A B2B Buyer’s Guide to General Steel Macon Georgia: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for general steel macon georgia

In today’s competitive landscape, sourcing high-quality general steel from Macon, Georgia, presents unique challenges for international B2B buyers. Whether you’re involved in construction, manufacturing, or infrastructure projects, understanding the nuances of steel supply can significantly impact your operations. This comprehensive guide delves into the diverse offerings from General Steel in Macon, highlighting the types of steel products available, their various applications, and essential supplier vetting processes.

As a key player in the steel industry, General Steel provides a wide range of carbon, stainless, and aluminum products, along with value-added services like fabrication and processing. Buyers from Africa, South America, the Middle East, and Europe will find insights into cost considerations, shipping logistics, and regulatory compliance tailored to their specific regions.

By equipping you with actionable intelligence and best practices, this guide empowers informed purchasing decisions, ensuring that you can navigate the complexities of sourcing steel effectively. With a focus on quality, reliability, and long-term partnerships, you’ll gain the confidence needed to secure the right steel solutions for your projects, no matter where you are in the world.

Understanding general steel macon georgia Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hot-Rolled Steel | Produced by rolling steel at high temperatures, resulting in a rough surface finish. | Structural applications, automotive parts | Pros: Cost-effective, versatile. Cons: Less precise dimensions. |

| Cold-Rolled Steel | Manufactured at room temperature, providing a smoother finish and tighter tolerances. | Precision components, furniture frames | Pros: High strength, excellent surface finish. Cons: Higher cost. |

| Stainless Steel | Alloyed with chromium to resist corrosion, available in various grades. | Food processing, medical equipment | Pros: Corrosion-resistant, aesthetic appeal. Cons: More expensive than carbon steel. |

| Aluminum Steel | Lightweight metal with high strength-to-weight ratio, often used in structural applications. | Aerospace, transportation, packaging | Pros: Lightweight, resistant to corrosion. Cons: Lower tensile strength compared to steel. |

| Rebar | Steel bars used to reinforce concrete structures, enhancing tensile strength. | Construction, infrastructure projects | Pros: Increases structural integrity, widely available. Cons: Requires proper placement and installation. |

What are the Characteristics and Suitability of Hot-Rolled Steel?

Hot-rolled steel is produced by rolling steel at elevated temperatures, making it easier to shape and form. This type of steel is characterized by its rough surface finish and lower cost, making it a popular choice for structural applications such as beams and columns in construction. B2B buyers should consider the application requirements, as hot-rolled steel may not be suitable for projects that demand precise dimensions or a smooth finish.

How Does Cold-Rolled Steel Compare for Precision Needs?

Cold-rolled steel undergoes processing at room temperature, resulting in a smoother surface and tighter tolerances. This makes it ideal for precision components, such as automotive parts and furniture frames. B2B buyers looking for high-strength materials with excellent surface quality should consider cold-rolled steel, despite its higher cost compared to hot-rolled options. The investment is often justified by the enhanced performance and aesthetic appeal.

Why Choose Stainless Steel for Corrosion Resistance?

Stainless steel is renowned for its corrosion resistance, thanks to the addition of chromium. It comes in various grades to suit different applications, particularly in industries like food processing and medical equipment where hygiene is paramount. While stainless steel is more expensive than carbon steel, its durability and aesthetic qualities make it a valuable choice for B2B buyers focused on long-term performance and compliance with health standards.

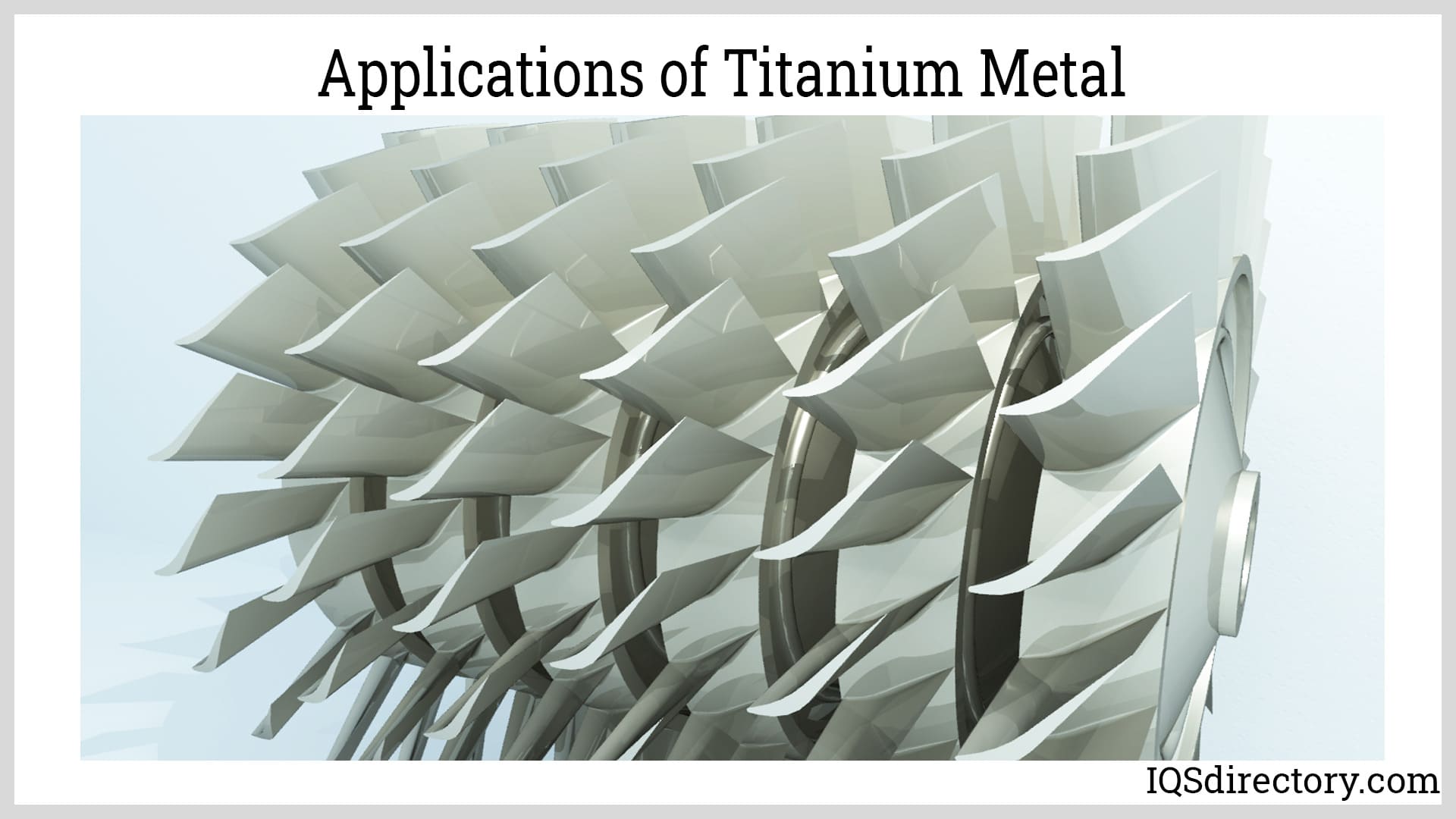

What are the Benefits of Aluminum Steel in Structural Applications?

