A B2B Buyer’s Guide to Floor To Ceiling Room Divider: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for floor to ceiling room divider

In an increasingly interconnected world, the demand for versatile and functional solutions such as floor-to-ceiling room dividers is on the rise. B2B buyers face the challenge of sourcing high-quality dividers that not only meet aesthetic and functional requirements but also align with specific business needs across diverse markets. This guide serves as a comprehensive resource, addressing key considerations such as types of dividers, their applications in various sectors, and essential criteria for supplier vetting.

From offices in Nigeria to educational institutions in Germany, the applications of room dividers are vast, offering privacy, noise reduction, and space optimization. Understanding the nuances of different materials—such as wood, metal, and fabric—can significantly impact both the performance and cost-effectiveness of your investment. Furthermore, insights into pricing strategies and market trends will empower international buyers to make informed purchasing decisions.

By navigating the complexities of the global market for floor-to-ceiling room dividers, this guide equips businesses in Africa, South America, the Middle East, and Europe with the knowledge needed to select the right products for their unique environments. Whether you are looking to enhance office productivity or create adaptable spaces in educational settings, our guide provides the actionable insights you need to succeed in your sourcing journey.

Understanding floor to ceiling room divider Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wall-Mounted | Fixed to walls, often offers acoustic properties | Offices, conference rooms, hospitals | Pros: Space-saving, permanent solution. Cons: Limited flexibility; installation required. |

| Ceiling-Mounted | Suspended from the ceiling, can be sliding or folding | Retail spaces, event venues, schools | Pros: Versatile, can create temporary spaces. Cons: Installation complexity; may require ceiling reinforcement. |

| Freestanding | Portable and self-supporting, often modular | Trade shows, open offices, temporary setups | Pros: Easy to move and reconfigure. Cons: May require more floor space; stability concerns in high-traffic areas. |

| Acoustic Dividers | Designed to reduce sound transmission, often heavy-duty | Call centers, educational institutions | Pros: Enhances privacy and focus. Cons: Heavier; can be more expensive. |

| Tension Rod Dividers | Utilizes tension rods for installation, no permanent fixtures | Residential, temporary offices, rentals | Pros: Easy installation, no wall damage. Cons: Limited height options; may not be as sturdy. |

What are Wall-Mounted Room Dividers and Their Suitability for B2B Buyers?

Wall-mounted room dividers are fixed to existing walls, creating permanent divisions within spaces. These dividers often incorporate acoustic materials to enhance sound insulation, making them ideal for offices, conference rooms, and hospitals where noise control is essential. When considering these options, B2B buyers should evaluate the wall structure, as installation requires secure mounting. The durability and design should align with the organization’s aesthetic and functional needs, while the permanent nature means buyers should be confident in their space planning.

How Do Ceiling-Mounted Room Dividers Enhance Versatility in Commercial Spaces?

Ceiling-mounted dividers are suspended from the ceiling and can slide or fold, offering flexibility in space management. These are particularly advantageous in retail environments and event venues where temporary divisions are needed. B2B buyers should consider the ceiling height and structure, as these dividers may require additional support. The versatility allows for quick adjustments in space configurations, making them suitable for dynamic environments. However, the installation complexity and potential need for reinforcement should be factored into purchasing decisions.

What Advantages Do Freestanding Room Dividers Offer for Temporary Setups?

Freestanding room dividers are portable and self-supporting, making them an excellent choice for trade shows, open offices, and temporary setups. Their modular nature allows for easy reconfiguration, catering to changing space requirements. B2B buyers should assess the stability of these dividers, especially in high-traffic areas, as they may require more floor space. While they provide flexibility and ease of movement, the potential for instability must be weighed against the need for a versatile layout.

