A B2B Buyer’s Guide to Gearbox Flushing Machine: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for gearbox flushing machine

In today’s competitive automotive landscape, sourcing a reliable gearbox flushing machine presents a significant challenge for international B2B buyers. The importance of maintaining optimal transmission performance through effective flushing cannot be overstated; it not only enhances vehicle longevity but also ensures superior driving comfort. This guide serves as a comprehensive resource, detailing various types of gearbox flushing machines, their applications, and key considerations for supplier vetting and cost analysis.

As markets in Africa, South America, the Middle East, and Europe continue to evolve, understanding the nuances of gearbox flushing technology becomes essential for businesses aiming to stay ahead. Buyers will benefit from insights into advanced features, such as high-efficiency cleaning mechanisms and manufacturer-approved devices, which can differentiate their service offerings in a crowded marketplace.

Furthermore, this guide empowers decision-makers by providing actionable strategies for selecting the right machinery that aligns with their operational needs and budget constraints. By focusing on best practices and industry standards, we aim to facilitate informed purchasing decisions that enhance service quality and profitability. Whether you are in Saudi Arabia, Brazil, or any other emerging market, this guide equips you with the knowledge necessary to navigate the complexities of sourcing gearbox flushing machines effectively.

Understanding gearbox flushing machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Automatic Transmission Fluid Flushing Machine | Designed for complete oil circuit flushing without aggressive cleaners | Automotive repair shops, fleet maintenance | Pros: Efficient cleaning, reduces wear; Cons: Higher initial investment. |

| Compact Flush Machine | Portable and suitable for all types of automatic transmissions | Mobile service providers, small workshops | Pros: Space-saving, versatile; Cons: May lack advanced features. |

| Digital Automatic Transmission Flush Machine | Quick operation (under 20 minutes), user-friendly interface | High-volume service centers | Pros: Fast service, real-time data; Cons: Requires training for optimal use. |

| Multi-Fluid Flush Machine | Capable of flushing multiple types of fluids (ATF, CVT, etc.) | Diverse automotive services | Pros: Versatility for various vehicles; Cons: Complexity in operation. |

| Fully Automatic Flush Machine | Automated processes, built-in diagnostics, and reporting features | Large workshops and dealerships | Pros: Reduces labor costs, improves accuracy; Cons: Higher maintenance costs. |

What Are the Characteristics of an Automatic Transmission Fluid Flushing Machine?

Automatic Transmission Fluid (ATF) flushing machines are specialized devices designed to effectively clean the oil circuit of automatic transmissions. These machines operate by flushing out old fluid and contaminants, ensuring that fresh oil circulates throughout the system. They are particularly suitable for automotive repair shops and fleet maintenance operations where maintaining vehicle performance is critical. Buyers should consider the machine’s efficiency, compatibility with various transmission types, and the potential for generating additional revenue through services.

How Do Compact Flush Machines Differ from Other Types?

Compact flush machines are portable and designed for versatility, making them ideal for mobile service providers and smaller workshops. These machines can handle various automatic transmission types and are designed for ease of use. While they save space and can be moved easily, buyers should weigh their limited advanced features against the need for efficiency in high-demand environments.

What Are the Benefits of a Digital Automatic Transmission Flush Machine?

Digital ATF flush machines are known for their quick operation, typically completing a flush in under 20 minutes. They feature user-friendly interfaces that allow technicians to monitor and control the flushing process easily. Such machines are particularly beneficial for high-volume service centers that require rapid turnaround times. However, the need for technician training to maximize the machine’s capabilities is a consideration for potential buyers.

Why Choose a Multi-Fluid Flush Machine?

Multi-fluid flush machines are designed to accommodate various types of fluids, including ATF and CVT oils, making them suitable for a wide range of vehicles. This versatility is advantageous for automotive services that handle diverse makes and models. While they offer broad application potential, the complexity of operation may require additional training for technicians, which should be factored into purchasing decisions.

What Advantages Do Fully Automatic Flush Machines Offer?

Fully automatic flush machines automate the flushing process, often incorporating built-in diagnostics and reporting features. These machines are ideal for large workshops and dealerships where efficiency and accuracy are paramount. They can significantly reduce labor costs and improve service quality. However, buyers should be aware of the higher maintenance costs associated with these advanced systems, which can impact overall operational budgets.

Key Industrial Applications of gearbox flushing machine

| Industry/Sector | Specific Application of gearbox flushing machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Flushing automatic transmissions in vehicles | Enhances vehicle performance, extends transmission life | Compatibility with a range of vehicle brands and models |

| Heavy Machinery | Maintenance of gearboxes in construction equipment | Reduces downtime, improves operational efficiency | Durability and ease of use in demanding environments |

| Marine Industry | Flushing gearboxes in marine vessels | Prevents costly repairs, ensures reliable operation | Resistance to harsh marine conditions |

| Oil & Gas | Maintenance of drilling equipment gearboxes | Increases reliability, minimizes operational disruptions | Compliance with industry regulations and standards |

| Manufacturing | Flushing gearboxes in industrial machinery | Enhances machine lifespan, reduces maintenance costs | Availability of specialized adapters for various machines |

How is a gearbox flushing machine utilized in the automotive repair industry?

In the automotive repair sector, gearbox flushing machines are essential for servicing automatic transmissions. They effectively remove old transmission fluid, contaminants, and deposits, ensuring that only clean, fresh oil circulates within the system. This process helps restore shifting quality and prolongs the life of the transmission, addressing common issues such as hard shifting and delayed gear changes. For international buyers, especially in regions like Africa and South America, sourcing machines that comply with local vehicle specifications and offer robust support is crucial.

What role does a gearbox flushing machine play in heavy machinery maintenance?

In the heavy machinery sector, gearbox flushing machines are pivotal for maintaining construction equipment, such as excavators and bulldozers. Regular flushing ensures that gearboxes operate smoothly by eliminating dirt and sludge that can accumulate over time. This proactive maintenance reduces the risk of breakdowns, thereby minimizing costly downtime and enhancing operational efficiency. Buyers in the Middle East and Europe should consider machines that can withstand rugged conditions and offer adaptability for various equipment brands.

How can gearbox flushing machines benefit the marine industry?

