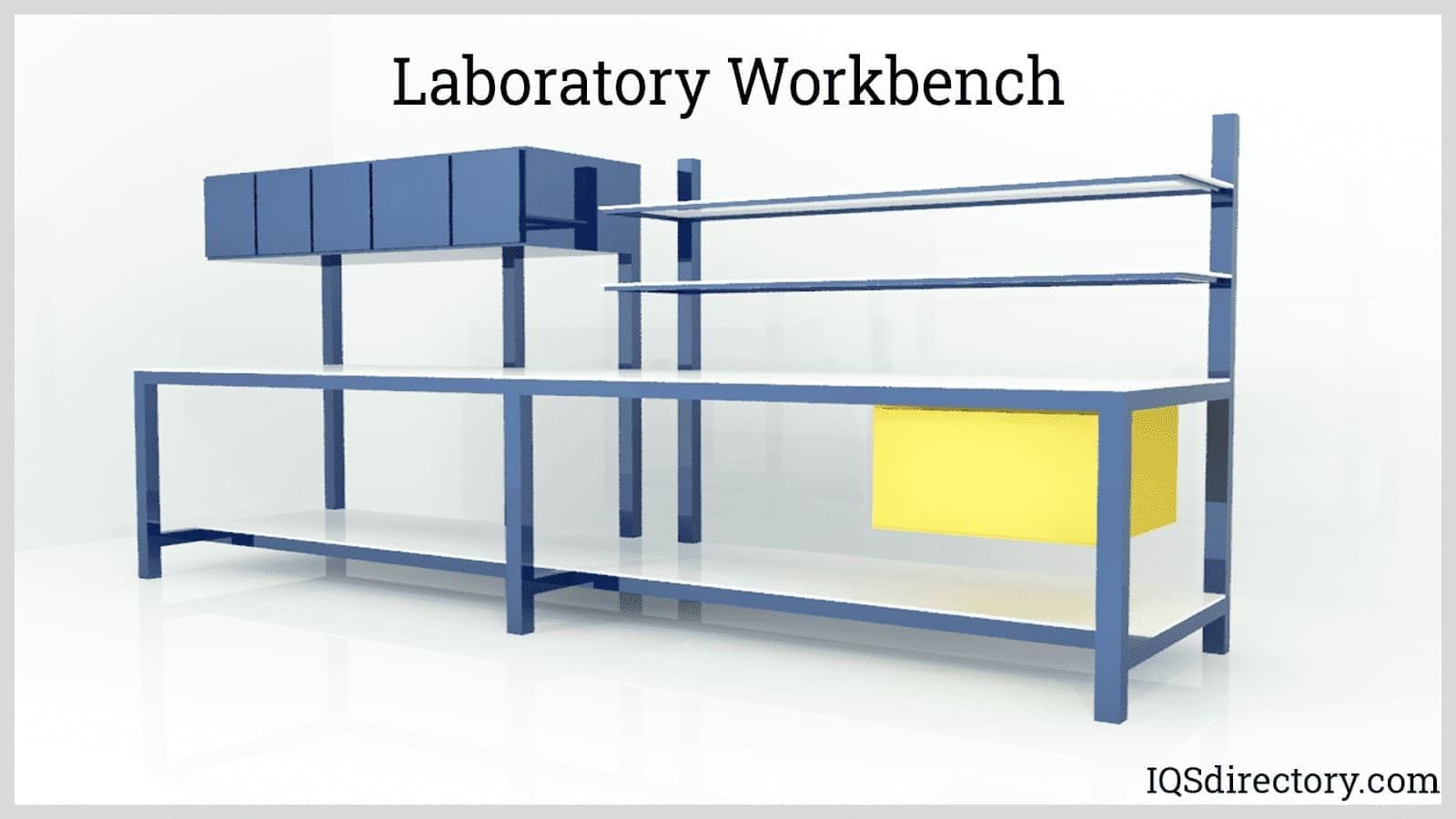

Illustrative image related to lab benchtop

Pros: Its durability and resistance to rust and corrosion make it a long-lasting option. Stainless steel also has a sleek, modern appearance that enhances the aesthetics of any lab.

Cons: The primary disadvantage is its cost, which can be higher than other materials. Additionally, stainless steel can be prone to scratching and denting, which may affect its appearance over time.

Impact on Application: Stainless steel is ideal for laboratories that require high levels of cleanliness, such as pharmaceutical and food testing labs. Its compatibility with a variety of chemicals further enhances its utility.

Considerations for International Buyers: Buyers should be aware of the different grades of stainless steel (e.g., 304 vs. 316) and their respective corrosion resistance properties. Compliance with health and safety standards is also critical.