Aluminum steel is a lightweight alternative to traditional steel, offering a high strength-to-weight ratio. This makes it particularly useful in aerospace and transportation industries, where reducing weight can lead to increased efficiency. B2B buyers should weigh the benefits of aluminum’s corrosion resistance and lightweight nature against its lower tensile strength compared to steel, especially when evaluating structural integrity requirements.

How Does Rebar Enhance Construction Projects?

Rebar, or reinforcing bar, is essential in construction for increasing the tensile strength of concrete structures. It is widely used in infrastructure projects, providing the necessary support to withstand various stresses. B2B buyers should consider the quality and specifications of rebar, as proper placement and installation are crucial for maximizing its benefits. Its availability and cost-effectiveness make it a staple in construction materials.

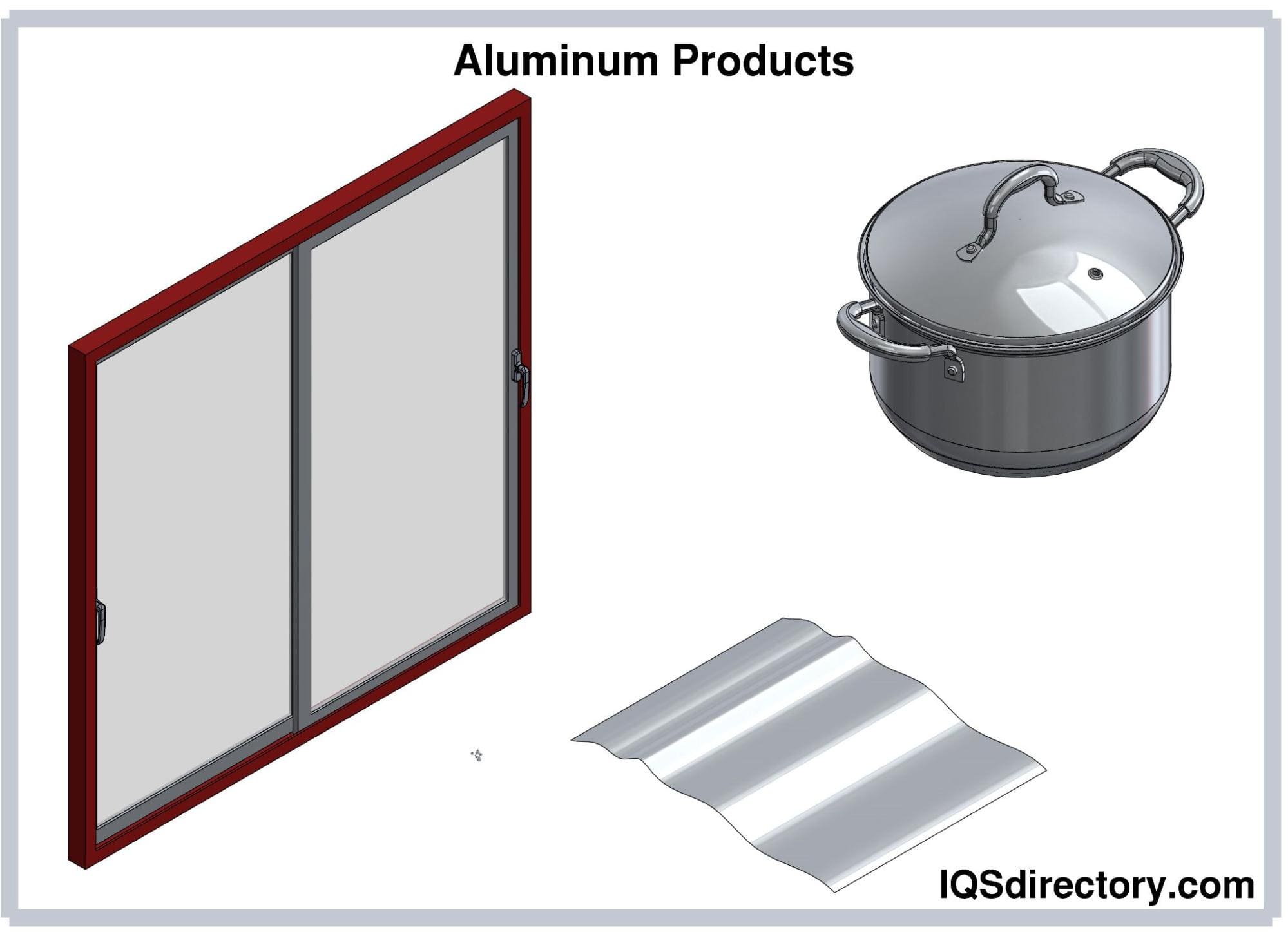

Key Industrial Applications of general steel macon georgia

| Industry/Sector | Specific Application of general steel macon georgia | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural steel for commercial buildings | Provides strength and durability, essential for safety standards | Ensure compliance with local building codes and regulations |

| Transportation | Noise barrier solutions for highways and railways | Enhances safety and comfort for commuters and reduces noise pollution | Evaluate material properties for durability and weather resistance |

| Energy | Fabrication of components for renewable energy projects | Supports sustainable energy initiatives and reduces carbon footprint | Assess availability of specific steel grades for energy applications |

| Manufacturing | Custom metal fabrication for machinery and equipment | Improves operational efficiency and product reliability | Consider precision fabrication capabilities and lead times |

| Oil & Gas | Steel piping and structural components for drilling sites | Essential for operational safety and effective resource extraction | Verify sourcing of high-quality, corrosion-resistant materials |

How is General Steel in Macon, Georgia, Applied in the Construction Sector?

In the construction industry, General Steel in Macon, Georgia, provides structural steel essential for commercial building projects. The strength and durability of their steel products meet stringent safety standards, ensuring that structures can withstand environmental stresses. International buyers from regions like Africa and South America must prioritize sourcing from a supplier that adheres to local building codes and regulations, ensuring compliance while also meeting project timelines.

What Role Does General Steel Play in Transportation Infrastructure?

General Steel supplies noise barrier solutions tailored for highways and railways, significantly enhancing commuter safety and comfort while mitigating noise pollution. These barriers are crucial for urban planning and infrastructure development, particularly in densely populated areas. B2B buyers from the Middle East and Europe should evaluate the material properties of these steel products, focusing on durability and weather resistance, to ensure long-lasting performance in varying climates.

How is General Steel Contributing to Renewable Energy Initiatives?

In the energy sector, General Steel fabricates components used in renewable energy projects, such as wind and solar farms. Their materials support sustainable initiatives, helping businesses reduce their carbon footprint. International buyers should assess the availability of specific steel grades that comply with energy applications, as this will impact the efficiency and longevity of their projects.

