A B2B Buyer’s Guide to Honda Civic R 10Th Gen Bodykit: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for honda civic r 10th gen bodykit

The global demand for the Honda Civic R 10th Gen bodykit is on the rise, presenting a unique challenge for B2B buyers looking to source high-quality aftermarket parts. With a plethora of options available, from carbon fiber components to complete body kits, navigating this diverse market can be daunting. This guide aims to simplify the process by providing a comprehensive overview of the types of body kits available, their applications, and essential criteria for supplier vetting.

International buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Nigeria—will find valuable insights tailored to their specific needs. By exploring factors such as cost, quality, and supplier reliability, this guide empowers businesses to make informed purchasing decisions. Additionally, it addresses the nuances of shipping logistics and compliance with local regulations, ensuring a seamless procurement experience.

Equipped with this knowledge, B2B buyers can confidently engage with suppliers, optimize their purchasing strategy, and ultimately enhance their offerings in the competitive automotive aftermarket landscape. The information presented here not only aids in overcoming sourcing challenges but also positions businesses to capitalize on emerging market opportunities.

Understanding honda civic r 10th gen bodykit Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Body Kits | Comprehensive kits including bumpers, side skirts, and fenders. | Complete vehicle customization. | Pros: All-in-one solution, aesthetic appeal. Cons: Higher upfront cost, installation complexity. |

| Front Bumpers & Lips | Enhanced aerodynamics, aggressive styling, and lightweight materials. | Performance upgrades and aesthetic appeal. | Pros: Improves airflow, sporty look. Cons: May require additional modifications. |

| Side Skirts | Lowers the vehicle profile, improves aerodynamics. | Enhancing vehicle stance and stability. | Pros: Enhances look, reduces drag. Cons: Can be prone to scraping on uneven surfaces. |

| Rear Spoilers & Wings | Boosts downforce and stability at high speeds. | Performance tuning and aesthetic customization. | Pros: Improves handling, sporty appearance. Cons: Potentially increases drag. |

| Fenders & Widebody Kits | Wider wheel arches for larger tires, aggressive stance. | Off-road and performance applications. | Pros: Allows for bigger tires, unique look. Cons: May affect vehicle legality in some regions. |

What Are the Characteristics of Full Body Kits for Honda Civic R 10th Gen?

Full body kits for the Honda Civic R 10th Gen offer a comprehensive solution for buyers looking to transform their vehicles. These kits typically include front and rear bumpers, side skirts, and fenders, providing a cohesive aesthetic upgrade. B2B buyers should consider the complete nature of these kits, as they can streamline the purchasing process by eliminating the need for multiple suppliers. However, the upfront investment is generally higher, and installation may require professional assistance.

Illustrative image related to honda civic r 10th gen bodykit

How Do Front Bumpers & Lips Enhance Performance?

Front bumpers and lips are critical components for improving the aerodynamics of the Honda Civic R. These upgrades not only enhance the vehicle’s appearance but also optimize airflow, which can lead to better performance at high speeds. Businesses focused on performance tuning will find these components essential. However, potential buyers should be aware that these modifications might necessitate further adjustments to the vehicle.

Why Are Side Skirts Important for Vehicle Stability?

Side skirts play a vital role in lowering the vehicle’s profile, which helps reduce drag and improve stability at speed. For B2B buyers, these components are ideal for enhancing both aesthetics and performance. While they contribute positively to the vehicle’s look and function, buyers should consider the risk of scraping on uneven surfaces, which may require additional maintenance or replacement.

How Do Rear Spoilers & Wings Affect Handling?

Rear spoilers and wings are designed to increase downforce, enhancing vehicle stability during high-speed maneuvers. These components are particularly appealing to businesses involved in performance tuning and motorsport. While they offer significant handling benefits, buyers should evaluate the potential for increased drag and how this may affect fuel efficiency.

What Are the Benefits of Fenders & Widebody Kits?

Fenders and widebody kits provide an aggressive stance and allow for the installation of larger tires, catering to both performance and aesthetic preferences. These kits are especially popular among off-road and racing enthusiasts. However, businesses should consider local regulations regarding vehicle modifications, as widebody kits can sometimes affect legality.

Key Industrial Applications of honda civic r 10th gen bodykit

| Industry/Sector | Specific Application of Honda Civic R 10th Gen Bodykit | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Aftermarket | Customization and Performance Enhancement | Increases vehicle appeal and market competitiveness | Quality of materials (e.g., carbon fiber), supplier reliability, and compliance with local regulations |

| Motorsport | Race Vehicle Modifications | Enhances aerodynamics and performance in competitive settings | Certification for racing standards, weight optimization, and durability under high-stress conditions |

| Vehicle Resale & Leasing | Aesthetic Upgrades for Resale Value | Boosts resale price and attracts a wider customer base | Product compatibility with various models, installation support, and warranty provisions |

| Tuning Shops & Workshops | Installation Services for Performance Kits | Generates additional revenue through service offerings | Technical expertise, availability of installation tools, and training for staff on new products |

| Fleet Management | Standardization of Vehicle Appearance | Improves brand image and recognition across fleets | Bulk purchasing options, lead times for delivery, and maintenance support |

How is the Honda Civic R 10th Gen Bodykit Used in the Automotive Aftermarket?

In the automotive aftermarket, the Honda Civic R 10th Gen bodykit is primarily utilized for vehicle customization and performance enhancement. Businesses focus on appealing to consumers who seek to personalize their vehicles, thereby increasing the vehicle’s aesthetic value and market competitiveness. For international B2B buyers, especially in regions like Africa and South America, sourcing high-quality materials such as carbon fiber is crucial, as it directly impacts durability and performance. Additionally, suppliers must ensure compliance with local automotive regulations to avoid legal challenges.

