A B2B Buyer’s Guide to Habasit Belt: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for habasit belt

In today’s competitive landscape, sourcing the right Habasit belt can be a daunting challenge for international B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe. Companies must navigate a complex array of options to find belts that not only meet their operational needs but also enhance efficiency and reduce costs. This comprehensive guide addresses the critical aspects of selecting Habasit belts, covering various types, applications, and the nuances of supplier vetting.

From fabric-based conveyor belts to power transmission solutions, our guide explores the extensive offerings available from Habasit, a leader in the industry since 1946. We delve into specific applications across key sectors, including food and beverage, automotive, packaging, and material handling, providing insights into how these solutions can optimize productivity and sustainability.

Additionally, we will discuss crucial factors such as pricing strategies, negotiation tips, and long-term partnership considerations that empower B2B buyers to make informed purchasing decisions. By equipping you with actionable insights and a thorough understanding of the market, this guide aims to streamline your sourcing process and enhance your operational capabilities, ensuring your business remains competitive in a rapidly evolving global marketplace.

Understanding habasit belt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fabric-based Conveyor Belts | Made from woven materials, flexible and durable | Food processing, packaging, textile | Pros: High flexibility, customizable designs. Cons: May require more maintenance than other types. |

| Plastic Modular Belts | Constructed from interlocking plastic modules | Material handling, automotive, packaging | Pros: Easy to clean, low maintenance. Cons: Higher initial cost compared to fabric belts. |

| Power Transmission Belts | Designed for efficient power transfer | Manufacturing, automotive, machinery | Pros: High load capacity, energy-efficient. Cons: Limited flexibility compared to conveyor belts. |

| Monolithic Belts | Made from a single piece of material, seamless | Food processing, pharmaceuticals | Pros: Sanitary, durable, no joints. Cons: Less adaptable to varying applications. |

| Timing Belts | Equipped with teeth for precise movement | Robotics, automotive, industrial machinery | Pros: Accurate timing and synchronization. Cons: Can be sensitive to environmental conditions. |

What Are Fabric-based Conveyor Belts and Their Applications?

Fabric-based conveyor belts are versatile solutions made from woven materials, offering flexibility and durability. They are particularly suited for industries such as food processing, packaging, and textiles, where the ability to handle various product shapes and weights is essential. When purchasing these belts, B2B buyers should consider the specific requirements of their application, including load capacity and environmental conditions, as well as the potential for customization to meet unique operational needs.

How Do Plastic Modular Belts Stand Out in the Market?

Plastic modular belts are unique due to their interlocking design, which allows for easy cleaning and low maintenance. These belts are ideal for material handling and packaging applications, particularly in environments requiring high hygiene standards, such as the automotive and food sectors. Buyers should evaluate the initial investment versus long-term savings on maintenance and operational efficiency when considering plastic modular belts, as they often come with a higher upfront cost but lower overall lifecycle costs.

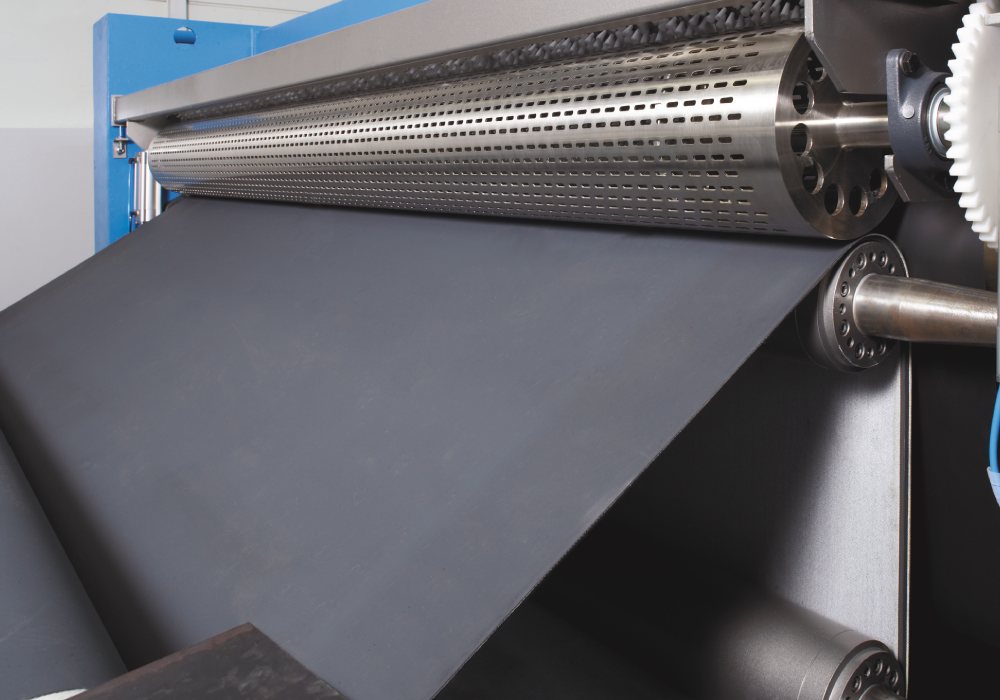

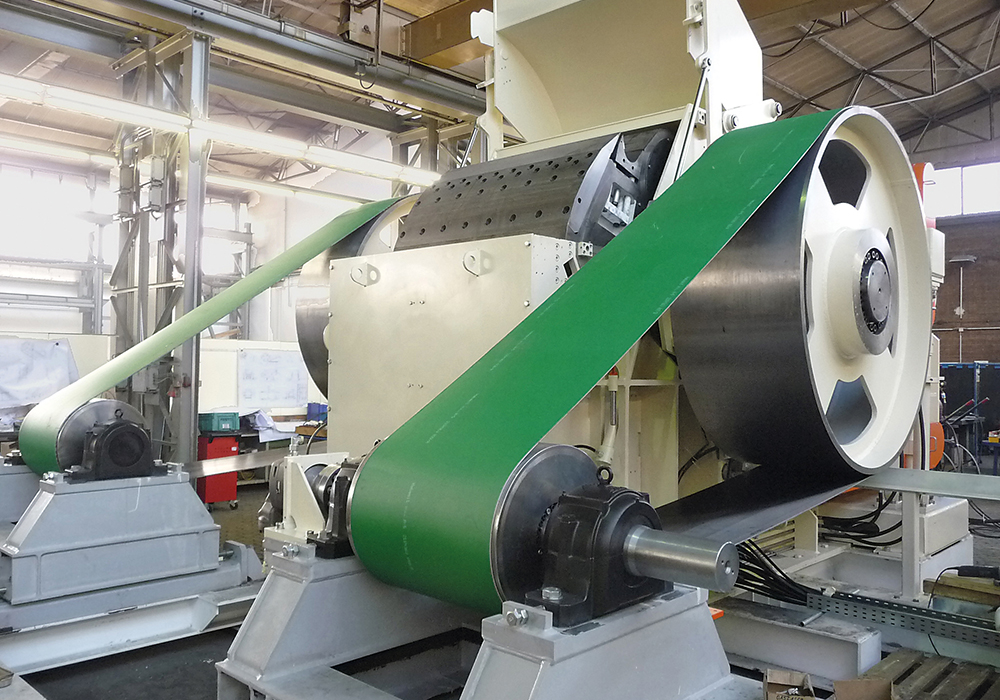

Illustrative image related to habasit belt

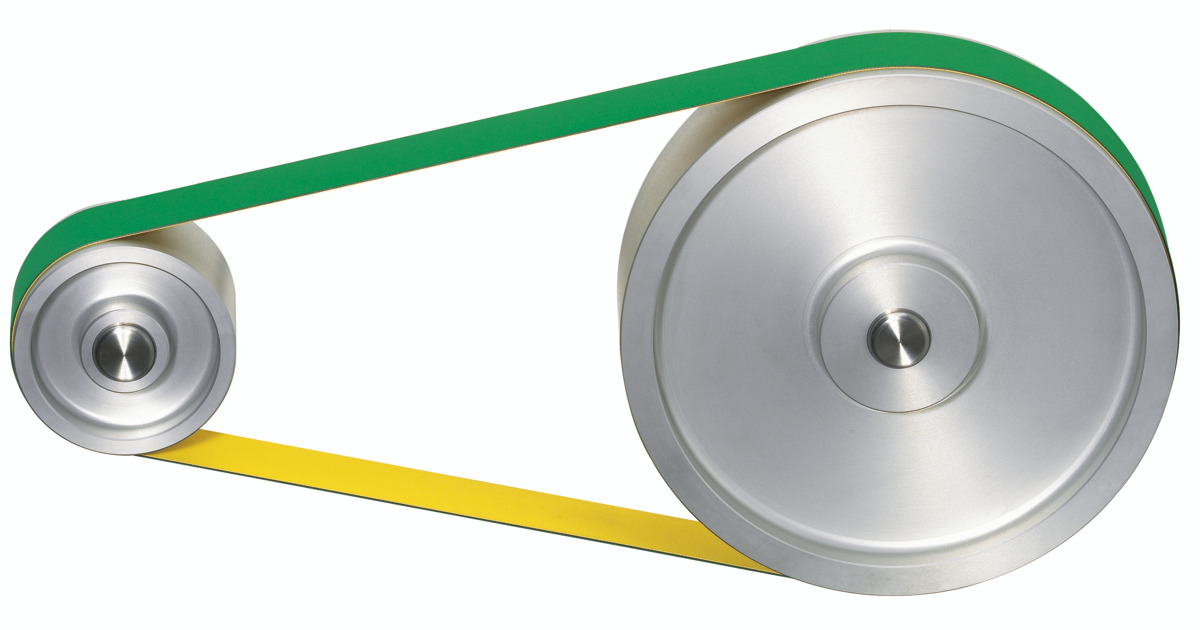

What Makes Power Transmission Belts Essential for Manufacturing?

