A B2B Buyer’s Guide to Hydraulic Cylinder And Piston: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for hydraulic cylinder and piston

Navigating the intricate landscape of the global market for hydraulic cylinders and pistons can be a daunting challenge for international B2B buyers. Sourcing reliable hydraulic components that meet both performance and regulatory standards is crucial, yet many face difficulties in finding trustworthy suppliers and understanding the specifications required for their applications. This comprehensive guide addresses these challenges head-on, providing valuable insights into the various types of hydraulic cylinders and pistons, their applications across industries, and the critical factors to consider when evaluating suppliers.

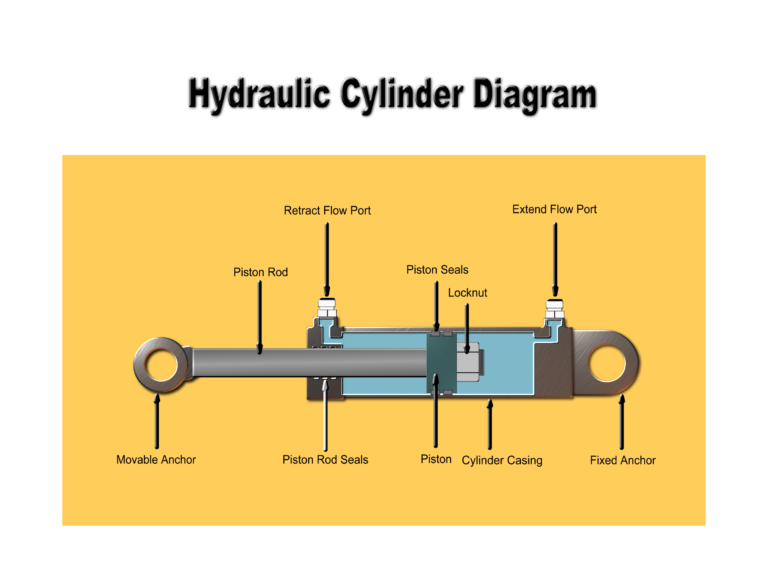

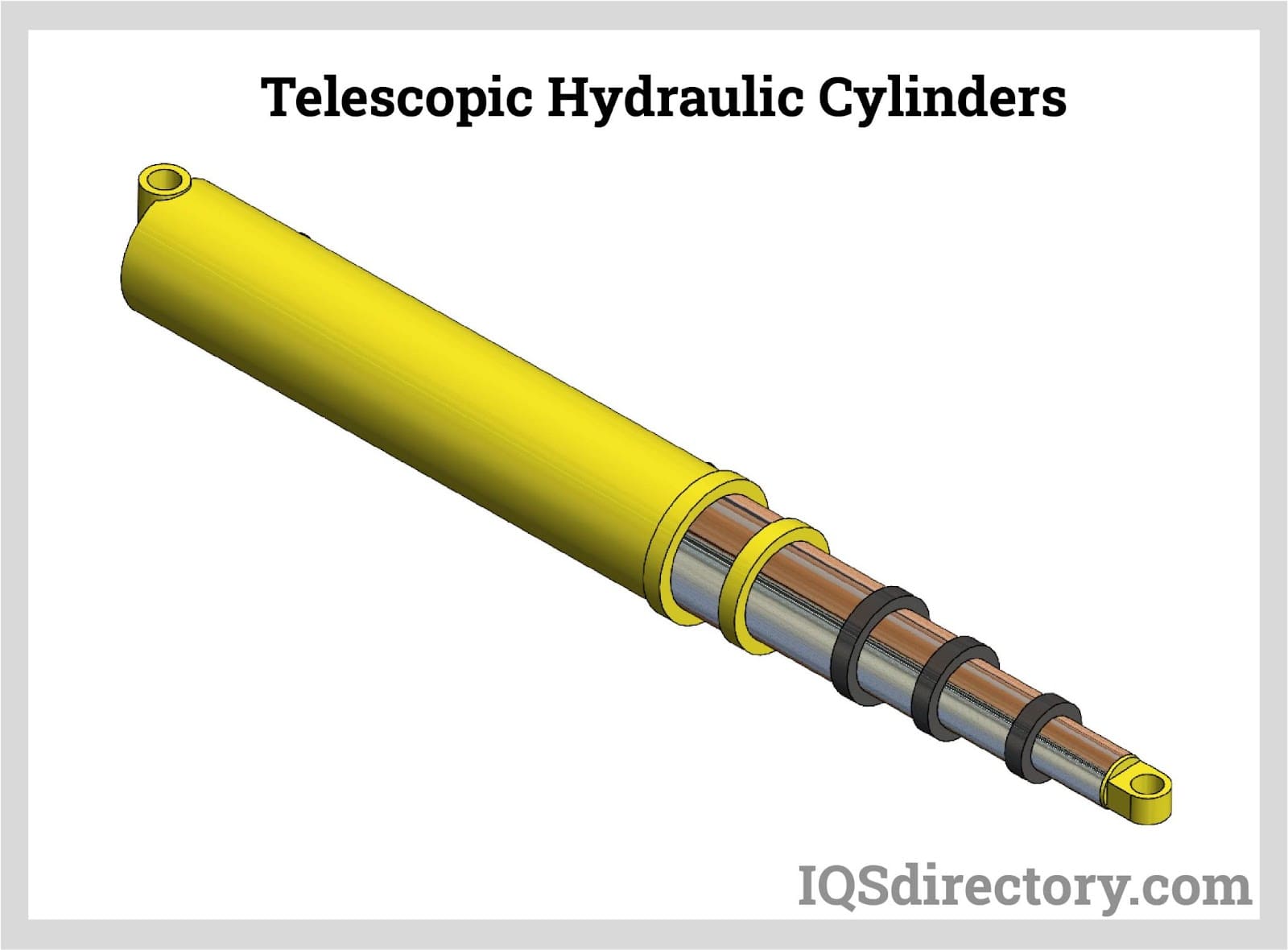

In this guide, readers will explore essential topics such as the different types of hydraulic cylinders, including single-acting and double-acting options, and the significance of specifications like bore diameter and stroke length. Additionally, we delve into supplier vetting processes, helping buyers identify reputable manufacturers and aftermarket providers. Understanding the cost structures associated with hydraulic components is also vital, as it enables informed budgeting and procurement decisions.

By empowering international B2B buyers—particularly those from Africa, South America, the Middle East, and Europe, including countries like Nigeria and Brazil—this guide equips them with the knowledge needed to make confident purchasing decisions. Whether you are a contractor, manufacturer, or distributor, the insights provided herein will enhance your ability to navigate the global market effectively and secure hydraulic solutions that drive operational success.

Understanding hydraulic cylinder and piston Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Acting Hydraulic Cylinder | Operates in one direction; uses hydraulic pressure to extend only | Construction, agriculture | Pros: Simplicity, cost-effective. Cons: Limited functionality, not suitable for tasks requiring retraction. |

| Double-Acting Hydraulic Cylinder | Can extend and retract; utilizes hydraulic pressure in both directions | Manufacturing, material handling | Pros: Versatile, allows for controlled movement. Cons: More complex and potentially higher maintenance costs. |

| Tie-Rod Hydraulic Cylinder | Features external rods for structural support; often used in low-pressure applications | Agricultural machinery, light-duty tasks | Pros: Durable, easy to repair. Cons: Bulkier design, less suitable for high-pressure applications. |

| Clevis End Hydraulic Cylinder | Equipped with clevis ends for easy mounting; designed for heavy-duty applications | Construction equipment, loaders | Pros: Robust design, suitable for heavy loads. Cons: May require specific mounting configurations. |

| Custom Hydraulic Cylinder | Tailored to specific requirements; various options for size, pressure, and materials | Specialized machinery, unique projects | Pros: High adaptability, meets exact specifications. Cons: Higher cost, minimum order quantities may apply. |

What Are the Key Characteristics of Single-Acting Hydraulic Cylinders?

Single-acting hydraulic cylinders are designed to exert force in one direction only, utilizing hydraulic pressure to extend the piston while relying on gravity or an external force for retraction. This type of cylinder is commonly used in applications where the load is primarily in one direction, such as in construction and agricultural equipment. When purchasing, buyers should consider the cylinder’s bore diameter, stroke length, and the specific application to ensure compatibility with their machinery.

How Do Double-Acting Hydraulic Cylinders Offer Versatility?

Double-acting hydraulic cylinders can generate force in both extending and retracting motions, making them highly versatile for various industrial applications. They are often used in manufacturing and material handling, where precise control over both movements is essential. Buyers should evaluate the hydraulic pressure ratings, bore diameter, and overall design to ensure the cylinder meets the demands of their specific operations, especially in dynamic environments.

