A B2B Buyer’s Guide to Gage It Inc: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for gage it inc

In today’s global market, sourcing reliable pressure gauges and liquid level measurement solutions can pose significant challenges for businesses in diverse regions such as Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Brazil. Gage It Inc. stands out as a trusted partner, offering a broad range of high-quality products and services tailored to meet the unique demands of various industries. This comprehensive guide delves into the offerings of Gage It Inc., including pressure gauges, backflow test kits, and specialized calibration services, ensuring that international B2B buyers can navigate the complexities of sourcing effectively.

Throughout this guide, we will explore the diverse applications of Gage It’s products across industries, providing insights into the supplier vetting process and cost considerations. Additionally, we will highlight the importance of quality assurance and certification, particularly for businesses operating in highly regulated sectors. By equipping B2B buyers with actionable knowledge and a clear understanding of the marketplace, this guide empowers them to make informed purchasing decisions that align with their operational needs and compliance requirements. With Gage It Inc. as your go-to source for precision instrumentation, you can confidently enhance your operational efficiency and reliability in any market landscape.

Understanding gage it inc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pressure Gauges | Measures pressure in various systems; available in analog and digital. | Oil & gas, chemical processing, HVAC systems | Pros: Accurate measurements, wide application. Cons: Calibration needed for precision. |

| Liquid Level Gauges | Monitors liquid levels; can be mechanical or electronic. | Water treatment, food processing, manufacturing | Pros: Reliable readings, customizable options. Cons: Environmental factors can affect accuracy. |

| Backflow Test Kits | Tools for testing backflow prevention devices; includes calibration tools. | Plumbing, construction, facility management | Pros: Essential for compliance, easy to use. Cons: Requires regular maintenance and certification. |

| Digital Test Gauges | Provides real-time digital readings; often features data logging. | Research laboratories, industrial applications | Pros: High precision, user-friendly interface. Cons: Higher cost compared to analog gauges. |

| Repairable & Recalibratable Gauges | Designed for longevity and serviceability; can be repaired and recalibrated. | Maintenance services, industrial sectors | Pros: Cost-effective over time, sustainable. Cons: Initial investment can be higher. |

What Are the Characteristics of Pressure Gauges and Their B2B Suitability?

Pressure gauges are essential instruments used to measure the pressure of gases and liquids in various systems. They can be classified into analog and digital formats, each catering to different operational needs. In B2B contexts, these gauges are prevalent in industries such as oil and gas, chemical processing, and HVAC systems, where precise pressure readings are crucial for safety and efficiency. Buyers should consider the calibration requirements and accuracy levels when selecting pressure gauges, as these factors directly impact operational reliability.

How Do Liquid Level Gauges Function and Where Are They Used?

Liquid level gauges provide crucial information about the levels of liquids in tanks and other containers. They can be mechanical, using float systems, or electronic, using sensors to provide readings. Industries like water treatment, food processing, and manufacturing rely on these gauges to ensure proper levels for safety and operational integrity. When purchasing, businesses should assess environmental factors that may affect gauge performance and the need for customization to fit specific applications.

Why Are Backflow Test Kits Important for Compliance in B2B Operations?

Backflow test kits are specialized tools designed to test the efficacy of backflow prevention devices, ensuring that contaminated water does not enter clean water supplies. These kits are vital in plumbing, construction, and facility management sectors, where compliance with safety regulations is non-negotiable. While they are user-friendly, buyers must remain vigilant about regular maintenance and certification to uphold safety standards and avoid potential liabilities.

What Advantages Do Digital Test Gauges Offer for Industrial Applications?

Digital test gauges represent the cutting edge of measurement technology, providing real-time readings and often featuring data logging capabilities. Their precision makes them suitable for research laboratories and various industrial applications. For B2B buyers, the ease of use and high accuracy are significant advantages; however, the initial investment can be higher than analog options, which may influence purchasing decisions based on budget constraints.

How Do Repairable and Recalibratable Gauges Provide Long-term Value?

Repairable and recalibratable gauges are designed to last longer and offer the possibility of maintenance, which can save costs over time. These gauges are particularly beneficial in maintenance-heavy industries, as they reduce the need for frequent replacements. Buyers should weigh the initial costs against the long-term savings and sustainability benefits when considering these instruments for their operations.

Key Industrial Applications of gage it inc

| Industry/Sector | Specific Application of gage it inc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Pressure Gauges for drilling operations | Ensures accurate pressure monitoring to prevent blowouts. | Need for high-pressure gauges; certification to NIST standards. |

| Water Management | Backflow Test Kits for municipal water systems | Protects water supply from contamination, ensuring safety. | Compliance with local regulations; rapid repair services. |

| HVAC Systems | Liquid Level Gauges for HVAC equipment | Maintains optimal fluid levels, improving system efficiency. | Durability in harsh environments; precision calibration. |

| Manufacturing | Digital Test Gauges for quality control | Enhances product quality through precise measurement. | Requirement for customization; fast turnaround for repairs. |

| Food & Beverage | Sanitary Gauges for processing equipment | Ensures compliance with health standards, preventing spoilage. | Need for hygienic designs; certifications for food safety. |

How is Gage It Inc. Utilized in the Oil & Gas Sector?

