A B2B Buyer’s Guide to Isolation Transformer Purpose: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for isolation transformer purpose

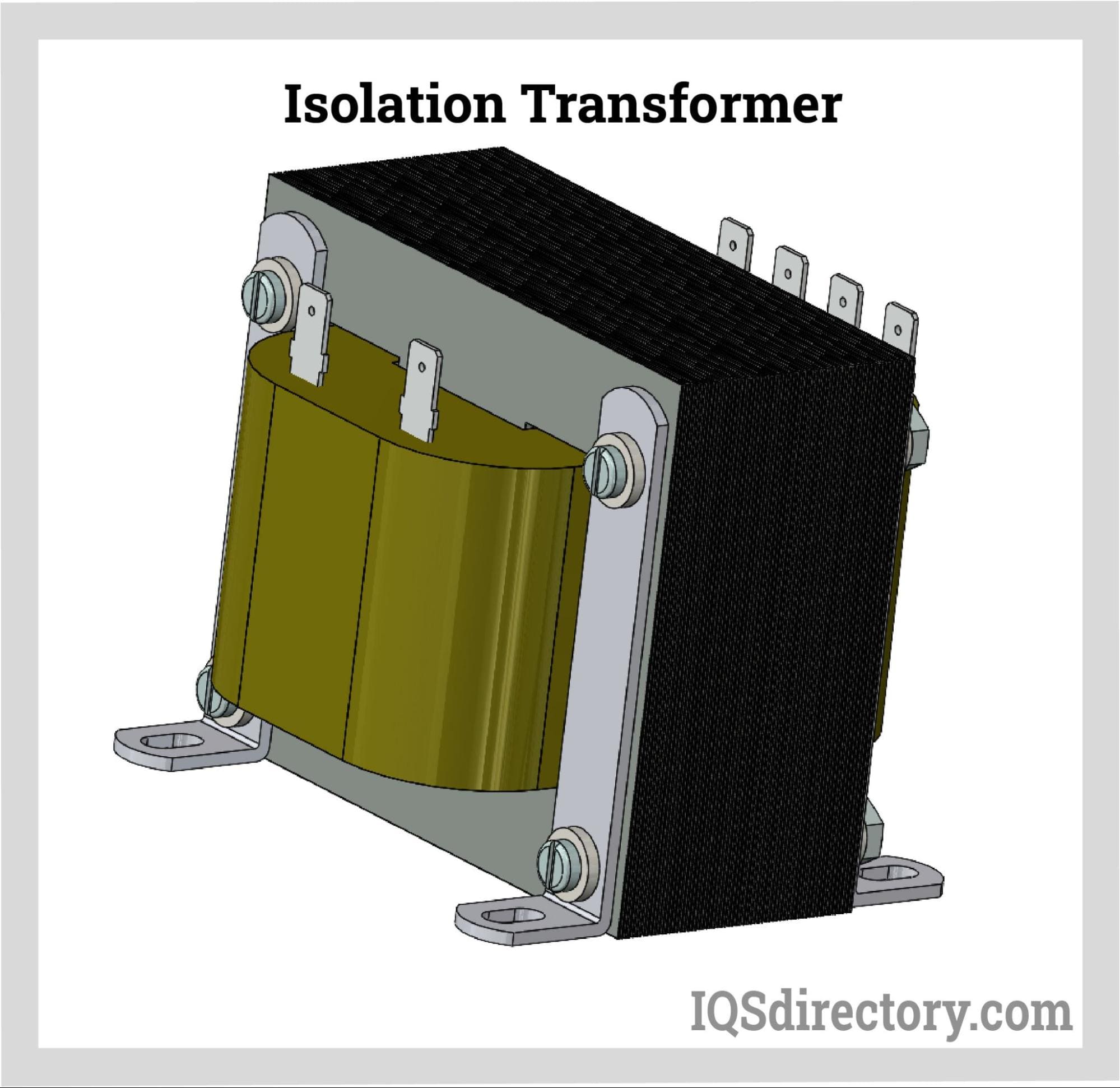

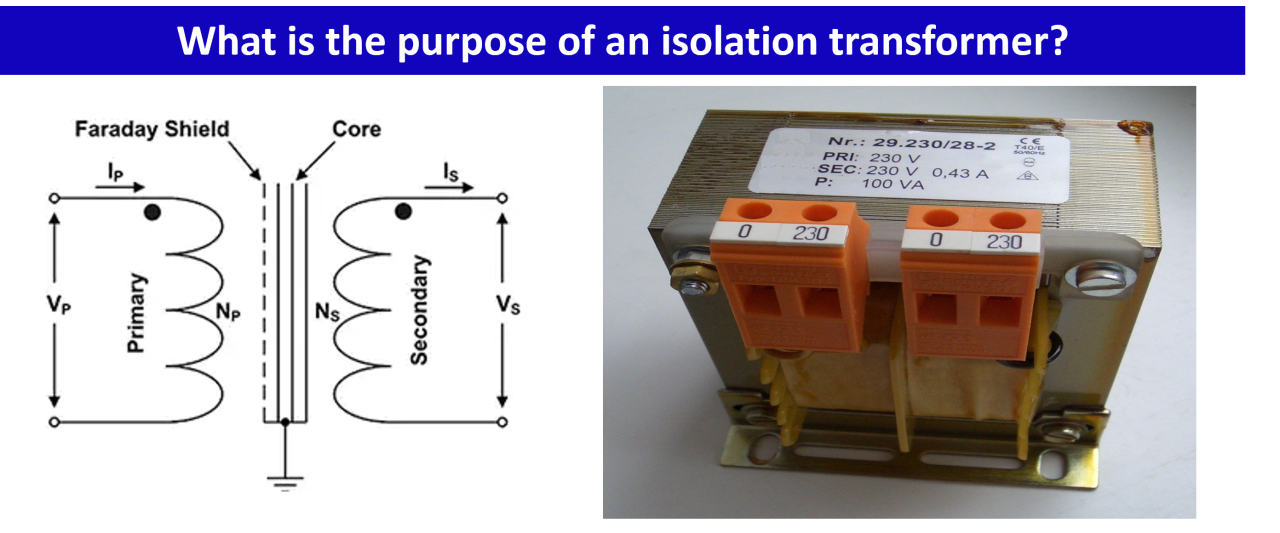

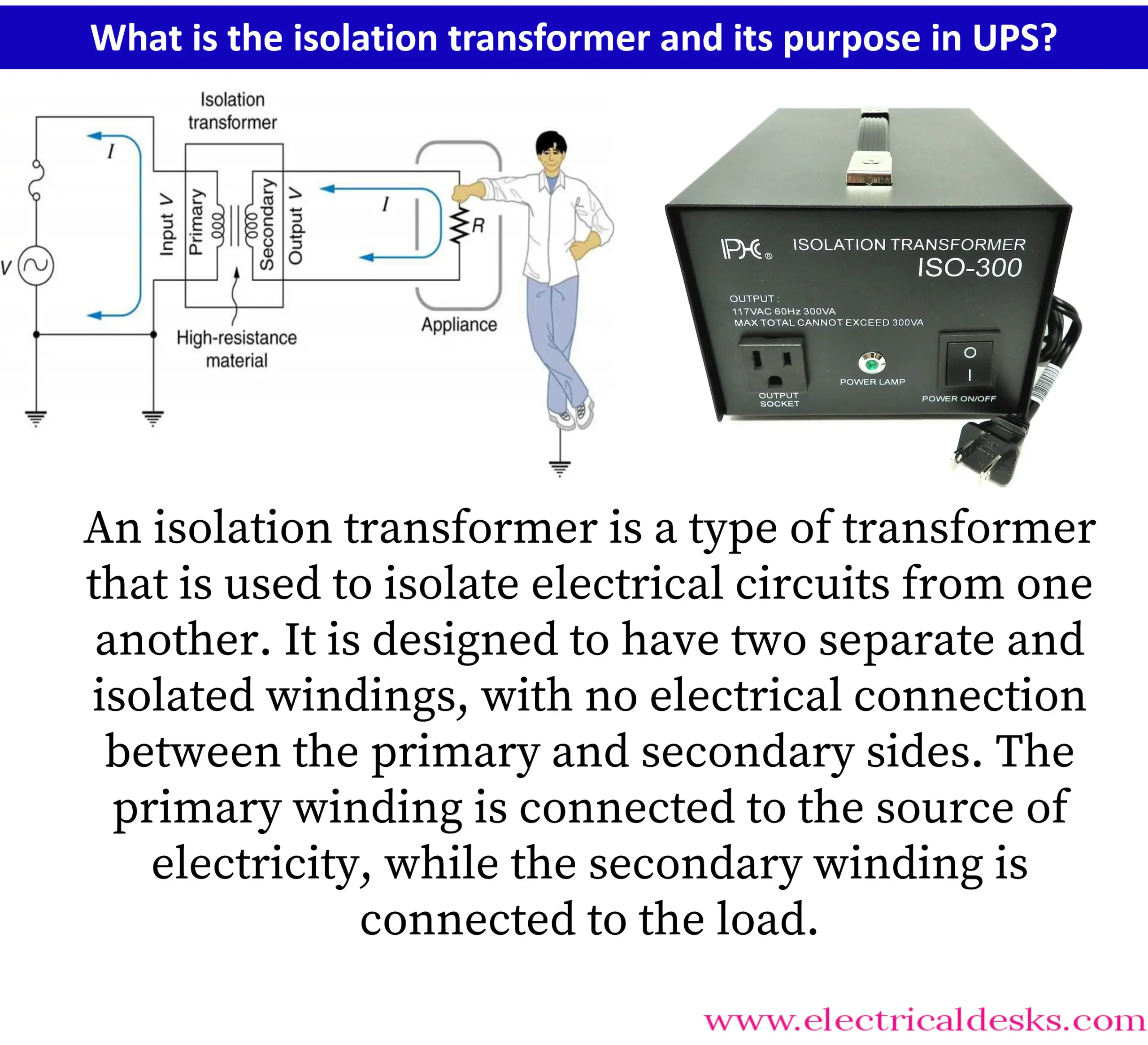

In today’s interconnected global economy, sourcing isolation transformers presents a unique challenge for B2B buyers aiming to enhance safety and efficiency within their electrical systems. As businesses across Africa, South America, the Middle East, and Europe (including key markets like Germany and Saudi Arabia) navigate the complexities of electrical isolation, understanding the purpose and functionality of isolation transformers becomes essential. These devices are not merely components; they are critical tools that mitigate risks associated with electrical noise, surges, and grounding failures.

This comprehensive guide delves into the multifaceted world of isolation transformers, offering insights into various types, including constant voltage transformers, ultra-isolation transformers, and galvanic isolation transformers, along with their specific applications across industries such as healthcare, telecommunications, and manufacturing. By exploring supplier vetting processes, cost considerations, and best practices for implementation, this guide empowers international buyers to make informed purchasing decisions.

With a focus on actionable insights and practical advice, this resource equips B2B stakeholders with the knowledge needed to select the right isolation transformer for their unique operational requirements. Whether you’re in the bustling markets of Johannesburg or the industrial hubs of Frankfurt, understanding the critical role of isolation transformers can lead to improved power quality, enhanced safety, and greater operational reliability.

Understanding isolation transformer purpose Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Constant Voltage Transformers | Maintains steady voltage output despite input fluctuations | Industrial machinery, electronic devices | Pros: Ensures stable operation; Cons: May have higher upfront costs. |

| Ultra Isolation Transformers | Offers superior electrical isolation, minimizing noise transfer | Medical devices, sensitive research equipment | Pros: High reliability; Cons: Can be expensive and bulky. |

| Drive Isolation Transformers | Designed for electric motor applications, reducing electrical noise | Manufacturing, HVAC systems | Pros: Clean power for motors; Cons: Limited to motor applications. |

| Galvanic Isolation Transformers | Provides complete electrical insulation, preventing current passage | Medical equipment, telecommunications | Pros: Enhanced safety; Cons: Installation complexity. |

| Dry Isolation Transformers | Uses dry air for insulation, suitable for various environments | Telecom, industrial, medical applications | Pros: Versatile and reliable; Cons: May require regular maintenance. |

What Are the Characteristics of Constant Voltage Transformers?