How Does Laminate Compare as a Lab Benchtop Material?

Laminate surfaces are often used for lab benchtops due to their affordability and versatility. They are available in various colors and finishes, allowing for customization.

Pros: Laminate is cost-effective and easy to install. It offers a wide range of aesthetic options and is relatively easy to clean.

Cons: However, laminate is less durable than other materials and can be damaged by heat and chemicals. It is not suitable for environments with high exposure to solvents or extreme temperatures.

Impact on Application: Laminate is best suited for educational labs or environments where cost is a primary concern. It is not recommended for heavy-duty applications.

Considerations for International Buyers: Buyers should ensure that the laminate meets local fire safety regulations and consider the environmental impact of the materials used in production.

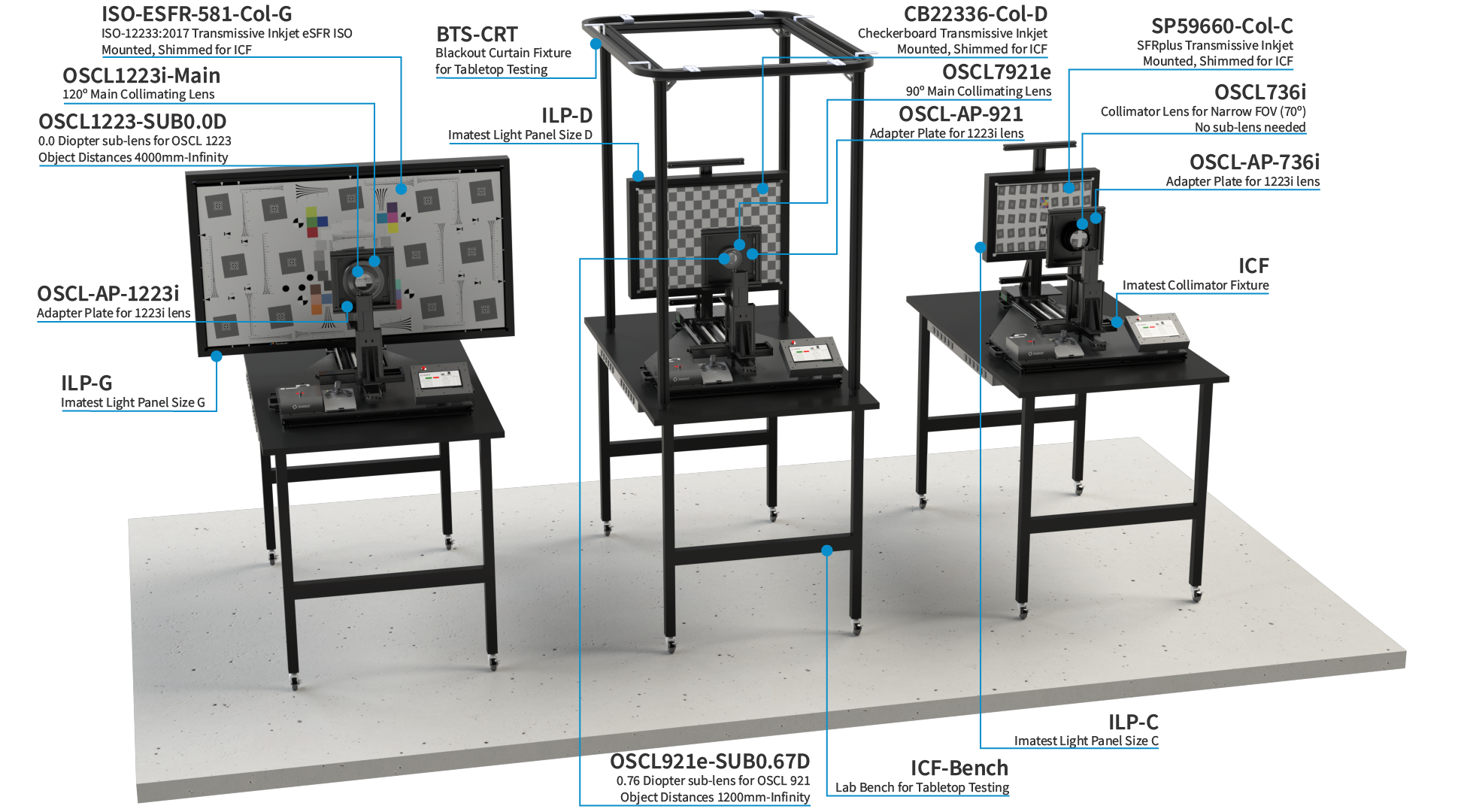

Illustrative image related to lab benchtop

What Are the Benefits of Epoxy Resin for Lab Benchtops?