In the oil and gas industry, Gage It Inc. provides essential pressure gauges that are critical for drilling operations. These gauges monitor pressure levels in real-time, helping to prevent dangerous blowouts that can lead to catastrophic failures and safety hazards. Buyers in this sector often require gauges capable of withstanding high pressures and harsh environmental conditions, necessitating adherence to NIST certification standards for reliability. International buyers must also consider the import regulations and potential logistical challenges when sourcing these products.

What Role Does Gage It Inc. Play in Water Management?

For municipal water management, Gage It Inc.’s backflow test kits are vital in maintaining the integrity of water supplies. These kits help ensure that contaminants do not enter the potable water system, safeguarding public health. Companies looking to procure these kits must be aware of local regulations regarding water quality and backflow prevention. Additionally, fast and efficient repair services are crucial, as these systems often require regular maintenance to remain compliant with safety standards.

Why Are Liquid Level Gauges Important for HVAC Systems?

In HVAC applications, Gage It Inc. offers liquid level gauges that are essential for maintaining optimal fluid levels within systems. Accurate monitoring ensures that HVAC systems operate efficiently, leading to energy savings and prolonged equipment life. Buyers should prioritize durability and precision in calibration when sourcing these gauges, particularly in regions with extreme temperatures. Furthermore, international buyers may need to navigate different standards and certifications that apply to HVAC equipment in their respective markets.

How Do Digital Test Gauges Benefit Manufacturing?

Manufacturers utilize Gage It Inc.’s digital test gauges for quality control processes. These instruments provide precise measurements that are critical in ensuring product quality and compliance with industry standards. Companies looking to purchase these gauges should consider customization options to meet specific manufacturing needs, as well as the availability of rapid repair services to minimize downtime in production. International buyers should also account for variations in measurement units and calibration standards across different countries.

In What Ways Are Sanitary Gauges Used in the Food & Beverage Industry?

In the food and beverage sector, Gage It Inc. supplies sanitary gauges that are crucial for processing equipment. These gauges help monitor pressure and temperature, ensuring compliance with health and safety regulations, which is vital for preventing spoilage and ensuring product quality. Buyers in this industry must ensure that the gauges meet hygienic design standards and possess the necessary certifications for food safety. Furthermore, sourcing from a supplier that provides reliable repair and calibration services can enhance operational efficiency and product integrity.

3 Common User Pain Points for ‘gage it inc’ & Their Solutions

Scenario 1: Delays in Calibration and Repair Services Impacting Production

The Problem: B2B buyers, particularly in industries reliant on precise measurements like manufacturing and oil and gas, often face significant downtime when their pressure gauges or liquid level gauges require calibration or repair. This downtime can lead to production delays, loss of revenue, and potential safety hazards if equipment is not functioning correctly. Buyers may experience frustration when service turnaround times are longer than expected, causing a ripple effect throughout their operations.

The Solution: To mitigate these delays, B2B buyers should prioritize building a strong relationship with Gage-It, Inc. by leveraging their in-house repair facility and fast turnaround times. It’s crucial to establish a regular maintenance schedule for all gauges to ensure they are calibrated and certified proactively, rather than reactively. This practice not only minimizes downtime but also ensures compliance with industry standards. Buyers can benefit from Gage-It’s no-charge evaluation service, which allows them to assess their equipment’s condition before shipping it for repair. Regular communication with Gage-It’s experienced sales staff can also help buyers understand lead times and plan their operations accordingly, thereby reducing the risk of unexpected downtime.

Scenario 2: Navigating Complex Regulations for Gauge Certification

The Problem: B2B buyers operating in sectors such as pharmaceuticals, food processing, and petrochemicals often grapple with stringent regulatory requirements regarding equipment certification. The complexity of ensuring that all gauges meet NIST (National Institute of Standards and Technology) certification standards can be overwhelming, particularly for international buyers who may face different regulations across their regions. Failing to comply can lead to costly penalties and operational disruptions.

The Solution: To navigate these regulatory complexities, buyers should take advantage of Gage-It’s calibration and certification services, which are aligned with NIST standards. It’s advisable for buyers to maintain a comprehensive inventory of all their measurement devices and engage with Gage-It for an initial consultation on certification requirements specific to their industry. Gage-It can provide tailored guidance on which gauges need certification and how often they should be calibrated based on usage. By integrating Gage-It’s certification process into their compliance strategy, buyers can ensure they meet all regulatory requirements efficiently, thereby minimizing risk and maintaining operational continuity.

Scenario 3: Customization Needs for Specialized Applications

The Problem: Many B2B buyers require customized gauges for specific industrial applications, such as unique pressure ranges or specialized materials that can withstand harsh environments. However, sourcing these custom solutions can be a daunting task, leading to confusion, delays, and sometimes even subpar products that do not meet operational needs.

The Solution: Buyers facing customization challenges should collaborate closely with Gage-It to explore their options for customized gauge and diaphragm seal assemblies. Gage-It’s expertise in creating tailored solutions means they can provide guidance on selecting the right specifications and materials based on the intended application. It’s beneficial for buyers to clearly outline their requirements, including environmental conditions and performance metrics, during initial discussions with Gage-It’s sales team. Additionally, Gage-It can assist in prototyping and testing custom gauges, ensuring that buyers receive products that meet their specific needs without unnecessary delays. This proactive approach not only streamlines the customization process but also ensures that the end products are reliable and effective for their intended uses.