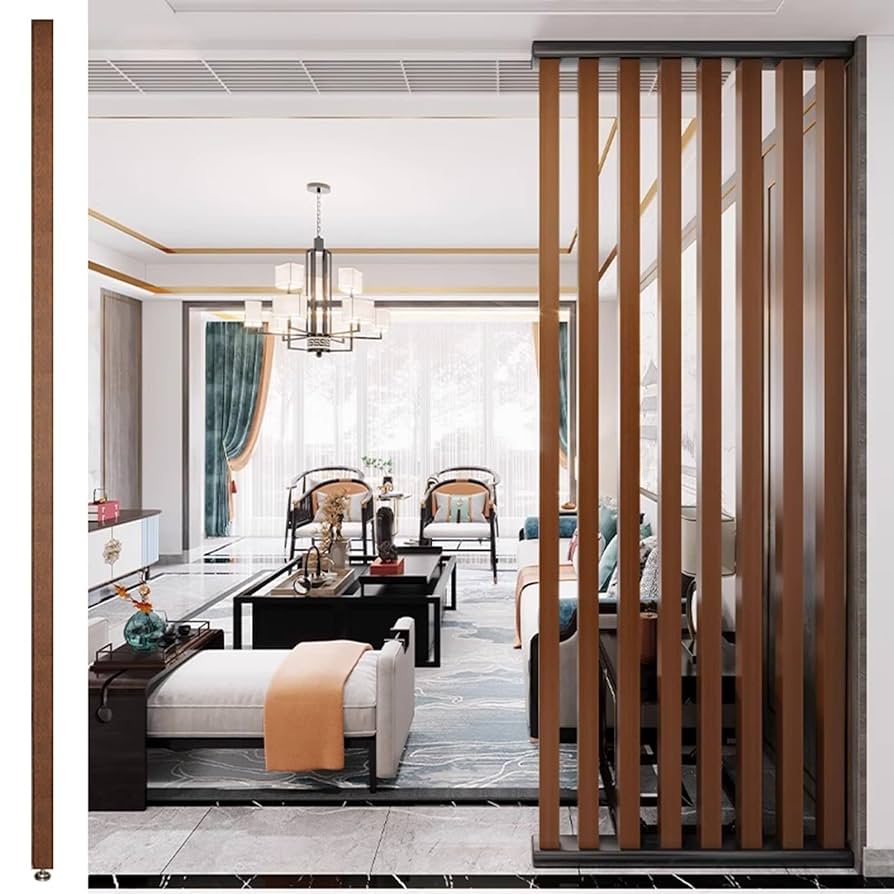

Illustrative image related to floor to ceiling room divider

Why Choose Acoustic Dividers for Enhanced Privacy in Work Environments?

Acoustic dividers are specifically designed to minimize sound transmission, making them ideal for call centers and educational institutions. These heavy-duty solutions not only provide physical separation but also enhance privacy and focus, which is critical in noisy environments. B2B buyers should consider the weight and installation requirements, as these dividers can be more expensive. Investing in acoustic solutions can lead to improved productivity and employee satisfaction, making them a worthwhile consideration for noise-sensitive applications.

What are the Benefits of Tension Rod Dividers for Flexible Space Management?

Tension rod dividers offer a unique installation method that does not require permanent fixtures, making them suitable for residential spaces, temporary offices, and rentals. These dividers are easy to set up and remove, allowing for quick changes without damaging walls. B2B buyers should evaluate height options, as they may be limited compared to other types, and consider the overall sturdiness, especially in more active environments. Their convenience and adaptability make them a popular choice for those seeking flexible space management solutions.

Key Industrial Applications of floor to ceiling room divider

| Industry/Sector | Specific Application of Floor to Ceiling Room Divider | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | Classrooms and Lecture Halls | Enhances privacy and minimizes distractions during lessons | Acoustic properties, customizable designs, durability |

| Healthcare | Patient Rooms and Waiting Areas | Provides privacy for patients while maintaining space efficiency | Easy-to-clean materials, compliance with health regulations |

| Corporate Offices | Open Workspace Division | Increases productivity by reducing noise and creating private meeting areas | Modular designs, aesthetic appeal, and ease of installation |

| Hospitality | Event Spaces and Conference Rooms | Flexible space management for varying event sizes | Aesthetic value, portable options, and soundproofing features |

| Retail | Merchandising Displays and Customer Flow Management | Enhances customer experience by creating distinct shopping areas | Visual appeal, lightweight materials, and ease of movement |

How are Floor to Ceiling Room Dividers Used in Education?

In educational settings, floor-to-ceiling room dividers are employed to create flexible classroom environments. These dividers allow for the transformation of large spaces into smaller, more intimate areas conducive to focused learning. They help solve the problem of noise pollution and distractions during lectures or group activities. Buyers in the education sector should consider options with acoustic insulation and customizable designs to adapt to various classroom layouts and teaching methods.

Illustrative image related to floor to ceiling room divider

What Role Do Floor to Ceiling Room Dividers Play in Healthcare Facilities?