What Makes Tie-Rod Hydraulic Cylinders Suitable for Low-Pressure Applications?

Tie-rod hydraulic cylinders feature external rods that provide structural integrity, making them suitable for low-pressure applications such as agricultural machinery. Their design allows for easier maintenance and repairs, which can be an advantage for companies looking to minimize downtime. Buyers should assess the pressure ratings, bore sizes, and intended use to ensure the cylinder’s performance aligns with their operational requirements.

Why Choose Clevis End Hydraulic Cylinders for Heavy-Duty Tasks?

Clevis end hydraulic cylinders are specifically designed for heavy-duty applications, often found in construction and loader equipment. Their robust construction and ease of mounting make them ideal for tasks that require significant lifting and pushing forces. When considering these cylinders, buyers should look at the load capacity, mounting configurations, and compatibility with existing machinery to ensure optimal performance.

How Can Custom Hydraulic Cylinders Meet Unique Project Needs?

Custom hydraulic cylinders are manufactured to meet specific project requirements, offering flexibility in size, pressure ratings, and materials. This adaptability makes them invaluable for specialized machinery and unique applications where standard options may not suffice. Buyers should be aware of the minimum order quantities and costs associated with custom cylinders, as well as the importance of clear specifications to achieve the desired functionality.

Key Industrial Applications of hydraulic cylinder and piston

| Industry/Sector | Specific Application of hydraulic cylinder and piston | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Lifting and lowering heavy equipment and materials | Enhanced efficiency in construction processes | Durability, pressure ratings, and compliance with local standards |

| Agriculture | Operating machinery for plowing, planting, and harvesting | Improved productivity and reduced manual labor | Compatibility with existing equipment and maintenance support |

| Manufacturing | Automation of assembly lines and material handling | Increased operational efficiency and reduced downtime | Customization options and quality certifications (ISO, etc.) |

| Mining | Hoisting and transporting materials in challenging terrains | Enhanced safety and reliability in harsh environments | Robustness, size specifications, and service availability |

| Waste Management | Compaction of waste materials in collection vehicles | Increased capacity and efficiency in waste collection | Weight capacity, seal quality, and resistance to corrosion |

How Are Hydraulic Cylinders and Pistons Used in Construction?

In the construction industry, hydraulic cylinders and pistons are vital for lifting and lowering heavy equipment, such as cranes and excavators. They enable precise control of heavy loads, significantly improving the efficiency of construction processes. Buyers in this sector should prioritize sourcing durable hydraulic components that meet local pressure ratings and industry standards to ensure reliability on site, especially in regions like Africa and South America where conditions can be demanding.

What Role Do Hydraulic Cylinders Play in Agriculture?

Hydraulic cylinders are extensively used in agricultural machinery for tasks such as plowing, planting, and harvesting. They facilitate the operation of tractors and other equipment, leading to enhanced productivity and reduced manual labor. International buyers should consider compatibility with existing machinery and the availability of maintenance support when sourcing these components, ensuring that they can operate effectively in diverse agricultural environments.

How Are Hydraulic Cylinders Essential in Manufacturing?

In manufacturing, hydraulic cylinders and pistons automate assembly lines and material handling processes. They provide the necessary force for moving heavy parts, increasing operational efficiency and minimizing downtime. When sourcing hydraulic components, manufacturers should look for customization options to fit their specific production needs, along with quality certifications to guarantee performance and safety standards.

Why Are Hydraulic Cylinders Critical in Mining Operations?

In the mining sector, hydraulic cylinders are crucial for hoisting and transporting materials, particularly in challenging terrains. Their robust design ensures enhanced safety and reliability, which is paramount in harsh mining environments. Buyers should focus on sourcing cylinders that meet stringent robustness and size specifications, as well as ensure that they have access to reliable service and support for maintenance.

How Do Hydraulic Cylinders Improve Waste Management?

Hydraulic cylinders are employed in waste management for compacting waste materials in collection vehicles, which increases capacity and efficiency in waste collection operations. This application is critical for maintaining operational effectiveness in urban areas. When sourcing these cylinders, it is essential to consider their weight capacity, seal quality, and resistance to corrosion, particularly for buyers in regions with diverse waste management challenges.

3 Common User Pain Points for ‘hydraulic cylinder and piston’ & Their Solutions

Scenario 1: Inconsistent Performance Under Load

The Problem: B2B buyers in industries such as construction and agriculture often face challenges with hydraulic cylinders that do not perform consistently under load. This inconsistency can lead to equipment failure, unplanned downtime, and ultimately financial loss. Buyers may find themselves dealing with cylinders that fail to extend or retract properly, resulting in delays in project timelines and increased labor costs. This situation can be particularly frustrating when the equipment is new or recently serviced, leading to questions about the quality of the components.

The Solution: To address this issue, buyers should prioritize sourcing hydraulic cylinders from reputable manufacturers who adhere to industry standards like ISO 9001:2015. When evaluating potential suppliers, it is crucial to inquire about the specifications of the cylinders, including bore diameter, rod diameter, and the materials used. Additionally, buyers should ensure that they are selecting the correct type of cylinder—single-acting versus double-acting—based on their specific application needs. Regular maintenance and proper installation can also mitigate performance inconsistencies. Implementing a routine inspection schedule to check for leaks, wear, and fluid levels can significantly enhance the reliability of hydraulic systems.

Scenario 2: High Replacement Costs Due to Wear and Tear

The Problem: Many B2B buyers experience high costs associated with the frequent replacement of hydraulic cylinders and pistons due to wear and tear. This issue is particularly pronounced in industries that involve heavy machinery or extreme operating conditions. Buyers may find that the lifespan of their hydraulic components is shorter than anticipated, leading to unexpected capital expenditure that disrupts budget forecasts and financial planning.

The Solution: To combat high replacement costs, buyers should consider investing in high-quality, durable hydraulic cylinders designed for their specific applications. Opting for cylinders with advanced materials and coatings can enhance resistance to wear, corrosion, and extreme temperatures. Additionally, buyers should evaluate the operating conditions and ensure that the hydraulic systems are not exceeding the recommended pressure ratings. Implementing a preventive maintenance program that includes regular lubrication, inspection of seals, and timely replacement of worn components can extend the lifespan of hydraulic cylinders and reduce overall costs. Furthermore, buyers should also engage with suppliers who offer warranties and after-sales support, ensuring they have recourse in case of premature failure.

Scenario 3: Difficulty in Sourcing Custom Hydraulic Solutions

The Problem: Many B2B buyers require custom hydraulic cylinders for specific applications but struggle to find suppliers who can deliver tailored solutions. This challenge is particularly acute in niche industries where standard cylinders do not meet operational requirements. The inability to source the right custom solutions can lead to project delays and hinder operational efficiency, causing frustration for procurement teams.

The Solution: Buyers facing this challenge should proactively communicate their specific needs to potential suppliers, including details such as pressure ratings, stroke lengths, and mounting configurations. Seeking manufacturers that specialize in custom hydraulic solutions can significantly enhance the chances of finding suitable products. It is advisable to request prototypes or engage in collaborative design processes with suppliers to ensure that the final product meets all operational specifications. Additionally, buyers should consider suppliers that offer a variety of customization options, such as different materials, seal types, and coatings, to ensure compatibility with their unique operating conditions. Establishing a good relationship with suppliers can also facilitate quicker adjustments and improvements in the design process, ultimately leading to more effective and timely solutions.

Strategic Material Selection Guide for hydraulic cylinder and piston

What Are the Key Materials for Hydraulic Cylinders and Pistons?

When selecting materials for hydraulic cylinders and pistons, it is essential to consider properties that directly influence performance, durability, and application suitability. The choice of material affects everything from the cylinder’s pressure rating to its resistance to environmental factors, particularly in diverse global markets such as Africa, South America, the Middle East, and Europe.

How Do Steel Alloys Perform in Hydraulic Applications?

Steel alloys are the most common materials used in hydraulic cylinders and pistons due to their excellent mechanical properties. Key properties include high tensile strength, good fatigue resistance, and the ability to withstand high pressures and temperatures (often exceeding 300°F). Additionally, steel can be treated or coated to enhance corrosion resistance.

Pros: Steel alloys are durable and can be manufactured to precise specifications, making them suitable for high-pressure applications. They are also relatively cost-effective compared to other materials.

Cons: However, steel is heavier, which can be a disadvantage in applications requiring lightweight solutions. It may also require additional coatings or treatments to prevent rust, especially in humid or corrosive environments.

