A B2B Buyer’s Guide to Hamon Deltak Inc Gt: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for hamon deltak inc gt

In the competitive landscape of global industrial solutions, sourcing efficient and reliable systems like those offered by Hamon Deltak Inc. can pose significant challenges for B2B buyers. As industries worldwide strive to enhance productivity and reduce operational costs, understanding the nuances of industrial boiler technologies becomes essential. This guide serves as a comprehensive resource, addressing critical aspects such as the various types of boilers—including watertube, firetube, and waste heat recovery boilers—alongside their diverse applications in sectors like power generation, oil and gas, and chemical processing.

By delving into key topics like supplier vetting, cost considerations, and the importance of maintenance and support services, this guide equips international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including Germany and Nigeria—with the insights necessary to make informed purchasing decisions. Recognizing the unique challenges these markets face, we aim to empower buyers with actionable strategies that not only enhance operational efficiency but also promote sustainable practices. In a world where reliability and innovation are paramount, understanding the offerings of Hamon Deltak Inc. can be the key to unlocking significant value in your industrial operations.

Understanding hamon deltak inc gt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Watertube Boilers | High efficiency, robust construction, water-cooled membrane wall design | Power generation, chemical processing, food and beverage | Pros: High durability and efficiency; Cons: Higher initial investment. |

| Firetube Boilers | Compact size, efficient combustion, low maintenance needs | Heating, sterilization, power generation | Pros: Easy installation; Cons: Limited steam capacity compared to watertube. |

| Waste Heat Recovery Boilers | Utilizes waste heat from industrial processes | Petrochemical, pulp and paper, cement industries | Pros: Enhances energy efficiency; Cons: Requires integration into existing systems. |

| High Pressure Boilers | Shell and tube design for creating high-pressure steam | Energy production, industrial heating | Pros: Effective for high-demand applications; Cons: Safety regulations can complicate installation. |

| Heat Recovery Steam Generators | Custom-engineered solutions for specific client needs | Utilities, oil refineries, power plants | Pros: Tailored designs; Cons: Longer lead times due to customization. |

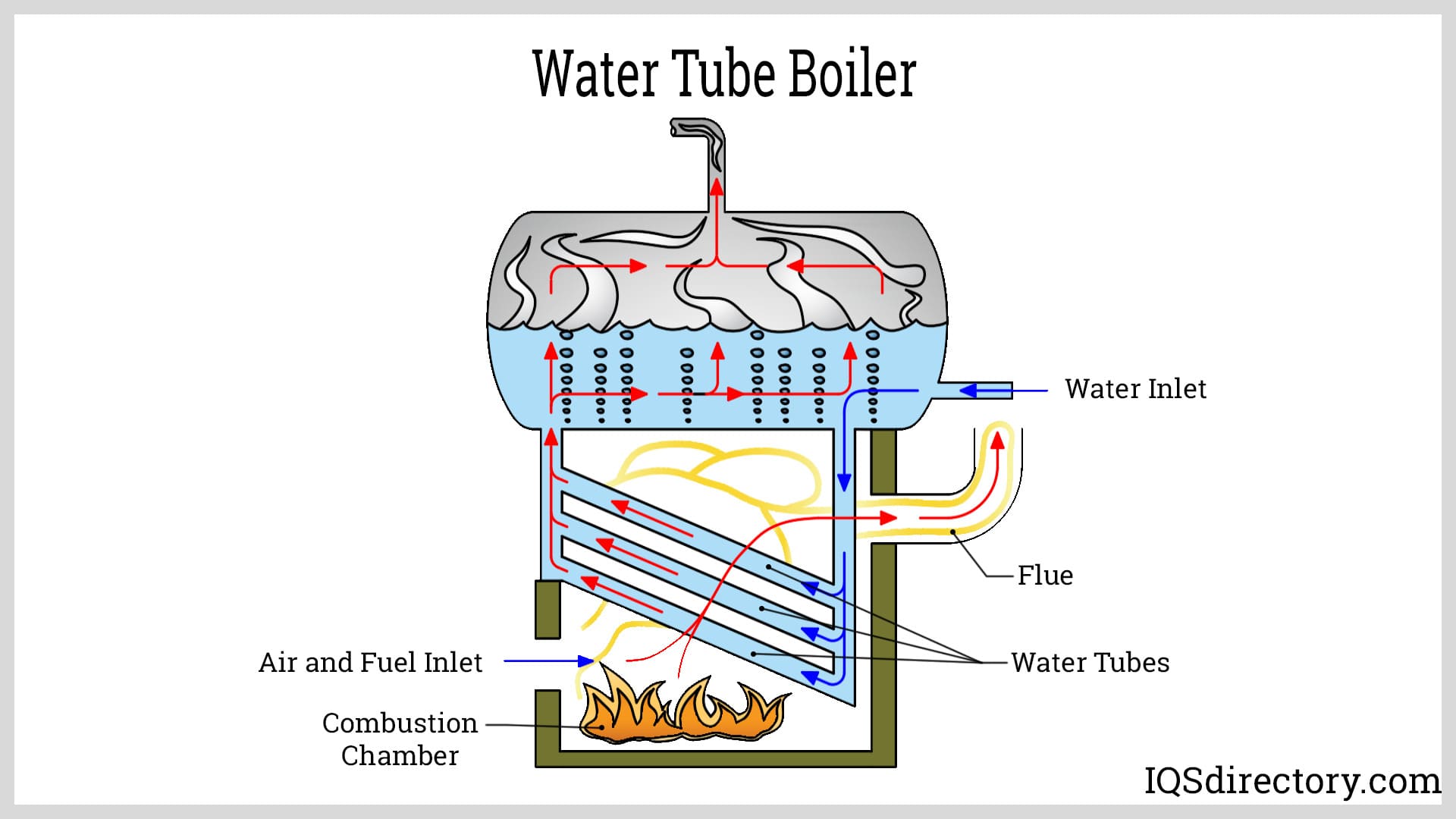

What are the Characteristics and Benefits of Watertube Boilers?

Watertube boilers are characterized by their high efficiency and robust construction, utilizing a water-cooled membrane wall design that ensures optimal heat transfer. They are particularly suitable for industries requiring large volumes of steam, such as power generation and chemical processing. When considering a watertube boiler, B2B buyers should evaluate their specific steam needs, as these systems often come with a higher initial investment but offer long-term savings through energy efficiency and durability.

How Do Firetube Boilers Stand Out in Industrial Applications?

Firetube boilers are known for their compact size and efficient combustion capabilities, making them a popular choice for applications such as heating and sterilization. Their low maintenance requirements and straightforward installation process make them appealing for businesses looking for quick deployment. Buyers should assess the scale of their operations, as firetube boilers may not provide the same steam capacity as watertube options, potentially limiting their use in larger industrial settings.

Why Choose Waste Heat Recovery Boilers for Energy Efficiency?

Waste heat recovery boilers are designed to capture and utilize waste heat from industrial processes, significantly enhancing energy efficiency. These systems are ideal for industries like petrochemicals and pulp and paper, where waste heat is abundant. B2B buyers should consider the integration challenges into existing processes, as these boilers require careful planning and engineering to maximize their benefits while ensuring compliance with environmental regulations.

What Are the Advantages of High Pressure Boilers?

High pressure boilers employ a shell and tube design that allows for the efficient generation of high-pressure steam, making them suitable for energy production and industrial heating applications. Buyers should be aware that while these systems are effective for high-demand scenarios, they also come with stringent safety regulations that can complicate installation and operation. Understanding local regulations and safety standards is crucial for successful procurement and deployment.

How Do Heat Recovery Steam Generators Cater to Custom Needs?

Heat recovery steam generators are custom-engineered to meet specific client requirements, providing tailored solutions for utilities and oil refineries. Their design flexibility allows them to address complex energy needs, but this customization often results in longer lead times. B2B buyers should weigh the benefits of a bespoke solution against the urgency of their project timelines, ensuring that their investment aligns with both operational goals and scheduling constraints.