Power transmission belts are engineered for efficient power transfer, making them crucial in manufacturing, automotive, and machinery applications. They are designed to handle high loads and provide energy efficiency, which can significantly reduce operational costs. B2B buyers should assess the load capacity and compatibility with existing machinery when selecting power transmission belts, as the wrong choice could lead to inefficiencies and increased wear.

Why Choose Monolithic Belts for Hygiene-Sensitive Industries?

Monolithic belts are constructed from a single piece of material, ensuring a seamless design that minimizes contamination risks. This characteristic makes them particularly suitable for food processing and pharmaceutical industries, where hygiene is paramount. Buyers should consider the durability and maintenance requirements of monolithic belts, as their lack of joints means fewer weak points, but they may also be less adaptable to diverse applications compared to other belt types.

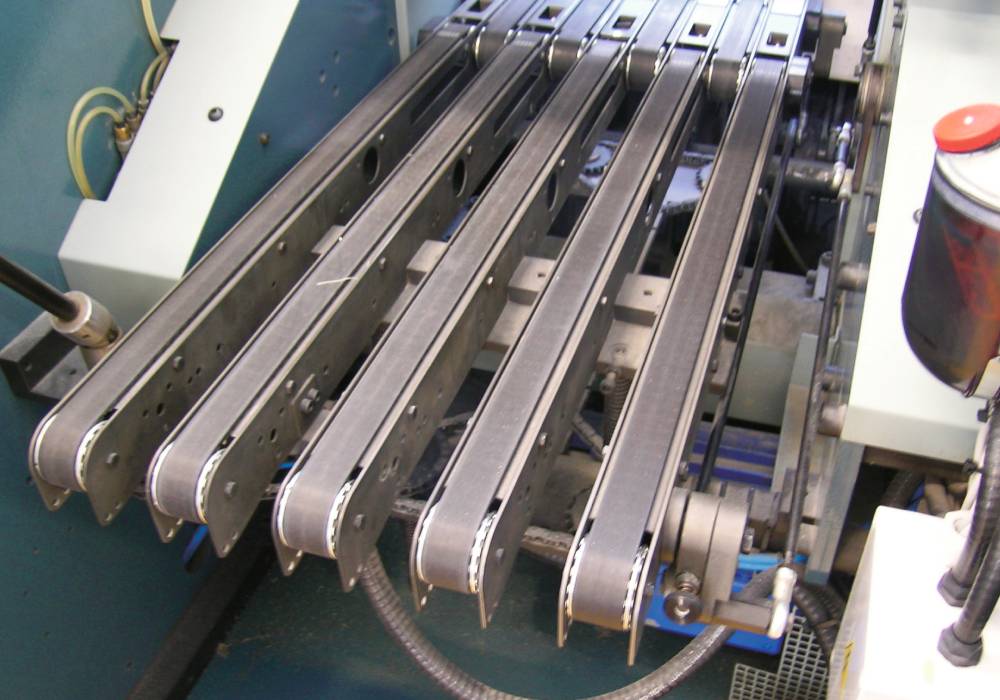

How Do Timing Belts Ensure Precision in Industrial Applications?

Timing belts feature teeth that enable precise movement and synchronization, making them essential in robotics, automotive, and industrial machinery applications. Their design ensures accurate timing, which is critical in high-speed operations. When purchasing timing belts, B2B buyers should focus on the operational environment, as these belts can be sensitive to temperature and humidity changes, impacting their performance and longevity.

Key Industrial Applications of habasit belt

| Industry/Sector | Specific Application of habasit belt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Conveyor systems for meat and poultry processing | Ensures hygiene and minimizes contamination risks | Compliance with food safety standards and certifications |

| Material Handling | Automated sorting and distribution systems | Increases operational efficiency and reduces downtime | Durability and adaptability to varying load capacities |

| Packaging | Packaging line conveyor belts | Enhances product handling and reduces labor costs | Customization options for different packaging types |

| Textile | Fabric belts for textile printing and processing | Provides consistent tension and high durability | Resistance to wear and chemical exposure |

| Automotive | Power transmission belts in assembly lines | Improves production speed and reliability | Compatibility with diverse machinery and load requirements |

How is Habasit Belt Used in the Food and Beverage Industry?

In the food and beverage sector, Habasit belts are integral to conveyor systems used in meat and poultry processing. These belts are designed to meet stringent hygiene standards, minimizing contamination risks while ensuring efficient transport of products through various stages of processing. International buyers, particularly from regions with strict food safety regulations, should prioritize sourcing belts that comply with relevant certifications, ensuring both quality and safety in their operations.

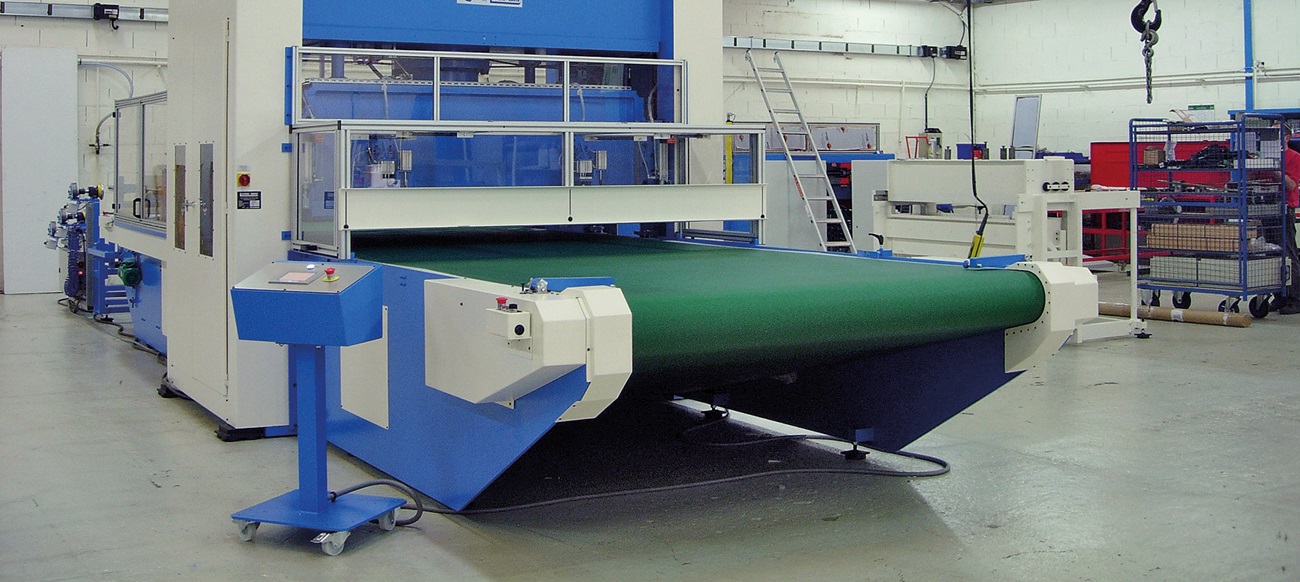

Illustrative image related to habasit belt

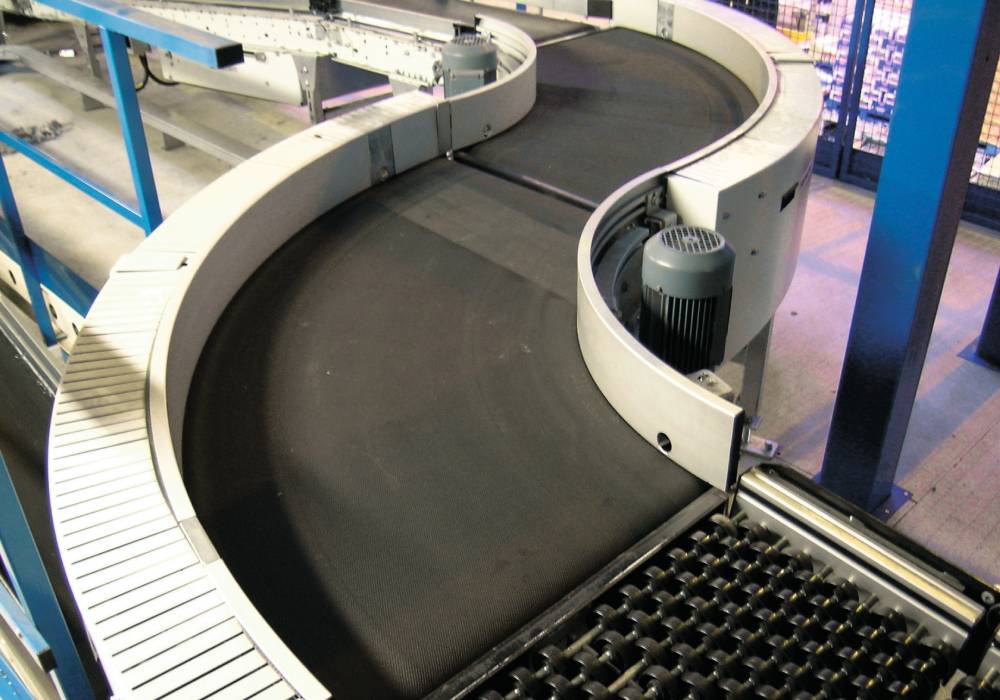

What Role Does Habasit Belt Play in Material Handling?

