A B2B Buyer’s Guide to Hinge Diagram: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for hinge diagram

In today’s competitive landscape, sourcing the right hinge diagram can pose a significant challenge for international B2B buyers. Understanding the various types of hinges—ranging from surface mount to concealed options—along with their specific applications is crucial for ensuring product functionality and longevity. This comprehensive guide delves into the intricacies of hinge diagrams, covering essential aspects such as hinge types, applications across different industries, supplier vetting strategies, and cost considerations.

By equipping buyers with this knowledge, the guide empowers decision-makers from diverse regions, including Africa, South America, the Middle East, and Europe (with a focus on markets like Germany and Saudi Arabia), to make informed purchasing choices. The insights provided herein will help mitigate risks associated with sourcing, allowing for the selection of high-quality products that meet regulatory standards and customer expectations.

Whether you’re looking to enhance your manufacturing processes, improve furniture design, or ensure seamless door functionality, this guide serves as a valuable resource. It not only clarifies the complexities of hinge diagrams but also positions your business for success in the global market. With actionable insights at your fingertips, you can confidently navigate your procurement journey, ensuring the right fit for your operational needs.

Understanding hinge diagram Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Overlay Hinges | Door wing overlaps the cabinet frame, providing a seamless look. | Kitchen cabinets, furniture design | Pros: Aesthetic appeal; easy installation. Cons: Limited adjustment options. |

| Inset Hinges | Hidden when the door is closed, allowing for flush surfaces. | High-end cabinetry, custom furniture | Pros: Clean, minimalist design; enhances aesthetics. Cons: Requires precise measurements. |

| Surface Mount Hinges | Mounted on the outside surfaces, easily visible. | Heavy-duty doors, storage solutions | Pros: Simple installation; robust for heavy use. Cons: Less aesthetic appeal; prone to wear. |

| Concealed Hinges | Hidden within the cabinet, providing a clean look. | Modern cabinetry, office furniture | Pros: Enhanced aesthetics; adjustable. Cons: May require specialized tools for installation. |

| Piano Hinges | Long continuous hinge for large doors and lids. | Pianos, toolboxes, and cabinets | Pros: Even weight distribution; durable. Cons: May require more space; complex installation. |

What Are Overlay Hinges and Their Key Characteristics?

Overlay hinges are designed to allow the cabinet door to overlap the cabinet frame, creating a seamless and aesthetically pleasing finish. This type of hinge is particularly popular in kitchen cabinetry and furniture design, where a smooth appearance is desired. B2B buyers should consider the ease of installation and the minimal adjustment options that come with overlay hinges. While they offer significant aesthetic benefits, the limited adjustability may require precise initial measurements to ensure proper alignment.

How Do Inset Hinges Enhance Cabinetry Designs?

Inset hinges are characterized by their ability to remain hidden when the cabinet door is closed, allowing for a flush surface that enhances the overall design of high-end cabinetry and custom furniture. These hinges are ideal for projects where a minimalist aesthetic is paramount. When purchasing inset hinges, B2B buyers should ensure accurate measurements and compatibility with the cabinetry to avoid installation issues. The clean design adds significant value, but the precision required can be a drawback for some applications.

What Are the Advantages of Surface Mount Hinges?

Surface mount hinges are attached directly to the outside surfaces of the cabinet door and frame, making them easily visible. They are commonly used in heavy-duty applications, such as storage solutions and industrial doors, where durability is essential. Buyers should appreciate the straightforward installation process and robust construction. However, the visibility of these hinges may detract from the overall aesthetic, and they may be more susceptible to wear over time compared to concealed options.

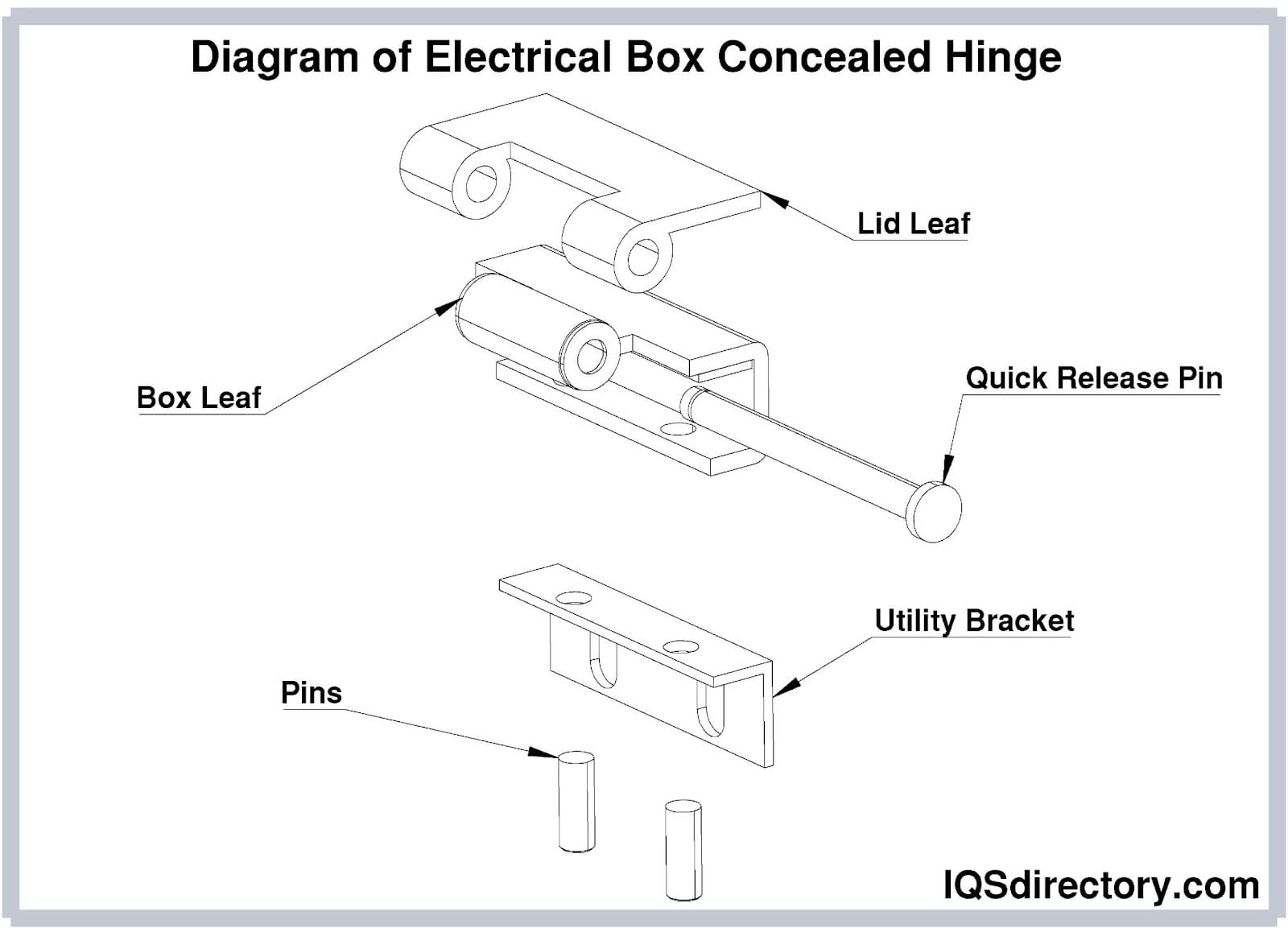

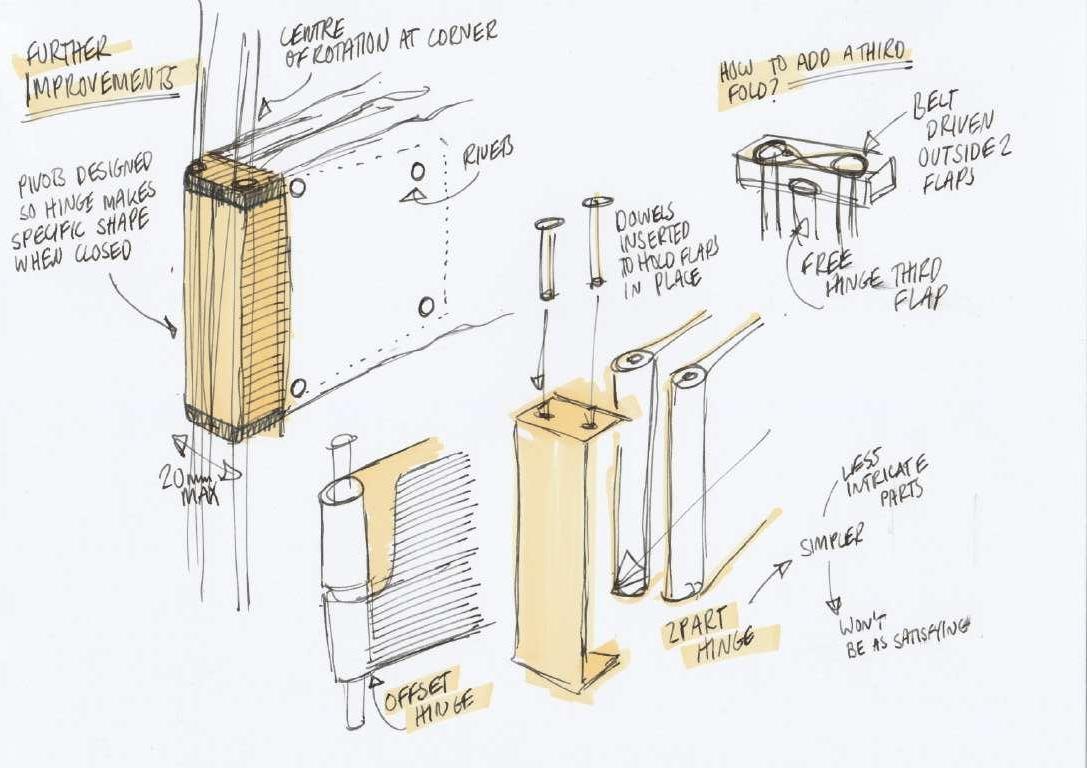

Why Choose Concealed Hinges for Modern Furniture?