What Custom Solutions Does General Steel Offer for Manufacturing?

General Steel provides custom metal fabrication services for various machinery and equipment, enhancing operational efficiency and product reliability. Their capabilities allow businesses to tailor steel components to specific needs, which is particularly beneficial for manufacturers looking to optimize performance. When sourcing from General Steel, buyers should consider the precision fabrication capabilities and lead times to ensure timely project execution.

How Does General Steel Support the Oil & Gas Industry?

In the oil and gas sector, General Steel supplies high-quality steel piping and structural components vital for drilling sites. These products are essential for ensuring operational safety and effective resource extraction. B2B buyers should verify that the sourced materials are corrosion-resistant and meet industry standards, as this will directly impact the safety and efficiency of their operations in challenging environments.

Illustrative image related to general steel macon georgia

3 Common User Pain Points for ‘general steel macon georgia’ & Their Solutions

Scenario 1: Sourcing Quality Steel Products on a Tight Deadline

The Problem: B2B buyers often face immense pressure to meet project deadlines while ensuring they procure quality steel products. In the case of General Steel in Macon, Georgia, buyers may struggle with limited availability of specific steel grades or sizes due to fluctuating inventory levels. This challenge is compounded when international shipping delays impact delivery schedules, jeopardizing project timelines and client satisfaction.

The Solution: To mitigate this issue, buyers should establish a direct communication channel with General Steel’s sales representatives to inquire about real-time inventory status. By leveraging local knowledge and expertise, buyers can specify their exact needs, including grades, sizes, and quantities, ensuring that the supplier can accommodate their requests promptly. Additionally, consider setting up a just-in-time inventory system that allows for the procurement of steel as needed, reducing excess stock while ensuring timely delivery. Engaging in a partnership with General Steel can also yield benefits such as priority access to new shipments, which can be crucial for urgent projects.

Scenario 2: Navigating Compliance and Quality Assurance Standards

The Problem: Buyers from international markets may encounter challenges related to compliance with regional and international steel standards. In industries such as construction and manufacturing, adhering to safety regulations and quality assurance standards is paramount. A buyer may find that the steel products sourced from General Steel need to meet specific certifications that are not clearly outlined in the product specifications.

The Solution: It is essential for buyers to conduct thorough research on the necessary compliance standards that apply to their projects, such as ASTM, ISO, or local regulations. When sourcing from General Steel, buyers should request detailed documentation and certifications for each product, ensuring they meet the required standards. Collaborating closely with General Steel’s technical team can provide insights into which products are best suited for compliance with the specific regulations in the buyer’s country. Additionally, maintaining a checklist of required certifications for each project can streamline the procurement process and avoid potential legal or safety issues.

Scenario 3: Limited Knowledge of Processing Capabilities

The Problem: Many B2B buyers may not fully understand the processing capabilities offered by General Steel, which can lead to missed opportunities for customization. For instance, if a buyer is unaware that General Steel can provide services such as rebar fabrication or galvanizing, they may end up ordering standard products that do not meet their specific project needs, resulting in additional costs and delays.

The Solution: To address this gap in knowledge, buyers should proactively engage with General Steel to learn about the full range of processing services available. Organizing a site visit or a virtual consultation can provide valuable insights into the equipment and capabilities of the facility. Buyers should prepare a list of potential projects and discuss how customized steel solutions can enhance efficiency and reduce costs. By understanding how to leverage General Steel’s processing services, buyers can optimize their orders and ensure they receive tailored solutions that align with their project requirements, ultimately enhancing project outcomes and customer satisfaction.

Strategic Material Selection Guide for general steel macon georgia

What Are the Key Properties of Common Steel Materials in Macon, Georgia?

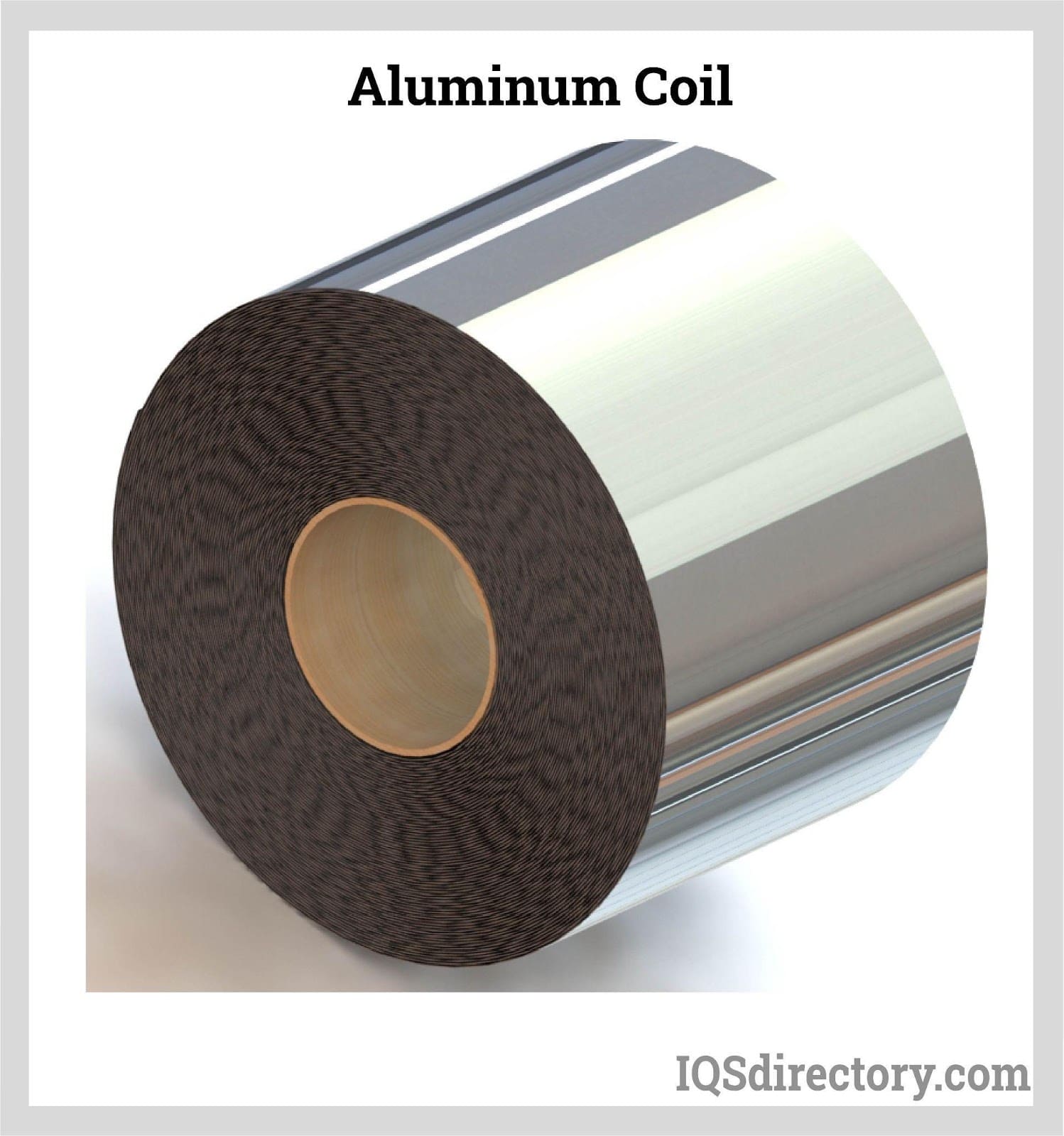

In the context of General Steel in Macon, Georgia, several materials are commonly used for various applications. Here, we analyze four prevalent steel materials: carbon steel, stainless steel, aluminum, and galvanized steel. Each material has unique properties that make it suitable for specific applications, particularly for international B2B buyers.

