A B2B Buyer’s Guide to Grounding Brush: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for grounding brush

In the complex landscape of industrial procurement, sourcing effective grounding brushes can pose a significant challenge for international B2B buyers. Grounding brushes are essential components for preventing static electricity buildup and protecting equipment from electrical damage, particularly in high-stakes industries like aerospace, automotive, and renewable energy. With a diverse array of types, materials, and applications available, understanding the nuances of grounding brushes is crucial for making informed purchasing decisions.

This comprehensive guide delves into the various types of grounding brushes, their specific applications, and the critical factors to consider when vetting suppliers. Buyers will learn about the importance of material selection, the role of grounding brushes in enhancing operational efficiency, and how to assess cost implications without compromising quality. Additionally, we provide insights tailored to the unique market dynamics in regions such as Africa, South America, the Middle East, and Europe, including countries like Brazil and Nigeria.

By leveraging the insights and actionable strategies outlined in this guide, B2B buyers will be empowered to navigate the global market with confidence, ensuring that they procure the right grounding brushes that meet their operational needs while adhering to regional standards and expectations. This guide aims to streamline the purchasing process, making it easier to identify reliable suppliers and optimize procurement strategies for grounding brushes.

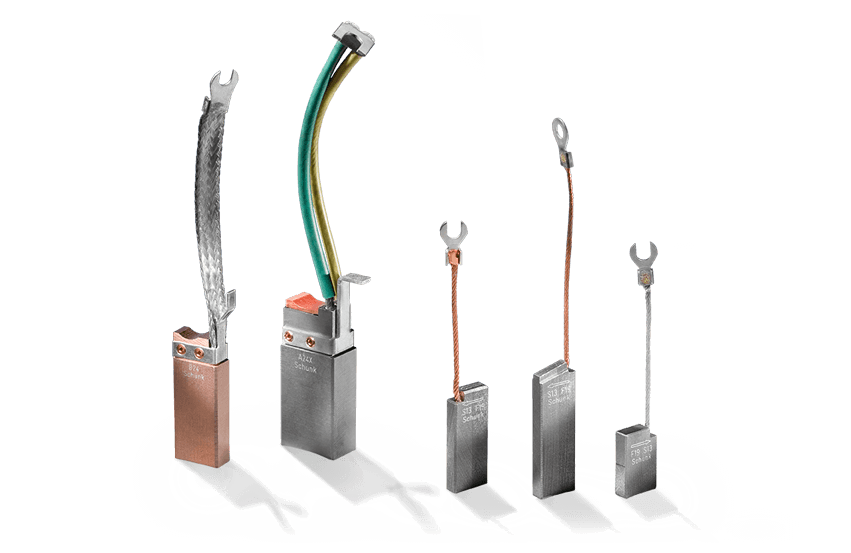

Understanding grounding brush Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Carbon Grounding Brush | Made from metal-graphite grades; high conductivity | Electric locomotives, wind turbines, hydro plants | Pros: Excellent conductivity; durable. Cons: Can be more expensive than alternatives. |

| Shaft Grounding Brush | Specifically designed for rotating shafts; low resistance | Motors, generators, and industrial machinery | Pros: Reduces wear on bearings; reliable. Cons: Limited to specific applications. |

| ESD Grounding Brush | Anti-static properties; suitable for cleanroom use | Electronics manufacturing, cleanrooms | Pros: Prevents static discharge; safe for sensitive components. Cons: May not be suitable for high-current applications. |

| Specialty Grounding Brush | Custom designs available; varied fill materials | Aerospace, military, and specialized equipment | Pros: Tailored solutions; high performance. Cons: Longer lead times for custom orders. |

| Lightning Protection Brush | Designed to dissipate lightning strikes; robust materials | Telecommunications, outdoor installations | Pros: Enhances safety; protects equipment. Cons: Higher cost due to specialized materials. |

What Are the Characteristics of Carbon Grounding Brushes?

Carbon grounding brushes are engineered from metal-graphite composites, providing exceptional electrical conductivity and longevity. These brushes are primarily used in applications such as electric locomotives, wind turbines, and hydroelectric plants, where they effectively prevent stray currents that can damage equipment. When purchasing, buyers should consider the specific conductivity needs of their applications and the potential for higher costs compared to other brush types, which may be offset by their durability and efficiency.

