A B2B Buyer’s Guide to Holographic Knee High Space Boots: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for holographic knee high space boots

In the rapidly evolving fashion landscape, sourcing high-quality holographic knee high space boots can present a significant challenge for international B2B buyers. As consumer preferences shift towards unique, eye-catching designs that seamlessly blend style and functionality, suppliers must navigate a competitive market filled with diverse options. This guide serves as an essential resource, offering a comprehensive overview of the various types of holographic knee high boots, their applications across different industries, and critical factors to consider when vetting suppliers.

From understanding the intricacies of material selection—such as the benefits of PU lenticular rubber versus leather—to evaluating cost structures and shipping logistics, this guide empowers buyers from Africa, South America, the Middle East, and Europe, including specific markets like Vietnam and Brazil. It aims to equip decision-makers with actionable insights to make informed purchasing choices that align with their business goals.

Moreover, the guide delves into market trends, pricing strategies, and potential return policies, ensuring that buyers are well-prepared to engage with suppliers effectively. By leveraging this knowledge, businesses can confidently expand their product offerings and meet the growing demand for innovative fashion solutions in their respective markets.

Understanding holographic knee high space boots Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Color-Changing Lenticular Boots | Lightweight, color-shifting effect, zip-up design | Fashion retail, promotional events | Pros: Eye-catching, unique appeal. Cons: May not suit all styles. |

| High-Stiletto Holographic Boots | Elevated heel, sleek silhouette, luxury materials | High-end fashion boutiques, runway shows | Pros: Adds sophistication, high demand. Cons: Higher price point. |

| Edgy Platform Holographic Boots | Chunky platform, multiple straps, bold designs | Alternative fashion markets, niche retailers | Pros: Trendy, attracts specific demographics. Cons: Limited versatility. |

| Functional Space Boots | Durable materials, designed for comfort and utility | Outdoor events, cosplay, themed parties | Pros: Practical, comfortable for long wear. Cons: Less fashionable appeal. |

| Customizable Holographic Boots | Options for personalized designs, colors, and sizes | Specialty stores, bespoke fashion | Pros: Unique branding opportunities. Cons: Longer lead times for production. |

What Are the Key Characteristics of Color-Changing Lenticular Boots?

Color-changing lenticular boots are designed with a unique outer material that shifts colors based on the angle of light. This lightweight design often features a zip-up closure for ease of wear. Primarily utilized in fashion retail and promotional events, these boots cater to buyers looking for eye-catching, standout footwear that appeals to younger demographics. When purchasing, B2B buyers should consider factors like durability and the ability to withstand frequent use, as well as the trends in customer preferences.

How Do High-Stiletto Holographic Boots Stand Out in the Market?

High-stiletto holographic boots are characterized by their luxurious materials, often featuring a sleek, pointed toe and a high heel. They are typically made from premium leather with a holographic finish that catches the eye. These boots are ideal for high-end fashion boutiques and runway shows, appealing to buyers focused on elegance and sophistication. B2B purchasers should keep in mind the higher price point and ensure that their target market aligns with luxury fashion trends.