In healthcare environments, these dividers are critical for maintaining patient privacy in rooms and waiting areas. They can create temporary partitions that allow for effective space utilization without compromising patient dignity. The materials used must be easy to sanitize and comply with health regulations, making sourcing from reputable manufacturers essential. Buyers should prioritize dividers that offer a balance of functionality and aesthetics, ensuring a calming environment for patients.

How Can Corporate Offices Benefit from Floor to Ceiling Room Dividers?

Corporate offices utilize floor-to-ceiling room dividers to create distinct workspaces within open-plan environments. This not only enhances productivity by reducing noise but also provides employees with private areas for meetings and focused work. When sourcing these dividers, businesses should consider modular designs that allow for easy reconfiguration as office needs evolve. Additionally, aesthetic appeal plays a significant role, as dividers can enhance the overall workplace atmosphere.

In What Ways Do Hospitality Venues Use Floor to Ceiling Room Dividers?

Hospitality venues, such as hotels and conference centers, often rely on floor-to-ceiling room dividers to manage space for events and meetings. These dividers allow for quick reconfiguration of large areas to accommodate different event sizes and types, enhancing the flexibility of the space. Buyers should look for visually appealing designs that complement the venue’s decor and consider soundproofing features to ensure a pleasant experience for attendees.

How Do Retail Environments Leverage Floor to Ceiling Room Dividers?

In retail, floor-to-ceiling room dividers are used to create distinct shopping areas or merchandising displays, guiding customer flow and enhancing the shopping experience. They help in segmenting products or creating themed sections without the need for permanent construction. When sourcing, retailers should focus on lightweight materials that are easy to move and visually attractive to maintain an engaging store environment.

3 Common User Pain Points for ‘floor to ceiling room divider’ & Their Solutions

Scenario 1: Struggling with Noise Control in Open Spaces

The Problem: In modern open office environments, noise can significantly hinder productivity. B2B buyers, especially in sectors such as technology and creative industries, often find that employees are easily distracted by surrounding conversations, phone calls, and other sounds. This issue is exacerbated in shared workspaces or large conference rooms, where multiple teams work in close proximity. The challenge lies in finding a solution that not only divides space but also effectively dampens sound without compromising the aesthetic of the office environment.

Illustrative image related to floor to ceiling room divider

The Solution: To address noise concerns, consider investing in floor-to-ceiling room dividers designed with acoustic properties. These dividers are specifically engineered to absorb sound, creating quieter work areas. When sourcing these products, it’s crucial to evaluate materials such as fabric-covered panels or sound-absorbing foam that enhance acoustic performance. Look for options that can be customized in size and color to fit seamlessly into your existing office design. Additionally, ensure that the dividers are easily movable or adjustable, allowing for flexible workspace configurations. Consulting with manufacturers who specialize in acoustic solutions can provide insights into the best products for your specific needs, leading to a more productive work environment.

Scenario 2: Navigating Compliance and Safety Regulations

The Problem: In industries such as healthcare and education, compliance with safety regulations is a primary concern. B2B buyers in these sectors may struggle with selecting room dividers that not only fulfill their functional requirements but also meet stringent regulatory standards for fire safety, durability, and hygiene. This complexity can lead to uncertainty and delays in decision-making, as the consequences of non-compliance can be severe, including fines and reputational damage.

The Solution: To navigate these challenges, it’s essential to thoroughly research and select floor-to-ceiling room dividers that are certified to meet relevant safety standards. Collaborate with suppliers who provide documentation of compliance with local and international regulations, such as fire ratings and material safety data sheets. Consider dividers made from non-toxic, easy-to-clean materials that are resistant to stains and bacteria, particularly in healthcare settings. Engaging with a consultant who specializes in compliance can also streamline the selection process, ensuring that all necessary criteria are met while maintaining functionality and design integrity. Regular training for staff on the importance of compliance and proper usage of these dividers can further enhance safety and efficiency in the workplace.

Scenario 3: Balancing Cost with Quality and Aesthetics

The Problem: Cost considerations are a major factor for B2B buyers when sourcing floor-to-ceiling room dividers. Many businesses grapple with the dilemma of finding high-quality products that fit within budget constraints. Low-cost options may compromise durability and aesthetics, leading to additional costs for replacements or repairs. Buyers often feel pressured to make compromises that could impact the overall look and functionality of their spaces.