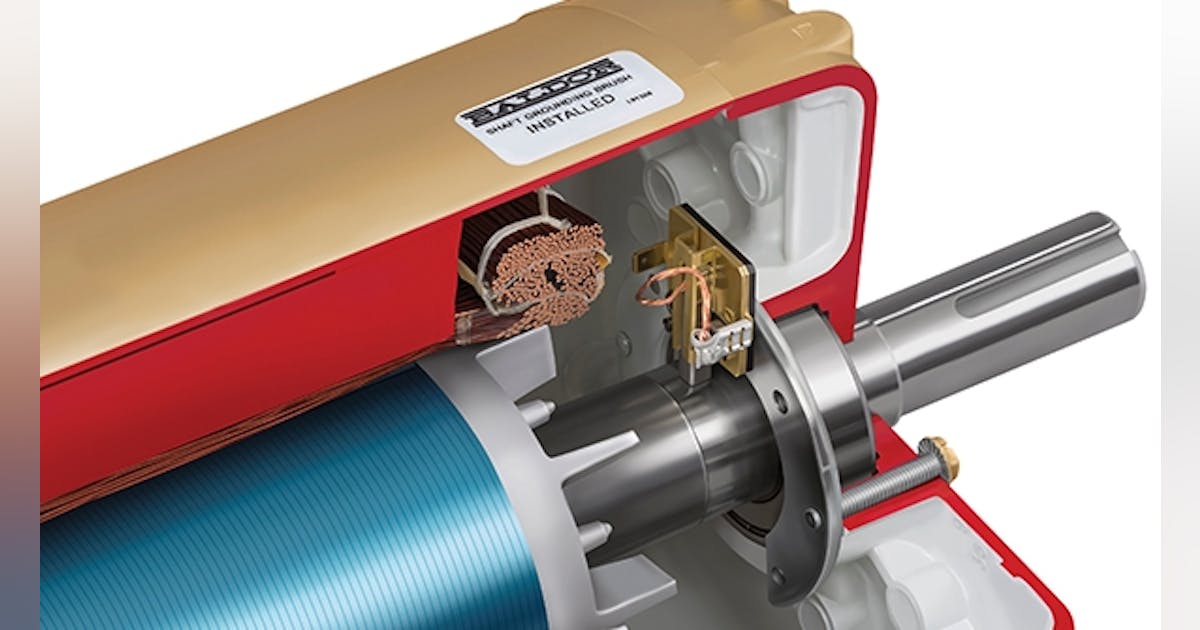

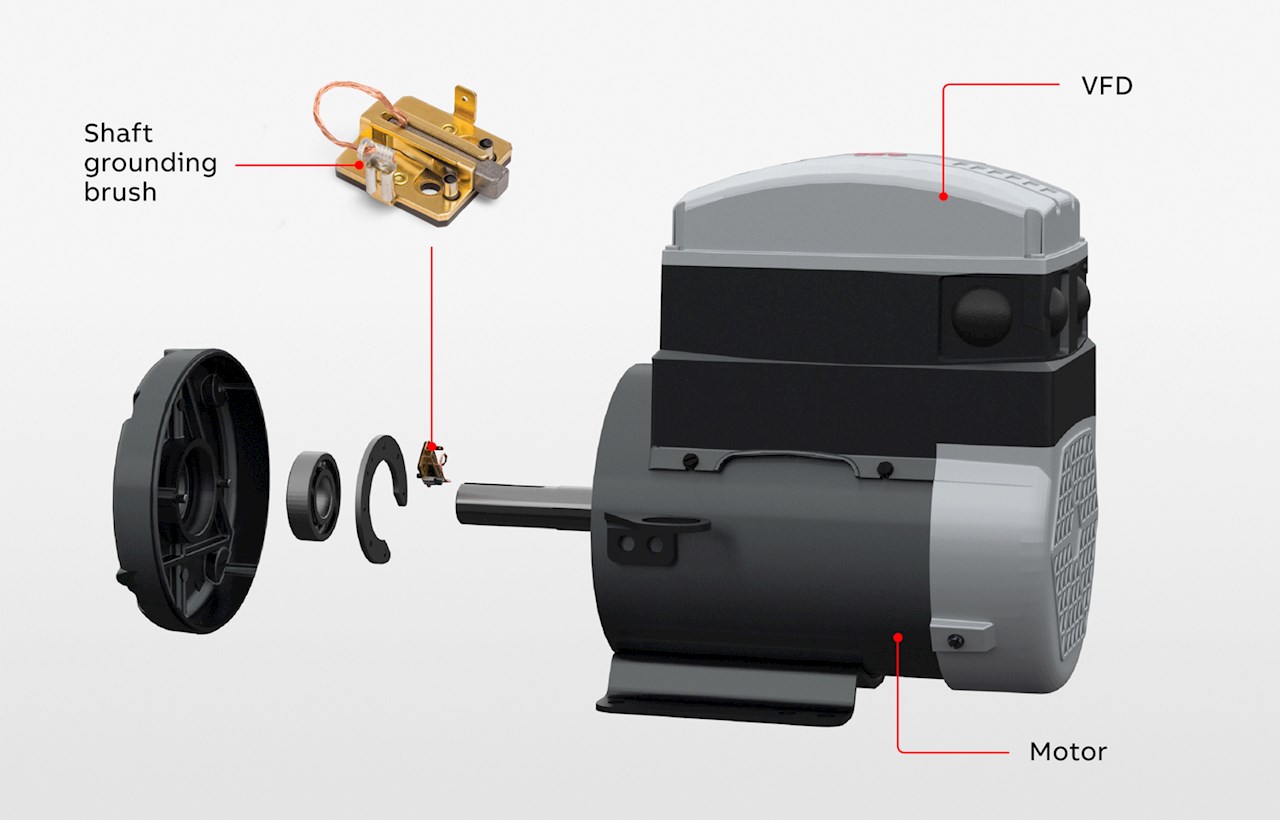

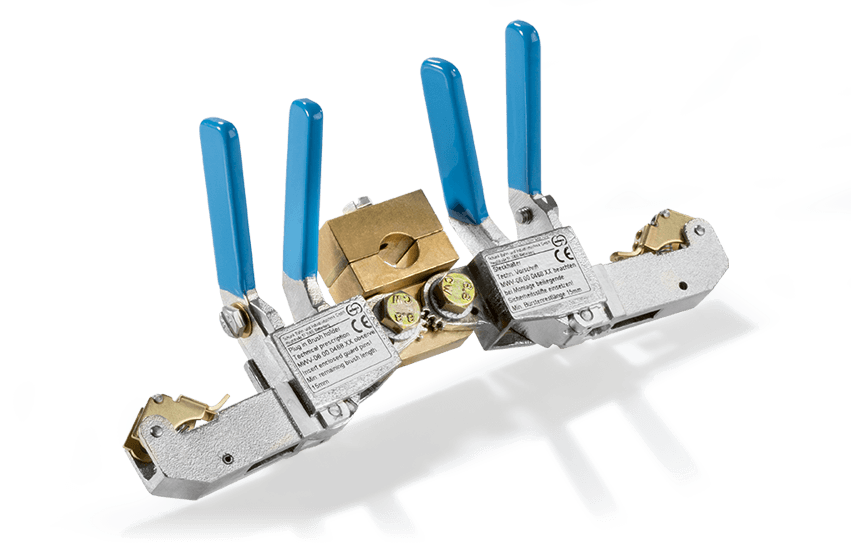

How Do Shaft Grounding Brushes Differ from Other Types?

Shaft grounding brushes are specifically designed for rotating shafts, offering low resistance paths to ground, thereby minimizing electrical wear on motor bearings. Commonly found in motors and generators, these brushes play a crucial role in extending the lifespan of machinery. Buyers should evaluate the compatibility of these brushes with their existing equipment and consider the importance of reducing maintenance costs through their use, despite their limited application scope.

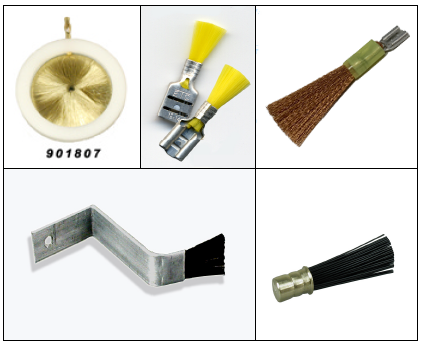

Illustrative image related to grounding brush

Why Choose ESD Grounding Brushes for Sensitive Environments?

ESD grounding brushes are crafted with anti-static properties, making them ideal for environments where static electricity can damage electronic components. They are widely utilized in electronics manufacturing and cleanroom settings. When selecting ESD brushes, B2B buyers should prioritize the specific ESD ratings and compliance standards relevant to their operations, while also being mindful that these brushes may not be suitable for high-current applications.

What Advantages Do Specialty Grounding Brushes Offer?

Specialty grounding brushes are customizable to meet specific industry needs, utilizing various fill materials and designs. These brushes are commonly employed in aerospace, military, and specialized equipment sectors, where performance requirements can vary significantly. Buyers should weigh the benefits of tailored solutions against the potential for longer lead times and higher costs associated with custom orders, ensuring that they align with project timelines and budgets.

How Do Lightning Protection Brushes Enhance Safety?

Lightning protection brushes are built to dissipate electrical surges from lightning strikes, safeguarding telecommunications and outdoor installations. They are constructed from robust materials that can withstand harsh conditions. For B2B buyers, the investment in lightning protection brushes is justified by the enhanced safety and protection they offer to critical infrastructure; however, the cost may be higher due to the specialized nature of these products.