Habasit belts are widely utilized in automated sorting and distribution systems within the material handling industry. These belts enhance operational efficiency by facilitating smooth and reliable transport of goods, which is crucial for minimizing downtime in high-volume environments. For B2B buyers in emerging markets, sourcing durable belts that can withstand heavy loads and varying environmental conditions is essential for maintaining productivity and reducing maintenance costs.

How Does Habasit Belt Enhance Packaging Operations?

In packaging operations, Habasit belts are employed to transport products through various stages of packaging lines. Their ability to enhance product handling and reduce labor costs makes them a valuable asset in this industry. Buyers should consider customization options that accommodate different packaging types and ensure that the belts can integrate seamlessly with existing machinery, thus maximizing efficiency and minimizing disruptions.

What Advantages Does Habasit Belt Offer the Textile Industry?

The textile industry benefits from Habasit belts used in processes such as textile printing and fabric processing. These belts provide consistent tension and high durability, which are vital for maintaining quality in textile production. Buyers should focus on sourcing belts that exhibit resistance to wear and chemical exposure, as these properties are critical for ensuring longevity and reliability in demanding textile applications.

Why is Habasit Belt Important in the Automotive Sector?

In the automotive industry, Habasit power transmission belts are crucial for assembly line operations. They improve production speed and reliability, allowing manufacturers to meet increasing demand without compromising quality. When sourcing belts for automotive applications, businesses must consider compatibility with various machinery types and the ability to handle diverse load requirements, ensuring smooth and efficient production processes.

3 Common User Pain Points for ‘habasit belt’ & Their Solutions

Scenario 1: Inefficient Production Due to Belt Downtime

The Problem: In manufacturing environments, unexpected belt failures can halt production lines, causing significant losses in both time and revenue. A B2B buyer may find themselves grappling with frequent downtime due to the subpar quality of conveyor belts that do not withstand the rigors of their specific operational demands. These interruptions can be particularly detrimental in industries such as food processing or packaging, where efficiency and reliability are paramount.

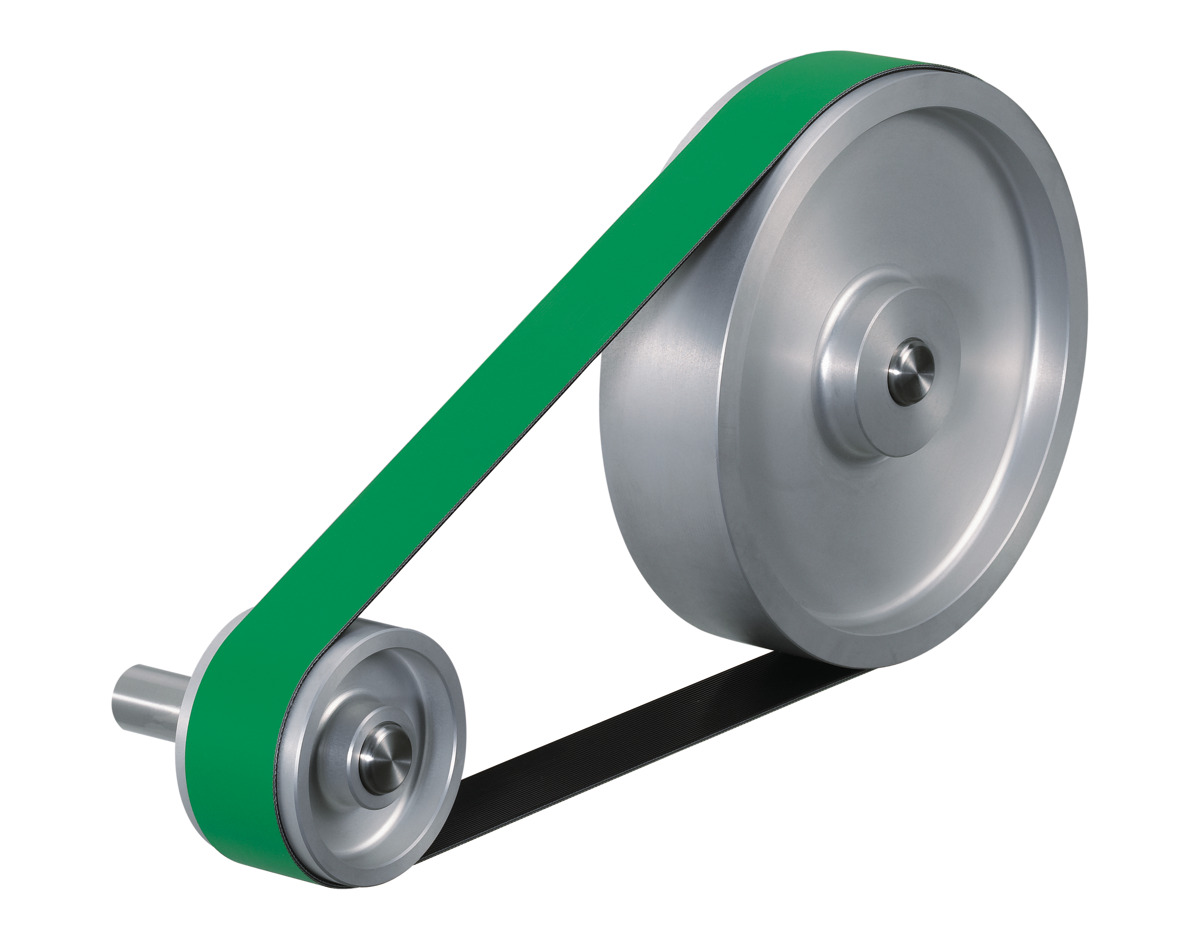

Illustrative image related to habasit belt

The Solution: To mitigate downtime, B2B buyers should focus on sourcing high-quality Habasit belts tailored to their operational needs. Begin by conducting a thorough analysis of the specific requirements of your production environment, including load capacities, temperature ranges, and exposure to various substances. Collaborate closely with Habasit’s representatives to identify the most suitable belt materials and designs that will enhance durability and performance. Implementing a routine maintenance schedule can also prevent unexpected failures. Regular inspections and timely replacements of worn-out belts will ensure consistent productivity and minimize disruptions.

Scenario 2: Difficulty in Belt Integration with Existing Systems

The Problem: Another common issue faced by B2B buyers is the challenge of integrating new Habasit belts into existing conveyor systems. Incompatibility can arise from different belt sizes, profiles, or connection methods, leading to inefficient operations and increased labor costs during installation. Buyers may experience frustration when their new belt fails to fit seamlessly into their established workflows, resulting in delays and additional expenses.

The Solution: To avoid integration issues, buyers should take proactive steps during the procurement process. Engage with Habasit’s technical support team to gain insights into the specific requirements for compatibility with existing systems. Utilize Habasit’s comprehensive selection of fabric-based and plastic modular belts, which can be customized to fit various applications. Before placing an order, ensure accurate measurements of the existing equipment and belt specifications. This diligence will facilitate a smoother installation process, thereby enhancing operational efficiency and reducing the likelihood of costly modifications.

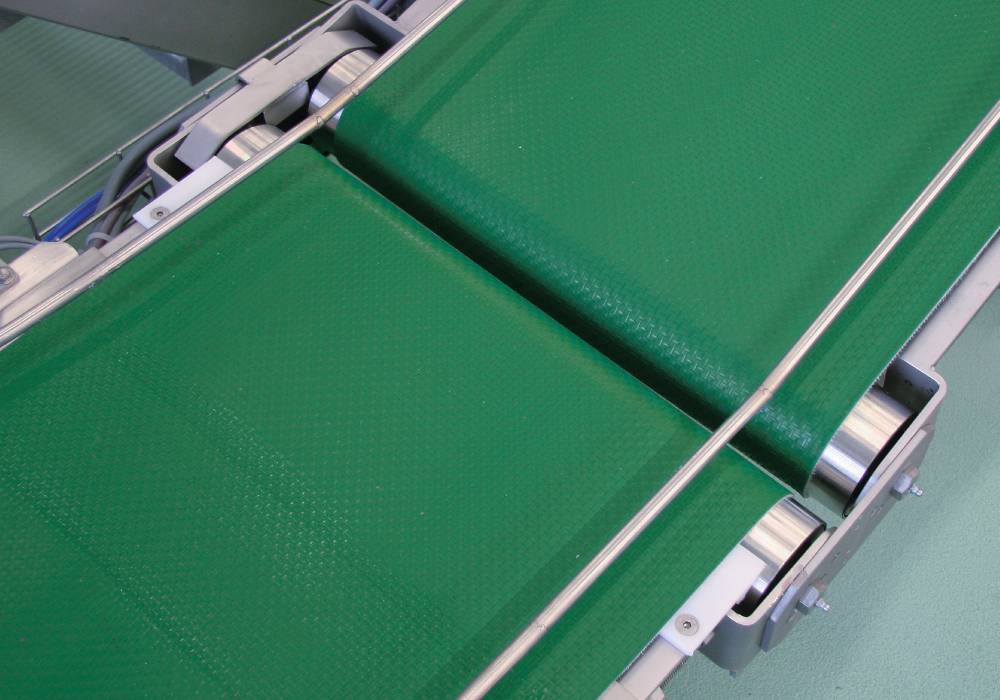

Illustrative image related to habasit belt

Scenario 3: Rising Energy Costs Impacting Operational Budgets

The Problem: As energy costs continue to rise, many B2B buyers are increasingly concerned about the energy efficiency of their operational processes. Conveyor systems powered by traditional belts may consume excessive energy, leading to inflated operational costs that can significantly impact the bottom line. This situation is particularly pressing for companies in regions with high energy prices, where every kilowatt saved can lead to substantial savings.