Constant Voltage Transformers (CVTs) are engineered to provide a stable voltage output regardless of fluctuations in the input voltage. This feature is particularly critical for industries reliant on sensitive electronic devices and machinery that require consistent performance. B2B buyers should consider the load capacity, efficiency ratings, and the potential need for additional protective features when evaluating CVTs. While they may entail a higher initial investment, the long-term savings from reduced equipment damage and downtime can justify the cost.

How Do Ultra Isolation Transformers Enhance Safety?

Ultra Isolation Transformers are specifically designed to offer superior electrical isolation, making them ideal for applications where electrical noise and interference can lead to significant operational risks, such as in medical devices and precision research equipment. Their construction involves advanced materials and techniques that minimize current transfer between the primary and secondary coils. Buyers should assess the specific isolation requirements of their applications, as well as the transformer’s size and weight, which can impact installation. Although they offer unparalleled safety, their higher cost and size may be drawbacks for some organizations.

What Makes Drive Isolation Transformers Unique?

Drive Isolation Transformers are tailored for powering electric motors, focusing on noise reduction and providing consistent power. They are commonly utilized in manufacturing and HVAC systems where motor efficiency is critical. B2B buyers should evaluate the transformer’s voltage ratings, insulation class, and compatibility with existing systems. While they excel in motor applications, their specialized nature may limit their versatility in other electrical setups, which is a consideration for companies looking for multi-purpose solutions.

Why Choose Galvanic Isolation Transformers?

Galvanic Isolation Transformers are essential for applications that require complete electrical insulation, preventing any direct current transfer between circuits. This makes them highly suitable for medical equipment and telecommunications where safety and reliability are paramount. When purchasing, businesses should consider the transformer’s insulation rating and the environment in which it will operate, as these factors can influence performance. The complexity of installation can be a downside, but the enhanced safety features they provide often outweigh this concern.

What Are the Advantages of Dry Isolation Transformers?

Dry Isolation Transformers utilize air as an insulating medium, making them suitable for a variety of environments, including telecommunications and industrial applications. Their design allows for flexibility in installation and operation, but regular maintenance may be necessary to ensure optimal performance. B2B buyers should assess the specific application requirements, including voltage and current specifications, before making a purchase. While they offer versatility and reliability, the maintenance aspect can be a consideration for businesses with limited resources.