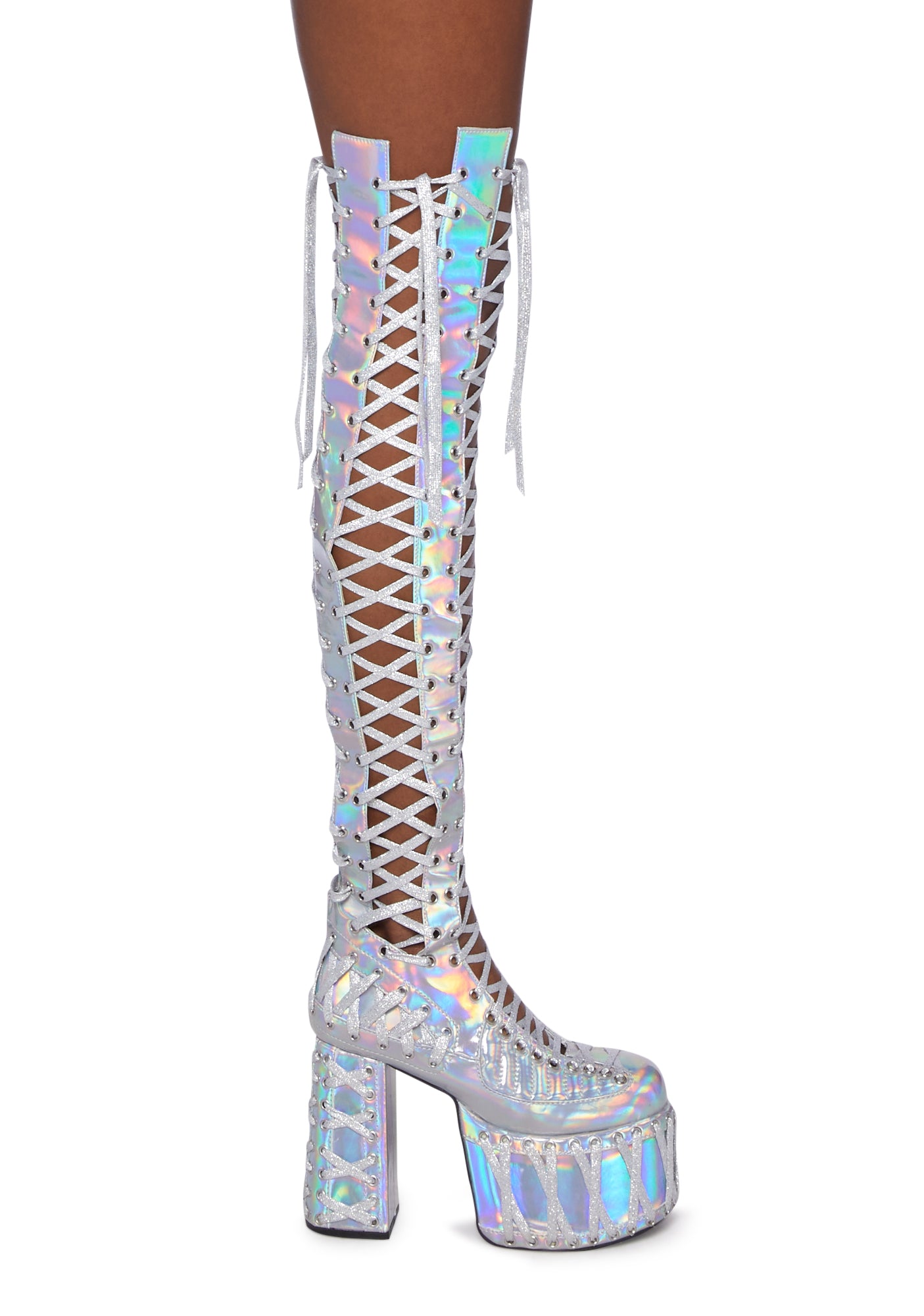

What Makes Edgy Platform Holographic Boots Popular?

Edgy platform holographic boots combine a chunky platform with bold design elements such as straps and metal detailing. These boots are particularly popular in alternative fashion markets and niche retailers, appealing to customers who favor unique and daring styles. Buyers should evaluate the potential for these boots to attract specific demographics, as well as their versatility in pairing with various outfits. However, they may not appeal to traditional fashion buyers seeking classic designs.

Why Choose Functional Space Boots for Practical Applications?

Functional space boots are designed with durability and comfort in mind, making them suitable for outdoor events, cosplay, and themed parties. They often feature materials that can withstand various environmental conditions while providing comfort for extended wear. B2B buyers in industries such as event planning or outdoor retail should consider these boots for their practicality and appeal to consumers looking for both style and function. However, they may lack the fashion-forward appeal that some buyers desire.

How Do Customizable Holographic Boots Offer Unique Opportunities?

Customizable holographic boots provide B2B buyers with the opportunity to offer personalized designs, colors, and sizes to their customers. This feature can be particularly appealing for specialty stores and bespoke fashion brands looking to differentiate themselves in a competitive market. Buyers should consider the lead time for production and the level of customization that can be offered, as these factors can influence customer satisfaction and repeat business.

Illustrative image related to holographic knee high space boots

Key Industrial Applications of holographic knee high space boots

| Industry/Sector | Specific Application of holographic knee high space boots | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | High-fashion boutiques showcasing unique designs | Attracts a niche market seeking innovative footwear | Quality of materials, design exclusivity, and sizing options |

| Entertainment & Events | Costumes for theatrical performances and festivals | Enhances visual impact and audience engagement | Durability under stage lights, comfort for extended wear |

| Cosplay & Gaming | Custom outfits for cosplay events and conventions | Unique products that cater to passionate fan bases | Availability of varied styles, customization options |

| Space & Aviation | Specialized footwear for astronauts or space-themed events | Safety and functionality in unique environments | Compliance with safety standards, lightweight materials |

| Art & Design Installations | Interactive art exhibits and installations | Provides an immersive experience for viewers | Collaboration with artists, adaptability to various designs |

How Are Holographic Knee High Space Boots Used in Fashion Retail?

In the fashion retail sector, holographic knee high space boots serve as statement pieces that attract trend-conscious consumers. High-fashion boutiques utilize these boots to showcase unique designs that appeal to fashion-forward clientele. Buyers in this sector should focus on sourcing high-quality materials and ensuring a diverse range of sizes to meet customer preferences. The ability to offer exclusive designs can significantly enhance brand appeal and drive sales.

What Role Do Holographic Knee High Space Boots Play in Entertainment & Events?

In the entertainment industry, particularly in theatrical performances and festivals, holographic knee high space boots are utilized to create visually striking costumes that captivate audiences. These boots enhance the overall aesthetic and can elevate a performance’s impact. For B2B buyers in this sector, sourcing boots that can withstand the rigors of stage use—such as heat from stage lights and extended wear—is crucial. Comfort and durability are essential considerations to ensure performers can focus on their roles without discomfort.

How Are Holographic Knee High Space Boots Used in Cosplay & Gaming?

Cosplay and gaming communities often seek out holographic knee high space boots to complete their costumes for conventions and events. These boots provide a unique and eye-catching element that enhances the authenticity of character portrayals. B2B buyers in this niche should prioritize sourcing options that allow for customization and a variety of styles to cater to diverse fandoms. Engaging with this passionate audience can lead to repeat business and brand loyalty.

Why Are Holographic Knee High Space Boots Important in Space & Aviation?

In the space and aviation sectors, specialized holographic knee high space boots can be designed for use in unique environments, such as space-themed events or astronaut training simulations. These boots must combine safety features with functional design, ensuring they are lightweight yet durable. Buyers should consider compliance with safety standards and the practical requirements of the intended use, as well as innovative design elements that enhance user experience.

How Are Holographic Knee High Space Boots Used in Art & Design Installations?

Holographic knee high space boots find a place in interactive art exhibits and design installations, where they can serve as part of the artistic expression or as functional pieces for participants. These installations aim to provide an immersive experience, and the boots can contribute significantly to the visual narrative. B2B buyers in this field should focus on collaboration with artists to ensure that the boots align with the overall vision of the installation, as well as adaptability to various artistic designs.

Illustrative image related to holographic knee high space boots

3 Common User Pain Points for ‘holographic knee high space boots’ & Their Solutions

Scenario 1: Sizing Confusion in Holographic Knee High Boots

The Problem: One of the most frequent challenges faced by B2B buyers is ensuring accurate sizing when ordering holographic knee high space boots. With varying international sizing standards (EU, US, UK), a buyer may inadvertently order the wrong size, leading to customer dissatisfaction and increased return rates. This issue is particularly relevant for retailers who cater to a diverse clientele across different regions, as a mismatch can result in lost sales and damaged relationships with end customers.