What Are the Key Properties and Applications of Carbon Steel?

Carbon steel is one of the most widely used materials in the steel industry due to its excellent strength and versatility. Key properties include high tensile strength and good machinability, making it ideal for structural applications. However, it has limited corrosion resistance, which can be a drawback in humid or corrosive environments.

Pros: Carbon steel is cost-effective and readily available, making it a popular choice for construction and manufacturing. Its durability allows it to withstand heavy loads, making it suitable for beams, columns, and various structural components.

Cons: The susceptibility to rust means that protective coatings or treatments are often necessary, adding to the overall cost. Additionally, its performance can degrade at high temperatures, which may limit its use in certain applications.

Impact on Application: Carbon steel is compatible with a wide range of media, but its corrosion resistance issues must be considered when used in environments with moisture or chemicals.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with ASTM standards, particularly ASTM A36 for structural steel. Understanding local environmental conditions is crucial for selecting the right protective measures.

Illustrative image related to general steel macon georgia

How Does Stainless Steel Compare in Performance?

Stainless steel is known for its superior corrosion resistance and aesthetic appeal, making it suitable for applications that require both durability and appearance. Key properties include high resistance to oxidation and staining, as well as good mechanical properties.

Pros: Its durability makes stainless steel ideal for food processing, medical equipment, and architectural applications. The material is also easy to clean, which is essential in industries that prioritize hygiene.

Cons: The primary disadvantage is its higher cost compared to carbon steel. Additionally, while it is resistant to corrosion, it is not entirely immune, especially in chloride-rich environments.

Impact on Application: Stainless steel is compatible with various media, including water, chemicals, and food products, making it versatile for many sectors.

Considerations for International Buyers: Compliance with international standards like ASTM A240 is essential. Buyers should also consider the specific grades of stainless steel, such as 304 or 316, depending on the application and environment.

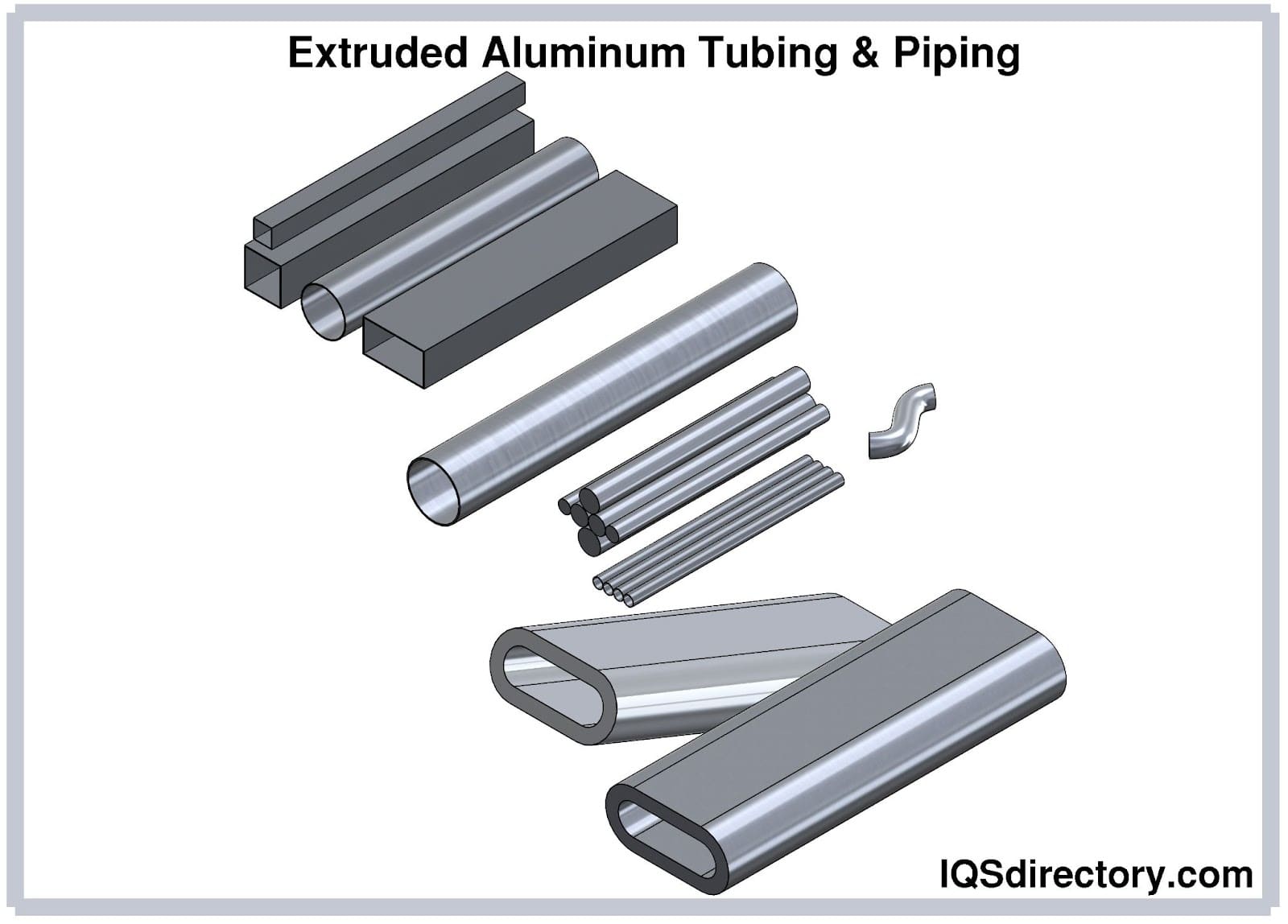

What Are the Benefits of Using Aluminum in Steel Applications?

Aluminum is increasingly used in construction and manufacturing due to its lightweight nature and resistance to corrosion. Key properties include a low density and high strength-to-weight ratio, making it ideal for applications where weight is a critical factor.

Pros: Aluminum is highly resistant to corrosion and does not require extensive protective coatings. Its lightweight nature can lead to lower transportation costs and easier handling during installation.