By addressing these common pain points with actionable strategies, B2B buyers can enhance their operational efficiency and maintain high standards in their industrial processes.

Strategic Material Selection Guide for gage it inc

What Are the Key Materials Used in Pressure Gauges and Their Applications?

When selecting materials for pressure gauges and related instrumentation, it is essential to consider properties that directly affect performance, durability, and compatibility with various media. Below, we analyze four common materials used in the manufacturing of products at Gage-It Inc., focusing on their properties, advantages, disadvantages, and implications for international buyers.

Stainless Steel: The Go-To Material for Durability

Key Properties: Stainless steel is renowned for its excellent corrosion resistance, high tensile strength, and ability to withstand extreme temperatures and pressures. It typically has a temperature rating of up to 400°F (204°C) and can handle pressures exceeding 10,000 psi, making it ideal for harsh industrial environments.

Pros & Cons: The primary advantage of stainless steel is its durability and longevity, which can lead to lower lifecycle costs. However, it is more expensive than other materials like plastic or carbon steel, and its manufacturing process can be complex, requiring specialized equipment.

Impact on Application: Stainless steel is compatible with a wide range of fluids, including corrosive and high-temperature media, making it suitable for applications in oil and gas, chemical processing, and food and beverage industries.

Considerations for International Buyers: Buyers from regions like the Middle East and Europe should ensure compliance with international standards such as ASTM A276 or DIN 17440. The higher cost may be justified by the material’s long-term performance and reliability.

Brass: A Cost-Effective Alternative

Key Properties: Brass offers good corrosion resistance and is suitable for moderate pressure and temperature applications, typically rated for pressures up to 1,500 psi and temperatures up to 250°F (121°C).

Pros & Cons: Brass is less expensive than stainless steel and easier to machine, which can reduce manufacturing complexity. However, it is not suitable for highly corrosive environments, as it can suffer from dezincification.

Impact on Application: Brass is commonly used in water and gas applications, making it suitable for plumbing and HVAC systems. It is less ideal for applications involving aggressive chemicals.

Considerations for International Buyers: Buyers should be aware of local regulations regarding the use of brass in potable water applications, as standards may vary significantly between regions like Africa and South America.

Plastic: Lightweight and Versatile

Key Properties: Plastic materials, such as polycarbonate and PVC, are lightweight and offer good chemical resistance. They are typically rated for lower pressure applications, generally up to 1,000 psi, and temperatures not exceeding 180°F (82°C).

Pros & Cons: The main advantage of plastic is its low cost and ease of manufacturing, allowing for rapid production. However, plastics can be less durable than metals and may not perform well under high-pressure or high-temperature conditions.

Impact on Application: Plastic gauges are often used in applications involving non-corrosive fluids, such as water or air. They are ideal for lightweight, portable applications.

Considerations for International Buyers: Buyers should ensure that the selected plastic complies with relevant standards for chemical compatibility and safety, particularly in regions with stringent regulations, such as Europe.

Aluminum: A Lightweight Option for Specific Applications

Key Properties: Aluminum is lightweight and has good corrosion resistance, typically rated for pressures up to 2,000 psi and temperatures up to 300°F (149°C).

Pros & Cons: The lightweight nature of aluminum makes it easy to handle and install, and it is generally less expensive than stainless steel. However, it is not as durable under extreme conditions and can be prone to corrosion in certain environments.

Impact on Application: Aluminum is suitable for applications where weight is a critical factor, such as in aerospace or automotive industries. However, it may not be suitable for corrosive environments.

Considerations for International Buyers: Buyers should verify that aluminum components meet relevant international standards, such as ASTM B221, to ensure quality and performance.

Summary Table of Material Selection for Gage-It Inc.

| Material | Typical Use Case for gage it inc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-pressure gauges in chemical processing | Exceptional durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Brass | Plumbing and HVAC applications | Cost-effective and easy to machine | Susceptible to dezincification | Medium |

| Plastic | Lightweight gauges for water/air | Low cost and rapid production | Limited pressure and temperature ratings | Low |

| Aluminum | Aerospace and automotive applications | Lightweight and cost-effective | Less durable under extreme conditions | Medium |

This guide provides essential insights into material selection, enabling international B2B buyers to make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for gage it inc

What Are the Main Stages of Manufacturing at Gage-It Inc.?

Gage-It Inc. employs a systematic approach in their manufacturing processes, ensuring that each gauge is produced to meet high standards of quality and precision. The manufacturing process generally consists of four main stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves sourcing high-quality materials that conform to industry standards. Gage-It Inc. typically utilizes stainless steel, brass, and other durable metals that provide the necessary strength and corrosion resistance for their gauges. Each material batch undergoes inspections to ensure compliance with specifications, setting the groundwork for subsequent stages.

-

Forming: During the forming stage, raw materials are shaped into components through various techniques such as machining, stamping, or forging. Gage-It Inc. utilizes CNC (Computer Numerical Control) machines for precision cutting and shaping, allowing for high accuracy and repeatability. This technology minimizes human error and enhances the overall efficiency of the manufacturing process.

-

Assembly: Once components are formed, they move to the assembly line. Skilled technicians assemble the individual parts into complete gauges, ensuring that each component fits perfectly. Automated assembly systems are often employed for tasks requiring speed and precision, while manual checks are conducted to ensure that each assembly meets quality standards.