The Solution: To mitigate sizing issues, it is crucial to implement a comprehensive sizing guide that includes detailed measurements for each size variant. Retailers should invest in high-quality size charts that convert between international sizing systems and provide additional information, such as calf circumference and shaft height. Providing visual aids, such as diagrams or videos demonstrating how to measure foot size accurately, can further assist buyers in making informed decisions. Additionally, encouraging customers to take advantage of fit guides and virtual fitting tools can help ensure that the right size is selected before placing an order, thereby reducing the likelihood of returns.

Scenario 2: Quality Assurance and Material Concerns

The Problem: B2B buyers often grapple with concerns regarding the quality and durability of holographic knee high boots, particularly when sourcing from new or overseas suppliers. With the rise of trendy materials like PU lenticular rubber and holographic finishes, there can be discrepancies in production standards, leading to products that may not meet the durability expectations of their target market. This could result in negative reviews, high return rates, and a tarnished brand reputation.

The Solution: To address quality assurance concerns, it is essential for buyers to establish stringent supplier vetting processes that prioritize manufacturers with a proven track record of quality control. Requesting samples before making bulk purchases allows buyers to assess the material, finish, and overall craftsmanship of the boots firsthand. Furthermore, integrating quality checks into the supply chain—such as third-party inspections or audits—can help ensure that the products received align with the expected standards. Buyers should also seek detailed product specifications and certifications from suppliers, ensuring transparency about the materials used and their respective qualities.

Illustrative image related to holographic knee high space boots

Scenario 3: Import Regulations and Shipping Challenges

The Problem: Navigating the complexities of international shipping and import regulations can be a significant pain point for B2B buyers of holographic knee high boots, especially those targeting markets in Africa, South America, and the Middle East. Customs delays, unexpected duties, and compliance with local regulations can create frustration and uncertainty, leading to potential financial losses and disrupted supply chains.

The Solution: To streamline the import process, buyers should conduct thorough research on the customs regulations and import duties specific to their target markets. Partnering with experienced logistics providers who specialize in international shipping can help mitigate risks and provide clarity on the necessary documentation. Buyers can also benefit from establishing relationships with local distributors who understand regional requirements, ensuring a smoother entry for products. Additionally, considering options like pre-paid duties or utilizing free trade agreements can enhance cost-effectiveness and reduce the likelihood of unexpected fees, thereby facilitating a more efficient supply chain.

Strategic Material Selection Guide for holographic knee high space boots

What Are the Key Materials Used in Holographic Knee High Space Boots?

Holographic knee-high space boots are crafted from a variety of materials, each offering unique properties that influence performance, durability, and aesthetic appeal. Understanding these materials is crucial for international B2B buyers to make informed purchasing decisions.

Illustrative image related to holographic knee high space boots

How Does PU Lenticular Rubber Perform in Holographic Boots?

PU lenticular rubber is a popular choice for the outer layer of holographic knee-high boots. This material is lightweight and flexible, making it comfortable for extended wear. It has a good resistance to abrasion and can withstand moderate temperature variations, which is essential for boots designed for diverse environments.

Pros: The lightweight nature of PU lenticular rubber enhances comfort, while its abrasion resistance contributes to durability. Additionally, it can be produced in various colors and finishes, including holographic effects, appealing to fashion-forward consumers.

Cons: However, PU lenticular rubber may not offer the highest level of temperature resistance compared to other materials, which could limit its use in extreme conditions. Manufacturing complexity can also increase costs, particularly for custom designs.

Impact on Application: This material is suitable for casual and fashion-oriented applications but may not be ideal for high-performance environments requiring extreme durability or temperature resistance.

Illustrative image related to holographic knee high space boots

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local regulations regarding synthetic materials, as well as consider the environmental impact of PU production.

What Role Does Faux Leather Play in Holographic Boot Construction?

Faux leather serves as the lining material in many holographic knee-high boots, providing a soft and comfortable interior. This material is often made from polyurethane or PVC, offering a leather-like appearance without the ethical concerns associated with animal products.

Pros: Faux leather is generally more affordable than genuine leather and can be produced in a variety of textures and colors. It is also easier to clean and maintain, which is a significant advantage for consumers.

Illustrative image related to holographic knee high space boots

Cons: On the downside, faux leather may not be as breathable as natural leather, which can lead to discomfort during prolonged wear. Additionally, its durability may not match that of high-quality leather, leading to potential wear and tear over time.

Impact on Application: Faux leather is suitable for fashion-oriented applications but may not hold up as well in rugged environments. It is ideal for buyers focused on aesthetics rather than extreme performance.

Considerations for International Buyers: Compliance with international standards for synthetic materials is essential. Buyers should also consider consumer preferences in their target markets, as some regions may favor eco-friendly materials.

How Does the Use of High-Quality Synthetic Fibers Enhance Performance?

High-quality synthetic fibers are often used in the construction of the sole and other structural components of holographic knee-high boots. These materials can provide excellent grip and flexibility, essential for comfort and performance.

Pros: Synthetic fibers can be engineered to offer high durability, resistance to wear, and lightweight properties. They can also be designed to provide specific attributes, such as waterproofing or enhanced traction.

Illustrative image related to holographic knee high space boots

Cons: While generally more durable than natural fibers, synthetic options can sometimes lack the aesthetic appeal of traditional materials. Additionally, they may have a higher environmental impact during production.

Impact on Application: These materials are well-suited for a range of applications, from casual wear to more demanding environments, depending on their specific properties.

Considerations for International Buyers: Buyers should be aware of the environmental regulations in their regions, particularly concerning the production and disposal of synthetic materials. Compliance with standards such as ASTM or ISO may also be necessary.

Illustrative image related to holographic knee high space boots

What Are the Benefits of Using Holographic Coatings in Boot Design?

Holographic coatings are applied to various materials to achieve the eye-catching visual effects associated with holographic knee-high boots. These coatings can be applied to both synthetic and natural materials.

Pros: Holographic coatings enhance the visual appeal of boots, making them stand out in the marketplace. They can also provide a layer of protection against scratches and wear.

