A B2B Buyer’s Guide to Hinge Leaf: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for hinge leaf

In today’s competitive landscape, sourcing the right hinge leaf can significantly impact the functionality and durability of products across various industries. B2B buyers face the challenge of navigating a vast global market, where understanding the nuances of hinge leaf specifications, applications, and supplier credibility is crucial. This comprehensive guide is designed to address these complexities, providing valuable insights into the different types of hinge leaves, their applications in residential and commercial settings, and effective strategies for vetting suppliers.

Within these pages, you will discover a detailed analysis of various hinge leaf types, including their materials, sizes, and functional advantages. We will also explore applications across sectors such as construction, furniture manufacturing, and automotive industries, emphasizing how selecting the right hinge leaf can enhance product performance. Furthermore, this guide will offer expert tips on supplier evaluation, helping you identify reliable partners who can meet your specific sourcing needs.

For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Germany—making informed purchasing decisions is essential. By leveraging the insights provided in this guide, you will be equipped to navigate the global hinge leaf market confidently, ensuring that you select high-quality components that align with your business objectives and customer expectations.

Understanding hinge leaf Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Butt Hinge | Simple design with two rectangular leaves and a pin connecting them | Doors, cabinets, and furniture | Pros: Cost-effective, widely available. Cons: Limited weight capacity. |

| Continuous Hinge | Runs the entire length of the door, distributing weight evenly | Heavy doors, gates, and large cabinets | Pros: Enhanced durability, stability. Cons: Requires precise installation. |

| Concealed Hinge | Hidden when the door is closed, adjustable for precise alignment | Cabinets and furniture applications | Pros: Aesthetic appeal, adjustable. Cons: Higher cost, complex installation. |

| Spring-Loaded Hinge | Contains a spring mechanism for automatic closing | Screen doors, patio doors | Pros: Convenience, self-closing feature. Cons: May wear out over time. |

| Strap Hinge | Long leaves for added strength, often decorative | Barn doors, gates, and outdoor furniture | Pros: High load capacity, aesthetic options. Cons: May require more space for installation. |

What are the key characteristics of Butt Hinges for B2B buyers?

Butt hinges are among the most common hinge types, featuring two rectangular leaves joined by a pin. Their straightforward design makes them easy to install and maintain, making them a cost-effective choice for many applications, particularly in doors and cabinets. When purchasing, buyers should consider the weight capacity and material, as some variations can be more durable than others. They are suitable for medium-weight applications but may not provide sufficient support for heavier doors.

How do Continuous Hinges enhance stability in B2B applications?

Continuous hinges, also known as piano hinges, extend the entire length of a door or panel, providing uniform weight distribution. This design increases stability, making them ideal for heavy doors, gates, and large cabinets where consistent support is essential. Buyers should assess the installation requirements, as these hinges often necessitate precise alignment and may require additional hardware. Their durability makes them a long-term investment for commercial settings, particularly in high-traffic areas.

Why are Concealed Hinges popular in furniture applications?

Concealed hinges are designed to remain hidden when the door is closed, offering a sleek and modern aesthetic. They are particularly popular in cabinetry and furniture applications where visual appeal is paramount. These hinges are often adjustable, allowing for fine-tuning of door alignment. Buyers should consider the complexity of installation and the higher costs associated with these hinges, as they may require specialized tools or skills. Their design, however, can significantly enhance the overall look of a product.

What advantages do Spring-Loaded Hinges offer for outdoor applications?

Spring-loaded hinges feature a built-in spring mechanism that allows doors to close automatically, making them particularly useful for screen and patio doors. This feature enhances convenience and is ideal for high-traffic areas. When considering these hinges, buyers should evaluate the durability of the spring mechanism, as wear can affect performance over time. They are an excellent option for outdoor applications where ease of use is essential, but potential maintenance should be factored into the purchasing decision.

In what scenarios are Strap Hinges most effective?

Strap hinges are characterized by their long leaves, which provide extra strength and support, making them suitable for heavy-duty applications such as barn doors and outdoor gates. Their decorative design also adds an aesthetic element to functional installations. Buyers should take into account the space required for installation, as strap hinges need more room to operate effectively. Their high load capacity and versatility make them a popular choice in both commercial and residential settings.

Key Industrial Applications of hinge leaf

| Industry/Sector | Specific Application of hinge leaf | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Architecture | Door and window installations | Ensures durability and functionality of openings | Material quality, load capacity, and corrosion resistance |

| Automotive | Vehicle door mechanisms | Enhances safety and ease of access | Compliance with industry standards and specifications |

| Furniture Manufacturing | Cabinet and drawer hardware | Provides smooth operation and longevity | Design compatibility, weight capacity, and finish options |

| Industrial Equipment | Access panels and machinery covers | Facilitates maintenance and operational efficiency | Customization options and material suitability |

| Agricultural Equipment | Barn doors and equipment access | Supports heavy-duty usage and reliability | Weather resistance and ease of installation |

How is hinge leaf used in construction and architecture?

In the construction and architecture sector, hinge leaves are integral to the installation of doors and windows. They provide the necessary pivot points for functionality while ensuring structural integrity. Buyers in this sector, particularly in regions like Africa and Europe, need to consider factors such as material quality and load capacity, as these can greatly affect the longevity and performance of the installations. Corrosion resistance is also a key requirement, especially in humid or coastal environments.

What role does hinge leaf play in the automotive industry?

In the automotive industry, hinge leaves are crucial components of vehicle door mechanisms. They enable smooth opening and closing, contributing to both safety and user convenience. B2B buyers must ensure that the hinge leaves meet specific industry standards for strength and durability. Additionally, sourcing hinges that are lightweight yet robust can improve fuel efficiency and performance, making it a significant consideration for manufacturers in South America and the Middle East.

How does hinge leaf enhance furniture manufacturing?

Within the furniture manufacturing sector, hinge leaves are essential for the operation of cabinets and drawers. They facilitate smooth movement, enhancing user experience and product longevity. Buyers should focus on design compatibility, ensuring that the hinge leaves match the aesthetic and functional requirements of their products. Weight capacity and finish options are also important, as they can affect both the durability and visual appeal of the final furniture pieces.