Concealed hinges are designed to be hidden within the cabinet, providing a clean and modern look that is highly sought after in contemporary cabinetry and office furniture. These hinges are adjustable, allowing for fine-tuning after installation, which can be beneficial in ensuring doors align perfectly. When considering concealed hinges, B2B buyers should evaluate the tools required for installation, as they may need specialized equipment. The aesthetic advantages are significant, but installation complexity can be a consideration.

What Makes Piano Hinges Suitable for Heavy Applications?

Piano hinges, also known as continuous hinges, run the entire length of a door or lid, distributing weight evenly and providing exceptional durability. They are often used in pianos, toolboxes, and large cabinets. B2B buyers should consider the strength and reliability of piano hinges for heavy applications. While they offer robust performance, the need for additional space and a more complex installation process can be potential drawbacks.

Key Industrial Applications of hinge diagram

| Industry/Sector | Specific Application of hinge diagram | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Cabinet door hinges in modular furniture systems | Enhanced design flexibility and durability | Material quality, load capacity, and compatibility with designs |

| Automotive | Hinge systems for vehicle doors and trunk lids | Improved safety and functionality | Corrosion resistance, weight specifications, and compliance with safety standards |

| Construction | Hinges for commercial and residential doors | Increased security and aesthetic appeal | Weather resistance, load-bearing capacity, and installation ease |

| Aerospace | Hinge mechanisms in aircraft access panels | Critical reliability and weight savings | Aerospace-grade materials, precision engineering, and regulatory compliance |

| Electronics | Hinges for laptop and tablet devices | Enhanced user experience through design ergonomics | Size constraints, durability under repeated use, and aesthetic integration |

How is the hinge diagram applied in furniture manufacturing?

In the furniture manufacturing sector, hinge diagrams are crucial for designing cabinet door systems, particularly in modular furniture. They enable manufacturers to visualize how different hinge types will function with various cabinet designs, ensuring that doors open smoothly and align properly. The right hinge can enhance the overall aesthetic while providing durability. Buyers should consider material quality and load capacity to ensure that the hinges can withstand daily use, especially in high-traffic environments.

What role do hinge diagrams play in the automotive industry?

In the automotive industry, hinge diagrams are essential for developing efficient and safe hinge systems for vehicle doors and trunk lids. They help engineers assess the movement and alignment of doors, ensuring that they operate seamlessly while maintaining structural integrity. The value lies in improved safety features and ease of use for consumers. Key sourcing considerations include corrosion resistance and compliance with safety standards, which are critical for vehicle longevity and performance.

How are hinge diagrams utilized in construction applications?

Hinge diagrams are vital in the construction industry for determining the best hinge types for commercial and residential doors. These diagrams help architects and builders visualize how hinges will affect door functionality, security, and design aesthetics. The benefits include increased security and improved usability of door systems. When sourcing hinges, considerations such as weather resistance and load-bearing capacity are essential to ensure that the products meet the demands of various climates and usage scenarios.

Why are hinge diagrams important in the aerospace sector?

In aerospace, hinge diagrams are used to design and implement hinge mechanisms for aircraft access panels. These diagrams are critical for ensuring that all components fit together precisely and function reliably under various flight conditions. The primary value lies in their ability to enhance safety and reduce weight, which is crucial in aviation. Buyers in this sector must prioritize aerospace-grade materials and precision engineering to meet stringent regulatory compliance and performance standards.

How do hinge diagrams enhance electronic device design?

In the electronics sector, hinge diagrams are utilized in the design of hinges for laptops and tablets, allowing for a better understanding of how devices will open and close. This application enhances user experience by ensuring ergonomic designs that facilitate ease of use. Buyers should focus on size constraints and durability, as hinges must withstand repeated use while maintaining aesthetic integration with the device’s design.

3 Common User Pain Points for ‘hinge diagram’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Hinge Type for Specific Applications

The Problem: B2B buyers often struggle to identify the most suitable hinge type for their specific application. For example, a furniture manufacturer may need to choose between concealed and surface-mounted hinges for a new line of cabinets. The challenge lies in understanding the differences in functionality, aesthetics, and installation requirements. Many buyers may also lack the technical knowledge to navigate the various hinge types and their specifications, leading to potential errors in procurement that can result in project delays and increased costs.

The Solution: To mitigate this challenge, B2B buyers should first conduct a thorough needs assessment for their specific application. This involves considering factors such as door weight, frequency of use, and desired aesthetics. Utilizing a comprehensive hinge diagram that outlines the various hinge types and their specific applications can provide clarity. Additionally, engaging with suppliers who offer expert advice can help buyers understand the nuances of each hinge type. It’s also advisable to request samples for testing, ensuring that the selected hinges meet performance expectations before finalizing bulk orders. By investing time in proper selection and supplier collaboration, businesses can avoid costly mistakes and enhance product quality.