Key Industrial Applications of hamon deltak inc gt

| Industry/Sector | Specific Application of hamon deltak inc gt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Power Generation | Waste Heat Recovery Boilers | Enhances energy efficiency and reduces operational costs | Compliance with local regulations and energy standards |

| Oil and Gas | Firetube Boilers for heating and process steam | Reliable steam supply for refining processes | Material quality and resistance to corrosive environments |

| Chemical Processing | Watertube Boilers for high-pressure steam generation | Supports large-scale chemical production efficiently | Customization options for specific chemical applications |

| Food and Beverage | Heat Recovery Steam Generators for cooking and sterilization | Improves sustainability and reduces energy consumption | Certifications for food safety and hygiene standards |

| Pulp and Paper | Modular Boiler Systems for steam supply | Reduces installation time and labor costs | Modular design compatibility with existing infrastructure |

How Does Hamon Deltak Inc GT Cater to Power Generation Needs?

In the power generation sector, Hamon Deltak’s waste heat recovery boilers are pivotal in enhancing energy efficiency. These systems capture and convert waste heat from flue gases into usable energy, significantly reducing fuel consumption and lowering operational costs. For international buyers, especially in regions like Africa and South America, the ability to comply with local energy regulations and standards is crucial when sourcing these systems. Additionally, understanding the local energy landscape can inform the selection of appropriate technologies that align with specific energy policies.

What Role Do Hamon Deltak Boilers Play in Oil and Gas Operations?

In the oil and gas industry, firetube boilers are extensively utilized for heating and providing process steam in refining operations. These boilers are designed for reliability and efficiency, ensuring a consistent steam supply critical for various processes. Buyers in the Middle East and Europe must consider the materials used in these boilers, as they need to withstand harsh and corrosive environments typical in oil extraction and refining. Furthermore, procurement decisions should factor in maintenance support and service availability to ensure operational continuity.

How Can Chemical Processing Benefit from Watertube Boilers?

Hamon Deltak’s watertube boilers are engineered for high-pressure steam generation, making them ideal for the chemical processing industry. These boilers support large-scale production processes, providing the necessary steam for reactions and distillations. For international B2B buyers, customization is key; specific chemical properties may require tailored boiler designs to ensure optimal performance and safety. Additionally, understanding local compliance requirements for emissions and safety standards is vital when sourcing these systems.

Why Are Heat Recovery Steam Generators Essential in the Food and Beverage Sector?

In the food and beverage sector, heat recovery steam generators play a crucial role in cooking and sterilization processes. By capturing and reusing waste heat, these systems not only improve sustainability but also significantly reduce energy consumption and costs. Buyers from regions like Africa and South America should prioritize suppliers with certifications for food safety and hygiene standards, as these are critical in maintaining product quality and compliance with local regulations.

What Advantages Do Modular Boiler Systems Offer to the Pulp and Paper Industry?

Modular boiler systems from Hamon Deltak provide significant advantages in the pulp and paper industry, particularly by reducing installation time and labor costs. These systems are designed for easy integration into existing infrastructure, which is essential for international buyers looking to minimize downtime during installation. Key considerations for procurement include the compatibility of modular designs with current operations and the availability of technical support during the transition phase.

3 Common User Pain Points for ‘hamon deltak inc gt’ & Their Solutions

Scenario 1: Navigating Complex Boiler Specifications for Diverse Applications

The Problem: B2B buyers often encounter challenges when trying to source industrial boilers that meet specific operational requirements across various applications. For example, a manufacturing plant in Nigeria might require a watertube boiler for power generation, while a chemical processing facility in Germany might need a firetube boiler for heating and sterilization. The complexity of specifications, including pressure ratings, efficiency standards, and fuel types, can lead to confusion and misalignment between expectations and what is actually delivered. This can result in project delays, increased costs, and operational inefficiencies.

The Solution: To effectively navigate these complexities, it is crucial for buyers to engage in a comprehensive consultation with Hamon Deltak’s engineering team early in the procurement process. Buyers should prepare a detailed outline of their operational needs, including specific application requirements, efficiency goals, and regulatory compliance standards relevant to their region. Hamon Deltak specializes in custom-engineered solutions; leveraging their expertise will ensure the selected boiler is tailored to the unique demands of the application. Additionally, considering modular designs can expedite installation and reduce field assembly time, which is essential for minimizing downtime during implementation.

Scenario 2: Managing Boiler Maintenance and Downtime

The Problem: Industrial boilers are critical to operations, and any unexpected downtime can lead to significant financial losses. B2B buyers, especially in sectors like oil and gas or food processing, often struggle with the need for effective maintenance strategies that minimize operational interruptions. The challenge is exacerbated by a lack of in-house expertise and the urgency of responding to boiler issues as they arise, which can lead to reactive maintenance rather than a proactive, strategic approach.

The Solution: To mitigate the risks associated with boiler downtime, buyers should establish a proactive maintenance partnership with Hamon Deltak. This can include enrolling in a tailored preventive maintenance program that offers regular inspections, cleaning, and prompt repairs. Buyers should also take advantage of Hamon Deltak’s training programs for their operational staff, enabling them to perform basic troubleshooting and routine maintenance. This knowledge transfer can empower teams to identify potential issues before they escalate, ensuring that the boiler operates at peak efficiency and reduces the likelihood of costly emergency repairs.