The marine industry relies heavily on gearbox flushing machines to maintain the performance of vessels. Flushing gearboxes in boats and ships prevents the buildup of harmful deposits that can lead to mechanical failures, ensuring reliable operation in harsh marine environments. This maintenance is vital for preventing costly repairs and enhancing safety at sea. When sourcing these machines, buyers should prioritize models that offer corrosion resistance and compliance with maritime regulations, particularly in regions like Saudi Arabia and Brazil.

Why are gearbox flushing machines important in the oil and gas sector?

In the oil and gas industry, gearbox flushing machines are crucial for maintaining drilling equipment and ensuring that gearboxes function optimally under high-stress conditions. Regular flushing helps to prevent failures that could disrupt operations and lead to significant financial losses. Buyers should focus on sourcing machines that meet stringent industry standards and offer durability to handle extreme conditions, which is especially relevant for buyers in remote or challenging environments.

How do gearbox flushing machines enhance manufacturing processes?

In manufacturing, gearbox flushing machines are used to maintain industrial machinery, ensuring that gearboxes operate efficiently and effectively. By removing old lubricants and contaminants, these machines help to extend the lifespan of equipment and reduce the frequency of maintenance interventions. This results in lower operational costs and increased productivity. Buyers should look for machines that come with various adapters to accommodate different machinery types, facilitating seamless integration into existing maintenance protocols.

3 Common User Pain Points for ‘gearbox flushing machine’ & Their Solutions

Scenario 1: Navigating High Initial Investment Costs for Gearbox Flushing Machines

The Problem: Many B2B buyers, particularly those in emerging markets such as Africa and South America, face the challenge of high initial investment costs when acquiring gearbox flushing machines. This financial burden can deter businesses from investing in essential equipment that enhances service offerings. Buyers may worry about the return on investment, especially in markets where customers are not fully aware of the benefits of gearbox flushing.

The Solution: To mitigate these concerns, buyers should look for suppliers that offer flexible financing options or leasing arrangements. For instance, companies like FUCHS provide support by covering a portion of the investment costs through oil agreements, which can significantly lower the financial barrier. Additionally, buyers should conduct a thorough cost-benefit analysis, emphasizing the long-term savings and revenue potential from offering gearbox flushing services. Engaging in partnerships with established brands can also enhance credibility and attract more customers, thereby ensuring a quicker return on investment.

Scenario 2: Overcoming Customer Skepticism Regarding Gearbox Flushing Benefits

The Problem: A prevalent issue faced by workshops is customer skepticism about the necessity and effectiveness of gearbox flushing. Many vehicle owners hold the outdated belief that automatic transmissions do not require regular oil changes. This misunderstanding can lead to reluctance in opting for flushing services, which hampers workshop revenue and growth.

The Solution: To effectively address this skepticism, workshops should invest in educational marketing strategies. This could involve creating informative brochures, hosting workshops, or utilizing digital platforms to share testimonials and case studies that illustrate the benefits of gearbox flushing. Additionally, workshops can offer initial promotional rates or bundled services that make it easier for customers to try the flushing service without a significant financial commitment. Building trust through transparency about the process and its benefits will encourage customers to prioritize gearbox maintenance.

Scenario 3: Ensuring Compatibility and Efficiency with Various Vehicle Models

The Problem: B2B buyers often struggle with ensuring that gearbox flushing machines are compatible with a wide range of vehicle models. Different manufacturers have varying specifications and fluid types, which can complicate the purchasing decision. This complexity can lead to inefficiencies, as workshops may need to invest in multiple machines or adapters to handle diverse vehicles, resulting in increased operational costs.

The Solution: Buyers should prioritize purchasing machines that offer versatility and compatibility with numerous vehicle brands and models. For example, machines like the Fortrons New Generation Automatic Transmission Fluid Exchange Machine come with optional adapter kits that cater to various manufacturers. It is also advisable to engage with suppliers that provide comprehensive training and support, ensuring that staff are well-versed in the operation of the equipment across different vehicles. Regularly updating the machine’s capabilities and keeping an inventory of necessary adapters can also streamline operations and reduce downtime, thereby enhancing overall efficiency in service delivery.

Strategic Material Selection Guide for gearbox flushing machine

What Materials Are Commonly Used in Gearbox Flushing Machines?

When selecting materials for gearbox flushing machines, it’s crucial to consider their properties, performance, and compatibility with various fluids. Here, we analyze four common materials: aluminum, stainless steel, high-density polyethylene (HDPE), and brass. Each material has unique characteristics that can significantly impact the machine’s performance and longevity.

Aluminum: Lightweight and Corrosion-Resistant

Aluminum is often used in the construction of gearbox flushing machines due to its lightweight nature and excellent corrosion resistance. It can withstand moderate temperatures and pressures, making it suitable for various automotive applications.

Pros:

– Lightweight, which aids in portability and ease of installation.

– Corrosion-resistant, reducing the risk of rust and degradation over time.

– Cost-effective compared to other metals.

Cons:

– Lower strength compared to stainless steel, which may limit its use in high-pressure applications.

– Prone to scratching and denting, which can affect aesthetics and functionality.

Impact on Application:

Aluminum is compatible with a wide range of fluids, including automatic transmission fluids (ATF). However, care must be taken to avoid exposure to highly aggressive chemicals that could cause corrosion.