Key Industrial Applications of isolation transformer purpose

| Industry/Sector | Specific Application of isolation transformer purpose | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Powering medical imaging equipment | Ensures clean power supply, reducing the risk of equipment failure and enhancing patient safety. | Compliance with medical regulations, reliability of power supply, and maintenance services. |

| Manufacturing | Supplying power to CNC machines | Provides electrical isolation to protect sensitive machinery from surges and electrical noise. | Voltage ratings, environmental conditions, and compatibility with existing systems. |

| Telecommunications | Supporting data centers and communication systems | Improves power quality, reducing downtime and maintenance costs associated with power disturbances. | Capacity to handle load fluctuations, efficiency ratings, and space considerations. |

| Research and Development | Powering sensitive laboratory equipment | Protects against electrical noise, ensuring accurate results and prolonging equipment lifespan. | Specific voltage and current requirements, certification for laboratory use, and service support. |

| Oil and Gas | Powering offshore drilling rigs | Enhances safety by isolating equipment from electrical faults, reducing risk of accidents. | Corrosion resistance, environmental certifications, and robustness to extreme conditions. |

How Do Isolation Transformers Benefit the Healthcare Sector?

In the healthcare industry, isolation transformers are crucial for powering medical imaging equipment like MRI and CT scanners. These devices require a stable and clean power supply to function accurately and safely. Isolation transformers mitigate the risk of electrical noise and surges that can lead to equipment malfunction, ultimately enhancing patient safety and the reliability of diagnostic results. Buyers in this sector must ensure that transformers comply with medical regulations and standards, while also considering the availability of maintenance services to ensure continuous operation.

What Role Do Isolation Transformers Play in Manufacturing?

In the manufacturing sector, particularly in facilities utilizing CNC (Computer Numerical Control) machines, isolation transformers are employed to provide a stable power supply. These transformers protect sensitive machinery from electrical surges and noise, which can lead to production errors and equipment damage. For international buyers, it is essential to consider the voltage ratings and environmental conditions of the transformer, ensuring compatibility with existing systems to maintain operational efficiency.

Why Are Isolation Transformers Important for Telecommunications?

Telecommunications companies rely heavily on isolation transformers to support data centers and communication systems. These transformers improve power quality, significantly reducing downtime and the associated maintenance costs from power disturbances. When sourcing isolation transformers, businesses must evaluate their capacity to handle load fluctuations and efficiency ratings, ensuring they meet the high demands of modern communication infrastructures.

How Do Isolation Transformers Enhance Research and Development?

In research and development environments, sensitive laboratory equipment requires a stable and isolated power source to ensure accurate results. Isolation transformers protect against electrical noise and fluctuations that could compromise experimental integrity. Buyers in this sector should focus on specific voltage and current requirements, as well as certifications for laboratory use, to ensure that the transformers meet their unique operational needs.

What Advantages Do Isolation Transformers Offer in the Oil and Gas Industry?

The oil and gas industry utilizes isolation transformers to power offshore drilling rigs, where safety is paramount. These transformers provide electrical isolation that reduces the risk of equipment failure due to electrical faults, which can lead to severe accidents. When sourcing transformers for such applications, buyers should consider factors like corrosion resistance, environmental certifications, and the robustness of the equipment to withstand extreme conditions typical in offshore environments.

3 Common User Pain Points for ‘isolation transformer purpose’ & Their Solutions

Scenario 1: Inconsistent Power Supply in Industrial Applications

The Problem: Many industrial facilities experience fluctuations in power supply, which can lead to equipment malfunctions, production delays, and safety hazards. B2B buyers in manufacturing, for instance, may find that their sensitive machinery is vulnerable to electrical noise and surges, resulting in increased downtime and maintenance costs. This issue is particularly critical in sectors such as pharmaceuticals and food processing, where consistent power quality is essential for operational efficiency and product safety.

The Solution: To address the challenge of inconsistent power supply, B2B buyers should consider investing in constant voltage isolation transformers. These transformers are designed to maintain a steady voltage output, even when input voltage levels fluctuate. When sourcing an isolation transformer, it’s crucial to assess the specific voltage requirements of your equipment and ensure that the transformer can handle the load without overheating. Additionally, working with reputable suppliers who offer customized solutions can help ensure that the transformer meets the unique demands of your facility. Regular maintenance and performance checks of the isolation transformer will also enhance its longevity and reliability, ultimately leading to improved operational efficiency and reduced risk of equipment failure.

Scenario 2: Safety Concerns in Medical Equipment

The Problem: In medical facilities, the safety of patients and staff is paramount. Electrical faults in medical devices can pose serious risks, including electric shocks and equipment failure during critical procedures. B2B buyers responsible for purchasing medical equipment must ensure that devices are safe from electrical interference and surges, which can be particularly problematic in environments with a high density of electronic devices.

The Solution: Galvanic isolation transformers are an effective solution for enhancing safety in medical settings. These transformers provide complete electrical insulation between the power supply and medical devices, significantly reducing the risk of electric shock and interference. When selecting a galvanic isolation transformer, it’s important to consider the specific medical applications and the level of isolation required. Buyers should consult with manufacturers to ensure compliance with medical standards and regulations. Implementing a routine testing and maintenance program for both the transformers and the connected medical devices can further enhance safety and reliability, ensuring that the equipment operates flawlessly during critical medical procedures.

Scenario 3: Harmonics and Equipment Efficiency Issues

The Problem: Businesses often face challenges related to harmonic distortion caused by non-linear loads such as computers and other electronic devices. This distortion can lead to inefficiencies, overheating, and equipment damage, resulting in increased operational costs and reduced lifespan of machinery. B2B buyers in sectors like IT and telecommunications are especially affected, as their operations rely heavily on clean and consistent power supply.

The Solution: To combat harmonics and improve equipment efficiency, B2B buyers should consider deploying isolation transformers specifically designed for harmonic correction. These transformers can filter out harmonics, ensuring that devices receive a clean and stable voltage supply. When sourcing these transformers, it’s vital to analyze the electrical load profiles of your operations and select a transformer that matches the harmonic characteristics of your equipment. Collaborating with a qualified electrical engineer can help in the proper specification of the transformer, ensuring that it effectively addresses harmonic issues. Additionally, integrating power monitoring systems can provide real-time data on power quality, allowing for proactive adjustments and maintenance, ultimately leading to enhanced equipment performance and longevity.

Strategic Material Selection Guide for isolation transformer purpose

When selecting materials for isolation transformers, it is crucial to consider properties that directly impact performance, durability, and compliance with international standards. Below, we analyze four common materials used in the construction of isolation transformers, focusing on their key properties, advantages and disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Copper in Isolation Transformers?

Copper is a widely used conductor in isolation transformers due to its excellent electrical conductivity and thermal properties. It typically has a temperature rating of up to 200°C and offers good corrosion resistance when properly coated.

Pros: Copper’s high conductivity ensures minimal energy loss during power transfer, making it ideal for applications requiring efficiency. Its durability allows for long-term use, reducing the frequency of replacements.

Cons: The primary drawback of copper is its cost, which is generally higher than alternatives like aluminum. Additionally, copper can be susceptible to corrosion if not adequately protected, particularly in humid environments.