-

Finishing: The final stage involves surface treatments, painting, or coating to enhance durability and aesthetics. Gage-It Inc. applies protective finishes that not only improve the product’s lifespan but also comply with international standards for safety and environmental impact. This stage is crucial for preparing products for rigorous testing and certification.

How Does Gage-It Inc. Ensure Quality Control Throughout Manufacturing?

Quality control (QC) is integral to Gage-It Inc.’s manufacturing process. The company adheres to both international and industry-specific standards, ensuring that every product meets rigorous quality benchmarks.

-

International Standards: Gage-It Inc. is committed to ISO 9001 certification, a globally recognized quality management standard. This certification underscores their dedication to continuous improvement and customer satisfaction. Compliance with ISO 9001 requires regular audits and documentation of processes, ensuring a high level of consistency across all operations.

-

Industry-Specific Standards: In addition to ISO 9001, Gage-It Inc. follows various industry-specific standards, such as CE marking for products sold in the European market and API standards for pressure gauges used in the oil and gas sector. These certifications ensure that the products not only meet safety and performance criteria but also comply with legal requirements in different regions.

-

QC Checkpoints: Gage-It Inc. implements multiple quality checkpoints throughout the manufacturing process. Incoming Quality Control (IQC) checks raw materials for compliance with specifications before they enter the production line. In-Process Quality Control (IPQC) monitors the manufacturing process to identify and rectify issues in real-time. Finally, Final Quality Control (FQC) ensures that the finished products undergo comprehensive testing before they are shipped to customers.

What Testing Methods Are Commonly Used for Gauges?

To verify the accuracy and reliability of their gauges, Gage-It Inc. employs a range of testing methods:

-

Calibrating Instruments: Calibration against certified standards ensures that gauges provide accurate readings. Gage-It Inc. uses NIST (National Institute of Standards and Technology) traceable standards, which are crucial for maintaining the integrity of measurements.

-

Pressure Testing: Gauges are subjected to pressure testing to ensure they can withstand operational conditions without failure. This testing is vital for applications in industries such as oil and gas, where accuracy and reliability are paramount.

-

Environmental Testing: Gauges may also undergo environmental testing to assess their performance under various temperature and humidity conditions. This testing is especially important for products intended for international markets, where environmental conditions can vary significantly.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential for ensuring product reliability.

-

Supplier Audits: Conducting supplier audits is one of the most effective ways to assess a manufacturer’s quality control processes. Buyers can request access to audit reports and certifications to evaluate compliance with international standards.

-

Quality Reports: Requesting quality control documentation, including test reports and calibration certificates, allows buyers to verify that products have undergone rigorous testing. Gage-It Inc. provides these documents to ensure transparency and build trust with their clients.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of a supplier’s quality control processes. These agencies can conduct on-site inspections and testing, offering an additional layer of assurance for buyers.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with international suppliers like Gage-It Inc., buyers must navigate various quality control nuances that can impact their purchasing decisions.

-

Compliance with Local Regulations: Different countries have specific regulations regarding the importation and use of industrial equipment. Buyers should ensure that the products meet local standards, which may differ from those in the supplier’s country.

-

Cultural Considerations: Understanding cultural differences in business practices can facilitate smoother communication and negotiation. Buyers from diverse regions may have unique expectations regarding quality and service, making it essential for suppliers to be adaptable.

-

Logistical Challenges: International shipping can introduce complexities that affect product quality. Buyers should consider how products are packaged and transported to minimize damage during transit. Gage-It Inc. employs robust packaging solutions to safeguard products during shipping.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when partnering with Gage-It Inc. This ensures that they receive high-quality gauges and instruments that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gage it inc’

To effectively procure from Gage-It Inc., a trusted provider of pressure gauges, liquid level gauges, and backflow test kits, B2B buyers should follow this structured checklist. This guide will help ensure a smooth sourcing process, aligning with your specific operational needs and compliance standards.

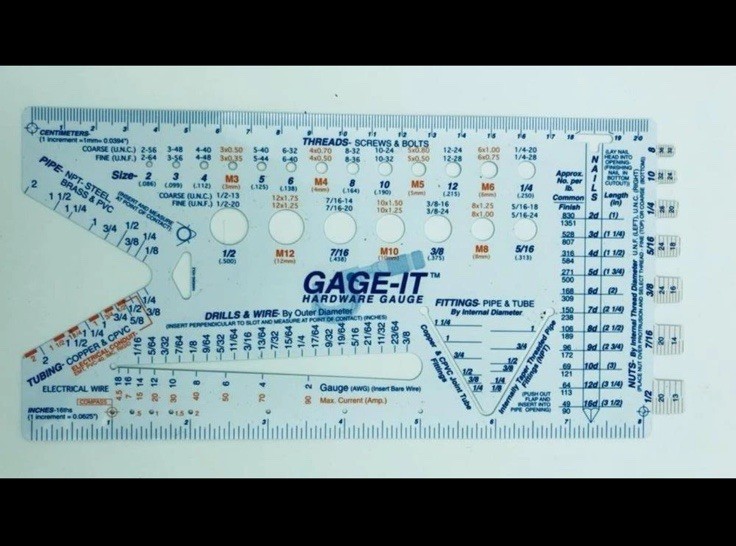

Step 1: Define Your Technical Specifications

Understanding your precise requirements is essential before initiating any procurement process. Specify the type of gauges you need—whether they are pressure gauges, liquid level gauges, or specialized backflow test kits. Consider factors such as pressure range, accuracy, and application to ensure that the products meet your operational standards.

