A B2B Buyer’s Guide to Kelebek Bıçak: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for kelebek bıçak

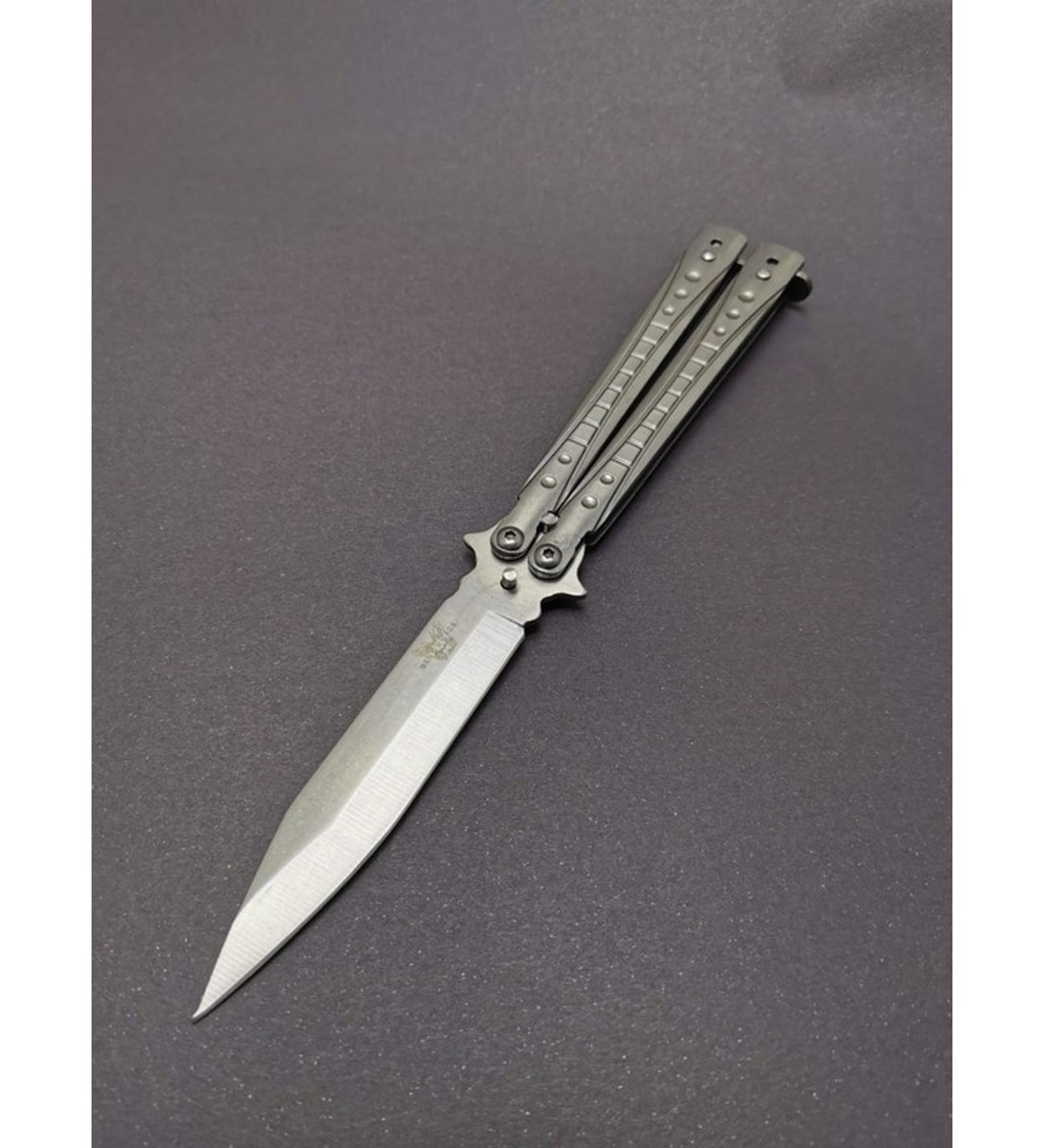

Navigating the global market for kelebek bıçak presents a unique set of challenges for B2B buyers, especially in diverse regions such as Africa, South America, the Middle East, and Europe. Sourcing high-quality butterfly knives that meet specific functional and aesthetic requirements can be daunting, given the myriad of options available. This guide aims to simplify that process, providing detailed insights into various types of kelebek bıçak, their applications, and the nuances of supplier vetting.

Buyers will find comprehensive information on pricing structures, materials used, and the latest trends influencing the market. Understanding these elements is crucial for making informed purchasing decisions that align with business needs and customer expectations. Furthermore, we will explore the significance of customer reviews and expert recommendations, which can guide buyers in selecting the best products for their target markets.

By the end of this guide, B2B buyers will be empowered with the knowledge to navigate the complexities of sourcing kelebek bıçak effectively. From understanding the competitive landscape to identifying reputable suppliers, this resource will enhance your ability to make strategic decisions that drive business success. Whether you are looking to stock your inventory or seeking unique products for niche markets, this guide serves as your roadmap to successful procurement in the butterfly knife sector.

Understanding kelebek bıçak Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Kelebek Bıçak | Traditional design, lightweight, easy to handle | Outdoor activities, everyday carry | Pros: User-friendly, versatile. Cons: Limited durability for heavy use. |

| Tactical Kelebek Bıçak | Heavy-duty construction, enhanced grip, robust materials | Military, law enforcement, survival gear | Pros: High durability, reliable performance. Cons: Heavier, may be more expensive. |

| Collector’s Edition | Unique designs, limited production, artisan craftsmanship | Collectors, gift markets | Pros: Aesthetic value, investment potential. Cons: Higher price, less practical for daily use. |

| Training Kelebek Bıçak | Blunt edge, designed for safe practice | Training facilities, self-defense classes | Pros: Safe for beginners, educational use. Cons: Not suitable for actual cutting tasks. |

| Custom Kelebek Bıçak | Tailored designs, personalized features, varied materials | Corporate gifts, personalized promotions | Pros: Unique branding opportunities, tailored to client preferences. Cons: Longer lead times for production. |

What are the Characteristics of Classic Kelebek Bıçak?