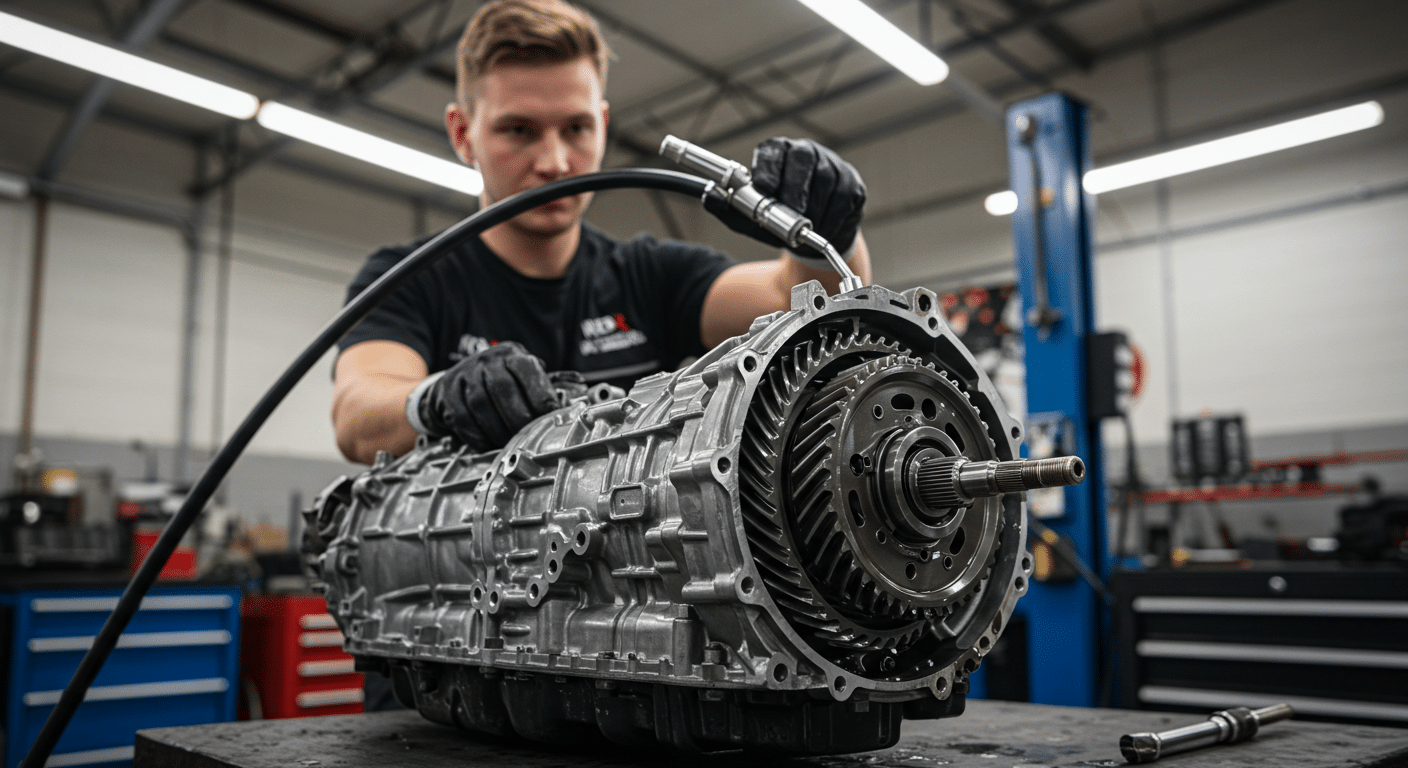

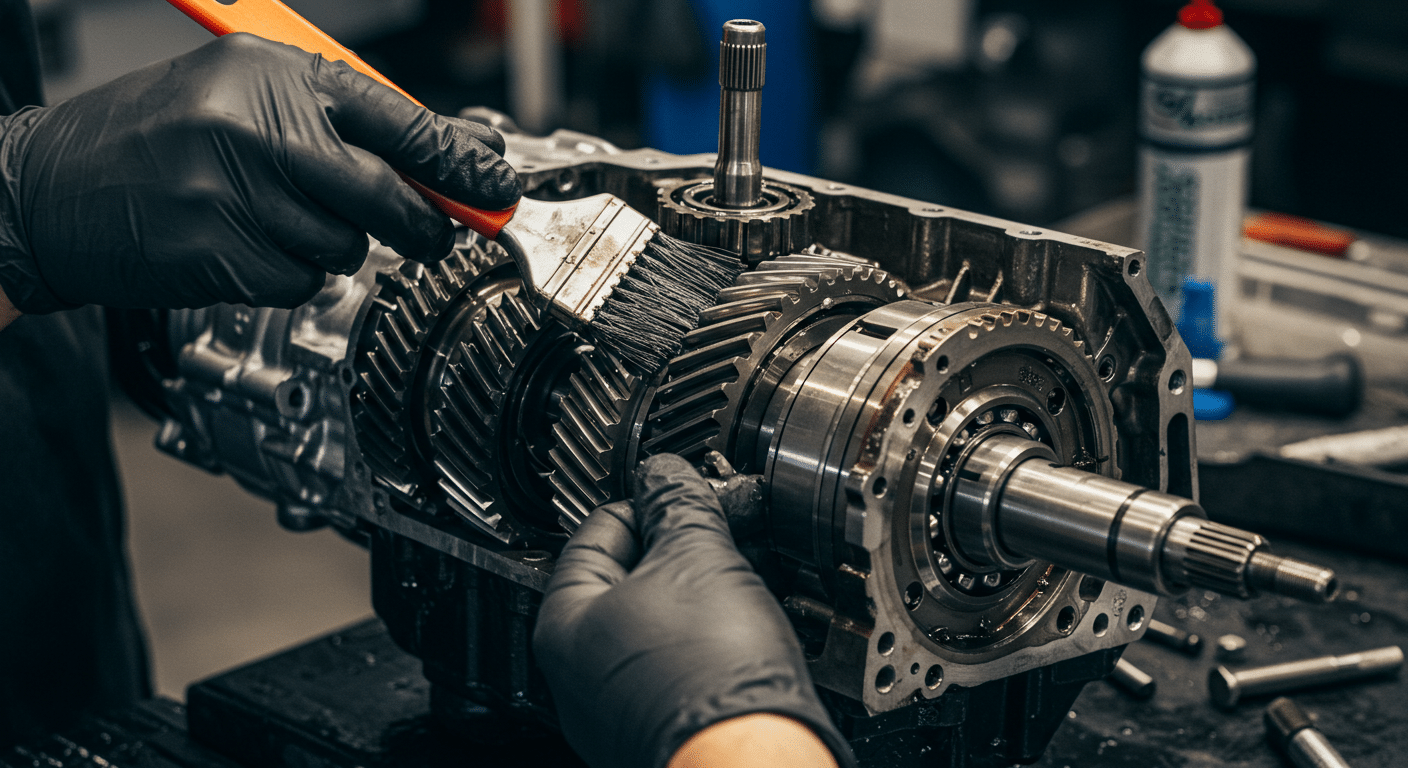

Illustrative image related to gearbox flushing machine

Considerations for International Buyers:

Aluminum components should comply with international standards such as ASTM B221 for extruded aluminum. Buyers in regions like Africa and South America may prioritize cost-effectiveness, while those in Europe may focus on durability and compliance with EU regulations.