Scenario 2: Inadequate Understanding of Hinge Diagrams and Specifications

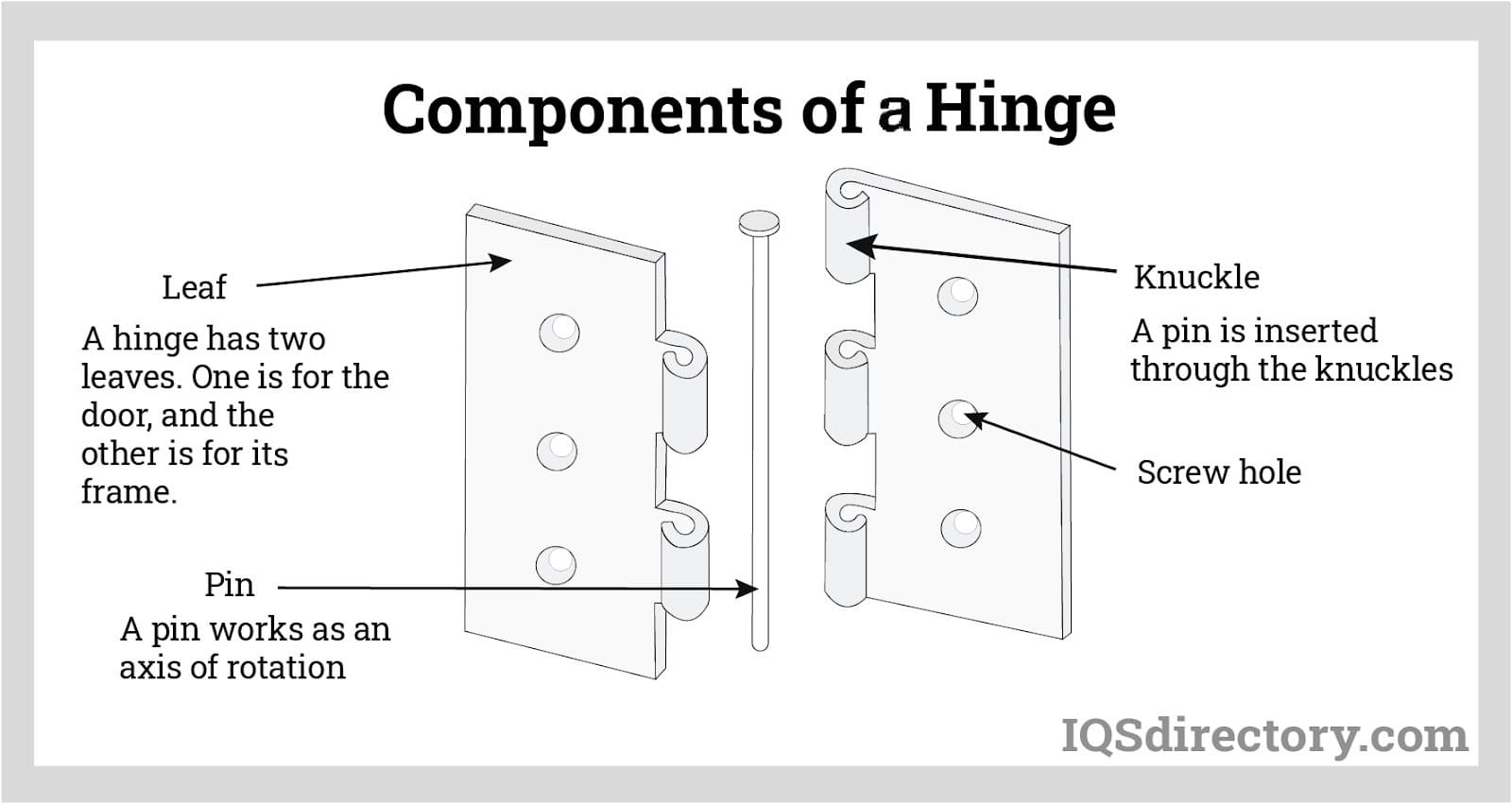

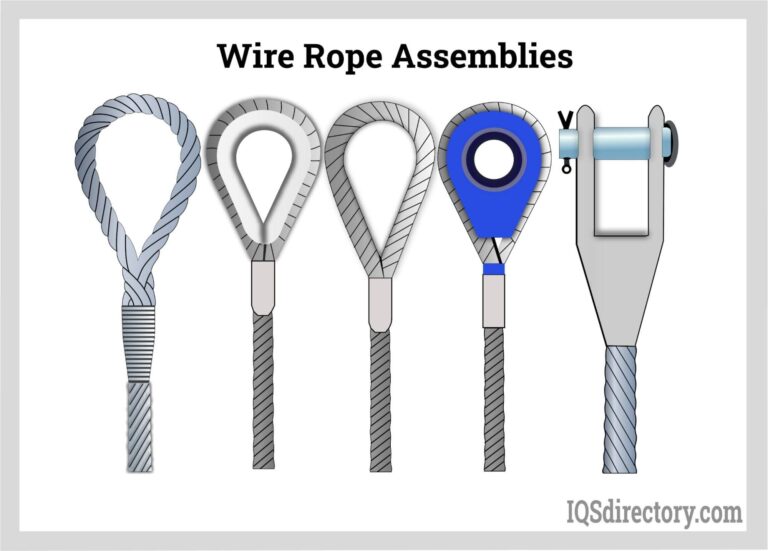

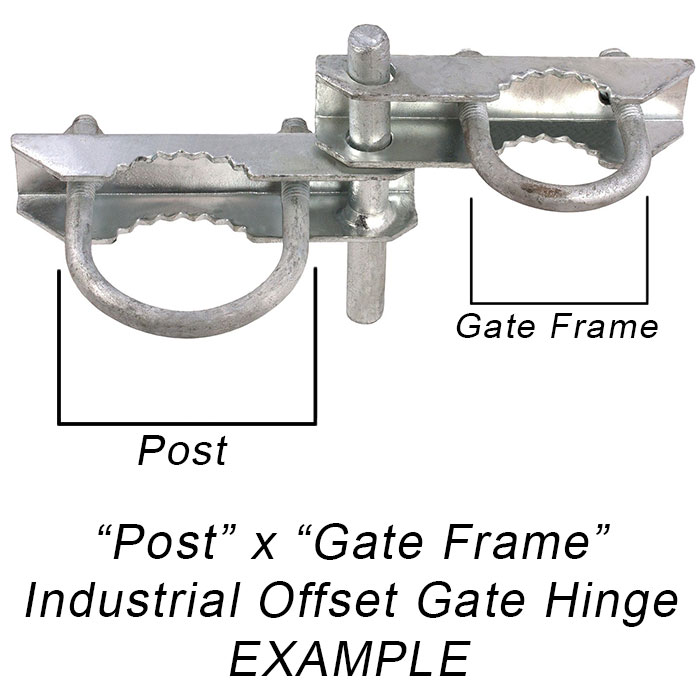

The Problem: Many B2B buyers encounter difficulties interpreting hinge diagrams and specifications. This issue often arises when buyers are unfamiliar with hinge anatomy, such as the frame wing, door wing, knuckle, and pin, which can lead to misordering or incorrect installations. For instance, a construction company may procure hinges that do not fit the intended cabinet design, resulting in project delays and wasted resources.

The Solution: To address this pain point, buyers should prioritize education on hinge diagrams and specifications. This can be achieved by leveraging resources such as training sessions, webinars, or detailed guides offered by suppliers. Suppliers often provide educational materials that explain hinge anatomy and how to read diagrams accurately. Additionally, creating a checklist of key specifications—such as door weight, mounting style, and overlay measurements—can streamline the ordering process. For visual learners, incorporating 3D modeling or video tutorials demonstrating installation can enhance understanding. By fostering a deeper comprehension of hinge diagrams, buyers can make informed decisions that reduce errors and ensure smooth project execution.

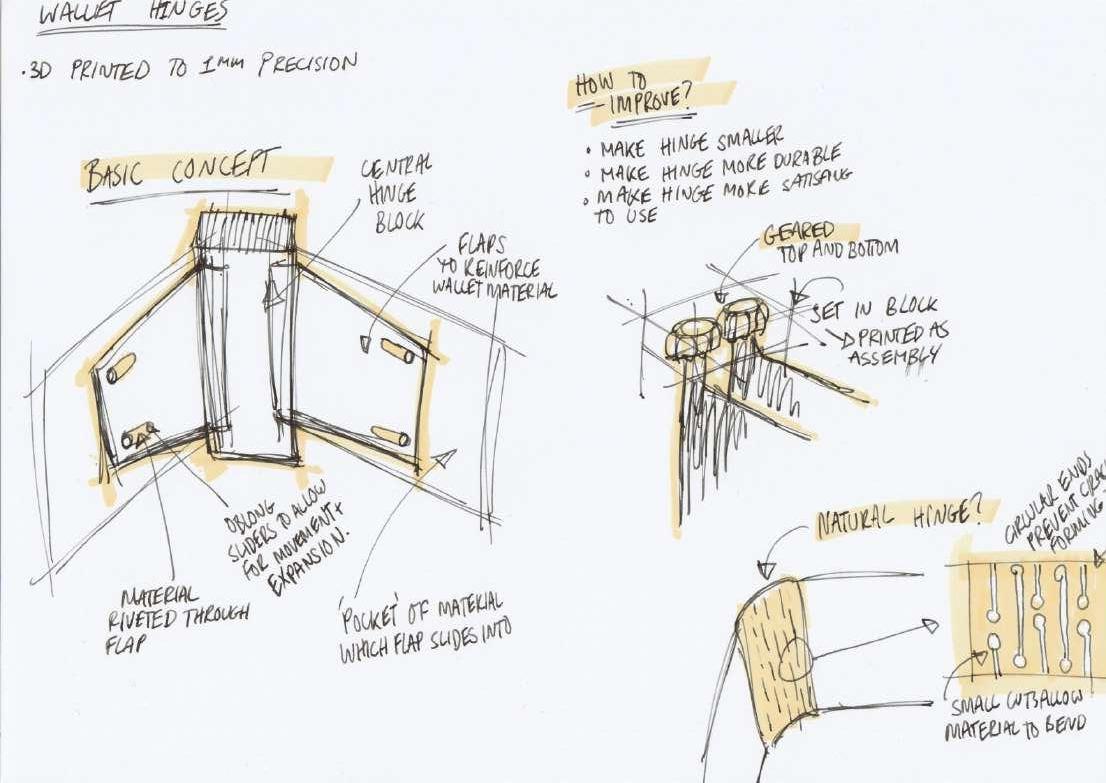

Illustrative image related to hinge diagram

Scenario 3: Challenges in Sourcing Quality Hinges Amidst Global Supply Chain Issues

The Problem: In today’s global market, B2B buyers often face difficulties in sourcing quality hinges due to supply chain disruptions, particularly in regions such as Africa, South America, and the Middle East. Buyers may find themselves dealing with inconsistent product availability, leading to project delays or reliance on subpar alternatives that compromise quality. This challenge is exacerbated by the varying quality standards and manufacturing practices across different regions.

The Solution: To navigate these sourcing challenges, B2B buyers should establish robust relationships with multiple suppliers to ensure a diverse supply chain. This strategy allows for contingency planning, where if one supplier faces delays, another can fulfill the order. Buyers should also prioritize suppliers who provide transparency regarding their manufacturing processes and quality control measures. Regular audits and on-site inspections can further ensure that the products meet the required standards. Additionally, leveraging technology such as procurement software can streamline the sourcing process, enabling buyers to track inventory levels and predict shortages. By adopting a proactive sourcing strategy, businesses can mitigate risks associated with supply chain disruptions and maintain consistent quality in their projects.

Strategic Material Selection Guide for hinge diagram

When selecting materials for hinges in various applications, B2B buyers must consider several factors, including performance properties, costs, and compliance with international standards. Below, we analyze four common materials used in hinge diagrams: stainless steel, brass, plastic, and aluminum. Each material has distinct characteristics that can impact its suitability for specific applications.

What are the Key Properties of Stainless Steel in Hinge Applications?

Stainless steel is renowned for its excellent corrosion resistance, particularly in environments exposed to moisture and chemicals. It can withstand high temperatures and pressures, making it suitable for heavy-duty applications. The most common grades used for hinges include 304 and 316, with 316 offering superior resistance to chlorides and marine environments.

Pros: Stainless steel hinges are durable and have a long lifespan, making them ideal for outdoor and industrial applications. They also maintain their aesthetic appeal over time.

Cons: The primary drawback is the higher cost compared to other materials. Manufacturing stainless steel hinges can be complex due to the need for specialized equipment.

Impact on Application: Stainless steel hinges are compatible with various media, including water, oils, and chemicals, making them versatile for different industries.

Considerations for International Buyers: Compliance with standards like ASTM A240 for stainless steel is crucial. Buyers from Europe, particularly Germany, often prefer materials that meet DIN standards, while Middle Eastern buyers may focus on corrosion resistance due to local environmental conditions.

How Does Brass Perform as a Material for Hinges?

Brass is an alloy of copper and zinc, known for its attractive appearance and good corrosion resistance. It is often used in decorative applications, such as cabinetry and furniture hinges.

Pros: Brass hinges are easy to machine and can be cast into complex shapes, allowing for intricate designs. They also have good resistance to corrosion in dry environments.

Cons: Brass is less durable than stainless steel and can tarnish over time, requiring maintenance to retain its appearance. It is also less suitable for high-stress applications.

Impact on Application: Brass is ideal for applications where aesthetics are important, but it may not perform well in environments with high humidity or exposure to harsh chemicals.

Considerations for International Buyers: Buyers should consider the common standards for brass, such as ASTM B36 for copper alloys. In regions like South America, the aesthetic appeal of brass may be more valued, while in Europe, functional performance may take precedence.