Classic Kelebek Bıçak features a traditional design that is lightweight and easy to handle, making it an excellent choice for everyday carry and outdoor activities. This type is typically made from quality stainless steel, ensuring a good balance between sharpness and durability. For B2B buyers, these knives are ideal for general use, making them popular among retailers and outdoor equipment suppliers. However, they may not withstand heavy-duty tasks, which could be a consideration for businesses requiring robust tools.

How Does a Tactical Kelebek Bıçak Stand Out?

Tactical Kelebek Bıçak is engineered for heavy-duty use, often incorporating enhanced grip and robust materials such as high-carbon steel or titanium. This design makes them suitable for military, law enforcement, and survival applications. B2B buyers in these sectors value the reliability and performance of tactical knives, especially in challenging environments. While they offer significant durability, the weight and cost may deter some buyers, particularly those seeking lightweight or budget-friendly options.

Why Choose a Collector’s Edition Kelebek Bıçak?

Collector’s Edition Kelebek Bıçak is characterized by unique designs and artisan craftsmanship, often produced in limited quantities. These knives appeal to collectors and gift markets, adding aesthetic and investment value. B2B buyers in the luxury goods sector or specialty shops can benefit from offering these exclusive items. However, their higher price point and less practical use for daily tasks may limit their appeal for businesses focused on functionality over aesthetics.

What is the Purpose of a Training Kelebek Bıçak?

Training Kelebek Bıçak is designed with a blunt edge for safe practice, making it suitable for training facilities and self-defense classes. These knives allow beginners to learn techniques without the risk of injury, making them an essential tool in educational environments. B2B buyers in the education and training sectors will find these knives beneficial for safety and instructional purposes. However, their lack of cutting capability means they are not suitable for practical applications outside of training.

How Can Custom Kelebek Bıçak Enhance Brand Identity?

Custom Kelebek Bıçak offers tailored designs and personalized features, allowing businesses to create unique branding opportunities. These knives can be used as corporate gifts or promotional items, appealing to clients seeking distinctive products. B2B buyers in marketing and corporate gifting can leverage this opportunity to enhance brand identity. However, the production time and potential costs associated with customization may be a consideration for businesses with tight budgets or timelines.

Key Industrial Applications of kelebek bıçak

| Industry/Sector | Specific Application of kelebek bıçak | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Outdoor Recreation | Camping and Survival Gear | Enhanced safety and efficiency in outdoor activities | Durability, weight, and ease of use for portability |

| Culinary Arts | Professional Chef Tools | Precision cutting and versatility in food preparation | Quality of materials, ergonomics, and design aesthetics |

| Manufacturing and Assembly | Tool for Precision Tasks in Production Lines | Increased productivity and reduced downtime | Material specifications, compliance with safety standards |

| Collectibles and Hobbies | Limited Edition Collector’s Items | High resale value and appeal to niche markets | Authenticity, craftsmanship, and limited availability |

| Security and Defense | Tactical Tools for Law Enforcement and Military Use | Reliability and effectiveness in critical situations | Compliance with regulations, durability, and functionality |

How is Kelebek Bıçak Used in Outdoor Recreation?

In the outdoor recreation sector, kelebek bıçak is widely used as a reliable tool for camping, hiking, and survival situations. Its design allows for quick deployment and ease of handling, making it suitable for various tasks such as food preparation, cutting ropes, or performing emergency repairs. For international buyers, especially in regions like Africa and South America, sourcing durable and lightweight options is essential to ensure they withstand harsh environments while remaining portable. Buyers should also consider ergonomic designs that enhance user comfort during extended use.

What Role Does Kelebek Bıçak Play in Culinary Arts?

In culinary arts, kelebek bıçak serves as a versatile tool for chefs, offering precision cutting capabilities for various ingredients. Its unique design allows for swift and efficient slicing, dicing, and chopping, which can be crucial in fast-paced kitchen environments. For B2B buyers in Europe and the Middle East, prioritizing high-quality materials that ensure longevity and sharpness is vital. Additionally, aesthetics play a role in the culinary sector, as chefs often prefer tools that complement their kitchen’s design and enhance their professional image.

How is Kelebek Bıçak Applied in Manufacturing and Assembly?

Within manufacturing and assembly industries, kelebek bıçak is utilized for precision tasks that require accuracy and reliability. It can be used for cutting materials, assembling components, or making quick adjustments on the production line. Businesses benefit from increased productivity and reduced downtime when using these tools, making them valuable assets in fast-paced environments. B2B buyers should focus on sourcing models that meet specific material and safety standards, ensuring they comply with regulations while maintaining operational efficiency.

Why are Kelebek Bıçak Important in Collectibles and Hobbies?

In the collectibles and hobbies sector, kelebek bıçak is often sought after as a limited-edition item, appealing to collectors for its craftsmanship and unique designs. The value of these knives can significantly appreciate over time, making them attractive investments. For buyers in niche markets, such as those in Brazil and Vietnam, sourcing authentic pieces with a limited availability is crucial. Ensuring the quality of craftsmanship and verifying the authenticity of the product are key considerations for buyers in this segment.

How Do Kelebek Bıçak Serve Security and Defense Needs?