Stainless Steel: Strength and Durability

Stainless steel is a preferred material for gearbox flushing machines due to its exceptional strength and resistance to corrosion and high temperatures. It is particularly advantageous in environments where durability is critical.

Pros:

– High strength-to-weight ratio, suitable for high-pressure applications.

– Excellent resistance to corrosion, ensuring longevity.

– Easy to clean and maintain.

Cons:

– Higher manufacturing costs compared to aluminum and HDPE.

– Heavier, which may affect portability.

Illustrative image related to gearbox flushing machine

Impact on Application:

Stainless steel is compatible with a wide variety of fluids, including aggressive chemicals, making it ideal for professional workshops that perform extensive flushing services.

Considerations for International Buyers:

Buyers should ensure compliance with standards such as ASTM A240 for stainless steel. In regions like the Middle East, where high temperatures are common, the thermal stability of stainless steel is a significant advantage.

High-Density Polyethylene (HDPE): Cost-Effective and Chemical Resistant

HDPE is increasingly used in gearbox flushing machines, particularly for components like tanks and hoses. Its chemical resistance and lightweight nature make it an attractive option.

Pros:

– Excellent chemical resistance, suitable for various automotive fluids.

– Lightweight and easy to handle.

– Cost-effective compared to metals.

Cons:

– Lower temperature and pressure ratings compared to metals, limiting its use in high-performance applications.

– Can become brittle over time if exposed to UV light.

Impact on Application:

HDPE is compatible with most automotive fluids, but its limitations in pressure ratings may restrict its use in heavy-duty applications.

Considerations for International Buyers:

Compliance with standards such as ASTM D3350 is essential. Buyers in developing regions may favor HDPE for its affordability and ease of use, while European buyers may focus on its environmental impact and recyclability.

Brass: Versatile and Durable

Brass is often used in fittings and connectors within gearbox flushing machines due to its excellent machinability and resistance to corrosion.

Illustrative image related to gearbox flushing machine

Pros:

– Good corrosion resistance, especially in moist environments.

– Excellent machinability, allowing for precise fittings and connections.

– Durable and long-lasting.

Cons:

– Higher cost compared to aluminum and HDPE.

– Susceptible to dezincification in certain environments, which can weaken the material.

Impact on Application:

Brass is suitable for various fluids but should be avoided in applications involving highly acidic or alkaline substances.

Considerations for International Buyers:

Brass components should comply with standards like ASTM B36. In regions like Brazil, where humidity can be an issue, the corrosion resistance of brass is a significant advantage.

Summary Table of Material Selection for Gearbox Flushing Machines

| Material | Typical Use Case for gearbox flushing machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Body and housing components | Lightweight and corrosion-resistant | Lower strength in high-pressure settings | Medium |

| Stainless Steel | High-pressure components and tanks | Exceptional strength and durability | Higher cost and weight | High |

| HDPE | Tanks and hoses | Excellent chemical resistance and cost-effective | Limited temperature and pressure ratings | Low |

| Brass | Fittings and connectors | Good machinability and corrosion resistance | Susceptible to dezincification | Medium |

This guide provides a comprehensive overview of material selection for gearbox flushing machines, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for gearbox flushing machine

What Are the Key Manufacturing Processes for Gearbox Flushing Machines?

The manufacturing of gearbox flushing machines involves several critical stages designed to ensure high performance, reliability, and compliance with international standards. Understanding these stages can empower B2B buyers to make informed decisions when sourcing these machines for their operations.

Material Preparation: What Materials Are Used in Manufacturing Gearbox Flushing Machines?

The first step in the manufacturing process is material preparation. Manufacturers typically utilize high-quality materials such as stainless steel, aluminum, and durable plastics to ensure longevity and resistance to corrosion. Stainless steel is particularly favored for its strength and resistance to chemical wear, which is crucial given the fluids handled by these machines.

Additionally, components like hoses, seals, and fittings must meet stringent durability requirements to withstand high pressures and temperatures during operation. Suppliers often source materials from certified vendors to guarantee compliance with industry standards, which can be a crucial factor for international buyers.

Forming: How Are Components Shaped and Assembled?

The forming stage involves shaping the prepared materials into components through processes such as machining, stamping, and injection molding. Advanced CNC (Computer Numerical Control) machines are frequently employed to achieve precise tolerances and high-quality finishes on critical components like pumps and valves.

Illustrative image related to gearbox flushing machine

Once the individual parts are formed, they undergo an assembly process. This stage is essential for integrating various components into a cohesive unit. Automated assembly lines may be used to enhance efficiency and reduce human error, while manual assembly is often reserved for intricate parts that require skilled craftsmanship.

Finishing: What Are the Final Touches Applied to Gearbox Flushing Machines?

Finishing processes, such as powder coating, anodizing, or polishing, are vital for enhancing the aesthetic appeal and functional performance of gearbox flushing machines. These processes not only improve the machine’s resistance to wear and corrosion but also ensure that it meets specific safety and regulatory standards.

Additionally, manufacturers may conduct surface treatments to improve the adhesion of coatings and enhance the overall durability of the machine. Ensuring a high-quality finish is crucial for attracting discerning international buyers who prioritize both aesthetics and functionality.

What Quality Assurance Measures Are Implemented in the Manufacturing of Gearbox Flushing Machines?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that gearbox flushing machines meet both international and industry-specific standards. Implementing rigorous QA protocols not only assures product reliability but also builds trust with B2B buyers.

What International Standards Should Buyers Look For?

International standards such as ISO 9001 are essential benchmarks for quality management systems. Compliance with ISO 9001 indicates that the manufacturer adheres to strict quality control processes throughout production, from material sourcing to final assembly.

Illustrative image related to gearbox flushing machine

Additionally, industry-specific certifications, such as CE marking in Europe and API certification for automotive equipment, ensure that the machines meet safety and performance criteria. These certifications can significantly influence the purchasing decisions of B2B buyers, particularly in regions like Europe and the Middle East, where regulatory compliance is paramount.