The Solution: Investing in energy-efficient Habasit belts can be a game changer for businesses looking to reduce their energy consumption. Habasit offers a range of belts designed with low-friction properties that not only enhance performance but also contribute to energy savings. B2B buyers should conduct a thorough energy audit of their conveyor systems to identify potential areas for improvement. By replacing conventional belts with Habasit’s innovative solutions, companies can reduce energy costs while maintaining high productivity levels. Additionally, buyers can explore the use of variable frequency drives (VFDs) in conjunction with these belts to optimize motor speeds and further enhance energy efficiency.

Strategic Material Selection Guide for habasit belt

What Are the Key Properties of Common Materials Used in Habasit Belts?

When selecting materials for Habasit belts, understanding the properties and suitability of each option is crucial for ensuring optimal performance in various applications. Below, we analyze four common materials used in Habasit belts, focusing on their key properties, advantages, limitations, and considerations for international B2B buyers.

Illustrative image related to habasit belt

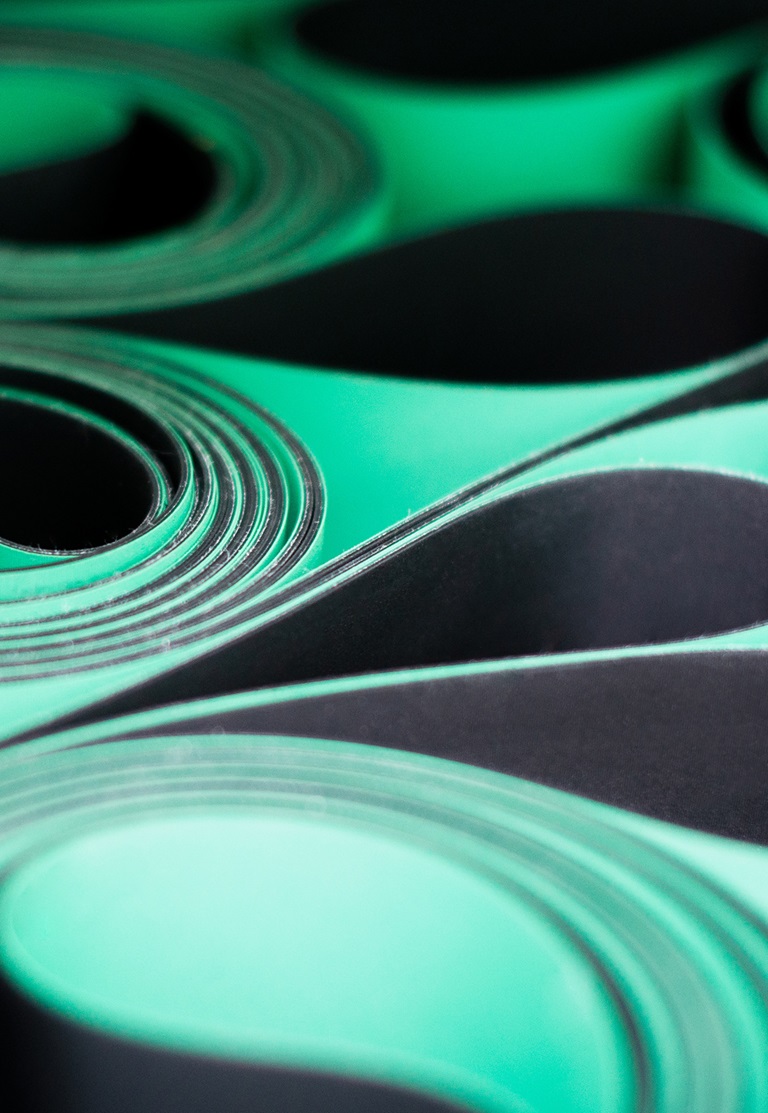

How Does Polyurethane (PU) Perform in Habasit Belts?

Polyurethane is known for its excellent abrasion resistance and flexibility, making it a popular choice for various conveyor applications. It typically operates effectively in temperature ranges from -30°C to +80°C, with some variants able to withstand even higher temperatures. The material also exhibits good chemical resistance, particularly against oils and greases.

Pros: Polyurethane belts are highly durable and provide a long service life, reducing the need for frequent replacements. They are also lightweight, which can lower energy consumption during operation.

Cons: The primary limitation of PU is its susceptibility to hydrolysis when exposed to water over extended periods, which can affect its longevity in wet environments. Additionally, the initial cost can be higher compared to other materials.

Impact on Application: PU belts are particularly suitable for food processing and packaging applications, where hygiene and resistance to contamination are paramount.

Illustrative image related to habasit belt

Considerations for International Buyers: Compliance with food safety standards (e.g., FDA, EU regulations) is critical for buyers in regions like Europe and North America. Buyers in Africa and South America should also consider local regulations regarding food safety.

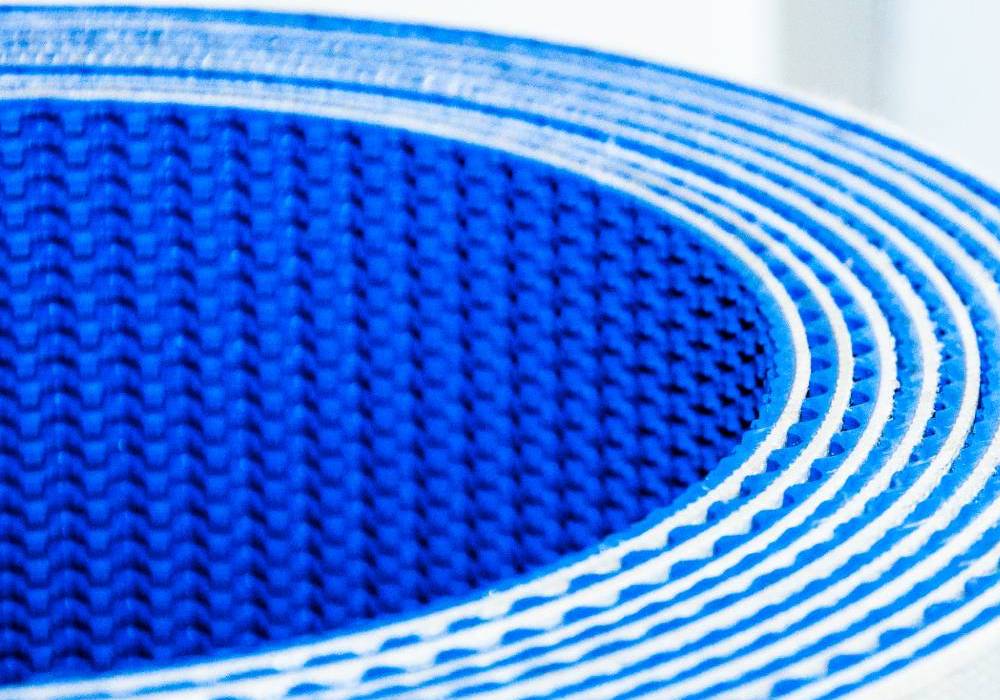

What Advantages Do PVC Belts Offer for Habasit Applications?

Polyvinyl chloride (PVC) is another widely used material for Habasit belts, known for its versatility and cost-effectiveness. PVC belts can typically handle temperatures from -10°C to +60°C and are resistant to a variety of chemicals, making them suitable for many industrial applications.

Pros: PVC belts are generally less expensive than PU options and offer good durability for standard applications. They also provide excellent grip, which is beneficial for inclined or vertical conveying.

Cons: However, PVC can become brittle over time, especially in extreme temperatures, and may not perform well in high-stress environments. Its chemical resistance is also not as robust as that of PU.

Illustrative image related to habasit belt

Impact on Application: PVC belts are commonly used in material handling, packaging, and light-duty applications, where cost and versatility are significant factors.

Considerations for International Buyers: Buyers should ensure that PVC belts meet local compliance standards, such as ASTM or DIN, especially in regions like Germany and Saudi Arabia, where regulatory scrutiny is high.

How Do Rubber Belts Compare in Terms of Performance?

Rubber belts are known for their exceptional durability and resistance to wear, making them ideal for heavy-duty applications. They can typically withstand temperatures ranging from -20°C to +70°C and are highly resistant to abrasion and impact.

Pros: The primary advantage of rubber belts is their ability to handle heavy loads and rough materials, making them suitable for construction and mining industries. They also provide excellent traction.

Cons: The downside is that rubber belts can be more expensive and heavier than other materials. Additionally, they may not be suitable for environments with high moisture levels, as rubber can degrade over time.

Illustrative image related to habasit belt

Impact on Application: Rubber belts are often used in the construction and automotive industries, where heavy loads and durability are critical.

Considerations for International Buyers: Buyers should consider the specific requirements of their industry, including compliance with safety standards and certifications relevant to their region.