Illustrative image related to grounding brush

Key Industrial Applications of grounding brush

| Industry/Sector | Specific Application of grounding brush | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

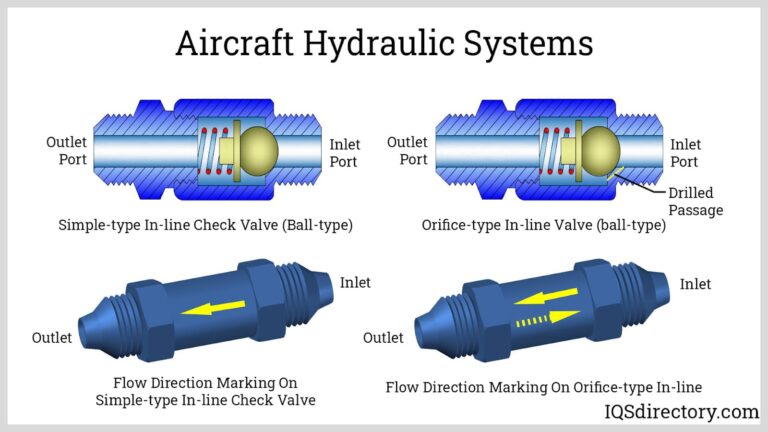

| Aerospace | Static electricity control in aircraft systems | Enhances safety by preventing electrical discharge, protecting sensitive equipment. | Ensure compliance with aviation standards and certifications. |

| Renewable Energy | Grounding in wind turbine generators | Prevents equipment damage and enhances operational efficiency. | Look for brushes with high electrical conductivity and durability. |

| Manufacturing | Equipment grounding in production lines | Reduces risk of equipment failure and improves product quality. | Consider material compatibility with specific machinery. |

| Marine | Grounding for marine electrical systems | Ensures safety and reliability in harsh environments. | Assess environmental resistance and maintenance requirements. |

| Transportation | Grounding in electric locomotives | Protects motors from damage and improves service life. | Focus on sourcing from suppliers with proven track records in rail applications. |

How is a grounding brush utilized in the aerospace industry, and what challenges does it address?

In the aerospace sector, grounding brushes are integral for managing static electricity in aircraft systems. They help prevent electrical discharges that could compromise sensitive avionics and navigation equipment. Given the high safety standards in aviation, buyers must ensure that grounding brushes meet stringent aerospace certifications and are made from materials that can withstand extreme conditions, including temperature fluctuations and moisture.

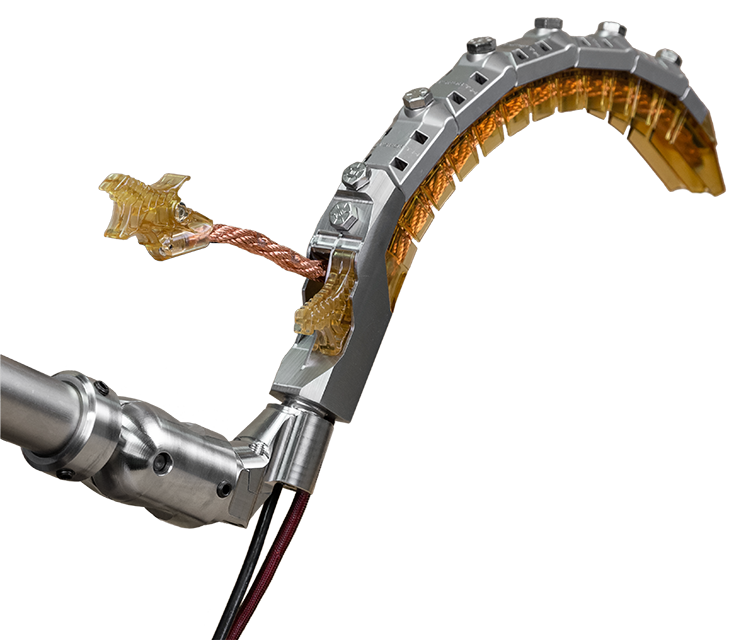

What role do grounding brushes play in renewable energy applications, particularly in wind turbines?

Grounding brushes are vital in wind turbine generators, where they prevent stray currents that can damage electrical components. By providing a reliable path to ground, these brushes enhance the efficiency and longevity of the turbines. Buyers in this sector should prioritize sourcing brushes with high electrical conductivity and resistance to environmental factors, as they operate in diverse and challenging conditions.

How do grounding brushes improve manufacturing processes?

In manufacturing environments, grounding brushes are employed to safeguard equipment from electrical surges and static buildup, which can lead to machinery failures and defective products. By ensuring a stable grounding connection, businesses can enhance operational efficiency and minimize downtime. When sourcing, manufacturers should consider the compatibility of brush materials with their specific machinery and the potential need for custom solutions.

Why are grounding brushes essential in marine applications?

Marine electrical systems are exposed to harsh conditions, making grounding brushes crucial for safety and reliability. They prevent corrosion and electrical faults that could endanger crew and equipment. Buyers in the marine sector should evaluate brushes based on their resistance to saltwater and extreme weather, as well as their ease of maintenance to ensure long-term performance.

Illustrative image related to grounding brush

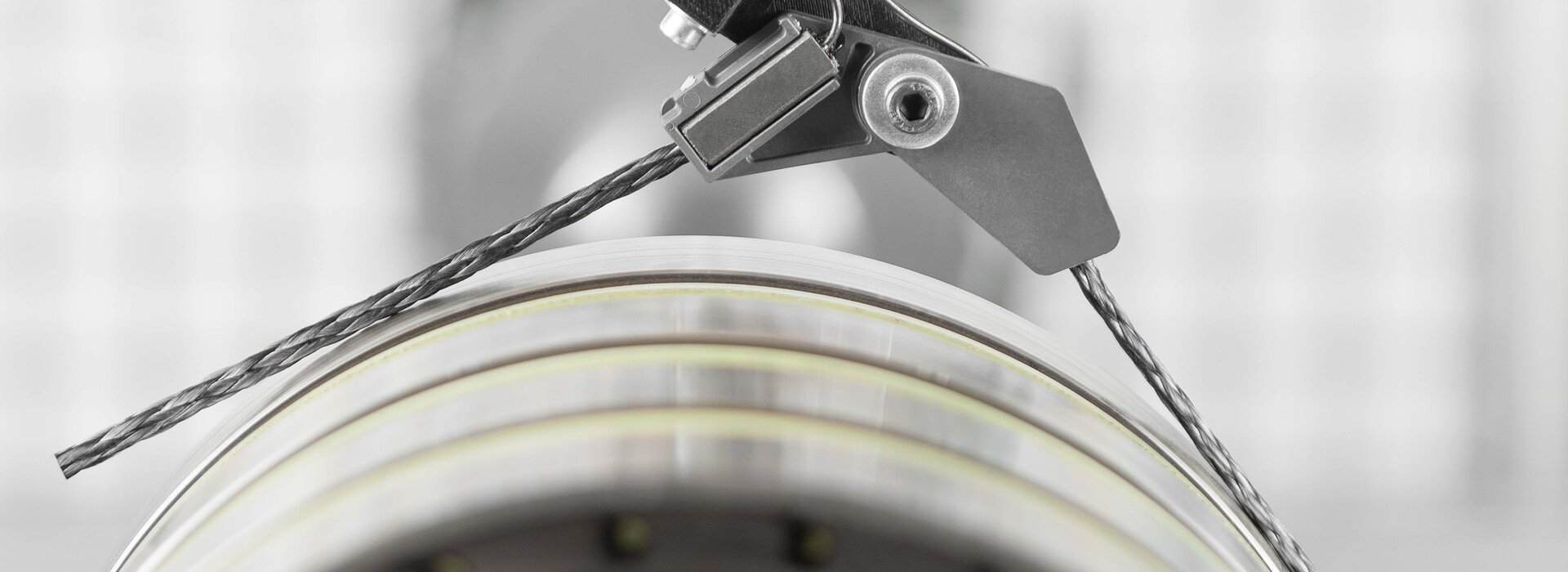

How do grounding brushes protect electric locomotives?