Cons: The application process for holographic coatings can be complex and may increase production costs. Additionally, the durability of the coating may vary, potentially leading to wear over time.

Impact on Application: Holographic coatings are particularly suited for fashion-forward applications, where aesthetics are a primary concern.

Considerations for International Buyers: Buyers should verify that the coatings comply with safety and environmental standards relevant to their markets. The longevity of the coating in different climates should also be considered.

Summary Table of Material Properties for Holographic Knee High Space Boots

| Material | Typical Use Case for holographic knee high space boots | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PU Lenticular Rubber | Outer layer for lightweight, fashionable boots | Lightweight and abrasion-resistant | Limited temperature resistance | Medium |

| Faux Leather | Lining for comfort and aesthetic appeal | Affordable and easy to maintain | Less breathable than natural leather | Low |

| High-Quality Synthetic Fibers | Sole and structural components for performance | High durability and flexibility | Aesthetic appeal may be lacking | Medium |

| Holographic Coatings | Applied for visual effects on various materials | Enhances aesthetic appeal | Complex application process | High |

This comprehensive analysis provides B2B buyers with essential insights into the materials used in holographic knee-high space boots, enabling them to make informed purchasing decisions tailored to their market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for holographic knee high space boots

What Are the Key Stages in the Manufacturing Process of Holographic Knee-High Space Boots?

The manufacturing of holographic knee-high space boots involves several critical stages, each designed to ensure the final product meets high standards of quality and performance. Understanding these stages can help B2B buyers make informed purchasing decisions.

Illustrative image related to holographic knee high space boots

How Is Material Prepared for Holographic Knee-High Boots?

The first stage in the manufacturing process is material preparation. This phase includes sourcing high-quality materials such as PU lenticular rubber, faux leather, and other synthetic fibers that offer durability and flexibility. Manufacturers often prioritize materials that exhibit the desired holographic effect, which is achieved through specialized coating techniques. The materials are inspected for defects before being cut into patterns according to the boot design specifications.

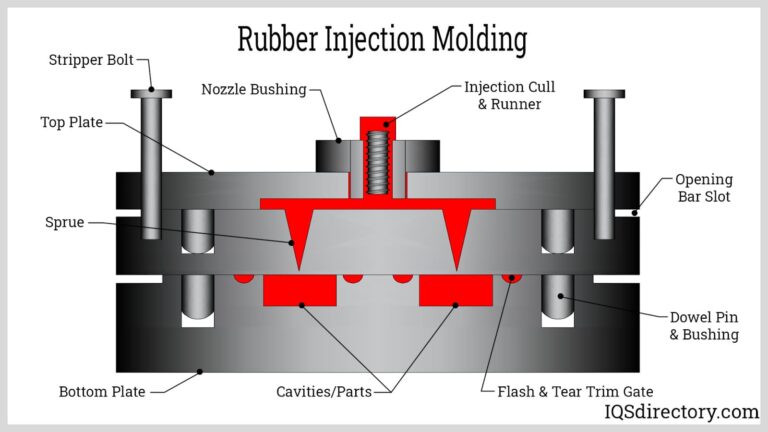

What Techniques Are Used in Forming the Boots?

Once the materials are prepared, they undergo forming, which involves shaping the cut pieces into the desired boot structure. Techniques such as heat molding and die-cutting are commonly used. Heat molding allows manufacturers to shape the materials accurately, ensuring a snug fit that conforms to various foot shapes. Die-cutting involves using precision tools to create uniform shapes from the material, which is essential for maintaining consistency in the final product.

How Are Holographic Knee-High Boots Assembled?

After forming, the next step is assembly. This stage combines the upper materials with the sole and lining. Assembly techniques can vary, but methods like adhesive bonding and stitching are prevalent. High-quality adhesives are crucial for ensuring longevity, especially for boots intended for rigorous use. The assembly process also includes adding zippers, decorative elements, and ensuring the boots are aesthetically appealing while maintaining functionality.

What Finishing Techniques Are Employed?

Finishing is the final stage in the manufacturing process, which includes polishing, applying protective coatings, and quality checks. This stage is critical for enhancing the visual appeal of holographic boots, ensuring that the holographic effect is vibrant and durable. Finishing touches also involve inspecting for any imperfections and ensuring that all components are securely attached.

What International Standards and Quality Assurance Practices Should B2B Buyers Consider?

Quality assurance (QA) is paramount in the production of holographic knee-high space boots. B2B buyers must be aware of relevant international standards and practices to ensure they are sourcing high-quality products.

Which International Standards Are Relevant for Quality Assurance?

ISO 9001 is one of the most recognized quality management standards globally. It emphasizes a process approach to quality management and is crucial for manufacturers aiming to enhance customer satisfaction through effective quality management systems. Additionally, CE marking may be relevant for products sold within the European market, indicating compliance with health and safety standards.

What Quality Control Checkpoints Should Be Implemented?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process. Key QC checkpoints include:

-

Incoming Quality Control (IQC): This step ensures that raw materials meet specified quality standards before production begins. Suppliers should provide certificates of conformity for materials used.

-

In-Process Quality Control (IPQC): This involves monitoring the manufacturing process to identify defects early. Regular checks during the forming and assembly stages help maintain quality.

-

Final Quality Control (FQC): At this stage, finished boots are thoroughly inspected for defects in design, material, and functionality. Common testing methods include visual inspections, stress tests, and performance evaluations.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must implement strategies to verify the quality control measures of their suppliers. This includes conducting audits and requesting detailed quality reports.

What Should Buyers Look for in Supplier Audits?

Audits should focus on evaluating the supplier’s adherence to international standards and their internal QC processes. Buyers can request to see audit reports from third-party organizations to ensure impartiality.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can provide an additional layer of assurance. These services typically include comprehensive evaluations of the manufacturing process, materials, and final products. Buyers can request inspections at various stages, from material sourcing to final product delivery, ensuring that quality standards are consistently met.