Cons: The primary limitation is its lower strength compared to steel, which may not make it suitable for heavy load-bearing applications. Additionally, aluminum can be more expensive than carbon steel.

Illustrative image related to general steel macon georgia

Impact on Application: Aluminum is compatible with various media, including water and some chemicals, but may not be suitable for environments with high mechanical stress.

Considerations for International Buyers: Compliance with standards like ASTM B221 is vital. Buyers should also consider the specific alloy types for their intended applications, especially in regions with varying environmental conditions.

How Does Galvanized Steel Enhance Performance in Various Applications?

Galvanized steel is carbon steel that has been coated with zinc to enhance corrosion resistance. Key properties include excellent durability and protection against rust, making it suitable for outdoor applications.

Illustrative image related to general steel macon georgia

Pros: The zinc coating significantly extends the lifespan of steel products, making galvanized steel ideal for construction, fencing, and automotive applications. It requires minimal maintenance compared to uncoated steel.

Cons: While the coating provides excellent protection, it can be damaged during fabrication, exposing the underlying steel to corrosion. Additionally, the cost can be higher than that of untreated carbon steel.

Impact on Application: Galvanized steel is compatible with various media and is particularly effective in outdoor environments where corrosion is a concern.

Considerations for International Buyers: Buyers should ensure compliance with ASTM A123 for hot-dip galvanized coatings. Understanding local standards and practices is essential for ensuring the longevity of galvanized products.

Illustrative image related to general steel macon georgia

Summary Table of Strategic Material Selection

| Material | Typical Use Case for general steel macon georgia | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Structural beams and columns | Cost-effective and durable | Susceptible to corrosion | Low |

| Stainless Steel | Food processing and medical equipment | Superior corrosion resistance | Higher cost compared to carbon steel | High |

| Aluminum | Lightweight structures and components | Lightweight and corrosion-resistant | Lower strength compared to steel | Med |

| Galvanized Steel | Outdoor construction and automotive parts | Extended lifespan due to zinc coating | Coating can be damaged during fabrication | Med |

This guide provides a comprehensive overview of key materials available through General Steel in Macon, Georgia, tailored for international B2B buyers. Understanding these materials’ properties, advantages, and limitations can facilitate informed decision-making for various applications.

In-depth Look: Manufacturing Processes and Quality Assurance for general steel macon georgia

What Are the Key Manufacturing Processes for Steel Products in Macon, Georgia?

The manufacturing processes for steel products at General Steel in Macon, Georgia, encompass several critical stages that ensure high-quality output. These stages include material preparation, forming, assembly, and finishing. Each phase is tailored to meet the specific needs of various industrial applications, from construction to energy sectors.

How is Material Prepared for Steel Manufacturing?

Material preparation is the foundational step in steel manufacturing. It begins with sourcing high-grade raw materials, primarily carbon steel, stainless steel, and aluminum. General Steel employs stringent supplier selection criteria to ensure the quality of materials meets international standards.

Once the raw materials are received, they undergo Incoming Quality Control (IQC) checks. This involves visual inspections and material testing to verify that specifications are met before proceeding. Any non-conforming materials are flagged for review, ensuring that only the highest quality inputs enter the production process.

Illustrative image related to general steel macon georgia

What Techniques Are Used in Steel Forming?

The forming stage involves shaping the prepared materials into desired forms. General Steel utilizes several key techniques, including hot and cold rolling, cutting, and bending. Hot rolling allows for the production of large sections and plates, while cold rolling is employed for producing thinner sheets with tighter tolerances.

Advanced machinery is used to execute precision operations like shearing, punching, and drilling, which are essential for creating complex shapes and configurations. Each technique is selected based on the specific requirements of the final product, balancing efficiency with quality.

How Is Assembly Managed in the Manufacturing Process?

Assembly is where the components are brought together to create the final product. General Steel employs skilled technicians who follow detailed assembly instructions to ensure accuracy and consistency. This stage may include welding, bolting, or fastening various parts together, depending on the product’s requirements.

Quality checks are integrated throughout the assembly process. In-Process Quality Control (IPQC) measures are employed to identify any defects or deviations from specifications immediately, allowing for corrective actions to be taken before proceeding to the next stage.

What Finishing Techniques Are Applied to Steel Products?

Finishing is the final stage in the manufacturing process, enhancing the product’s durability and aesthetic appeal. General Steel offers various finishing techniques, including galvanizing, painting, and surface treatment. These processes are vital for protecting steel from corrosion and wear, especially for products intended for outdoor or harsh environments.

The finishing stage also includes final inspections to ensure that the product meets all quality and aesthetic standards before it is shipped to customers. This ensures that international buyers receive products that not only function well but also present well.

How Does Quality Assurance Work in Steel Manufacturing?

Quality assurance (QA) is a crucial aspect of the manufacturing process at General Steel. The company adheres to internationally recognized standards such as ISO 9001 to maintain quality management systems. This ensures that every product consistently meets customer and regulatory requirements.

Illustrative image related to general steel macon georgia

What International Standards Are Relevant for Steel Manufacturing?

For B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, understanding the relevant standards is vital. Apart from ISO 9001, General Steel complies with industry-specific standards such as CE marking for European markets and API specifications for the oil and gas sector. These certifications signal a commitment to quality and safety in manufacturing processes.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are strategically placed throughout the manufacturing process. The key checkpoints include:

- Incoming Quality Control (IQC): Ensures raw materials meet specifications before processing.

- In-Process Quality Control (IPQC): Monitors production at various stages to catch defects early.

- Final Quality Control (FQC): Conducts final inspections before products are dispatched.

These checkpoints help maintain high standards and minimize the risk of defects reaching customers.

What Common Testing Methods Are Utilized?

Testing methods play a significant role in validating product quality. Common techniques include:

- Tensile Testing: Measures the strength and ductility of materials.

- Hardness Testing: Assesses material hardness to ensure it meets application requirements.

- Non-Destructive Testing (NDT): Techniques like ultrasonic and magnetic particle testing ensure structural integrity without damaging the product.

Each testing method is selected based on the material type and intended application, providing assurance to B2B buyers about product reliability.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, verifying a supplier’s quality control practices is crucial. Here are several actionable steps to ensure quality:

- Conduct Supplier Audits: Regular audits can provide insights into manufacturing practices, compliance with standards, and overall quality systems.

- Request Quality Reports: Suppliers should be able to provide documentation detailing their quality control processes, inspection results, and any certifications obtained.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the manufacturing process and product quality.

What Are the Quality Control Nuances for International Buyers?

Understanding the nuances of quality control is essential for B2B buyers, especially those from regions with varying standards. Buyers should be aware of:

- Cultural Differences in Quality Perception: Different regions may have distinct expectations regarding quality standards and testing methods.

- Regulatory Requirements: Familiarize yourself with local regulations that may affect product specifications, such as import standards in your region.

- Language Barriers: Ensure clear communication with suppliers regarding quality expectations and documentation requirements.