How Are Quality Control Checkpoints Established During Manufacturing?

Quality control (QC) checkpoints are integral to maintaining high standards during the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified standards before being used in production.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, periodic checks are conducted to monitor the quality of components and assemblies. This can include measuring tolerances and verifying the functionality of critical parts.

-

Final Quality Control (FQC): Before shipping, the finished gearbox flushing machines undergo comprehensive testing to ensure they meet performance specifications. This may involve functional tests, pressure tests, and safety inspections.

What Testing Methods Are Commonly Used for Gearbox Flushing Machines?

B2B buyers should be aware of the various testing methods employed to validate the performance and safety of gearbox flushing machines. Common testing techniques include:

-

Functional Testing: Ensures that the machine operates according to design specifications under normal operating conditions.

-

Pressure Testing: Verifies that the machine can withstand the pressures it will encounter during operation without leaking or failing.

-

Durability Testing: Assesses the machine’s performance over extended periods and under various operating conditions to ensure reliability and longevity.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is critical for ensuring product reliability. Here are some strategies to effectively assess a supplier’s QA measures:

What Role Do Audits Play in Supplier Evaluation?

Conducting audits of potential suppliers can provide valuable insights into their manufacturing processes and quality assurance practices. Audits can be performed by the buyer’s internal team or by third-party organizations specializing in supplier evaluations.

During an audit, buyers can review documentation related to quality management systems, observe production processes, and assess compliance with relevant standards and certifications. This firsthand evaluation can help mitigate risks associated with sourcing equipment from unfamiliar suppliers.

How Can Buyers Utilize Quality Control Reports?

Requesting quality control reports from suppliers can also provide clarity on their QA processes. These reports should detail the results of various quality checks, including IQC, IPQC, and FQC outcomes. A transparent supplier will readily provide these documents, allowing buyers to make informed decisions based on data.

What Are the Quality Control Nuances for International Buyers?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances that may impact their purchasing decisions. Regulatory requirements can vary significantly by region, necessitating a thorough understanding of local standards and compliance expectations.

Additionally, language barriers and differences in business practices can pose challenges during negotiations and contract discussions. It is advisable for buyers to engage local experts or consultants who understand the regional market dynamics and can facilitate smoother transactions.

Conclusion: Why Quality Assurance Is Essential for Gearbox Flushing Machines

In the competitive landscape of gearbox flushing machines, understanding the manufacturing processes and quality assurance measures is crucial for B2B buyers. By focusing on quality—from material selection to final testing—buyers can ensure they invest in reliable, high-performance equipment that meets their operational needs. Engaging with suppliers who prioritize quality and compliance will not only enhance operational efficiency but also contribute to long-term business success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gearbox flushing machine’

When sourcing a gearbox flushing machine, international B2B buyers must navigate a variety of factors to ensure they select the best equipment for their needs. This checklist serves as a practical guide to streamline the procurement process, helping buyers make informed decisions.

Illustrative image related to gearbox flushing machine

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Consider the types of vehicles you’ll service, the specific transmission fluids compatible with your market, and the capacity of the machine. Knowing these details will help you narrow down options that meet your operational needs.

Step 2: Research Supplier Reputation

Evaluating the reputation of potential suppliers is crucial. Look for companies with a strong track record in the industry, particularly those that provide robust customer support and have positive reviews from other B2B buyers. Utilize platforms like industry forums and social media to gather insights about the suppliers’ reliability and service quality.

Step 3: Evaluate Potential Suppliers

Before committing, vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. This step helps ensure that the supplier has experience with your specific requirements and can provide the level of service you expect.

- Check Certifications: Ensure that the supplier’s products comply with international standards and regulations. This is particularly important in regions like Europe and the Middle East, where compliance can affect market access.

- Assess Warranty and Support: Review the warranty terms and after-sales support offered. Reliable customer support can significantly reduce downtime in your operations.

Step 4: Analyze Machine Features

Different gearbox flushing machines come with various features that can enhance efficiency and ease of use. Look for machines that offer:

- Automatic Operation: Automatic machines can reduce labor costs and minimize human error, leading to more efficient service.

- Multi-Fluid Compatibility: Ensure that the machine can handle multiple types of transmission fluids, accommodating a diverse range of vehicles.

Step 5: Consider Cost and Financing Options

Cost is always a critical factor in procurement. While it’s important to stick to your budget, consider the total cost of ownership, including maintenance and operational costs.

Illustrative image related to gearbox flushing machine

- Explore Financing Options: Some suppliers may offer leasing or financing plans that can ease the upfront financial burden. Look for suppliers that provide transparent pricing structures without hidden fees.

Step 6: Request Demonstrations or Trials

Before finalizing your purchase, request a demonstration or trial of the gearbox flushing machine. This allows you to assess the machine’s performance in real-world conditions and ensure it meets your operational expectations.

- Engage Technicians: Involve your technicians in the demonstration process. Their hands-on feedback can provide valuable insights into the machine’s usability and efficiency.

Step 7: Finalize Contracts and Delivery Terms

Once you’ve selected a supplier and machine, review the contract thoroughly. Pay attention to delivery timelines, installation support, and any training offered. Clear agreements will help prevent misunderstandings and ensure a smooth transition when integrating the new equipment into your operations.

By following this checklist, you can make a well-informed decision when sourcing a gearbox flushing machine, ultimately enhancing your service offerings and operational efficiency.

Comprehensive Cost and Pricing Analysis for gearbox flushing machine Sourcing

What Are the Key Cost Components in Sourcing Gearbox Flushing Machines?

When sourcing gearbox flushing machines, buyers must consider several cost components that contribute to the overall price. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The quality and type of materials used in manufacturing the flushing machine significantly influence costs. High-quality components that ensure durability and efficiency can raise the initial investment but may lead to lower maintenance costs over time.

-

Labor: Labor costs vary based on the region and the complexity of the manufacturing process. Skilled labor in countries with higher wage standards may increase the overall price, but it can also ensure better craftsmanship and reliability.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as facility maintenance, utilities, and administrative expenses. Efficient operations can lower overhead, benefiting the final pricing.