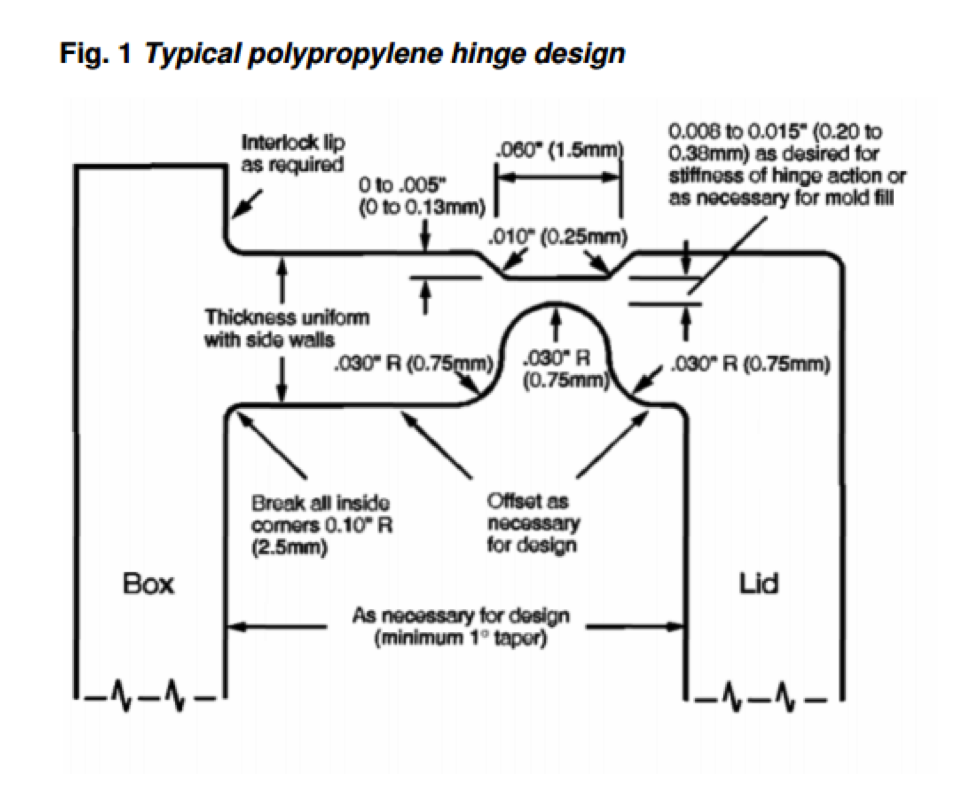

What Advantages Does Plastic Offer for Hinge Applications?

Plastic hinges, often made from materials like polyamide or polypropylene, are lightweight and resistant to corrosion, making them suitable for various applications, including marine environments.

Pros: Plastic hinges are cost-effective and can be produced in various colors and designs. They are also resistant to chemicals and moisture, making them ideal for outdoor use.

Cons: The primary limitation is their lower strength compared to metal hinges, which may not be suitable for heavy doors or high-load applications.

Impact on Application: Plastic hinges are compatible with various media, including water and some chemicals, but may not withstand extreme temperatures.

Considerations for International Buyers: Compliance with international standards like ISO for plastic materials is essential. Buyers from Africa may prioritize cost-effectiveness, while those in Europe may focus on sustainability and recyclability.

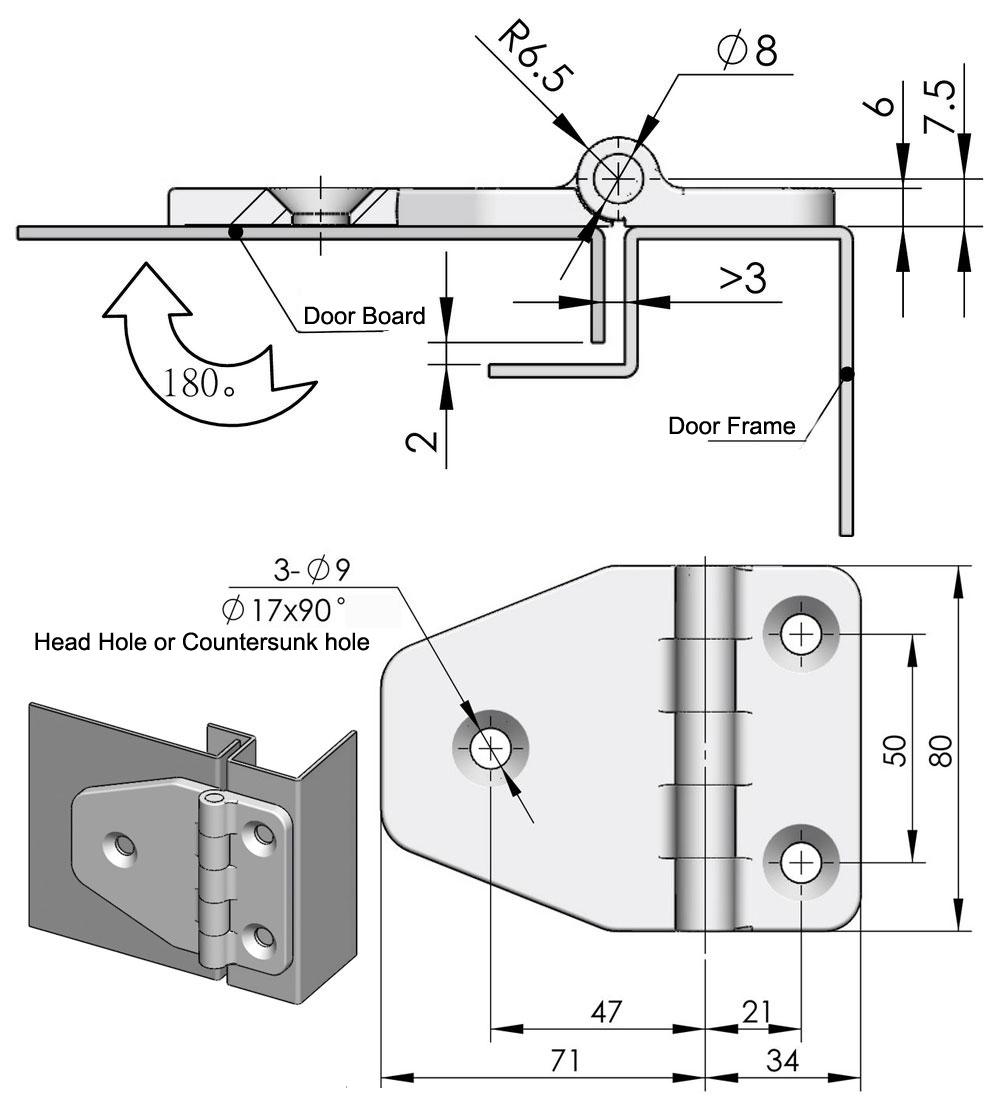

Illustrative image related to hinge diagram

How Does Aluminum Compare as a Material for Hinges?

Aluminum is lightweight and has good corrosion resistance, making it a popular choice for various applications, including automotive and aerospace.

Pros: Aluminum hinges are easy to manufacture and can be anodized for additional corrosion resistance. They are also lightweight, which can reduce the overall weight of the product.

Cons: While aluminum is durable, it may not be as strong as stainless steel, making it less suitable for heavy-duty applications. It can also be more expensive than plastic.

Impact on Application: Aluminum hinges are compatible with various media, including water and some chemicals, but may not perform well in high-temperature environments.

Illustrative image related to hinge diagram

Considerations for International Buyers: Compliance with standards such as ASTM B221 for aluminum is important. Buyers from the Middle East may prioritize lightweight materials for transport, while European buyers may focus on energy efficiency in manufacturing.

Summary Table of Material Selection for Hinges

| Material | Typical Use Case for hinge diagram | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Industrial and outdoor applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Brass | Decorative applications | Attractive appearance and easy machining | Less durable, tarnishes over time | Medium |

| Plastic | Marine and lightweight applications | Cost-effective and moisture resistant | Lower strength for heavy loads | Low |

| Aluminum | Automotive and aerospace applications | Lightweight and good corrosion resistance | Less strength than stainless steel | Medium |

This strategic material selection guide provides B2B buyers with essential insights to make informed decisions regarding hinge materials, ensuring compatibility with their specific applications and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for hinge diagram

What Are the Main Stages of Manufacturing Hinge Diagrams?

Manufacturing hinges involves a series of intricate steps that ensure both functionality and durability. The typical stages in the manufacturing process include material preparation, forming, assembly, and finishing.

Material Preparation: The first step involves selecting the right materials, which are often metals such as stainless steel, brass, or aluminum, depending on the hinge’s intended use. The materials are then cut to size and subjected to treatments such as annealing or hardening to enhance their properties. This stage is crucial as the quality of the raw materials directly impacts the performance of the finished hinges.