By taking these factors into account, B2B buyers can confidently navigate the complexities of international steel sourcing, ensuring they receive high-quality products tailored to their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘general steel macon georgia’

In today’s competitive marketplace, sourcing quality steel products requires careful planning and consideration, especially for international buyers looking to procure from General Steel in Macon, Georgia. This guide offers a practical checklist to help you navigate the procurement process effectively, ensuring you make informed decisions that align with your business needs.

1. Identify Your Project Requirements

Before starting your sourcing journey, clearly define the technical specifications of the steel products you need. This includes the type of steel (e.g., carbon, stainless, aluminum), dimensions, grades, and any specific processing requirements like cutting or galvanizing. Understanding your project requirements will help you communicate effectively with potential suppliers and ensure you receive suitable products.

Illustrative image related to general steel macon georgia

2. Research Potential Suppliers

Conduct thorough research to identify suppliers that can meet your specifications. Look for companies with a strong reputation in the industry, such as Triple-S Steel, which has a significant presence in Macon, Georgia. Utilize online directories, industry publications, and trade shows to gather a list of potential suppliers, ensuring they have the capacity to fulfill your order size and delivery timelines.

3. Evaluate Supplier Certifications

Verify that the suppliers you are considering have the necessary certifications and compliance with industry standards. Check for certifications such as ISO 9001, which indicates a commitment to quality management, and membership in relevant industry associations like the North American Steel Alliance. These credentials demonstrate a supplier’s reliability and adherence to best practices.

4. Request and Compare Quotes

Once you have shortlisted potential suppliers, request detailed quotes that outline pricing, lead times, and terms of service. Be sure to compare not only the costs but also the value-added services offered, such as processing capabilities and customer support. A comprehensive comparison will help you make a more informed decision based on both quality and price.

5. Review Supplier Experience and References

Before finalizing your choice, review the supplier’s experience in your specific industry or project type. Request references from previous clients, particularly those who have undertaken similar projects. This will provide insights into the supplier’s reliability, service quality, and ability to meet deadlines.

6. Negotiate Terms and Conditions

Engage in negotiations to establish favorable terms and conditions. Discuss payment terms, delivery schedules, and warranties or guarantees. Clear agreements help prevent misunderstandings and ensure both parties are aligned on expectations, which is crucial for long-term partnerships.

7. Plan for Logistics and Delivery

Finally, consider the logistics involved in transporting steel from Macon to your location. Evaluate shipping options, customs regulations, and potential import duties. A well-planned logistics strategy will minimize delays and ensure that your steel products arrive on time and in good condition.

By following this checklist, you can streamline your sourcing process and ensure that you procure high-quality steel products that meet your project’s needs while building strong relationships with reliable suppliers.

Comprehensive Cost and Pricing Analysis for general steel macon georgia Sourcing

What Are the Key Cost Components in General Steel Sourcing from Macon, Georgia?

When sourcing general steel from Macon, Georgia, international B2B buyers should be aware of several critical cost components that influence overall pricing. The primary cost components include:

-

Materials: The type of steel (carbon, stainless, aluminum) significantly affects pricing. Local suppliers like Triple-S Steel and General Steel offer a variety of materials, which can vary in cost based on market demand and availability.

-

Labor: Labor costs in Georgia are competitive, but they can fluctuate based on the skill level required for specific fabrication processes. For instance, skilled labor for welding or precision cutting may command higher wages, impacting overall costs.

-

Manufacturing Overhead: This includes expenses related to facility operations, utilities, and equipment maintenance. Overhead costs can vary based on the supplier’s operational efficiency and facility location.

-

Tooling: Specialized tooling for unique projects can add to initial costs. Buyers should consider whether the supplier has the necessary tooling readily available or if new tools will need to be fabricated.

-

Quality Control (QC): Implementing robust QC measures ensures product reliability but can contribute to higher costs. Suppliers with certifications (like ISO) may charge a premium for the assurance of quality.

-

Logistics: Transportation costs can vary significantly based on the shipping distance and method. For international buyers, additional logistics considerations include customs duties and import tariffs.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the market dynamics and average margins in the steel industry can help buyers gauge fair pricing.

How Do Price Influencers Affect General Steel Sourcing from Macon?

Several factors influence the pricing of general steel that buyers should consider:

-

Volume/MOQ: Bulk orders often qualify for discounts. Understanding the minimum order quantities (MOQ) can help buyers optimize their purchase size to achieve cost savings.

-

Specifications and Customization: Customized products may incur additional costs. When requesting specific dimensions or properties, buyers should clarify these requirements upfront to avoid unexpected charges.

-

Materials and Quality Certifications: Higher-quality materials or those with specific certifications can lead to increased costs. Buyers should assess their project needs against the quality offered to ensure they are paying for what is necessary.

-

Supplier Factors: The supplier’s reputation and reliability can influence pricing. Established suppliers may charge more due to their proven track record, while emerging suppliers might offer lower prices to attract business.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for pricing. They dictate the responsibilities for shipping, insurance, and tariffs, which can significantly affect the total landed cost of steel.

What Buyer Tips Can Enhance Cost-Efficiency in Steel Sourcing?

International buyers from regions such as Africa, South America, the Middle East, and Europe should consider these strategies to enhance cost-efficiency:

-

Negotiation: Engaging in discussions with suppliers can yield better pricing. Establishing a rapport may lead to favorable terms or discounts, especially for long-term contracts.

-

Total Cost of Ownership (TCO): Buyers should evaluate the TCO rather than just the upfront price. This includes considering maintenance, durability, and potential waste in their calculations.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, and factor in exchange rates when comparing prices. Additionally, understanding local market conditions can provide leverage during negotiations.

-

Research and Comparison: Conduct thorough market research and compare prices from multiple suppliers. This can help identify the best value propositions while ensuring quality standards are met.

In conclusion, understanding the cost structure, price influencers, and strategic buying tips can empower international B2B buyers to make informed decisions when sourcing general steel from Macon, Georgia. Prices may vary, and it is advisable to request quotes and specifications tailored to your unique project requirements.

Alternatives Analysis: Comparing general steel macon georgia With Other Solutions

Understanding Alternatives in Steel Supply Solutions

In the competitive landscape of steel supply, businesses often face the challenge of selecting the most suitable provider or solution for their specific needs. General Steel in Macon, Georgia, offers a comprehensive range of steel products and services, but various alternatives can meet similar requirements. Evaluating these options based on performance, cost, ease of implementation, maintenance, and best use cases can empower B2B buyers to make informed decisions that align with their operational goals.

| Comparison Aspect | General Steel Macon Georgia | Alternative 1: Triple-S Steel | Alternative 2: Macon Carbon Metric |

|---|---|---|---|

| Performance | High-quality carbon and stainless steel; extensive processing capabilities | Extensive inventory; specializes in noise barrier steel; strong processing services | Focused on piping solutions; high durability and reliability |

| Cost | Competitive pricing, with potential for bulk discounts | Slightly higher due to extensive service offerings | Generally lower for piping products, but varies by specification |

| Ease of Implementation | Established logistics; good customer support | Strong regional presence ensures timely deliveries | Local supplier advantage; quick turnaround for piping needs |

| Maintenance | Low maintenance due to robust materials; support available | Offers maintenance services; high quality minimizes issues | Regular maintenance needed for piping systems |

| Best Use Case | Ideal for construction and industrial projects requiring diverse steel solutions | Best for large projects needing comprehensive steel services | Best for plumbing and HVAC systems requiring durable pipes |

Exploring Triple-S Steel as an Alternative

Triple-S Steel, which acquired General Steel’s assets, has positioned itself as a leading provider of steel products and processing services. The company boasts a substantial inventory and specializes in noise barrier steel, making it an excellent choice for projects that require specific structural solutions. While their costs may be slightly higher, the extensive service offerings and processing capabilities justify the investment. For businesses engaged in large-scale construction or infrastructure projects, Triple-S Steel provides a reliable partner with a strong logistical framework.