Grounding brushes are critical in electric locomotives, where they mitigate the risk of damage from stray currents and enhance the overall reliability of the motors. By providing a low-resistance path to ground, they help extend the service life of electrical components. When sourcing for this application, it is essential to select suppliers with expertise in rail-specific grounding solutions to ensure compliance with industry standards and performance expectations.

3 Common User Pain Points for ‘grounding brush’ & Their Solutions

Scenario 1: Ensuring Equipment Longevity in Manufacturing

The Problem: In manufacturing environments, static electricity can wreak havoc on machinery and sensitive electronic components. A common pain point for B2B buyers is the risk of equipment damage due to stray currents, which can lead to costly repairs and downtime. Buyers often struggle with selecting the right grounding brush that effectively mitigates these risks while ensuring compatibility with their existing machinery. The consequences of inadequate grounding can include reduced operational efficiency and increased maintenance costs, making it imperative to choose the right product.

The Solution: To address this challenge, buyers should consider sourcing grounding brushes specifically designed for their equipment’s specifications. This involves looking for brushes made from high-quality metal-graphite materials that provide excellent conductivity and low resistance to ground. It’s essential to consult technical data sheets and product literature to understand the recommended applications and compatibility with existing systems. Additionally, establishing a routine maintenance schedule that includes regular inspections of grounding brushes will help ensure optimal performance and prolong equipment lifespan. Training staff on the importance of grounding and the proper handling of brushes can further enhance system reliability.

Illustrative image related to grounding brush

Scenario 2: Overcoming Static Electricity in Electronics Manufacturing

The Problem: In industries such as electronics manufacturing, the presence of static electricity can lead to product failures and defects. B2B buyers often find themselves in a bind when their grounding brushes fail to eliminate static charges effectively, resulting in compromised product quality. The stakes are particularly high in environments where even minor static discharges can damage sensitive components, leading to significant financial losses and customer dissatisfaction.

The Solution: To mitigate static electricity issues, buyers should prioritize grounding brushes designed specifically for ESD (Electrostatic Discharge) environments. When sourcing these brushes, it’s vital to select models that have been tested and certified for ESD compliance. Additionally, buyers should evaluate the brush’s material composition, as brushes made from synthetic fibers or conductive materials often provide better performance in dissipating static. Implementing a comprehensive ESD management program that includes training for employees on the correct use of grounding brushes will also help reinforce best practices and reduce the risk of static-related issues.

Scenario 3: Finding the Right Grounding Brush for Diverse Applications

The Problem: Many B2B buyers face the challenge of needing a versatile grounding brush that can be utilized across different applications and environments. This need often leads to confusion when trying to identify which type of grounding brush will best suit their varied requirements, from manufacturing plants to cleanrooms and outdoor installations. The wrong choice can lead to ineffective grounding, posing safety risks and resulting in operational inefficiencies.

The Solution: To effectively navigate this challenge, buyers should conduct a thorough needs assessment to determine the specific applications for their grounding brushes. This includes evaluating factors such as environmental conditions, the types of machinery in use, and any industry-specific regulations. Buyers should also consider customizable options that allow them to specify features such as brush size, material, and fill type based on their diverse needs. Collaborating with suppliers who offer expert consultations can further assist in making informed decisions. By choosing a grounding brush that provides versatility without compromising performance, buyers can ensure a safer and more efficient operational environment across their facilities.

Strategic Material Selection Guide for grounding brush

When selecting materials for grounding brushes, it is crucial to understand the specific properties and performance characteristics of each material. This analysis focuses on four common materials used in grounding brushes: copper, graphite, metal-graphite composites, and stainless steel. Each material has unique benefits and drawbacks that can significantly influence application performance and cost-effectiveness.

What are the Key Properties of Copper for Grounding Brushes?

Copper is widely recognized for its excellent electrical conductivity, making it a preferred choice for grounding brushes. It has a high melting point (1,984°F or 1,085°C) and is resistant to corrosion, especially when alloyed with other metals. The primary advantage of copper lies in its ability to efficiently conduct electricity, which is essential for grounding applications.

Pros and Cons: Copper brushes are durable and provide reliable performance in various environments. However, they can be susceptible to oxidation, which may reduce conductivity over time. Additionally, the cost of copper can fluctuate significantly, affecting overall project budgets.

Impact on Application: Copper is compatible with a wide range of media, including water and oil, making it suitable for use in diverse industrial settings.

Considerations for International Buyers: Compliance with standards such as ASTM B187 (for copper) is essential for buyers in regions like Africa and South America, where local regulations may vary.

How Does Graphite Perform in Grounding Brush Applications?

Graphite is another popular material for grounding brushes, known for its good electrical conductivity and thermal stability. It operates effectively at high temperatures (up to 750°F or 400°C) and is resistant to chemical corrosion.

Pros and Cons: Graphite brushes have a long lifespan and perform well in high-speed applications. However, they can be brittle and may require careful handling during installation. The cost of graphite is generally moderate, making it an attractive option for many applications.

Illustrative image related to grounding brush

Impact on Application: Graphite is particularly effective in environments where high temperatures and chemical exposure are common, such as in power generation and industrial machinery.

Considerations for International Buyers: Buyers should consider compliance with international standards like DIN 51900, which governs the use of graphite in industrial applications.

What Advantages Do Metal-Graphite Composites Offer for Grounding Brushes?

Metal-graphite composites combine the benefits of both metals and graphite, providing high electrical conductivity and mechanical strength. These brushes can operate effectively in a wide range of temperatures and have a low wear rate.

Pros and Cons: The primary advantage of metal-graphite composites is their enhanced durability and resistance to wear, making them suitable for high-performance applications. However, they can be more expensive to manufacture, which may impact project budgets.

Impact on Application: These composites are ideal for applications requiring high reliability and performance, such as in electric locomotives and wind turbines.

Illustrative image related to grounding brush

Considerations for International Buyers: Compliance with specific industry standards, such as JIS B 2311 for electrical contacts, is essential for buyers in regions like the Middle East and Europe.

Why Choose Stainless Steel for Grounding Brushes?

Stainless steel is known for its corrosion resistance and mechanical strength, making it a viable option for grounding brushes in harsh environments. It can withstand high temperatures (up to 1,500°F or 815°C) and is relatively easy to manufacture.

Pros and Cons: The durability of stainless steel brushes makes them suitable for long-term use. However, their electrical conductivity is lower than that of copper or graphite, which may limit their effectiveness in certain applications. Stainless steel is generally more expensive than copper and graphite.

Illustrative image related to grounding brush

Impact on Application: These brushes are particularly effective in environments exposed to moisture or chemicals, such as food processing and marine applications.