In security and defense applications, kelebek bıçak is employed as a tactical tool by law enforcement and military personnel. Its quick-deploy mechanism and robust construction make it effective in high-stress situations. Reliability and functionality are paramount, as these tools must perform under pressure. B2B buyers in this sector need to consider compliance with national and international regulations, along with the durability of materials used, to ensure that the knives meet operational standards and enhance safety.

3 Common User Pain Points for ‘kelebek bıçak’ & Their Solutions

Scenario 1: Sourcing Quality Kelebek Bıçak for Retail

The Problem:

B2B buyers, especially those in the retail sector, often struggle with sourcing high-quality ‘kelebek bıçak’ that meet both aesthetic and functional standards. With a plethora of suppliers available globally, distinguishing between manufacturers that offer genuine craftsmanship and those that provide subpar products can be daunting. Retailers may find themselves overwhelmed by varying price points, quality inconsistencies, and the risk of receiving counterfeit products that could tarnish their brand reputation.

The Solution:

To mitigate these challenges, buyers should prioritize establishing relationships with verified and reputable suppliers. Conduct thorough research to identify manufacturers with a strong track record and positive reviews in the industry. Utilizing platforms that provide seller ratings, such as Trendyol or specialized B2B marketplaces, can aid in verifying seller credibility. Additionally, buyers should request samples before placing bulk orders to assess the quality firsthand. It’s also beneficial to visit trade shows or manufacturer facilities when possible, as this direct engagement can lead to better terms and a more reliable supply chain.

Scenario 2: Managing Inventory for Seasonal Demand

The Problem:

Another common pain point for B2B buyers of ‘kelebek bıçak’ is managing inventory levels in anticipation of seasonal demand fluctuations. For instance, outdoor and tactical knife sales may peak during summer and holiday seasons. Buyers often face the risk of overstocking, which ties up capital, or understocking, which can lead to missed sales opportunities and customer dissatisfaction. This challenge is exacerbated by the unpredictability of market trends and consumer preferences.

The Solution:

Implementing a data-driven inventory management system can significantly alleviate this issue. Buyers should analyze past sales data to identify trends and peak buying seasons for ‘kelebek bıçak’. Leveraging inventory management software that integrates with sales platforms can help in forecasting demand more accurately. Additionally, establishing flexible agreements with suppliers for quick replenishment can provide a buffer against sudden increases in demand without the burden of holding excessive stock. Regularly reviewing and adjusting inventory levels based on real-time sales analytics will ensure that stock aligns with market needs.

Scenario 3: Navigating Import Regulations and Compliance

The Problem:

B2B buyers dealing with ‘kelebek bıçak’ often face the complex landscape of import regulations and compliance issues. Different countries have varying rules regarding the importation of knives, which can include restrictions on blade length, design, and materials used. This complexity can lead to delays in shipping, unexpected tariffs, or even confiscation of goods at customs, creating significant headaches for importers.

The Solution:

To navigate these regulatory challenges effectively, buyers should invest time in understanding the specific import regulations of their target markets. Engaging with a customs broker who specializes in knife imports can provide invaluable insights and help streamline the import process. Buyers should also familiarize themselves with the documentation required for compliance, such as product safety certificates and customs declarations. Keeping abreast of changes in regulations by subscribing to industry newsletters or joining trade associations can further help in avoiding compliance pitfalls and ensuring smooth transactions.

Strategic Material Selection Guide for kelebek bıçak

What Are the Key Materials Used in Kelebek Bıçak Manufacturing?

When selecting materials for kelebek bıçak, several factors come into play, including performance characteristics, cost, and regional preferences. Below, we analyze four common materials used in the production of these knives, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, making it suitable for various environments, including humid or wet conditions. It typically withstands temperatures up to 800°C and is robust against wear and tear.

Illustrative image related to kelebek bıçak

Pros & Cons:

The primary advantage of stainless steel is its durability and resistance to rust, which prolongs the knife’s lifespan. However, it can be more expensive than other materials and may require more complex manufacturing processes, which can increase production costs.

Impact on Application:

Stainless steel is compatible with various media, including food and outdoor environments. This makes it a preferred choice for both culinary and tactical applications.

Considerations for International Buyers:

Buyers from regions like Europe may expect compliance with specific standards such as ASTM or DIN for stainless steel grades. Understanding local regulations regarding food safety and materials is crucial, especially in the food service industry.

Illustrative image related to kelebek bıçak

2. Carbon Steel

Key Properties:

Carbon steel is renowned for its superior edge retention and sharpness. It can handle high pressure and temperature variations but is less resistant to corrosion compared to stainless steel.

Pros & Cons:

The main advantage of carbon steel is its ability to achieve a razor-sharp edge, making it ideal for precision cutting tasks. However, it is prone to rust if not properly maintained, which can deter some users.

Impact on Application:

Carbon steel is particularly suitable for applications where sharpness is critical, such as culinary knives. However, it may not be the best choice for environments exposed to moisture.

Considerations for International Buyers:

In regions with high humidity, such as parts of Africa and South America, buyers should consider the maintenance requirements of carbon steel. Compliance with local standards for knife manufacturing and safety is also essential.

3. Titanium

Key Properties:

Titanium is lightweight yet incredibly strong, with excellent corrosion resistance. It can withstand extreme temperatures and is non-reactive, making it suitable for various applications.

Illustrative image related to kelebek bıçak

Pros & Cons:

The primary advantage of titanium is its strength-to-weight ratio, making it an excellent choice for portable knives. However, it is generally more expensive and can be challenging to machine, which may increase manufacturing complexity.