What Nuances Should International B2B Buyers Be Aware of?

When sourcing holographic knee-high space boots, international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must be aware of specific nuances in quality assurance and logistics.

How Do Import Regulations Impact Quality Control?

Import regulations can vary significantly between countries, affecting the quality assurance process. Buyers should familiarize themselves with local import regulations regarding footwear, including any certifications required for the products to enter their markets. Ensuring compliance with these regulations can prevent costly delays and rejections at customs.

What Are the Challenges of Sourcing from Diverse Markets?

Sourcing from diverse markets can present challenges related to communication, quality consistency, and cultural differences in business practices. B2B buyers should establish clear communication channels and set specific expectations regarding quality standards and delivery timelines.

Conclusion

Understanding the manufacturing processes and quality assurance practices for holographic knee-high space boots is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, as well as adhering to international quality standards, businesses can ensure they are sourcing high-quality products. Implementing thorough QC checkpoints and engaging in supplier audits will further enhance the assurance of quality, ultimately leading to successful business transactions in the global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘holographic knee high space boots’

Introduction

This guide serves as a comprehensive checklist for B2B buyers looking to procure holographic knee-high space boots. As this niche product gains traction in various markets, understanding the key steps in the sourcing process will help ensure that you select the right suppliers and products that meet your business needs.

Step 1: Define Your Target Market and Customer Preferences

Understanding your target market is crucial for successful sourcing. Identify the regions where demand is growing, such as Africa, South America, the Middle East, and Europe. Additionally, gather insights on customer preferences regarding styles, colors, and sizes to tailor your order effectively.

- Research local trends: Investigate popular styles and materials favored by consumers in your target regions.

- Engage with potential customers: Use surveys or focus groups to gather direct feedback on desired features and price points.

Step 2: Establish Technical Specifications

Clearly outline the technical specifications required for the boots. This includes materials, sizes, and any unique features such as waterproofing or insulation.

Illustrative image related to holographic knee high space boots

- Material considerations: Ensure that the outer material is durable yet lightweight, such as PU lenticular rubber, which can enhance the holographic effect.

- Size ranges: Provide a comprehensive size chart that aligns with international standards to avoid fitting issues.

Step 3: Research and Evaluate Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in holographic footwear. This step is vital to ensure product quality and reliability.

- Request documentation: Ask for company profiles, product catalogs, and references from other clients.

- Check online reviews: Look for feedback from other businesses that have sourced from these suppliers to gauge their reputation.

Step 4: Verify Supplier Certifications and Compliance

Ensure that your suppliers comply with international quality standards and regulations relevant to your market.

- Quality certifications: Look for suppliers with ISO certifications or similar credentials that demonstrate adherence to quality control measures.

- Compliance with import/export regulations: Verify that suppliers can handle necessary paperwork for international shipping, including customs documentation.

Step 5: Assess Pricing and Payment Terms

Evaluate the pricing structure and payment terms offered by potential suppliers. This is crucial for maintaining your profit margins.

- Compare pricing: Request quotes from multiple suppliers and assess what is included in the price (e.g., shipping, duties).

- Negotiate payment terms: Discuss options such as deposits, payment upon delivery, or extended payment plans that can ease cash flow.

Step 6: Review Shipping and Delivery Options

Understand the logistics involved in shipping and delivery timelines. This will impact your inventory management and customer satisfaction.

Illustrative image related to holographic knee high space boots

- Shipping methods: Inquire about different shipping options, including express and standard delivery, to align with your needs.

- Handling international logistics: Ensure the supplier can manage customs clearance and any potential delays specific to your target regions.

Step 7: Plan for After-Sales Support and Returns

Establish a clear understanding of after-sales support and return policies to enhance customer satisfaction.

- Return policies: Ensure the supplier has a fair return policy in case of defects or unsold inventory.

- Customer support: Assess the level of support provided post-sale, including warranty details and responsiveness to queries.

By following this checklist, you will be better positioned to successfully source high-quality holographic knee-high space boots that meet the demands of your market and ensure satisfaction among your customers.

Comprehensive Cost and Pricing Analysis for holographic knee high space boots Sourcing

What Are the Key Cost Components in Sourcing Holographic Knee High Space Boots?

When sourcing holographic knee high space boots, understanding the cost structure is crucial for making informed purchasing decisions. The primary components of cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Illustrative image related to holographic knee high space boots

-

Materials: The choice of materials significantly impacts the overall cost. Holographic knee high boots are typically made from specialized materials such as PU lenticular rubber and faux leather, which can vary in price based on quality and sourcing location. Higher quality materials often lead to increased durability and aesthetic appeal, which can justify a higher price point.

-

Labor: Labor costs will vary based on the region of manufacturing. Countries with lower labor costs may offer competitive pricing, but it’s essential to consider the skill level and craftsmanship required for producing high-quality footwear. This is particularly relevant for intricate designs or customization.

-

Manufacturing Overhead: This encompasses the costs related to running the manufacturing facility, including utilities, rent, and equipment maintenance. Efficient production processes can help minimize overhead costs, but these savings may not always be passed on to the buyer.

-

Tooling: Custom tooling for specific designs or sizes can add a significant upfront cost. Buyers should evaluate whether the tooling costs can be amortized over a large order volume to reduce the per-unit cost.

-

Quality Control (QC): Implementing rigorous QC processes is essential to ensure product quality and compliance with international standards. This may involve additional costs but can prevent costly returns and damage to brand reputation.

-

Logistics: Shipping costs can vary widely depending on the origin of the goods and the destination. Buyers should consider freight options, including Incoterms, which define responsibilities between the buyer and seller regarding shipping costs and risks.

-

Margin: Finally, the profit margin that suppliers build into their pricing can vary. Understanding typical margins in the footwear industry can help buyers negotiate better deals.

How Do Price Influencers Affect Holographic Knee High Space Boots Pricing?