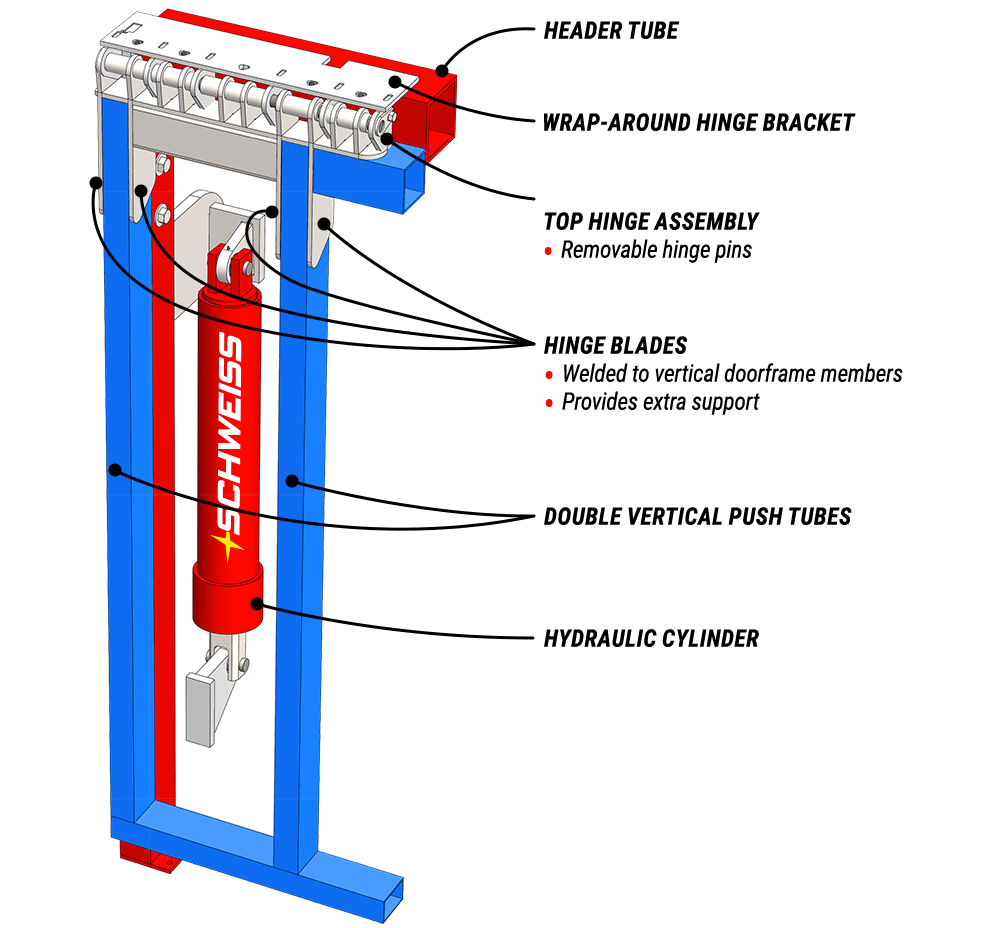

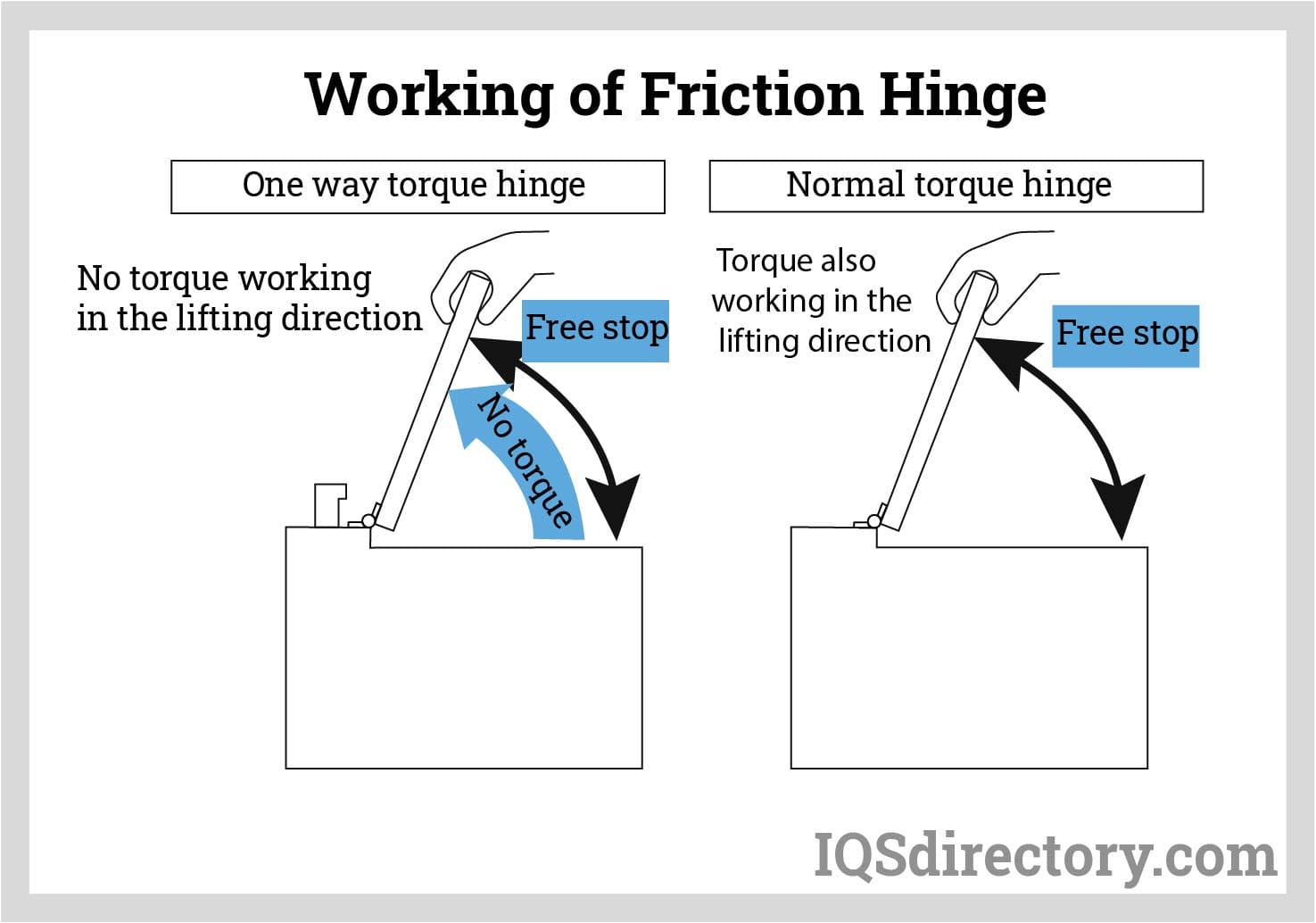

Illustrative image related to hinge diagram

Forming: This stage involves shaping the hinge components through processes like stamping, forging, or machining. Advanced techniques such as CNC (Computer Numerical Control) machining ensure precision in forming complex shapes and dimensions. For instance, during the stamping process, large sheets of metal are shaped into hinge parts using dies, while forging involves shaping the metal through compressive forces, resulting in stronger components.

Assembly: Once the components are formed, they are assembled into functional hinges. This process may include attaching the knuckle, pin, and wings, ensuring that the hinge operates smoothly. Automated assembly lines can enhance efficiency, but manual assembly is often employed for intricate designs requiring a higher level of craftsmanship.

Finishing: The final stage involves applying protective coatings, such as electroplating or powder coating, to prevent corrosion and enhance aesthetics. Surface treatments not only improve durability but also allow for customization, catering to specific industry requirements or client preferences.

What Quality Control Measures Are Essential for Hinge Manufacturing?

Quality control (QC) is integral to the hinge manufacturing process, ensuring that products meet international standards and customer specifications. Various international standards, such as ISO 9001, provide frameworks for maintaining quality across manufacturing processes.

What Are the Relevant International Standards?

ISO 9001 is a widely recognized quality management standard that emphasizes process consistency, customer satisfaction, and continuous improvement. In addition to ISO, industry-specific certifications like CE marking for products sold within the European Economic Area and API (American Petroleum Institute) standards for oil and gas applications may also apply.

What Are the QC Checkpoints in Manufacturing?

QC checkpoints are strategically integrated throughout the manufacturing process to catch defects early. These include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before processing begins.

- In-Process Quality Control (IPQC): During manufacturing, operators conduct regular checks to monitor dimensions, tolerances, and other critical parameters, ensuring adherence to specifications.

- Final Quality Control (FQC): After assembly, final inspections are performed to verify the overall functionality and appearance of the hinge. This may include operational tests to ensure smooth movement and strength tests to assess durability.

What Common Testing Methods Are Used in Hinge Quality Control?

Testing methods play a vital role in quality assurance, providing measurable data that can be used to validate the quality of hinges. Common testing techniques include:

- Dimensional Inspection: Using calipers, gauges, and other measuring tools to ensure that each component meets the specified dimensions.

- Functional Testing: Assessing the hinge’s performance under various conditions, including load tests to determine its ability to withstand operational stresses.

- Corrosion Resistance Testing: Exposing hinges to salt spray tests or other corrosive environments to evaluate their durability over time.

- Fatigue Testing: Subjecting hinges to repeated stress cycles to assess their longevity and reliability.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential to ensure product reliability. Here are several strategies:

- Conducting Audits: Regular audits of suppliers can provide insight into their QC processes and compliance with international standards. Buyers should consider on-site visits to assess manufacturing practices directly.

- Requesting Quality Reports: Suppliers should be able to provide comprehensive quality reports detailing their QC processes, test results, and certifications. This documentation serves as a formal verification of their commitment to quality.

- Utilizing Third-Party Inspections: Engaging third-party inspection agencies can offer unbiased evaluations of a supplier’s manufacturing quality. These agencies can conduct inspections at various stages of production and provide detailed reports on compliance with specified standards.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate specific nuances when it comes to quality control and certification, especially in diverse markets. Understanding regional standards and certifications is crucial for compliance and market entry.

- Regional Standards: Different regions may have unique standards that affect the acceptance of products. For example, the European Union has stringent requirements for CE marking, while North America may emphasize ANSI (American National Standards Institute) standards. Buyers should familiarize themselves with these requirements to avoid compliance issues.

- Language and Documentation: Many suppliers may provide documentation in their native language. Buyers should ensure they understand all technical specifications and certifications, which may require translation services.

- Cultural Considerations: The approach to quality and regulatory compliance can vary across regions. Understanding cultural attitudes towards quality assurance can help buyers establish better relationships with suppliers, ultimately leading to improved collaboration and product quality.