Illustrative image related to honda civic r 10th gen bodykit

What Role Does the Honda Civic R Bodykit Play in Motorsports?

Motorsport applications of the Honda Civic R 10th Gen bodykit are centered around race vehicle modifications. These bodykits are designed to enhance aerodynamics, which is critical for improving speed and handling during competitive events. For B2B buyers in the Middle East and Europe, particularly those involved in racing, it is essential that the bodykits meet specific racing standards and certifications. Additionally, considerations such as weight optimization and durability under extreme conditions are vital for maintaining competitive performance.

How Can the Bodykit Enhance Vehicle Resale and Leasing Opportunities?

In the vehicle resale and leasing sector, the Honda Civic R 10th Gen bodykit serves as an aesthetic upgrade that significantly boosts resale value. By enhancing the vehicle’s look and appeal, businesses can attract a broader customer base, ultimately leading to higher sale prices. For international buyers, especially in markets like Germany and Nigeria, understanding the compatibility of bodykits with various models is essential. Moreover, buyers should seek suppliers who offer installation support and warranty provisions to ensure a seamless customer experience.

Why is the Bodykit Important for Tuning Shops and Workshops?

Tuning shops and workshops leverage the Honda Civic R 10th Gen bodykit to provide installation services for performance kits. This not only enhances their service offerings but also generates additional revenue. For businesses in this sector, technical expertise in the installation process is critical. Buyers should consider suppliers that provide training for staff on new products and ensure the availability of necessary installation tools, as this will facilitate smoother operations and customer satisfaction.

Illustrative image related to honda civic r 10th gen bodykit

How Does the Bodykit Benefit Fleet Management?

In fleet management, the Honda Civic R 10th Gen bodykit is utilized to standardize vehicle appearance, improving brand image and recognition across fleets. This is particularly beneficial for businesses looking to create a cohesive identity in the market. For international buyers, especially in regions with diverse vehicle models, bulk purchasing options and lead times for delivery are key considerations. Additionally, maintenance support from suppliers can ensure that the fleet remains visually appealing and operationally efficient.

3 Common User Pain Points for ‘honda civic r 10th gen bodykit’ & Their Solutions

Scenario 1: Sourcing Quality Bodykits for the Honda Civic 10th Gen

The Problem: One of the primary challenges B2B buyers face when sourcing body kits for the Honda Civic 10th Gen is ensuring the quality and durability of the products. With a saturated market filled with various suppliers, distinguishing between reputable manufacturers and those offering subpar materials can be daunting. Buyers are often concerned about the longevity of the body kits, particularly when exposed to harsh weather conditions, which can lead to premature wear and tear. Furthermore, improper installation can result in additional costs, delays, and potential damage to the vehicle.

The Solution: To effectively navigate this challenge, buyers should prioritize working with established suppliers known for their quality assurance processes. Conducting thorough research on potential vendors, including checking customer reviews and ratings, can provide insights into their reliability. It’s advisable to request samples or detailed product specifications, including materials used (like carbon fiber or FRP), to evaluate durability before making bulk purchases. Additionally, buyers should consider partnering with suppliers who offer installation support or training, ensuring that the kits are fitted correctly to mitigate any issues related to installation and enhance the overall performance of the body kits.

Scenario 2: Compatibility Issues with Bodykit Components

The Problem: Another common pain point for B2B buyers is compatibility issues between different components of the Honda Civic 10th Gen body kits. Many buyers may assume that all body kit parts are interchangeable, but variations in model specifications and aftermarket modifications can lead to significant mismatches. This not only complicates the installation process but also increases the risk of product returns and customer dissatisfaction, impacting the buyer’s bottom line.

The Solution: To minimize compatibility issues, buyers should engage in detailed discussions with their suppliers about the specific model variants they are working with. Maintaining a comprehensive database of the Civic 10th Gen’s specifications, including any aftermarket modifications previously made to vehicles, can be beneficial. Suppliers who provide detailed fitment guides or compatibility charts can help buyers make informed decisions. Furthermore, establishing a clear line of communication with the supplier during the ordering process allows for the confirmation of component compatibility, reducing the likelihood of errors and enhancing customer satisfaction.

Scenario 3: Understanding Legal and Regulatory Compliance for Bodykits

The Problem: Navigating legal and regulatory compliance related to vehicle modifications is a significant concern for B2B buyers in the automotive aftermarket. Different regions have varying laws regarding the modification of vehicles, including body kits, which can affect the legality of certain components. Buyers may face challenges related to emissions regulations, safety standards, and import/export restrictions, leading to potential fines or product recalls.

The Solution: Buyers should proactively seek information regarding the local regulations that govern vehicle modifications in their target markets. This can involve consulting legal experts or industry associations that specialize in automotive compliance. Establishing a partnership with suppliers who are knowledgeable about these regulations is crucial; they should be able to provide documentation and certifications that prove compliance with relevant standards. Additionally, buyers can benefit from participating in industry trade shows or forums where they can learn about regulatory updates and best practices in vehicle modifications, ensuring that their offerings remain compliant and marketable.

Strategic Material Selection Guide for honda civic r 10th gen bodykit

When selecting materials for the Honda Civic R 10th Gen bodykit, it is crucial to consider the unique properties, advantages, and limitations of each material to ensure optimal performance and compliance with international standards. Below is an analysis of four common materials used in bodykit production: Carbon Fiber, Fiberglass Reinforced Plastic (FRP), Polypropylene (PP), and Acrylonitrile Butadiene Styrene (ABS).

Illustrative image related to honda civic r 10th gen bodykit

What Are the Key Properties of Carbon Fiber for Bodykits?

Carbon fiber is renowned for its exceptional strength-to-weight ratio, making it a preferred choice for high-performance automotive applications. It can withstand high temperatures (up to 150°C) and offers excellent rigidity and tensile strength. Additionally, carbon fiber exhibits low thermal expansion, which helps maintain dimensional stability under varying temperature conditions.