Considerations for International Buyers: Compliance with standards such as ASTM A240 (for stainless steel) is critical for buyers in regions like Brazil and Nigeria, where regulatory requirements may differ.

Summary Table of Material Selection for Grounding Brushes

| Material | Typical Use Case for grounding brush | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | General industrial applications | Excellent electrical conductivity | Susceptible to oxidation | Medium |

| Graphite | High-temperature environments | Long lifespan and thermal stability | Brittle and requires careful handling | Medium |

| Metal-Graphite | High-performance applications | Enhanced durability and wear resistance | Higher manufacturing costs | High |

| Stainless Steel | Corrosive or moisture-rich environments | Corrosion resistance | Lower electrical conductivity | High |

This strategic material selection guide provides essential insights for international B2B buyers looking to optimize their grounding brush applications. Understanding the properties, advantages, and limitations of each material can significantly impact performance, compliance, and cost-effectiveness in various industrial settings.

In-depth Look: Manufacturing Processes and Quality Assurance for grounding brush

What Are the Main Stages in the Manufacturing Process of Grounding Brushes?

The manufacturing of grounding brushes is a multi-stage process that involves several key phases: material preparation, forming, assembly, and finishing. Each stage is critical to ensure the final product meets stringent performance and quality standards.

Material Preparation: The process begins with the selection of raw materials. Grounding brushes often utilize metal-graphite composites due to their excellent electrical conductivity and durability. The graphite is purified and blended with metal powders such as copper or silver. This mixture is then pressed into molds to create the brush’s body, ensuring a uniform density and strength.

Illustrative image related to grounding brush

Forming: Once the materials are prepared, they undergo forming processes. This can include compression molding or extrusion, depending on the design specifications. The forming stage shapes the brush, ensuring it fits the intended application, such as in electric motors or generators. Precision is crucial, as any deviation can impact the brush’s performance and lifespan.

Assembly: After forming, components are assembled. This might involve attaching the brush to a holder or integrating it with other electrical components. Careful handling is essential during this stage to prevent contamination or damage, which could compromise the electrical properties of the grounding brush.

Finishing: The final stage involves finishing processes such as machining, surface treatment, or coating. These processes enhance the brush’s performance characteristics, such as reducing friction or improving corrosion resistance. Quality checks are often conducted at this stage to ensure compliance with specifications before the product is packaged for shipment.

What Quality Assurance Standards Should B2B Buyers Consider for Grounding Brushes?

Quality assurance in the manufacturing of grounding brushes is vital for ensuring reliability and performance. International standards such as ISO 9001 are widely recognized and provide a framework for quality management systems. Compliance with these standards indicates a commitment to consistent quality and customer satisfaction.

In addition to ISO 9001, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may also be relevant, especially for buyers in sectors such as energy or transportation. These certifications ensure that products meet specific safety and quality requirements, which can vary by market and application.

What Are the Key Quality Control Checkpoints in Grounding Brush Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process, with several critical checkpoints:

Incoming Quality Control (IQC): At this initial stage, raw materials are inspected for quality and compliance with specifications. This includes testing the properties of the metal and graphite used to ensure they meet the required standards for conductivity and durability.

In-Process Quality Control (IPQC): During the manufacturing stages, ongoing inspections are conducted to monitor the forming and assembly processes. This may involve measuring dimensions, checking for defects, and conducting electrical tests to ensure that the brushes are functioning as intended.

Final Quality Control (FQC): After finishing, the final product undergoes rigorous testing. This includes electrical performance tests, durability assessments, and visual inspections. Any products that do not meet the required specifications are rejected or reworked.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are some effective strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand. This can include reviewing documentation, observing processes, and evaluating the facility’s overall compliance with international standards.

-

Quality Reports: Requesting detailed quality reports can provide insights into a supplier’s QC history. These reports should include data on past inspections, testing results, and any corrective actions taken for non-conformities.

-

Third-Party Inspections: Engaging third-party inspection services can add an additional layer of assurance. These independent organizations can conduct random checks and audits of the manufacturing process, providing unbiased assessments of quality.

-

Certification Verification: Buyers should verify that suppliers hold relevant certifications, such as ISO 9001 or CE, by checking with the issuing bodies. This ensures that the supplier adheres to recognized quality management practices.

What Common Testing Methods Are Used in Quality Control for Grounding Brushes?

Quality control for grounding brushes employs various testing methods to ensure products meet performance standards. Common methods include:

Illustrative image related to grounding brush

-

Electrical Resistance Testing: This test measures the electrical resistance of the brushes to ensure they provide a low path of resistance to ground. High resistance can lead to inefficiencies and equipment damage.

-

Durability Testing: Grounding brushes are subjected to wear tests to simulate operational conditions. This helps assess their lifespan and performance under stress.

-

Thermal Conductivity Tests: These tests evaluate how well the brush dissipates heat, which is crucial for preventing overheating in applications like electric motors.

-

Mechanical Testing: This includes checks for tensile strength and flexibility, ensuring that the brushes can withstand operational forces without breaking or degrading.

What Nuances Should International B2B Buyers Consider in Quality Assurance for Grounding Brushes?

International buyers should be aware of specific nuances in quality assurance that can affect their procurement decisions. Factors such as regional regulations, import/export standards, and local market practices can influence quality control measures.

In many regions, local certifications may be required in addition to international standards. For example, in the European market, CE marking is essential for compliance with EU directives. Similarly, buyers in the Middle East may need to consider local regulatory standards that govern electrical components.

Understanding these nuances can help buyers navigate the complexities of international procurement, ensuring that they select suppliers who can meet both local and international quality expectations. Additionally, establishing clear communication with suppliers regarding quality standards and expectations is crucial for maintaining product quality across borders.

By considering these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing grounding brushes, ensuring they select reliable suppliers that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘grounding brush’

This guide serves as a practical checklist for B2B buyers aiming to procure grounding brushes. Grounding brushes are essential for preventing static buildup and protecting equipment in various industries, including manufacturing, electronics, and transportation. By following these steps, buyers can ensure they select the right product for their specific needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it is vital to establish your technical requirements. Consider factors such as the intended application, environmental conditions, and electrical specifications.

– Key Considerations:

– Brush material (e.g., metal-graphite, copper) and its conductivity.

– Size and dimensions that fit your equipment.

– Operating speed range and pressure requirements.

Step 2: Research and Identify Potential Suppliers

Begin by compiling a list of suppliers known for manufacturing high-quality grounding brushes. Utilize industry directories, trade shows, and online platforms to identify potential vendors.

– What to Look For:

– Companies with a strong reputation and positive reviews.

– Suppliers specializing in your specific industry.

– Availability of custom solutions if your requirements are unique.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications, such as ISO 9001:2015. Certifications ensure that the manufacturer adheres to industry standards for quality and safety.

– Why It Matters:

– Certified suppliers are more likely to produce reliable and durable products.

– Compliance with international standards is crucial for global trade and can simplify import/export processes.

Illustrative image related to grounding brush

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples of the grounding brushes from shortlisted suppliers. Testing samples allows you to evaluate the product’s performance in your specific application.

– Testing Criteria:

– Check for electrical conductivity and resistance.

– Assess the durability and wear rate under operational conditions.