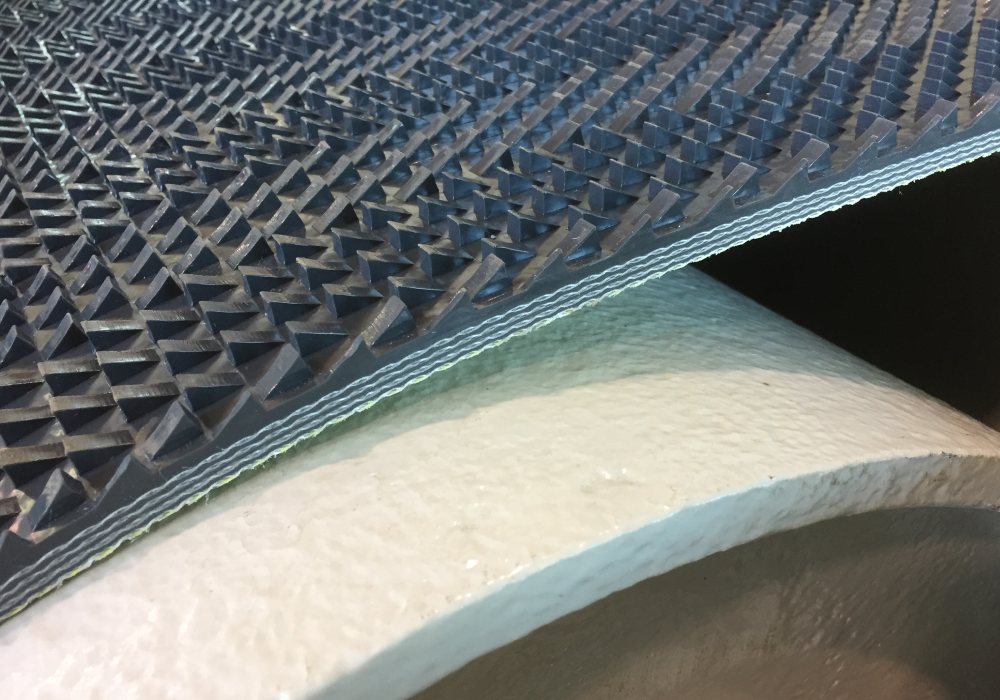

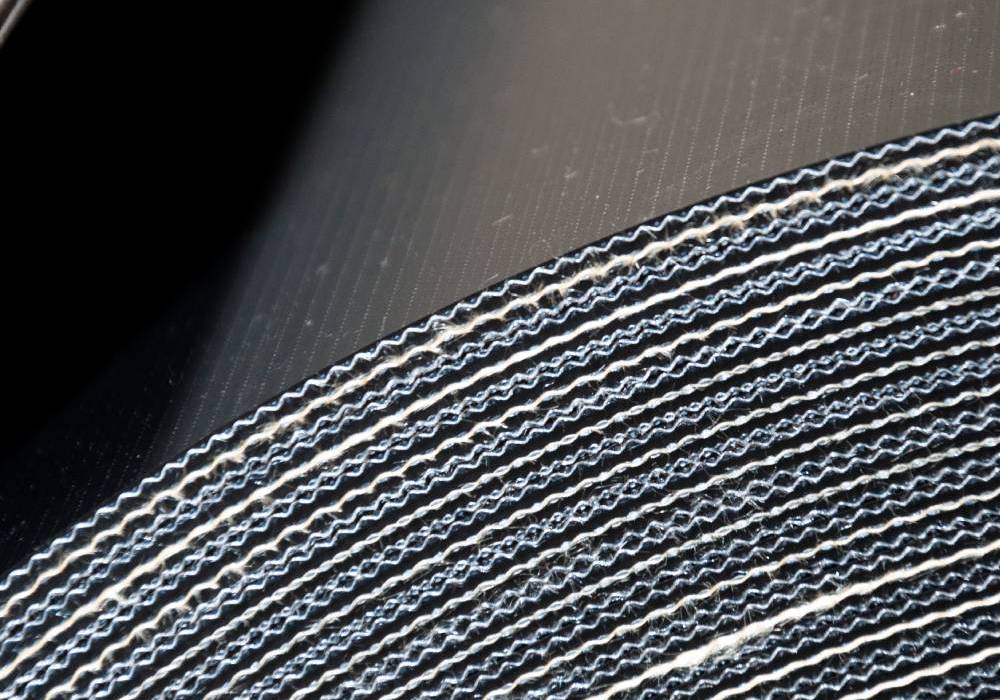

What Role Do Fabric-Based Belts Play in Habasit Solutions?

Fabric-based belts, often made from polyester or nylon, are designed for lightweight applications and can operate effectively in temperatures from -10°C to +70°C. They are known for their flexibility and ease of installation.

Pros: These belts are typically less expensive and easier to manufacture, making them suitable for a wide range of applications. They also offer good resistance to tearing.

Cons: The primary limitation is their lower durability compared to other materials, which may lead to more frequent replacements in high-stress applications.

Illustrative image related to habasit belt

Impact on Application: Fabric-based belts are ideal for light-duty applications, such as in the textile and food industries, where flexibility and cost-effectiveness are essential.

Considerations for International Buyers: Buyers should ensure that fabric-based belts comply with relevant industry standards, particularly in food processing, where hygiene is a priority.

Summary Table of Material Selection for Habasit Belts

| Material | Typical Use Case for habasit belt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane (PU) | Food processing, packaging | Excellent abrasion resistance | Susceptible to hydrolysis | Medium |

| Polyvinyl Chloride (PVC) | Material handling, packaging | Cost-effective and versatile | Can become brittle over time | Low |

| Rubber | Construction, automotive | Exceptional durability | Heavier and more expensive | High |

| Fabric-based | Textile, light-duty applications | Flexible and easy to install | Lower durability | Low |

This guide provides a comprehensive overview of material selection for Habasit belts, helping international B2B buyers make informed decisions tailored to their specific industry needs and regional compliance requirements.

Illustrative image related to habasit belt

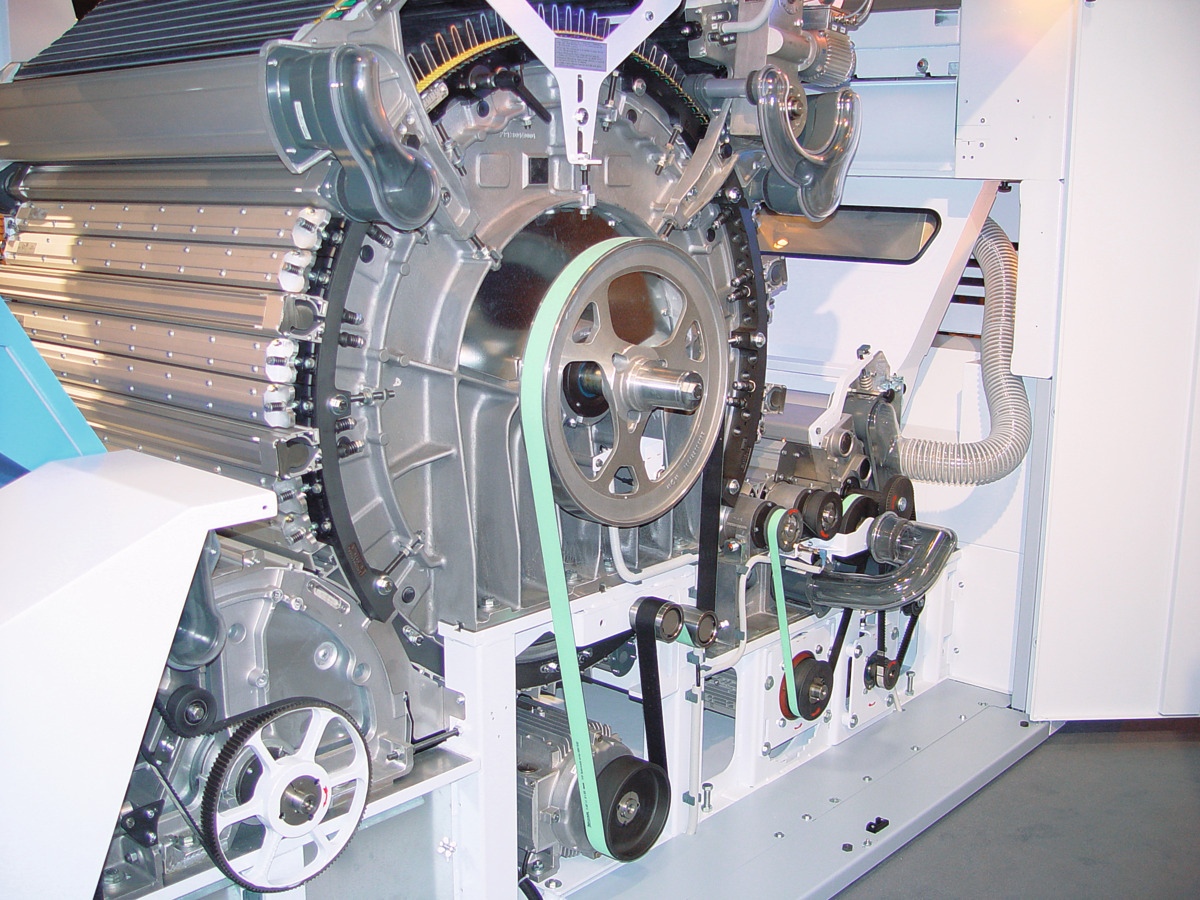

In-depth Look: Manufacturing Processes and Quality Assurance for habasit belt

What are the Main Stages in the Manufacturing Process of Habasit Belts?