Impact on Application:

Titanium is ideal for outdoor and tactical applications where weight is a concern, such as camping and survival knives. Its non-reactive nature also makes it suitable for food-related uses.

Considerations for International Buyers:

Buyers in Europe and the Middle East may prefer titanium for its lightweight properties, especially in outdoor gear. Understanding the material’s compliance with international standards is vital for ensuring product quality.

Illustrative image related to kelebek bıçak

4. G10 Composite

Key Properties:

G10 is a high-pressure fiberglass laminate that is lightweight, durable, and resistant to moisture and chemicals. It can withstand high temperatures and is often used for knife handles.

Pros & Cons:

The key advantage of G10 is its excellent grip and ergonomic properties, making it comfortable for extended use. However, it may not be as aesthetically pleasing as natural materials, which could be a drawback for collectors.

Impact on Application:

G10 is particularly suitable for tactical and outdoor knives, providing a secure grip even in wet conditions. Its durability makes it a popular choice for heavy-use applications.

Illustrative image related to kelebek bıçak

Considerations for International Buyers:

Buyers from regions like South America and Africa may appreciate G10 for its practical benefits in outdoor environments. Awareness of local preferences for handle materials can influence purchasing decisions.

Summary Table of Material Selection for Kelebek Bıçak

| Material | Typical Use Case for kelebek bıçak | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Culinary and tactical applications | Excellent corrosion resistance | Higher cost, complex manufacturing | Medium |

| Carbon Steel | Precision cutting, culinary knives | Superior edge retention | Prone to rust, requires maintenance | Medium |

| Titanium | Outdoor and tactical knives | Lightweight and strong | High cost, challenging to machine | High |

| G10 Composite | Tactical and outdoor knives | Excellent grip and durability | Less aesthetic appeal | Medium |

This analysis provides B2B buyers with essential insights into material selection for kelebek bıçak, enabling informed purchasing decisions tailored to their specific needs and regional preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for kelebek bıçak

What Are the Key Stages in the Manufacturing Process of Kelebek Bıçak?

The manufacturing of kelebek bıçak, or butterfly knives, involves several critical stages that ensure both functionality and quality. Each stage is meticulously designed to cater to the specific characteristics of these knives, which are valued for their aesthetic and practical features.

Material Preparation: How Are Raw Materials Selected and Processed?

The process begins with the selection of high-quality materials, typically stainless steel, titanium, or high-carbon steel. These materials are chosen for their durability, corrosion resistance, and ability to maintain a sharp edge. Once selected, the materials undergo several preparatory steps, including cutting and heat treatment. The heat treatment process is crucial as it affects the hardness and flexibility of the blade, ensuring that it can withstand rigorous use without breaking.

Illustrative image related to kelebek bıçak

Forming: What Techniques Are Used to Shape Kelebek Bıçak?

The forming stage involves shaping the blade and handles using techniques such as forging or CNC machining. Forging is often preferred for high-end models as it creates a stronger blade through the alignment of the metal’s crystalline structure. CNC machining offers precision and consistency, allowing for complex designs and ergonomic shapes. This stage is critical in achieving the desired balance and weight distribution that users expect from a high-quality kelebek bıçak.

Assembly: How Are the Components Put Together?

After forming, the assembly stage involves attaching the blade to the handles. This is typically achieved through a pivot system that allows for smooth opening and closing. The assembly must be precise to ensure that the knife operates safely and effectively. Additional components such as safety locks may also be integrated during this stage, enhancing user safety.

Finishing: What Are the Final Touches Applied to Kelebek Bıçak?

The finishing stage is where the knife is polished and coated. This may involve bead blasting, anodizing, or applying protective coatings to enhance aesthetic appeal and corrosion resistance. Quality control checks are integrated into this phase to ensure that the final product meets the required standards for sharpness, finish, and overall quality.

How Is Quality Assurance Maintained in Kelebek Bıçak Manufacturing?

Quality assurance is a cornerstone of the manufacturing process for kelebek bıçak. It involves rigorous checks at various stages to ensure that the final product meets both international and industry-specific standards.

What International Standards Apply to Kelebek Bıçak Production?

Manufacturers often adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards demonstrates a commitment to maintaining consistent quality throughout the manufacturing process. Additionally, certifications such as CE mark or API (American Petroleum Institute) standards may apply, particularly if the knives are intended for specific industries or uses.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint ensures that the raw materials meet specified standards before production begins.

- In-Process Quality Control (IPQC): During manufacturing, IPQC monitors production processes to identify and rectify any deviations from quality standards in real-time.

- Final Quality Control (FQC): The final inspection occurs before packaging, where knives are evaluated for sharpness, functionality, and aesthetic quality.

What Common Testing Methods Are Used to Ensure Knife Quality?

Several testing methods are employed to assess the quality of kelebek bıçak:

- Sharpness Tests: These tests measure the blade’s cutting ability using standardized materials.

- Durability Tests: These involve stress testing to evaluate the blade’s resilience under various conditions.

- Corrosion Resistance Tests: Samples may be subjected to saltwater exposure to assess how well they withstand rust and degradation.

How Can B2B Buyers Verify the Quality Control Processes of Suppliers?

B2B buyers should adopt a proactive approach to verify the quality control processes of potential suppliers.

What Steps Can Buyers Take to Conduct Supplier Audits?

-

Supplier Audits: Conducting on-site audits allows buyers to review the manufacturing processes, quality control checkpoints, and compliance with international standards. This firsthand observation is invaluable.

-

Requesting Documentation: Buyers should request quality assurance documentation, including ISO certification, test reports, and inspection records. This paperwork can provide insights into the manufacturer’s adherence to quality standards.