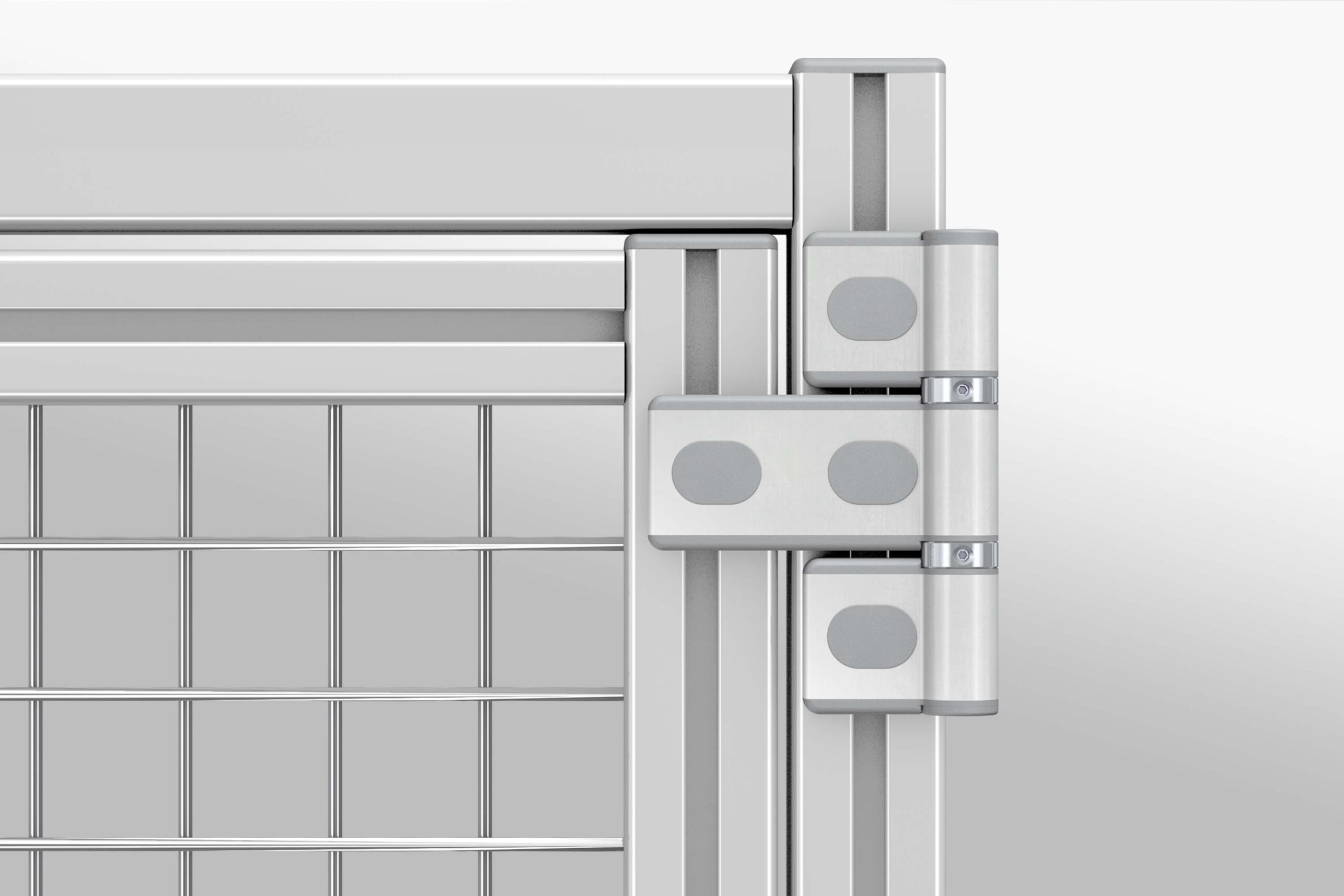

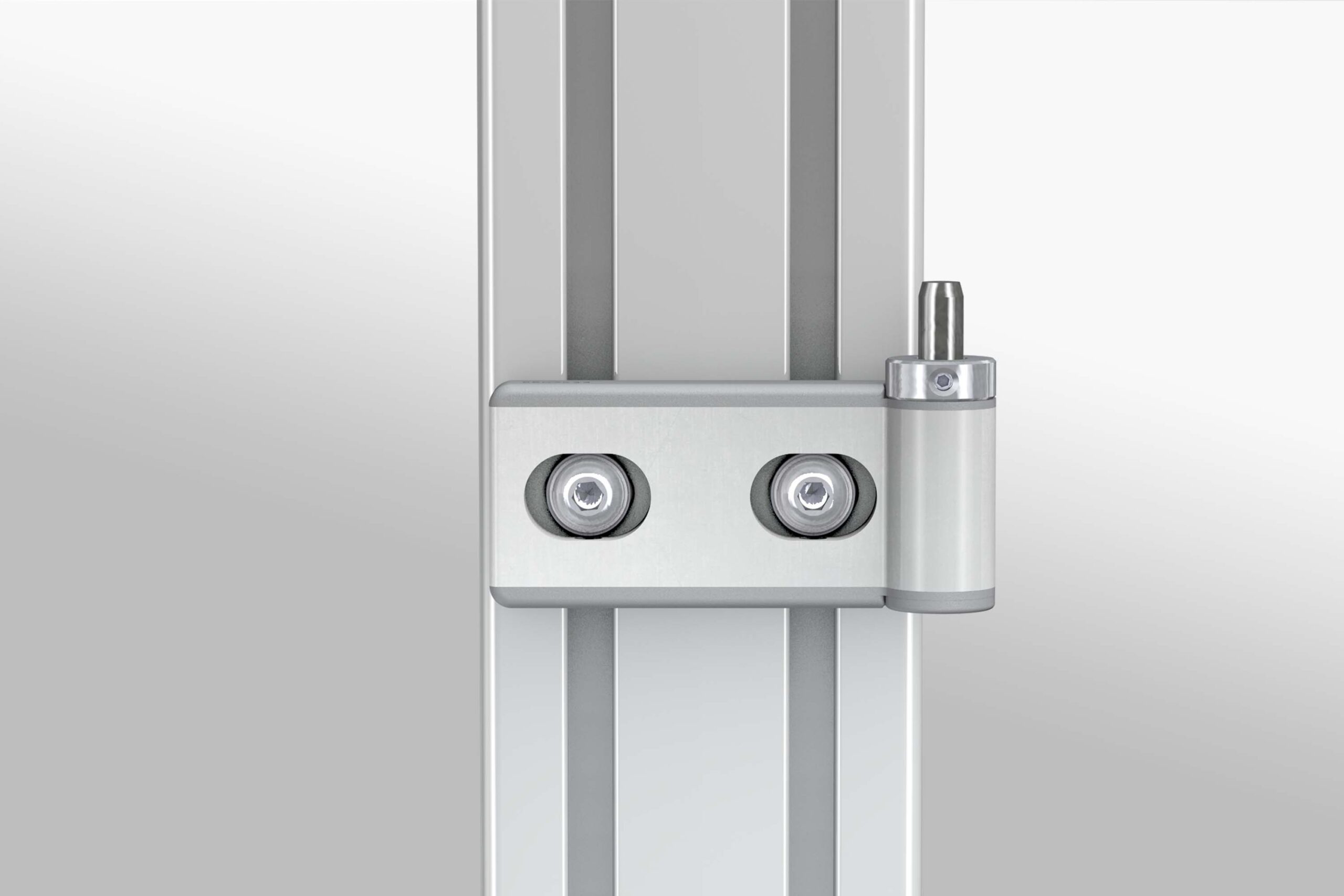

Illustrative image related to hinge leaf

In what ways is hinge leaf utilized in industrial equipment?

Hinge leaves are commonly used in industrial equipment for access panels and machinery covers. They provide reliable access for maintenance and repairs, which is crucial for operational efficiency. B2B buyers in this sector should look for customization options that cater to specific equipment designs. Additionally, the material suitability is vital, as it must withstand harsh industrial environments while maintaining functionality.

How is hinge leaf applied in agricultural equipment?

In the agricultural sector, hinge leaves are vital for barn doors and access to various types of equipment. They must support heavy-duty usage while ensuring reliability in outdoor conditions. Buyers need to prioritize weather resistance and ease of installation when sourcing hinge leaves for agricultural applications. This is particularly relevant for buyers in regions with extreme weather conditions, ensuring that their equipment remains functional and accessible year-round.

3 Common User Pain Points for ‘hinge leaf’ & Their Solutions

Scenario 1: Difficulty Sourcing Quality Hinge Leaf Products in Diverse Markets

The Problem: Many B2B buyers, particularly those operating in regions like Africa and South America, face significant challenges when sourcing hinge leaves that meet their specific quality and regulatory standards. Inconsistent product availability, varying specifications, and unreliable suppliers can lead to costly delays and compromised product integrity. Buyers often struggle to find manufacturers who can provide hinge leaves that are not only durable but also compatible with their existing systems.

The Solution: To effectively source quality hinge leaves, buyers should prioritize establishing relationships with reputable suppliers who have a proven track record in their region. Conducting thorough due diligence is essential; this includes checking supplier certifications, customer reviews, and product specifications. Utilizing platforms that aggregate supplier data can streamline this process. Additionally, consider working with local distributors who understand regional regulations and can provide insights into the best materials suited for specific climates and applications. Developing a clear specification document that outlines the required dimensions, materials, and performance standards can also help ensure that the hinge leaves sourced meet all necessary criteria.

Scenario 2: Incompatibility with Existing Systems and Equipment

The Problem: A common issue arises when B2B buyers purchase hinge leaves that do not fit or function well with their existing equipment. This can happen when there is a lack of clear communication about the specific requirements for hinge leaves or when buyers assume that standard sizes will suffice. Such incompatibility can lead to operational inefficiencies, increased maintenance costs, and potential safety hazards.