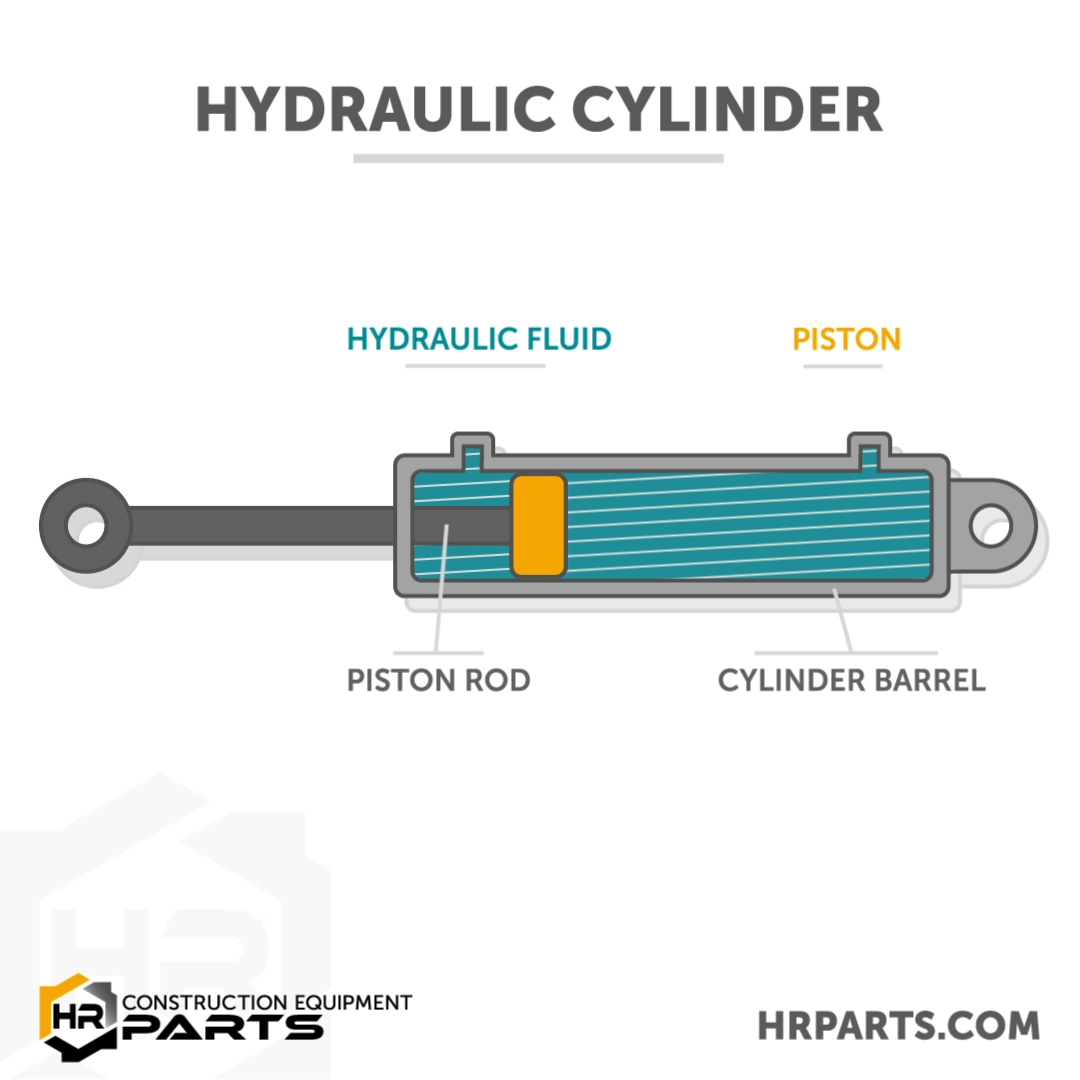

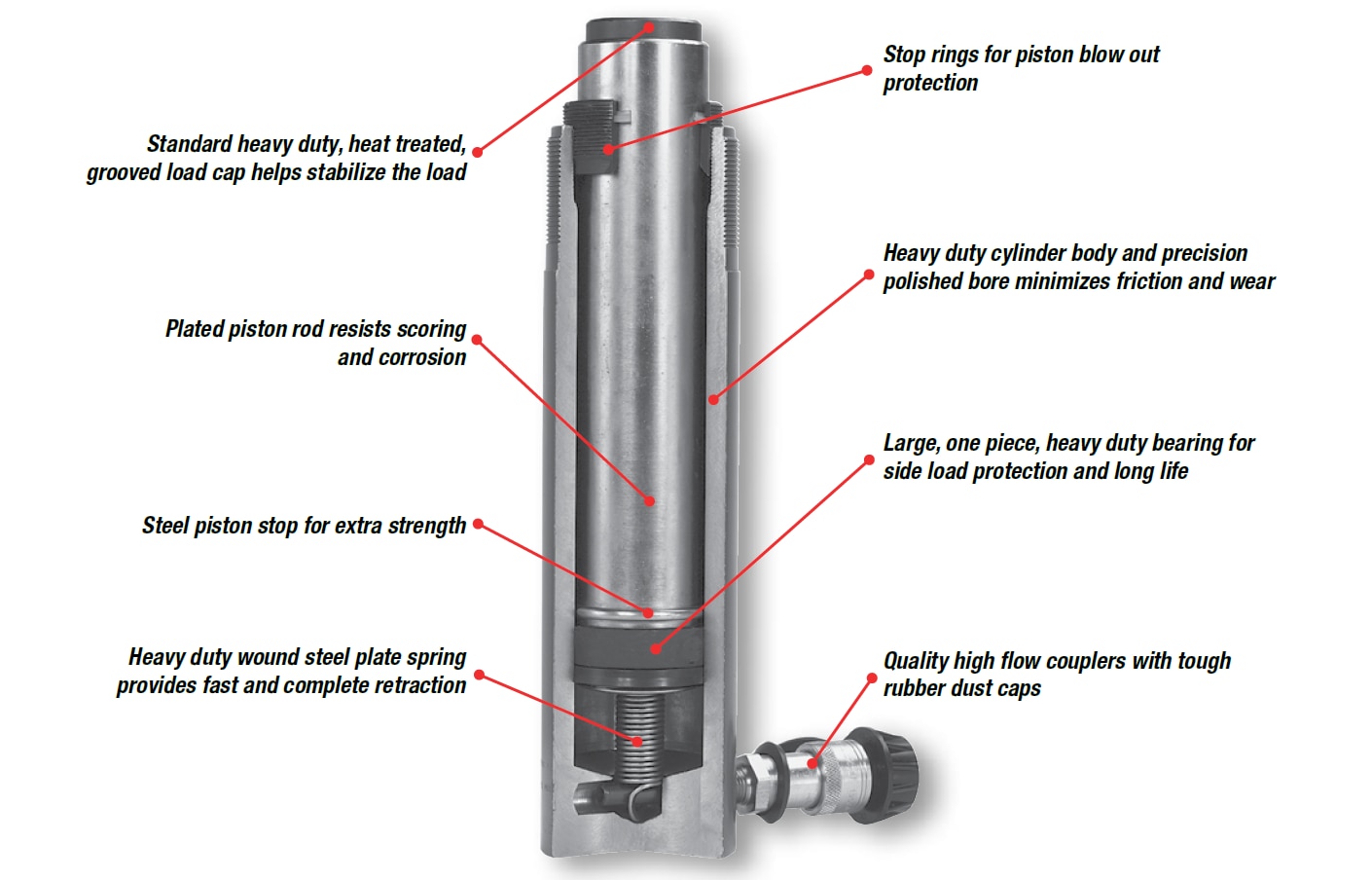

Illustrative image related to hydraulic cylinder and piston

Impact on Application: Steel alloys are compatible with a wide range of hydraulic fluids, making them versatile for various industrial applications.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM or DIN. In regions like Nigeria and Brazil, where environmental conditions can be harsh, selecting the right coating for steel can significantly impact longevity.

What Advantages Do Aluminum Alloys Offer for Hydraulic Components?

Aluminum alloys are increasingly used in hydraulic cylinders and pistons due to their lightweight nature and excellent corrosion resistance. Key properties include lower density compared to steel, which can improve fuel efficiency in mobile applications. Aluminum can also maintain performance in temperatures up to 250°F.

Pros: The primary advantage of aluminum is its weight, which is beneficial for applications where reducing mass is critical. It also resists corrosion naturally, reducing maintenance needs.

Cons: On the downside, aluminum alloys generally have lower tensile strength than steel, making them less suitable for extremely high-pressure applications. They may also be more expensive due to the cost of raw materials and processing.

Impact on Application: Aluminum is particularly suitable for hydraulic systems that operate in corrosive environments, such as marine applications or agricultural machinery exposed to fertilizers.

Considerations for International Buyers: Buyers in regions like the Middle East, where high temperatures and humidity are prevalent, should consider aluminum for its corrosion resistance. Compliance with local standards is also essential.

How Do Composite Materials Enhance Hydraulic Cylinder Performance?