Pros: Carbon fiber is incredibly durable and lightweight, enhancing vehicle performance and fuel efficiency. Its aesthetic appeal also allows for sleek designs that attract consumers.

Cons: The manufacturing process for carbon fiber is complex and costly, leading to higher retail prices. Additionally, repairs can be challenging due to the material’s specific bonding requirements.

Impact on Application: Carbon fiber is compatible with high-performance applications where weight reduction is critical, such as racing. However, it may not be suitable for lower-cost segments due to its price.

Considerations for International Buyers: Compliance with standards like ASTM D7264 for composite materials is essential. Buyers from regions such as Europe and the Middle East may prioritize suppliers who can demonstrate adherence to these standards.

Illustrative image related to honda civic r 10th gen bodykit

How Does Fiberglass Reinforced Plastic (FRP) Compare?

FRP is another popular material for bodykits, known for its versatility and cost-effectiveness. It has good corrosion resistance and can handle moderate temperatures (up to 120°C). FRP can be molded into complex shapes, making it suitable for intricate designs.

Pros: The material is relatively inexpensive and offers good durability. It is easier to manufacture compared to carbon fiber, allowing for lower production costs.

Cons: While FRP is durable, it is heavier than carbon fiber, which can affect performance. It is also more susceptible to UV degradation unless treated.

Impact on Application: FRP is suitable for a wide range of applications, including both performance and aesthetic enhancements. It is particularly favored in markets where cost is a significant factor.

Considerations for International Buyers: Buyers should verify that FRP products meet local standards for automotive components, such as DIN 75200 in Germany, to ensure safety and compliance.

Illustrative image related to honda civic r 10th gen bodykit

What Are the Advantages of Polypropylene (PP)?

Polypropylene is a thermoplastic polymer known for its excellent impact resistance and flexibility. It can withstand temperatures up to 100°C and is resistant to many chemicals, making it a practical choice for automotive applications.

Pros: PP is lightweight and cost-effective, making it ideal for mass production. Its resistance to moisture and chemicals enhances durability in various environments.

Cons: While PP is strong, it lacks the rigidity of carbon fiber and FRP, which may limit its use in high-performance applications. Additionally, it can be less aesthetically appealing compared to other materials.

Impact on Application: PP is suitable for components that require flexibility and impact resistance, such as bumpers and side skirts. However, its use in premium bodykits may be limited due to aesthetic considerations.

Considerations for International Buyers: Compliance with international standards like ISO 9001 for quality management systems is crucial for ensuring product reliability.

Why Choose Acrylonitrile Butadiene Styrene (ABS)?

ABS is a thermoplastic known for its toughness and impact resistance. It can withstand temperatures up to 80°C and is commonly used in automotive applications due to its excellent surface finish and ease of molding.

Pros: ABS is affordable and offers good durability. It can be easily painted and customized, making it a popular choice for aftermarket modifications.

Cons: The material is less heat-resistant than others, which could lead to deformation under extreme conditions. Additionally, it may not provide the same level of performance enhancement as carbon fiber.

Illustrative image related to honda civic r 10th gen bodykit

Impact on Application: ABS is suitable for aesthetic components where cost and appearance are priorities. It is widely used in the aftermarket sector.

Considerations for International Buyers: Buyers should ensure that ABS products comply with local automotive safety standards to avoid legal issues.

Summary Table of Material Selection for Honda Civic R 10th Gen Bodykit

| Material | Typical Use Case for Honda Civic R 10th Gen Bodykit | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Fiber | High-performance components, full bodykits | Exceptional strength-to-weight ratio | High cost and complex manufacturing | High |

| Fiberglass Reinforced Plastic (FRP) | Bumpers, side skirts, spoilers | Cost-effective and versatile | Heavier than carbon fiber, UV degradation | Medium |

| Polypropylene (PP) | Bumpers, side skirts | Lightweight and impact-resistant | Less rigidity, limited aesthetic appeal | Low |

| Acrylonitrile Butadiene Styrene (ABS) | Aesthetic components, aftermarket modifications | Affordable and easy to customize | Lower heat resistance, potential deformation | Low |

This analysis provides a comprehensive overview of the materials commonly used in the Honda Civic R 10th Gen bodykit, equipping international B2B buyers with the knowledge needed to make informed purchasing decisions.

Illustrative image related to honda civic r 10th gen bodykit

In-depth Look: Manufacturing Processes and Quality Assurance for honda civic r 10th gen bodykit

What Are the Key Stages in the Manufacturing Process of Honda Civic R 10th Gen Bodykits?

The manufacturing process for Honda Civic R 10th Gen bodykits involves several crucial stages, each designed to ensure high-quality output that meets the demands of B2B buyers. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-grade materials, typically carbon fiber and fiberglass-reinforced plastics (FRP). Suppliers often conduct rigorous material testing to verify that the raw materials meet industry standards. The materials are then cut and shaped according to the specifications provided by design engineers.

-

Forming: In this stage, advanced techniques such as vacuum forming, injection molding, or lay-up processes are employed. Each technique has its advantages; for instance, vacuum forming allows for the creation of complex shapes while maintaining structural integrity. This is particularly important for components like side skirts and front bumpers, where aerodynamics and aesthetics play critical roles.

-

Assembly: After individual components are formed, they undergo assembly. This may involve bonding or fastening parts together to create the final product. Automated assembly lines are often utilized to enhance precision and efficiency, particularly for larger orders.

-

Finishing: The final stage involves surface treatment, which may include painting, polishing, or applying protective coatings. This not only enhances the aesthetic appeal but also ensures durability against environmental factors. Quality assurance checks are performed at each stage to identify defects early.

How Is Quality Assurance Implemented in the Manufacturing of Bodykits?