The Solution: To mitigate the risk of incompatibility, it is crucial for buyers to conduct a comprehensive needs assessment before purchasing hinge leaves. This involves measuring existing hinge dimensions and understanding the mechanical requirements of the equipment they are working with. Buyers should engage with technical support from suppliers to confirm that the hinge leaf specifications match their needs. Furthermore, consider utilizing CAD software to visualize how the new hinge leaves will integrate with existing systems. This proactive approach not only ensures compatibility but also helps in avoiding costly modifications or replacements.

Scenario 3: High Maintenance Costs Due to Poor Quality Materials

The Problem: Many businesses find themselves facing escalating maintenance costs due to the frequent replacement of low-quality hinge leaves. This issue is particularly prevalent in industries with high usage rates, such as manufacturing and logistics, where hinges are subjected to constant wear and tear. Buyers often underestimate the long-term costs associated with cheaper, lower-quality products, leading to budget overruns and operational downtime.

The Solution: Investing in high-quality hinge leaves made from durable materials is essential for reducing maintenance costs over time. Buyers should focus on sourcing hinge leaves that are specifically designed for heavy-duty applications, including those with corrosion-resistant coatings or enhanced load-bearing capabilities. Establishing partnerships with manufacturers that offer warranties and guarantees can also provide peace of mind regarding product longevity. Conducting a cost-benefit analysis that compares the initial investment in quality hinge leaves against the potential savings in maintenance and replacements can help justify the higher upfront cost. Additionally, implementing a regular inspection and maintenance schedule can extend the life of the hinges, further optimizing operational efficiency.

Strategic Material Selection Guide for hinge leaf

When selecting materials for hinge leaves, it is crucial to consider their properties, applications, and the specific needs of international B2B buyers. Below is an analysis of four common materials used for hinge leaves: stainless steel, brass, aluminum, and plastic. Each material has unique characteristics that influence their performance and suitability for various applications.

Illustrative image related to hinge leaf

What Are the Key Properties of Stainless Steel for Hinge Leaves?

Stainless steel is renowned for its exceptional corrosion resistance and strength. It can withstand high temperatures and pressures, making it suitable for environments where durability is paramount. The most common grades used in hinge manufacturing are 304 and 316, with 316 offering superior corrosion resistance, particularly in marine or chemical environments.

Pros: Stainless steel hinges are highly durable and require minimal maintenance. They are also aesthetically pleasing, often used in high-end applications.