Impact on Application: Copper is compatible with various media and is particularly effective in environments requiring high reliability, such as medical and industrial applications.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM and IEC for electrical components, while also considering the local availability of copper and its pricing fluctuations.

Illustrative image related to isolation transformer purpose

How Does Aluminum Compare as a Material for Isolation Transformers?

Aluminum is another popular choice for winding materials in isolation transformers. It has a lower density than copper, making it lighter and easier to handle, with a temperature rating similar to that of copper.

Pros: The primary advantage of aluminum is its cost-effectiveness; it is generally cheaper than copper. Its lightweight nature can also reduce shipping costs and installation complexity.

Cons: However, aluminum has lower electrical conductivity compared to copper, which may lead to higher energy losses in some applications. It is also more prone to oxidation, which can affect performance over time.

Impact on Application: Aluminum is suitable for applications where weight is a critical factor, such as in portable or mobile transformer units.

Considerations for International Buyers: Buyers should check for compliance with local standards and certifications, especially in regions like South America and Africa, where material quality can vary significantly.

Illustrative image related to isolation transformer purpose

What Are the Benefits of Using Silicon Steel in Isolation Transformers?

Silicon steel is often used in the core of isolation transformers due to its magnetic properties. It typically operates effectively at temperatures up to 150°C and is designed to minimize energy losses due to hysteresis and eddy currents.

Pros: The use of silicon steel can significantly enhance the efficiency of transformers by reducing core losses, which is crucial for energy-saving applications. It also provides good mechanical strength and durability.

Cons: The manufacturing process for silicon steel can be complex and costly, impacting the overall price of the transformer. Additionally, it may not perform as well in extremely high temperatures compared to other materials.

Impact on Application: Silicon steel is particularly effective in applications where energy efficiency is a priority, such as renewable energy systems.

Illustrative image related to isolation transformer purpose

Considerations for International Buyers: Compliance with international standards like DIN and JIS is essential, especially for buyers in Germany and Japan, where quality assurance is critical.

Why Is Insulation Material Important in Isolation Transformers?

Insulation materials, such as epoxy resin or polyester, are critical for ensuring the safety and efficiency of isolation transformers. These materials can withstand high temperatures, often rated up to 180°C, and provide excellent electrical insulation properties.

Pros: High-quality insulation materials enhance safety by preventing electrical shorts and improving the overall reliability of the transformer. They also contribute to the longevity of the transformer by protecting against environmental factors.

Cons: The main disadvantage is the cost, as high-grade insulation materials can significantly increase the overall manufacturing expense. Additionally, some insulation materials may have limitations in extreme environmental conditions.

Impact on Application: Insulation materials are vital in applications involving high voltages or sensitive electronics, where safety is paramount.

Considerations for International Buyers: Buyers should ensure that insulation materials meet local and international standards for electrical safety, particularly in regions with stringent regulations like Europe.

Summary Table of Material Selection for Isolation Transformers

| Material | Typical Use Case for isolation transformer purpose | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Medical and industrial applications | High electrical conductivity | Higher cost, corrosion risk | High |

| Aluminum | Portable transformer units | Cost-effective and lightweight | Lower conductivity, oxidation risk | Medium |

| Silicon Steel | Energy-efficient transformers | Reduces core losses | Complex manufacturing process | High |

| Insulation Material | High voltage and sensitive electronics | Enhances safety and reliability | Higher cost, environmental limitations | Medium |

This comprehensive analysis provides B2B buyers with essential insights into material selection for isolation transformers, ensuring informed decisions that align with their operational needs and regional standards.

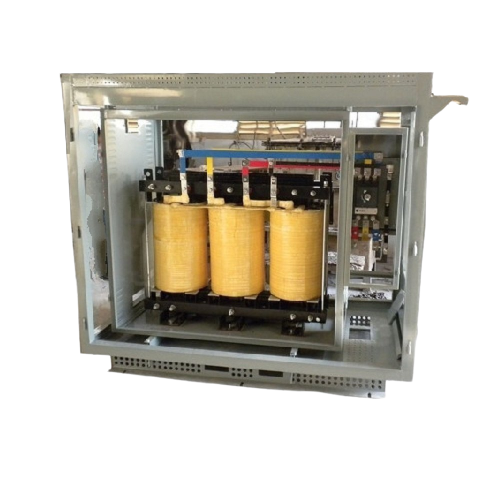

In-depth Look: Manufacturing Processes and Quality Assurance for isolation transformer purpose

What Are the Key Stages in the Manufacturing Process of Isolation Transformers?

The manufacturing of isolation transformers involves several critical stages designed to ensure high performance and reliability. Understanding these stages can help B2B buyers select suppliers that meet their specific needs.

Material Preparation: What Materials Are Used in Isolation Transformers?

The first step in the manufacturing process is material preparation. High-quality electrical steel is often used for the core, chosen for its magnetic properties that minimize energy losses. Copper or aluminum is typically used for the windings, with copper being favored for its superior conductivity. Insulation materials are also critical, and manufacturers may choose from various options, such as polyester, PVC, or special impregnated materials, depending on the intended application and environmental conditions.