Composite materials, often made from a combination of polymers and reinforcing fibers, are gaining traction in hydraulic applications. Key properties include high strength-to-weight ratios and excellent resistance to corrosion and wear.

Pros: Composites can be tailored for specific performance characteristics, making them suitable for specialized applications. They are lightweight and can reduce overall system weight significantly.

Cons: However, composites can be more expensive to manufacture and may not be suitable for high-temperature applications. They also require careful handling and installation to avoid damage.

Impact on Application: Composite materials are ideal for applications where weight savings are critical, such as aerospace or automotive sectors.

Considerations for International Buyers: Buyers should ensure that the composites meet relevant standards such as JIS for Japan or ISO for international compliance. Understanding the local market’s acceptance of composites is also crucial.

What Role Does Cast Iron Play in Hydraulic Systems?

Cast iron is another material option for hydraulic cylinders and pistons, known for its excellent wear resistance and ability to dampen vibrations. Key properties include good compressive strength and moderate corrosion resistance.

Illustrative image related to hydraulic cylinder and piston

Pros: Cast iron is durable and can withstand heavy loads, making it suitable for industrial applications. Its ability to absorb shock can enhance system longevity.

Cons: However, cast iron is brittle and can fracture under excessive tensile stress. Its weight can also be a disadvantage in mobile applications.

Impact on Application: Cast iron is often used in heavy machinery where durability is prioritized over weight.

Considerations for International Buyers: Buyers should be aware of the specific grades of cast iron available and their compliance with local standards, especially in regions like South America, where industrial applications may vary widely.

Illustrative image related to hydraulic cylinder and piston

Summary Table of Material Selection for Hydraulic Cylinders and Pistons

| Material | Typical Use Case for hydraulic cylinder and piston | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel Alloys | High-pressure industrial applications | High strength and durability | Heavier and may require coatings | Medium |

| Aluminum Alloys | Lightweight mobile applications | Lightweight and corrosion-resistant | Lower tensile strength | High |

| Composites | Aerospace and specialized applications | Tailored performance and lightweight | Higher manufacturing costs | High |

| Cast Iron | Heavy machinery and industrial applications | Excellent wear resistance and shock absorption | Brittle and heavy | Medium |

This guide provides a comprehensive overview of the materials used in hydraulic cylinders and pistons, enabling B2B buyers to make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for hydraulic cylinder and piston

What Are the Main Stages in the Manufacturing Process of Hydraulic Cylinders and Pistons?

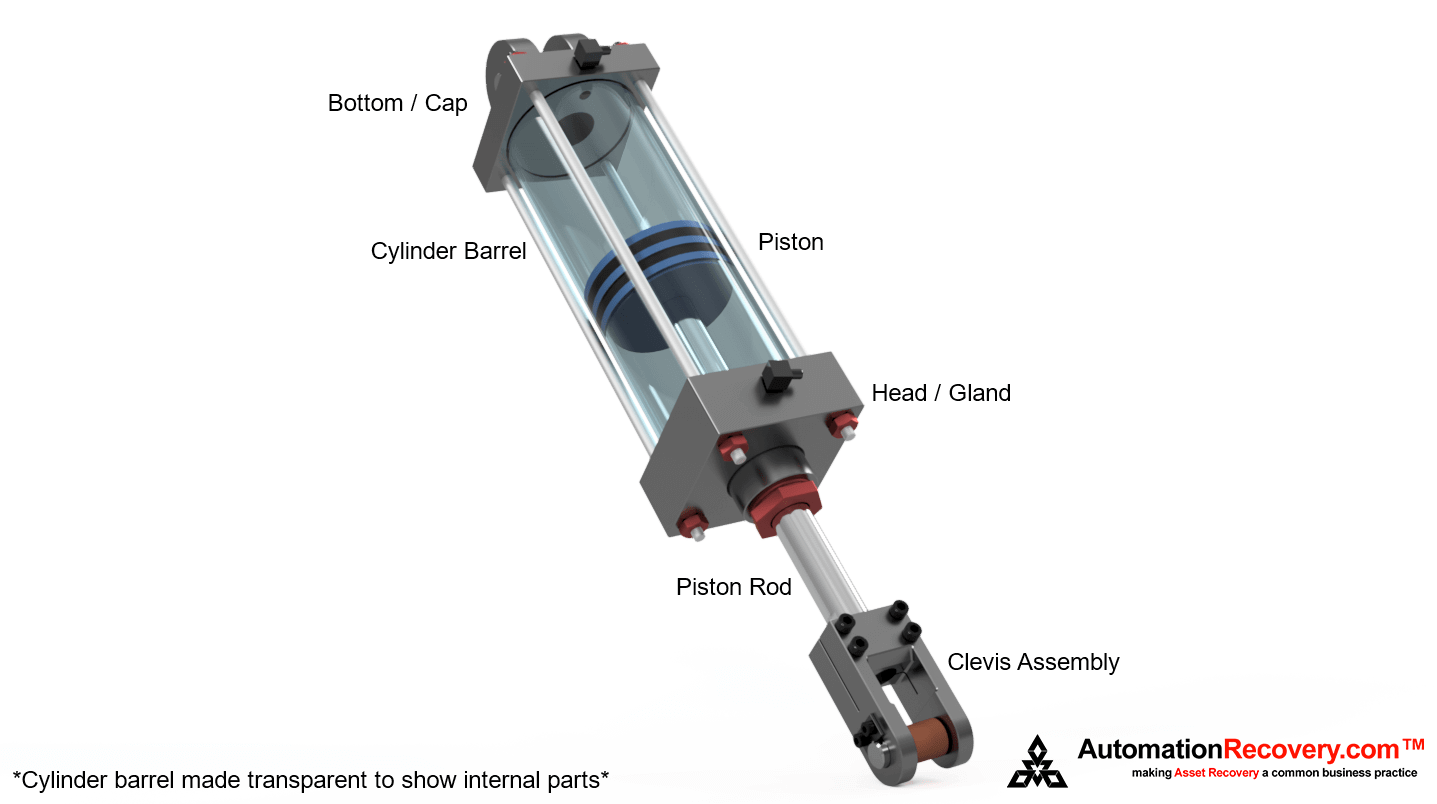

The manufacturing of hydraulic cylinders and pistons involves several critical stages that ensure the final product meets industry standards for performance and durability. Each stage is meticulously planned and executed, encompassing material preparation, forming, assembly, and finishing.

How Is Material Prepared for Hydraulic Cylinder and Piston Production?

Material preparation is the foundational step in the manufacturing process. High-quality raw materials, such as steel or aluminum alloys, are selected based on their mechanical properties and compatibility with hydraulic applications. The materials undergo rigorous inspection to ensure they meet specified chemical and physical requirements. This step often includes cutting raw materials to size and conducting heat treatment processes to enhance material strength and resistance to fatigue.