Illustrative image related to floor to ceiling room divider

The Solution: To achieve a balance between cost, quality, and aesthetics, start by conducting a thorough cost-benefit analysis of different room divider options. Prioritize suppliers known for high-quality materials and craftsmanship, even if their initial prices are higher. Investing in durable, stylish dividers can lead to long-term savings by reducing the need for replacements. Consider modular designs that offer flexibility for future reconfigurations, allowing you to adapt the space without additional costs. Additionally, seek out manufacturers that provide warranties or guarantees on their products, as these can be indicators of quality and reliability. Engage in discussions with suppliers about bulk purchasing discounts or financing options to make high-quality dividers more accessible within your budget. By prioritizing quality and versatility, you can create an attractive, functional workspace that aligns with your financial goals.

Strategic Material Selection Guide for floor to ceiling room divider

What Are the Key Materials for Floor to Ceiling Room Dividers?

When selecting materials for floor to ceiling room dividers, it is essential to consider their properties, advantages, and limitations, especially from a B2B perspective. This section analyzes four common materials: wood, metal, glass, and fabric. Each material has unique characteristics that can influence the performance and suitability of the dividers in various applications.

How Does Wood Perform as a Material for Room Dividers?

Wood is a traditional choice for room dividers, appreciated for its aesthetic appeal and versatility. Key properties include excellent thermal insulation and sound absorption, making it suitable for environments requiring privacy. However, wood is susceptible to warping and moisture damage, particularly in humid climates, which can be a concern for buyers in tropical regions like parts of Africa and South America.

Pros: Wood offers a natural look, is easy to work with, and can be customized in various finishes. It also has a relatively low cost compared to other materials.

Cons: The main drawbacks include susceptibility to pests and moisture, as well as a higher maintenance requirement. Compliance with fire safety standards can also be a concern, necessitating treatments that may increase costs.