-

Third-Party Inspections: Engaging third-party inspection services can further validate the quality claims of suppliers. These independent assessments can uncover potential issues that may not be visible during initial reviews.

What Nuances Should International B2B Buyers Consider Regarding QC and Certification?

International B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be aware of several nuances:

-

Regulatory Compliance: Different regions may have specific regulations regarding knife manufacturing and sales. Understanding these local regulations is crucial to ensure compliance and avoid legal issues.

-

Cultural Preferences: The design and functionality of kelebek bıçak may vary based on cultural preferences and usage. Buyers should communicate these preferences to suppliers to ensure that products meet market demands.

-

Logistics and Supply Chain Considerations: Quality assurance processes can be affected by logistics and supply chain dynamics. Buyers should consider lead times, shipping conditions, and potential impacts on product quality during transportation.

By focusing on these key aspects of the manufacturing and quality assurance processes for kelebek bıçak, B2B buyers can make informed decisions and establish long-term partnerships with reliable suppliers. This approach not only enhances product quality but also supports successful market entry and growth in diverse international markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘kelebek bıçak’

To effectively source ‘kelebek bıçak’ (butterfly knives) for your business, it is essential to follow a structured approach. This checklist will guide you through the critical steps necessary to ensure that you procure high-quality products that meet your specific requirements.

Illustrative image related to kelebek bıçak

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications of the ‘kelebek bıçak’ you need. Consider factors such as blade material, size, weight, and design features. This step is vital as it helps you communicate your needs accurately to potential suppliers and ensures that the products align with your target market’s preferences.

Step 2: Research and Identify Reliable Suppliers

Conduct thorough research to identify reputable suppliers who specialize in ‘kelebek bıçak’. Utilize online marketplaces, industry directories, and trade shows to compile a list of potential vendors. Focus on suppliers with a track record of quality and reliability, as this will minimize risks associated with sourcing inferior products.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with positive reviews and a history of meeting delivery timelines and quality standards. This evaluation helps you avoid potential issues that could disrupt your supply chain.

Step 4: Verify Compliance with Regulations

Ensure that the suppliers you consider comply with international regulations and standards relevant to knife manufacturing and sales. This may include certifications for quality assurance (e.g., ISO) and adherence to safety standards. Compliance not only reflects the supplier’s commitment to quality but also protects your business from legal repercussions.

Step 5: Request Samples for Testing

Before placing a large order, request samples of the ‘kelebek bıçak’ to assess their quality firsthand. This step allows you to evaluate the materials, craftsmanship, and overall functionality of the knives. Testing the samples ensures that they meet your specifications and provides an opportunity to identify any potential issues before bulk procurement.

Step 6: Negotiate Terms and Pricing

Once you are satisfied with the samples, initiate negotiations on pricing, payment terms, and delivery schedules. Be clear about your budget and explore options for bulk discounts or long-term partnership agreements. Effective negotiation can lead to better pricing and terms that are beneficial for both parties.

Step 7: Establish a Quality Control Process

After finalizing your supplier, implement a quality control process to monitor the quality of the products upon arrival. This may involve regular inspections and assessments to ensure that the delivered knives meet your specifications and quality standards consistently. Establishing this process helps maintain product integrity and customer satisfaction.

By following this checklist, you can streamline your sourcing process for ‘kelebek bıçak’, ensuring that you partner with the right suppliers and procure high-quality products that meet your business needs.

Comprehensive Cost and Pricing Analysis for kelebek bıçak Sourcing

What Are the Key Cost Components in Kelebek Bıçak Production?

When sourcing kelebek bıçak, understanding the cost structure is crucial for accurate budgeting and decision-making. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality stainless steel, titanium, or carbon fiber can increase the price but enhance durability and performance. Specialty finishes and coatings also contribute to material costs.

-

Labor: Skilled labor is essential in the manufacturing of kelebek bıçak, particularly for intricate designs and customizations. Labor costs can vary based on geographic location, with regions offering lower wages potentially reducing overall expenses.

-

Manufacturing Overhead: This encompasses costs related to the production facility, utilities, and maintenance of machinery. Efficient manufacturing processes can lower these overhead costs, affecting the final pricing.

-

Tooling: The initial setup for production, including molds and specialized machinery, constitutes a significant upfront investment. Tooling costs are often amortized over large production runs, making them a crucial factor in pricing.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability and compliance with international standards. While this adds to costs, it is essential for maintaining reputation and reducing return rates.

-

Logistics: Transporting kelebek bıçak from the manufacturer to the buyer involves shipping, customs clearance, and handling fees. Understanding the logistics costs, especially for international shipments, is vital for accurate pricing.

-

Margin: Suppliers typically add a margin to cover risks and ensure profitability. This margin can vary widely depending on the supplier’s market positioning and the competitive landscape.

How Do Price Influencers Impact Kelebek Bıçak Sourcing?

Several factors influence the pricing of kelebek bıçak, particularly for B2B buyers:

-

Volume/MOQ: Buying in larger quantities often leads to lower per-unit costs. Manufacturers may offer discounts for bulk orders, making it advantageous for businesses looking to stock inventory.

-

Specifications and Customization: Custom designs or specific features can increase costs. Buyers should clearly outline their specifications to get accurate quotes and avoid unexpected price increases.

-

Material Choices: The selection of materials not only affects durability but also the price. Specialty materials may come at a premium but could be worth the investment for specific applications.

-

Quality Certifications: Products with certifications for quality and safety may carry higher price tags. However, these certifications can be crucial for compliance in various markets.

-

Supplier Factors: The reputation, reliability, and location of suppliers can influence pricing. Established suppliers with a track record of quality may charge more but offer peace of mind.