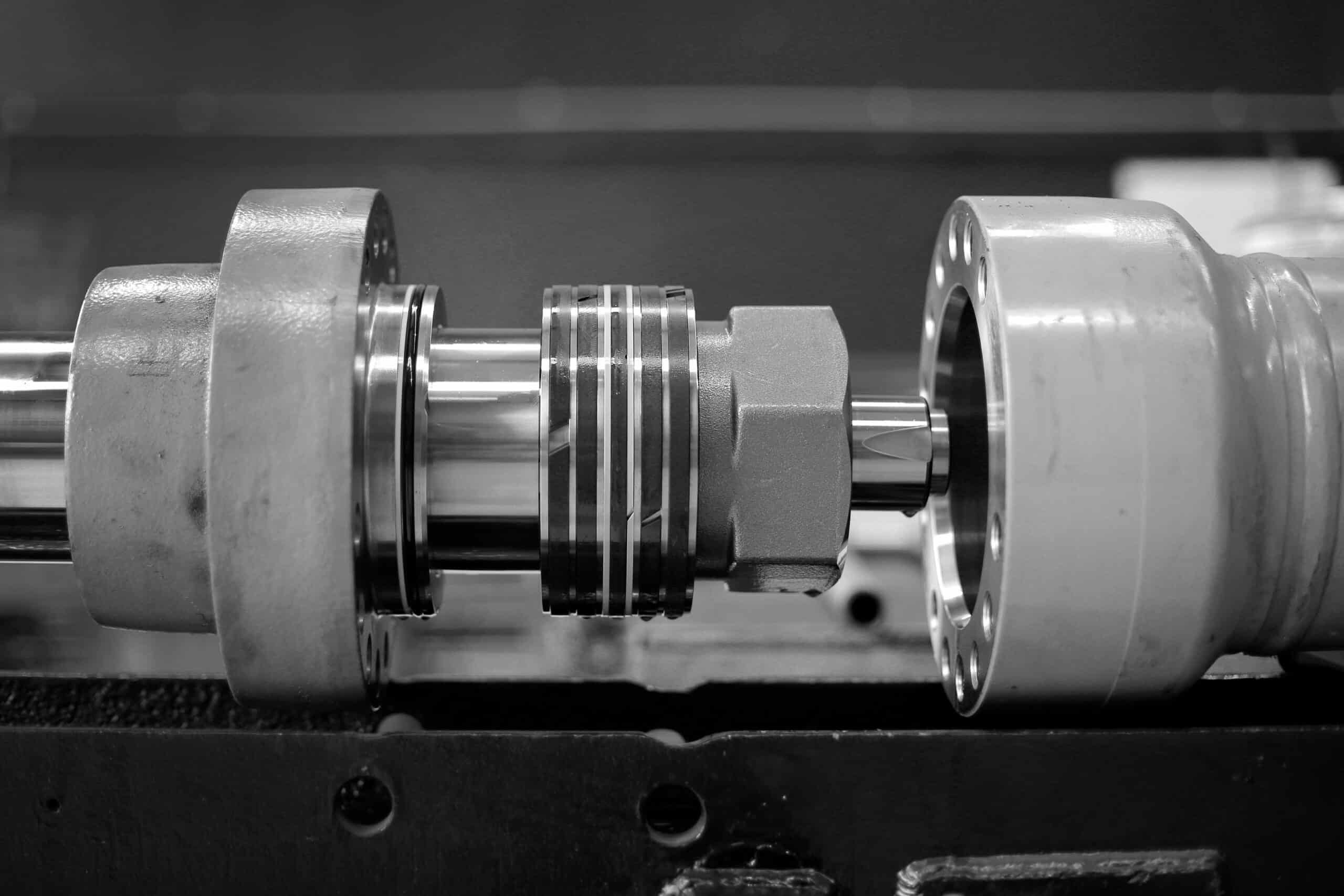

What Forming Techniques Are Used in Hydraulic Cylinder and Piston Manufacturing?

The forming stage includes techniques like machining, forging, and welding. Machining is essential for creating precise dimensions on cylinder barrels and pistons, utilizing CNC (Computer Numerical Control) machines for accuracy. Forging is often employed for components that require enhanced strength, as it aligns the grain structure of the metal. For assembling parts, welding techniques such as TIG (Tungsten Inert Gas) welding are commonly used to join various components, ensuring structural integrity and leak-proof seals.

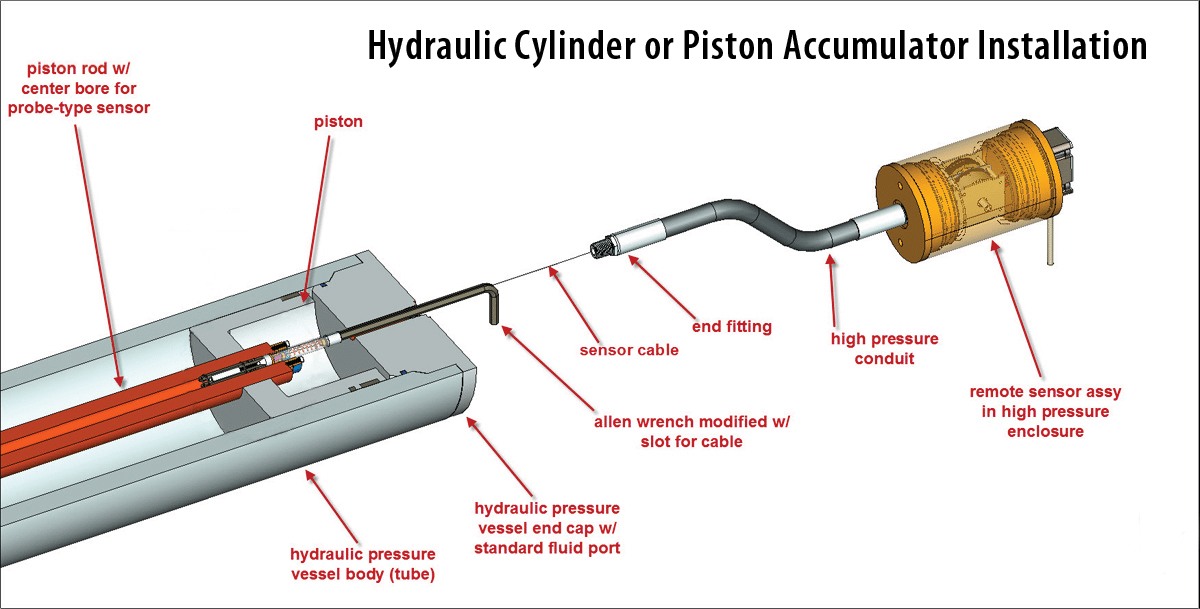

How Is the Assembly Process Conducted for Hydraulic Cylinders and Pistons?

Assembly is a critical phase where all components come together to create the final product. This includes fitting the piston within the cylinder barrel, attaching the piston rod, and securing seals and other accessories. Each assembly line typically follows a standardized procedure to minimize errors. Automated systems may be used to enhance efficiency, while skilled technicians perform quality checks at various stages of assembly to ensure everything is in order before moving to the finishing stage.

What Finishing Processes Are Essential for Hydraulic Cylinders and Pistons?

The finishing stage involves surface treatment and coating processes that enhance durability and performance. Techniques such as anodizing or powder coating provide corrosion resistance, while grinding and polishing ensure smooth surfaces for optimal sealing and operation. These finishing processes are vital, particularly for components that will be exposed to harsh environments, such as those found in construction or agricultural applications.

What Quality Assurance Standards Are Relevant for Hydraulic Cylinders and Pistons?

Quality assurance (QA) is critical in the manufacturing of hydraulic cylinders and pistons, ensuring that products meet international and industry-specific standards. The ISO 9001 certification is a widely recognized quality management standard that focuses on continuous improvement and customer satisfaction. For hydraulic components, additional certifications like CE marking for compliance with EU regulations or API (American Petroleum Institute) certifications for oil and gas applications may be relevant.

Illustrative image related to hydraulic cylinder and piston

How Are Quality Control Checkpoints Integrated Into the Manufacturing Process?

Quality control (QC) is implemented at various checkpoints throughout the manufacturing process. Incoming Quality Control (IQC) checks raw materials upon arrival to ensure they meet specifications. In-Process Quality Control (IPQC) monitors production to catch defects early, while Final Quality Control (FQC) involves comprehensive testing of the finished products. Common testing methods include pressure testing, dimensional checks, and performance assessments under simulated operational conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Buyers can request documentation of certifications, including ISO and other relevant quality standards. Conducting audits of the manufacturing facility is another effective way to assess the supplier’s commitment to quality. Moreover, third-party inspections can provide an unbiased evaluation of the manufacturing process and product quality.

What Are the Specific Quality Control and Certification Nuances for International Buyers?

International buyers need to consider several nuances regarding quality control and certification. Different regions may have varying standards and regulations, which can affect the compliance of hydraulic cylinders and pistons. For instance, products intended for the European market may require CE certification, while those for the American market may need to comply with ANSI or API standards. Understanding these differences is essential for ensuring that products are not only compliant but also suitable for their intended applications.

How Do International Standards Impact the Selection of Hydraulic Cylinders and Pistons?

Selecting hydraulic cylinders and pistons often involves understanding how international standards impact product quality and performance. Buyers should be aware of the implications of sourcing components from different regions, as manufacturing practices and quality standards can vary significantly. By prioritizing suppliers with recognized certifications and proven quality control processes, B2B buyers can mitigate risks and ensure they receive reliable products that meet their operational needs.

Conclusion: Ensuring Quality and Reliability in Hydraulic Cylinder and Piston Manufacturing

In summary, the manufacturing processes and quality assurance measures for hydraulic cylinders and pistons are multi-faceted and critical for delivering high-performance products. By understanding the stages of manufacturing, the importance of quality control, and the nuances of international standards, B2B buyers can make informed decisions and foster partnerships with reliable suppliers. This comprehensive approach not only enhances operational efficiency but also ensures the longevity and reliability of hydraulic systems across various industries.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hydraulic cylinder and piston’

Introduction

Sourcing hydraulic cylinders and pistons requires careful consideration of technical specifications, supplier reliability, and compliance with industry standards. This guide provides a step-by-step checklist to help international B2B buyers streamline their procurement process, ensuring they select the right components for their applications while minimizing risks and maximizing value.

1. Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. This includes determining the bore diameter, rod diameter, stroke length, and whether you need single-acting or double-acting cylinders.

Illustrative image related to hydraulic cylinder and piston

- Bore Diameter: Ensure compatibility with existing equipment.

- Stroke Length: Consider the operational needs and the space available in your machinery.

2. Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in hydraulic cylinders and pistons. Look for companies with a strong reputation in your target regions, such as Africa, South America, the Middle East, and Europe.

- Industry Experience: Prioritize suppliers with a proven track record in your specific industry.

- Customer Reviews: Check testimonials and ratings to gauge customer satisfaction and service quality.

3. Evaluate Supplier Certifications

Verify that your chosen suppliers hold relevant certifications, such as ISO 9001:2015. This ensures that they adhere to international quality management standards, which is crucial for maintaining product reliability and safety.

- Quality Assurance: Certifications reflect a commitment to consistent quality.

- Regulatory Compliance: Ensure that products meet local and international regulations.

4. Request Product Samples

Before placing a bulk order, request samples of the hydraulic cylinders and pistons you are considering. This allows you to assess the quality, fit, and performance of the products firsthand.

- Quality Check: Evaluate the materials, finish, and overall build quality.

- Performance Testing: Conduct tests under actual working conditions to confirm reliability.

5. Assess Customization Options

Consider whether the supplier can provide custom solutions tailored to your specific needs. Many applications require unique specifications that off-the-shelf products may not meet.

- Flexibility: Suppliers offering customization can better meet your operational requirements.

- Minimum Order Quantities: Be aware of the minimum quantities required for custom orders.

6. Negotiate Pricing and Terms

Once you have narrowed down your options, engage in price negotiations. Ensure that you understand the full cost implications, including shipping, taxes, and potential tariffs.

- Bulk Discounts: Inquire about volume pricing and any applicable discounts.

- Payment Terms: Clarify payment options and terms to avoid misunderstandings later.

7. Establish a Communication Plan

After selecting a supplier, set up a clear communication plan to facilitate smooth interactions throughout the procurement process. Regular updates and open lines of communication can help address any issues promptly.

- Contact Points: Designate key contacts on both sides for efficient communication.

- Feedback Loop: Establish a mechanism for providing feedback on product performance and service quality.

By following this checklist, B2B buyers can enhance their procurement process, ensuring they select high-quality hydraulic cylinders and pistons that meet their operational needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for hydraulic cylinder and piston Sourcing

Analyzing the costs and pricing for hydraulic cylinders and pistons is critical for international B2B buyers aiming to make informed sourcing decisions. Understanding the cost structure, price influencers, and effective negotiation strategies can significantly enhance procurement efficiency, particularly in regions like Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for Hydraulic Cylinders and Pistons?

The cost structure of hydraulic cylinders and pistons typically encompasses several key components:

-

Materials: The primary materials include high-strength steel and aluminum, which are essential for durability and performance. The choice of materials directly influences the overall cost, with high-grade materials typically commanding higher prices.

-

Labor: Labor costs vary based on the location of manufacturing. Regions with lower labor costs can lead to reduced overall pricing but may also affect quality and consistency.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Investment in tooling is necessary for producing custom components. The complexity of the design will affect the tooling costs, which can be significant for specialized hydraulic components.

-

Quality Control (QC): Ensuring that products meet industry standards requires investment in quality control measures, which can add to the overall cost.

-

Logistics: Transportation costs, including shipping and handling, are a critical factor, especially for international buyers. The choice of shipping method and distance from the manufacturer can significantly impact logistics costs.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market demand and competition.

How Do Price Influencers Impact Hydraulic Cylinder and Piston Pricing?

Several factors can influence the pricing of hydraulic cylinders and pistons:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for discounts, making it essential for buyers to assess their purchasing capacity against MOQ requirements.

-

Specifications and Customization: Custom specifications can lead to higher costs due to increased complexity in production. Buyers should weigh the benefits of customization against potential cost increases.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (such as ISO) can elevate costs but also ensure reliability and compliance with industry standards.

-

Supplier Factors: Supplier reputation, experience, and location can affect pricing. Established suppliers may charge more due to their reliability and quality assurance.

-

Incoterms: The selected Incoterms (International Commercial Terms) will determine who bears the shipping costs and risks, influencing the overall total cost of ownership.

What Tips Can Buyers Use to Negotiate Better Prices?

To optimize sourcing costs, buyers should consider the following strategies:

-

Leverage Volume Discounts: By consolidating orders or collaborating with other businesses, buyers can achieve better pricing through bulk purchasing.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors such as maintenance costs, lifespan, and potential downtime, which can impact overall expenses.

-

Negotiate Terms: Engage suppliers in discussions about payment terms, delivery schedules, and warranty conditions to enhance the value of the purchase.

-

Understand Pricing Nuances: Familiarize yourself with regional market conditions and pricing structures, especially in diverse markets like Nigeria and Brazil, where currency fluctuations and economic factors can affect costs.

-

Explore Local Suppliers: For buyers in Africa and South America, sourcing from local manufacturers can reduce shipping costs and lead times, enhancing overall procurement efficiency.

Conclusion

While indicative prices for hydraulic cylinders and pistons can range widely (e.g., from $40 to over $900 depending on specifications), understanding the underlying cost components and price influencers is crucial for making informed purchasing decisions. By employing strategic negotiation techniques and considering the total cost of ownership, international B2B buyers can optimize their sourcing strategies effectively.

Illustrative image related to hydraulic cylinder and piston

Alternatives Analysis: Comparing hydraulic cylinder and piston With Other Solutions

Exploring Alternatives to Hydraulic Cylinders and Pistons

In the realm of mechanical systems, hydraulic cylinders and pistons are widely recognized for their efficiency in generating linear motion through hydraulic pressure. However, there are several alternative solutions that can achieve similar objectives, each with its own unique advantages and disadvantages. Understanding these alternatives is crucial for B2B buyers looking to optimize their operations and make informed purchasing decisions.

| Comparison Aspect | Hydraulic Cylinder And Piston | Pneumatic Cylinder | Electric Linear Actuator |

|---|---|---|---|

| Performance | High force output; continuous operation | Moderate force output; rapid cycling | High precision; variable speed |

| Cost | Moderate to high; depending on specifications | Generally lower; maintenance costs can add up | Higher initial investment; lower operational costs |

| Ease of Implementation | Requires hydraulic system setup; specialized knowledge | Easier setup; less complex | Simple integration; requires electrical infrastructure |

| Maintenance | Regular maintenance needed; potential for leaks | Requires periodic checks; less frequent than hydraulic | Low maintenance; fewer moving parts |

| Best Use Case | Heavy-duty applications in construction, agriculture | Light to moderate applications; quick movements | Applications requiring precision and control, such as robotics |

What Are the Advantages and Disadvantages of Pneumatic Cylinders?

Pneumatic cylinders utilize compressed air to generate movement. One of their significant advantages is the speed at which they operate, making them ideal for applications requiring rapid cycling and shorter task durations. They are generally less expensive than hydraulic systems, making them a cost-effective choice for light to moderate applications. However, pneumatic systems may not provide the same force output as hydraulic cylinders, limiting their use in heavy-duty scenarios. Additionally, they can experience pressure drops and may require more frequent maintenance checks to ensure optimal performance.

How Do Electric Linear Actuators Compare?

Electric linear actuators convert electrical energy into mechanical motion, offering high precision and the ability to control speed and position accurately. This makes them suitable for applications in robotics, automation, and anywhere precise movements are required. While the initial investment can be higher than hydraulic or pneumatic options, they often incur lower operational costs due to fewer moving parts and reduced maintenance needs. However, electric actuators may not be suitable for environments where high force output is necessary, such as in heavy construction or industrial applications.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting the most suitable solution for their needs, B2B buyers should consider the specific requirements of their applications, including the desired performance, budget constraints, and maintenance capabilities. Hydraulic cylinders and pistons are optimal for high-force applications, while pneumatic cylinders provide speed and cost-effectiveness for lighter tasks. Electric linear actuators excel in precision and control, making them ideal for automation. By evaluating these factors, buyers can make informed decisions that align with their operational goals and enhance their productivity.

Essential Technical Properties and Trade Terminology for hydraulic cylinder and piston

What Are the Key Technical Properties of Hydraulic Cylinders and Pistons?

Understanding the essential technical properties of hydraulic cylinders and pistons is crucial for B2B buyers involved in sectors such as construction, agriculture, and manufacturing. Here are some key specifications to consider:

1. Bore Diameter

The bore diameter refers to the internal diameter of the cylinder where the piston moves. It directly impacts the force output of the hydraulic cylinder, as a larger bore allows for greater fluid volume and, consequently, more force generation. In B2B terms, selecting the correct bore diameter is essential for ensuring that the hydraulic system can handle the required load without failure.

2. Rod Diameter

The rod diameter is the diameter of the piston rod that extends from the hydraulic cylinder. This property is critical for determining the strength and durability of the cylinder under load. A larger rod diameter typically offers better resistance to bending and buckling, making it a vital specification for applications involving heavy loads or dynamic movements.