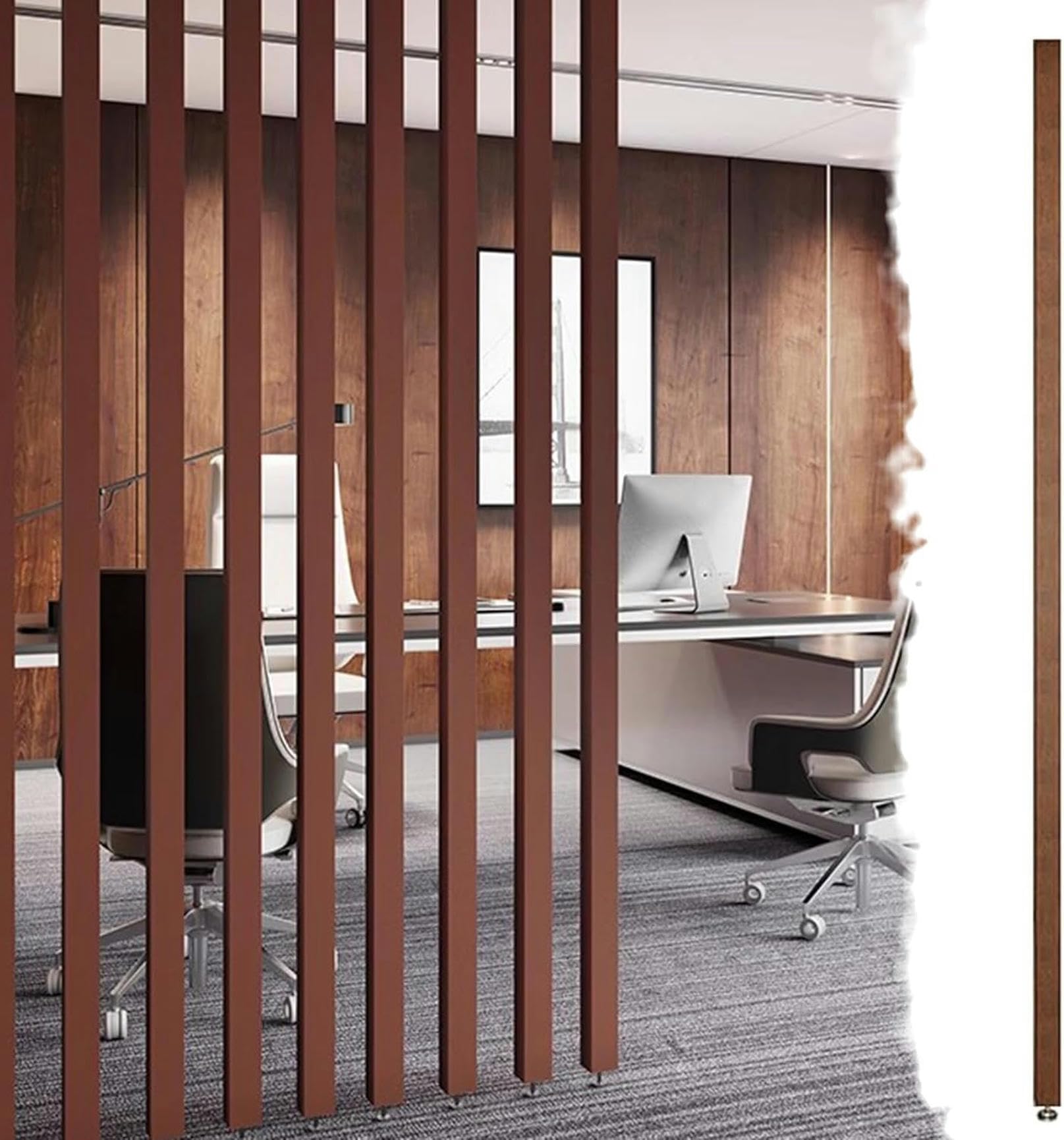

Illustrative image related to floor to ceiling room divider

What Are the Benefits of Metal in Room Divider Applications?

Metal, particularly aluminum and steel, is gaining popularity for its durability and modern aesthetic. Key properties include high strength-to-weight ratios and resistance to corrosion, making metal dividers suitable for high-traffic areas and environments with varying temperatures.

Pros: Metal is highly durable, low-maintenance, and can be easily fabricated into various designs. It is also fire-resistant, which aligns with safety standards in many regions.

Cons: The primary limitation is the higher cost of metal compared to wood or fabric. Additionally, metal can conduct heat and cold, which may be uncomfortable in extreme climates without proper insulation.

How Does Glass Enhance the Functionality of Room Dividers?

Glass dividers are favored for their ability to create an open, airy feel while maintaining separation. Key properties include excellent light transmission and sound insulation, depending on the thickness and type of glass used.

Pros: Glass offers a sleek, modern appearance and can enhance the aesthetic appeal of any space. It is also easy to clean and maintain.

Illustrative image related to floor to ceiling room divider

Cons: The main disadvantages are its fragility and higher installation complexity. Glass can also be more expensive and may require specialized handling during transport and installation, which is a consideration for international buyers.

Why Choose Fabric for Flexible Room Dividers?

Fabric dividers are increasingly popular for their flexibility and ease of installation. Key properties include lightweight construction and the ability to be easily customized in terms of color and design.

Pros: Fabric is cost-effective, lightweight, and can be easily transported. It allows for creativity in design and can be used in various settings, from offices to homes.

Cons: The limitations include lower durability and potential for staining or wear over time. Fabric dividers may also require regular cleaning and maintenance, which can be a concern for businesses looking for low-maintenance solutions.

Illustrative image related to floor to ceiling room divider

Summary Table of Material Selection for Floor to Ceiling Room Dividers

| Material | Typical Use Case for floor to ceiling room divider | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Offices, schools, residential spaces | Aesthetic appeal and insulation | Susceptible to moisture and pests | Low |

| Metal | High-traffic areas, modern offices | Durability and low maintenance | Higher cost and thermal conductivity | High |

| Glass | Conference rooms, modern offices | Light transmission and aesthetics | Fragility and installation complexity | High |

| Fabric | Flexible spaces, temporary setups | Cost-effective and customizable | Lower durability and maintenance needs | Medium |

In conclusion, understanding the properties, advantages, and limitations of these materials is crucial for international B2B buyers. Compliance with local standards and preferences in design and functionality can significantly impact the selection process, ensuring that the chosen material meets both aesthetic and practical needs.

In-depth Look: Manufacturing Processes and Quality Assurance for floor to ceiling room divider

What Are the Main Stages of Manufacturing Floor to Ceiling Room Dividers?