-

Incoterms: Understanding the shipping terms (Incoterms) is essential. They dictate who is responsible for shipping costs, insurance, and tariffs, impacting the total cost of ownership.

What Are the Best Tips for Negotiating Kelebek Bıçak Prices?

When negotiating prices for kelebek bıçak, consider the following strategies to maximize value:

-

Research and Compare: Gather quotes from multiple suppliers to understand the market rate. This information can empower you during negotiations.

-

Leverage Volume Discounts: If you plan to make repeat purchases, use this to negotiate better terms. Suppliers are often willing to reduce prices for guaranteed business.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, durability, and potential resale value. A higher upfront cost may lead to lower long-term expenses.

-

Be Transparent About Needs: Clearly communicate your requirements and budget constraints to suppliers. This transparency can facilitate better offers and foster long-term partnerships.

-

Timing Your Orders: Consider placing orders during off-peak seasons when manufacturers may be more willing to negotiate prices due to lower demand.

Disclaimer on Pricing

It’s important to note that prices for kelebek bıçak can fluctuate based on market conditions, material availability, and supplier pricing strategies. Always request updated quotes and confirm final pricing before placing orders to ensure budget accuracy.

Alternatives Analysis: Comparing kelebek bıçak With Other Solutions

Understanding the Alternatives for Kelebek Bıçak

When evaluating the ‘kelebek bıçak’ (butterfly knife), it is essential to consider alternative solutions that may offer similar functionalities or advantages. This analysis will compare the kelebek bıçak with other knife types, providing B2B buyers with insights into performance, cost, implementation, maintenance, and ideal use cases.

Comparison Table

| Comparison Aspect | Kelebek Bıçak | Fixed Blade Knife | Folding Knife |

|---|---|---|---|

| Performance | High agility and quick deployment | Superior durability and stability | Versatile with compact design |

| Cost | Moderate to high | Varies widely; can be high-end | Generally low to moderate |

| Ease of Implementation | Requires skill to use effectively | Simple; ready to use | Easy to use; user-friendly |

| Maintenance | Requires occasional sharpening | Low; minimal upkeep needed | Moderate; depends on quality |

| Best Use Case | Martial arts, tricks, display | Survival, heavy-duty tasks | Everyday carry, general utility |

Detailed Breakdown of Alternatives

Fixed Blade Knife

Fixed blade knives are known for their robustness and reliability. They typically feature a single, solid blade without any moving parts, which contributes to their durability. This design makes them ideal for heavy-duty tasks, such as outdoor survival and tactical operations. However, fixed blades can be bulkier and less versatile for everyday carry compared to the kelebek bıçak. The cost can vary significantly depending on the brand and materials used, but they often represent a solid investment for professional users seeking reliability.

Folding Knife

Folding knives offer a balance between portability and functionality. They come in various designs and sizes, making them suitable for everyday carry and general utility purposes. Their compact nature allows for easy storage, but they may not match the agility and quick deployment of a kelebek bıçak. Additionally, folding knives are generally easier to use for novice users, enhancing their appeal in consumer markets. Pricing for folding knives can be quite affordable, making them accessible for a wide range of buyers.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate knife for your business or personal needs, consider the specific use cases and the environment in which the knife will be employed. The ‘kelebek bıçak’ excels in scenarios requiring agility and trick performance but may not be the best choice for heavy-duty tasks. Fixed blade knives are ideal for durability and reliability, while folding knives provide convenience and versatility for everyday tasks. By understanding the strengths and weaknesses of each option, B2B buyers can make informed decisions that align with their operational requirements and budget considerations.

Essential Technical Properties and Trade Terminology for kelebek bıçak

What Are the Key Technical Properties of Kelebek Bıçak?

Understanding the essential technical properties of kelebek bıçak (butterfly knives) is crucial for B2B buyers, particularly when making informed purchasing decisions. Here are several critical specifications that buyers should consider:

-

Material Grade

– Kelebek bıçaklar are typically constructed from high-quality materials such as stainless steel, titanium, or carbon fiber. The grade of material impacts the knife’s durability, corrosion resistance, and overall performance. For instance, stainless steel offers a good balance between hardness and rust resistance, making it ideal for both functional and collectible knives. -

Blade Length and Thickness

– Blade length and thickness are critical specifications that affect both usability and legality. Longer blades may be preferred for tactical applications, while shorter blades are often more practical for everyday carry. The thickness influences the knife’s strength and cutting ability. Buyers should consider local regulations regarding blade dimensions to ensure compliance. -

Weight and Balance

– The weight of the kelebek bıçak affects its handling and usability. A well-balanced knife allows for better control and precision during use. Lightweight models are often favored for everyday carry, while heavier knives may appeal to collectors and enthusiasts who value heft and sturdiness. -

Locking Mechanism

– The locking mechanism is vital for safety and functionality. Various designs exist, including spring-assisted and manual locks, each offering different advantages in terms of reliability and ease of use. A robust locking mechanism ensures that the blade remains securely in place during both use and transport, which is essential for both safety and performance. -

Ergonomic Design

– Ergonomics play a significant role in user comfort and efficiency. A well-designed handle provides a secure grip, reducing the risk of slippage during use. This is particularly important for professional users or those engaging in outdoor activities where grip can be compromised by moisture or dirt. -

Finish and Aesthetics

– The finish of the kelebek bıçak can enhance its appeal, especially for collectors. Options may include polished, matte, or coated surfaces that not only add to the knife’s aesthetic but also impact its resistance to wear and corrosion. Buyers should consider how the finish aligns with their branding or customer expectations.

What Are Common Trade Terms in the Kelebek Bıçak Industry?