Step 5: Inquire About Warranty and Support

Understand the warranty terms and after-sales support provided by the supplier. A robust warranty can indicate the supplier’s confidence in their product quality.

– Key Questions:

– What is covered under the warranty, and for how long?

– Are there provisions for technical support or replacements?

Step 6: Negotiate Terms and Pricing

Once you’ve selected a preferred supplier, engage in discussions regarding pricing, payment terms, and delivery timelines. Effective negotiation can lead to better deals and improved terms.

– Negotiation Tips:

– Compare quotes from multiple suppliers.

– Consider long-term relationships that may lead to bulk discounts.

Step 7: Finalize the Order and Monitor Delivery

After agreeing on terms, finalize your order and ensure that all specifications are clearly documented. Monitor the delivery process to ensure timely receipt of the products.

– What to Track:

– Shipping timelines and methods.

– Confirmation of product specifications upon arrival.

By following this step-by-step checklist, B2B buyers can streamline the sourcing process for grounding brushes, ensuring they make informed decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for grounding brush Sourcing

What Are the Key Cost Components in Grounding Brush Manufacturing?

The cost structure of grounding brushes typically includes several critical components: materials, labor, manufacturing overhead, tooling, quality control, logistics, and margin.

-

Materials: The choice of fill material (such as metal-graphite, copper, or synthetic fibers) significantly affects costs. High-quality materials often yield better performance but come at a higher price. For instance, metal-graphite grades provide superior conductivity but can be more expensive than traditional options.

-

Labor: Labor costs vary depending on the region and the complexity of the manufacturing process. Skilled labor is often required for precision tasks, particularly in custom brush production, which can increase overall costs.

-

Manufacturing Overhead: This includes expenses related to equipment maintenance, facility costs, and utilities. Efficient production techniques can help minimize these costs, but they also depend on the scale of operations.

-

Tooling: Custom tooling may be necessary for specialized designs, impacting initial costs. However, investing in quality tooling can enhance production efficiency and product quality in the long run.

-

Quality Control (QC): Robust QC processes are essential to ensure product reliability. Companies may incur additional costs for testing and certification, especially for industries with strict compliance requirements.

-

Logistics: Transportation and warehousing costs can vary significantly based on location. International shipping, particularly to regions like Africa or South America, can add substantial costs due to customs duties and tariffs.

-

Margin: Suppliers typically add a markup to cover their costs and ensure profitability. Understanding this margin is vital when negotiating prices.

How Do Pricing Influencers Affect Grounding Brush Costs?

Several factors influence the pricing of grounding brushes, particularly for B2B buyers in diverse markets such as Africa, South America, the Middle East, and Europe.

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Larger orders often qualify for bulk discounts, making them more cost-effective per unit.

-

Specifications and Customization: Custom designs tailored to specific applications can lead to increased costs due to the need for specialized materials and tooling. Clear communication of requirements can mitigate unexpected expenses.

-

Material Quality and Certifications: Higher quality materials and certifications (like ISO or RoHS compliance) can lead to increased costs. However, these investments often result in better durability and performance, contributing to lower total ownership costs.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can influence pricing. Suppliers with advanced technology or proven track records may command higher prices.

-

Incoterms: Understanding the terms of sale is critical. Incoterms dictate who bears the risk and costs at various points in the supply chain. Buyers should consider these terms when evaluating offers.

What Are Effective Buyer Tips for Negotiating Grounding Brush Prices?

When sourcing grounding brushes, particularly from international suppliers, buyers can adopt several strategies to optimize costs:

-

Negotiate Terms: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Establishing a long-term relationship may lead to better pricing and service.

-

Focus on Total Cost of Ownership (TCO): Assess the long-term costs associated with the grounding brushes, including maintenance, replacement frequency, and operational efficiency. A lower upfront cost may not always equate to a better deal.

-

Research Market Prices: Understanding the average market price for grounding brushes in your region can provide leverage during negotiations. Utilize industry reports and competitor pricing to inform your strategy.

-

Consider Local Suppliers: Sourcing from local manufacturers can reduce logistics costs and lead times, enhancing overall efficiency. Additionally, local suppliers may offer better customization options.

-

Stay Informed on Regulatory Changes: Compliance with local regulations can impact pricing. Staying updated on changes can help you avoid unexpected costs and ensure compliance.

Disclaimer on Indicative Prices

Prices for grounding brushes can vary widely based on the factors discussed. The information provided is for general guidance and should not be considered as definitive pricing. Always request quotes from multiple suppliers to ensure competitive pricing tailored to your specific requirements.

Alternatives Analysis: Comparing grounding brush With Other Solutions

In the quest for effective grounding solutions, various technologies exist that serve similar functions as grounding brushes. Understanding the strengths and weaknesses of these alternatives is crucial for B2B buyers who are looking to optimize their electrical safety measures.

| Comparison Aspect | Grounding Brush | Carbon Brush | Grounding Cable |

|---|---|---|---|

| Performance | High electrical conductivity; suitable for various speeds (15m to 60m/s) | Excellent for high-load applications; prevents stray currents | Reliable for static discharge; requires proper installation |

| Cost | Moderate initial investment; long-term durability | Varies widely based on material; generally higher for high-performance grades | Low to moderate cost; installation can increase overall expense |

| Ease of Implementation | Straightforward installation; can be integrated into existing systems | May require specialized handling and installation | Installation complexity can be high; needs grounding points |

| Maintenance | Low maintenance; periodic inspections recommended | Moderate maintenance; lifespan depends on wear | Low maintenance but requires regular checks for integrity |

| Best Use Case | Ideal for rotating machinery and motors | Suitable for heavy machinery and generators | Best for static-sensitive environments like electronics manufacturing |

What Are the Pros and Cons of Using Carbon Brushes?

Carbon brushes are widely employed in heavy machinery and electrical systems where high load is a consideration. Their primary advantage lies in their ability to handle significant electrical currents while preventing damage from stray currents. However, they typically require more specialized handling and installation, which can increase upfront costs and complicate maintenance. Additionally, their lifespan can vary significantly based on the application and wear, necessitating regular checks to ensure optimal performance.

How Do Grounding Cables Compare to Grounding Brushes?

Grounding cables are another alternative that provides a reliable means for static discharge. They are generally less expensive than grounding brushes and can be easily sourced. However, their effectiveness heavily depends on proper installation and the existence of suitable grounding points. Installation can be complex, particularly in environments with intricate machinery or systems, and improper installation can lead to safety hazards. While they require minimal maintenance, regular inspections are essential to ensure they remain intact and functional.

Illustrative image related to grounding brush

Conclusion: How to Choose the Right Grounding Solution for Your Needs?

When selecting a grounding solution, B2B buyers should consider several factors, including performance requirements, budget constraints, and the specific environmental conditions of their operations. Grounding brushes offer excellent performance and ease of implementation for rotating machinery, while carbon brushes are suited for high-load applications but may require more careful handling. Grounding cables provide a cost-effective option but necessitate proper installation to ensure safety. By evaluating these aspects, buyers can make informed decisions that align with their operational needs and safety standards.