Cons: The primary drawback is cost; stainless steel is generally more expensive than other materials. Additionally, manufacturing can be complex due to its hardness, which may require specialized tooling.

Impact on Application: Stainless steel hinges are ideal for outdoor applications, industrial settings, and environments with exposure to moisture or chemicals. They are compliant with international standards such as ASTM and DIN, making them suitable for global markets.

How Does Brass Perform as a Material for Hinge Leaves?

Brass is an alloy of copper and zinc, known for its excellent machinability and corrosion resistance. It offers a warm aesthetic appeal, making it a popular choice for decorative applications.

Pros: Brass hinges are resistant to corrosion and tarnishing, especially in dry environments. They are also easy to work with, allowing for intricate designs.

Cons: Brass is softer than stainless steel, which can lead to wear over time, especially in high-traffic applications. It is also more susceptible to environmental factors like humidity, which can cause tarnishing.

Impact on Application: Brass hinges are commonly used in residential settings, cabinetry, and decorative doors. Buyers in regions with high humidity, such as parts of Africa and South America, should consider the potential for tarnishing and choose finishes that mitigate this issue.

What Are the Benefits of Using Aluminum for Hinge Leaves?

Aluminum is lightweight, corrosion-resistant, and offers good strength-to-weight ratios. It is often anodized to enhance its surface properties, making it suitable for various applications.

Pros: The lightweight nature of aluminum makes it easy to handle and install. It is also cost-effective and resistant to rust, which is beneficial in humid environments.

Cons: While aluminum is strong, it is not as durable as stainless steel, especially in heavy-duty applications. It may also deform under high stress.

Impact on Application: Aluminum hinges are suitable for lightweight doors, screens, and applications where weight is a concern. International buyers should ensure compliance with local standards, as aluminum grades can vary significantly.

When Should Plastic Be Considered for Hinge Leaves?

Plastic hinges are made from various polymers, offering a lightweight and cost-effective alternative to metal. They are often used in environments where corrosion is a concern.

Pros: Plastic hinges are resistant to corrosion, lightweight, and often less expensive than metal alternatives. They can also be manufactured in various colors and styles.

Cons: The primary limitation is their lower load-bearing capacity compared to metals. They may not perform well in high-temperature environments, as some plastics can warp or degrade.

Impact on Application: Plastic hinges are ideal for applications such as lightweight doors, cabinets, and enclosures. Buyers should consider the specific type of plastic to ensure compatibility with their application and environmental conditions.

Summary Table of Material Selection for Hinge Leaves

| Material | Typical Use Case for hinge leaf | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Industrial, outdoor applications | Exceptional corrosion resistance | Higher cost and manufacturing complexity | High |

| Brass | Decorative and residential doors | Aesthetic appeal and machinability | Softer, susceptible to tarnishing | Medium |

| Aluminum | Lightweight doors and screens | Lightweight and cost-effective | Lower durability under stress | Low |

| Plastic | Lightweight and non-load bearing | Corrosion resistance and low cost | Limited load capacity and temperature sensitivity | Low |

This guide provides a comprehensive overview of the material selection process for hinge leaves, enabling international B2B buyers to make informed decisions based on their specific requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for hinge leaf

What Are the Key Stages in the Manufacturing Process of Hinge Leaves?

The manufacturing process for hinge leaves involves several critical stages that ensure the final product meets industry standards and customer expectations.

Illustrative image related to hinge leaf

Material Preparation: What Materials Are Typically Used for Hinge Leaves?

Hinge leaves are primarily made from metals such as stainless steel, brass, and aluminum. The choice of material depends on the intended application and environmental conditions. For instance, stainless steel is favored for its corrosion resistance, making it suitable for outdoor or high-humidity applications. The manufacturing process begins with sourcing high-quality raw materials, which are then cut to specified dimensions. This stage often involves the use of advanced cutting technologies, such as laser cutting or water jet cutting, to achieve precision.

How Are Hinge Leaves Formed and Shaped?

The next step in the process is forming the hinge leaves. This can be accomplished through various techniques, including stamping, forging, or machining. Stamping is a widely used method that involves pressing the metal sheet into a mold to create the desired shape and features, such as knuckles or attachment points. Forging, on the other hand, involves shaping the metal through localized compressive forces, which can enhance the strength of the hinge leaf. The choice of forming technique can affect both the mechanical properties and the aesthetic finish of the hinge.

What Is Involved in the Assembly of Hinge Leaves?

After the hinge leaves are formed, the next step is assembly. This phase includes attaching various components, such as pins and bushings, which are essential for the hinge’s functionality. Automated assembly lines are often employed to ensure consistency and efficiency. During this stage, manufacturers may also conduct preliminary quality checks to identify any defects early in the process, ensuring that only high-quality components move forward.

How Are Hinge Leaves Finished for Final Presentation?

The finishing stage is crucial for both aesthetic appeal and functional durability. Common finishing techniques include anodizing, powder coating, or plating, which provide corrosion resistance and enhance the hinge’s visual characteristics. For instance, anodizing aluminum can improve its surface hardness and corrosion resistance, while powder coating allows for a variety of color options. This stage not only adds to the product’s lifespan but also contributes to its marketability.

What Quality Assurance Measures Are Essential in Hinge Leaf Production?

Quality assurance is a critical aspect of hinge leaf manufacturing, ensuring that products meet both international and industry-specific standards.

Which International Standards Should B2B Buyers Be Aware Of?

International standards like ISO 9001 play a vital role in quality management systems across various industries, including hinge manufacturing. This standard emphasizes continuous improvement and customer satisfaction, which are essential for maintaining competitive advantage. Additionally, industry-specific certifications such as CE for European markets or API for oil and gas applications may be relevant, depending on the end-use of the hinge.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial phase assesses the quality of raw materials before production begins. Inspecting materials for compliance with specifications helps prevent defects in the final product.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC checks ensure that processes are being followed correctly. This can include monitoring machinery performance and measuring critical dimensions of hinge leaves to ensure they meet design specifications.

-

Final Quality Control (FQC): Once the hinges are assembled and finished, FQC involves comprehensive testing to verify that the final product meets all quality standards. This can include functional testing, dimensional verification, and aesthetic checks.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial to ensure product reliability.