Familiarizing yourself with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are several common trade terms relevant to kelebek bıçak transactions:

-

OEM (Original Equipment Manufacturer)

– This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of kelebek bıçak, OEM suppliers might create custom designs or private-label knives for brands, allowing for unique product offerings in the market. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to ensure they meet supplier requirements while also managing their inventory effectively. Lower MOQs can benefit smaller businesses or those looking to test new products. -

RFQ (Request for Quotation)

– An RFQ is a document that buyers send to suppliers to request pricing and other relevant information on specific products. Including details such as specifications, quantities, and delivery timelines can help suppliers provide accurate quotes that facilitate informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping responsibilities, risk transfer, and cost allocation, which are crucial for smooth international trade. -

Lead Time

– Lead time refers to the amount of time it takes from placing an order until the product is delivered. Understanding lead times is essential for planning inventory and ensuring timely fulfillment of customer orders. -

Warranty and After-Sales Support

– These terms relate to the guarantees provided by manufacturers regarding the quality and durability of their products. Knowing the warranty terms and the level of after-sales support can help B2B buyers assess the long-term value of their investment in kelebek bıçak.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions, ensuring they select the right kelebek bıçak products that meet their specific needs and market demands.

Illustrative image related to kelebek bıçak

Navigating Market Dynamics and Sourcing Trends in the kelebek bıçak Sector

What Are the Key Market Dynamics and Trends Affecting Kelebek Bıçak Sourcing?

The global market for kelebek bıçak (butterfly knives) is shaped by a blend of traditional craftsmanship and modern manufacturing techniques. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek to diversify their product offerings, understanding current market dynamics becomes crucial. The rising demand for high-quality, durable, and aesthetically appealing knives has led to a surge in both production and sourcing opportunities. Key trends include an increased focus on customization, where buyers look for unique designs that cater to specific markets or customer preferences.

Technological advancements in manufacturing, such as CNC machining and laser cutting, have enabled manufacturers to produce intricate designs with higher precision, thus appealing to collectors and enthusiasts alike. Additionally, e-commerce platforms are emerging as vital channels for international buyers, providing access to diverse suppliers and enabling price comparisons. With the growing popularity of outdoor activities and tactical sports, the demand for functional yet stylish kelebek bıçak has also escalated, creating new opportunities for businesses to position their products effectively.

How Is Sustainability Influencing Sourcing in the Kelebek Bıçak Sector?

Sustainability is increasingly becoming a cornerstone of sourcing strategies within the kelebek bıçak sector. As environmental concerns rise, both consumers and businesses are prioritizing ethical sourcing practices. For B2B buyers, this means seeking suppliers who utilize sustainable materials, such as recycled metals and eco-friendly packaging. Companies that are transparent about their supply chain and adhere to ethical labor practices are more likely to gain a competitive edge.

Moreover, green certifications play a significant role in influencing purchasing decisions. Certifications such as ISO 14001 (Environmental Management) can reassure buyers of a supplier’s commitment to reducing environmental impact. As the market evolves, the integration of sustainability into product design—such as using biodegradable materials for handles—will likely become more prominent. Buyers who prioritize these factors can not only enhance their brand reputation but also align themselves with a growing demographic of environmentally conscious consumers.

What Is the Historical Context of Kelebek Bıçak in the B2B Market?

The kelebek bıçak has a rich history, deeply rooted in both functionality and artistry. Originally used as tools for practical purposes, these knives gained popularity in the mid-20th century as collectibles and performance items. The evolution from a simple folding knife to a symbol of craftsmanship is significant for B2B buyers today, as it illustrates the blend of utility and design that modern consumers seek.

Illustrative image related to kelebek bıçak

This historical context is crucial for businesses looking to market kelebek bıçak effectively. Understanding the heritage and traditional techniques involved in their production can enhance marketing strategies, appealing to both practical users and collectors. By emphasizing craftsmanship and the rich history of these knives, B2B buyers can differentiate their offerings in a competitive marketplace, catering to diverse consumer interests.

Frequently Asked Questions (FAQs) for B2B Buyers of kelebek bıçak

-

1. How do I ensure the quality of kelebek bıçak when sourcing internationally?

To guarantee the quality of kelebek bıçak, it’s essential to vet suppliers thoroughly. Request samples to assess craftsmanship and materials used. Look for suppliers with certifications that indicate compliance with international quality standards, such as ISO 9001. Additionally, consider visiting the manufacturing facility if possible, or using third-party inspection services to verify the production processes and material quality before placing a bulk order. -

2. What is the best kelebek bıçak for outdoor activities?

The ideal kelebek bıçak for outdoor activities should be durable, lightweight, and easy to handle. Models made from high-quality stainless steel or titanium are recommended for their corrosion resistance and sharpness retention. Look for ergonomic designs that provide a secure grip and consider features like a locking mechanism for safety. Brands known for their outdoor knives often have specialized designs that cater to camping, fishing, or hunting needs. -

3. What customization options are available for kelebek bıçak orders?

Many manufacturers offer customization options, including blade size, handle materials, and engraving services. You can request specific designs, colors, or even packaging tailored to your brand. Be sure to communicate your requirements clearly and ask for a minimum order quantity (MOQ) for custom designs, as this can vary significantly between suppliers. -

4. What are the typical minimum order quantities (MOQs) for kelebek bıçak?

MOQs for kelebek bıçak can range from as low as 50 units to several hundred, depending on the supplier and the complexity of the design. It’s advisable to clarify MOQs before engaging in negotiations. Smaller orders might incur higher per-unit costs, while larger orders can provide better pricing and terms. Always confirm the MOQ upfront to avoid unexpected costs. -