Epoxy resin is another durable option that offers excellent chemical resistance and can handle high temperatures. It is often used in labs that require a high degree of cleanliness.

Pros: Epoxy resin is highly resistant to chemicals and can be molded into various shapes, providing flexibility in design. Its seamless surface minimizes the risk of contamination.

Cons: The main limitation is its cost, which can be higher than laminate. Additionally, installation can be complex, requiring skilled labor.

Impact on Application: Epoxy resin is ideal for laboratories that deal with hazardous materials or require a sterile environment.

Considerations for International Buyers: Compliance with local regulations regarding chemical exposure and safety is essential. Buyers should also consider the availability of skilled labor for installation.

Summary Table of Lab Benchtop Materials

| Material | Typical Use Case for lab benchtop | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Phenolic Resin | Chemical laboratories | Excellent chemical resistance | Higher cost, prone to chipping | High |

| Stainless Steel | Pharmaceutical and food testing labs | Durable and easy to sterilize | Higher cost, scratches easily | High |

| Laminate | Educational labs | Cost-effective and customizable | Less durable, heat-sensitive | Low |

| Epoxy Resin | Labs requiring high cleanliness | Excellent chemical resistance | Higher cost, complex installation | High |

This guide provides a comprehensive overview of the strategic selection of materials for lab benchtops, enabling B2B buyers to make informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for lab benchtop

What are the Key Stages in the Manufacturing Process of Lab Benchtops?

The manufacturing process of lab benchtops involves several critical stages that ensure the final product meets the necessary specifications and quality standards. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Materials Are Commonly Used?

The first step in manufacturing lab benchtops is material preparation. Common materials include various types of wood, metal (such as stainless steel), and composite materials. Each material offers distinct advantages, such as corrosion resistance and durability. For instance, stainless steel is favored for its easy maintenance and resistance to chemical spills, while phenolic resin is often used for its robustness and heat resistance. Proper sourcing of these materials is essential; suppliers should provide certifications to guarantee the quality and suitability of the materials used.

How Are Lab Benchtops Formed and Assembled?

Following material preparation, the next stage is forming. This includes cutting, shaping, and machining the materials into the required dimensions. Advanced techniques such as CNC (Computer Numerical Control) machining are commonly employed to ensure precision and consistency.

Illustrative image related to lab benchtop

Once the individual components are formed, they are assembled. This stage may involve welding, bolting, or using adhesives, depending on the materials and design of the benchtop. Quality during assembly is crucial, as any misalignment or poor joining can compromise the structural integrity and usability of the product.

What Finishing Techniques Are Applied?

The finishing stage enhances the benchtop’s aesthetic appeal and functional characteristics. Common finishing techniques include painting, laminating, and applying protective coatings. For instance, applying a laminate can provide an additional layer of protection against scratches and chemicals, while powder coating metal surfaces can improve corrosion resistance. Each finishing method has implications for both appearance and long-term durability, making it a critical consideration for buyers.

How is Quality Assurance Implemented in Lab Benchtop Manufacturing?

Quality assurance (QA) is vital in the manufacturing of lab benchtops to ensure that products meet both international and industry-specific standards.

What International Standards Should B2B Buyers Look For?

B2B buyers should be aware of relevant international standards such as ISO 9001, which establishes criteria for a quality management system. Compliance with these standards indicates that the manufacturer has a systematic approach to managing quality and can consistently provide products that meet customer and regulatory requirements. Additionally, CE marking is often required in Europe, indicating that the product complies with EU safety, health, and environmental protection standards.

How Are Quality Control Checkpoints Structured?

Quality control (QC) checkpoints are established at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specifications. Materials that fail to meet standards are either rejected or returned to the supplier.

-

In-Process Quality Control (IPQC): During manufacturing, periodic checks are conducted to monitor the production process. This ensures that any deviations from quality standards are identified and rectified promptly.

-

Final Quality Control (FQC): Once production is complete, a thorough inspection of the finished product is carried out. This includes dimensional checks, surface finish evaluations, and functional testing.

Common testing methods include mechanical testing for strength and durability, chemical resistance testing, and environmental simulations to assess performance under various conditions.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

Verifying a supplier’s quality assurance practices is crucial for B2B buyers, particularly in international markets. Here are some actionable steps to ensure supplier reliability:

What Auditing Processes Should Be Employed?