The manufacturing process of Habasit belts is a meticulous journey that ensures high-quality outcomes tailored to diverse industrial applications. The primary stages include material preparation, forming, assembly, and finishing, each incorporating specific techniques to guarantee performance and reliability.

How is Material Prepared for Habasit Belts?

Material preparation is the first crucial step in manufacturing Habasit belts. This involves selecting high-grade raw materials, such as polyester and polyamide fabrics, which are known for their strength and durability. These materials undergo rigorous inspections to ensure they meet the required specifications before they are processed. Advanced techniques, such as weaving and coating, are employed to enhance properties like abrasion resistance and flexibility, making the belts suitable for various applications, from food processing to material handling.

What Techniques are Used in Forming Habasit Belts?

Once the materials are prepared, the forming stage begins. This involves cutting the fabric into specific dimensions and shapes according to the design requirements of the belt. Techniques such as molding and extrusion may be employed, depending on the type of belt being produced. For instance, plastic modular belts are often manufactured using injection molding, allowing for intricate designs and custom configurations that meet specific operational needs. The forming stage is critical, as it sets the foundation for the belt’s performance in real-world applications.

How are Habasit Belts Assembled?

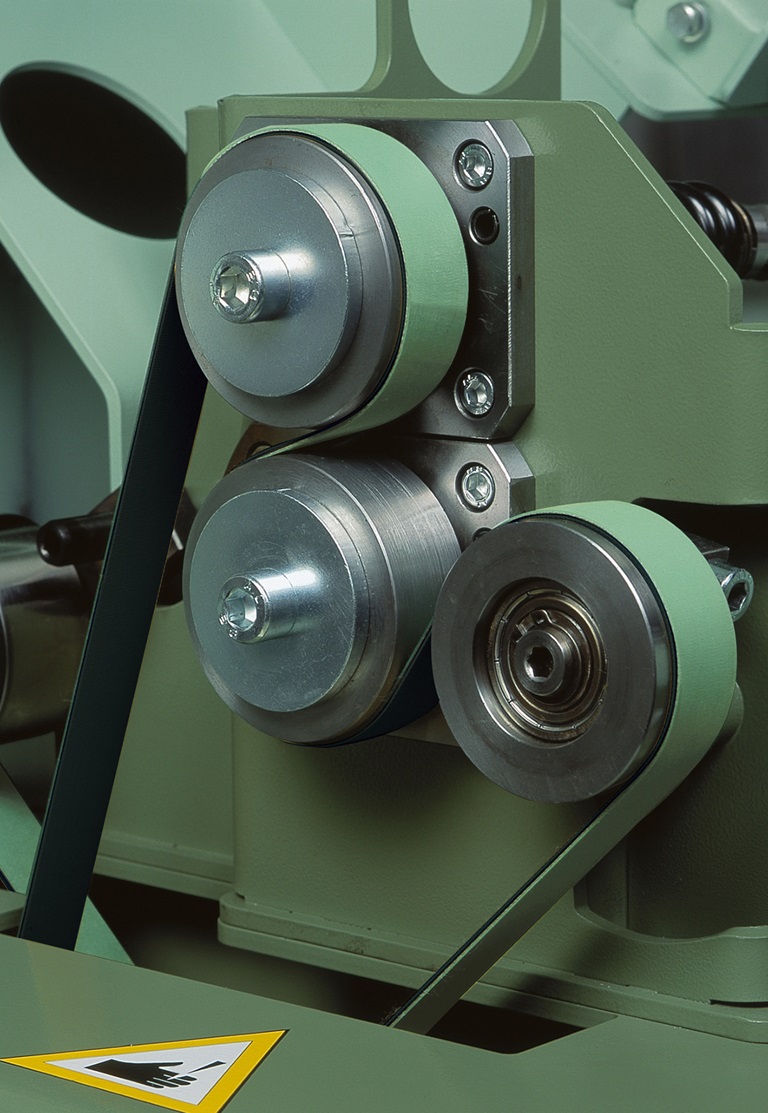

The assembly stage involves joining various components of the belt to create a functional product. Habasit utilizes several joining methods, including mechanical and thermal techniques, to ensure strong and reliable connections. The choice of joining method is pivotal, as it can significantly impact the belt’s operational efficiency and longevity. Quality control is integrated into this stage, where each joint is inspected for strength and durability before moving on to the finishing process.

Illustrative image related to habasit belt

What Finishing Techniques are Applied to Habasit Belts?

Finishing touches play a vital role in the final quality of Habasit belts. This stage includes surface treatments to enhance characteristics such as friction, grip, and resistance to various environmental factors. Techniques like coating with specialized compounds or applying anti-static treatments ensure that the belts perform optimally in their intended environments. Final inspections are conducted to confirm that the belts meet strict quality standards before they are packaged and shipped to customers.

How is Quality Assurance Managed for Habasit Belts?

Quality assurance is a cornerstone of Habasit’s manufacturing ethos, ensuring that every belt produced meets both international and industry-specific standards. The company adheres to ISO 9001, a globally recognized standard for quality management systems, which guides their processes from design through production and delivery.

What International Standards are Relevant for Habasit Belt Quality Assurance?

In addition to ISO 9001, Habasit complies with several other international standards relevant to specific industries. For instance, CE marking is essential for products sold within the European Economic Area, indicating compliance with health, safety, and environmental protection standards. In the automotive sector, standards like API (American Petroleum Institute) certification may apply, depending on the belt’s application. Understanding these certifications is crucial for B2B buyers to ensure that they are sourcing products that meet their regulatory requirements.

What are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are strategically integrated throughout the manufacturing process to maintain high standards. These include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing stages help identify any defects early, allowing for corrective actions.

- Final Quality Control (FQC): The final product undergoes rigorous testing to ensure it meets all performance and quality criteria before shipment.

Common testing methods include tensile strength tests, abrasion resistance tests, and dimensional accuracy assessments, ensuring that each belt can withstand the demands of its intended application.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential for ensuring product reliability. Here are several actionable strategies:

-

Conduct Supplier Audits: Regular audits of suppliers can help assess their quality management systems and manufacturing capabilities. This can include reviewing their compliance with international standards and their internal quality control processes.

-

Request Quality Reports: Buyers should ask suppliers for detailed quality assurance reports that outline their testing methodologies and results. This transparency can build trust and provide insights into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of the manufacturing processes and quality assurance practices. This is especially important for buyers in regions with varying regulatory environments.

-

Understand Quality Certification Nuances: Different regions may have specific certifications or compliance requirements. B2B buyers should familiarize themselves with these nuances to ensure that the belts they purchase are compliant with local regulations and standards.

-

Utilize Technology for Transparency: Many modern suppliers leverage technology to provide real-time data on manufacturing processes and quality metrics. Buyers can benefit from platforms that offer visibility into the production lifecycle, facilitating informed decision-making.

Conclusion

In summary, the manufacturing processes and quality assurance practices employed by Habasit are designed to ensure that their belts meet the highest standards of performance and reliability. By understanding the intricacies of these processes, B2B buyers can make informed purchasing decisions, ensuring that they select the right products for their operational needs. Whether through direct engagement with suppliers, audits, or leveraging technology, buyers can effectively navigate the complexities of sourcing high-quality belts in today’s global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘habasit belt’

Introduction

Sourcing a Habasit belt requires a structured approach to ensure that you select the right product and supplier for your specific needs. This checklist will guide B2B buyers through the essential steps to procure Habasit belts efficiently, ensuring quality, reliability, and cost-effectiveness in your operations.

Step 1: Define Your Technical Specifications

Before initiating your search, clearly outline the technical specifications required for your application. This includes belt type, size, load capacity, and material compatibility. Knowing these details helps streamline the sourcing process and ensures you select a belt that meets your operational demands.

Illustrative image related to habasit belt

- Belt Type: Determine if you need a fabric-based conveyor belt, modular belt, or a timing belt based on your application.

- Load Capacity: Assess the weight and type of materials the belt will carry to avoid premature wear or failure.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in Habasit belts. Look for companies with a solid reputation and extensive industry experience. This step is crucial to ensure you partner with a reliable supplier capable of meeting your needs.

- Reputation: Check online reviews, testimonials, and case studies from other businesses in your industry.

- Industry Experience: Prefer suppliers with a proven track record in your specific sector, whether it be food processing, automotive, or packaging.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications that guarantee product quality and compliance with international standards. This step is vital for ensuring that the belts you procure are safe and reliable.

- Quality Standards: Look for certifications like ISO 9001, which indicate a commitment to quality management.

- Industry Compliance: Ensure the supplier complies with specific regulations relevant to your industry, especially for food-related applications.

Step 4: Request Samples for Testing

Before finalizing your order, request samples of the Habasit belts you are considering. Testing samples in your operational environment is essential to assess their performance and compatibility.

Illustrative image related to habasit belt

- Performance Testing: Evaluate factors like durability, flexibility, and resistance to wear and tear.

- Compatibility Checks: Ensure the belt integrates seamlessly with your existing machinery and processes.

Step 5: Analyze Pricing and Payment Terms

Once you have selected a few potential suppliers, compare their pricing structures and payment terms. This step is essential for budgeting and financial planning.