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing hinge diagrams and ensure they receive products that meet their operational needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hinge diagram’

In the competitive landscape of B2B procurement, sourcing the right hinge diagram is vital for ensuring product compatibility and operational efficiency. This checklist serves as a comprehensive guide for international buyers, particularly those from Africa, South America, the Middle East, and Europe, to navigate the complex sourcing process effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful procurement process. Identify the exact type of hinge required—consider factors like size, material, load capacity, and specific application needs. This clarity helps in narrowing down potential suppliers who can meet your specific requirements.

- Considerations:

- Different hinge types (e.g., overlay, inset, or surface mount) may be required based on your application.

- Ensure compatibility with existing cabinetry or structures.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in hinge diagrams relevant to your needs. Look for established manufacturers with a solid reputation in the industry, as well as those who have experience serving your geographical market.

- Action Points:

- Utilize trade directories and industry-specific platforms to compile a list of potential suppliers.

- Review their product offerings and customer feedback to gauge reliability.

Step 3: Evaluate Supplier Certifications and Standards

Before proceeding with any supplier, verify their certifications and adherence to international quality standards. This step is crucial to ensure that the products meet safety and performance requirements, particularly when dealing with mechanical components like hinges.

- Key Standards:

- Look for ISO certifications or compliance with regional standards that pertain to your industry.

- Request documentation or proof of quality assurance practices.

Step 4: Request Samples and Technical Documentation

Engaging suppliers by requesting samples and technical documentation is a proactive approach to assess product quality and compatibility. This step allows you to physically evaluate the hinge diagrams and ensure they align with your specifications.

- Important Documents:

- Ask for technical drawings, installation guides, and material data sheets.

- Evaluate the quality of the samples against your requirements.

Step 5: Negotiate Terms and Conditions

Once you have shortlisted suppliers, initiate negotiations focusing on pricing, payment terms, and delivery schedules. Clear communication about your expectations and requirements can lead to more favorable terms.

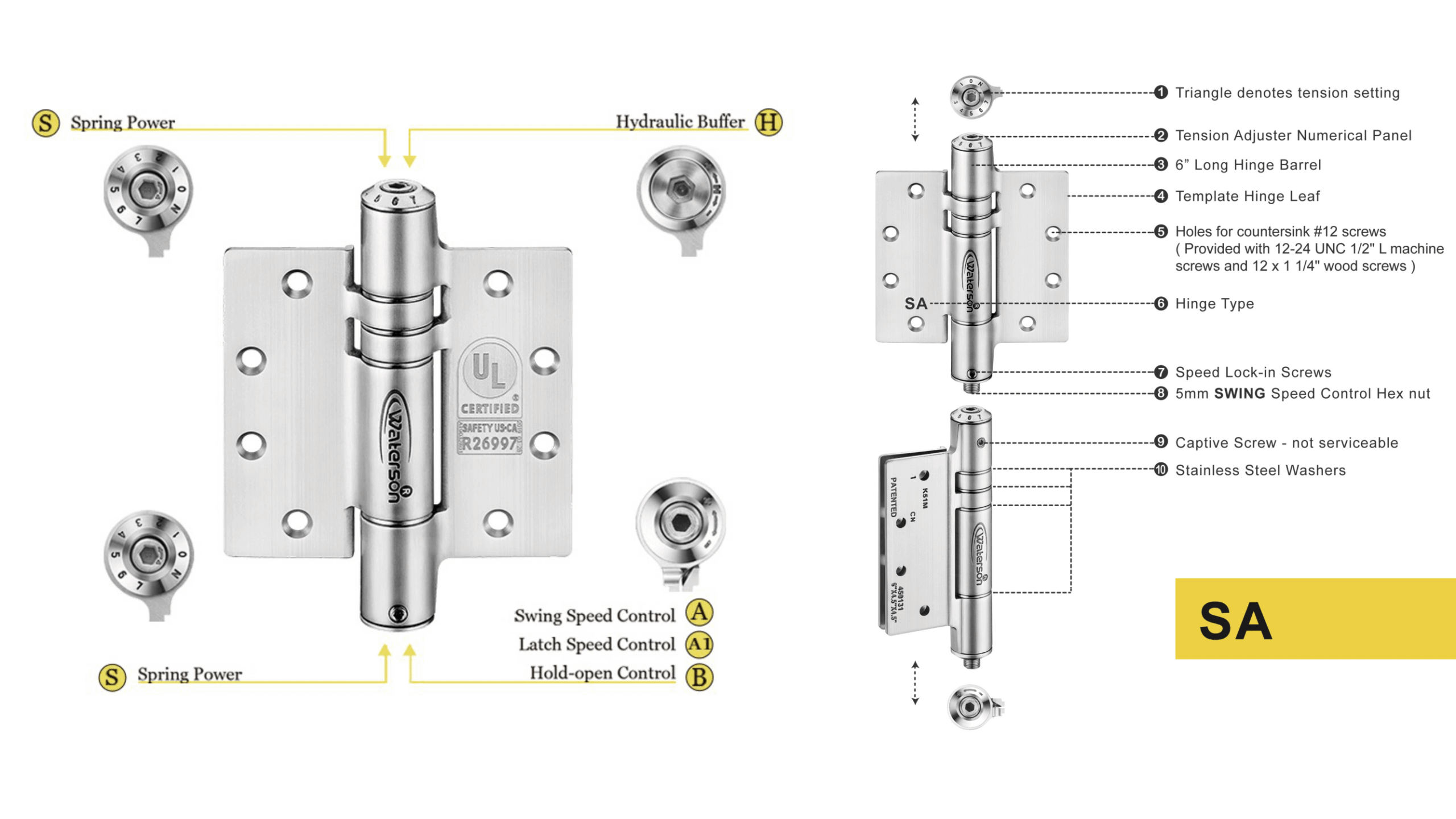

Illustrative image related to hinge diagram

- Negotiation Tips:

- Discuss bulk purchase discounts or long-term contract options.

- Ensure that delivery timelines align with your project schedules.

Step 6: Establish a Quality Control Process

Implementing a quality control process is essential to ensure that the hinges received meet the agreed specifications. This can involve setting up inspection protocols and performance testing during the initial batches.

- Quality Assurance Measures:

- Define acceptance criteria for the hinges based on functionality and durability.

- Consider periodic audits of supplier quality practices.

Step 7: Maintain Open Communication Channels

Establishing and maintaining open lines of communication with your suppliers is vital for addressing any issues that may arise during production or delivery. Regular updates can foster a collaborative relationship, ensuring smoother transactions in the future.

- Effective Communication Strategies:

- Schedule regular check-ins to discuss progress and any potential challenges.

- Utilize digital tools for real-time updates and feedback.

By following this checklist, B2B buyers can streamline their sourcing process for hinge diagrams, ensuring they make informed decisions that align with their technical and operational needs.

Comprehensive Cost and Pricing Analysis for hinge diagram Sourcing

What Are the Key Cost Components in Hinge Diagram Sourcing?

When sourcing hinge diagrams, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly affects the cost. Common materials include steel, brass, and plastic. Higher-quality materials or specialty alloys can increase durability and performance, but they also elevate costs.

-

Labor: Labor costs vary depending on the region and the skill level required for manufacturing. Countries with higher labor costs, such as those in Western Europe, may impact overall pricing, while regions with lower labor costs can offer savings.

-

Manufacturing Overhead: This encompasses indirect costs related to production, including utilities, depreciation of equipment, and factory maintenance. Efficient manufacturing processes can help reduce these overheads.

-

Tooling: Custom tooling for specific hinge designs can be a significant upfront cost. However, once amortized over large production runs, this cost can be minimized, making it crucial for buyers to consider their order volume.

-

Quality Control (QC): Ensuring product quality is vital, especially for international buyers who may face strict compliance requirements. Investment in QC processes can add to costs but is essential for minimizing defects and ensuring product reliability.

-

Logistics: Shipping and handling costs can vary greatly depending on the shipping method, distance, and weight of the products. Consideration of Incoterms is vital to clarify responsibilities for shipping and customs duties.

-

Margin: Supplier margins will vary based on market conditions, competition, and the supplier’s business model. Understanding the typical margins in your industry can aid in negotiations.

How Do Price Influencers Impact Hinge Diagram Sourcing?

Several factors influence the pricing of hinge diagrams, making it essential for buyers to be aware of these nuances:

-

Volume/MOQ: Minimum Order Quantities (MOQs) often dictate pricing. Larger orders typically reduce per-unit costs due to economies of scale, while smaller orders may incur higher prices.

-

Specifications and Customization: Unique specifications or customized designs can increase costs. Ensure that your requirements are clear to avoid unexpected charges later.

-

Materials and Quality Certifications: The choice of materials and any required certifications (like ISO or CE marks) can affect pricing. Higher quality or certified products often come at a premium.

-

Supplier Factors: The supplier’s reputation, reliability, and geographical location can impact both pricing and lead times. Establishing a strong relationship with suppliers can lead to better pricing and service.

-

Incoterms: Understanding Incoterms helps clarify who is responsible for shipping, insurance, and tariffs, which can influence overall pricing. This is particularly important for international transactions.

What Are the Best Negotiation Tips for B2B Buyers in Hinge Diagram Sourcing?

To achieve cost efficiency when sourcing hinge diagrams, buyers should consider the following strategies:

-

Negotiate on Volume: Leverage potential order sizes to negotiate better pricing. Suppliers are often willing to offer discounts for larger commitments.

-

Evaluate Total Cost of Ownership (TCO): Focus on the TCO rather than just the upfront costs. Consider factors such as durability, maintenance, and potential failure costs when evaluating hinge options.

-

Research and Compare: Conduct thorough market research to understand average pricing and specifications. Comparing multiple suppliers can provide leverage during negotiations.