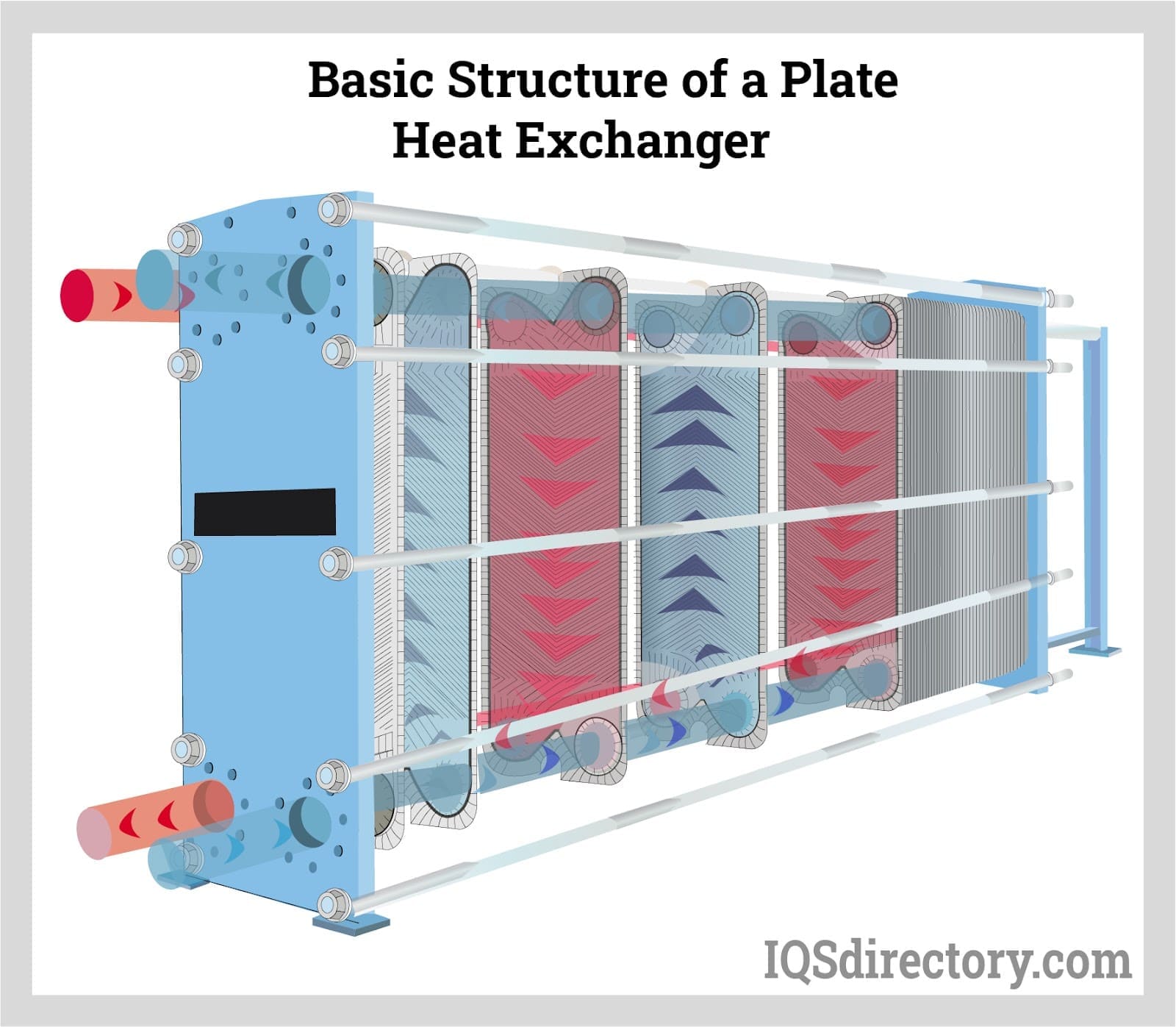

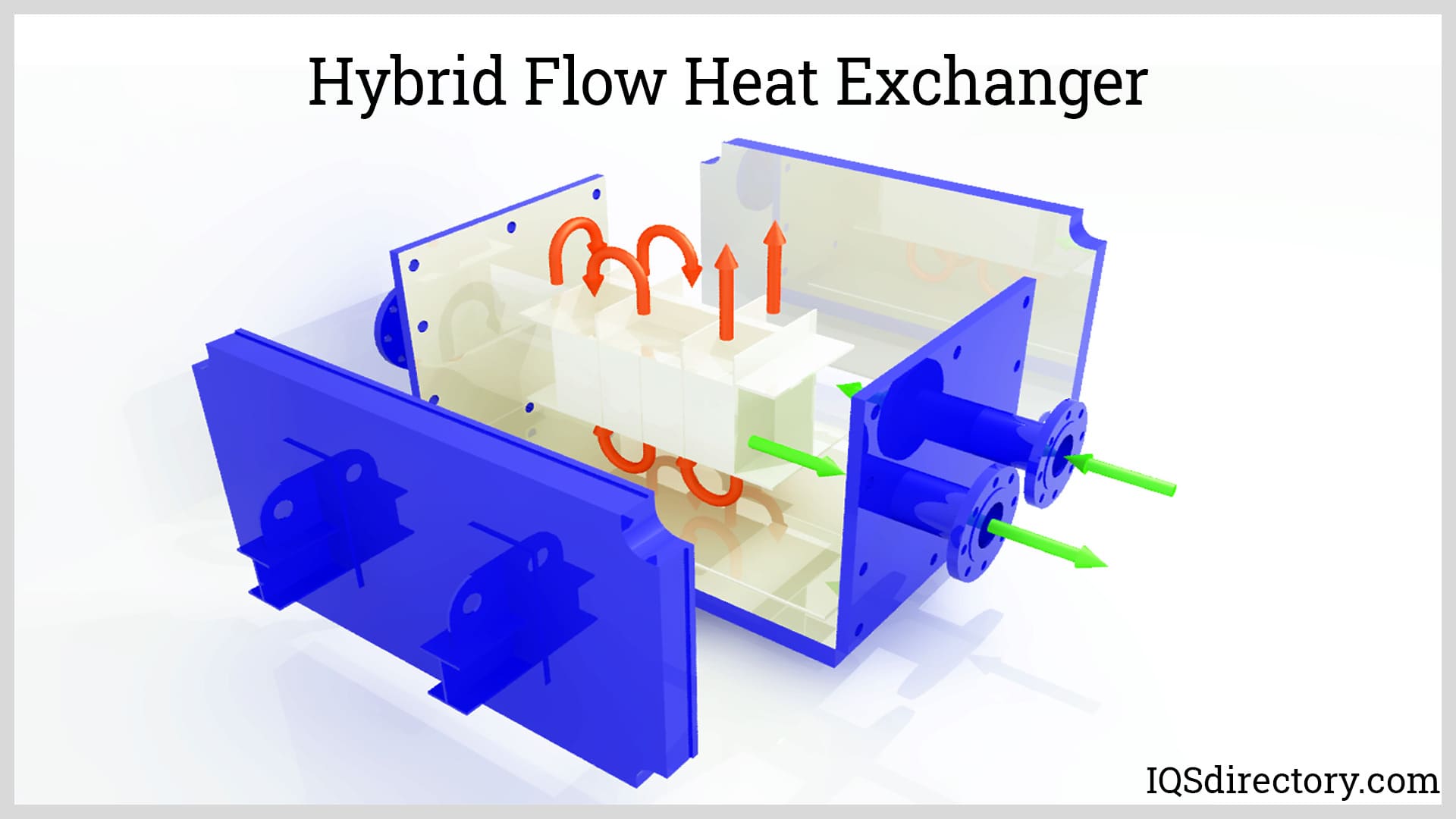

Illustrative image related to hamon deltak inc gt

Scenario 3: Integrating Waste Heat Recovery Solutions for Sustainability

The Problem: With increasing pressure to improve energy efficiency and reduce carbon footprints, many B2B buyers are seeking ways to integrate waste heat recovery systems into their operations. However, they often face challenges in identifying the right technology that aligns with their existing infrastructure and operational processes. Additionally, concerns about the upfront investment and return on investment (ROI) can lead to hesitation in adopting these sustainable technologies.

The Solution: Buyers should start by conducting a comprehensive energy audit in collaboration with Hamon Deltak’s engineering team to identify potential areas for waste heat recovery. This audit will assess existing systems and determine the viability of integrating waste heat recovery boilers into their operations. It is also essential to evaluate the long-term financial benefits, including lower energy costs and potential government incentives for sustainable practices. Hamon Deltak can provide customized solutions that demonstrate a clear ROI, allowing buyers to justify the investment while enhancing their sustainability efforts. Engaging in pilot projects can also serve as a low-risk way to evaluate the effectiveness of these systems before full-scale implementation.

Strategic Material Selection Guide for hamon deltak inc gt

What Are the Key Materials Used in Hamon Deltak’s Industrial Boilers?

Hamon Deltak, Inc. utilizes a variety of materials in the construction of its industrial boilers, each selected for its unique properties and suitability for specific applications. Understanding these materials is crucial for international B2B buyers looking to invest in reliable and efficient boiler systems.

How Do Carbon Steel and Stainless Steel Compare for Boiler Applications?

Carbon Steel is a common choice for boiler construction due to its excellent strength and weldability. It typically has a high-temperature and pressure rating, making it suitable for high-performance applications. However, carbon steel is prone to corrosion, especially in high-moisture environments, which can lead to increased maintenance costs over time.

Stainless Steel, on the other hand, offers superior corrosion resistance, making it ideal for applications involving aggressive media or environments. Its durability under high temperatures and pressures is also noteworthy. However, stainless steel tends to be more expensive and may complicate manufacturing processes due to its hardness, which can require specialized welding techniques.

For international buyers, especially in regions like Europe and the Middle East, compliance with standards such as ASTM and DIN is essential. Buyers should also consider the local availability of these materials, as sourcing can impact overall costs and project timelines.

What Role Does Alloy Steel Play in Enhancing Boiler Performance?

Alloy Steel is engineered to provide enhanced mechanical properties and resistance to extreme temperatures and pressures. This material is often used in high-performance applications where additional strength and durability are required. The main advantage of alloy steel is its ability to withstand harsh operating conditions, which can significantly extend the lifespan of boiler systems.

However, the complexity of manufacturing with alloy steel can lead to higher costs. Additionally, it may require more specialized knowledge for installation and maintenance, which can be a consideration for international buyers who may need to train local staff.