Buyers should conduct regular audits of potential suppliers to assess their manufacturing processes and quality control systems. These audits can be performed in-house or through third-party organizations that specialize in quality assessments. During an audit, buyers should evaluate documentation related to production processes, quality control measures, and compliance with international standards.

How Can Reports and Certifications Be Used for Verification?

Requesting detailed QC reports and certifications can provide insights into a supplier’s commitment to quality. Buyers should look for documentation that outlines the results of quality tests, compliance with standards like ISO 9001, and any relevant industry-specific certifications. This documentation not only verifies adherence to quality standards but also builds trust in the supplier’s capabilities.

Illustrative image related to lab benchtop

What Role Do Third-Party Inspections Play in Quality Assurance?

Third-party inspections serve as an additional layer of assurance for buyers. Engaging an independent inspection agency to review the manufacturing process, materials, and final products can provide unbiased verification of quality claims. This is especially important for international buyers who may face challenges in assessing suppliers located in different regions.

What Are the Nuances of Quality Control for International Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control when sourcing lab benchtops internationally.

How Do Local Regulations Affect Quality Standards?

Different regions may have unique regulations and standards that impact quality assurance. For example, buyers in Europe must comply with CE regulations, while those in the Middle East may need to adhere to local safety standards. Understanding these regional requirements is essential for ensuring compliance and avoiding potential legal issues.

What Challenges Might Buyers Face in Quality Verification?

International buyers may encounter challenges related to language barriers, differences in business practices, and varying levels of supplier transparency. To mitigate these risks, establishing clear communication channels and setting expectations upfront can help ensure a smoother procurement process. Additionally, utilizing local representatives or consultants can facilitate better engagement with suppliers and enhance quality assurance efforts.

Illustrative image related to lab benchtop

By understanding the manufacturing processes and quality assurance standards relevant to lab benchtops, B2B buyers can make informed decisions that align with their operational needs and compliance requirements, ultimately leading to successful procurement outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lab benchtop’

Introduction

Sourcing lab benchtops is a critical undertaking for businesses aiming to equip their laboratories with functional, durable, and safe workspaces. This guide outlines essential steps to help B2B buyers effectively navigate the procurement process, ensuring they select the right benchtop solutions that meet their specific laboratory needs.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clearly outline the technical requirements of your lab benchtops. Consider factors such as size, material, load-bearing capacity, and resistance to chemicals or corrosion. Understanding your specifications ensures that you select benches that can withstand the demands of your specific applications, enhancing safety and efficiency in your lab environment.

Step 2: Assess Regulatory Compliance Needs

Ensure that the lab benchtops you are considering meet relevant industry regulations and standards. Depending on your location, this may include certifications for safety, environmental impact, and material safety. Compliance is crucial not only for legal reasons but also for maintaining a safe working environment and ensuring the longevity of your equipment.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to determine their reliability and product quality. Request detailed company profiles, product catalogs, and references from businesses in similar sectors. Look for suppliers with a proven track record of successful deliveries and customer satisfaction, as this can significantly impact your lab’s operational efficiency.

Illustrative image related to lab benchtop

- Tip: Consider suppliers with local representatives or support, especially if you are in regions like Africa or South America where logistics can be challenging.

Step 4: Request Samples or Demonstrations

Whenever possible, request samples or arrange for demonstrations of the lab benchtops. This allows you to assess the quality, durability, and suitability of the products firsthand. Observing the benchtops in action can provide insights into how they will perform in your specific laboratory conditions.

Step 5: Compare Pricing and Value

Collect and compare pricing from multiple suppliers, but don’t make decisions based solely on cost. Evaluate the overall value, including warranty options, service agreements, and the quality of materials used. A slightly higher upfront cost may be justified if it leads to greater durability and reduced replacement needs in the long term.

Step 6: Consider Customization Options

Assess whether you need custom solutions for your lab benchtops. Customization can be crucial for maximizing space and functionality in specialized laboratory environments. Discuss potential modifications with suppliers to ensure that you can achieve the optimal layout and features that align with your operational requirements.

Step 7: Finalize Logistics and Support Agreements

Once you have selected your supplier, finalize logistics, including delivery timelines and installation services. Ensure that your agreement includes post-purchase support, such as maintenance services and warranty coverage. A reliable support structure is essential for minimizing downtime and addressing any issues that may arise after installation.

By following these steps, B2B buyers can make informed decisions when sourcing lab benchtops, ensuring they invest in durable, compliant, and functional solutions that support their laboratory operations effectively.

Comprehensive Cost and Pricing Analysis for lab benchtop Sourcing

What Are the Key Cost Components in Lab Benchtop Sourcing?