Several factors can influence the pricing of holographic knee high space boots:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Suppliers often provide discounts for larger orders, making it essential for buyers to assess their needs and negotiate accordingly.

-

Specifications/Customization: Custom designs or specific features can increase costs. Buyers should weigh the benefits of customization against potential price increases and consider whether standard options would suffice.

-

Materials and Quality Certifications: Boots made from premium materials or those that meet specific quality certifications may command higher prices. It’s crucial for buyers to assess the value these certifications bring to their target market.

-

Supplier Factors: The reputation and reliability of suppliers can also impact pricing. Established suppliers may charge more due to their proven track record, while emerging manufacturers might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is vital for international buyers. Different terms can affect the total landed cost, including shipping, insurance, and duties.

What Tips Can Help Buyers Optimize Costs When Sourcing Holographic Knee High Space Boots?

For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiate: Always negotiate prices, especially for bulk orders. Suppliers may have flexibility in pricing, particularly if they are eager to secure a contract.

-

Consider Total Cost of Ownership: Beyond the purchase price, consider the total cost of ownership, which includes logistics, potential returns, and maintenance. Investing in higher-quality boots may reduce long-term costs associated with replacements or repairs.

-

Stay Informed on Pricing Nuances: Be aware of market trends and pricing fluctuations in the footwear industry. Economic conditions, material shortages, or changes in manufacturing capabilities can impact prices.

-

Research Supplier Backgrounds: Conduct thorough research on potential suppliers to ensure they have a solid reputation for quality and reliability. This can prevent unforeseen costs related to quality issues.

-

Plan for Import Fees and Taxes: When sourcing internationally, factor in potential import fees and taxes, which can significantly affect the total cost. Understanding local regulations can aid in budgeting more accurately.

By strategically analyzing these components and influencers, B2B buyers can make informed decisions that optimize their sourcing of holographic knee high space boots while managing costs effectively.

Alternatives Analysis: Comparing holographic knee high space boots With Other Solutions

Understanding Alternatives for Holographic Knee High Space Boots

When considering the acquisition of holographic knee high space boots, it’s essential to evaluate alternative solutions that may offer similar benefits or meet specific business needs. Various products exist that can fulfill the aesthetic and functional requirements of footwear in niche markets, such as fashion-forward industries, performance arts, or unique promotional events. This analysis will compare holographic knee high space boots against two viable alternatives: high-visibility reflective boots and custom 3D-printed footwear.

Comparison Table

| Comparison Aspect | Holographic Knee High Space Boots | High-Visibility Reflective Boots | Custom 3D-Printed Footwear |

|---|---|---|---|

| Performance | Eye-catching, lightweight, stylish | Highly visible, durable, functional | Tailored fit, unique designs |

| Cost | $625 – $1,300 | $150 – $300 | $200 – $500 |

| Ease of Implementation | Moderate (fashion retail) | Easy (standard retail) | Complex (requires technology) |

| Maintenance | Moderate (care for materials) | Low (easy to clean) | Variable (depends on materials) |

| Best Use Case | Fashion events, art installations | Construction, outdoor work | Fashion shows, unique projects |

Detailed Breakdown of Alternatives

High-Visibility Reflective Boots

High-visibility reflective boots are designed primarily for safety in low-light conditions, making them ideal for industries such as construction and outdoor work. They typically feature durable materials that withstand harsh environments and provide essential protection. However, while they are functional, they lack the unique aesthetic appeal of holographic boots. For businesses prioritizing safety without sacrificing visibility, these boots offer a practical solution at a significantly lower cost.

Illustrative image related to holographic knee high space boots

Custom 3D-Printed Footwear

Custom 3D-printed footwear represents a cutting-edge alternative that allows businesses to design shoes tailored to specific requirements, including fit and style. This technology enables the production of unique designs that can stand out in fashion-forward markets. However, the initial cost can be higher than traditional footwear, and the implementation process may be more complex, requiring advanced technology and expertise. Businesses in need of highly customized footwear solutions may find this option appealing, despite the challenges of maintenance and production.

Conclusion: How to Choose the Right Footwear Solution

When selecting the right footwear solution, B2B buyers should consider their specific operational needs, budget constraints, and desired aesthetic outcomes. Holographic knee high space boots offer a unique blend of style and lightweight performance, making them suitable for creative sectors. In contrast, high-visibility reflective boots provide essential safety features at a lower cost for industries focused on protection. Meanwhile, custom 3D-printed footwear caters to niche markets that value uniqueness and personalization, albeit with higher complexity and cost. By assessing these factors, buyers can make informed decisions that align with their business objectives and target audience preferences.

Essential Technical Properties and Trade Terminology for holographic knee high space boots

What Are the Key Technical Properties of Holographic Knee High Space Boots?

Understanding the essential technical properties of holographic knee high space boots is crucial for B2B buyers looking to make informed purchasing decisions. Here are the critical specifications to consider:

1. Material Composition

The outer material is typically made from PU (polyurethane) lenticular rubber, known for its lightweight and durable properties. The lining is often faux leather, offering comfort while being eco-friendly. The sole is generally constructed from PU as well, providing flexibility and shock absorption. This material composition is essential as it directly impacts the product’s performance, durability, and aesthetic appeal, especially in diverse markets like Africa and South America.

2. Sizing Specifications

Holographic knee high boots come in various sizes, often denoted in EU, US, and UK formats. For example, EU 35 corresponds to US 4.5. Providing detailed sizing charts is vital for ensuring accurate fit, minimizing returns, and enhancing customer satisfaction. Buyers must pay attention to the size conversions and the average calf circumference, as these can vary significantly across different regions.

Illustrative image related to holographic knee high space boots

3. Weight Tolerance

The weight of these boots is an important factor, particularly for shipping and logistics. Most holographic knee high boots are designed to be ultra-lightweight, which reduces shipping costs and enhances customer comfort. Buyers should inquire about the weight tolerance to ensure the boots meet the requirements of their specific market, especially for regions where shipping logistics are challenging.