-

Tooling: The cost of specialized tools required for the production of gearbox flushing machines can be significant. Custom tooling may be necessary for unique designs, which adds to the initial investment.

-

Quality Control (QC): Implementing rigorous QC measures ensures that the machines meet industry standards and certifications. While this may increase costs, it mitigates the risk of product failures and enhances long-term customer satisfaction.

-

Logistics: Shipping costs, customs duties, and insurance are critical factors in the total cost. The geographical location of the supplier and the buyer’s market can influence logistics expenses significantly.

-

Margin: Finally, suppliers will add a profit margin to their costs, which can vary widely based on market conditions, competition, and perceived value.

How Do Price Influencers Impact the Cost of Gearbox Flushing Machines?

Several price influencers play a crucial role in determining the final cost of gearbox flushing machines, particularly for international buyers.

-

Volume/MOQ: Minimum order quantities (MOQ) and the volume of purchase can lead to significant price breaks. Larger orders typically allow for lower per-unit costs due to economies of scale.

-

Specifications/Customization: Custom-built machines tailored to specific needs can increase costs. Buyers should weigh the benefits of customization against potential budget constraints.

-

Materials and Quality Certifications: The choice of materials used in the machine’s construction affects both durability and performance. Machines with higher quality certifications may carry a premium price but can result in lower total ownership costs through reduced maintenance and longer lifespan.

-

Supplier Factors: The reputation and reliability of the supplier impact pricing. Established suppliers may charge more due to their brand reputation, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) is vital for international buyers. These terms dictate the responsibilities for shipping, insurance, and tariffs, which can affect the overall cost.

What Are the Best Negotiation Tips for International Buyers?

For international buyers, especially from regions such as Africa, South America, the Middle East, and Europe, effective negotiation can lead to better pricing and terms.

-

Research and Benchmarking: Understanding market prices and standards can empower buyers to negotiate effectively. Comparing multiple suppliers can help identify reasonable price ranges.

-

Total Cost of Ownership: Emphasizing long-term benefits, such as reduced maintenance costs and warranty periods, can justify a higher initial investment and provide leverage in negotiations.

-

Flexible Payment Terms: Negotiating favorable payment terms can ease cash flow pressures, allowing businesses to invest in additional equipment or services.

-

Building Relationships: Establishing a strong relationship with suppliers can lead to better terms and potential discounts in the future. Regular communication and trust-building are key.

Conclusion

Understanding the comprehensive cost structure and pricing dynamics of gearbox flushing machines is essential for B2B buyers. By analyzing the various cost components, recognizing the influential factors, and employing effective negotiation strategies, buyers can make informed decisions that align with their operational needs and budgetary constraints. Keep in mind that prices can vary widely based on supplier, region, and specific machine specifications, so thorough research and strategic negotiation are critical for success.

Alternatives Analysis: Comparing gearbox flushing machine With Other Solutions

In the competitive landscape of automotive maintenance, the need for effective gearbox servicing solutions has led to the emergence of various technologies and methods. Understanding the strengths and weaknesses of these alternatives can significantly influence a B2B buyer’s decision, particularly in regions such as Africa, South America, the Middle East, and Europe. Below, we explore how the gearbox flushing machine compares to other viable solutions.

| Comparison Aspect | Gearbox Flushing Machine | Automatic Transmission Fluid Exchange Machine | Traditional Oil Change Method |

|---|---|---|---|

| Performance | High efficiency; cleans entire system thoroughly | Quick fluid replacement; may leave residues | Limited cleaning; only drains and refills oil |

| Cost | Higher initial investment; potential for long-term profits | Moderate cost; quick ROI due to speed | Low initial cost; frequent repeat services needed |

| Ease of Implementation | Requires training; may need specific adaptors | User-friendly; often plug-and-play | Simple; minimal training required |

| Maintenance | Requires regular servicing and calibration | Low maintenance; self-cleaning features | Minimal; regular oil checks needed |

| Best Use Case | Ideal for workshops focused on comprehensive transmission care | Suitable for high-volume service centers | Best for budget-conscious customers or DIYers |

What Are the Advantages and Disadvantages of an Automatic Transmission Fluid Exchange Machine?

The Automatic Transmission Fluid Exchange Machine offers a unique blend of speed and efficiency. It can replace fluid in under 20 minutes, making it suitable for high-volume service centers. However, while it excels in quick fluid replacement, it may not fully clean the system, potentially leaving residues that could affect long-term performance. This compromise on thoroughness may not meet the needs of workshops prioritizing comprehensive maintenance.

How Does the Traditional Oil Change Method Compare?

The Traditional Oil Change Method is the most straightforward approach, requiring minimal equipment and training. It is cost-effective, making it appealing for budget-conscious customers or DIY enthusiasts. However, this method does not provide the deep cleaning benefits of a gearbox flushing machine, as it only drains and refills oil. As a result, significant amounts of old fluid can remain trapped in the system, potentially leading to performance issues over time.

What Makes the Gearbox Flushing Machine a Superior Choice?

The gearbox flushing machine stands out for its ability to thoroughly clean the entire transmission system, ensuring that old fluid and contaminants are completely removed. While it requires a higher initial investment, the potential for generating additional revenue through premium services can offset costs. Moreover, it positions workshops as specialists in transmission care, catering to customers who prioritize long-term vehicle performance.

How Can B2B Buyers Choose the Right Solution?

When selecting the right gearbox servicing solution, B2B buyers should assess their target market, budget constraints, and service volume. Those aiming to establish a niche in high-quality transmission services may find the gearbox flushing machine to be a worthwhile investment. Conversely, workshops with a focus on quick turnaround times and lower costs might lean towards the automatic transmission fluid exchange machine or even the traditional oil change method. Ultimately, understanding customer needs and aligning service offerings with those needs will guide buyers to the best choice for their business.

Essential Technical Properties and Trade Terminology for gearbox flushing machine

What Are the Key Technical Properties of Gearbox Flushing Machines?