-

Clarify Payment Terms: Flexible payment options can improve cash flow. Discuss terms that may allow for extended payment periods or discounts for early payment.

-

Stay Informed About Market Trends: Awareness of global supply chain issues, material shortages, or geopolitical factors can give you an edge in negotiations, allowing you to time your purchases strategically.

Disclaimer on Pricing

Pricing for hinge diagrams can fluctuate based on market conditions, material costs, and supplier availability. It is advisable to obtain multiple quotes and conduct a thorough cost analysis to ensure a competitive and fair price. Always confirm the specifics with suppliers to get the most accurate and current pricing.

Alternatives Analysis: Comparing hinge diagram With Other Solutions

Exploring Alternatives to Hinge Diagrams in B2B Applications

In the realm of B2B decision-making, understanding various methodologies for visualizing processes is crucial. Hinge diagrams serve as a valuable tool for illustrating the relationships between components in a system. However, there are alternative solutions that can offer different advantages depending on the context and requirements of a business. This analysis presents a comparison between hinge diagrams and two viable alternatives: flowcharts and Gantt charts.

Illustrative image related to hinge diagram

| Comparison Aspect | Hinge Diagram | Flowchart | Gantt Chart |

|---|---|---|---|

| Performance | Effective for displaying relationships and dependencies | Ideal for sequential processes and decision-making | Excellent for project scheduling and tracking |

| Cost | Generally low (basic software tools) | Low to moderate (varies by software) | Moderate (software may be more specialized) |

| Ease of Implementation | Simple to create and modify | Easy to understand; software available | Requires familiarity with project management tools |

| Maintenance | Minimal once established | Moderate; updates needed with process changes | Requires regular updates for project timelines |

| Best Use Case | System design and architecture | Process mapping and analysis | Project management and timelines |

What are the Advantages and Disadvantages of Flowcharts?

Flowcharts are widely recognized for their ability to break down complex processes into clear, step-by-step visuals. They excel in environments where decision-making paths are critical, making them particularly useful for operational workflows and quality control processes. The simplicity of flowcharts allows for quick understanding and easier communication among team members. However, their limitations become apparent when dealing with systems that involve numerous interdependencies, as they may become cluttered and less effective in conveying relationships compared to hinge diagrams.

How Do Gantt Charts Compare to Hinge Diagrams?

Gantt charts are a staple in project management, providing a visual timeline for tasks and milestones. They are particularly advantageous for tracking project progress and resource allocation over time. Their structured layout allows teams to see overlapping tasks and dependencies clearly, making it easy to manage deadlines. However, Gantt charts can become complex and unwieldy for larger projects, and they require ongoing updates to maintain accuracy, which can lead to additional overhead for project managers.

How Can B2B Buyers Choose the Right Solution?

When selecting a visual representation method, B2B buyers should consider the specific needs of their organization. Hinge diagrams are particularly suited for technical and engineering contexts where understanding system relationships is paramount. In contrast, flowcharts are excellent for process-oriented tasks, while Gantt charts shine in project management scenarios. Ultimately, the choice should be guided by the nature of the information being conveyed, the audience’s familiarity with the tools, and the complexity of the processes involved. By aligning the visual tool with organizational goals and team capabilities, businesses can enhance communication and decision-making efficiency.

Illustrative image related to hinge diagram

Essential Technical Properties and Trade Terminology for hinge diagram

What Are the Key Technical Properties of Hinge Diagrams for B2B Buyers?

When evaluating hinge diagrams, several technical properties are essential to ensure that the products meet the required specifications and standards. Here are some critical specifications to consider:

-

Material Grade

– The material used for hinges, such as stainless steel, brass, or plastic, directly affects durability and performance. For instance, stainless steel offers corrosion resistance, making it ideal for outdoor or high-humidity environments. Understanding material grade helps buyers select hinges that match their application needs, influencing longevity and maintenance costs. -

Load Capacity

– Load capacity refers to the maximum weight a hinge can support without failing. This property is crucial in applications where heavy doors or cabinets are involved. Buyers must assess the load requirements of their specific use case to ensure safety and functionality. Selecting a hinge with inadequate load capacity can lead to premature failure and costly replacements. -

Tolerance Levels

– Tolerance levels indicate the acceptable variations in dimensions during manufacturing. High tolerance levels are critical for precision applications where alignment is essential, such as in machinery or high-end cabinetry. Buyers should prioritize suppliers that adhere to strict tolerance standards to ensure compatibility and performance. -

Finish and Coating

– The finish or coating on a hinge can enhance its aesthetic appeal and protect it from environmental factors. Common finishes include polished, brushed, or powder-coated options. Buyers should consider the aesthetic and functional implications of different finishes, particularly in visible applications where appearance matters. -

Operating Angle

– The operating angle denotes how far a hinge can open, impacting accessibility and usability. For example, a hinge designed for a 180-degree opening may be necessary for certain applications, such as kitchen cabinets. Understanding the required operating angle is vital for ensuring that the hinge meets the functional requirements of the project.

Which Trade Terminology Should B2B Buyers Understand in the Hinge Industry?

Familiarity with industry-specific terminology can significantly enhance communication and negotiation in hinge procurement. Here are some essential terms to know:

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the hinge industry, buyers often seek OEM suppliers to ensure that they receive components that meet their specific quality and performance standards. Understanding this term helps buyers identify reputable suppliers and manufacturers. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly relevant for B2B buyers as it affects inventory management and procurement strategies. Knowing the MOQ can help buyers plan their purchases more effectively and avoid overstocking or stockouts. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. It is a standard practice in B2B transactions, allowing buyers to compare prices and terms from multiple suppliers. Understanding how to create and interpret RFQs can streamline the purchasing process and lead to better negotiation outcomes. -

Incoterms (International Commercial Terms)

– Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk management, and delivery obligations, ensuring smoother international trade processes. -

Lead Time

– Lead time refers to the amount of time it takes for an order to be fulfilled after it has been placed. This is crucial for project planning and inventory management. Buyers should communicate their lead time requirements clearly to suppliers to ensure timely delivery and avoid project delays.

By understanding these technical properties and industry terms, B2B buyers can make informed decisions when selecting hinge solutions, ultimately enhancing their operational efficiency and project success.

Navigating Market Dynamics and Sourcing Trends in the hinge diagram Sector

What Are the Key Market Dynamics and Trends in the Hinge Diagram Sector?

The hinge diagram sector is experiencing significant transformations driven by globalization, technological advancements, and evolving consumer preferences. In recent years, international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, have observed a shift towards more sophisticated hinge designs that enhance functionality and aesthetics. The rise of e-commerce platforms has facilitated access to a broader range of hinge types, allowing buyers to compare products easily and make informed decisions. Additionally, the integration of smart technology in hinge mechanisms is emerging as a key trend, particularly in the construction and furniture sectors, where automated systems enhance user convenience and security.

Another dynamic influencing the market is the increasing demand for customization. Businesses are seeking tailored solutions that meet specific operational needs, pushing suppliers to offer more versatile hinge options. Furthermore, the growing emphasis on supply chain transparency and efficiency is reshaping sourcing strategies. Buyers are now prioritizing partnerships with suppliers who can demonstrate reliability, quick turnaround times, and robust quality control processes. These trends underline the importance of agility and innovation in the hinge diagram sector, compelling suppliers to adapt swiftly to changing market demands.

How Is Sustainability Shaping Sourcing Strategies in the Hinge Diagram Sector?

Sustainability has become a cornerstone of sourcing strategies in the hinge diagram sector, as environmental concerns gain prominence across industries. The impact of manufacturing processes on the environment is under scrutiny, prompting buyers to seek out suppliers who adhere to sustainable practices. This includes the use of eco-friendly materials, such as recycled metals and sustainably sourced wood, which are increasingly favored in product design.

The importance of ethical supply chains cannot be overstated, especially for international buyers who are increasingly aware of the social and environmental implications of their purchases. Certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) are becoming critical in the decision-making process. Buyers are encouraged to verify that their suppliers hold these certifications, ensuring that products are not only high-quality but also produced with minimal environmental impact. This shift towards sustainability is not just a trend; it is rapidly becoming a requirement for doing business in the global marketplace.

What Is the Historical Context Behind the Evolution of Hinge Diagrams?

The evolution of hinge diagrams can be traced back to ancient civilizations, where simple pivot mechanisms were first utilized in doors and gates. As architectural designs became more complex, so did the hinge systems, leading to the development of various types tailored for specific applications. The industrial revolution marked a significant turning point, introducing mass production techniques that made hinges more accessible and affordable.

In modern times, advancements in materials science and engineering have further transformed hinge design, enabling the creation of highly specialized products that cater to a diverse range of industries, from automotive to furniture. This historical context underscores the importance of innovation in the hinge sector, as today’s B2B buyers benefit from a rich legacy of design and technology evolution that continues to influence product development and sourcing strategies.

Illustrative image related to hinge diagram

Frequently Asked Questions (FAQs) for B2B Buyers of hinge diagram

1. How do I choose the right hinge type for my application?

Selecting the appropriate hinge type depends on various factors, including the door style, weight, and intended use. For example, overlay hinges are ideal for cabinets where the door overlaps the frame, while inset hinges are suited for flush-mounted doors. Consider the material and finish of the hinge as well; stainless steel options are excellent for moisture-prone areas. Consulting with suppliers can also provide insights into which hinge types are most commonly used in your specific industry or region.

2. What is the best way to source hinge diagrams internationally?

When sourcing hinge diagrams internationally, leverage online platforms that specialize in hardware and architectural components. Utilize B2B marketplaces like Alibaba or global trade directories to find reputable suppliers. Ensure that the suppliers provide detailed hinge diagrams and specifications. Additionally, consider requesting samples or prototypes to verify quality and compatibility with your existing products before placing bulk orders.