The manufacturing process for floor to ceiling room dividers involves several key stages: material preparation, forming, assembly, and finishing. Each stage is critical to ensuring the final product meets both aesthetic and functional requirements, particularly for B2B buyers in diverse markets.

How Is Material Prepared for Room Dividers?

Material preparation begins with sourcing high-quality raw materials, which may include wood, metal, glass, or synthetic composites. Suppliers often prioritize sustainable sourcing to align with eco-friendly trends and regulations, particularly in regions like Europe and South America where such practices are increasingly demanded.

Illustrative image related to floor to ceiling room divider

Once sourced, materials undergo several pre-processing techniques such as cutting, sanding, and treating. For wooden components, this may involve drying and treating to prevent warping. Metal elements may be coated for corrosion resistance. This stage sets the foundation for durability and performance, which are critical factors for B2B clients seeking long-lasting solutions.

What Techniques Are Used in the Forming Stage?

The forming stage is where the raw materials are shaped into the components of the room dividers. Techniques vary depending on the material:

-

For Wood and Composites: CNC (Computer Numerical Control) machines are commonly used for precision cutting and shaping. This ensures uniformity across multiple units, which is vital for large-scale projects.

-

For Metal Components: Processes like bending, welding, and laser cutting are employed. These techniques allow for the creation of strong, lightweight frames that are essential for structural integrity.

-

For Glass Elements: Tempering and laminating processes are utilized to enhance safety and durability. Tempered glass is particularly important in commercial applications to reduce the risk of breakage.

These techniques allow manufacturers to produce customizable designs that meet specific client needs while maintaining high standards of quality.

How Is Assembly Conducted for Room Dividers?

Assembly involves bringing together all the components into a finished product. This stage often includes the use of advanced technologies such as robotic assembly for precision and efficiency.

Illustrative image related to floor to ceiling room divider

Quality control measures are integrated into the assembly line, where workers perform checks at various points to ensure that components fit together correctly and meet design specifications. For B2B buyers, understanding the assembly process is crucial, as it directly affects lead times and the final product’s reliability.

What Finishing Processes Are Applied?

Finishing processes enhance the aesthetic appeal and functionality of the room dividers. Common techniques include:

-

Painting and Coating: These processes protect against wear and tear while providing color options that match client specifications. High-quality finishes are essential for projects in high-visibility areas like offices and hospitality venues.

-

Upholstery and Textiles: For dividers with fabric elements, manufacturers may use various upholstery techniques to ensure durability and ease of cleaning. This is particularly important in healthcare and educational settings.

-

Final Quality Checks: Each unit undergoes a thorough inspection to identify defects or inconsistencies before packaging and shipping.

What Are the Key Quality Assurance Practices for Room Dividers?

Quality assurance (QA) is crucial in the manufacturing of floor to ceiling room dividers, ensuring that products meet international and industry-specific standards.

Illustrative image related to floor to ceiling room divider

Which International Standards Are Relevant?

For B2B buyers, understanding the applicable quality standards is essential. Common international standards include:

-

ISO 9001: This standard focuses on quality management systems and is widely recognized across various industries. Compliance signifies a commitment to quality and continuous improvement.

-

CE Marking: Particularly relevant in Europe, CE marking indicates that products meet EU safety, health, and environmental protection requirements.

-

API Standards: For dividers used in specific industries, such as oil and gas, adherence to American Petroleum Institute (API) standards may be necessary.

What Are the Quality Control Checkpoints in Manufacturing?

Quality control is typically structured around several checkpoints:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards. B2B buyers should verify that suppliers have robust IQC processes in place.

-

In-Process Quality Control (IPQC): This stage includes monitoring the manufacturing process itself, ensuring that production methods are consistent and that any defects are caught early.

-

Final Quality Control (FQC): Before products are packaged and shipped, a final inspection is conducted to confirm that all units meet quality specifications. Documentation of these checks can be critical for B2B buyers looking to ensure product reliability.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to ensure that their suppliers adhere to quality control standards:

-

Supplier Audits: Conducting regular audits of manufacturing facilities can provide insights into the processes and quality control measures in place. This is particularly important for buyers in regions with varying quality standards.

-

Requesting Quality Reports: Suppliers should be able to provide documentation of their quality assurance processes, including certifications and test results. Buyers can use this information to assess reliability.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of product quality and compliance with international standards. This is especially valuable for buyers in Africa and South America, where local suppliers may vary in their adherence to global standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various nuances in quality control, including cultural differences in manufacturing practices and differing regulatory environments.