When sourcing lab benchtops, understanding the cost structure is vital for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials directly impacts the cost. Options range from standard laminates to high-grade stainless steel and phenolic resin, each with varying costs. Corrosion-resistant and durable materials may command a premium but offer longevity and reduced maintenance costs.

-

Labor: Labor costs vary significantly based on geographical location and the complexity of manufacturing processes. Skilled labor in regions like Europe may be more expensive than in South America or Africa, influencing overall pricing.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient production processes can help mitigate these costs.

-

Tooling: The initial setup for manufacturing, including molds and machinery, can be a significant upfront investment. Custom designs may require additional tooling, impacting the overall cost.

-

Quality Control (QC): Ensuring compliance with safety and performance standards incurs costs. Rigorous QC processes are essential, especially for international buyers who require certifications.

-

Logistics: Shipping and handling costs can vary widely based on distance, shipping method, and freight terms. Incoterms play a crucial role in defining who bears these costs.

-

Margin: Suppliers typically apply a profit margin to cover their risks and ensure sustainability. This margin can vary based on market competition and supplier reputation.

How Do Price Influencers Impact Lab Benchtop Costs?

Several factors can influence the pricing of lab benchtops:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs due to economies of scale. Understanding the MOQ can help buyers negotiate better pricing.

-

Specifications and Customization: Customized designs or specific features can significantly increase costs. Buyers should assess whether these customizations are necessary for their applications.

-

Materials and Quality Certifications: Higher quality materials or specific certifications (e.g., ISO, ANSI) can raise costs but ensure compliance with industry standards, which is critical for laboratory environments.

-

Supplier Factors: The reliability and reputation of suppliers can affect pricing. Established suppliers with a track record of quality may charge more but offer greater assurance in terms of product performance and service.

-

Incoterms: The choice of shipping terms (e.g., FOB, CIF) can greatly affect total costs. Understanding these terms helps buyers anticipate additional charges, including duties and taxes.

What Are the Best Practices for Negotiating Lab Benchtop Prices?

B2B buyers can adopt several strategies to enhance cost-efficiency in lab benchtop sourcing:

-

Leverage Volume Discounts: By consolidating orders or collaborating with other buyers, you can achieve better pricing through bulk purchasing.

-

Assess Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, operational costs, and potential downtime. Investing in higher-quality benches may save money over time.

-

Conduct Market Research: Understanding the market landscape and competitor pricing can strengthen your negotiation position. This includes exploring alternative suppliers or materials that meet your specifications.

-

Be Clear About Specifications: Providing detailed specifications can reduce misunderstandings and potential cost overruns. Ensure that suppliers understand your exact needs to avoid unnecessary charges.

-

Understand Pricing Nuances for International Transactions: Factors such as currency fluctuations, import duties, and local regulations can affect pricing for international buyers, especially in regions like Africa and the Middle East. Being aware of these can help you plan and budget more effectively.

Conclusion

Sourcing lab benchtops involves a complex interplay of cost components and pricing influencers. By understanding these factors and employing strategic negotiation techniques, international B2B buyers can optimize their purchasing decisions and achieve cost-effective solutions tailored to their laboratory needs. Always remember to request indicative prices and be prepared for fluctuations based on market conditions and supplier negotiations.

Alternatives Analysis: Comparing lab benchtop With Other Solutions

When considering laboratory setups, selecting the right workspace is crucial for efficiency and safety. While lab benchtops are a popular choice for their versatility, there are alternative solutions that may better suit specific operational needs. This section provides a detailed comparison of lab benchtops with two viable alternatives: mobile lab tables and modular laboratory systems.

| Comparison Aspect | Lab Benchtop | Mobile Lab Table | Modular Laboratory System |

|---|---|---|---|

| Performance | High durability, designed for various lab tasks | Moderate, suitable for flexible work environments | High, customizable layouts for diverse applications |

| Cost | Moderate to high, depending on materials | Generally lower, depending on features | Higher initial investment, but long-term savings possible |

| Ease of Implementation | Requires assembly and setup | Quick setup, often requires minimal assembly | Complex installation, may require professional help |

| Maintenance | Low, easy to clean and maintain | Low, typically lightweight and portable | Moderate, depends on modular components used |

| Best Use Case | Ideal for static lab environments | Excellent for mobile labs or changing project needs | Suitable for dynamic lab environments with changing needs |

What are the Pros and Cons of Using Mobile Lab Tables?

Mobile lab tables offer significant flexibility and are designed for environments where space and function may need to change frequently. Their lightweight construction allows for easy relocation, making them ideal for temporary projects or educational settings. However, their performance may be limited compared to a fixed lab benchtop, which is engineered for heavier tasks. Additionally, while they are generally more affordable, the cost can increase with added features such as advanced materials or adjustable heights.