When considering a gearbox flushing machine for your business, it’s essential to understand several critical technical properties that impact performance and reliability. Here are the key specifications to evaluate:

-

Flow Rate

The flow rate, typically measured in liters per minute (LPM), indicates how quickly the machine can flush out old transmission fluid and replace it with new oil. A higher flow rate allows for more efficient cleaning, reducing service time and improving workshop productivity. For instance, machines that can achieve flow rates of 10-20 LPM can typically perform a complete flush in under 30 minutes, which is crucial for high-volume service environments. -

Pressure Range

The pressure range, often measured in bar or psi, indicates the machine’s ability to effectively displace old fluid and contaminants from the gearbox. Machines that operate at higher pressures can ensure a thorough clean, which is vital for maintaining transmission performance and longevity. Typical pressure ranges for effective flushing machines are between 2 to 4 bar. -

Material Quality

The construction material of the flushing machine, usually a combination of high-grade plastics and metals, affects its durability and resistance to chemical corrosion. Machines made from robust materials ensure longevity and reliability, especially when handling various transmission fluids that may be corrosive. Look for machines that specify high-quality materials to ensure you get a reliable product. -

Filtration System

A dual or multi-stage filtration system is critical for removing contaminants during the flushing process. High-performance filters capture debris and particles that could damage the transmission if left unchecked. Machines equipped with advanced filtration systems not only enhance cleaning effectiveness but also help maintain the quality of the new fluid being introduced. -

Compatibility with Transmission Types

Gearbox flushing machines should be compatible with a wide range of automatic transmission types. This includes support for various OEM specifications to ensure compliance with manufacturer requirements. Machines that offer multiple adaptors or universal compatibility can significantly expand your service capabilities and customer base. -

Ease of Use and Automation Features

User-friendly interfaces and automation features, such as digital displays and programmable settings, enhance operational efficiency. These features allow technicians to perform flushes with minimal training, reducing the potential for human error and ensuring consistent service quality.

What Are Common Trade Terminology and Jargon Related to Gearbox Flushing Machines?

Understanding industry terminology is essential for effective communication and negotiation in the B2B environment. Here are some common terms related to gearbox flushing machines:

-

OEM (Original Equipment Manufacturer)

OEM refers to the company that manufactures components or equipment that may be marketed by another manufacturer. In the context of gearbox flushing machines, ensuring compatibility with OEM specifications is critical for service providers to maintain warranty and service standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For gearbox flushing machines and associated parts, understanding MOQ helps businesses plan inventory and manage procurement costs effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for a specific quantity of goods or services. In the context of gearbox flushing machines, an RFQ can help you gather pricing and terms from multiple suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that outline the responsibilities of buyers and sellers in the shipping process. Familiarity with these terms helps businesses understand their obligations regarding shipping costs, risk, and insurance when purchasing gearbox flushing machines from international suppliers. -

Warranty and Service Agreements

These terms refer to the conditions under which a product is guaranteed and the support provided by the manufacturer. Understanding warranty specifics is crucial for assessing the long-term value and potential service costs associated with gearbox flushing machines. -

Calibration

Calibration refers to the process of adjusting the machine’s settings to ensure accurate measurements and operations. Regular calibration is essential for maintaining the machine’s efficiency and reliability, impacting service quality and customer satisfaction.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when investing in gearbox flushing machines, ensuring they select the right equipment for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the gearbox flushing machine Sector

What Are the Current Market Dynamics and Key Trends Influencing Gearbox Flushing Machines?

The global gearbox flushing machine market is experiencing robust growth, driven by increased vehicle maintenance awareness and technological advancements in automotive servicing. One of the primary drivers is the growing recognition among workshop owners of the importance of regular transmission maintenance, which has shifted from being an optional service to a necessity. This trend is particularly strong in regions like Africa, South America, the Middle East, and Europe, where the vehicle population is expanding rapidly.

Emerging technologies, such as automated flushing systems and digital monitoring capabilities, are transforming the way workshops operate. These innovations not only improve efficiency but also enhance the precision of oil exchanges, thereby reducing waste and improving service quality. For B2B buyers, sourcing partners that provide advanced technology—like the Gear+ flushing device or compact solutions from manufacturers like Motul—can offer a competitive edge in service delivery.

Additionally, the market is witnessing a shift towards service models that emphasize sustainability. Workshops are increasingly adopting practices that minimize environmental impact, such as using eco-friendly fluids and efficient flushing methods that reduce waste. Buyers should seek suppliers who align with these trends, ensuring they are equipped to meet both current demands and future regulations.

How Is Sustainability Shaping the Sourcing of Gearbox Flushing Machines?

Sustainability has become a critical consideration in the sourcing of gearbox flushing machines, influencing buyer decisions across all regions. The environmental impact of automotive servicing is significant, particularly concerning the disposal of used fluids and the energy consumption of flushing equipment. B2B buyers are now prioritizing suppliers that demonstrate a commitment to sustainability through ethical sourcing practices and environmentally friendly product offerings.

A growing number of manufacturers are obtaining green certifications for their products, indicating compliance with stringent environmental standards. This includes using recyclable materials in the construction of flushing machines and ensuring that the chemicals involved in the flushing process are less harmful to the environment. For instance, suppliers that provide non-aggressive cleaning solutions and promote technologies designed to minimize oil waste are increasingly favored.

Furthermore, the importance of transparent supply chains cannot be overstated. Buyers are looking for partners who can guarantee the ethical sourcing of materials, ensuring that their products are not only high-quality but also produced in a socially responsible manner. By aligning with suppliers that prioritize sustainability, B2B buyers can enhance their brand reputation and appeal to a growing consumer base that values environmental stewardship.

What Has Been the Evolution of Gearbox Flushing Machines and Their Role in the Automotive Sector?

The evolution of gearbox flushing machines has been marked by significant technological advancements that reflect broader trends in the automotive industry. Initially, transmission servicing involved basic oil changes that often left residual fluids in the system. However, the introduction of flushing technology revolutionized this process, allowing for a comprehensive clean that improves transmission performance and longevity.

Over the years, manufacturers have enhanced flushing machines with features such as automated fluid exchanges, real-time monitoring, and compatibility with various vehicle models. This evolution has enabled workshops to provide a higher level of service, attracting a more diverse clientele and fostering customer loyalty.

As the automotive sector continues to embrace technological innovation and sustainability, the future of gearbox flushing machines looks promising. B2B buyers who stay informed about these advancements and align with forward-thinking suppliers will be well-positioned to capitalize on emerging opportunities in the market.