Quality assurance (QA) in the manufacturing of Honda Civic R 10th Gen bodykits is paramount to ensuring that products meet both international and industry-specific standards.

-

Adherence to International Standards: Many manufacturers comply with ISO 9001 standards, which focus on quality management systems. This certification indicates a commitment to consistent quality and customer satisfaction. Additional certifications like CE mark (indicating compliance with European health, safety, and environmental protection standards) and API standards may also be relevant, especially for suppliers targeting the European and Middle Eastern markets.

-

Quality Control Checkpoints: Effective QA processes incorporate several checkpoints throughout the manufacturing stages:

– Incoming Quality Control (IQC): This initial checkpoint verifies the quality of incoming materials before they enter the production line.

– In-Process Quality Control (IPQC): During manufacturing, products are regularly inspected to ensure they meet predefined specifications.

– Final Quality Control (FQC): After assembly, the final products undergo comprehensive testing to ensure they meet quality and safety standards. -

Common Testing Methods: Various testing methods are employed, including dimensional inspections, visual inspections, and performance testing. For instance, components might be subjected to stress tests to evaluate their durability and performance under real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying the quality control of suppliers is crucial for mitigating risks associated with product defects and ensuring reliability.

-

Conducting Supplier Audits: One of the most effective ways to assess a supplier’s quality control practices is through on-site audits. This allows buyers to evaluate the manufacturing processes, quality control systems, and compliance with international standards firsthand.

-

Requesting Quality Reports: Buyers should ask suppliers for detailed quality assurance reports, which outline testing procedures, results, and compliance with standards. This documentation can provide insight into the supplier’s commitment to quality.

-

Engaging Third-Party Inspection Services: For added assurance, buyers can opt for third-party inspections. These independent entities conduct thorough evaluations of the manufacturing processes and the final products, ensuring that they meet specified standards.

-

Understanding Certification Nuances: International buyers should be aware that certification requirements may vary by region. For example, while CE marking is crucial for European markets, different standards may apply in Africa and South America. Understanding these nuances will help buyers select suppliers that comply with relevant regulations.

What Challenges Do International B2B Buyers Face in Quality Assurance?

International B2B buyers often face unique challenges when assessing quality assurance in the manufacturing of bodykits.

-

Cultural Differences in Quality Standards: Different regions may have varying perceptions of quality, which can lead to misunderstandings. Buyers need to be clear about their expectations and ensure that suppliers are aligned with those standards.

-

Logistical Challenges: Shipping and logistics can impact the quality of products. Buyers should establish clear agreements regarding packaging and transport to minimize damage during transit.

-

Regulatory Compliance: Navigating the complex landscape of international regulations can be daunting. Buyers must stay informed about the specific compliance requirements in their target markets to avoid legal complications.

-

Communication Barriers: Language and time zone differences can hinder effective communication between buyers and suppliers. Establishing a clear communication protocol is essential for addressing issues promptly.

In summary, understanding the manufacturing processes and quality assurance protocols for Honda Civic R 10th Gen bodykits is essential for B2B buyers looking to make informed purchasing decisions. By focusing on quality at every stage—from material preparation to final inspection—buyers can ensure they are sourcing high-quality products that meet their specifications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘honda civic r 10th gen bodykit’

Introduction

This practical sourcing guide aims to assist B2B buyers in procuring high-quality body kits for the Honda Civic 10th Generation. The aftermarket parts market is vast, and understanding how to navigate it effectively can lead to successful sourcing and cost-effective purchases. Follow this checklist to ensure a streamlined procurement process that meets your specific requirements.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, it’s essential to outline your technical specifications for the body kit. This includes the materials you prefer, such as carbon fiber or fiberglass, and the specific components you need, such as bumpers, side skirts, or spoilers. Having clear specifications helps prevent miscommunication and ensures you receive parts that fit your requirements.

Step 2: Research Potential Suppliers

Conduct thorough research on potential suppliers specializing in Honda Civic body kits. Utilize platforms like Alibaba, TradeIndia, or regional automotive parts suppliers to gather information. Pay attention to their product range, reviews, and reputation in the industry, as this will help you identify reliable partners.

Step 3: Verify Supplier Certifications

Before finalizing any deals, verify the certifications and compliance standards of the suppliers. Look for ISO certifications or industry-specific quality assurance marks. This step is crucial as it ensures that the products meet international safety and quality standards, reducing the risk of defective parts.

Illustrative image related to honda civic r 10th gen bodykit

Step 4: Request Samples

Always request samples of the body kits or specific components before placing a bulk order. This allows you to assess the quality, finish, and fitment of the products. Analyzing samples can help you avoid potential issues when the full order arrives, saving both time and costs.

Step 5: Evaluate Pricing and Payment Terms

Compare pricing from various suppliers to ensure you are getting a competitive rate. Look beyond just the unit price; consider shipping costs, potential tariffs, and payment terms. Opt for suppliers offering flexible payment terms, which can improve cash flow and reduce financial strain.

Step 6: Assess Shipping and Delivery Options

Discuss shipping methods and delivery timelines with your selected suppliers. Evaluate their logistics capabilities, especially if you are sourcing from international suppliers. Efficient shipping is crucial to maintaining your inventory levels and ensuring timely delivery to your customers.

Illustrative image related to honda civic r 10th gen bodykit

Step 7: Establish a Long-Term Relationship

Once you’ve successfully sourced your body kits, aim to establish a long-term relationship with your suppliers. Open lines of communication and regular feedback can lead to better pricing, priority service, and improved product offerings in the future. Building a partnership can enhance your supply chain efficiency and foster mutual growth.

By following these steps, B2B buyers can navigate the complexities of sourcing Honda Civic 10th Gen body kits effectively, ensuring quality products and successful partnerships in the aftermarket automotive market.