Step 2: Research Supplier Reputation and Experience

Investigate Gage-It Inc.’s market presence and history. With over three decades of experience, the company has established a reputation for reliability and quality in the industrial market. Look for customer testimonials, case studies, and any industry certifications that validate their service quality.

- Industry Certifications: Ensure they possess relevant certifications, such as NIST calibration, which demonstrates adherence to industry standards.

Step 3: Verify Product Quality and Compliance

Before placing an order, assess the quality of the products being offered. Gage-It Inc. specializes in high-quality gauges and instruments. Check for product specifications that align with international quality standards and ensure that the products are certified for compliance with local regulations in your region.

- Customization Options: Inquire about the availability of customized gauge and diaphragm seal assemblies, which can cater to unique operational needs.

Step 4: Evaluate After-Sales Support and Services

An essential aspect of sourcing is the availability of after-sales support. Gage-It Inc. provides comprehensive services, including repair, calibration, and certification of gauges. Ensure that you understand the terms of their service agreements, including turnaround times for repairs and calibration services.

- Fast Turnaround: Look for guarantees on service speed, which can minimize downtime in your operations.

Step 5: Request Samples or Demonstrations

Whenever possible, request samples or demonstrations of the products you are considering. This allows you to assess the functionality and quality firsthand. It’s particularly important for specialized equipment, as it helps ensure compatibility with your existing systems.

- Trial Periods: Discuss potential trial periods for products to evaluate their performance in real-world conditions.

Step 6: Review Pricing and Payment Terms

Carefully review the pricing structure and payment terms offered by Gage-It Inc. Ensure that you understand all costs involved, including shipping and handling. Consider the total cost of ownership rather than just the initial purchase price to make informed financial decisions.

- Bulk Purchase Discounts: Inquire about potential discounts for bulk purchases or long-term contracts, which can provide significant savings.

Step 7: Establish Clear Communication Channels

Finally, set up clear communication channels with your supplier. Establish points of contact for inquiries and support to facilitate a smooth procurement process. Effective communication can help address any issues promptly and maintain a positive business relationship.

By following these steps, B2B buyers can ensure a strategic and efficient sourcing process with Gage-It Inc., leading to successful procurement and operational efficiency.

Illustrative image related to gage it inc

Comprehensive Cost and Pricing Analysis for gage it inc Sourcing

What Are the Key Cost Components Influencing Pricing at Gage-It Inc.?

Understanding the cost structure behind Gage-It Inc.’s pricing is crucial for international B2B buyers. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The cost of raw materials for pressure gauges, liquid level gauges, and backflow test kits significantly impacts overall pricing. High-quality materials can increase initial costs but often lead to enhanced durability and performance, thus offering better value over time.

-

Labor: Skilled labor is essential for manufacturing and servicing precision instruments. Labor costs can vary based on geographic location and local wage standards. Gage-It’s commitment to quality service may require higher labor investment, which is reflected in the pricing structure.

-

Manufacturing Overhead: This includes the costs associated with the facility, equipment maintenance, and utilities. Given Gage-It’s in-house repair facility, overhead can be substantial but is crucial for maintaining quality control during production and servicing.

-

Tooling: Investment in specialized tooling for customized gauges and assemblies can add to initial costs. However, these costs can be amortized over larger production runs, potentially lowering the price per unit for bulk orders.

-

Quality Control: Gage-It emphasizes calibration and certification to NIST standards, which ensures product reliability. This rigorous QC process incurs costs that are ultimately passed on to the buyer, but it guarantees a higher level of precision and trustworthiness in the products.

-

Logistics: Shipping and handling costs, particularly for international buyers, can significantly affect total pricing. Factors such as shipping methods, distances, and customs duties must be considered in the final pricing.

-

Margin: Gage-It Inc. aims for a competitive margin that reflects its quality and service. Buyers should be aware that while margins may vary, the focus on reliability and expert support justifies the pricing.

What Price Influencers Should International Buyers Consider?

Several factors influence the pricing dynamics of Gage-It Inc.’s offerings:

-

Volume/MOQ: Bulk purchasing often leads to reduced per-unit costs. Buyers should inquire about minimum order quantities (MOQs) and negotiate terms that could lead to discounts on larger orders.

-

Specifications and Customization: Customized products tend to have higher costs due to the additional time and resources required for production. Buyers should clarify their specifications early in the negotiation process to understand the impact on pricing.

-

Materials and Quality Certifications: The choice of materials and necessary certifications can substantially affect costs. Higher-grade materials may result in a higher upfront price but can lower the total cost of ownership through increased longevity and reliability.

-

Supplier Factors: Establishing a relationship with Gage-It can facilitate better pricing. Long-term partnerships may lead to favorable terms and insights into upcoming promotions or bulk pricing options.

-

Incoterms: Understanding the shipping terms is vital for international transactions. Incoterms dictate who is responsible for shipping costs and risks, which can significantly influence the total price for international buyers.

What Are Essential Buyer Tips for Negotiating with Gage-It Inc.?

To maximize value when sourcing from Gage-It Inc., international buyers should consider the following strategies:

-

Negotiate Early and Clearly: Start discussions about pricing and terms early in the procurement process. Clear communication about needs and expectations can facilitate better negotiation outcomes.