How Do Modular Laboratory Systems Compare?

Modular laboratory systems provide a highly customizable solution, allowing organizations to design their workspace according to specific needs. They can be adapted to accommodate various equipment, workflows, and personnel, making them suitable for research labs or production environments. However, the complexity of installation can pose challenges, often requiring professional services to ensure a functional layout. Although the upfront costs are higher, the potential for reconfiguration can lead to long-term savings and efficiency gains.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting between lab benchtops and alternative solutions, B2B buyers should assess their specific operational requirements, budget constraints, and the nature of their laboratory work. If stability and durability are paramount, a lab benchtop may be the best choice. For environments that demand flexibility, mobile lab tables can provide the necessary adaptability. Conversely, for organizations anticipating growth or changes in their operations, investing in a modular laboratory system might yield the best long-term results. Each option has its advantages and considerations, and understanding these can help buyers make informed decisions that align with their strategic objectives.

Essential Technical Properties and Trade Terminology for lab benchtop

What Are the Key Technical Properties of Lab Benchtops?

In the laboratory setting, the selection of benchtops is critical for ensuring safety, efficiency, and reliability. Here are some essential technical properties that B2B buyers should consider:

-

Material Grade: The material of the benchtop is paramount. Common materials include stainless steel, phenolic resin, and epoxy resin. Stainless steel offers corrosion resistance and durability, making it suitable for chemical handling. Phenolic resin provides a non-porous surface that resists stains and chemicals, ideal for biological labs. Understanding material grade helps ensure that the benchtop can withstand specific laboratory conditions.

-

Load-Bearing Capacity: This specification defines the maximum weight that a benchtop can support. For instance, heavy-duty lab tables can often bear weights up to 2,000 lbs (approximately 907 kg). Knowing the load-bearing capacity is essential for ensuring that the benchtop can accommodate the equipment and materials used in your laboratory without risk of failure.

-

Height Adjustability: Adjustable height features allow users to modify the benchtop’s height for ergonomic benefits. This is crucial for promoting a comfortable working environment, particularly in labs where multiple users may work at the same station. Height-adjustable tables can also facilitate the use of specialized equipment that requires specific working heights.

-

Vibration Resistance: Some lab benches are designed with vibration-dampening features, especially those used in analytical labs or precision work. This property is important for ensuring the accuracy of sensitive instruments. Choosing a benchtop with vibration resistance can enhance the reliability of test results and measurements.

-

Chemical Resistance: The ability of a benchtop to resist various chemicals is vital in laboratories that handle aggressive reagents. Different materials offer varying degrees of resistance to acids, bases, and solvents. Ensuring that the benchtop material is compatible with the chemicals used in your laboratory will prevent damage and prolong the life of the furniture.

-

Surface Finish: The finish of the benchtop can affect both its aesthetic appeal and functionality. Options may include laminate, powder-coated, or polished surfaces. A proper finish not only enhances the lab’s appearance but also contributes to cleanliness and ease of maintenance.

What Are Common Trade Terms Used in Lab Benchtop Procurement?

Understanding industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of lab benchtops, buyers often interact with OEMs to source high-quality components tailored for specific laboratory needs.

-

MOQ (Minimum Order Quantity): This is the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for buyers to plan their purchases effectively, especially for large-scale laboratory setups or when procuring specialized equipment.

-

RFQ (Request for Quotation): An RFQ is a document issued by a buyer to solicit price bids from suppliers for specific products or services. In the context of lab benchtops, submitting an RFQ can help buyers obtain competitive pricing and terms from multiple vendors.

-

Incoterms: Short for International Commercial Terms, these are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps in understanding shipping costs, risk allocation, and delivery timelines when procuring lab equipment from global suppliers.

-

Lead Time: This term refers to the amount of time between placing an order and receiving it. In laboratory settings, understanding lead times for lab benchtops is crucial for project planning and ensuring timely availability of equipment for ongoing research or testing.

-

Warranty: A warranty is a guarantee provided by the manufacturer regarding the quality and performance of the benchtop. Knowing the warranty terms helps buyers assess the long-term value and reliability of their investment.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their laboratory’s operational requirements and budget constraints.

Illustrative image related to lab benchtop

Navigating Market Dynamics and Sourcing Trends in the lab benchtop Sector

What are the Key Trends Shaping the Global Lab Benchtop Market?