What Methods Can Buyers Use to Audit Supplier Quality?

Conducting audits is one effective way to assess a supplier’s quality assurance practices. Buyers can request to review the supplier’s quality management documentation, including ISO certifications and internal QC reports. Additionally, third-party inspections can provide an unbiased evaluation of the supplier’s processes and products. Engaging with independent quality assurance organizations can also add an extra layer of credibility.

What Testing Methods Should Buyers Consider?

Common testing methods for hinge leaves include:

-

Mechanical Testing: This evaluates properties such as tensile strength, hardness, and fatigue resistance, which are critical for the durability of hinges in various applications.

-

Corrosion Testing: For hinges used in outdoor or humid environments, corrosion resistance tests can help predict the longevity of the product under adverse conditions.

-

Dimensional Inspection: Using precision measurement tools, buyers can verify that the dimensions of hinge leaves conform to specified tolerances.

What Are the Unique Quality Control Nuances for International B2B Buyers?

International buyers must navigate various quality control nuances that can differ based on regional standards and practices.

How Do Regional Standards Affect Quality Assurance?

In Europe, for instance, compliance with CE marking is essential for many products, including hinges, indicating conformity with health, safety, and environmental protection standards. In contrast, buyers in Africa and South America may encounter different regulatory frameworks that require additional certifications or local compliance checks. Understanding these regional differences is vital for buyers to avoid potential legal and operational challenges.

What Should Buyers Know About Supplier Relationships?

Building strong relationships with suppliers can facilitate better communication regarding quality assurance practices. Regular updates on quality improvements and changes in production processes can enhance trust and collaboration. Furthermore, engaging suppliers in discussions about quality expectations can lead to better alignment and mutual benefits.

By comprehensively understanding the manufacturing processes and quality assurance measures for hinge leaves, B2B buyers can make informed decisions that align with their needs and ensure the reliability and durability of their products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hinge leaf’

To assist B2B buyers in successfully procuring hinge leaves, this practical sourcing guide outlines key steps to ensure a smooth and efficient purchasing process. By following this checklist, buyers can make informed decisions that align with their operational needs.

Step 1: Define Your Technical Specifications

Clearly outlining the technical specifications for hinge leaves is essential. This includes dimensions, materials, load capacity, and compatibility with existing products. Having precise specifications helps streamline communication with suppliers and ensures that the purchased products meet your operational requirements.

- Considerations:

- Edge lengths, thickness, and weight capacity.

- Material type (e.g., aluminum, stainless steel) based on environmental factors.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in hinge leaves. Look for manufacturers with a solid reputation in your region or industry. A reliable supplier can provide consistent quality and service, which is crucial for maintaining operational efficiency.

- Resources:

- Online directories, trade shows, and industry publications.

- Supplier reviews and testimonials from other businesses.

Step 3: Evaluate Supplier Certifications and Compliance

Before finalizing any procurement, verify that suppliers meet necessary certifications and compliance standards. Certifications such as ISO 9001 indicate adherence to quality management systems, while other industry-specific certifications may be relevant.

- Key Certifications:

- Quality management (ISO 9001).

- Environmental management (ISO 14001).

Step 4: Request Samples and Product Specifications

Obtaining samples is a vital step to assess the quality and suitability of the hinge leaves. This allows you to evaluate the product firsthand and ensure it meets your specifications before placing a bulk order.

- What to Look For:

- Durability and finish quality.

- Ease of installation and functionality.

Step 5: Negotiate Terms and Conditions

Engage in discussions with potential suppliers to negotiate favorable terms and conditions. This includes pricing, payment terms, lead times, and warranty provisions. A well-negotiated agreement can lead to long-term savings and better supplier relationships.

- Considerations:

- Bulk order discounts and payment flexibility.

- Warranty duration and coverage details.

Step 6: Assess Logistics and Shipping Options

Understanding the logistics and shipping options available is crucial for timely delivery. Discuss shipping costs, delivery timelines, and any potential customs regulations that may impact your order, especially for international shipments.

- Logistics Considerations:

- Shipping methods and associated costs.

- Customs documentation and import tariffs.

Step 7: Establish a Quality Control Process

After procurement, implement a quality control process to ensure that the hinge leaves received meet your specifications. Regular inspections and feedback loops with the supplier can help maintain product quality over time.

- Quality Control Steps:

- Inspect products upon arrival for compliance with specifications.

- Maintain ongoing communication with the supplier regarding any quality issues.

By following this checklist, B2B buyers can streamline their sourcing process for hinge leaves, ensuring they procure high-quality products that meet their operational needs effectively.

Comprehensive Cost and Pricing Analysis for hinge leaf Sourcing

What Are the Key Cost Components in Hinge Leaf Sourcing?

In the sourcing of hinge leaves, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The choice of materials significantly impacts the cost. Common materials include aluminum, stainless steel, and brass, with prices varying based on quality and market demand. For instance, anodized aluminum hinges may be less expensive than brass but offer different performance characteristics.

-

Labor: Labor costs depend on the manufacturing location. Countries with lower labor costs can provide a competitive advantage; however, this must be balanced against potential quality issues.

-

Manufacturing Overhead: This includes utilities, facility costs, and administrative expenses. Efficient manufacturing processes can help lower overhead, but these savings are often contingent on volume.

-

Tooling: Initial tooling costs can be substantial, particularly for custom hinge designs. These costs are amortized over production runs, making high-volume orders more cost-effective in the long run.

-

Quality Control: Ensuring product quality through rigorous QC processes incurs additional costs but is crucial for maintaining standards, especially for international buyers who may have stringent regulations.

-

Logistics: Shipping and handling costs can vary widely based on the supplier’s location and the chosen Incoterms. These terms define responsibilities for shipping costs, insurance, and tariffs, which can affect overall pricing.

-

Margin: Suppliers typically apply a markup to cover their costs and generate profit. Understanding the supplier’s pricing strategy can provide insights into potential negotiation points.

How Do Volume and Customization Affect Pricing for Hinge Leaves?

Volume and Minimum Order Quantity (MOQ) are significant price influencers in hinge leaf sourcing. Suppliers often offer tiered pricing, where larger orders result in lower per-unit costs. This is particularly relevant for B2B buyers who can forecast their needs and commit to larger volumes.