-

Assess Total Cost of Ownership: Consider not only the purchase price but also the costs associated with maintenance, repairs, and potential downtime. A slightly higher upfront cost may lead to lower overall expenses if the product is more reliable.

-

Leverage Market Insights: Understanding regional pricing trends and competitor offerings can strengthen your negotiation position. Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of their local market conditions and leverage them when discussing pricing.

-

Be Informed about Pricing Nuances: International buyers should be mindful of currency fluctuations, trade tariffs, and local regulations that may affect pricing. Staying informed can help in making timely purchasing decisions and negotiating better terms.

Conclusion

While Gage-It Inc. offers high-quality products and services, understanding the underlying cost structure, price influencers, and effective negotiation strategies is essential for international B2B buyers. By being informed and strategic, buyers can ensure they receive the best value for their investments in precision instrumentation.

Alternatives Analysis: Comparing gage it inc With Other Solutions

When evaluating industrial measurement solutions, it’s essential for B2B buyers to explore alternatives that not only meet their operational requirements but also align with their budgetary constraints and implementation capabilities. This analysis compares Gage It Inc. against two other viable alternatives: Wika Instruments and Ashcroft Inc. These companies provide similar products and services in pressure measurement and gauge calibration, making them relevant competitors in the marketplace.

| Comparison Aspect | Gage It Inc. | Wika Instruments | Ashcroft Inc. |

|---|---|---|---|

| Performance | High accuracy with a wide range of gauges | Excellent reliability and advanced technology | Known for durability and precision |

| Cost | Competitive pricing with customizable solutions | Mid-range pricing; value for advanced features | Higher price point, reflecting brand reputation |

| Ease of Implementation | User-friendly online ordering and support | Comprehensive documentation and support | Requires more training for complex products |

| Maintenance | In-house repair and calibration services available | Extensive service network for maintenance | Strong warranty and support services |

| Best Use Case | Ideal for diverse industrial applications | Suitable for high-tech industries and automation | Best for rugged environments with high demands |

What Makes Wika Instruments a Strong Alternative to Gage It Inc.?

Wika Instruments is recognized for its advanced technology and reliability. They offer a broad range of pressure and temperature measurement solutions, particularly suited for industries requiring high precision, such as pharmaceuticals and aerospace. While Wika products tend to be priced in the mid-range, they provide significant value through advanced features like smart technology integration. However, potential buyers should consider that their products may require more extensive training for optimal use, which could increase initial implementation costs.

How Does Ashcroft Inc. Compare with Gage It Inc.?

Ashcroft Inc. is well-regarded for its durability and precision in manufacturing gauges. They cater to industries that demand robust performance under extreme conditions, such as oil and gas and heavy manufacturing. Their products typically come at a higher price point, reflecting the brand’s reputation for quality. Ashcroft also provides strong support services and warranties, ensuring long-term reliability. However, the complexity of some products may necessitate a more involved training process for users, potentially complicating implementation.

Conclusion: How Can B2B Buyers Choose the Right Solution?

Choosing the right measurement solution involves a careful assessment of specific operational needs, budget constraints, and the technical capabilities of available options. Gage It Inc. stands out for its competitive pricing and a wide range of customizable products, making it suitable for various industrial applications. In contrast, Wika Instruments and Ashcroft Inc. excel in specialized industries where precision and durability are paramount. B2B buyers should weigh these factors against their unique requirements to make an informed decision that aligns with their operational goals and financial considerations.

Essential Technical Properties and Trade Terminology for gage it inc

What are the Essential Technical Properties for Gage-It Inc Products?

When evaluating products from Gage-It Inc, several technical properties stand out, ensuring reliability and performance across various industrial applications. Understanding these specifications is crucial for B2B buyers making informed purchasing decisions.

-

Material Grade

The material grade of pressure gauges and liquid level gauges typically refers to the type of metal or alloy used in construction. Common materials include stainless steel, brass, and carbon steel. The choice of material affects the gauge’s durability, resistance to corrosion, and suitability for specific applications, such as high-pressure environments. For B2B buyers, selecting the appropriate material grade ensures longevity and reliability in demanding operational conditions. -

Pressure Range

Each gauge comes with a specified pressure range, which defines the minimum and maximum pressure it can accurately measure. This is vital for applications in industries like oil and gas, where precise pressure readings are essential for safety and efficiency. Buyers must assess the operating conditions of their systems to ensure the selected gauges can handle the required pressure levels without risking failure or inaccuracy. -

Calibration Accuracy

Calibration accuracy indicates how closely a gauge’s readings align with true values, typically expressed as a percentage of full scale. High calibration accuracy is essential for maintaining operational standards and compliance with industry regulations. For B2B buyers, investing in gauges with superior calibration accuracy minimizes operational risks and enhances overall process efficiency. -

Temperature Rating

The temperature rating specifies the range of temperatures the gauge can withstand while maintaining functionality. This is particularly important in industries where equipment operates in extreme conditions. Understanding the temperature ratings helps buyers select gauges that can perform optimally in their specific environments, ensuring reliability and accuracy. -

Ingress Protection (IP) Rating

An IP rating denotes the level of protection a device has against dust and moisture. For equipment used in harsh environments, such as manufacturing plants or outdoor installations, a higher IP rating signifies greater durability. Buyers should consider the operational environment when evaluating IP ratings to ensure long-term performance and protection from environmental factors.