Essential Technical Properties and Trade Terminology for grounding brush

Grounding brushes are essential components in electrical systems, providing effective pathways for stray currents to prevent electrical failures and ensure the safety and longevity of equipment. Understanding their technical properties and trade terminology is crucial for B2B buyers, particularly when sourcing these components internationally.

What Are the Key Technical Properties of Grounding Brushes?

-

Material Grade

Grounding brushes are typically made from materials like metal-graphite, which combines the benefits of high conductivity and wear resistance. The selection of material impacts the brush’s performance, including its ability to dissipate electrical charges effectively. For B2B buyers, choosing the right material grade can lead to enhanced durability and lower maintenance costs. -

Electrical Conductivity

The ability of a grounding brush to conduct electricity is measured in siemens (S). High conductivity ensures that the brush can efficiently channel stray currents away from sensitive equipment. This is particularly important in industries such as automotive and aerospace, where electrical integrity is critical. Buyers should prioritize brushes with low resistance to minimize energy losses. -

Operating Speed Range

Grounding brushes are designed to operate effectively across various speeds, typically ranging from 15 m/s to 60 m/s. The operating speed influences the brush’s wear rate and performance. Buyers must consider the specific application of the brush to ensure it can withstand the operational demands without premature failure. -

Mechanical Tolerance

Tolerance refers to the permissible limits of variation in a brush’s dimensions, which can affect its fit and functionality. Precise tolerances ensure that the brush maintains consistent contact with the rotating shaft, reducing wear and enhancing performance. For B2B procurement, understanding tolerance specifications is vital to avoid compatibility issues. -

Pressure Rating

This specification indicates the optimal pressure that should be applied to the brush during operation. A proper pressure rating ensures effective contact with the surface while minimizing wear. Buyers should consult manufacturers to determine the appropriate pressure settings for their specific applications to enhance performance and lifespan. -

Temperature Resistance

Grounding brushes may encounter varying thermal conditions depending on their application. Materials with high-temperature resistance prevent degradation and maintain performance under heat stress. Buyers should select brushes that can operate effectively within the expected temperature ranges of their operational environments.

What Are Common Trade Terms Related to Grounding Brushes?

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are used in another company’s end products. Understanding whether a grounding brush is OEM can ensure compatibility with existing systems, which is critical for B2B buyers looking for reliable replacements. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it affects inventory management and cost efficiency. Knowing the MOQ can help in planning purchases and budgeting. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price for specific goods or services. For buyers, issuing an RFQ for grounding brushes helps in comparing quotes and ensuring competitive pricing, which is essential for making informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to clarify shipping, insurance, and delivery responsibilities, thereby minimizing misunderstandings and ensuring smooth logistics. -

Lead Time

This refers to the amount of time it takes from placing an order to receiving the product. For grounding brushes, lead time can vary based on manufacturing processes and supply chain logistics. Buyers should account for lead time in their project timelines to avoid delays. -

Certification Standards

Certifications such as ISO 9001 indicate that a manufacturer meets international quality management standards. For B2B buyers, verifying certification standards can provide assurance of product quality and consistency, which is critical in industries with strict regulatory requirements.

In summary, understanding the technical properties and trade terminology associated with grounding brushes is essential for B2B buyers. This knowledge not only aids in making informed purchasing decisions but also helps in fostering strong supplier relationships and ensuring operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the grounding brush Sector

What Are the Key Drivers Influencing the Grounding Brush Market?

The grounding brush market is experiencing notable growth due to several global drivers. A significant factor is the increased focus on electrical safety across various industries, which enhances demand for grounding solutions that prevent static discharge and stray currents. Furthermore, the rise in renewable energy projects, particularly in wind and hydroelectric sectors, has led to a surge in the need for effective grounding systems to protect sensitive equipment. Emerging technologies, such as IoT-enabled monitoring systems, are also transforming sourcing strategies as buyers seek high-performance grounding solutions that integrate with smart infrastructure.

Illustrative image related to grounding brush

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly prioritizing suppliers that offer comprehensive product information and customization options. The trend toward digital procurement platforms is reshaping how buyers source grounding brushes, with a growing preference for suppliers who can provide detailed specifications and technical support online. Additionally, the push for operational efficiency is driving buyers to adopt just-in-time inventory practices, influencing supplier relationships and contract negotiations.

How Are Sustainability and Ethical Sourcing Reshaping the Grounding Brush Industry?

Sustainability is becoming a pivotal concern in the grounding brush sector, pushing manufacturers and suppliers to adopt eco-friendly practices. The environmental impact of sourcing materials, particularly metals and composites used in grounding brushes, has prompted buyers to seek products that minimize ecological footprints. This shift is reflected in the increasing demand for materials that are recycled or sourced from sustainable suppliers.

Ethical supply chains are also gaining importance among B2B buyers. Companies are now more inclined to partner with manufacturers who demonstrate transparency in their sourcing practices, ensuring that materials are obtained responsibly and without exploiting labor. Certifications such as ISO 14001 (Environmental Management) and RoHS (Restriction of Hazardous Substances) are becoming critical criteria in supplier selection. Buyers can enhance their brand reputation and meet regulatory compliance by prioritizing suppliers with these certifications, thus aligning with the broader corporate responsibility initiatives.

How Has the Grounding Brush Sector Evolved Over Time?

The grounding brush sector has undergone significant evolution, particularly in response to technological advancements and increasing safety regulations. Initially, grounding brushes were primarily made from simple materials, focusing mainly on functionality. However, with the rise of electric motors and sophisticated electrical systems, the demand for more advanced materials, such as metal-graphite composites, emerged to enhance conductivity and durability.

Illustrative image related to grounding brush

In recent years, the integration of smart technology into grounding systems has transformed product offerings. Modern grounding brushes are now designed to work in tandem with digital monitoring systems, allowing for real-time tracking of performance and maintenance needs. This evolution reflects a broader trend in manufacturing, where innovation and technology play critical roles in meeting the complex demands of today’s industrial applications. Buyers are now equipped with a wider range of options that offer enhanced performance, sustainability, and compliance with global standards, making informed sourcing decisions more crucial than ever.

Frequently Asked Questions (FAQs) for B2B Buyers of grounding brush

-

How do I choose the right grounding brush for my application?

Selecting the right grounding brush involves assessing several factors, including the specific application, the materials involved, and the environmental conditions. Consider the electrical conductivity requirements, as different brushes use various fill materials like metal-graphite or copper. Evaluate the brush’s compatibility with your equipment and its ability to prevent issues such as static electricity or stray currents. Consulting with suppliers about your operational needs can help ensure you select a product that meets industry standards and enhances equipment longevity. -

What are the key benefits of using a grounding brush?

Grounding brushes provide essential protection for electrical equipment by preventing damage from stray currents and eliminating static electricity. They are crucial in various industries, including manufacturing, automotive, and energy production. By maintaining proper grounding, these brushes help enhance the safety and efficiency of machinery, reducing downtime and maintenance costs. Furthermore, they contribute to compliance with safety regulations, which is particularly important in international markets. -

What customization options are available for grounding brushes?

Many manufacturers offer customization options for grounding brushes to suit specific needs. Customizations can include variations in brush size, fill material, and handle types. Buyers can also request specific designs tailored to particular applications or operational environments. Engaging with suppliers early in the sourcing process can facilitate discussions about your requirements and enable the creation of a product that best fits your operational needs. -

What is the minimum order quantity (MOQ) for grounding brushes?