4. Design Features

Key design features such as heel height, platform height, and closure type (e.g., side zip or back zip) significantly influence both style and functionality. For example, designs with high stiletto heels (like 110mm) appeal to fashion-forward consumers, while those with platforms (5.5 inches) may attract a different demographic. Buyers must align these design features with their target audience’s preferences to ensure market acceptance.

5. Production Lead Time

The time it takes to manufacture and ship the boots is a critical factor for B2B transactions. Standard lead times can range from 3 to 5 business days for domestic orders, but international orders may take longer. Understanding lead times allows businesses to manage inventory effectively and meet customer demands promptly.

What Are the Common Trade Terms Relevant to Holographic Knee High Space Boots?

Familiarity with industry jargon and trade terminology can greatly assist B2B buyers in navigating the procurement process. Here are some common terms:

1. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This is crucial for buyers as it impacts budgeting and inventory management. Understanding the MOQ helps in negotiating better terms and ensuring that the order aligns with market demand.

2. OEM (Original Equipment Manufacturer)

OEM denotes a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, partnering with an OEM can provide opportunities for customized products tailored to specific market needs, enhancing competitive advantage.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. This process is essential for buyers to evaluate options and make informed purchasing decisions. A well-structured RFQ can lead to better pricing and service terms.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. For example, EXW (Ex Works) indicates that the buyer takes on all shipping costs and risks once the goods are made available at the seller’s premises. Understanding these terms is vital for managing logistics and costs effectively.

Illustrative image related to holographic knee high space boots

5. Lead Time

Lead time refers to the total time from placing an order to receiving the product. Knowing the lead time is critical for inventory management and planning, especially in fast-paced markets where trends can change rapidly.

By grasping these technical properties and trade terms, B2B buyers can streamline their purchasing processes and make strategic decisions that align with their business goals.

Navigating Market Dynamics and Sourcing Trends in the holographic knee high space boots Sector

What Are the Key Market Dynamics and Trends Influencing Holographic Knee High Space Boots?

The holographic knee high space boots market is witnessing a surge driven by several global factors, including an increase in the demand for unique fashion statements and the growing popularity of festival and streetwear culture. This trend is particularly pronounced in emerging markets such as Africa, South America, and parts of Europe, where consumers are increasingly seeking bold, eye-catching designs. The rise of social media platforms has further amplified this trend, as influencers showcase these distinctive styles, creating a ripple effect among consumers.

Illustrative image related to holographic knee high space boots

Additionally, technological advancements in materials have paved the way for innovative designs and functionalities. For instance, the use of lenticular rubber and PU materials not only enhances the visual appeal but also contributes to lightweight and comfortable wear. B2B buyers are increasingly focused on sourcing these innovative materials to stay competitive in the market. Furthermore, the global supply chain dynamics are evolving, with more emphasis on direct sourcing from manufacturers to reduce costs and improve lead times. International buyers should be aware of regional preferences and adjust their sourcing strategies accordingly, particularly when targeting markets with distinct cultural aesthetics, such as Vietnam and Brazil.

How Is Sustainability and Ethical Sourcing Shaping the Holographic Knee High Boots Market?

Sustainability has become a crucial aspect of sourcing strategies in the fashion industry, including the market for holographic knee high space boots. B2B buyers are increasingly prioritizing suppliers that adhere to ethical practices, ensuring that materials are sourced responsibly and production processes minimize environmental impact. This shift is not merely a trend but a response to consumer demand for transparency and accountability in fashion.

Using eco-friendly materials, such as recycled plastics or sustainably sourced faux leathers, can significantly reduce the environmental footprint of these products. Moreover, certifications such as Global Recycled Standard (GRS) and OEKO-TEX® can provide assurance to buyers regarding the sustainability of their supply chain. By aligning with manufacturers that prioritize ethical practices, B2B buyers can enhance their brand image and appeal to a growing segment of environmentally conscious consumers.

What Is the Evolution of Holographic Knee High Space Boots in the B2B Context?

The evolution of holographic knee high space boots can be traced back to the late 20th century, where the incorporation of synthetic materials began to transform footwear design. Initially embraced within niche subcultures, these boots gained traction in mainstream fashion as designers began to explore bold textures and colors. The 2010s marked a significant turning point, as holographic effects became synonymous with high fashion, driven by brands that catered to a younger, more adventurous demographic.

Today, the market is characterized by a diverse range of styles, from high-end designer models to more accessible, streetwear-inspired options. This diversification has opened new avenues for B2B buyers, allowing them to cater to various consumer segments while capitalizing on the ongoing trend of personalization and self-expression in fashion. Understanding this evolution is essential for international buyers looking to make informed sourcing decisions and align their offerings with current market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of holographic knee high space boots

1. How do I solve issues with sizing and fit when sourcing holographic knee-high space boots?

To address sizing and fit issues, ensure to request detailed sizing charts from suppliers. Sizes can vary significantly across brands and regions, so it’s crucial to confirm that the measurements align with your target market’s preferences. Consider ordering samples to test fit and comfort before placing a larger order. Additionally, discuss potential customization options with suppliers, such as adjusting calf circumference or boot length, to cater to specific customer needs.

2. What is the best way to identify reliable suppliers for holographic knee-high space boots?

Identifying reliable suppliers involves thorough vetting. Start by researching manufacturers with a proven track record in producing similar products. Request references or case studies from other clients. Utilize platforms like Alibaba or global trade shows to find verified suppliers. Conduct factory visits if possible, or use third-party inspection services to assess production quality. Always ensure that the supplier adheres to international quality standards and has a transparent production process.

3. What are common minimum order quantities (MOQs) for holographic knee-high space boots?

Minimum order quantities can vary widely based on the manufacturer and the complexity of the design. Typically, MOQs for footwear like holographic knee-high boots range from 100 to 500 pairs. However, some suppliers may offer lower MOQs for initial orders or samples. Be prepared to negotiate MOQs based on your purchasing power, and consider consolidating orders with other products to meet the supplier’s requirements.