The global lab benchtop market is witnessing a transformative shift driven by technological advancements, heightened safety standards, and an increasing focus on customization. Key drivers include the growing demand for efficient laboratory workflows and the need for versatile workspaces that can accommodate various scientific applications. In regions such as Africa and South America, investment in laboratory infrastructure is rising, spurred by governmental initiatives and private sector growth. Meanwhile, countries in the Middle East and Europe are emphasizing the adoption of smart lab technologies, such as IoT-enabled equipment that enhances data management and operational efficiency.

Emerging trends highlight the importance of modular and adaptable lab furniture, allowing for rapid reconfiguration as research needs evolve. Additionally, the demand for mobile lab benches is on the rise, particularly in developing regions where space optimization is critical. International buyers should also be aware of the competitive landscape, which is increasingly influenced by suppliers offering comprehensive solutions that integrate furniture with laboratory equipment and consumables. As such, international sourcing strategies must consider not only product availability but also supplier reliability and service capabilities.

How is Sustainability Influencing Sourcing Decisions in the Lab Benchtop Sector?

Sustainability is becoming a cornerstone of sourcing decisions in the lab benchtop sector. The environmental impact of laboratory furniture manufacturing, including resource consumption and waste generation, is under scrutiny. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials and minimizing carbon footprints. This shift is particularly pronounced in Europe, where stringent regulations and consumer expectations drive demand for eco-friendly products.

Illustrative image related to lab benchtop

Ethical sourcing is equally critical, with a growing emphasis on transparency throughout the supply chain. Buyers are encouraged to seek out suppliers that adhere to certifications like ISO 14001 for environmental management and those that utilize materials sourced from responsibly managed forests, such as FSC-certified wood. Furthermore, suppliers offering green certifications for their products not only enhance their marketability but also resonate well with environmentally conscious organizations. By aligning sourcing strategies with sustainability goals, international buyers can enhance their brand reputation while contributing to global environmental initiatives.

What is the Historical Context of Lab Benchtop Development?

The evolution of lab benchtops can be traced back to the early 20th century when scientific advancements demanded more organized and efficient laboratory spaces. Initially, lab furniture was simplistic and functional, often made from wood and metal. As laboratories became more specialized, the need for versatile and durable workspaces led to the introduction of various materials, including phenolic resin and stainless steel, known for their chemical resistance and durability.

Over the decades, the design and functionality of lab benchtops have continued to evolve, integrating ergonomic considerations and modular designs to accommodate diverse research activities. The rise of technology, particularly in the late 20th and early 21st centuries, has further influenced this sector, leading to the development of smart lab furniture equipped with digital interfaces and connectivity options. This historical context underscores the ongoing innovation within the lab benchtop market, providing a foundation for future advancements that prioritize both functionality and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of lab benchtop

-

1. How do I choose the right lab benchtop for my laboratory needs?

Choosing the right lab benchtop involves assessing your specific laboratory tasks, available space, and the types of materials you’ll be working with. Consider the load-bearing capacity, surface material (e.g., stainless steel, phenolic resin), and resistance to chemicals or vibrations. Additionally, evaluate features like adjustability, mobility, and storage options. Engage with suppliers who can provide tailored recommendations based on your laboratory’s unique requirements. -

2. What are the key features to look for in a lab benchtop?

When selecting a lab benchtop, prioritize features such as durability, ease of cleaning, and chemical resistance. Adjustable height options can enhance ergonomics, while mobile units offer flexibility for various lab configurations. Look for corrosion-resistant finishes and sturdy construction to ensure long-term performance. Additionally, consider integrated storage solutions to maximize workspace efficiency. -

3. What are the typical lead times for lab benchtop orders?

Lead times for lab benchtops can vary significantly based on factors such as customization, supplier location, and order volume. Standard products may have shorter lead times (2-4 weeks), while customized solutions can take 6-12 weeks or longer. Always confirm lead times with your supplier during the negotiation phase to ensure your project timelines align with their production schedules. -

4. What minimum order quantities (MOQs) should I expect when sourcing lab benchtops?

Minimum order quantities for lab benchtops typically depend on the manufacturer and the specific products you’re interested in. Some suppliers may offer MOQs as low as one unit for standard items, while customized or specialized products may have higher MOQs (e.g., 5-10 units). Always clarify MOQs with potential suppliers early in the procurement process to avoid unexpected costs or delays. -

5. How can I verify the credibility of a lab benchtop supplier?

To verify a lab benchtop supplier’s credibility, conduct thorough research by checking their business credentials, customer reviews, and case studies. Look for certifications relevant to your industry, such as ISO or ASTM standards. Additionally, request references from other clients and consider visiting their facilities if possible. Engaging with third-party verification services can also provide insights into their reliability and performance history. -