5. What payment terms should I negotiate with kelebek bıçak suppliers?

When negotiating payment terms, aim for flexibility that suits your cash flow. Common practices include a deposit upfront (typically 30-50%) with the balance due upon delivery or after inspection. Consider using secure payment methods like letters of credit or escrow services for larger transactions to mitigate risks. Always ensure that the payment terms are clearly outlined in the contract to prevent disputes later. -

6. How can I find reliable suppliers of kelebek bıçak?

To find trustworthy suppliers, start by researching online marketplaces and trade directories. Attend industry trade shows or exhibitions to connect directly with manufacturers. Utilize platforms like Alibaba or Global Sources, but ensure to read reviews and request references. Networking with industry peers can also lead to recommendations for reputable suppliers who have a proven track record in quality and reliability. -

7. What logistics considerations should I be aware of when importing kelebek bıçak?

Logistics for importing kelebek bıçak involve understanding shipping methods, customs duties, and regulations specific to your country. Choose between air freight for faster delivery or sea freight for cost savings, considering your inventory needs. Familiarize yourself with import regulations, including any restrictions on knife imports in your region, to avoid delays. Working with a logistics partner experienced in international shipping can simplify the process. -

8. How do I handle quality assurance for bulk orders of kelebek bıçak?

Implement a quality assurance (QA) plan that includes pre-production samples, in-process inspections, and final product evaluations. Specify QA standards in your purchase order to ensure alignment with your expectations. Consider hiring third-party inspection services to conduct random checks during production and before shipment. Establish clear communication channels with your supplier to address any quality concerns promptly and effectively.

Top 5 Kelebek Bıçak Manufacturers & Suppliers List

1. Trendyol – Kelebek Bıçak Modelleri

Domain: trendyol.com

Registered: 2009 (16 years)

Introduction: Kelebek bıçak modelleri, estetik ve fonksiyonel özellikleriyle dikkat çeker. Üstün işçilikle üretilen bu bıçaklar, kaliteli malzemeler kullanılarak dayanıklılık sağlanır. Fiyatları, kullanılan malzeme ve tasarım özelliklerine göre değişiklik gösterir. Kelebek bıçak çeşitleri, klasik tasarımlardan modern detaylarla süslenmiş özel üretim modellere kadar geniş bir ürün yelpazesi sunar. Kullanıcı dost…

2. Bicak Ltd – Kelebek Çakılar

Domain: bicakltd.com.tr

Registered: 2022 (3 years)

Introduction: Kelebek Çakılar: 70 adet ürün mevcut. Ürünler arasında Benchmade markalı çeşitli desenli ve temalı kelebek çakılar bulunmaktadır. Fiyat aralığı 400,00 TL ile 900,00 TL arasında değişmektedir. Ürünler arasında el yapımı, perçinli, kuru kafa desenli, ejderha desenli, ahşap kabze gibi çeşitler bulunmaktadır. Ücretsiz kargo seçeneği mevcuttur. Öne çıkan ürünler: Benchmade Gold Ejderha Desenli Kelebek …

3. Hepsiburada – Kelebek Çakları

Domain: hepsiburada.com

Registered: 2000 (25 years)

Introduction: Kelebek çakları, fiyatları -9223372036854775808₺’den başlayan modellerdir. Hepsiburada’da çeşitli kategorilerde ürünler bulunmaktadır. Elektronik, bilgisayar, telefon, beyaz eşya, ev aletleri, moda, spor, kozmetik ve daha birçok kategoride ürünler mevcuttur. Ayrıca, güvenli alışveriş, mobil uygulama ile alışveriş imkanı ve kolay iade süreçleri sunulmaktadır.

4. Pinterest – Kelebek Bıçak Panosu

Domain: tr.pinterest.com

Registered: 2009 (16 years)

Introduction: This company, Pinterest – Kelebek Bıçak Panosu, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Çiçeksepeti – Çok Fonksiyonlu Çakı

Domain: ciceksepeti.com

Registered: 2002 (23 years)

Introduction: Çok Fonksiyonlu Çakı Fiyatları – Çiçeksepeti, çeşitli markaların çok fonksiyonlu çakılarını sunmaktadır. Ürünler arasında kişiye özel tasarımlar, el yapımı çakılar ve kamp çakıları bulunmaktadır. Fiyat aralığı 199,00 TL’den başlayarak 3.248,00 TL’ye kadar çıkmaktadır. Ürünler, kesme, vidalama, kablo sıkma, tırnak kesme, balık temizleme, konserve açma gibi birçok işlev sunmaktadır. Ayrıca, ergonomi…

Strategic Sourcing Conclusion and Outlook for kelebek bıçak

In conclusion, strategic sourcing of kelebek bıçak presents a compelling opportunity for B2B buyers in diverse regions, including Africa, South America, the Middle East, and Europe. Understanding the unique characteristics and diverse offerings of kelebek bıçak can empower businesses to make informed purchasing decisions. The variety in designs, materials, and functionalities allows for tailored solutions that meet specific industry needs, whether for professional use, outdoor activities, or collector’s items.

Moreover, leveraging supplier relationships and exploring promotional opportunities can lead to significant cost savings and enhanced product quality. Engaging with established manufacturers and distributors ensures access to high-quality products that are crucial for maintaining a competitive edge in the market.

As the demand for versatile and aesthetically pleasing cutting tools continues to grow, now is the time for international buyers to capitalize on this trend. By prioritizing strategic sourcing, businesses can not only enhance their product offerings but also build lasting partnerships that drive growth. Embrace the opportunity to explore the rich landscape of kelebek bıçak and position your business for success in the evolving global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to kelebek bıçak

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.