Illustrative image related to general steel macon georgia

Evaluating Macon Carbon Metric for Piping Solutions

Macon Carbon Metric stands out as a dedicated supplier of pipes, catering primarily to industrial and residential projects. Their focus on high-quality piping solutions makes them an ideal alternative for companies in need of robust plumbing or HVAC systems. The competitive pricing and quick turnaround times enhance their appeal, especially for smaller projects or those with urgent timelines. However, businesses should note that while Macon Carbon Metric excels in piping, it may not offer the same breadth of steel products as General Steel or Triple-S Steel, making it less suitable for comprehensive construction needs.

Conclusion: Choosing the Right Steel Solution for Your Business

When selecting a steel supplier, B2B buyers should assess their specific project requirements, budget constraints, and desired service levels. General Steel in Macon, Georgia, provides a well-rounded offering for diverse construction needs, while alternatives like Triple-S Steel and Macon Carbon Metric cater to specialized demands. By carefully analyzing the performance, cost, implementation ease, and maintenance considerations of each option, businesses can make strategic decisions that not only meet their immediate needs but also support long-term operational success.

Essential Technical Properties and Trade Terminology for general steel macon georgia

What Are the Key Technical Properties of General Steel in Macon, Georgia?

When considering general steel from Macon, Georgia, it is essential to understand several technical properties that directly impact quality, performance, and suitability for various applications. Here are some of the most critical specifications:

-

Material Grade

Material grades indicate the chemical composition and mechanical properties of steel. Common grades include ASTM A36 for structural steel and ASTM A992 for high-strength applications. Understanding the material grade is vital for B2B buyers to ensure the steel meets industry standards and project requirements, thus preventing costly failures and ensuring structural integrity. -

Yield Strength

Yield strength refers to the amount of stress that a material can withstand while still returning to its original shape. For instance, structural steels like A36 have a yield strength of around 36,000 psi. Knowing the yield strength helps businesses assess whether the steel can support the intended loads in construction or manufacturing applications, ensuring safety and compliance with engineering specifications. -

Tolerance

Tolerance is the permissible limit or limits of variation in a physical dimension. In the context of steel, this can refer to dimensions such as thickness, width, or length. Precise tolerances are crucial for ensuring that steel components fit together correctly, which is particularly important in sectors like construction and manufacturing where accuracy can impact overall project timelines and costs. -

Ductility

Ductility measures a material’s ability to deform under tensile stress. Steel with high ductility can absorb energy and deform without fracturing, making it ideal for seismic applications. For B2B buyers, understanding ductility is key when selecting materials for projects in areas prone to earthquakes or heavy loads, as it affects the longevity and safety of structures. -

Corrosion Resistance

Corrosion resistance is the ability of steel to withstand environmental factors that cause deterioration. For instance, galvanized steel offers enhanced protection against rust and corrosion. Buyers need to consider corrosion resistance based on the application environment, especially for outdoor or industrial uses, to ensure durability and reduce maintenance costs.

What Are Common Trade Terminologies in the Steel Industry?

Understanding industry terminology is crucial for effective communication and negotiation in the steel supply chain. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the steel industry, this term often applies to manufacturers of steel components used in larger machinery. Knowing who the OEM is can help buyers gauge product quality and compatibility. -

MOQ (Minimum Order Quantity)

MOQ is the smallest order size that a supplier is willing to accept. Understanding MOQ is essential for B2B buyers, as it can affect inventory management and cash flow. Suppliers may have different MOQs based on material type or grade, influencing purchasing decisions. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific goods or services. In the steel industry, RFQs are often used to gather pricing and terms for large orders. By submitting an RFQ, buyers can ensure they receive competitive pricing and suitable terms from multiple suppliers. -

Incoterms

Incoterms (International Commercial Terms) are standardized terms that define the responsibilities of buyers and sellers regarding shipping and delivery. Familiarity with Incoterms is crucial for international transactions, as they clarify who is responsible for shipping costs, insurance, and risks during transit, helping to avoid disputes. -

Steel Processing Services

This term refers to the various operations performed on steel to prepare it for specific applications, including cutting, welding, and coating. Understanding the available processing services helps B2B buyers select suppliers that can deliver customized solutions tailored to their project needs.

By familiarizing yourself with these technical properties and trade terms, you can make informed decisions that enhance your procurement process and ensure the success of your projects involving general steel from Macon, Georgia.

Navigating Market Dynamics and Sourcing Trends in the general steel macon georgia Sector

What are the Current Market Dynamics and Key Trends in the General Steel Sector in Macon, Georgia?

The steel market in Macon, Georgia, is influenced by a combination of global economic factors and localized demand trends. As a vital hub for steel distribution, Macon benefits from its strategic location, providing access to critical transportation networks. Current drivers include increased infrastructure investments, particularly in the U.S. and emerging economies in Africa and South America. These investments are pushing demand for steel products, from structural components to specialized items like noise barrier steel, which is increasingly required for urban development projects.

Illustrative image related to general steel macon georgia

Emerging technologies in sourcing and supply chain management are shaping how international buyers approach procurement. Automation and data analytics are enhancing inventory management, allowing suppliers to maintain optimal stock levels and reduce lead times. For buyers from regions like Vietnam and Brazil, these advancements mean greater reliability in sourcing high-quality steel products. Furthermore, the rise of digital marketplaces is simplifying international transactions, enabling buyers to connect with suppliers more efficiently.

How is Sustainability Influencing Steel Sourcing in the B2B Market?

Sustainability and ethical sourcing are becoming paramount in the steel industry, particularly for international buyers who are increasingly mindful of environmental impact. The production of steel is traditionally resource-intensive, but companies in Macon, like Triple-S Steel, are investing in processes that minimize their carbon footprint. This includes utilizing recycled materials and adopting energy-efficient manufacturing practices.

B2B buyers are encouraged to seek suppliers who prioritize green certifications and sustainable practices. Certifications such as LEED (Leadership in Energy and Environmental Design) and ISO 14001 can indicate a commitment to environmental stewardship. Moreover, sourcing from suppliers that utilize eco-friendly materials not only enhances corporate responsibility but can also lead to long-term cost savings. As global markets increasingly favor sustainable products, aligning procurement strategies with these values is essential for maintaining competitiveness.