6. What payment terms should I negotiate when sourcing lab benchtops internationally?

When sourcing lab benchtops internationally, negotiate payment terms that protect your interests, such as a letter of credit or escrow service for large orders. Standard terms include a deposit (20-50%) upfront, with the balance due upon delivery or inspection. Be sure to discuss currency options, payment methods (wire transfer, credit card), and any additional fees related to international transactions. -

7. How do I ensure quality assurance for lab benchtops during production?

Quality assurance can be ensured by establishing clear specifications with your supplier and requesting regular updates throughout the production process. Implementing quality control measures such as pre-shipment inspections can help verify that products meet agreed-upon standards. Additionally, consider including warranty terms that cover defects and performance issues to safeguard your investment. -

8. What logistics considerations should I keep in mind when importing lab benchtops?

When importing lab benchtops, consider factors such as shipping methods (air vs. sea), customs regulations, and potential tariffs or duties in your destination country. Collaborate with logistics partners experienced in handling laboratory equipment to streamline the shipping process. It’s also crucial to plan for potential delays due to customs clearance and ensure you have adequate insurance coverage for your shipment.

Top 4 Lab Benchtop Manufacturers & Suppliers List

1. Fisher Scientific – Laboratory Benches and Tables

Domain: fishersci.com

Registered: 1995 (30 years)

Introduction: Laboratory benches and tables designed for safe laboratory tasks and handling of reagents and samples. Features include corrosion-resistant and vibration-resistant finishes, mobile units available. Color options include Almond, Amber Stain, Auburn Stain, Black, Gray, Green, Maple, Mocha Stain, Natural Maple, Oak, Silver, Teal, White, among others. Product types include various configurations of st…

2. Lab Furniture & Fume Hoods – Epoxy Resin Countertops

Domain: labfurnitureandfumehoods.com

Registered: 2014 (11 years)

Introduction: Laboratory Epoxy Resin Countertops: Investment: HIGH $$$, Appearance: Low sheen finish – black and colors, Chemical Resistance: Excellent, Heat Resistance: Excellent, Impact Resistance: Good, Moisture Resistance: Excellent, Bacteria Resistance: Excellent, Suggested Areas of Use: Excellent performance in all areas.

3. BTLab Systems – Cell Freezing System

Domain: btlabsystems.com

Registered: 2013 (12 years)

Introduction: {“products”:[{“name”:”Cell Freezing System”,”description”:”The CellHome Cell Freezing System, in combination with a -80°C freezer or dry ice locker.”,”price”:”$120.00″},{“name”:”Microplate Shaker”,”description”:”Features LED digital display. The simple and easy operation panel can accurately display.”,”price”:”$996.00″},{“name”:”Glass Beads Sterilizer, 300C Dry Heat Sterilizer”,”description”:”The …

4. TrippNT – Benchtop Workstation Products

Domain: trippnt.com

Registered: 1995 (30 years)

Introduction: Benchtop/Workstation Products:

1. pH Meter Supplies Organizer Workstation – SKU: 50039, Price: $262.95

2. Rotating Triple Shelf Organizer – SKU: 50015, Price: $253.48

3. Lab Entry Changing Station – SKU: 50193, Price: $483.88

4. Extra Large Bench Top Workstation – SKU: 50377, Price: $404.53

5. Deluxe Bench Booster Workstation – SKU: 50014, Price: $365.20

6. Extra Large Bench Top Workstation with D…

Strategic Sourcing Conclusion and Outlook for lab benchtop

As the landscape of laboratory operations continues to evolve, strategic sourcing of lab benchtops emerges as a critical factor for enhancing operational efficiency and ensuring safety. Key takeaways highlight the importance of selecting benches that are not only durable and resistant to various chemicals but also adaptable to diverse laboratory needs. By investing in high-quality, customizable solutions, international B2B buyers can optimize their laboratory environments, accommodating everything from rigorous testing to routine tasks.

Illustrative image related to lab benchtop

Moreover, the accessibility of various materials—ranging from stainless steel to phenolic resin—provides opportunities for organizations to align their lab infrastructure with specific operational requirements and budget constraints. Engaging with reputable suppliers ensures that buyers benefit from the latest innovations and compliance with safety standards, which is especially crucial in regions like Africa, South America, the Middle East, and Europe.

Looking ahead, the demand for versatile and sustainable lab furniture will only grow. Buyers are encouraged to leverage strategic sourcing not merely as a procurement function but as a means to drive innovation and improve laboratory productivity. By taking proactive steps today, organizations can build a robust foundation for future growth and adaptability in their laboratory operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.