Illustrative image related to isolation transformer purpose

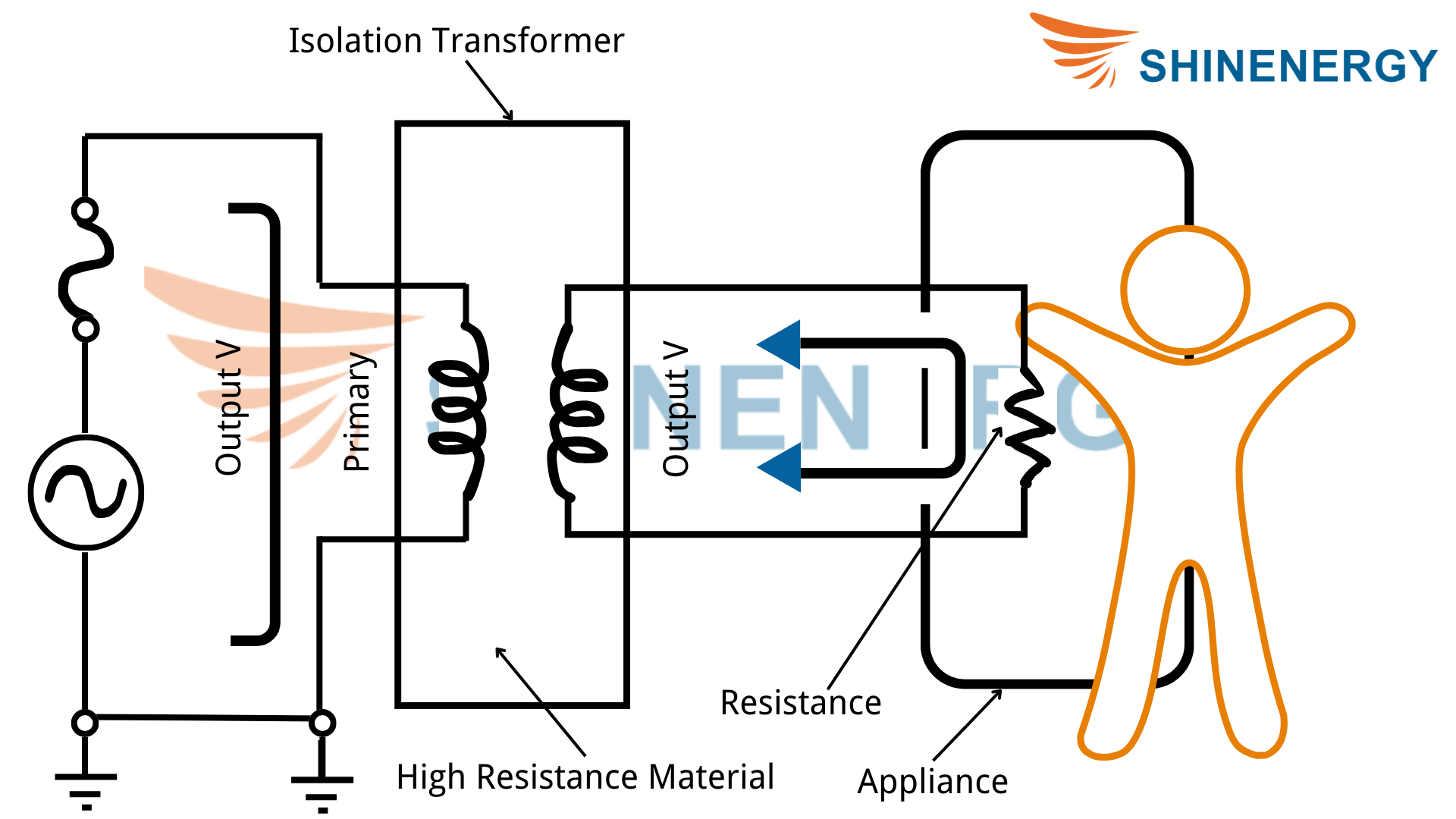

How Are the Core and Windings Formed?

Once the materials are prepared, the next step is forming the core and windings. The core is usually laminated to reduce eddy currents, which can lead to energy losses. This lamination process involves stacking thin sheets of steel, which are then coated with an insulating material to prevent electrical contact.

For the windings, the manufacturing process may involve precise winding techniques, often using automated machines to ensure uniformity and accuracy. The winding process can vary based on the transformer type; for instance, ultra-isolation transformers may require additional layers of insulation to achieve the desired level of electrical isolation.

What Does the Assembly Process Entail?

The assembly stage is where the core and windings come together. The assembled core is often mounted on a frame that provides structural integrity. The windings are then attached to the core, and additional insulation materials are applied to ensure electrical safety.

During assembly, it’s crucial to maintain strict tolerances to guarantee the performance of the transformer. Automated assembly lines are increasingly common, allowing for higher precision and reduced assembly time.

How Is the Finishing Process Conducted?

The final stage in manufacturing is the finishing process, which involves several steps, including:

- Testing and Quality Control: Initial tests may include insulation resistance testing and continuity checks to ensure the windings are properly connected.

- Coating: Applying a protective coating can enhance durability and resistance to environmental factors.

- Labeling: Proper labeling is essential for compliance with international standards and for the end-users’ reference.

- Packaging: Transformers are carefully packaged to prevent damage during transport, often including anti-static materials if electronics are involved.

What Are the Quality Assurance Protocols for Isolation Transformers?

Quality assurance is critical in the manufacturing of isolation transformers, ensuring that they meet both safety and performance standards. Here are some key quality assurance protocols relevant to B2B buyers.

Which International Standards Should Buyers Be Aware Of?

B2B buyers should be familiar with several international standards that govern the quality of isolation transformers. The ISO 9001 standard is a widely recognized quality management system that ensures manufacturers maintain high-quality processes. Additionally, certifications like CE mark and API (American Petroleum Institute) may be relevant depending on the application of the transformers.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are essential throughout the manufacturing process. The following checkpoints are commonly implemented:

- Incoming Quality Control (IQC): This is conducted on raw materials and components to verify their compliance with specifications before production begins.

- In-Process Quality Control (IPQC): This involves continuous monitoring during the manufacturing process to identify and rectify any defects early.

- Final Quality Control (FQC): After assembly, the final product undergoes rigorous testing, including electrical tests, thermal imaging, and performance evaluations to ensure it meets all specifications.

What Testing Methods Are Commonly Used?

Common testing methods for isolation transformers include:

- Dielectric Strength Testing: Ensures that insulation can withstand high voltages without failure.

- Temperature Rise Testing: Measures the temperature increase under load to ensure safe operation.

- Load Testing: Evaluates the transformer’s performance under simulated operational conditions.

- Harmonic Distortion Testing: Assesses how well the transformer can handle non-linear loads without introducing excessive harmonic distortion.

How Can B2B Buyers Verify Supplier Quality Control?

Verification of a supplier’s quality control processes is essential for B2B buyers, particularly in international markets. Here are some actionable steps to ensure supplier quality:

- Supplier Audits: Conducting regular audits of suppliers can help verify compliance with international standards and internal quality processes.

- Requesting Quality Reports: Suppliers should provide detailed quality reports, including test results and compliance certifications, which can be reviewed to assess their quality assurance measures.

- Engaging Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of the manufacturer’s processes and product quality.

What Are the Quality Control Nuances for International Buyers?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding regional compliance and quality expectations is crucial.

- Customs and Import Regulations: Each region may have specific regulations regarding electrical equipment that must be adhered to for successful importation.

- Local Standards and Compliance: Beyond international standards, local certifications may also be required, particularly in regions with stringent safety regulations.

- Cultural Considerations: Building relationships with suppliers in different regions may require an understanding of cultural nuances that affect business practices.

By gaining insights into the manufacturing processes and quality assurance protocols for isolation transformers, B2B buyers can make informed decisions that align with their operational needs and compliance requirements. This understanding not only aids in supplier selection but also ensures the long-term reliability and safety of the electrical systems they integrate these transformers into.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘isolation transformer purpose’

In the realm of electrical engineering, sourcing an isolation transformer requires a methodical approach to ensure that the chosen device meets your specific operational needs. This guide serves as a practical checklist for B2B buyers, helping you navigate the complexities of selecting an isolation transformer tailored for your applications.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clarify your technical requirements for the isolation transformer. Consider factors such as voltage ratings, power capacity, and the environment in which the transformer will operate.

– Voltage Levels: Determine the input and output voltage levels required for your application.

– Power Rating: Assess the total wattage that the transformer must handle to ensure efficiency and prevent overloads.

Step 2: Identify the Type of Isolation Transformer Needed

Isolation transformers come in various types, each suited for specific applications. Identify which type aligns with your operational needs.

– Constant Voltage Transformers: Ideal for environments with fluctuating voltage levels.

– Ultra Isolation Transformers: Necessary for sensitive medical or research applications where electrical noise must be minimized.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Reputation and Experience: Look for suppliers with a solid reputation and extensive experience in manufacturing isolation transformers.

– Certifications: Ensure the supplier complies with relevant international standards, such as ISO or CE certifications, to guarantee product quality.

Step 4: Request Detailed Product Specifications

Obtain comprehensive specifications for the isolation transformers you are considering. This should include technical data sheets and performance metrics.

– Material Quality: Inquire about the materials used in the windings and insulation, as these affect durability and performance.

– Efficiency Ratings: Check for efficiency ratings to ensure that the transformer will operate effectively within your energy budget.