4. How can I customize holographic knee-high space boots for my brand?

Customization options often include color variations, materials, and design elements such as logos or unique patterns. Discuss your specific requirements with potential suppliers, as many manufacturers offer custom services. Be aware that custom orders may have higher MOQs and longer lead times. Request prototypes to ensure the final product aligns with your expectations before committing to a larger production run.

5. What payment terms should I expect when sourcing holographic knee-high space boots internationally?

Payment terms can vary by supplier but generally include options like a deposit upfront (commonly 30-50%) and the balance upon completion or prior to shipping. It’s crucial to clarify these terms before placing an order. Consider using secure payment methods, such as letters of credit or escrow services, to protect your investment. Ensure that you understand any additional costs, such as shipping and import duties, which can impact your overall budget.

6. How do I ensure quality assurance (QA) when importing holographic knee-high space boots?

Quality assurance can be achieved by implementing a multi-step inspection process. First, request samples to evaluate the craftsmanship and material quality. During production, consider hiring a third-party inspection service to conduct on-site checks, ensuring that the products meet your standards. Additionally, establish clear quality control criteria and communicate them with your supplier to avoid discrepancies upon delivery.

7. What logistics considerations should I keep in mind when importing holographic knee-high space boots?

When importing, consider factors such as shipping methods, costs, and delivery timelines. Air freight is faster but more expensive, while sea freight is cost-effective for larger orders but takes longer. Ensure you have a clear understanding of the Incoterms (like EXW or FOB) to define responsibilities for shipping and customs clearance. Collaborate with a logistics partner familiar with international trade regulations to streamline the process.

8. What are the key trends in the market for holographic knee-high space boots?

Current trends include a growing demand for unique, eye-catching designs and sustainable materials. Consumers increasingly favor customizable options that reflect personal style. Additionally, the rise of social media influencers in fashion has amplified interest in distinctive footwear like holographic boots. Stay informed about market trends by attending fashion expos and following industry reports to ensure your offerings align with consumer preferences.

Top 6 Holographic Knee High Space Boots Manufacturers & Suppliers List

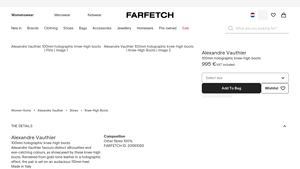

1. Alexandre Vauthier – 100mm Holographic Knee-High Boots

Domain: farfetch.com

Registered: 2003 (22 years)

Introduction: {“brand”:”Alexandre Vauthier”,”product_name”:”100mm Holographic Knee-High Boots”,”color”:”Pink”,”price”:”$1,300″,”import_duties”:”included”,”heel_height”:”110mm”,”material”:”gold-tone leather”,”effect”:”holographic”,”toe_style”:”pointed toe”,”fastening”:”side zip”,”insole”:”branded”,”boot_height”:”knee-high”,”heel_type”:”high stiletto”,”composition”:”Other fibres 100%”,”made_in”:”Italy”,”farfetch_…

2. Demonia – Swing-815 Boots

Domain: demoniacult.com

Registered: 2017 (8 years)

Introduction: Demonia “Swing-815” Boots – Black Holographic Patent

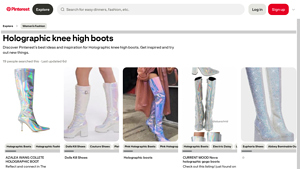

3. AZALEA WANG – Collette Holographic Boot

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: AZALEA WANG Collette Holographic Boot, glossy color-changing holographic PU upper, knee-high shaft height, pointed toe silhouette, slim stiletto heel, cushioned insole, unique squared heel structure, tonal inner ankle zipper closure, approximate measurements from size 7.5, PU Upper, PU Lining, TPU Outsole.

4. Rave Wonderland – Demonia Shaker White Holo Knee High Boots

Domain: ravewonderland.com

Registered: 2013 (12 years)

Introduction: Demonia Shaker White Holo Knee High Boots

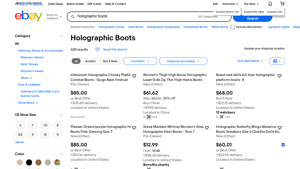

5. Dolls Kill – Holographic Platform Boots

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Holographic Boots available on eBay include various styles and brands such as: 1. Dolls Kill blue holographic platform boots – Size 8, New, Price: ILS 226.35, Delivery: ILS 134.65. 2. 8-inch high heel holographic print closed toe lace-up dance platform ankle boots, New, Price: ILS 709.95, Free international shipping. 3. Iridescent holographic chunky platform combat boots, Pre-Owned, Price: ILS 282…

6. Tragic Beautiful – Neon Holo Shoes & Platform Heels

Domain: tragicbeautiful.com

Registered: 2005 (20 years)

Introduction: Neon Holo Shoes | Platform Heels & Boots | Pleaser & Demonia Australia

Strategic Sourcing Conclusion and Outlook for holographic knee high space boots

As the market for holographic knee-high space boots continues to evolve, strategic sourcing remains crucial for B2B buyers aiming to capitalize on this trend. The unique appeal of these boots, characterized by their striking designs and innovative materials, presents significant opportunities for retailers looking to differentiate their offerings. Understanding the diverse price points—from budget-friendly options to luxury designs—enables buyers to cater to various customer segments effectively.

In addition, the importance of supplier relationships cannot be overstated. Establishing connections with manufacturers who prioritize quality and sustainability will not only enhance product offerings but also ensure a reliable supply chain, particularly for international buyers in regions such as Africa, South America, the Middle East, and Europe.

Looking ahead, embracing technological advancements in production and distribution will be key. This sector is poised for growth, and buyers are encouraged to explore collaborative ventures that leverage digital platforms for marketing and sales. By adopting a proactive sourcing strategy, businesses can position themselves advantageously in the competitive landscape of holographic knee-high space boots. Now is the time to engage with suppliers and innovate your product line to meet the demands of a fashion-forward consumer base.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.