Comprehensive Cost and Pricing Analysis for honda civic r 10th gen bodykit Sourcing

What Are the Key Cost Components in Sourcing Honda Civic R 10th Gen Bodykits?

When analyzing the cost structure for sourcing bodykits for the Honda Civic R 10th Gen, several key components must be considered:

-

Materials: The choice of materials significantly influences the cost. Bodykits can be made from various materials such as fiberglass, carbon fiber, and reinforced plastic (FRP). Carbon fiber components, while offering superior strength and weight savings, typically range from $5,130 to $6,780 for a full kit, as seen in the offerings from suppliers like Robot Craftsman.

-

Labor: Labor costs are associated with manufacturing processes, including molding, cutting, and finishing. Labor rates can vary by region, with some countries in Africa and South America having lower labor costs compared to Europe. This discrepancy can be leveraged for cost-effective sourcing.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and administrative expenses. Manufacturers often factor these costs into their pricing, so understanding the overhead structure can help buyers gauge the overall pricing strategy.

-

Tooling: Custom tooling for specific bodykit designs can add significant costs. This is particularly relevant for buyers seeking unique or bespoke designs. Investment in tooling may be justified if the order volume is high enough to spread these costs over multiple units.

-

Quality Control (QC): Implementing stringent QC processes ensures that the products meet quality standards. While this may increase initial costs, it can save money in the long run by reducing returns and warranty claims.

-

Logistics: Shipping and handling play a critical role, especially for international buyers. Costs can vary based on distance, shipping method, and the chosen Incoterms, which define the responsibilities of buyers and sellers.

-

Margin: Suppliers typically add a profit margin on top of their costs, which can vary significantly. Understanding the typical margin for bodykit suppliers can help buyers negotiate better prices.

How Do Price Influencers Affect the Cost of Honda Civic R 10th Gen Bodykits?

Several factors influence the final price of bodykits, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders can often secure discounts, making it essential for businesses to assess their purchasing strategies. Suppliers may offer lower prices for bulk orders, which can significantly reduce the cost per unit.

-

Specifications and Customization: Customized components typically cost more than standard options. Buyers should weigh the benefits of customization against potential cost increases.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., ISO standards) can increase costs but also enhance product durability and performance. Buyers should evaluate whether the added cost aligns with their target market’s expectations.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium for their products due to their proven track record.

-

Incoterms: The choice of Incoterms affects logistics costs and responsibilities. Understanding these terms can help buyers avoid unexpected costs.

What Tips Can Help Buyers Negotiate Better Prices for Bodykits?

-

Effective Negotiation: Buyers should prepare for negotiations by understanding the market and the supplier’s cost structure. Leverage volume commitments to negotiate better terms.

-

Focus on Cost-Efficiency: Consider the total cost of ownership, which includes not only the purchase price but also shipping, installation, and potential maintenance costs. This broader perspective can lead to better purchasing decisions.

-

Understand Pricing Nuances: International buyers should be aware of regional pricing differences and how local economic conditions can affect costs. For instance, tariffs and taxes may apply when importing bodykits, particularly for buyers in Europe or the Middle East.

-

Build Long-Term Relationships: Establishing a strong relationship with suppliers can lead to more favorable terms and pricing over time. Regular communication and loyalty can result in better deals.

Conclusion

Understanding the cost components, price influencers, and strategic negotiation tips is crucial for international B2B buyers sourcing Honda Civic R 10th Gen bodykits. By carefully analyzing these factors, businesses can make informed decisions that maximize their purchasing power while ensuring quality and compliance with market demands. As prices can fluctuate based on various conditions, it is advisable to request indicative pricing and remain flexible in negotiations.

Alternatives Analysis: Comparing honda civic r 10th gen bodykit With Other Solutions

Exploring Alternatives to the Honda Civic R 10th Gen Bodykit

When considering enhancements for the Honda Civic R 10th Gen, it’s essential to evaluate various alternatives that can achieve similar aesthetic and performance goals. This analysis compares the Honda Civic R 10th Gen Bodykit against two viable alternatives: aftermarket body kits and OEM modifications. Understanding the nuances of each option can help B2B buyers make informed decisions tailored to their specific requirements.

| Comparison Aspect | Honda Civic R 10th Gen Bodykit | Aftermarket Body Kits | OEM Modifications |

|---|---|---|---|

| Performance | Enhanced aerodynamics and downforce | Varies by design; potential for improved handling | Factory-tested for reliability |

| Cost | Moderate to high ($5,130 – $6,780) | Wide range ($200 – $5,000) | Generally higher ($1,000 – $3,000) |

| Ease of Implementation | Moderate; requires professional installation | Varies; some kits are DIY-friendly | Straightforward; typically dealer-installed |

| Maintenance | Requires regular checks for wear | Varies; depends on material quality | Low; designed for durability |

| Best Use Case | Performance enthusiasts seeking maximum customization | Budget-conscious buyers looking for variety | Buyers preferring reliability and brand assurance |

In-Depth Evaluation of Alternatives

Aftermarket Body Kits

Aftermarket body kits offer a diverse range of options tailored to different aesthetics and performance needs. With prices ranging from $200 to $5,000, they cater to various budgets. Many aftermarket kits can be installed by the buyer, reducing labor costs. However, the performance impact can be inconsistent, as not all kits undergo the same level of testing. Buyers should thoroughly research brands and materials to ensure quality and performance align with their expectations.

OEM Modifications

Original Equipment Manufacturer (OEM) modifications provide a sense of reliability and assurance due to their factory testing and compatibility. While the costs are generally higher, ranging from $1,000 to $3,000, they promise durability and a seamless fit with the vehicle’s existing design. These modifications are often straightforward to implement, typically handled by dealerships. However, the downside is the limited customization options compared to aftermarket kits, which might not satisfy performance enthusiasts looking for a unique touch.