Step 5: Assess After-Sales Support and Warranty

A robust after-sales support system is vital for maintenance and troubleshooting. Evaluate the warranty and support options offered by the supplier.

– Warranty Terms: Understand the warranty period and what it covers to protect your investment.

– Technical Support: Ensure that the supplier provides reliable technical support for installation and maintenance.

Step 6: Consider Logistics and Delivery Times

Logistics can significantly impact your procurement process. Discuss delivery timelines and transportation arrangements with the supplier.

– Shipping Options: Evaluate shipping methods that align with your project timelines.

– Import Regulations: Be aware of any import regulations specific to your region to avoid delays.

Illustrative image related to isolation transformer purpose

Step 7: Negotiate Pricing and Payment Terms

Finally, engage in discussions about pricing and payment terms. Aim for a mutually beneficial agreement that reflects the value of the isolation transformer.

– Bulk Discounts: Inquire about discounts for bulk purchases, which can lead to significant savings.

– Payment Flexibility: Explore payment options that suit your budget and cash flow needs.

By following this checklist, B2B buyers can make informed decisions when sourcing isolation transformers, ensuring they meet both technical specifications and operational requirements.

Comprehensive Cost and Pricing Analysis for isolation transformer purpose Sourcing

What Are the Key Cost Components for Isolation Transformers?

Understanding the cost structure of isolation transformers is vital for B2B buyers. The primary cost components include:

-

Materials: The raw materials, including copper for windings and silicon steel for cores, significantly influence the overall cost. High-quality materials enhance performance and longevity, but they also increase costs.

-

Labor: Manufacturing isolation transformers requires skilled labor, particularly for winding and assembly. Labor costs can vary significantly based on geographic location, affecting the total price.

-

Manufacturing Overhead: This encompasses expenses related to factory maintenance, utilities, and equipment depreciation. Efficient operations can reduce overhead costs, contributing to more competitive pricing.

-

Tooling: Initial setup costs for specialized tooling can be substantial, particularly for custom transformers. However, these costs can be amortized over larger production runs, making economies of scale critical.

-

Quality Control (QC): Rigorous testing and quality assurance processes are essential to ensure reliability, especially in sensitive applications like medical equipment. QC costs can vary depending on certification requirements and testing standards.

-

Logistics: Transportation and shipping expenses, including freight and insurance, are crucial components. Incoterms play a vital role in defining responsibilities for costs and risks during shipping, particularly for international buyers.

-

Margin: Suppliers typically include a profit margin that reflects their operational costs and market conditions. This margin can vary widely based on the supplier’s position in the market and their unique value propositions.

How Do Volume and Specifications Affect Pricing for Isolation Transformers?

The price of isolation transformers can be significantly influenced by order volume and specifications:

-

Volume/MOQ: Higher order volumes often lead to lower unit prices due to economies of scale. Manufacturers may have minimum order quantities (MOQs) that can impact pricing strategies, especially for smaller businesses.

-

Specifications/Customization: Custom designs, such as specific voltage ratings or additional insulation features, can increase costs. Buyers should be clear about their requirements to avoid unnecessary expenses.

What Buyer Tips Can Help Negotiate Better Prices for Isolation Transformers?

B2B buyers can implement several strategies to optimize their purchasing process:

-

Negotiation: Establishing a rapport with suppliers can facilitate better pricing. Leverage competitive quotes from multiple suppliers to negotiate better terms.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also installation, maintenance, and operational efficiency. An upfront investment in higher-quality transformers can lead to long-term savings.

-

Pricing Nuances for International Buyers: Understanding local market conditions, currency fluctuations, and regional regulations is crucial, especially for buyers from Africa, South America, the Middle East, and Europe. These factors can significantly affect pricing and availability.

What Are the Pricing Considerations for Different Markets?

When sourcing isolation transformers, international buyers should be aware of specific market considerations:

-

Quality and Certifications: In regions like Germany and Saudi Arabia, compliance with local safety and quality standards can influence costs. Buyers should confirm that the products meet necessary certifications to avoid issues during inspections.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established manufacturers may charge a premium for their proven track record, while new entrants might offer lower prices to gain market share.

Disclaimer on Indicative Prices

Pricing for isolation transformers can vary widely based on the factors mentioned above. It is advisable for buyers to obtain detailed quotes from multiple suppliers to ensure they are making informed purchasing decisions. Always consider the broader implications of cost, including long-term performance and reliability, to achieve the best value.

Alternatives Analysis: Comparing isolation transformer purpose With Other Solutions

In today’s rapidly evolving electrical landscape, businesses often seek solutions that provide reliable power quality and protection against electrical noise and surges. While isolation transformers serve a crucial role in achieving these objectives, several alternative solutions can also meet similar needs. This analysis will compare the purpose of isolation transformers against two viable alternatives: Power Conditioners and Surge Protectors.

Comparison Table

| Comparison Aspect | Isolation Transformer Purpose | Power Conditioner | Surge Protector |

|---|---|---|---|

| Performance | Excellent for noise reduction and voltage stabilization | Good for filtering noise and maintaining voltage | Effective at blocking surges but limited in noise filtering |

| Cost | Higher initial investment | Moderate initial investment | Low initial investment |

| Ease of Implementation | Requires professional installation | Generally easy to install | Very easy to install |

| Maintenance | Low maintenance | Moderate maintenance | Low maintenance |

| Best Use Case | Sensitive medical and industrial applications | General electronics and IT equipment | Basic home and office use |

Detailed Breakdown of Alternatives

Power Conditioner

Power conditioners are devices designed to improve the quality of power delivered to electrical equipment. They filter out electrical noise, stabilize voltage, and can even provide surge protection. The main advantage of power conditioners is their ability to improve overall system performance, particularly for sensitive electronics. However, they may not offer the same level of electrical isolation as isolation transformers, which could be a critical factor for applications requiring strict safety standards. Additionally, while they come at a moderate cost, the return on investment may be lower for certain applications where isolation is paramount.

Surge Protector

Surge protectors are designed to safeguard equipment from voltage spikes caused by lightning strikes or power surges. They are relatively inexpensive and easy to install, making them accessible for businesses of all sizes. However, surge protectors primarily focus on preventing damage from transient voltage surges and do not address issues related to electrical noise or voltage fluctuations. As a result, while they are suitable for general home and office use, they may not be adequate for environments where sensitive equipment is in operation, such as hospitals or research laboratories.

Conclusion

When selecting the right electrical solution, B2B buyers must assess their specific needs, including the level of protection required, the types of equipment being used, and budget constraints. Isolation transformers are ideal for critical applications that require complete electrical isolation and noise reduction, making them essential in medical and industrial settings. In contrast, power conditioners offer a balanced approach to enhancing power quality for general electronics, while surge protectors provide a cost-effective solution for basic surge protection. Ultimately, the decision should align with the operational requirements and safety standards relevant to the buyer’s industry.

Essential Technical Properties and Trade Terminology for isolation transformer purpose

What Are the Key Technical Properties of Isolation Transformers?

When evaluating isolation transformers for your business needs, understanding critical specifications is essential. Here are several key properties to consider:

Illustrative image related to isolation transformer purpose

-

Winding Configuration

– Definition: This refers to the arrangement of the primary and secondary coils within the transformer. Common configurations include delta and wye (star).