3. What factors should I consider when vetting hinge suppliers?

When vetting hinge suppliers, evaluate their experience, reputation, and customer reviews. Look for certifications that indicate quality standards, such as ISO or CE markings. It’s also beneficial to assess their manufacturing capabilities and whether they offer customization options. Establish clear communication regarding lead times, minimum order quantities (MOQ), and after-sales support to ensure a reliable partnership.

4. Can I customize hinge designs for my project?

Yes, many suppliers offer customization options for hinge designs. You can specify dimensions, materials, finishes, and functionality based on your project’s requirements. It’s essential to discuss these details with your supplier early in the process to ensure they can meet your specifications. Be prepared to provide detailed drawings or diagrams to facilitate accurate production.

5. What are the typical minimum order quantities (MOQ) for hinges?

Minimum order quantities for hinges can vary widely based on the supplier and the type of hinge being ordered. Generally, MOQs may range from 100 to 1,000 pieces, especially for standard designs. However, custom designs might have higher MOQs due to the additional setup costs. Always confirm MOQs with the supplier during the negotiation phase to align with your inventory needs.

6. What payment terms should I expect when purchasing hinges internationally?

Payment terms for international hinge purchases often include options like a letter of credit, advance payment, or payment upon delivery. Commonly, suppliers may request a deposit (30-50%) upfront, with the balance due before shipment. Discussing payment terms early in negotiations can help avoid misunderstandings and ensure that the transaction proceeds smoothly.

7. How can I ensure quality assurance when sourcing hinges?

To ensure quality assurance, request detailed product specifications and certifications from your suppliers. Conduct factory visits if possible, or engage third-party inspection services to evaluate the production process and finished products. Implementing a quality control checklist that includes testing for durability, functionality, and finish can also help maintain standards.

8. What logistics considerations should I keep in mind when importing hinges?

When importing hinges, consider shipping methods, costs, and delivery timelines. Evaluate whether air freight or sea freight is more suitable for your order size and urgency. Be aware of customs regulations and potential tariffs in your country. Collaborating with a logistics partner experienced in international trade can streamline the import process and help you navigate any complexities that arise.

Illustrative image related to hinge diagram

Top 7 Hinge Diagram Manufacturers & Suppliers List

1. Pinterest – Wood Interior Doors

2. Hardware Hut – Cabinet Hinge Types

Domain: hardwarehut.com

Registered: 1998 (27 years)

Introduction: Cabinet Hinge Types: 1. Reversible Hinges: Can be used on left or right-hand cabinet doors. 2. Wrap Around Hinges: a. Full Wrap-Around: Frame wing wraps three sides of the frame (no longer in production). b. Partial Wrap-Around: Frame wing wraps two sides of the frame. 3. Face Frame (Semi-Concealed) Hinges: Frame wing visible when door is closed, door wing concealed. 4. Surface Mount Hinges: Both …

3. Woodstock Supply – Installation Guidelines

Domain: woodstocksupply.com

Registered: 2001 (24 years)

Introduction: This company, Woodstock Supply – Installation Guidelines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. BBC – Hinges Explained

Domain: bbc.co.uk

Registered: 1996 (29 years)

Introduction: A hinge is a simple mechanism that allows movement between two linked objects, enabling one object to swing open and closed while fastened to another. It consists of two plates called ‘leaves’ made of metal or sturdy material, joined in the middle by a pin that acts as the pivot point. There are various types of hinges, including butt hinges (common on doors and windows), flag hinges (easier to ta…

5. Facebook – Cabinet Hinge Adjustment Guide

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This image is an instructional diagram explaining how to adjust a modern European-style cabinet hinge, also known as a concealed hinge. It shows the three main adjustment screws and the corresponding door movements they control: 1. Lateral Adjustment: Controls the gap between the door and the cabinet, as well as the alignment of the door with other cabinet doors. 2. Vertical Adjustment: Controls t…

6. Fine Homebuilding – Self-Centering Bits

Domain: finehomebuilding.com

Registered: 1997 (28 years)

Introduction: Self-centering bits for hinge hole alignment, available for less than $15; 3-inch screws for securing doors to framing; poplar wood plugs for correcting screw hole locations.

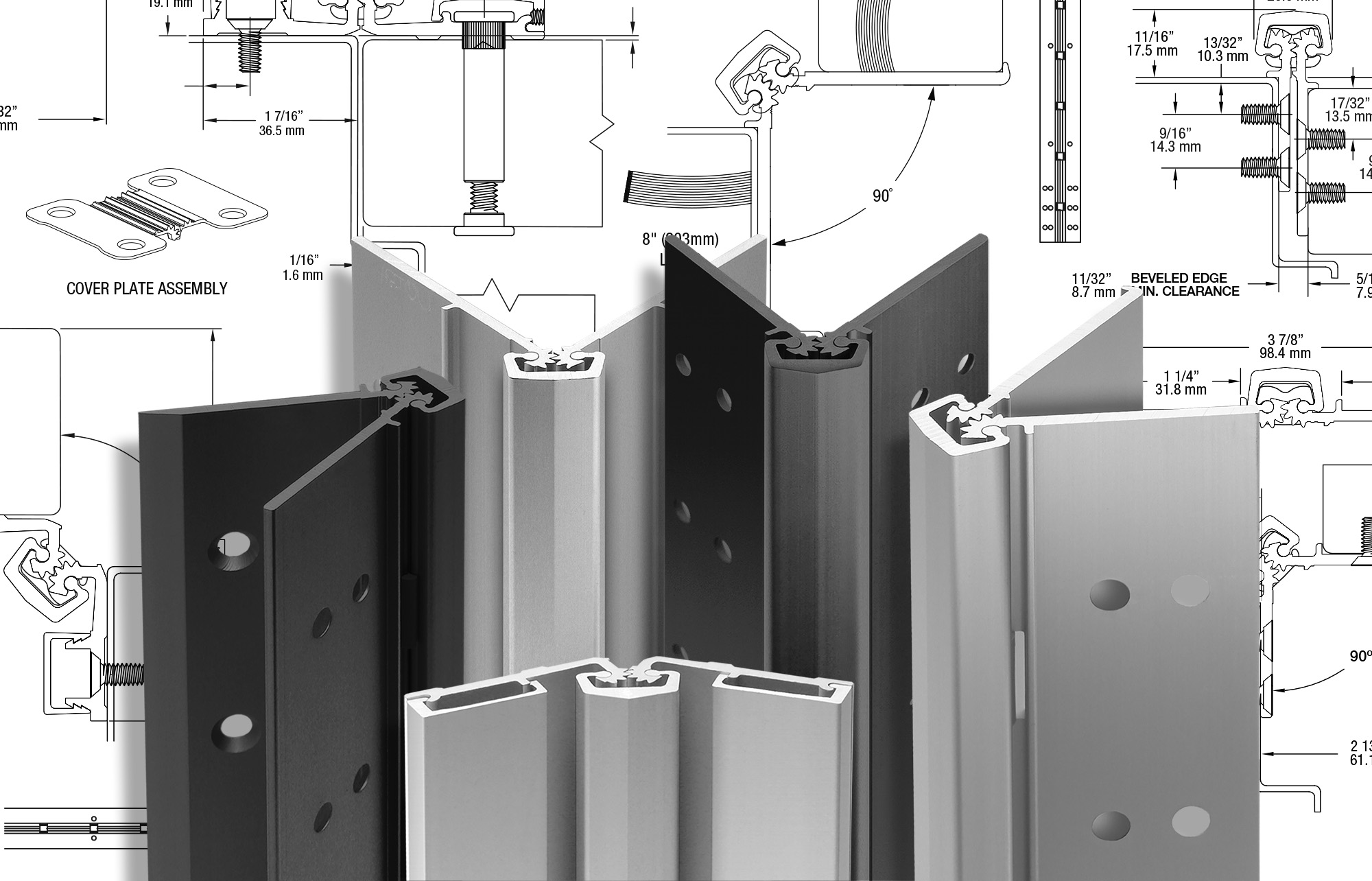

7. Select Hinges – Concealed Geared Continuous Hinges

Domain: select-hinges.com

Registered: 1999 (26 years)

Introduction: Concealed Geared Continuous Hinges

– Product Ratings: HD300, HD600, LL

– Door Compatibility: For 1-3/4″ (44.45 mm) doors, some models for 2″ (50.8 mm) to 2-1/4″ (57.15 mm) doors

– Certification: All SL11, SL12, SL14, SL18, SL24, SL26, SL27 geared continuous hinges are BHMA Grade 1 certified

– Fire Ratings: 90-minute and 3-hour fire ratings available

– Features: Beveled frame leaf for weather-strip…

Strategic Sourcing Conclusion and Outlook for hinge diagram

In today’s competitive landscape, effective strategic sourcing of hinge diagrams is essential for international B2B buyers. Understanding the diverse types of hinges—such as surface mount, overlay, and inset—enables organizations to select the most suitable products for their specific applications. This knowledge not only enhances product performance but also drives cost efficiencies and optimizes supply chain management.

Strategic sourcing allows companies to cultivate strong relationships with suppliers, ensuring access to high-quality materials and innovative designs. By leveraging these relationships, buyers can negotiate better pricing, lead times, and service levels, which are critical for maintaining a competitive edge in markets across Africa, South America, the Middle East, and Europe.

As we look to the future, the demand for customized and sustainable hinge solutions will only grow. International buyers are encouraged to embrace these sourcing strategies, focusing on collaboration and innovation. By doing so, they can better meet the evolving needs of their customers while positioning themselves as leaders in their respective industries. Engage with suppliers today to unlock the full potential of your hinge sourcing strategy and stay ahead in this dynamic marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to hinge diagram

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.