Illustrative image related to honda civic r 10th gen bodykit

Making the Right Choice for Your Business Needs

When choosing between the Honda Civic R 10th Gen Bodykit, aftermarket body kits, and OEM modifications, B2B buyers should consider several factors. Assessing performance requirements, budget constraints, and the importance of brand reliability will guide you toward the best solution. For businesses focused on customization and performance enhancements, the Honda Civic R bodykit or aftermarket options may be preferable. Conversely, if reliability and a factory-standard finish are paramount, OEM modifications could be the ideal choice. Ultimately, aligning the selected body enhancement with your business objectives and customer preferences will lead to the best investment decision.

Essential Technical Properties and Trade Terminology for honda civic r 10th gen bodykit

What Are the Key Technical Properties of Honda Civic R 10th Gen Bodykits?

Understanding the essential technical properties of bodykits for the Honda Civic R 10th Gen is crucial for B2B buyers in the automotive aftermarket. Here are some critical specifications that should be considered:

-

Material Composition

– Definition: Bodykits are typically made from materials such as carbon fiber, fiberglass reinforced plastic (FRP), and polyurethane (PP). Each material offers different levels of durability, weight, and aesthetic appeal.

– Importance: Buyers should consider the material based on performance needs and cost. For example, carbon fiber is lightweight and strong, making it ideal for performance enhancements, while FRP is more affordable but may not offer the same structural integrity. -

Weight Tolerance

– Definition: This refers to the maximum weight that the bodykit can support without compromising structural integrity. It is particularly important for components like bumpers and spoilers.

– Importance: Understanding weight tolerance helps ensure that the bodykit will not negatively affect vehicle performance or handling. B2B buyers must match the product specifications with their customers’ needs for performance vehicles. -

Fitment Precision

– Definition: Fitment precision indicates how well the bodykit aligns with the original vehicle’s specifications. It is often measured in millimeters.

– Importance: Proper fitment is crucial to avoid installation issues and ensure the aesthetic appeal of the vehicle. Poor fitment can lead to increased labor costs and customer dissatisfaction. -

UV Resistance

– Definition: This property measures the ability of the bodykit material to withstand damage from ultraviolet (UV) light exposure.

– Importance: For buyers in regions with high sun exposure, UV resistance is vital to prevent fading and degradation of the bodykit. Products with good UV resistance will maintain their appearance longer, offering better value to customers. -

Surface Finish

– Definition: The surface finish pertains to the texture and gloss level of the bodykit. Common finishes include matte, glossy, and textured.

– Importance: The finish impacts both aesthetics and maintenance. A glossy finish may enhance visual appeal but can show scratches more readily, while matte finishes can hide imperfections but may require special cleaning products.

What Are Common Trade Terms in the Bodykit Industry?

Familiarity with trade terminology can streamline negotiations and purchasing processes. Here are some essential terms relevant to the Honda Civic R 10th Gen bodykit market:

Illustrative image related to honda civic r 10th gen bodykit

-

OEM (Original Equipment Manufacturer)

– Definition: Refers to parts made by the original manufacturer of the vehicle. OEM parts are designed to fit and perform like the original components.

– Importance: B2B buyers often choose OEM parts for their reliability and compatibility, which can be a strong selling point for their customers. -

MOQ (Minimum Order Quantity)

– Definition: This term specifies the smallest quantity of a product that a supplier is willing to sell.

– Importance: Understanding MOQ is critical for buyers to manage inventory costs effectively. It helps in planning purchases and maintaining stock levels. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document that a buyer sends to suppliers asking for price quotes for specific products.

– Importance: Utilizing RFQs allows buyers to compare prices and terms from multiple suppliers, ensuring they get the best deal possible. -

Incoterms (International Commercial Terms)

– Definition: These are a set of rules that define the responsibilities of buyers and sellers in international shipping.

– Importance: Knowledge of Incoterms helps buyers understand shipping costs and risks, ensuring clarity in transactions, especially in international markets like Africa, South America, and the Middle East. -

Lead Time

– Definition: Lead time refers to the amount of time it takes from placing an order to receiving the product.

– Importance: Understanding lead times is essential for inventory management and customer satisfaction. Buyers must align their orders with customer demand to avoid stockouts.

Incorporating these technical properties and industry terms will empower B2B buyers to make informed decisions when sourcing bodykits for the Honda Civic R 10th Gen, ultimately enhancing their product offerings and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the honda civic r 10th gen bodykit Sector

What Are the Current Market Dynamics and Key Trends in the Honda Civic R 10th Gen Bodykit Sector?

The Honda Civic R 10th Gen bodykit sector is experiencing significant growth, driven by a surge in automotive customization and performance enhancement among car enthusiasts. Globally, there is a rising demand for high-quality aftermarket parts, particularly in regions like Africa, South America, the Middle East, and Europe. Factors such as increased disposable income, a growing interest in car modifications, and a thriving online marketplace have contributed to this trend.

International B2B buyers are increasingly leveraging technology to source these parts. E-commerce platforms have made it easier for buyers to access a broader range of products, compare prices, and evaluate suppliers. Additionally, advancements in logistics and supply chain management are improving delivery times and reducing costs. Emerging trends include the popularity of carbon fiber and fiberglass-reinforced plastic (FRP) materials, which offer lightweight and durable options for bodykits, appealing to performance-oriented consumers.

Illustrative image related to honda civic r 10th gen bodykit

Moreover, customization trends are evolving, with buyers seeking unique designs that enhance aesthetics while improving vehicle performance. This has led to the rise of specialized manufacturers who focus on niche markets, providing tailored solutions that meet specific customer preferences. As the market matures, international B2B buyers must stay informed about emerging technologies and supplier innovations to maintain a competitive edge.