– Importance: The winding configuration affects the voltage transformation ratio and the transformer’s ability to handle different load types. Selecting the appropriate configuration can enhance efficiency and performance, particularly in industrial settings. -

Insulation Material

– Definition: The type of insulation used between the primary and secondary windings, often made from materials such as polyester, paper, or epoxy resin.

– Importance: High-quality insulation materials are vital for ensuring safety and reliability. They help prevent electrical leakage and thermal damage, particularly in environments with high humidity or temperature fluctuations. -

Voltage Rating

– Definition: The maximum voltage the transformer can handle, which is critical for ensuring compatibility with your electrical systems.

– Importance: Choosing a transformer with the correct voltage rating is crucial to prevent equipment damage and ensure optimal operation. This is especially relevant for businesses in regions with varying voltage standards. -

Power Rating (kVA)

– Definition: This indicates the maximum power output of the transformer, measured in kilovolt-amperes (kVA).

– Importance: Understanding the power rating helps ensure that the transformer can adequately support your electrical load without risk of overheating or failure. It’s essential for maintaining operational efficiency in industrial applications. -

Efficiency Rating

– Definition: The ratio of useful power output to the total power input, typically expressed as a percentage.

– Importance: High-efficiency transformers reduce energy costs and minimize heat generation, leading to lower maintenance expenses. This is particularly beneficial for businesses aiming to reduce operational costs. -

Frequency Rating

– Definition: The frequency at which the transformer operates optimally, commonly 50 Hz or 60 Hz.

– Importance: Selecting a transformer with the correct frequency rating ensures compatibility with your electrical systems, which is crucial for maintaining equipment performance and avoiding failures.

What Are Common Trade Terms Related to Isolation Transformers?

In the B2B landscape, understanding industry jargon can facilitate smoother transactions and negotiations. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Knowing whether a transformer is an OEM product can assure buyers of quality and compatibility with existing systems. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Understanding the MOQ is crucial for budget planning and inventory management, particularly for businesses with specific volume needs. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to request price offers from suppliers for specific products.

– Relevance: An RFQ helps streamline the procurement process, enabling buyers to compare pricing and terms from multiple suppliers effectively. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined commercial terms used in international trade to clarify the responsibilities of buyers and sellers.

– Relevance: Familiarity with Incoterms helps buyers understand shipping costs, risks, and delivery responsibilities, ensuring smoother international transactions. -

Lead Time

– Definition: The time it takes from placing an order until the product is delivered.

– Relevance: Understanding lead times is crucial for project planning and ensuring that equipment is available when needed, especially in industries with tight timelines. -

Certification Standards

– Definition: Industry-specific standards that products must meet to ensure safety and performance, such as ISO or IEC certifications.

– Relevance: Products that meet recognized certification standards provide assurance of quality and compliance, which is critical for businesses operating in regulated industries.

In summary, grasping these technical properties and trade terms can empower B2B buyers to make informed decisions regarding isolation transformers, enhancing operational efficiency and safety in their applications.

Navigating Market Dynamics and Sourcing Trends in the isolation transformer purpose Sector

What Are the Current Market Dynamics for Isolation Transformers?

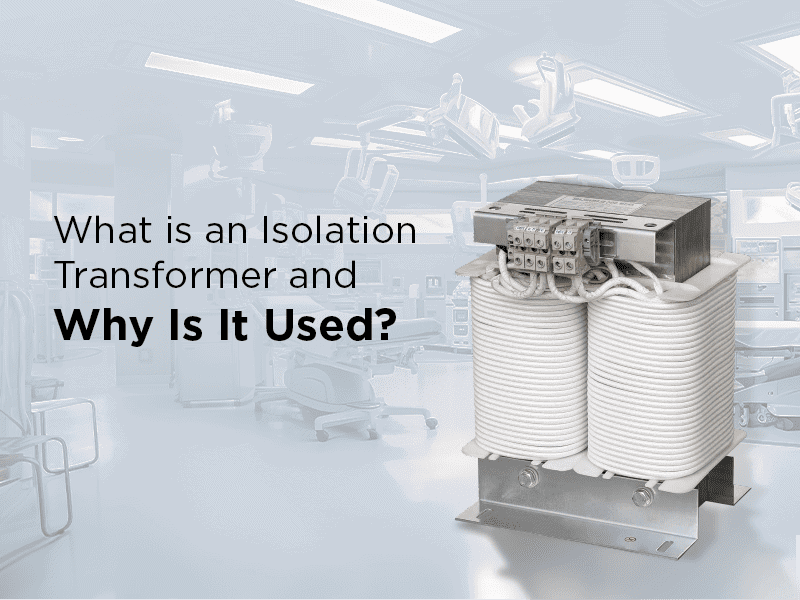

The global market for isolation transformers is experiencing significant growth, driven by the increasing demand for electrical safety and reliability across various sectors, including healthcare, manufacturing, and telecommunications. In regions like Africa, South America, the Middle East, and Europe, B2B buyers are particularly focused on sourcing isolation transformers that can provide enhanced safety features and protect sensitive equipment from electrical noise and surges. Key trends include the adoption of ultra-isolation transformers in medical and research applications, where precision and safety are paramount.

Moreover, the rise of renewable energy sources is influencing the market dynamics, as businesses seek to integrate isolation transformers into their energy management systems to ensure stable and consistent power supply. The ongoing digitization of industries also necessitates sourcing transformers that can handle harmonic distortion effectively, a common issue with non-linear loads. International buyers are increasingly looking for suppliers that not only provide high-quality products but also offer customization options to meet specific operational requirements.

As markets evolve, understanding local regulations and standards becomes essential for B2B buyers. For example, in Europe and Germany, compliance with CE marking and other safety certifications is crucial, while buyers in Saudi Arabia may need to adhere to the Saudi Standards, Metrology and Quality Organization (SASO) guidelines. This emphasizes the importance of sourcing from manufacturers who are well-versed in the regulations applicable to their respective regions.

Illustrative image related to isolation transformer purpose

How Does Sustainability Influence the Sourcing of Isolation Transformers?

Sustainability is becoming a critical consideration for B2B buyers when sourcing isolation transformers. The environmental impact of manufacturing processes and the lifecycle of transformers can no longer be overlooked. Buyers are increasingly seeking suppliers who prioritize sustainable practices, such as using eco-friendly materials and implementing energy-efficient manufacturing processes.

Ethical sourcing is equally important, as businesses aim to build supply chains that reflect their values and commitment to social responsibility. This includes ensuring that materials are sourced from suppliers that adhere to fair labor practices and environmental stewardship. Certifications like ISO 14001 for environmental management and other “green” certifications can significantly enhance a supplier’s appeal to international buyers.

Furthermore, the use of recyclable materials in the production of isolation transformers is gaining traction. As businesses shift towards circular economy principles, transformers designed for easy disassembly and recycling can help reduce waste and promote sustainability. B2B buyers should consider these factors when evaluating suppliers, as a commitment to sustainability not only benefits the environment but can also enhance brand reputation and customer loyalty.

What Is the Historical Context of Isolation Transformers in the B2B Sector?

The concept of isolation transformers dates back to the early 20th century, primarily used in industrial applications to enhance safety and reduce electrical noise. Initially, these transformers were employed in basic electrical systems, but as technology advanced, their application expanded significantly. In the mid-20th century, the use of isolation transformers became commonplace in medical equipment, where the need for electrical safety was critical.