Which Trade Terminology Should B2B Buyers Understand?

Familiarity with industry-specific jargon is essential for effective communication and negotiation in B2B transactions. Here are several key terms relevant to Gage-It Inc’s offerings.

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of Gage-It Inc, it signifies that their products can be integrated into larger systems manufactured by other companies. Understanding OEM relationships helps buyers identify compatibility and sourcing options. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is significant for B2B buyers as it affects inventory management and cost-effectiveness. Knowing the MOQ can help businesses plan their purchases efficiently, avoiding excess inventory or stockouts. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific products or services. For B2B buyers, issuing an RFQ is a critical step in obtaining competitive pricing and ensuring that they understand the cost implications of their purchases. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade regarding shipping, insurance, and tariffs. Familiarity with these terms helps B2B buyers navigate global transactions, ensuring clarity in terms of delivery responsibilities and risk management. -

Calibration Certification

Calibration certification is a formal verification that a gauge meets specified accuracy standards, often recognized by regulatory bodies. For buyers, ensuring that their gauges come with calibration certification is essential for compliance and operational integrity, particularly in industries with stringent regulations.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing products from Gage-It Inc, ensuring they meet their operational needs while adhering to industry standards.

Illustrative image related to gage it inc

Navigating Market Dynamics and Sourcing Trends in the gage it inc Sector

What Are the Key Market Dynamics and Trends Influencing the Gage It Inc Sector?

The global market for industrial measurement and control instruments is experiencing significant growth, driven by technological advancements and increasing demand for precision in various sectors. Key trends include the rising adoption of digital technologies, such as IoT and AI, which enhance the capabilities of pressure and liquid level gauges. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly looking for suppliers who can provide not only high-quality products but also integrated solutions that enhance operational efficiency.

Emerging markets are witnessing substantial investments in infrastructure and industrial projects, necessitating reliable measurement and control systems. In regions like Saudi Arabia and Brazil, government initiatives aimed at diversifying economies and improving industrial output are propelling demand for products like those offered by Gage It Inc. Furthermore, the trend towards online ordering and e-commerce platforms is reshaping the purchasing landscape, enabling buyers to easily access products and services, including calibration and certification.

As businesses navigate these market dynamics, the focus is increasingly on suppliers who can demonstrate reliability and fast turnaround times, critical for maintaining operational continuity. Buyers are also seeking partners with a proven track record of customer service and technical support, which is essential in a landscape where precision instruments play a pivotal role in industrial operations.

How Is Sustainability and Ethical Sourcing Shaping the Gage It Inc Sector?

Sustainability and ethical sourcing are becoming paramount considerations for B2B buyers in the gage manufacturing sector. The environmental impact of production processes and the materials used in manufacturing pressure gauges and related instruments are under scrutiny. Companies are increasingly expected to adopt practices that minimize waste and reduce carbon footprints, which can significantly influence purchasing decisions.

For Gage It Inc, implementing sustainable practices could involve sourcing raw materials from certified suppliers who adhere to environmental regulations and standards. Certifications such as ISO 14001 for environmental management systems can enhance credibility and attract buyers who prioritize sustainability. Additionally, the use of recyclable or eco-friendly materials in the production of gauges can further align with the growing demand for green products.

Ethical supply chains are also gaining traction, with buyers interested in transparency regarding labor practices and sourcing origins. By ensuring that their supply chain adheres to ethical standards, Gage It Inc can build trust and loyalty among international buyers, particularly in markets where corporate social responsibility is highly valued. Establishing a reputation for ethical sourcing can be a competitive advantage in the B2B landscape.

What Is the Evolution of Gage It Inc and Its Relevance to B2B Buyers?

Founded in 1991, Gage It Inc has evolved to become a prominent player in the industrial measurement sector, specializing in pressure gauges, liquid level gauges, and backflow test kits. Over the years, the company has expanded its offerings to include comprehensive repair, calibration, and certification services, establishing itself as a trusted partner for industries requiring precision instrumentation.

This evolution reflects a broader trend in the B2B marketplace where suppliers are not only product vendors but also service providers who enhance the value proposition through expertise and support. For international buyers, particularly those in emerging markets, Gage It Inc’s commitment to quality and reliability positions it as a preferred supplier, capable of meeting the diverse needs of various industries. By continuously adapting to market demands and technological advancements, Gage It Inc remains relevant and competitive, ensuring that it can effectively serve the growing global market for industrial gauges and instruments.

Frequently Asked Questions (FAQs) for B2B Buyers of gage it inc

-

How do I ensure the quality of pressure gauges from Gage-It Inc?

To guarantee the quality of pressure gauges from Gage-It Inc, you can request calibration and certification services, which are provided according to NIST standards. Gage-It Inc has an in-house repair facility that conducts thorough evaluations of their products. Additionally, you can review customer testimonials and case studies that highlight the reliability of their products. Engaging with their experienced sales staff can also help you understand the specifications and applications of their gauges, ensuring they meet your operational requirements. -

What types of pressure gauges are available for industrial applications?