How Is Sustainability and Ethical Sourcing Impacting the Honda Civic R 10th Gen Bodykit Market?

Sustainability is becoming a cornerstone of the automotive aftermarket industry, including the Honda Civic R 10th Gen bodykit sector. With increasing awareness about environmental issues, B2B buyers are now prioritizing suppliers who adopt sustainable practices. The use of eco-friendly materials, such as recycled plastics and sustainably sourced carbon fiber, is gaining traction. Buyers are encouraged to seek out suppliers who can provide certifications that demonstrate their commitment to environmental responsibility.

Ethical sourcing is equally important, as businesses are scrutinizing their supply chains to ensure compliance with social and environmental standards. This includes verifying that suppliers uphold fair labor practices and minimize their carbon footprints. For international buyers, particularly in regions with varying regulations, understanding the implications of sustainability and ethical sourcing is essential for maintaining brand reputation and customer loyalty.

Furthermore, many manufacturers are beginning to offer products that highlight their sustainable credentials, such as ‘green’ certifications or eco-labels. By prioritizing these products, B2B buyers can not only meet growing consumer demand for sustainable options but also contribute positively to the global push for environmental stewardship.

What Is the Evolution of the Honda Civic R 10th Gen Bodykit Market?

The evolution of the Honda Civic R 10th Gen bodykit market reflects broader trends in the automotive industry. Initially, aftermarket modifications were largely limited to performance enhancements, but as consumer preferences shifted towards aesthetics and personalization, bodykits became a focal point for customization. The introduction of advanced materials like carbon fiber and FRP has transformed the landscape, offering consumers lightweight yet durable options that enhance both performance and style.

Illustrative image related to honda civic r 10th gen bodykit

Over the years, the market has witnessed the rise of specialized manufacturers catering to specific niches, allowing for greater diversity in product offerings. This evolution has been marked by increased competition, prompting companies to innovate continuously and improve product quality. As a result, the Honda Civic R 10th Gen bodykit sector is now characterized by a blend of performance, aesthetics, and sustainability, making it a dynamic area for international B2B buyers to explore.

Frequently Asked Questions (FAQs) for B2B Buyers of honda civic r 10th gen bodykit

-

How do I ensure the quality of the Honda Civic R 10th Gen bodykit I am sourcing?

To ensure the quality of the bodykit, conduct thorough supplier vetting. Request samples to assess material quality and craftsmanship. Look for suppliers with ISO certifications or industry-specific quality standards. It’s also beneficial to read reviews and testimonials from other buyers. Establish clear quality assurance protocols, such as inspections during production and before shipment, to mitigate risks associated with low-quality products. -

What is the best material for a Honda Civic R 10th Gen bodykit?

The best materials for a Honda Civic R 10th Gen bodykit are typically carbon fiber and fiberglass-reinforced plastic (FRP). Carbon fiber is favored for its lightweight and high strength, providing better performance and aesthetics. FRP offers good durability at a lower cost. Depending on your target market’s preferences and budget, consider which material aligns best with your customers’ needs for performance, weight, and price. -

What are the common customization options available for Honda Civic R 10th Gen bodykits?

Customization options for Honda Civic R 10th Gen bodykits often include color finishes, specific design alterations, and additional aerodynamic features. Some suppliers may offer bespoke designs tailored to client specifications. It’s crucial to communicate your customization requirements clearly and confirm the supplier’s capability to meet these requests. Discuss lead times and additional costs associated with custom orders to manage expectations effectively. -

What are the typical minimum order quantities (MOQs) for Honda Civic R 10th Gen bodykits?

Minimum order quantities can vary significantly depending on the supplier and the type of bodykit. Generally, MOQs range from 5 to 20 units for standard products. For custom designs, MOQs may be higher. It’s essential to clarify these terms upfront to ensure they align with your business model and market demand. Suppliers may offer flexibility based on long-term partnerships or larger orders. -

What payment terms should I expect when sourcing Honda Civic R 10th Gen bodykits?

Payment terms can vary widely by supplier and region. Common practices include a 30% deposit upon order confirmation and the remaining balance before shipment. Some suppliers may accept letters of credit or escrow services for larger orders, providing additional security. Always negotiate payment terms that suit your cash flow and ensure you understand the implications of each option before proceeding. -

How can I effectively manage logistics when importing bodykits internationally?

To manage logistics effectively, partner with a reliable freight forwarder experienced in international shipping. They can help navigate customs regulations, documentation, and tariffs. It’s essential to understand the shipping terms (e.g., FOB, CIF) and choose the right shipping method (air vs. sea) based on urgency and budget. Track shipments closely and maintain open communication with suppliers to address any potential issues promptly. -

What are the key factors to consider when vetting suppliers for Honda Civic R 10th Gen bodykits?

When vetting suppliers, consider their manufacturing capabilities, experience in the automotive aftermarket, and adherence to quality standards. Verify their certifications and request references from previous clients. It’s also beneficial to assess their communication responsiveness and willingness to accommodate your specific needs. A reliable supplier should have a proven track record of delivering quality products on time. -

How do I handle potential disputes with suppliers regarding bodykit quality or delivery?

To handle disputes effectively, establish clear terms and conditions in your contract, outlining quality standards and delivery timelines. In case of a dispute, communicate directly with the supplier to resolve issues amicably. Document all correspondence and agreements. If necessary, escalate the matter through mediation or arbitration as specified in your contract. Maintaining a professional relationship can often lead to quicker resolutions.

Top 10 Honda Civic R 10Th Gen Bodykit Manufacturers & Suppliers List

1. Performance Speed Shop – Civic 10th Gen Carbon Fiber Body Kit

Domain: performancespeedshop.com

Introduction: Civic 10th Gen aftermarket parts, carbon fiber body kit – PSS. Live stock status shown on website. For Pre-order & Back ordered items please call in at 1-(844) 421-0594 for ETA before placing order.