3. Stroke Length

The stroke length is the distance the piston can travel within the cylinder. This specification is crucial for applications that require specific movement ranges. Understanding the required stroke length helps buyers select the right hydraulic cylinder for their equipment, ensuring compatibility and optimal performance.

4. Operating Pressure

Operating pressure indicates the maximum pressure that a hydraulic cylinder can withstand during operation. This property is vital for ensuring safety and reliability in hydraulic systems. B2B buyers must match the operating pressure of the hydraulic cylinder with the requirements of their application to prevent system failures or accidents.

5. Material Composition

The material used for the cylinder and piston significantly affects durability and performance. Common materials include high-strength steel and aluminum alloys, each offering different benefits such as weight reduction or corrosion resistance. Buyers should consider environmental conditions and application demands when selecting materials to ensure longevity and reliability.

6. Sealing Mechanisms

Seals play a crucial role in preventing hydraulic fluid leakage and maintaining pressure within the system. Various sealing materials and designs are available, depending on the application and fluid type. Understanding the sealing mechanisms can help buyers ensure that their hydraulic cylinders operate efficiently and minimize maintenance needs.

What Are Common Trade Terminologies in Hydraulic Cylinder Transactions?

Familiarity with industry-specific terminology is essential for effective communication and negotiation in B2B transactions. Here are several key terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of hydraulic cylinders, knowing whether a supplier is an OEM can assure buyers of the quality and compatibility of parts for their systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product that a supplier is willing to sell. This term is crucial for B2B buyers as it directly impacts inventory management and purchasing strategy. Understanding MOQ can help companies avoid excess inventory and align purchases with their operational needs.

3. RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests pricing and terms from suppliers for specific products. This step is essential for comparing offers and ensuring that buyers receive competitive pricing and favorable terms for hydraulic cylinders and pistons.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in terms of shipping, risk, and costs. Familiarity with Incoterms is vital for B2B buyers to understand their obligations and rights during the transportation of hydraulic cylinders, which can be critical in international trade.

5. Hydraulic Fluid

Hydraulic fluid is the medium through which hydraulic energy is transmitted. Understanding the types of hydraulic fluids and their properties is important for ensuring compatibility with hydraulic systems and optimizing performance.

6. Custom Cylinders

Custom cylinders are tailored hydraulic cylinders designed to meet specific requirements not covered by standard products. B2B buyers may need custom solutions for unique applications, making it important to discuss customization options with suppliers.

Illustrative image related to hydraulic cylinder and piston

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions that optimize their procurement processes and enhance the efficiency of their hydraulic systems.

Navigating Market Dynamics and Sourcing Trends in the hydraulic cylinder and piston Sector

What Are the Current Market Dynamics and Key Trends in the Hydraulic Cylinder and Piston Sector?

The hydraulic cylinder and piston market is witnessing significant growth driven by the increasing demand for automation and advanced machinery across various sectors, including construction, agriculture, and manufacturing. The global push for enhanced efficiency and productivity is propelling the adoption of hydraulic systems, particularly in developing regions such as Africa and South America. In these markets, the emphasis on infrastructure development and agricultural modernization is particularly pronounced, offering substantial opportunities for B2B buyers.

Emerging technologies are reshaping sourcing trends in this sector. Digital transformation is facilitating better supply chain management through data analytics and IoT integration, enabling buyers to make informed decisions based on real-time data. Furthermore, the rise of e-commerce platforms is simplifying procurement processes, allowing international buyers to source hydraulic components from a broader range of suppliers. Additionally, manufacturers are increasingly offering custom solutions tailored to specific application needs, appealing to diverse industrial requirements.

Buyers should also be aware of fluctuating raw material costs and supply chain disruptions, which can impact pricing and availability. As geopolitical tensions and economic shifts continue to influence global trade, establishing strong relationships with reliable suppliers and diversifying sourcing strategies will be essential for maintaining a competitive edge in the hydraulic cylinder and piston market.

Illustrative image related to hydraulic cylinder and piston

How Is Sustainability Influencing Sourcing Decisions in the Hydraulic Cylinder and Piston Sector?

Sustainability has become a pivotal consideration in the hydraulic cylinder and piston sector, as environmental awareness among consumers and businesses grows. The production of hydraulic cylinders can have significant environmental impacts, including energy consumption and waste generation. Consequently, international buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices and ethical sourcing.

One of the key trends in this area is the adoption of ‘green’ certifications and materials. Suppliers that utilize recycled materials, eco-friendly coatings, and energy-efficient manufacturing processes are gaining favor among B2B buyers. Certifications such as ISO 14001 (Environmental Management) and ISO 50001 (Energy Management) are becoming critical indicators of a supplier’s dedication to sustainability.

Moreover, establishing ethical supply chains is crucial for mitigating risks associated with labor practices and environmental compliance. Buyers from regions like Africa and South America are particularly attuned to these issues, as they seek to partner with suppliers that adhere to international labor standards and environmental regulations. By aligning sourcing strategies with sustainability goals, businesses can enhance their brand reputation while contributing to global environmental efforts.

What Is the Historical Context of the Hydraulic Cylinder and Piston Industry for B2B Buyers?

The hydraulic cylinder and piston industry has evolved significantly since its inception in the late 19th century, primarily driven by advancements in engineering and manufacturing processes. Initially, hydraulic systems were limited to basic applications; however, the industrial revolution catalyzed the development of more sophisticated hydraulic machinery.

Illustrative image related to hydraulic cylinder and piston

In the latter half of the 20th century, the introduction of high-strength materials and improved design technologies led to the proliferation of hydraulic systems in various sectors, including construction and agriculture. Today, hydraulic cylinders are integral components in heavy machinery, enabling precise control and enhanced performance.

This historical context is essential for B2B buyers as it underscores the importance of innovation and reliability in hydraulic component sourcing. Understanding the evolution of hydraulic technology can aid buyers in making informed decisions about product specifications, supplier capabilities, and the overall suitability of hydraulic solutions for their specific applications.

Frequently Asked Questions (FAQs) for B2B Buyers of hydraulic cylinder and piston

-

How do I choose the right hydraulic cylinder for my application?

Choosing the right hydraulic cylinder involves assessing several critical factors. Start by determining the bore diameter and rod diameter that best fits your machinery. Evaluate the stroke length required for your application and consider whether you need a single-acting or double-acting cylinder based on the type of movement. Additionally, assess the materials and coatings for durability, especially if operating in harsh environments. Finally, consult with suppliers to ensure compatibility with your hydraulic system and to receive expert recommendations tailored to your specific needs. -

What are the key specifications to consider when sourcing hydraulic pistons?

When sourcing hydraulic pistons, focus on specifications such as the piston design (wide or narrow), materials used, and the pressure rating. It’s essential to understand the application environment to choose pistons that can withstand the necessary load and pressure. Also, consider the dimensions, including bore size and stroke length, to ensure compatibility with your hydraulic cylinder. Lastly, inquire about any available customization options that can enhance performance for your specific applications. -

What are the common payment terms for international purchases of hydraulic components?

Payment terms can vary significantly between suppliers, but common practices include a percentage deposit upon order confirmation, with the remaining balance due before shipment. Some suppliers may offer letter of credit arrangements, especially for larger orders. It’s crucial to clarify payment methods accepted, such as wire transfers or credit terms, and to ensure that the terms align with your cash flow management. Always review the terms carefully to avoid any unexpected charges or issues during the transaction process. -

How do I vet potential suppliers for hydraulic cylinders and pistons?

Vetting suppliers involves multiple steps to ensure reliability and quality. Start by checking their certifications, such as ISO 9001, which indicates adherence to quality management standards. Look for customer testimonials and case studies to assess their track record in your industry. Request product samples to evaluate the quality firsthand, and inquire about their manufacturing processes and warranty policies. Additionally, engage in discussions about their logistics capabilities to ensure they can meet your delivery timelines. -

What are the minimum order quantities (MOQs) for hydraulic cylinders and pistons?

Minimum order quantities (MOQs) can vary significantly based on the supplier and product type. For standard hydraulic cylinders, MOQs may range from 10 to 50 units, while custom designs typically require larger orders, often starting at 50 units or more. Always inquire about the MOQ before placing an order to ensure it fits within your procurement strategy. Some suppliers may offer flexibility for smaller orders, especially for repeat customers or established relationships. -

What logistics considerations should I keep in mind when importing hydraulic components?

When importing hydraulic components, consider shipping methods, lead times, and customs regulations. Choose between air freight for speed or sea freight for cost-effectiveness, depending on your urgency. Ensure that the supplier provides necessary documentation for customs clearance, including invoices, packing lists, and certificates of origin. Be aware of import duties and taxes applicable in your country to avoid unexpected costs. Establish a reliable logistics partner to help navigate these processes efficiently. -

How can I ensure quality assurance for hydraulic cylinders and pistons?