Gage-It Inc offers a wide variety of pressure gauges tailored for industrial applications, including liquid-filled gauges, digital test gauges, high-pressure gauges, and mechanical HVAC gauges. Each type is designed to provide accurate measurements under specific conditions, making them suitable for different processes. If you need customized solutions, Gage-It Inc also provides tailored gauge and diaphragm seal assemblies, enabling you to choose the best gauge for your specific needs. -

How can I place an international order with Gage-It Inc?

Placing an international order with Gage-It Inc is straightforward. You can visit their website to access their online ordering system, which facilitates international transactions. Ensure you provide accurate shipping details and select your preferred payment method. For larger orders or specific inquiries, contacting their sales team directly via phone or email is advisable, as they can offer assistance with logistics and any additional documentation required for customs clearance. -

What are the minimum order quantities (MOQ) for custom gauges?

Gage-It Inc typically sets minimum order quantities (MOQ) for custom gauge requests based on the complexity and specifications of the product. It is best to discuss your requirements directly with their sales staff, who can provide specific MOQ details based on your needs. This ensures that your order is processed efficiently while meeting your operational demands. -

What payment terms does Gage-It Inc offer for international buyers?

Gage-It Inc offers various payment options suitable for international buyers, including credit card payments and wire transfers. Payment terms may vary based on the order size and the buyer’s credit history with the company. It is advisable to confirm payment terms during the initial discussions with the sales team to ensure clarity and avoid any delays in processing your order. -

How does Gage-It Inc handle logistics for international shipping?

Gage-It Inc collaborates with reliable logistics partners to manage international shipping efficiently. They ensure that products are packaged securely to prevent damage during transit. When placing your order, discuss shipping options with their sales representatives, who can provide details on shipping times, costs, and tracking information. They also assist in preparing any necessary documentation for customs clearance to facilitate a smooth delivery process. -

What certifications do Gage-It Inc products hold?

All products from Gage-It Inc are certified to meet industry standards, including NIST certification for their calibration services. This certification ensures that the gauges are accurate and reliable for industrial applications. Buyers can request documentation of these certifications when placing their orders, providing peace of mind regarding the quality and compliance of their instruments. -

How can I get support for repairs and calibration of my gauges?

Gage-It Inc offers comprehensive support for repairs and calibration of gauges through their dedicated service department. You can send your gauges directly to their facility for evaluation and repair, with a no-charge evaluation process in place. Their experienced technicians perform calibration and certification services, ensuring your instruments maintain optimal performance. For detailed instructions on sending items for repair, visit their website or contact their customer service team.

Top 4 Gage It Inc Manufacturers & Suppliers List

1. Gage-It, Inc. – Pressure & Liquid Level Gauges

Domain: gageitinc.com

Registered: 2000 (25 years)

Introduction: Gage-It, Inc. offers a variety of products including:

– All Pressure Gauges

– Sprinkler & Fire Pump Gauges

– Liquid Filled Gauges

– Industrial Process & Liquid Level Gauges

– Mechanical & HVAC Gauges

– Digital Test Gauges

– High Pressure Gauges

– Repairable & Recalibratable Gauges

– Backflow Test Kits and Accessories

– Customized Gauge & Diaphragm Seal Assemblies

– Thermowells.

Servic…

2. Gage-It, Inc. – Pressure Gauges

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Gage-It, Inc. offers a variety of pressure gauges including process gauges, contractor gauges, low pressure gauges, precision test gauges, stainless steel gauges, and liquid filled gauges. They serve industries such as automotive, biotechnology, dairy/food, government, printing, and pharmaceutical.

3. Gage-It, Inc. – Backflow Test Kits

Domain: backflowtestkits.com

Registered: 2003 (22 years)

Introduction: Gage-It, Inc. offers backflow test kits and accessories. Their Mid-West Backflow Gauges can perform all known test procedures recommended by ABPA, ASSE, AWWA, CSA, FCCC, HR-USC, NEWWA, and UF-TREEO. The company provides calibration and service centers, along with literature and stocking distributors.

4. Gage-It – Pressure Gauges & Backflow Test Kits

Domain: highergov.com

Registered: 2022 (3 years)

Introduction: Gage-It – Your Source for Pressure Gauges, Liquid Level Gauges & Backflow Test Kits. Repair & Certification. Expert Advice, Fast Delivery. Order Online!

Strategic Sourcing Conclusion and Outlook for gage it inc

In the evolving landscape of industrial instrumentation, Gage-It Inc. stands out as a trusted partner for international B2B buyers seeking high-quality pressure and liquid level gauges, along with comprehensive calibration and repair services. Their commitment to customer satisfaction, demonstrated through fast turnaround times and expert advice, positions them as a reliable source for various industries. For buyers from Africa, South America, the Middle East, and Europe, leveraging strategic sourcing with Gage-It Inc. can enhance operational efficiency and ensure compliance with international standards.

Strategic sourcing not only optimizes procurement processes but also fosters long-term relationships that are vital in today’s competitive market. By choosing Gage-It Inc., businesses can benefit from their extensive experience, diverse product offerings, and tailored solutions that meet specific needs. This proactive approach to sourcing can lead to significant cost savings and improved product reliability.

Looking ahead, international buyers are encouraged to explore the innovative solutions offered by Gage-It Inc. Embracing these advanced instrumentation products and services will empower businesses to achieve greater precision and efficiency in their operations. Connect with Gage-It Inc. today to unlock the potential for growth and success in your industrial applications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.