Frequently Asked Questions (FAQs) for B2B Buyers of gearbox flushing machine

-

How do I solve the problem of selecting the right gearbox flushing machine?

To choose the right gearbox flushing machine, consider factors such as compatibility with various vehicle models, efficiency in oil replacement, and ease of use. Look for machines that are designed to meet manufacturer specifications and offer features like automatic operation, built-in filters, and quick turnaround times. Additionally, evaluate the support and training provided by the supplier, as well as warranty options. Always request product demonstrations or trial periods to ensure the machine meets your workshop’s needs. -

What is the best gearbox flushing machine for a workshop in Africa?

The best gearbox flushing machine for a workshop in Africa should be robust, reliable, and suitable for the local automotive market. Machines that can handle various automatic transmission fluids and offer efficient cleaning capabilities are ideal. Look for suppliers that provide comprehensive support, including training and spare parts. Brands like FUCHS and Motul have established reputations for quality and service, making them viable options. Ensure the machine is adaptable to local conditions, such as voltage and temperature variations. -

How can I vet suppliers of gearbox flushing machines?

Vetting suppliers involves checking their reputation, product quality, and customer service. Start by researching online reviews and testimonials from other B2B buyers. Request references and case studies to understand their track record. Evaluate their certifications and compliance with international standards. It’s also beneficial to visit their facilities or attend trade shows to assess their operations firsthand. Establish clear communication to gauge their responsiveness and willingness to support your business needs. -

What customization options are available for gearbox flushing machines?

Many suppliers offer customization options to tailor gearbox flushing machines to specific workshop requirements. Customizations may include modifications for different transmission types, unique branding, or specific software features. Discuss your needs with potential suppliers to explore available options. Ensure that any modifications do not compromise the machine’s efficiency or compliance with manufacturer specifications. A well-customized machine can enhance service quality and operational efficiency in your workshop. -

What are the minimum order quantities (MOQs) for gearbox flushing machines?

Minimum order quantities (MOQs) for gearbox flushing machines can vary significantly between suppliers. Some manufacturers may have no MOQ for individual units, while others might require bulk orders to ensure cost-effectiveness. It’s essential to discuss your purchasing plans with suppliers to find flexible options that suit your budget. In regions like Africa and South America, where market demand may vary, some suppliers might offer lower MOQs to encourage local business growth. -

What payment terms should I expect when purchasing a gearbox flushing machine?

Payment terms for purchasing gearbox flushing machines can differ among suppliers. Typically, you may encounter options like full upfront payment, a deposit followed by balance upon delivery, or installment plans. International buyers should be aware of additional costs like shipping, taxes, and customs duties. Always negotiate terms that protect your interests, and consider using secure payment methods such as letters of credit for larger transactions. Clear communication about payment expectations helps avoid misunderstandings. -

How can I ensure quality assurance (QA) for gearbox flushing machines?

To ensure quality assurance for gearbox flushing machines, request detailed product specifications, certifications, and warranty information from suppliers. Inquire about their quality control processes and any testing procedures they perform on their machines before shipment. Additionally, consider third-party inspections if purchasing in bulk. Establishing a clear agreement regarding product quality and performance standards in your contract can also safeguard your investment. -

What logistics considerations should I keep in mind for importing gearbox flushing machines?

When importing gearbox flushing machines, logistics considerations include shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder experienced in handling machinery to navigate international shipping complexities. Ensure that all necessary documentation, such as invoices, packing lists, and certificates of origin, is in order to facilitate smooth customs clearance. Plan for potential delays and be aware of any import tariffs or taxes that may apply in your region to avoid unexpected costs.

Top 4 Gearbox Flushing Machine Manufacturers & Suppliers List

1. Robinair – Transmission Fluid Exchanger

2. FUCHS – Gear+ Automatic Transmission Fluid Flushing System

Domain: fuchs.com

Registered: 1996 (29 years)

Introduction: Gear+ Automatic Transmission Fluid Flushing System: 1. Effective flushing device designed according to manufacturer specifications for cleaning automatic transmissions. 2. Investment support from FUCHS covering part of the costs with no hidden fees. 3. Manufacturer approval from Mercedes-Benz. 4. Loss-free flushing requiring up to 50% less fresh oil. 5. High-quality construction “Made in Germany”….

3. Motul – Flush Machine

Domain: motulevo.com

Registered: 2013 (12 years)

Introduction: Flush machine which can be used for oil changes; compact, reliable, and fully automatic; suitable for every type of automatic transmission; features two electronic scales, an oil filter with magnet, and a printer; developed by Motul technicians based on field experience; part of the MotulEvo project dedicated to automatic gearbox maintenance; includes a full package of products and services for re…

4. Hot Flusher – Transmission Cooler Flushing Machine

Domain: hotflusher.com

Registered: 2000 (25 years)

Introduction: Hot Flush Transmission Cooler Flushing Machine

– Cleans 99.9999% of contamination from transmission oil coolers and lines

– Uses automatic transmission fluid as a cleaning agent, heated to optimum temperature

– Features patented process that includes rapid flow reversal to dislodge debris

– Trusted by over 10,000 automotive shops

– No expensive chemical detergents required

– Cost-effective solutio…

Strategic Sourcing Conclusion and Outlook for gearbox flushing machine

In conclusion, the strategic sourcing of gearbox flushing machines presents a lucrative opportunity for international B2B buyers looking to enhance service offerings and profitability. Investing in advanced flushing technology, such as the Gear+ system or the digital ATF machines, not only facilitates effective cleaning and maintenance of automatic transmissions but also positions workshops as specialists in a high-demand service area.

By prioritizing quality equipment that meets manufacturer specifications, workshops can significantly reduce operating costs and improve customer satisfaction. Emphasizing the necessity of regular transmission maintenance can help educate end-users about the risks of neglecting this service, thereby driving demand and increasing revenue potential.

As markets across Africa, South America, the Middle East, and Europe continue to evolve, embracing innovative solutions like gearbox flushing machines will be essential for staying competitive. We encourage you to explore partnerships with reputable suppliers to secure the best technology and support available. Now is the time to invest in your workshop’s future and establish a reputation as a leader in transmission care.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to gearbox flushing machine