To ensure quality assurance, request detailed information about the supplier’s manufacturing process, including quality control measures in place. Ask for certifications that demonstrate compliance with international standards. Conduct inspections during production or prior to shipment, if feasible, to verify that products meet your specifications. Additionally, consider establishing a clear return policy for defective products and maintaining open communication with the supplier to address any quality issues promptly. -

What customization options are available for hydraulic cylinders and pistons?

Many suppliers offer customization options to meet specific application needs. Customizations can include variations in bore and rod diameters, stroke lengths, and material choices. You may also request specific coatings for enhanced durability or specialized seals for different pressure ratings. Some manufacturers can produce hydraulic cylinders tailored to unique dimensions or operational requirements, but be prepared for higher MOQs and longer lead times. Discuss your requirements with potential suppliers to explore the full range of customization possibilities.

Top 6 Hydraulic Cylinder And Piston Manufacturers & Suppliers List

1. CRC – Durable Industrial Pistons

Domain: crconline.com

Registered: 2000 (25 years)

Introduction: This company, CRC – Durable Industrial Pistons, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Titan Fittings – Hydraulic Cylinders

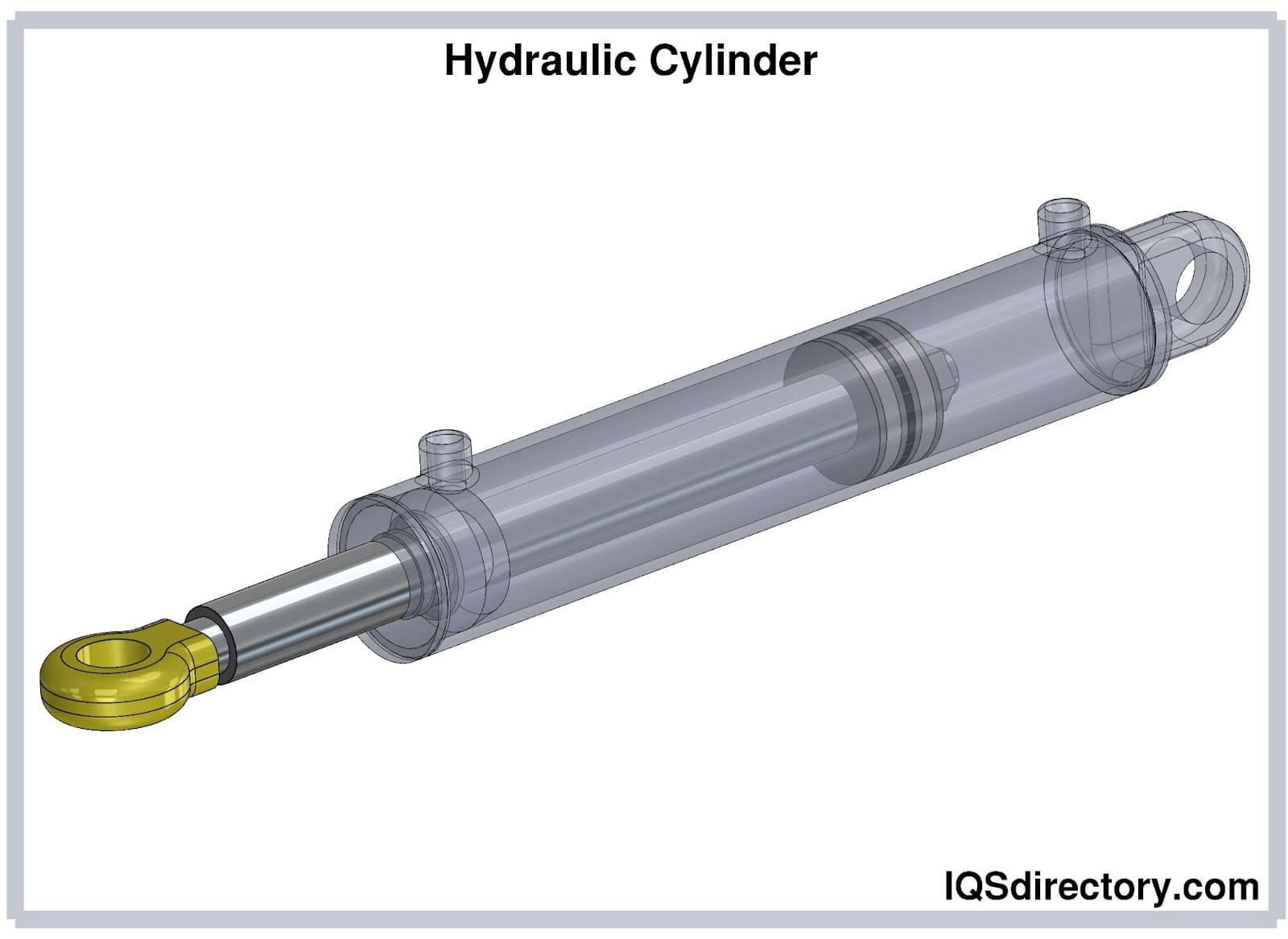

Domain: titanfittings.com

Registered: 2014 (11 years)

Introduction: Hydraulic cylinders are mechanical devices that use hydraulic fluid to generate force in a linear motion. Key components include: 1. Cylinder barrel – main body, made from durable materials like steel, providing a smooth inner surface. 2. Piston – generates linear force, typically made from durable materials and may have special treatments for corrosion resistance. 3. Piston rod – transmits force …

3. Passion Engineering – Hydraulic Cylinder Types

Domain: passionengineering.com

Registered: 2010 (15 years)

Introduction: Types of Hydraulic Cylinders: 1. Conventional Double Acting: Highly controllable, develops both compressive and tensile forces, ports at both ends. 2. Conventional Single Acting: High-pressure fluid ports at cap ends only, requires external forces for retraction. 3. Ram: Single-acting with large rods, no pistons, used in jacks and presses. 4. Double Rod: Rods extend through both cylinder heads, eq…

4. Hydraulic Piston – Various Types of Cylinders

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Hydraulic Piston in other Hydraulic & Pneumatic Cylinders for sale on eBay. Categories include various types of cylinders such as Single-Rod Cylinder, Tie-Rod Cylinder, Welded Cylinder, Compact Cylinder, Telescopic Cylinder, Double-Rod Cylinder, Hollow Plunger Cylinder, Rodless Cylinder, and Rotary Cylinder. Brands available include Enerpac, Parker, SMC, Bimba, Magister Hydraulics, Festo, SPX, Mil…

5. Case 580D – Hydraulic Piston Solutions

Domain: tractorbynet.com

Registered: 1999 (26 years)

Introduction: Hydraulic piston information discussed in a forum thread. Key points include: 1. Difficulty in removing a bolt from an outrigger cylinder on a Case 580D tractor, with suggestions that it may be left-hand threaded or simply very tight. 2. Use of PB Blaster for loosening, and recommendations for tools such as a 3/4″ breaker bar and impact wrench. 3. Mention of the importance of patience and proper t…

6. Yates – Hydraulic Cylinder Types

Domain: yatesind.com

Registered: 1999 (26 years)

Introduction: Hydraulic Cylinder Types: Tie Rod Cylinders, Welded Cylinders, Mill Duty Cylinders, Heavy Duty Hydraulic, Heavy Duty Pneumatic, Medium Duty Hydraulic, Light Duty Pneumatic, Light Duty Hydraulic. Key Components: Barrel (single-acting and double-acting), Cylinder Head/End Caps, Hydraulic Cylinder Base/Gland, Hydraulic Cylinder Piston, Piston Rod (cold-rolled steel with hard chrome plating), Seal Gla…

Strategic Sourcing Conclusion and Outlook for hydraulic cylinder and piston

As the global demand for hydraulic cylinders and pistons continues to rise, strategic sourcing becomes essential for international B2B buyers. By understanding the diverse range of applications and specifications—such as bore diameter, rod diameter, and material types—buyers can ensure they select the most suitable components for their operations. Engaging with reputable manufacturers, particularly those adhering to international quality standards, can significantly enhance reliability and performance, which is crucial in sectors ranging from construction to agriculture.

Moreover, the ability to customize hydraulic solutions allows companies to meet specific project requirements efficiently. Buyers from regions like Africa, South America, the Middle East, and Europe should leverage the competitive landscape to negotiate better terms and optimize their supply chains.

Looking ahead, it is imperative for businesses to stay informed about technological advancements and market trends in hydraulic systems. By doing so, they can not only enhance operational efficiency but also position themselves strategically for future growth. Now is the time to evaluate your sourcing strategy—consider reaching out to leading suppliers to explore innovative solutions tailored to your unique needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.