2. eBay – 10th Gen Civic Body Kits

Domain: ebay.com

Introduction: 10th Gen Civic Body Kit available on eBay includes various products such as:

– 5pcs Red Front Bumper Lip Body Kit Spoiler for Honda Civic 10th Gen 2019-2020, priced at $178.44 with free international shipping.

– Black & Red Front Bumper Lip for Civic Si & FK7 Hatchback 2017-2021, priced at $59.99 plus $118.15 delivery.

– Blue Front Bumper Lip Body Kit Spoiler Cover for Honda Civic 10th Gen 2019-20…

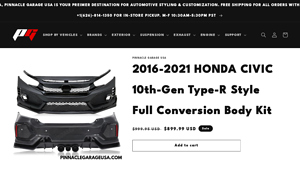

3. Pinnacle Garage – 2016-2021 Honda Civic Type-R Front Bumper Conversion

Domain: pinnaclegarageusa.com

Registered: 2023 (2 years)

Introduction: {“product_name”: “2016-2021 Honda Civic 10th-Gen Type-R Style Front Bumper Conversion”, “price”: “$899.99 USD”, “original_price”: “$999.95 USD”, “materials”: [“ABS Plastic”, “Polypropylene”, “Carbon Fiber”, “FRP”, “Aluminum”, “Metal”], “shipping”: “Free shipping within the contiguous United States (excludes PR/HI/AR)”, “shipping_time”: “2-3 business days for in-stock orders”, “return_policy”: {“re…

4. CivicX – 3D Printed Aero Kit for 2016+ Honda Civic

Domain: civicx.com

Registered: 2015 (10 years)

Introduction: 3D printed custom aero kit for 2016+ Honda Civic (FK8 platform) including front lip, sideskirts, rear spats, front intakes, and door flare finisher garnishes. Available for purchase and download on Etsy (JMJRDesign). Recommended printer size for front lip is 350mm compatibility, with a center part length of 421mm. Suggested filament types include ASA/ABS or ApolloX for front intakes and door garni…

5. ABS Dynamics – TYPE-R Style Front Lip

Domain: absdynamics.com

Registered: 2002 (23 years)

Introduction: 10th-Gen Civic products for Honda Civic models from 2016 to 2021 include various body kits, spoilers, diffusers, and other accessories. Key items include: 1. TYPE-R Style Front Lip (Gloss Carbon Accent) – $297.00 2. TYPE-R Style Rear Lip Diffuser (PP Unpainted) – $296.96 3. TYPE-R Style Rear Diffuser (PP Unpainted) – $314.96 4. TYPE-R Style Side Under Panel with Carbon Accent – $269.10 5. TYPE-R R…

6. Honda – Civic Sedan Type R Body Kit

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: normal Honda Civic Sedan with Type R body kit

7. Honda – Civic 10th Gen Carbon Fiber Kit

Domain: carbonshowroom.com

Introduction: Honda Civic 10th Gen Carbon Fiber Body Kit & Accessories

8. Kevman – Full Wide Body Kit for 10th Gen Civic Coupe

Domain: kevmannz.com

Registered: 2016 (9 years)

Introduction: Full wide body kit for 10th Gen Civic Coupe (2016-2020)

9. Ikon Motorsports – 2016-2018 Honda Civic Body Kit

Domain: drivenbystyle.com

Registered: 2008 (17 years)

Introduction: {“Product Name”: “2016-2018 Honda Civic 10TH Gen Type R Style Body Kit”, “Material”: “Polyurethane”, “Part Number”: “13-HD121-D”, “Condition”: “New”, “Brand”: “Ikon Motorsports”, “MSRP”: “$2,357.80”, “Discounted Price”: “$1,199.99”, “Weight”: “10.00 lbs”, “Fitment”: {“Make”: “Honda”, “Model”: “Civic”, “Years”: [2016, 2017, 2018]}, “Package Contents”: [“Front Bumper Cover”, “Rear Bumper Cover”, “Si…

10. Robot Body Kits – 10th Gen Honda Civic Widebody Kit

Domain: robotbodykits.com

Registered: 2022 (3 years)

Introduction: Robot 10th Gen Honda Civic SEDAN / Hatchback FRP Complete Widebody Kit

– Type: Widebody Kit

– Material: FRP (Fiberglass Reinforced Plastic)

– Price: $1,900.00 USD

– SKU: Not specified

– Components:

– Widebody Arches

– Optional Side Skirts

– Optional Front Bumper & Lip

– Installation Requirements:

– Cutting or removing original front bumper support bracket for front bumper installation.

…

Strategic Sourcing Conclusion and Outlook for honda civic r 10th gen bodykit

In navigating the dynamic landscape of the Honda Civic 10th Generation body kit market, strategic sourcing emerges as a pivotal approach for international B2B buyers. By understanding key suppliers, product quality, and pricing structures, businesses can optimize their procurement processes and enhance their competitive edge. The variety of body kit options—ranging from carbon fiber components to full kits—offers buyers the flexibility to meet diverse customer demands while ensuring high performance and aesthetic appeal.

Furthermore, establishing relationships with reputable vendors can lead to better pricing, improved lead times, and access to exclusive products. As markets in Africa, South America, the Middle East, and Europe continue to grow, the opportunity to capitalize on the aftermarket parts segment is significant.

Illustrative image related to honda civic r 10th gen bodykit

Looking ahead, international buyers are encouraged to invest in partnerships that prioritize quality and innovation. This approach not only fosters brand loyalty but also positions businesses to thrive in an increasingly competitive market. Embrace the potential of strategic sourcing to elevate your offerings and meet the evolving expectations of Honda Civic enthusiasts globally.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to honda civic r 10th gen bodykit

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.