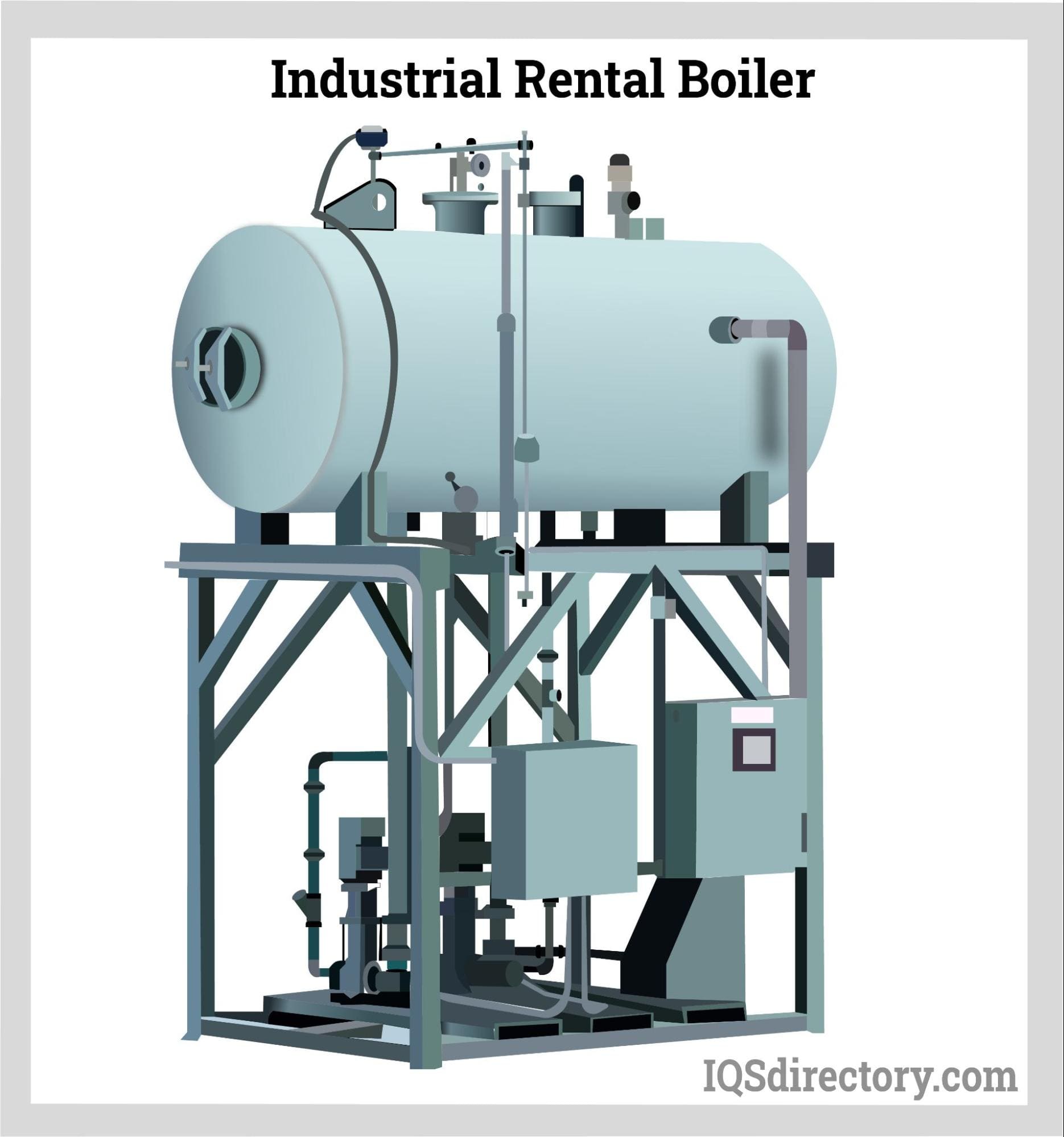

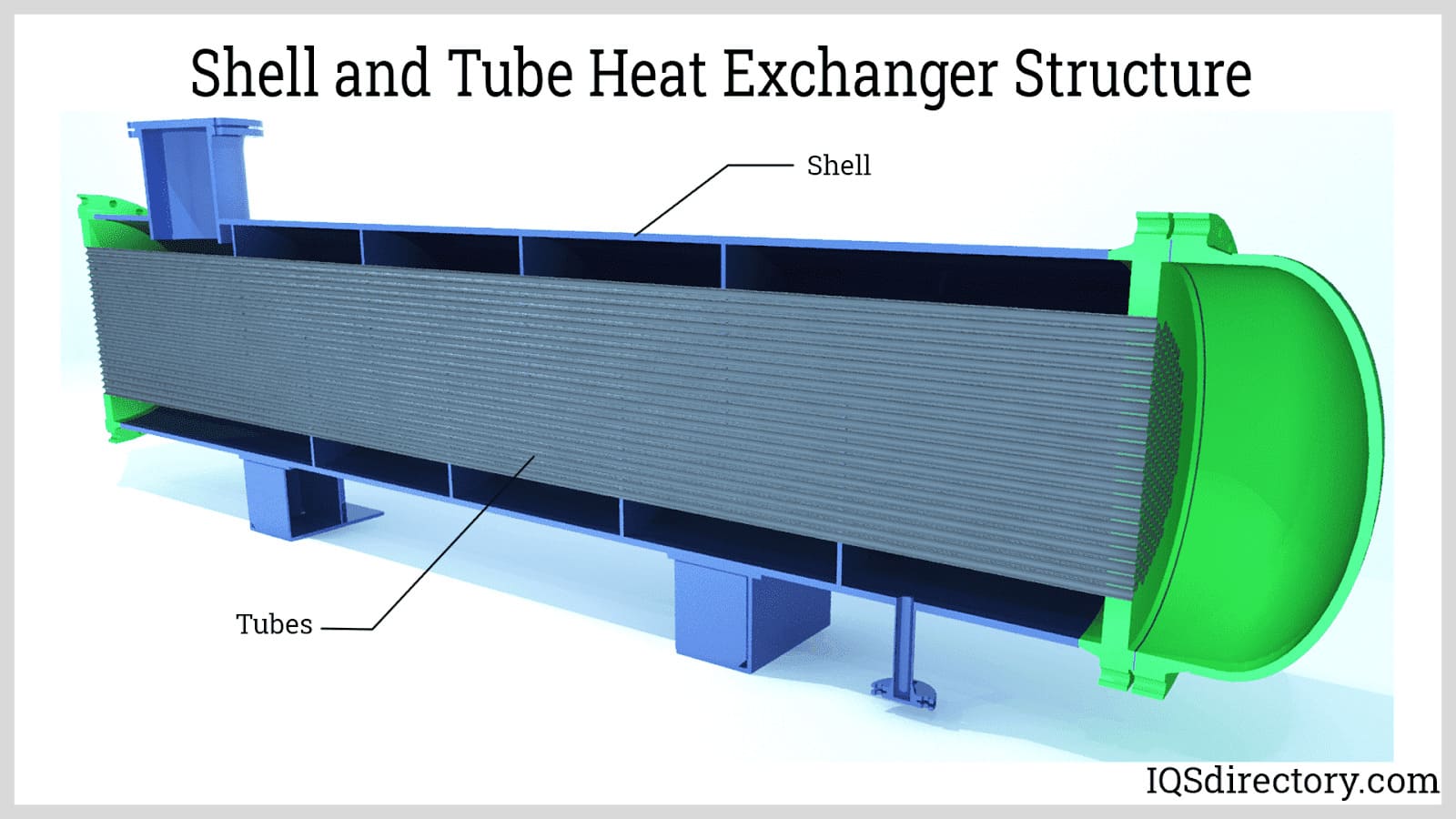

Illustrative image related to hamon deltak inc gt

Why Is the Selection of Composite Materials Important for Waste Heat Recovery?

Composite Materials are increasingly being used in waste heat recovery applications due to their lightweight and high-strength characteristics. These materials can be tailored to meet specific thermal and mechanical requirements, making them suitable for innovative designs in boiler systems. Their resistance to corrosion and thermal fatigue enhances the overall efficiency of heat recovery systems.

The downside of composite materials is their relatively high cost and the complexity involved in their manufacturing and installation. International buyers should be aware of the certification requirements for composites, as different regions may have varying standards for performance and safety.

Summary of Material Properties and Considerations for International Buyers

| Material | Typical Use Case for hamon deltak inc gt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General boiler construction | High strength and weldability | Prone to corrosion | Medium |

| Stainless Steel | High-performance and corrosion-resistant applications | Excellent corrosion resistance and durability | Higher cost and complex manufacturing | High |

| Alloy Steel | High-temperature and pressure applications | Enhanced mechanical properties | Higher cost and specialized knowledge required | Medium to High |

| Composite Materials | Waste heat recovery systems | Lightweight and customizable | High cost and complex installation | High |

This strategic material selection guide provides valuable insights for B2B buyers, enabling them to make informed decisions based on the specific needs of their operations and compliance with international standards. Understanding the properties, advantages, and limitations of these materials can significantly impact the performance and longevity of boiler systems in diverse industrial applications.

In-depth Look: Manufacturing Processes and Quality Assurance for hamon deltak inc gt

What Are the Key Stages in the Manufacturing Process of Hamon Deltak Inc.?