- Total Cost of Ownership: Consider not just the upfront cost but also maintenance and operational costs associated with the belt.

- Payment Flexibility: Look for suppliers offering favorable payment terms that align with your cash flow requirements.

Step 6: Check Delivery and Lead Times

Inquire about delivery schedules and lead times for your order. This is critical to ensure that your production timelines are met without unnecessary delays.

- Lead Time: Confirm how long it will take to receive your belts once the order is placed.

- Shipping Options: Explore various shipping methods to find the most cost-effective and timely solutions.

Step 7: Establish Communication Channels

Ensure that you have clear communication channels with your supplier for ongoing support and inquiries. Establishing a strong relationship is crucial for future needs and troubleshooting.

Illustrative image related to habasit belt

- Dedicated Account Manager: Having a point of contact can streamline communication and enhance service.

- Support Availability: Confirm the supplier’s responsiveness for queries and support during and after the purchasing process.

Following this checklist will empower you to make informed decisions when sourcing Habasit belts, enhancing your operational efficiency and reliability.

Comprehensive Cost and Pricing Analysis for habasit belt Sourcing

What Are the Key Cost Components in Habasit Belt Sourcing?

When sourcing Habasit belts, understanding the cost structure is essential for making informed purchasing decisions. The primary components of cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly impacts the cost of Habasit belts. Options vary from fabric-based to plastic modular belts, each with its unique pricing based on quality and performance characteristics. Higher-grade materials, such as those designed for the food and beverage industry, typically incur greater costs due to their specialized properties.

-

Labor and Manufacturing Overhead: Labor costs include wages for skilled workers involved in the production process. Manufacturing overhead encompasses utilities, maintenance, and other indirect costs associated with production. Efficient production processes can help mitigate these costs, leading to more competitive pricing.

-

Tooling and Quality Control: Custom tooling for specific applications adds to initial costs but is crucial for ensuring product reliability. Quality control measures, including testing and certification, are necessary to meet industry standards, particularly for sectors like automotive and food processing, where safety is paramount.

-

Logistics: Transportation and warehousing costs must also be factored in. These costs can vary based on the shipping method, distance, and whether the supplier uses cost-effective logistics partners.

-

Margin: Suppliers will include a margin in their pricing to cover business operations and profit. Understanding the typical margins in the industry can help buyers negotiate better deals.

What Factors Influence Pricing for Habasit Belts?

Several factors influence the pricing of Habasit belts, which B2B buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for bulk discounts, making it crucial to assess the volume needed for operations. Suppliers may impose MOQs that can affect pricing flexibility.

-

Specifications and Customization: Custom belts tailored to specific applications or industry requirements may incur higher costs due to additional design and production efforts. Buyers should evaluate the necessity of customization against its benefits.

-

Quality and Certifications: The presence of industry certifications (e.g., ISO, FDA) can affect pricing. Higher quality and certified products often justify a premium price due to the assurance of performance and compliance.

-

Supplier Factors: Supplier reputation, reliability, and location play a vital role in pricing. Established suppliers with a track record may charge more but can offer better service and product quality.

-

Incoterms: Understanding the agreed Incoterms (International Commercial Terms) is crucial as they determine who is responsible for shipping costs and risks. This can significantly influence the total landed cost of the belts.

What Tips Can Help Buyers Optimize Costs in Habasit Belt Sourcing?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency in sourcing Habasit belts:

-

Effective Negotiation: Engage suppliers in discussions about pricing, especially when placing large orders. Understanding the supplier’s cost structure can provide leverage in negotiations.

-

Total Cost of Ownership (TCO): Assess the TCO rather than just the upfront cost. Consider factors like durability, maintenance, and energy consumption to make a well-rounded decision. A cheaper belt may lead to higher long-term costs due to frequent replacements or repairs.

-

Leverage Technology: Utilize procurement software and tools to compare prices and suppliers efficiently. This can help identify the best deals and streamline the ordering process.

-

Stay Informed About Market Trends: Keeping abreast of market dynamics can provide insights into pricing trends and potential supply chain issues, enabling better decision-making.

-

Consider Local Suppliers: In some regions, local suppliers may offer competitive pricing with reduced shipping costs and faster delivery times, enhancing overall cost-efficiency.

Conclusion

When sourcing Habasit belts, understanding the intricate cost structure and pricing influences is vital for making cost-effective decisions. By considering these factors and employing strategic sourcing practices, buyers can optimize their procurement processes and achieve better value for their investments. Always remember that indicative prices may vary, and it’s advisable to conduct thorough market research before finalizing purchases.

Illustrative image related to habasit belt

Alternatives Analysis: Comparing habasit belt With Other Solutions

Understanding Alternative Solutions to Habasit Belts

In the competitive landscape of industrial applications, selecting the right belt solution is crucial for optimizing performance and operational efficiency. While Habasit belts are renowned for their quality and versatility across various industries, it is beneficial for B2B buyers to consider alternative solutions that may better align with their specific needs. Below, we explore two viable alternatives, examining key aspects that influence decision-making.

Comparison Table

| Comparison Aspect | Habasit Belt | Alternative 1: PVC Conveyor Belt | Alternative 2: Modular Plastic Belt |

|---|---|---|---|

| Performance | High durability and reliability; suitable for diverse applications | Moderate durability; good for lightweight materials | Excellent modularity; allows for quick repairs |

| Cost | Premium pricing reflecting quality and customization | Lower initial cost; may require more frequent replacements | Mid-range; cost-effective for large systems |

| Ease of Implementation | Requires specialized knowledge for installation | Straightforward installation process | Moderate complexity; may need skilled labor |

| Maintenance | Low maintenance due to robust design | Higher maintenance needs; prone to wear | Low maintenance; easy to replace individual modules |

| Best Use Case | Heavy-duty applications in food, packaging, and automotive industries | General-purpose use in light material handling | Ideal for complex layouts and applications requiring frequent cleaning |

Detailed Breakdown of Alternatives

1. PVC Conveyor Belt

PVC conveyor belts are an economical alternative to Habasit belts, primarily used in light to moderate material handling applications. They offer a lower upfront cost, making them attractive for businesses operating on tight budgets. However, their performance can be inconsistent, especially under heavy loads or harsh conditions. Maintenance can become a concern as they wear more quickly than Habasit belts, necessitating more frequent replacements. For operations that do not require the durability of high-end belts, PVC may suffice.

2. Modular Plastic Belt

Modular plastic belts are designed for flexibility and ease of maintenance, making them a solid alternative for certain industrial applications. Their modular nature allows for quick replacements of damaged sections, reducing downtime. These belts excel in environments where cleaning is essential, such as food processing, due to their ability to be disassembled easily. However, the initial complexity of installation can be a barrier, as it may require skilled labor to ensure proper setup. Additionally, while they are cost-effective for larger systems, their overall durability may not match that of Habasit belts in demanding applications.

Making the Right Choice for Your Business Needs

When evaluating belt solutions, B2B buyers should carefully consider their specific operational requirements, including the types of materials being handled, the environment in which the belts will operate, and budget constraints. Habasit belts stand out for their exceptional reliability and performance in heavy-duty applications, making them a worthwhile investment for industries like food processing and automotive. In contrast, PVC and modular plastic belts may be more suitable for lighter applications or where cost is a significant factor. Ultimately, the right choice will depend on a comprehensive assessment of performance needs, maintenance capabilities, and long-term operational goals.

Essential Technical Properties and Trade Terminology for habasit belt

What Are the Essential Technical Properties of Habasit Belts?

When selecting Habasit belts for your operations, understanding their technical properties is crucial to ensure optimal performance and longevity. Here are some key specifications to consider:

Illustrative image related to habasit belt

-

Material Grade: Habasit belts are crafted from various materials, including polyurethane, PVC, and rubber. Each material grade is tailored for specific applications, impacting the belt’s durability, flexibility, and resistance to wear. B2B buyers must choose the appropriate material based on the operational environment, such as food processing or heavy-duty industrial applications.

-

Belt Width and Length Tolerance: Precision in dimensions is vital. The tolerance levels for belt width and length define how closely the actual measurements align with specified values. For example, a tighter tolerance can lead to more efficient machine operation and reduced downtime. Buyers should assess their machinery requirements to ensure proper fit and functionality.

-

Belt Thickness: The thickness of a Habasit belt influences its load-bearing capacity and flexibility. Thicker belts typically offer greater strength and resistance to deformation, making them suitable for heavy loads. Understanding the specific load requirements of your application can guide the selection of the appropriate belt thickness.

-

Temperature Resistance: Habasit belts are designed to operate effectively within specific temperature ranges. Knowing the temperature limits is essential, especially in industries like food and beverage, where high temperatures can compromise belt integrity. Selecting belts that can withstand the operational temperature is critical to prevent failures and ensure consistent production.

-

Surface Texture: The surface texture of a belt can enhance its grip and influence product handling. Habasit offers various surface finishes, from smooth to textured options, tailored to different materials and products. Buyers should consider the nature of the products being transported and choose the appropriate surface texture to minimize slippage and damage.

Which Trade Terms Are Commonly Used in the Habasit Belt Industry?

Familiarizing yourself with industry jargon is essential for effective communication and negotiation in the B2B space. Here are several common terms related to Habasit belts:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce equipment and components that are used in other companies’ end products. When sourcing Habasit belts, knowing whether your supplier is an OEM can indicate the quality and compatibility of the belts with your machinery.