Minimum order quantities can vary significantly among suppliers, often depending on the type of grounding brush and the level of customization required. Some manufacturers may allow smaller orders for standard products, while custom brushes typically require higher MOQs to justify production costs. It is advisable to inquire about MOQs during initial discussions with suppliers to ensure that your purchasing plans align with their production capabilities. -

What payment terms should I expect when sourcing grounding brushes internationally?

Payment terms can vary widely depending on the supplier and the specific arrangement negotiated. Common terms include upfront payment, partial payment upon order confirmation, and the balance upon shipment. In international transactions, it’s also important to consider the methods of payment accepted, such as letters of credit, wire transfers, or PayPal. Always clarify payment terms early in the negotiation process to avoid misunderstandings and ensure a smooth transaction. -

How do I vet suppliers for grounding brushes?

Vetting suppliers is crucial to ensuring product quality and reliability. Start by researching their reputation in the industry through reviews and testimonials. Verify their certifications, such as ISO 9001, to ensure they adhere to quality management standards. Request samples to assess the quality of their products, and inquire about their production capabilities and lead times. Additionally, consider visiting the supplier’s facility if feasible, or utilize third-party inspection services for added assurance. -

What quality assurance measures should I look for in grounding brushes?

Quality assurance measures may include rigorous testing for electrical conductivity, durability, and performance under various conditions. Suppliers should provide documentation of their quality control processes and any relevant certifications. Look for manufacturers who adhere to international standards and have a transparent quality assurance protocol, such as regular inspections and testing of raw materials. A reliable supplier will also offer warranties or guarantees on their products to instill confidence in your purchase. -

What logistics considerations are important for importing grounding brushes?

When importing grounding brushes, consider logistics factors such as shipping costs, delivery times, and customs regulations in your country. It’s vital to understand the import duties and taxes that may apply to your order. Collaborate with suppliers who have experience in international shipping to ensure compliance with regulations and smooth delivery. Establishing a reliable logistics partner can also enhance the efficiency of your supply chain and reduce potential delays in receiving your products.

Top 8 Grounding Brush Manufacturers & Suppliers List

1. Gordon Brush – Grounding Brushes

Domain: gordonbrush.com

Registered: 1998 (27 years)

Introduction: Grounding Brushes: 1. Part Number: 904430 – Fill Material: Crimped Phosphor Bronze Brush Wire, Trim: 1-1/4″, Overall Length: 2-1/4″, Price: $16.75/each, $50.25/pkg (3/pkg). 2. Part Number: 905045 – Fill Material: Super fine Carbon Fiber filament, Trim: 3/4″, Overall Length: 1-1/2″, Price: $18.95/each, $113.70/pkg (6/pkg).

2. McMaster – Grounding Brushes

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Grounding Brushes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

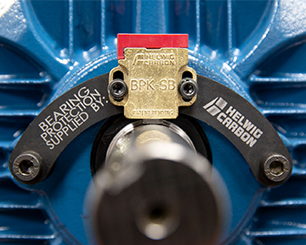

3. Helwig Carbon – BPK™ Bearing Protection Kits

Domain: helwigcarbon.com

Registered: 1997 (28 years)

Introduction: Helwig Carbon’s BPK™ (Bearing Protection Kits) offer advanced shaft grounding solutions, utilizing proprietary silver graphite brushes and durable brass or Teflon holders. Key features include:

– Longevity: Kits last 10 years or more.

– Superior Protection: Minimizes damaging induced motor shaft currents.

– Optimal Grounding: Provides the lowest resistance path to ground.

– Versatile Performan…

4. Sohre Turbomachinery – High Performance Shaft Grounding Brushes

Domain: scs-turbo.com

Registered: 2021 (4 years)

Introduction: Sohre Turbomachinery provides high performance, high reliability bristle type fiber brushes for shaft grounding (shaft earthing) of stray electrical shaft currents. The brushes are also suitable for instrument signal transmission and on-line diagnostic work for generators or electric motors.

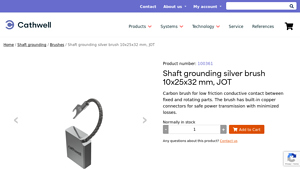

5. JOT – Shaft Grounding Silver Brush

Domain: cathwell.com

Registered: 2010 (15 years)

Introduction: {“product_name”: “Shaft grounding silver brush”, “dimensions”: “10x25x32 mm”, “brand”: “JOT”, “product_number”: “100361”, “material”: “Compacted and synthesized mix of 80% silver and 20% graphite (CA20)”, “features”: [“Carbon brush for low friction conductive contact between fixed and rotating parts”, “Built-in copper connectors for safe power transmission with minimized losses”], “applications”: …

6. AEGIS® – SGR & PRO Series

Domain: blog.est-aegis.com

Registered: 2004 (21 years)

Introduction: AEGIS® SGR: Good for about 40 amps; designed for shaft grounding with a band of fibers providing 360-degree contact around the shaft. AEGIS® PRO Series: Can handle up to 120 amps; suitable for high-frequency current applications. Both products offer more surface area contact compared to carbon brushes, reducing hotspotting issues. AEGIS Shaft Grounding Rings come with a 2-year extended warranty ag…

7. Mersen – Grounding and Lightning Protection Brushes

Domain: us.mersen.com

Registered: 2006 (19 years)

Introduction: Grounding and lightning protection brushes from Mersen are made of metal-graphite grades, which consist of purified natural graphite and metal powders (copper, silver) that are pressed and baked for solidity and cohesion. Key features include: high electrical conductivity, low path of resistance to ground, and a wide speed range (15m to 60m/s). Applications include electric locomotives, diesel ele…

8. Schunk Group – Grounding Brushes for Wind Turbines

Domain: schunk-group.com

Registered: 1997 (28 years)

Introduction: Grounding Brushes for wind turbines, designed for shaft grounding of wind power generators. Features modern grounding brushes and carbon fiber-based systems. Effectively diverts capacitive currents away from the shaft, preventing damage to bearings and gearboxes. Benefits include: modern carbon brush materials, high reliability and efficiency, suitable for onshore and offshore stations, excellent …

Strategic Sourcing Conclusion and Outlook for grounding brush

As the demand for reliable grounding brushes continues to grow across various industries, strategic sourcing has emerged as a pivotal factor for B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. Understanding the unique specifications and applications of grounding brushes—from their role in preventing stray currents to their use in lightning protection—can significantly influence procurement decisions.

Investing in high-quality grounding brushes not only safeguards equipment but also enhances operational efficiency. Buyers should prioritize suppliers who offer diverse options tailored to specific industry needs, ensuring compliance with international standards and local regulations. Furthermore, engaging with manufacturers that emphasize innovation and sustainability can lead to long-term partnerships that benefit both parties.

Looking ahead, it is essential for international buyers to stay informed about technological advancements and market trends in grounding solutions. By adopting a proactive approach to sourcing, businesses can better position themselves to leverage new opportunities and mitigate risks associated with electrical safety. Make informed decisions today to secure a competitive edge in tomorrow’s market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to grounding brush

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.