Hamon Deltak Inc. employs a rigorous manufacturing process designed to deliver high-quality industrial boilers and heat recovery systems. This process consists of several key stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Manufacturing?

The first step involves sourcing high-quality materials, primarily steel, which is vital for the durability and performance of the boilers. Hamon Deltak collaborates closely with trusted suppliers to ensure that the materials meet stringent specifications. Once sourced, materials undergo thorough inspections before being released for manufacturing. This initial quality check is critical to ensure that only materials meeting industry standards are utilized in production.

What Forming Techniques Are Used?

In the forming stage, advanced manufacturing techniques come into play. Hamon Deltak uses state-of-the-art machinery to shape the raw materials into the required components. Techniques such as cutting, bending, and welding are employed, with a particular emphasis on precision to achieve the desired specifications. The company adheres to American Society of Mechanical Engineers (ASME) welding standards, ensuring that every weld is executed with utmost care and expertise.

How Does Assembly Happen in the Manufacturing Process?

The assembly stage is where individual components come together to create the final product. Hamon Deltak emphasizes modularization in its assembly process, allowing for larger components to be shipped and assembled more efficiently on-site. This approach not only reduces field assembly time but also enhances overall quality, as components are assembled in a controlled environment. Skilled technicians oversee this process, ensuring that each unit is built to the client’s specifications.

What Finishing Techniques Are Applied?

Finishing is the final stage of manufacturing, where boilers undergo surface treatment and quality checks. Processes such as painting, coating, and polishing are applied to enhance durability and aesthetic appeal. This stage also includes rigorous quality control checks to ensure that every product meets the established performance and safety standards before leaving the facility.

What Quality Control Measures Are in Place at Hamon Deltak Inc.?

Quality assurance is a cornerstone of Hamon Deltak’s manufacturing process. The company adheres to various international and industry-specific standards, including ISO 9001, which outlines requirements for a quality management system. These certifications signal the company’s commitment to delivering high-quality products consistently.

How Are Quality Control Checkpoints Structured?

Quality control at Hamon Deltak is organized into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint ensures that raw materials meet specified standards before they enter the production line. Any subpar materials are rejected at this stage.

-

In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are conducted to monitor the quality of components. This helps identify any deviations from the required specifications early on.

-

Final Quality Control (FQC): Once assembly is complete, the final products undergo a comprehensive evaluation. This includes functional testing, pressure testing, and other assessments to ensure that the boilers perform optimally under operational conditions.

What Testing Methods Are Commonly Used?

Hamon Deltak employs various testing methods to validate the quality and safety of its products. These methods include:

- Hydrostatic Testing: Used to check for leaks and verify the structural integrity of the boilers.

- Performance Testing: Evaluates the efficiency and output of the boilers under simulated operational conditions.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic and radiographic testing are used to detect internal flaws without damaging the components.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is crucial. Here are actionable strategies to ensure supplier reliability:

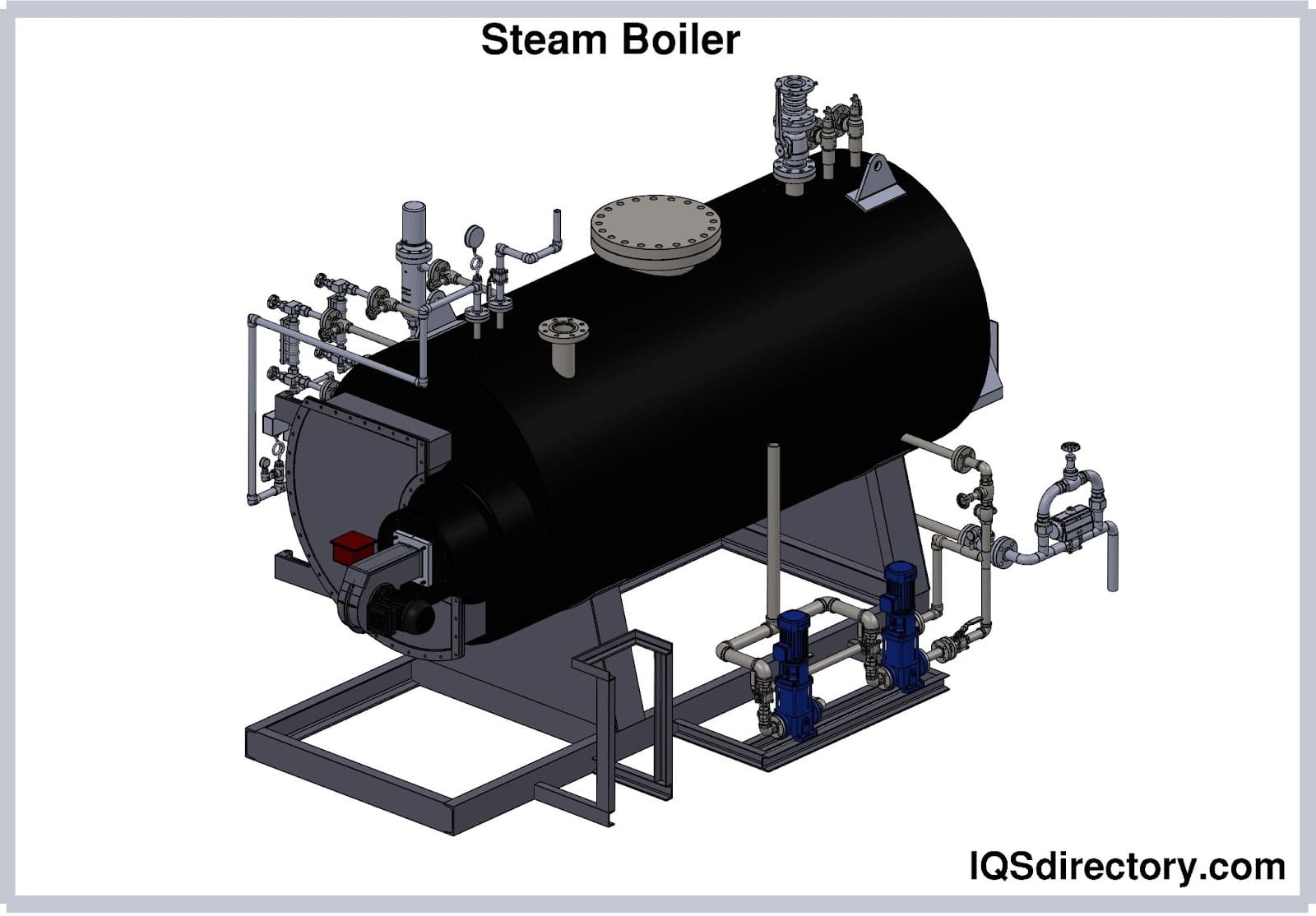

Illustrative image related to hamon deltak inc gt

What Are the Steps for Conducting Supplier Audits?

Conducting thorough supplier audits can provide valuable insights into a manufacturer’s quality control processes. Buyers should consider:

- On-Site Visits: Arranging visits to the manufacturing facility allows buyers to observe the quality control processes in action and assess compliance with international standards.

- Document Review: Requesting access to quality control documentation, including inspection reports, certificates, and compliance audits, can provide transparency regarding the supplier’s practices.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can add an extra layer of assurance. Independent inspectors can validate the quality of materials and workmanship, ensuring that products meet the required specifications before shipment. This is especially pertinent for buyers in regions with stringent import regulations.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers must be aware of specific quality control and certification nuances that may affect their purchasing decisions. For instance, certifications such as CE marking for products sold in the European market and API standards for the oil and gas sector play a critical role in ensuring compliance with local regulations. Buyers should ensure that their suppliers are equipped to meet these standards to avoid potential compliance issues.

How Can B2B Buyers Stay Informed About Quality Standards?

Staying updated on evolving quality standards is essential for B2B buyers. Engaging in industry forums, subscribing to relevant publications, and attending trade shows can provide valuable insights into best practices and emerging trends in quality assurance. Networking with other industry professionals can also facilitate knowledge sharing about reliable suppliers and quality control practices.