Customization also plays a critical role. Tailored specifications can lead to higher costs due to the additional resources required for design and production adjustments. Buyers should weigh the benefits of customization against the potential increase in price.

What Other Factors Influence Hinge Leaf Pricing?

Several additional factors can influence pricing, including material quality, certifications, and supplier reputation. High-quality materials and certifications (e.g., ISO, CE) can justify higher prices but may also ensure better performance and longevity, reducing the Total Cost of Ownership (TCO).

Moreover, the supplier’s experience, reliability, and customer service can also affect costs. Suppliers with a strong track record may charge a premium, but this often translates into better support and product reliability.

What Negotiation Strategies Can B2B Buyers Use to Optimize Costs?

When negotiating hinge leaf prices, B2B buyers should focus on building long-term relationships with suppliers. This can lead to better pricing agreements and favorable payment terms. Here are several strategies:

- Leverage Volume: Commit to larger orders or long-term contracts to secure discounts.

- Seek Multiple Quotes: Comparing offers from various suppliers can provide leverage in negotiations.

- Discuss Payment Terms: Flexible payment arrangements can sometimes lead to better pricing.

- Consider Total Cost of Ownership: Highlighting the long-term savings from higher-quality products can justify higher initial costs.

What Are the Pricing Nuances for International Buyers?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of the nuances in pricing. Currency fluctuations, import tariffs, and local regulations can significantly impact the total cost.

Illustrative image related to hinge leaf

Understanding the Incoterms used in contracts is crucial, as they dictate who bears the cost and risk at each stage of shipping. For example, “FOB” (Free on Board) means the seller covers costs until the goods are loaded onto the shipping vessel, while “CIF” (Cost, Insurance, and Freight) includes shipping costs to the buyer’s port.

Disclaimer on Indicative Prices

It is important to note that the prices mentioned are indicative and subject to change based on market conditions, supplier pricing strategies, and other economic factors. Buyers are encouraged to conduct thorough market research and engage in detailed discussions with suppliers to obtain accurate and current pricing.

Alternatives Analysis: Comparing hinge leaf With Other Solutions

Exploring Alternatives to Hinge Leaf Solutions

When considering hinge leaf solutions for various applications, it’s essential to explore alternative methods that can deliver similar functionality. This analysis will compare hinge leaves against two viable alternatives: concealed hinges and continuous hinges. Each option offers distinct benefits and drawbacks, making it crucial for B2B buyers to assess which solution aligns best with their specific operational needs.

Comparison Table

| Comparison Aspect | Hinge Leaf | Concealed Hinges | Continuous Hinges |

|---|---|---|---|

| Performance | Good for standard applications | Excellent for aesthetics and space-saving | High durability and weight distribution |

| Cost | Moderate ($10-$20 per unit) | Higher ($20-$50 per unit) | Variable ($15-$30 per unit) |

| Ease of Implementation | Simple installation | Requires precise alignment | Straightforward installation |

| Maintenance | Low maintenance | Low, but harder to access | Low, but wear can be visible |

| Best Use Case | General doors and cabinets | Modern cabinetry and doors | Heavy doors, chests, and lids |

Detailed Breakdown of Alternatives

What Are the Benefits and Drawbacks of Concealed Hinges?

Concealed hinges, often used in cabinetry, are known for their aesthetic appeal as they remain hidden when doors are closed. This design enhances the overall look of furniture and cabinetry, making it ideal for modern interior designs. However, they tend to be more expensive and require precise installation, which may involve additional labor costs. Their maintenance is generally low, but accessing them for repairs or adjustments can be challenging, potentially leading to increased downtime.

How Do Continuous Hinges Compare to Hinge Leaf Solutions?

Continuous hinges, also known as piano hinges, run the entire length of the door, providing even weight distribution and increased strength. They are particularly effective for heavy doors, such as those found in commercial applications. The straightforward installation process is a significant advantage, as it requires fewer components than other hinge types. However, the visible wear over time can be a drawback, as it may detract from the aesthetic appeal of the door or cabinet. Continuous hinges are versatile but may not suit all design preferences.

Illustrative image related to hinge leaf

How Should B2B Buyers Choose the Right Solution?

Choosing the right hinge solution depends on various factors, including the specific application, budget, and aesthetic requirements. For general use, hinge leaves offer a cost-effective and straightforward option. If aesthetics and modern design are priorities, concealed hinges might be the best choice despite their higher cost. Conversely, for heavy-duty applications requiring robust support, continuous hinges are a reliable alternative. Ultimately, B2B buyers should evaluate the performance, cost, and ease of maintenance to make an informed decision that aligns with their operational needs and project specifications.

Essential Technical Properties and Trade Terminology for hinge leaf

What Are the Key Technical Properties of Hinge Leaf?

When selecting hinge leaves for various applications, understanding their technical properties is essential. Here are some critical specifications that buyers should consider:

-

Material Grade

The material used for hinge leaves significantly affects their durability and functionality. Common materials include stainless steel, aluminum, and brass. Stainless steel is ideal for outdoor applications due to its corrosion resistance, while aluminum is lightweight and cost-effective. Buyers should assess the material grade based on the specific environmental conditions the hinge will face. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension of the hinge leaf. Tight tolerances are essential for precision applications, ensuring that the hinge operates smoothly without binding or excessive wear. In B2B contexts, specifying the correct tolerance can prevent costly rework or product failures, making it crucial for manufacturers and end-users alike. -

Weight Capacity

Each hinge leaf has a specified weight capacity, which dictates its suitability for various applications. Understanding this capacity is vital for ensuring that the hinge can adequately support the door or gate it is attached to. Overloading a hinge can lead to premature failure, affecting safety and functionality. -

Surface Finish

The surface finish of a hinge leaf not only impacts aesthetics but also its resistance to wear and corrosion. Common finishes include anodized, polished, and powder-coated. Buyers should select finishes that align with their operational environment to maximize longevity and performance. -

Edge Length and Configuration

The dimensions of the hinge leaf, including edge length, play a crucial role in compatibility with doors and frames. Different configurations (e.g., square, rounded) may be required based on the application. This specification is particularly important for manufacturers who need to ensure that their products fit correctly within their designs.