-

MOQ (Minimum Order Quantity): MOQ is the smallest amount of product that a supplier is willing to sell. Understanding the MOQ for Habasit belts can help businesses gauge their purchasing power and manage inventory effectively. Buyers should ensure that the MOQ aligns with their operational needs to avoid overstocking or stockouts.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing and terms for specific products. In the context of Habasit belts, issuing an RFQ allows buyers to compare costs, lead times, and terms from different suppliers, facilitating informed decision-making.

-

Incoterms (International Commercial Terms): These are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers to understand their obligations and rights in transactions involving Habasit belts.

-

Lead Time: This term refers to the time taken from placing an order to its delivery. In industries where operational efficiency is critical, understanding lead times for Habasit belts can help in planning and maintaining production schedules.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing Habasit belts, ensuring that they select the right products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the habasit belt Sector

What Are the Key Market Dynamics Influencing the Habasit Belt Sector?

The global market for Habasit belts is experiencing significant transformation driven by several key factors. Firstly, the rising demand for automation across various industries, particularly in manufacturing and logistics, is propelling the need for efficient conveyor and power transmission solutions. Countries in Africa, South America, and the Middle East are increasingly investing in modernizing their infrastructure, which is leading to a surge in demand for high-quality belting solutions that enhance productivity and reduce operational costs. In Europe, particularly in Germany, the push for Industry 4.0 is further accelerating the adoption of advanced conveyor systems, necessitating innovative and customizable belt solutions.

Emerging technologies such as IoT and AI are reshaping sourcing trends in the Habasit belt sector. B2B buyers are increasingly looking for suppliers who can provide integrated solutions that leverage these technologies for predictive maintenance and operational efficiency. Additionally, the trend toward digital procurement processes, including the use of e-commerce platforms for sourcing, is gaining traction, enabling buyers to streamline their purchasing processes and improve supply chain transparency.

Illustrative image related to habasit belt

How Is Sustainability and Ethical Sourcing Shaping the Habasit Belt Market?

Sustainability is becoming a crucial consideration for B2B buyers in the Habasit belt sector. As companies face increasing pressure from consumers and regulatory bodies to minimize their environmental impact, the demand for sustainable and ethically sourced materials is on the rise. The use of eco-friendly materials, such as recycled plastics and biodegradable options, is gaining traction among manufacturers who wish to align their products with sustainability goals.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing their suppliers’ practices, seeking certifications that validate environmentally responsible production methods. For example, certifications like ISO 14001, which focuses on effective environmental management systems, are becoming essential for suppliers aiming to establish credibility and trust with their B2B clients. By prioritizing suppliers with green certifications, companies not only enhance their brand reputation but also contribute positively to the environment.

What Is the Historical Context of the Habasit Belt Sector?

The Habasit belt sector has evolved significantly since the company’s inception in 1946 in Basel, Switzerland. Initially focused on providing basic conveyor solutions, Habasit has expanded its offerings to include a diverse range of fabric-based conveyor belts, plastic modular belts, and specialized power transmission belts. The company’s commitment to innovation and quality has enabled it to establish a strong global presence, operating in over 70 countries.

Illustrative image related to habasit belt

Historically, the sector has seen shifts in focus from traditional manufacturing to more specialized applications, driven by advancements in technology and changing customer needs. As industries evolved, so did the requirements for more efficient, durable, and customizable belting solutions. Today, Habasit stands as a leader in providing tailored solutions that meet the diverse demands of various sectors, including food and beverage, packaging, and automotive, highlighting its adaptability and commitment to customer satisfaction in a competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of habasit belt

1. How do I solve issues related to belt performance in my production line?

To address performance issues with Habasit belts, start by assessing the specific problem, such as slippage, wear, or misalignment. Ensure that the belt is compatible with your application requirements, including load capacity and environmental conditions. Regular maintenance and proper tension adjustments can mitigate many performance issues. If problems persist, consulting with Habasit’s technical support can provide tailored solutions and recommendations based on their extensive industry expertise.

2. What is the best type of Habasit belt for food processing applications?

For food processing, the best choice is often a fabric-based conveyor belt that meets hygiene standards and offers durability. Habasit provides belts designed specifically for food applications, featuring non-porous surfaces and easy cleaning capabilities. It’s essential to select a belt that can withstand the specific temperatures and chemicals used in your processing environment. Consulting with Habasit’s specialists can ensure you choose the most suitable belt for your food handling needs.

Illustrative image related to habasit belt

3. How can I customize Habasit belts to fit my specific operational needs?

Habasit offers extensive customization options for their belts, including material selection, size adjustments, and specific surface treatments. To initiate the customization process, provide detailed specifications regarding your application, including load types, environmental factors, and any unique operational challenges. Their engineering team can then collaborate with you to design a belt that meets your precise requirements, ensuring optimal performance and longevity.

4. What is the minimum order quantity (MOQ) for Habasit belts?

The minimum order quantity for Habasit belts can vary depending on the specific product and customization options. Generally, standard products may have lower MOQs, while customized solutions may require larger orders. It’s advisable to reach out directly to a Habasit representative or authorized distributor to discuss your needs and obtain precise information regarding MOQs for your desired belts.

5. What payment terms should I expect when sourcing Habasit belts internationally?

Payment terms for international orders of Habasit belts typically include options such as advance payment, letter of credit, or net payment terms based on your creditworthiness. Terms can vary by region and specific agreements with distributors. It’s important to clarify payment options with your supplier upfront to ensure smooth transactions and avoid potential delays in order fulfillment.

Illustrative image related to habasit belt

6. How does Habasit ensure quality assurance for their belts?

Habasit maintains rigorous quality assurance protocols throughout their manufacturing process. This includes raw material testing, in-process inspections, and final product evaluations to ensure compliance with international standards. Certifications such as ISO 9001 underline their commitment to quality. For added assurance, buyers can request specific quality documentation or certifications relevant to their industry needs.

7. What logistics options are available for shipping Habasit belts to my region?

Habasit offers various logistics solutions tailored to international shipping, including air freight and sea freight options. Delivery times and costs can depend on your location and the volume of your order. It’s beneficial to discuss logistics with your supplier to determine the most efficient and cost-effective shipping method, including tracking options and customs clearance support to ensure timely delivery.

8. How can I vet suppliers of Habasit belts before making a purchase?

To vet suppliers, research their reputation in the industry by checking reviews, testimonials, and case studies. Ask for references from existing clients to gauge their reliability and service quality. Additionally, assess their experience with Habasit products and their capability to provide technical support and customization options. Engaging in a direct conversation to clarify your needs and understanding their response time can further ensure you’re partnering with a competent supplier.

Illustrative image related to habasit belt

Top 3 Habasit Belt Manufacturers & Suppliers List

1. Habasit – Belting Solutions

Domain: habasit.com

Registered: 1999 (26 years)

Introduction: Habasit offers a wide range of belting solutions including fabric-based conveyor belts, plastic modular belts and chains, power transmission belts, monolithic belts, and timing belts. Their products are tailored for various industries such as Food and Beverage, Material Handling, Packaging, Textile, Paper, Automotive, and Construction. Key features include high reliability, long service life, ener…

2. Habasit – Flat Belts and Conveyor Solutions

Domain: us.misumi-ec.com

Registered: 2007 (18 years)

Introduction: Habasit Flat Belts: 1. Conveyor Belts – TPU, Light Duty, Green, HNB-8E Series: Number Of Plies: 2-ply, Surface Cover Color: Green, Surface Cover Shape: Flat, Surface Cover Material: Polyurethane, Tension Member Material: Polyester, Ships as soon as 12 Days. 2. Conveyor Belts – NBR, Paper Processing Belt, Green, HAM-5P Series: Belt Specification: General Purpose, Number Of Plies: 3-ply, Surface Cov…

3. Habasit – Conveyor Belting Solutions

Domain: beltpower.com

Registered: 1998 (27 years)

Introduction: Habasit offers a wide range of belting products including: Conveyor Belting (Lightweight, Food Conveyor Belting – FDA, USDA, AAA Dairy, General, Incline), Machine Tapes, Power Transmission Conveyor Belting, Airport/Distribution Conveyor Belting, Modular Belting, Modular Plastic Belting, Table Top Conveyor Chains, Wire Belting, Timing/Drive Belts, Extruded Profiles, Round Belts, Rubber Drive Belts,…

Strategic Sourcing Conclusion and Outlook for habasit belt

In the ever-evolving landscape of industrial solutions, the strategic sourcing of Habasit belts stands as a crucial factor for businesses aiming to enhance operational efficiency. Buyers across Africa, South America, the Middle East, and Europe can leverage Habasit’s extensive range of conveyor and power transmission belts, designed for diverse industries such as food and beverage, packaging, automotive, and textiles. By prioritizing high-quality products and tailored solutions, companies can not only optimize productivity but also significantly reduce maintenance costs, ensuring a reliable supply chain.

Investing in Habasit belts means committing to sustainability and efficiency, as these products are engineered for long service life and reduced energy consumption. As global demand for high-performance solutions continues to rise, now is the time to engage with Habasit’s innovative offerings.

International B2B buyers are encouraged to explore partnerships with Habasit to unlock the potential for growth and operational excellence in their respective markets. Embrace the opportunity to enhance your production capabilities—contact Habasit today and take the first step towards a more efficient future.

Illustrative image related to habasit belt

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.