Conclusion

Understanding the manufacturing processes and quality assurance measures at Hamon Deltak Inc. is vital for B2B buyers aiming to procure high-quality industrial boilers and heat recovery systems. By leveraging the outlined insights and strategies, buyers can make informed decisions, ensuring they partner with a supplier committed to excellence and reliability in their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hamon deltak inc gt’

Introduction

This sourcing guide is designed to assist B2B buyers in navigating the procurement process for industrial boilers and energy solutions from Hamon Deltak Inc. With a strong emphasis on quality, customer satisfaction, and innovation, this checklist will streamline your decision-making and ensure that you select the right products and services for your operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful procurement process. This includes understanding the type of boiler you require—whether it’s a watertube, firetube, or waste heat recovery boiler—as well as capacity, efficiency, and any specific regulatory requirements applicable in your region. Detailed specifications help in evaluating suppliers effectively and ensuring that the products meet your operational demands.

Step 2: Research Supplier Capabilities

Conduct thorough research on Hamon Deltak Inc. and its capabilities. Look into their experience in your specific industry, as well as their history of successful projects and innovations in boiler technology. This information will provide insights into their expertise and reliability, which is crucial for long-term partnerships.

- Assess Engineering Expertise: Verify their engineering capabilities and past projects to understand how they tailor solutions to meet diverse client needs.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s essential to vet potential suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for testimonials or feedback regarding product performance and customer service.

- Check for Repeat Business: A high percentage of repeat customers or referrals can indicate reliability and satisfaction with the supplier’s offerings.

Step 4: Verify Compliance and Certifications

Ensuring that the supplier adheres to international quality standards is critical. Verify that Hamon Deltak Inc. holds relevant certifications, such as ASME (American Society of Mechanical Engineers) and ISO, which indicate adherence to quality and safety standards in manufacturing.

- Review Quality Assurance Processes: Inquire about their quality control measures and how they ensure compliance during the manufacturing process.

Step 5: Request Detailed Quotations

Once you have narrowed down your options, request detailed quotations from Hamon Deltak Inc. Ensure that these quotations include pricing, delivery timelines, installation services, and warranty information. A comprehensive quote allows for better comparison and informed decision-making.

- Evaluate Total Cost of Ownership: Consider not just the initial purchase price but also installation, maintenance, and operational costs over the equipment’s lifespan.

Step 6: Engage in Technical Discussions

Initiate discussions with Hamon Deltak’s technical team to clarify any uncertainties. Engaging with engineers or technical experts can provide deeper insights into the product’s functionality, installation requirements, and potential customizations.

- Discuss Modularization Options: Ask about modular designs that may reduce installation time and labor costs, which can be particularly beneficial for large-scale projects.

Step 7: Plan for After-Sales Support

Finally, consider the after-sales support provided by Hamon Deltak Inc. Comprehensive training, technical support, and maintenance services are vital for ensuring the long-term performance of your boiler systems.

- Inquire About Training Programs: Assess the training programs available for your staff to ensure they can operate and maintain the equipment effectively.

By following this step-by-step sourcing checklist, you will be better equipped to procure the right industrial boiler solutions from Hamon Deltak Inc., ensuring your operational needs are met with quality and efficiency.

Comprehensive Cost and Pricing Analysis for hamon deltak inc gt Sourcing

What Are the Key Cost Components for Sourcing from Hamon Deltak Inc.?

When considering a partnership with Hamon Deltak Inc. for industrial boilers and energy solutions, understanding the cost structure is crucial. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The cost of raw materials, such as steel and specialized components, is a significant portion of the total expenditure. Prices can fluctuate based on market demand and availability, which may affect overall project costs.

-

Labor: Skilled labor is essential for the engineering, manufacturing, and installation of customized boiler systems. Labor costs can vary based on the complexity of the project and the expertise required.

-

Manufacturing Overhead: This includes costs related to facility operations, utilities, and indirect labor. Efficient manufacturing processes, such as modularization, help reduce overhead, ultimately impacting the pricing structure.

-

Tooling: Investment in tooling is necessary for producing high-quality, customized boilers. The initial tooling costs can be high but are amortized over the production volume.

-

Quality Control (QC): Ensuring compliance with international standards and certifications requires rigorous QC processes. These costs are often factored into the pricing to maintain product integrity.

-

Logistics: Transportation and shipping costs can vary significantly based on the destination and Incoterms used. Buyers should consider the logistics involved in delivering large boiler components, which may require specialized transportation.

-

Margin: Hamon Deltak, like any manufacturer, incorporates a profit margin into their pricing. This margin can be influenced by competition, market demand, and the level of customization offered.

What Influences Pricing for Hamon Deltak Inc. Products?

Several factors influence the pricing of Hamon Deltak’s products, including order volume, specifications, material quality, and supplier relationships.

-

Volume/MOQ: Pricing often benefits from economies of scale. Larger orders may lead to lower per-unit costs, making it advantageous for buyers to consolidate their purchasing.

-

Specifications and Customization: Customized solutions tailored to specific operational needs can lead to higher costs. However, these customizations can enhance efficiency and reduce long-term operational expenses.

-

Material Quality and Certifications: Higher quality materials and certifications may increase upfront costs but can lead to greater reliability and reduced maintenance expenses over time.

-

Supplier Factors: The choice of suppliers for raw materials and components can impact pricing. Strong relationships with reliable suppliers can lead to better pricing and terms.

-

Incoterms: The choice of Incoterms can significantly affect pricing. Buyers should understand how responsibilities for shipping, insurance, and tariffs are allocated, as these can add to the total cost.

What Tips Can Help Buyers Negotiate Better Prices with Hamon Deltak Inc.?

To optimize costs and negotiate effectively with Hamon Deltak, buyers should consider the following strategies:

-

Negotiate Based on Volume: Leverage order size to negotiate better pricing terms. Larger contracts can offer more negotiating power, potentially leading to discounts or more favorable payment terms.

-

Assess Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the equipment, including maintenance, energy consumption, and potential downtime. A higher initial investment may be justified if it results in lower operational costs.

-

Understand Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of local regulations, tariffs, and shipping costs that may affect pricing. Engaging with local representatives can provide insights into potential hidden costs.

-

Request Detailed Quotes: Ensure that quotes include a breakdown of all cost components, allowing for better comparisons and negotiation points. Transparency in pricing can help identify areas for cost reduction.

-

Build Long-term Relationships: Establishing a strong relationship with Hamon Deltak can lead to better pricing and service over time, as trust and understanding of each other’s operations grow.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, project specifications, and negotiations. Always request a formal quote for accurate pricing tailored to your specific needs.