As industries evolved, the design and functionality of isolation transformers adapted to meet the increasing complexity of electrical systems. The introduction of new materials and technologies has led to the development of specialized types of isolation transformers, such as ultra-isolation and dry isolation transformers, catering to specific needs across various sectors. Today, isolation transformers are integral to modern electrical systems, providing essential safety features and power quality improvements, making them a vital component for B2B buyers across multiple industries.

In summary, understanding the market dynamics, sustainability considerations, and historical context of isolation transformers equips international B2B buyers with the insights necessary to make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of isolation transformer purpose

-

How do I solve electrical noise issues in my equipment?

To address electrical noise issues, consider using an isolation transformer. These transformers provide complete electrical isolation between circuits, significantly reducing electrical interference. By isolating your equipment, you enhance power quality and minimize disruptions caused by noise, ensuring that sensitive devices operate reliably. When selecting an isolation transformer, assess the specific requirements of your application, such as the type of electrical noise present and the voltage levels involved. -

What is the best isolation transformer for sensitive medical equipment?

For sensitive medical equipment, ultra-isolation transformers are ideal. They offer the highest level of electrical isolation, protecting against electrical noise and potential surges. These transformers employ advanced construction techniques to minimize any transfer of current between primary and secondary coils, ensuring the accuracy and safety of medical devices. Always consult with manufacturers about the specific needs of your medical applications to select the appropriate transformer. -

How can I ensure the quality of the isolation transformers I purchase?

To ensure quality, vet suppliers by checking their certifications, such as ISO 9001, and reviewing their manufacturing processes. Request product samples and performance data to verify that the transformers meet your specifications. Additionally, inquire about their quality assurance protocols, warranty terms, and after-sales support to ensure that you’re investing in reliable products that will perform well over time. -

What customization options are available for isolation transformers?

Many manufacturers offer customization options to meet specific operational requirements. This can include tailored voltage ratings, sizes, and mounting configurations. When discussing your needs with suppliers, be clear about your application and any unique environmental conditions, such as temperature or humidity, to ensure that the transformer is optimized for your situation. Custom solutions can greatly enhance the performance and reliability of the transformer in your application. -

What are the minimum order quantities (MOQ) for isolation transformers?

Minimum order quantities (MOQ) can vary significantly among manufacturers and depend on factors like transformer type and customization needs. Generally, MOQs may range from a single unit for standard models to larger quantities for custom designs. When sourcing, discuss your requirements with potential suppliers to negotiate favorable terms that align with your project needs, especially if you are a smaller business or just entering the market. -

What payment terms should I expect when sourcing isolation transformers?

Payment terms can vary widely based on the supplier’s policies and the buyer’s creditworthiness. Common terms include a deposit upfront (typically 30-50%) with the balance due upon delivery or net 30/60 days after receipt of goods. Always negotiate payment terms that suit your cash flow and ensure you understand any penalties for late payments. Additionally, consider using secure payment methods that provide buyer protection. -

How can I efficiently manage logistics for importing isolation transformers?

Efficient logistics management involves selecting reliable shipping partners and understanding international trade regulations. Ensure you have a clear plan for customs clearance, including all necessary documentation. Work closely with your suppliers to coordinate shipping schedules and consider using freight forwarders who specialize in electrical equipment to navigate complexities. Familiarize yourself with import duties and taxes in your region to avoid unexpected costs. -

What are the key factors to consider when selecting a supplier for isolation transformers?

When choosing a supplier, evaluate their experience in the industry, reputation, and customer reviews. Look for manufacturers with a solid track record in producing high-quality isolation transformers, especially in your specific application area. Additionally, assess their customer service, lead times, and ability to provide technical support. Engaging with multiple suppliers to compare offerings can help you find the best fit for your business needs.

Top 6 Isolation Transformer Purpose Manufacturers & Suppliers List

1. Payton Group – Isolation Transformers

Domain: paytongroup.com

Registered: 1997 (28 years)

Introduction: Isolation transformers transfer electrical power between circuits without direct electrical connection, providing complete electrical isolation. Key types include: 1. Constant Voltage Transformers (CVTs) – maintain steady voltage output despite input fluctuations. 2. Ultra Isolation Transformers – offer high levels of isolation, reducing electrical noise, used in sensitive applications. 3. Drive I…

2. IQS Directory – Isolation Transformers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Isolation transformers are immobile devices designed to physically and electrically separate primary and secondary windings, ensuring complete isolation between circuits and allowing energy transfer through magnetic induction. They play a crucial role in adjusting voltage levels, mitigating voltage spikes, and preventing grounding issues, thereby reducing ground loop interference and noise effects…

3. Aktif – Isolation Transformers

Domain: aktif.net

Registered: 1999 (26 years)

Introduction: Isolation transformers are static devices designed with separate primary and secondary windings, providing physical and electrical separation between circuits. They transfer electrical energy using magnetic induction, primarily to eliminate voltage spikes in supply lines. Types include Ultra Isolation Transformer, Galvanic Isolation Transformer, Drive Isolation Transformers, and Dry Isolation Tran…

4. Powersystems International – Isolation Transformers

Domain: powersystemsinternational.com

Registered: 2003 (22 years)

Introduction: Isolation transformers are designed to isolate two different electrical circuits, improving safety by preventing faults from transferring along the stages. They are constructed with primary and secondary windings that remain separated, ensuring electrical shock protection for staff and patients, particularly in high-dependency applications like medical equipment. Advantages include safety, noise r…

5. Nantech – Isolation Transformers

Domain: nantech.in

Registered: 2012 (13 years)

Introduction: Isolation transformers are used to transfer electrical power from an AC power source to a device while ensuring safety by separating the power device from the power source. They provide galvanic isolation, protecting against electric shock and reducing electrical noise. Key features include:

– Separation of input and output circuits to prevent contact.

– Mitigation of electrocution risks.

– Cus…

6. Electronics – 100KVA UPS with Isolation Transformer

Domain: electronics.stackexchange.com

Registered: 2009 (16 years)

Introduction: 100KVA UPS; Inputs: 3 phase, neutral, ground from service panel; Outputs: 3 phase, ground (no neutral connected to load); Isolation transformer required for grounding and fault current limitation; Benefits: limits fault current, reduces electrical disturbances, provides isolated ground, minimizes common-mode noise and transients, electrostatic shielding for noise reduction.

Strategic Sourcing Conclusion and Outlook for isolation transformer purpose

In conclusion, isolation transformers are pivotal in safeguarding electrical systems across various industries, offering benefits such as enhanced power quality, noise reduction, and improved safety. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, strategic sourcing of these transformers can lead to significant operational efficiencies and risk mitigation. By investing in high-quality isolation transformers, businesses can ensure compliance with safety standards and enhance the reliability of their electrical infrastructure.

As you consider procurement options, prioritize suppliers that demonstrate a deep understanding of your specific industry needs and can provide tailored solutions. A strategic approach to sourcing can unlock value not only in terms of cost but also in long-term performance and safety.

Looking ahead, the demand for isolation transformers is expected to grow as industries continue to prioritize safety and reliability. Engage with reputable manufacturers and distributors to explore innovative solutions that can meet your unique requirements and position your organization for success in an increasingly competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to isolation transformer purpose

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.