What Are Common Trade Terms Used in the Hinge Industry?

Understanding industry jargon is essential for effective communication and negotiation. Here are several common terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the hinge industry, this term is vital for identifying suppliers who provide components that meet specific quality and compatibility standards for assembly into larger products. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers, as it can affect inventory management and cash flow. Suppliers often set MOQs to ensure that production costs are covered, making it essential for buyers to factor this into their procurement strategies. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products or services. This process is vital for obtaining competitive bids and ensuring that all potential suppliers are evaluated on a level playing field. It’s a standard practice in B2B transactions, especially for bulk purchases. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global trade. Understanding these terms helps clarify who is responsible for shipping, insurance, and tariffs, which is crucial for international B2B transactions involving hinge leaves. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. This metric is particularly important in the hinge industry, where delays can disrupt production schedules. Buyers should always inquire about lead times to ensure alignment with their project timelines.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions, enhancing their procurement processes and ensuring the successful integration of hinge leaves into their applications.

Navigating Market Dynamics and Sourcing Trends in the hinge leaf Sector

What Are the Current Market Dynamics and Key Trends Affecting the Hinge Leaf Sector?

The hinge leaf market is experiencing significant growth driven by several global factors. Increasing construction activities, particularly in emerging economies across Africa, South America, the Middle East, and Europe, are propelling demand for high-quality hardware components. The rise in urbanization and the expansion of the real estate sector in countries like Nigeria and Germany have led to a burgeoning demand for reliable and durable hinge solutions. Furthermore, the trend toward automation and smart home technologies is prompting manufacturers to innovate, integrating advanced materials and designs into their products.

Emerging technologies such as 3D printing and digital prototyping are revolutionizing the hinge manufacturing process, allowing for rapid prototyping and customization. Buyers are increasingly seeking suppliers who can offer flexibility in design and quicker turnaround times. Additionally, the rise of e-commerce platforms is reshaping sourcing strategies, providing international buyers with access to a wider range of suppliers and competitive pricing.

Sourcing trends indicate a shift toward centralized procurement strategies, where buyers aim to consolidate their supply chains to streamline operations and reduce costs. This is particularly relevant for B2B buyers looking to source hinge leaves in bulk. Moreover, there is a growing emphasis on data-driven decision-making, with businesses utilizing analytics to optimize inventory management and supplier relationships.

How Are Sustainability and Ethical Sourcing Changing the Hinge Leaf Industry?

Sustainability is becoming a critical focus for B2B buyers in the hinge leaf sector. The environmental impact of manufacturing processes is under scrutiny, with many companies seeking to minimize their carbon footprints. Ethical sourcing practices are increasingly important, as buyers prefer suppliers who adhere to sustainable manufacturing standards and demonstrate a commitment to social responsibility.

The use of ‘green’ materials, such as recycled metals and eco-friendly coatings, is gaining traction among manufacturers. Certifications such as ISO 14001 for environmental management systems and LEED (Leadership in Energy and Environmental Design) certification are becoming essential for suppliers aiming to attract environmentally-conscious buyers. These certifications not only enhance a company’s credibility but also align with the growing consumer demand for sustainable products.

Moreover, the integration of circular economy principles in the hinge manufacturing process is fostering innovation. This approach emphasizes the reuse and recycling of materials, thereby reducing waste and promoting resource efficiency. Buyers looking to source hinge leaves must prioritize suppliers who incorporate these practices into their operations, ensuring that their procurement strategies align with broader sustainability goals.

How Has the Hinge Leaf Sector Evolved Over Time?

The hinge leaf sector has undergone significant transformation since its inception. Initially, hinges were crafted from simple materials and designed primarily for functionality. Over time, advancements in metallurgy and manufacturing techniques have led to the production of more sophisticated and durable hinge leaves.

The introduction of various hinge types, such as concealed, spring-loaded, and continuous hinges, has diversified the market, catering to a wide range of applications from residential doors to heavy industrial uses. As consumer preferences shifted towards aesthetic appeal and customization, manufacturers began to offer a variety of finishes and styles, enhancing the decorative aspects of hinge leaves.

Today, the hinge leaf market is characterized by a blend of functionality, design, and sustainability, reflecting the evolving needs of B2B buyers. As the industry continues to innovate, the focus on technology and ethical sourcing will shape the future of hinge leaf procurement.

Illustrative image related to hinge leaf

Frequently Asked Questions (FAQs) for B2B Buyers of hinge leaf

-

How do I solve issues with hinge leaf compatibility?

To address compatibility concerns with hinge leaves, it’s crucial to first identify the specifications of your existing hardware. Measure the dimensions, weight capacity, and type of hinge currently in use. Consult with suppliers who provide detailed product data and CAD drawings to ensure a precise match. Additionally, verify the material and finish to ensure durability and aesthetic alignment with your applications. Engaging with manufacturers that offer customization options can also help you source hinge leaves that meet specific operational requirements. -

What is the best material for hinge leaves in humid environments?

For humid environments, stainless steel or brass hinge leaves are ideal due to their corrosion-resistant properties. Stainless steel, particularly those with higher chromium content, offers superior resistance to rust and wear, making it suitable for outdoor applications or areas with high moisture levels. Brass, while more traditional, provides a classic look and good durability against environmental factors. Always consider the finish and coating options available to further enhance resistance to corrosion in specific conditions. -

What are the typical minimum order quantities (MOQs) for hinge leaves?

Minimum order quantities for hinge leaves can vary significantly depending on the manufacturer and material. Generally, MOQs can range from as low as 100 pieces for standard models to several thousand for custom or specialized designs. It’s advisable to discuss your requirements directly with suppliers to negotiate terms that fit your purchasing plans. Additionally, bulk orders often lead to better pricing, so consider the potential for future needs when evaluating MOQs. -

How can I vet suppliers for hinge leaf products?

To effectively vet suppliers, begin by researching their reputation within the industry through reviews and testimonials. Verify their manufacturing capabilities, certifications, and compliance with international standards, such as ISO. Request samples to assess the quality of their products, and inquire about their production lead times and flexibility in accommodating changes. Establish clear communication channels and engage in discussions about their quality assurance processes to ensure they can meet your demands consistently. -

What payment terms should I expect when sourcing hinge leaves internationally?