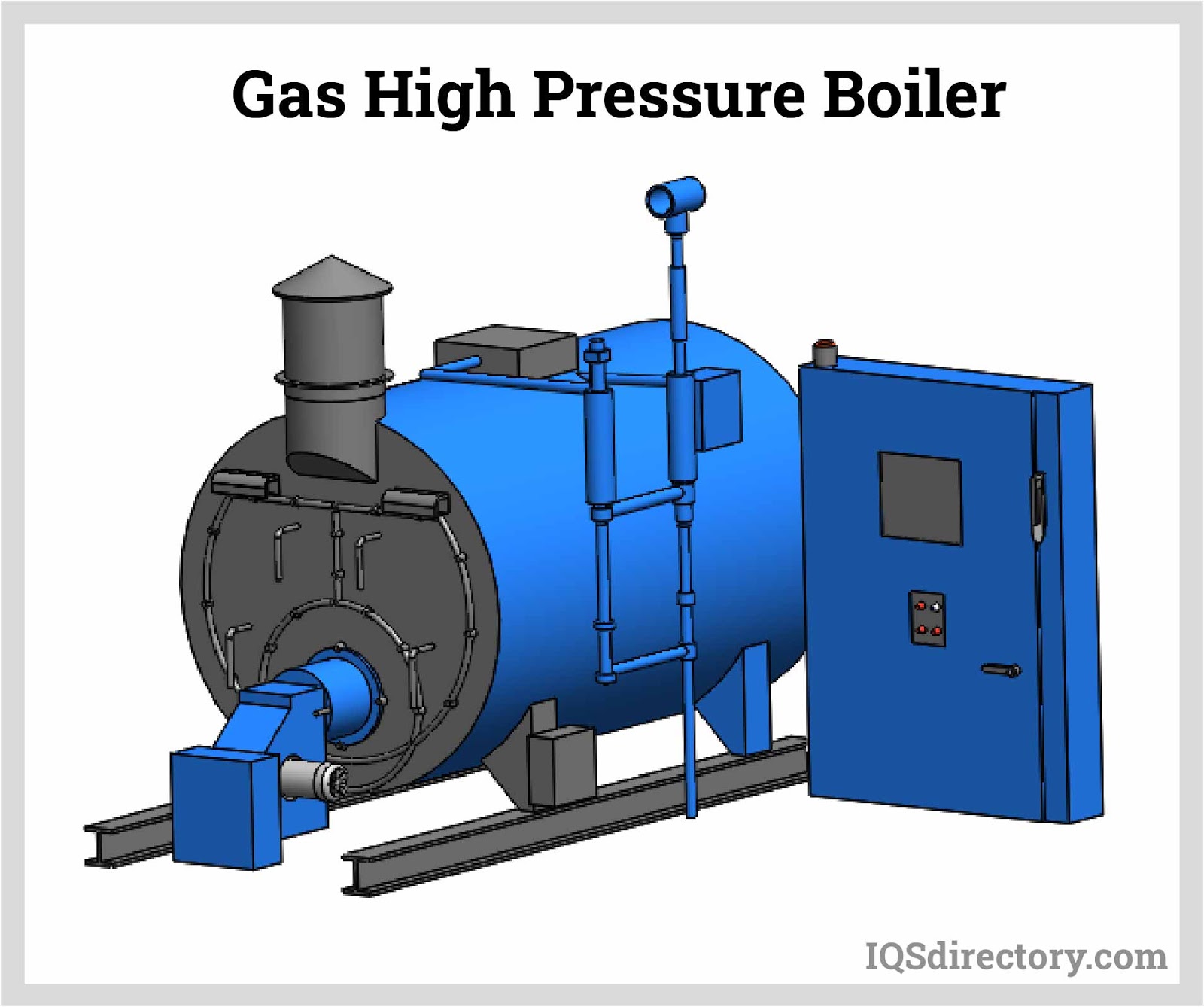

Illustrative image related to hamon deltak inc gt

Alternatives Analysis: Comparing hamon deltak inc gt With Other Solutions

Understanding Alternatives in Industrial Boiler Solutions

In the industrial boiler market, buyers often face a multitude of options, each offering unique features and benefits. Understanding the alternatives to Hamon Deltak Inc. GT is crucial for businesses aiming to optimize efficiency, reduce costs, and enhance operational reliability. This section compares Hamon Deltak Inc. GT with two notable alternatives: Miura Boiler Co., Ltd. and Nationwide Boiler Inc.

Comparison Table

| Comparison Aspect | Hamon Deltak Inc GT | Miura Boiler Co., Ltd. | Nationwide Boiler Inc. |

|---|---|---|---|

| Performance | High efficiency with robust construction, tailored solutions for diverse industries | Compact design with rapid steam generation capabilities | Versatile solutions with a wide range of boiler types |

| Cost | Competitive pricing, with value-added engineering | Generally higher initial costs, but lower operational costs | Flexible pricing, depending on rental or purchase options |

| Ease of Implementation | Modular design facilitates easy installation | Quick setup with pre-packaged units | Installation can be straightforward, but may require customization |

| Maintenance | Comprehensive service offerings, including preventive maintenance | Low maintenance due to advanced technology | Extensive support available, but may require more frequent checks |

| Best Use Case | Ideal for power generation, chemical processing, and heat recovery | Best suited for industries needing quick steam and space-saving solutions | Excellent for temporary needs or emergency situations with rental options |

Detailed Breakdown of Alternatives

Miura Boiler Co., Ltd.

Miura is renowned for its innovative approach to steam generation, offering compact and efficient boilers. The primary advantage of Miura boilers is their rapid startup time, which can significantly enhance operational flexibility. However, the initial investment can be higher compared to Hamon Deltak, although this is often offset by lower operational costs due to energy efficiency. Their low maintenance requirements make them an attractive option for businesses aiming to minimize downtime. Miura’s solutions are best suited for facilities that require quick steam availability and have space constraints.

Nationwide Boiler Inc.

Nationwide Boiler specializes in providing a wide range of boiler solutions, including rental services. This flexibility allows businesses to meet temporary demands without committing to a permanent investment. One significant advantage of Nationwide Boiler is its extensive inventory, enabling quick deployment in emergency situations. However, maintenance can be more intensive, and the need for regular checks might increase operational costs over time. Nationwide Boiler is ideal for companies that prioritize versatility and immediate availability, particularly in fluctuating market conditions.

Illustrative image related to hamon deltak inc gt

Conclusion: How to Choose the Right Boiler Solution

Selecting the right boiler solution depends on various factors, including specific operational needs, budget constraints, and maintenance capabilities. For businesses focused on long-term investment in efficiency and tailored solutions, Hamon Deltak Inc. GT stands out with its robust offerings and comprehensive service. Conversely, for those requiring rapid steam generation and space efficiency, Miura presents a compelling option. Lastly, if flexibility and immediate deployment are paramount, Nationwide Boiler’s rental services may be the best fit. B2B buyers should assess their unique requirements and operational goals to make an informed decision that aligns with their strategic objectives.

Essential Technical Properties and Trade Terminology for hamon deltak inc gt

What Are the Key Technical Properties of Hamon Deltak Inc. Boilers?

Understanding the technical properties of Hamon Deltak Inc. boilers is crucial for B2B buyers, especially when making investment decisions in industrial equipment. Here are some essential specifications that influence performance, efficiency, and longevity:

1. Material Grade

The material grade used in boiler construction significantly impacts durability and resistance to corrosion and high temperatures. Hamon Deltak typically employs high-grade carbon and stainless steels, which are designed to withstand the rigors of continuous operation in demanding environments. Selecting the right material grade ensures that the boiler can perform efficiently while minimizing maintenance costs.

2. Pressure Rating

Pressure rating defines the maximum operating pressure a boiler can handle safely. Hamon Deltak’s boilers are engineered to operate at various pressure levels depending on the application—ranging from low to high-pressure boilers. Understanding pressure ratings is essential for compliance with safety regulations and for optimizing the steam generation process, especially in industries like power generation and petrochemicals.

3. Heat Transfer Efficiency

This property measures how effectively a boiler can convert fuel energy into usable steam or hot water. Hamon Deltak’s innovative designs, such as watertube and waste heat recovery boilers, are engineered for optimal heat transfer efficiency, which translates to lower fuel consumption and reduced operational costs. Buyers should prioritize high-efficiency models to enhance energy savings and sustainability.

4. Modularization Capability

Modularization refers to the design approach of fabricating boiler components in sections that can be easily assembled on-site. Hamon Deltak focuses on modular designs to reduce field assembly time and labor costs. This approach is vital for international buyers who may face logistical challenges, as it simplifies installation and minimizes downtime.

5. Emissions Compliance

With increasing environmental regulations, understanding emissions compliance is crucial. Hamon Deltak’s boilers are designed to meet stringent emission standards, ensuring that buyers are not only compliant but also contributing to sustainability efforts. This property is especially relevant for industries operating in regions with strict environmental laws.

Illustrative image related to hamon deltak inc gt

What Common Trade Terms Should B2B Buyers Know?

Navigating the industrial boiler market involves understanding specific trade terminology that can affect procurement and operational decisions. Here are key terms that buyers should be familiar with:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of Hamon Deltak, buyers may engage with OEMs for components that require specific certifications or performance standards, ensuring compatibility and reliability in their boiler systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budget planning, especially for international buyers who may be looking to purchase multiple units of specialized equipment. Knowing the MOQ can help in negotiating better terms and pricing.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific goods or services. B2B buyers should utilize RFQs when seeking detailed pricing information from Hamon Deltak, allowing for comparison across suppliers and ensuring that all necessary specifications are addressed.

Illustrative image related to hamon deltak inc gt

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping agreements. Familiarity with Incoterms is critical for buyers engaging in international transactions, as they clarify who is responsible for shipping, insurance, and tariffs, reducing the risk of misunderstandings.

5. Lead Time

Lead time is the period between placing an order and receiving the product. Understanding lead times is vital for project planning, especially in industries where downtime can lead to significant financial losses. Buyers should inquire about lead times when discussing projects with Hamon Deltak to align timelines with operational needs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational goals and regulatory requirements, ensuring successful procurement and implementation of Hamon Deltak Inc. products.

Navigating Market Dynamics and Sourcing Trends in the hamon deltak inc gt Sector

What Are the Key Trends Shaping the Hamon Deltak Inc GT Sector?