How Has the General Steel Industry in Macon, Georgia Evolved Over Time?

The general steel industry in Macon has a rich history dating back to the mid-20th century. Originally founded as General Steel in 1956, the company established itself as a key player in the regional market. In 2013, it was acquired by Triple-S Steel, which rebranded the operation while preserving its legacy of quality and service. This evolution reflects broader trends in the steel sector, where consolidation and strategic acquisitions have allowed companies to expand their product offerings and geographic reach.

As the industry has matured, Macon has adapted to meet changing market demands, including the rise of value-added services such as custom fabrication and processing capabilities. This adaptability positions Macon as a vital resource for international B2B buyers seeking reliable steel solutions in a competitive landscape. The ongoing commitment to innovation and customer service continues to define the steel market in this region, ensuring its relevance in a rapidly evolving global economy.

Frequently Asked Questions (FAQs) for B2B Buyers of general steel macon georgia

-

How do I ensure quality when sourcing steel from Macon, Georgia?

To ensure quality when sourcing steel from Macon, Georgia, it’s crucial to partner with reputable suppliers like Triple-S Steel, which has a long history in the industry. Look for suppliers that adhere to recognized quality standards and certifications, such as ISO or ASTM. Request samples and specifications to verify the quality of the steel, and consider visiting the facility if feasible. Establishing clear communication regarding your quality expectations and having a robust quality assurance process in place can also mitigate risks. -

What types of steel products are available from suppliers in Macon, Georgia?

Suppliers in Macon, Georgia, offer a diverse range of steel products, including hot-rolled and cold-rolled carbon steel, stainless steel, aluminum, and various structural shapes. Additionally, you can find specialty products like rebar, plates, sheets, and noise barrier steel. It is advisable to discuss your specific project requirements with suppliers to determine the best product fit. Customization options are often available, allowing you to order steel tailored to your project needs. -

What are the minimum order quantities (MOQs) for steel products in Macon?

Minimum order quantities (MOQs) can vary significantly among suppliers in Macon, Georgia. Generally, larger suppliers may have flexible MOQs based on product type and availability. It’s advisable to directly communicate with potential suppliers to understand their MOQs and negotiate terms that align with your project requirements. Smaller orders may incur additional fees or may be subject to longer lead times, so factor this into your planning. -

What payment terms can I expect when sourcing steel internationally?

Payment terms for international steel sourcing typically range from upfront payments to net 30 or net 60 terms, depending on the supplier’s policies and your relationship with them. Many suppliers may require a deposit, especially for custom orders. It’s essential to clarify payment methods accepted (e.g., wire transfer, letters of credit) and consider using secure payment options to protect your investment. Establishing a reliable payment history can also lead to more favorable terms in future transactions. -

How do I vet potential steel suppliers in Macon, Georgia?

When vetting potential steel suppliers, consider their industry experience, customer reviews, and certifications. Check if they are members of industry associations like the North American Steel Alliance, which can indicate credibility. Request references from previous clients and assess their response times and customer service quality. A site visit can provide valuable insights into their operations and capabilities, helping you ensure they align with your quality and service expectations. -

What logistics considerations should I keep in mind when importing steel?

Logistics is a critical factor when importing steel, as it involves coordination between suppliers, shipping companies, and customs authorities. Consider the shipping methods available (e.g., container shipping, flatbed trucks) and the associated costs. Ensure that your supplier can meet your delivery timelines and that you have a clear understanding of customs regulations in your country. Working with a logistics partner experienced in international trade can help streamline this process and mitigate potential delays. -

Can I customize steel products to meet specific project requirements?

Yes, many suppliers in Macon, Georgia, offer customization options for steel products. You can request specific dimensions, grades, and finishes based on your project needs. Discuss your requirements with the supplier’s technical team to ensure they can accommodate your specifications. Custom orders may have longer lead times and different pricing structures, so it’s important to plan accordingly and confirm all details before placing an order. -

What are the common quality assurance practices for steel suppliers?

Common quality assurance practices among steel suppliers include regular material testing, adherence to industry standards, and implementation of robust inspection protocols. Suppliers often conduct tests such as tensile strength, chemical composition analysis, and dimensional checks. Ask potential suppliers about their quality control procedures and any certifications they hold. Establishing clear quality expectations and having a formal agreement on QA processes can help ensure that the materials you receive meet your project’s standards.

Top 3 General Steel Macon Georgia Manufacturers & Suppliers List

1. Triple S Steel – Structural Steel Solutions

Domain: triple-s-steel.com

Registered: 2024 (1 years)

Introduction: Steel Angle Bar, Bar Grating, Beam, Jumbo Beam, Standard I-Beam, Wide Flange Beam, Channel, Hot-Rolled Steel Bar Channel, MC Channel (Car, Ship, & Jr.), Stair-Stringer Channel, Structural Steel Channel, Rebar, Decking, Composite Deck, Roof Deck, Steel Joists, Expanded Metal Standard (Raised), Expanded Metal Flattened, Expanded Metal Grating, Floor Plate, Metal Building Components, Pipe, Steel Plat…

2. Triple-S Steel® – Diverse Steel Products

Domain: sss-steel.com

Registered: 1997 (28 years)

Introduction: Triple-S Steel® offers a diverse range of steel products and processing services, including:

– **Materials:**

– Carbon Steel

– Alloy Steel

– Stainless & Aluminum

– Copper, Brass, Copper Nickel

– **Shapes:**

– Angle

– Bar

– Beam

– Channel

– Pipe

– Plate

– Sheet

– Tube

– **Steel Decking:**

– Composite Deck

– Roof Deck

– **Expanded Metal & Grating:** …

3. Family Owned Business – CFO/Controller Opportunity

Domain: indeed.com

Registered: 1998 (27 years)

Introduction: This company, Family Owned Business – CFO/Controller Opportunity, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for general steel macon georgia

In today’s competitive landscape, strategic sourcing from General Steel in Macon, Georgia, offers unparalleled advantages for international B2B buyers. With a rich history dating back to the 1950s, the facility now under Triple-S Steel has evolved into a leading supplier of a diverse range of steel products, including carbon, stainless, and aluminum options. This location not only boasts substantial inventory but also advanced processing capabilities that cater to the specific needs of various industries, from construction to energy.

The value of strategic sourcing lies in its ability to ensure timely delivery of high-quality materials, tailored solutions, and competitive pricing. By partnering with a reputable supplier like General Steel, businesses can enhance their operational efficiency and gain a competitive edge in their respective markets.

As global demand for steel continues to rise, the opportunities for collaboration and growth are significant. International buyers from regions such as Africa, South America, the Middle East, and Europe are encouraged to explore the robust offerings and innovative solutions available through General Steel in Macon. Embrace the potential of strategic sourcing today to secure a reliable supply chain that can support your business objectives for years to come.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.