Payment terms for international transactions often vary by supplier and may include options like advance payment, letters of credit, or payment upon delivery. Common terms include a 30% deposit with the balance payable before shipment or upon delivery. It’s essential to negotiate terms that protect your interests and consider using secure payment methods to mitigate risks. Familiarize yourself with currency exchange rates and any additional fees that may arise from international transactions to budget accordingly. -

What quality assurance measures should I look for in hinge leaf suppliers?

Look for suppliers who implement rigorous quality assurance measures, such as ISO certifications and adherence to industry standards. Inquire about their testing procedures, including material inspections, dimensional checks, and performance evaluations. Understanding their return and warranty policies is also crucial, as this indicates their commitment to product quality. Establishing a clear line of communication regarding quality expectations can help ensure that the products delivered meet your specifications. -

How do I handle logistics and shipping when importing hinge leaves?

When importing hinge leaves, it’s important to understand the logistics involved, including selecting a reliable freight forwarder who can navigate customs regulations and ensure timely delivery. Discuss shipping options with suppliers, considering factors like shipping time, costs, and insurance. Ensure that all necessary documentation is in order, including invoices, packing lists, and certificates of origin. Familiarize yourself with import duties and taxes applicable in your country to avoid unexpected costs. -

Can hinge leaves be customized for specific applications?

Yes, many manufacturers offer customization options for hinge leaves to meet specific application needs. Customization can include variations in size, material, finish, and even design features like added strength or unique shapes. When discussing your requirements with suppliers, provide detailed specifications and any relevant drawings or CAD files. This will help ensure that the final product aligns with your operational needs and integrates seamlessly into your existing systems.

Top 6 Hinge Leaf Manufacturers & Suppliers List

1. Andersen – Insect Screen Upper Hinge Leaf

Domain: parts.andersenwindows.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “Insect Screen Upper Hinge Leaf”, “Series”: “400 Series”, “Product Line”: “400 Series Frenchwood Hinged Patio Door”, “Part Number”: “2579476”, “Color”: “White”, “Price”: “$10.18”, “Description”: “White upper leaf hinge”, “Compatibility”: “Works with 400 Series Frenchwood Hinged Patio Door”, “Hinge Requirements”: {“Unit Height 68 or 611”: “2 hinges required”, “Unit Height 80”: “3 h…

2. Reddit – Industrial Countertop Hinge

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Proper hinge for table leaf with square edge, counter flap hinge, heavy countertop support, industrial aesthetic, detachable leaf option.

3. Andersen – Upper Hinge Leaf for Screen Doors

Domain: allaboutdoors.com

Registered: 1997 (28 years)

Introduction: {“Product Name”: “Andersen Upper Hinge Leaf for Screen Doors”, “Part Number”: “1269106”, “Price”: “$9.57”, “Description”: “Upper Hinge Leaf, 3 inch height, mounted on the Insect Screen.”, “Compatibility”: “6-8 and 6-11 doors require 2 hinge sets; 8-0 door requires 3 hinge sets. One hinge set consists of an upper hinge leaf, a lower hinge leaf, and a hinge pin.”, “Colors Available”: [“White”, “Terr…

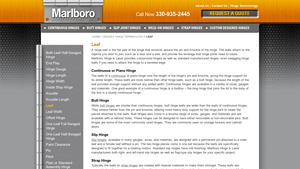

4. Marlboro Hinge – Variety of Hinge Types

Domain: marlborohinge.com

Registered: 2002 (23 years)

Introduction: Marlboro Hinge & Laser offers a variety of hinge types including Continuous Hinges, Butt Hinges, Slip Joint Hinges, Weld-On Hinges, and Strap Hinges. Key features include:

– Continuous Hinges: Leaf runs the length of the hinge’s pin and knuckle, available in various sizes, gauges, and materials.

– Butt Hinges: Shorter than continuous hinges with wider leafs, available with removable or non-removab…

5. Do It Yourself – Installing Hinges on Interior Doors

Domain: doityourself.com

Registered: 1995 (30 years)

Introduction: The discussion revolves around the installation of hinges on interior doors, specifically whether it matters which hinge leaf goes on the door versus the jamb. Key points include: 1. One hinge leaf has 2 knuckles and the other has 3 knuckles. 2. The orientation of the hinge is more dependent on the handedness of the door (right or left). 3. The pin of the hinge can be reversed, allowing for flexib…

6. Elesa – Leaf & Butt Hinges

Domain: reidsupply.com

Registered: 2004 (21 years)

Introduction: {“product_name”: “Leaf & Butt Hinges”, “description”: “Free-swinging leaf hinges, also known as butt hinges, offer no resistance and consist of two flat plates joined by a pin through a center barrel.”, “availability”: “In stock”, “brands”: [“Elesa”, “Reid Select”, “EMKA”], “materials”: [“Reinforced Polyamide-Based (PA) Technopolymer”, “Steel”, “Stainless Steel”, “Aluminum”, “Die Cast Zinc Alloy”,…

Strategic Sourcing Conclusion and Outlook for hinge leaf

The hinge leaf segment presents significant opportunities for international B2B buyers, especially in emerging markets across Africa, South America, the Middle East, and Europe. The diversity in hinge leaf types—from simple butt hinges to specialized concealed and continuous hinges—allows businesses to cater to various applications, enhancing both functionality and aesthetic appeal.

Strategic sourcing plays a crucial role in optimizing supply chains, ensuring access to high-quality materials, and maintaining competitive pricing. By leveraging strong supplier relationships and understanding regional market demands, companies can not only reduce costs but also improve product offerings to meet local preferences.

As industries continue to evolve, the demand for innovative and durable hinge solutions will grow. Buyers are encouraged to explore partnerships with manufacturers who prioritize sustainability and technological advancements in hinge design. By doing so, they can enhance operational efficiency and drive long-term growth.

In conclusion, now is the opportune time for international B2B buyers to reassess their sourcing strategies for hinge leaves, ensuring they remain competitive and responsive to market trends. Embrace the potential of strategic sourcing to unlock value and secure a robust supply chain for the future.

Illustrative image related to hinge leaf

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.