The industrial boiler market is witnessing significant transformation driven by technological advancements, sustainability initiatives, and evolving customer demands. Global drivers such as the increasing need for energy efficiency, stringent environmental regulations, and the push towards renewable energy sources are reshaping the landscape for industrial boiler manufacturers. B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are increasingly prioritizing suppliers that offer innovative and sustainable solutions.

Emerging trends include the rise of modularization in manufacturing processes, which allows for quicker assembly and reduced field time. This is particularly relevant for buyers looking for efficient installation and maintenance of complex systems. Additionally, the integration of IoT technologies into boiler systems is enhancing operational efficiency and predictive maintenance capabilities, providing buyers with real-time data analytics to optimize performance. As clients seek to minimize downtime and improve productivity, suppliers that leverage these technologies will stand out in the competitive market.

Moreover, the focus on waste heat recovery systems is gaining traction, as industries aim to enhance their energy efficiency and reduce operational costs. With more companies recognizing the potential of harnessing waste heat, the demand for sophisticated waste heat recovery boilers is on the rise. For international buyers, aligning with suppliers like Hamon Deltak that offer tailored solutions to meet specific industry needs is crucial for long-term success.

How Is Sustainability Influencing Sourcing Decisions in the Hamon Deltak Inc GT Sector?

Sustainability is no longer a niche consideration but a core element of sourcing strategies in the industrial boiler sector. As environmental concerns escalate, companies are increasingly held accountable for their carbon footprints and resource utilization. The demand for environmentally friendly products and ethical supply chains is compelling suppliers to adopt sustainable practices and materials.

Illustrative image related to hamon deltak inc gt

Hamon Deltak Inc. is at the forefront of this shift, focusing on waste heat recovery solutions that enhance energy efficiency while minimizing emissions. For B2B buyers, the importance of sourcing from manufacturers that prioritize sustainability cannot be overstated. Ethical supply chains ensure that materials are sourced responsibly, reducing the environmental impact associated with production. Buyers should look for certifications such as ISO 14001, which indicates a commitment to effective environmental management systems.

Incorporating ‘green’ certifications and materials into procurement strategies not only aligns with corporate sustainability goals but also enhances brand reputation. As markets in Africa, South America, the Middle East, and Europe become more environmentally conscious, the ability to demonstrate sustainable practices will increasingly influence purchasing decisions.

How Has Hamon Deltak Inc. Evolved to Meet B2B Needs?

Founded in 1972, Hamon Deltak Inc. has evolved significantly to meet the changing demands of the industrial boiler market. Initially focused on heat recovery steam generators, the company has expanded its product line to include a variety of industrial boilers tailored for diverse applications, including power generation and chemical processing. This evolution is marked by a strong emphasis on innovation, quality, and customer satisfaction.

Over the years, Hamon Deltak has adapted its manufacturing processes to incorporate advanced technologies, such as modularization, which has improved efficiency and reduced lead times. By continuously investing in engineering and technology, the company has built a robust reputation for delivering high-quality, customized solutions that address complex challenges faced by industries worldwide. This commitment to innovation and customer-centricity has resulted in a loyal client base, with a significant portion of business stemming from repeat customers and referrals. As Hamon Deltak continues to evolve, it remains well-positioned to support B2B buyers in navigating the complexities of the industrial boiler landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of hamon deltak inc gt

-

How do I ensure the reliability of Hamon Deltak’s industrial boilers?

To ensure the reliability of Hamon Deltak’s industrial boilers, consider their extensive industry experience and customer testimonials. The company has a proven track record, with approximately 80% of its business coming from repeat customers and referrals. Additionally, inquire about their compliance with international standards and certifications, as well as their commitment to quality assurance processes, including preventive and reactive maintenance services. Engaging in direct discussions with their technical support team can also provide insights into their service capabilities and product reliability. -

What types of industrial boilers does Hamon Deltak offer?

Hamon Deltak specializes in various types of industrial boilers, including watertube, firetube, and waste heat recovery boilers. Each type is engineered for specific applications: watertube boilers are known for high efficiency and durability, firetube boilers offer compact design and easy maintenance, while waste heat recovery boilers enhance energy efficiency by utilizing heat from flue gases. Understanding the specific needs of your industry—be it power generation, chemical processing, or food and beverage—can help in selecting the most suitable boiler type. -

What customization options are available for Hamon Deltak’s products?

Hamon Deltak provides extensive customization options tailored to meet specific client requirements. Every project is engineered based on individual specifications, ensuring that the solutions fit seamlessly into existing systems. Buyers can request modifications in design, size, and functionality to align with operational needs. Engaging with their engineering team early in the procurement process allows for a more collaborative approach to customization, ensuring that the final product meets both performance and regulatory standards. -

What are the minimum order quantities (MOQ) for Hamon Deltak products?

The minimum order quantities (MOQ) for Hamon Deltak products can vary based on the type of boiler and specific project requirements. It’s essential to discuss your project scope with their sales team to determine the MOQ applicable to your order. In some cases, smaller quantities may be available for specific models or during promotional periods, but larger orders typically yield better pricing and delivery terms. Establishing a clear understanding of your needs upfront can facilitate a smoother procurement process. -

What are the payment terms for international buyers sourcing from Hamon Deltak?

Hamon Deltak offers flexible payment terms for international buyers, typically including options like advance payment, letter of credit, or payment upon delivery. The specific terms can vary based on the size of the order, customer relationship, and regional regulations. It’s advisable to discuss payment preferences early in negotiations to establish a mutually agreeable arrangement. Additionally, understanding any potential tariffs or taxes applicable to your region can help in budgeting for the total cost of acquisition. -

How does Hamon Deltak ensure quality assurance for their boilers?

Hamon Deltak adheres to stringent quality assurance protocols throughout the manufacturing process. They comply with over 600 American Society of Mechanical Engineers (ASME) welding procedures and conduct rigorous testing to ensure that every boiler meets high performance and safety standards. Regular inspections and maintenance programs are also part of their service offerings, helping clients maintain optimal boiler operation. Engaging in discussions about their QA processes can provide buyers with confidence in the reliability of their products. -

What logistics support does Hamon Deltak provide for international shipping?

Hamon Deltak understands the complexities of international logistics and provides comprehensive support to ensure timely delivery. They coordinate with reputable shipping partners to manage the transportation of large and heavy boiler components, taking care of customs clearance and documentation. Buyers should communicate their delivery timelines and any specific logistical challenges they foresee, allowing Hamon Deltak to tailor their shipping solutions accordingly. This proactive approach can significantly reduce delays and enhance the overall procurement experience. -

What after-sales support can I expect from Hamon Deltak?

Hamon Deltak is committed to providing robust after-sales support, which includes installation, commissioning, and ongoing maintenance services. Their technical support team is available 24/7 to address any operational queries or issues that may arise post-installation. Additionally, they offer training programs to empower your staff with the necessary skills to operate and maintain the boilers effectively. Engaging with their after-sales team early can help ensure a smooth transition and long-term operational efficiency of your equipment.

A Look at Hamon Deltak Inc Gt Manufacturers & Suppliers

Could not verify enough suppliers for hamon deltak inc gt to create a list at this time.

Strategic Sourcing Conclusion and Outlook for hamon deltak inc gt

In today’s competitive global market, strategic sourcing has emerged as a crucial component for businesses seeking to enhance operational efficiency and sustainability. Hamon Deltak Inc. stands out with its commitment to innovative industrial boiler solutions, tailored to meet the specific needs of diverse sectors, including power generation and chemical processing. Their emphasis on quality, modularization, and customer satisfaction not only underscores their engineering excellence but also highlights the importance of sourcing reliable partners who prioritize performance and reliability.

Illustrative image related to hamon deltak inc gt

International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, can greatly benefit from collaborating with Hamon Deltak. The company’s proven track record of delivering customized solutions, combined with its extensive experience across various international standards, positions it as a trusted ally for businesses looking to optimize their energy systems.

As you explore opportunities for sourcing industrial boilers, consider the strategic advantages of partnering with Hamon Deltak. By leveraging their expertise and innovative technologies, you can enhance your operational capabilities while contributing to sustainability goals. Connect with Hamon Deltak today to discover how their solutions can power your success and drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to hamon deltak inc gt