Buyers should be aware of:

-

Local Compliance Requirements: Understanding local laws and regulations regarding product safety and quality in the target market is crucial. For example, while CE marking is mandatory in Europe, similar requirements may not exist in Africa or South America.

-

Communication Barriers: Effective communication with suppliers regarding quality expectations is essential. Language differences can lead to misunderstandings, so clear specifications and documentation are vital.

-

Cultural Expectations: Different regions may have varying expectations regarding quality and service levels. Buyers should conduct thorough research to ensure that their suppliers align with their quality standards.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing floor to ceiling room dividers, ensuring they receive products that meet their specific needs and expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘floor to ceiling room divider’

When sourcing floor-to-ceiling room dividers, a structured approach is essential to ensure you select the right product and supplier for your business needs. This guide provides a practical checklist to help international B2B buyers navigate the procurement process effectively.

Illustrative image related to floor to ceiling room divider

Step 1: Define Your Technical Specifications

Before starting your search, clearly outline the technical requirements for your room dividers. Consider factors such as dimensions, materials, and design features.

– Dimensions: Ensure the dividers meet the height and width requirements of your space.

– Materials: Decide whether you need acoustic properties, durability, or aesthetic qualities.

Step 2: Research Market Trends and Innovations

Understanding the latest trends in room dividers can provide insights into what features are in demand. Investigate what materials and designs are popular in various markets, especially in regions like Africa, Europe, and South America.

– Sustainability: Look for eco-friendly materials, which are increasingly preferred by businesses.

– Technology Integration: Consider options that incorporate technology, such as soundproofing or digital displays.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers to ensure they can meet your requirements. Request detailed company profiles, product catalogs, and references from other businesses in your industry.

– Experience: Look for suppliers with a proven track record in providing room dividers.

– Certifications: Ensure they comply with international quality standards relevant to your region.

Step 4: Request Samples and Demonstrations

Before finalizing your order, request samples or demonstrations of the room dividers. This step is crucial to assess the quality and functionality of the products.

– Quality Assessment: Evaluate the material and craftsmanship firsthand.

– Installation Process: Understand the installation requirements and whether they align with your capabilities.

Step 5: Analyze Pricing and Payment Terms

Obtain detailed quotes from multiple suppliers to compare pricing structures. Pay attention to the total cost, including shipping and installation, as well as payment terms.

– Bulk Discounts: Inquire about discounts for larger orders, which can significantly reduce costs.

– Payment Flexibility: Ensure the payment terms align with your budget and cash flow needs.

Step 6: Verify Warranty and After-Sales Support

Before making a purchase, confirm the warranty and support offered by the supplier. A strong warranty can protect your investment against defects or issues.

– Duration and Coverage: Understand what the warranty covers and its duration.

– Support Services: Ensure the supplier offers reliable after-sales support, including installation assistance and maintenance.

Step 7: Finalize the Order and Monitor Delivery

Once you have selected a supplier, finalize the order and establish clear timelines for delivery. Monitor the process to ensure that the dividers arrive on schedule and meet your specifications.

– Communication: Maintain regular contact with the supplier to track the order status.

– Inspection Upon Arrival: Inspect the dividers immediately upon delivery to address any issues promptly.

Illustrative image related to floor to ceiling room divider

By following this checklist, B2B buyers can confidently procure floor-to-ceiling room dividers that meet their specific needs while ensuring quality and reliability in their sourcing process.

Comprehensive Cost and Pricing Analysis for floor to ceiling room divider Sourcing

What Are the Key Cost Components in Sourcing Floor to Ceiling Room Dividers?

When analyzing the cost structure for floor to ceiling room dividers, several key components must be considered:

-

Materials: The choice of materials significantly impacts cost. Common options include wood, metal, glass, and various composites. For instance, solid wood may be more expensive than engineered wood, while glass dividers often come with higher costs due to manufacturing and safety standards.

-

Labor: Labor costs encompass both the production workforce and installation teams. Skilled labor for custom installations can be pricier, particularly in regions where labor costs are higher.

-

Manufacturing Overhead: This includes the costs associated with running the factory, such as utilities, rent, and equipment maintenance. Efficient production processes can help mitigate these costs.

-

Tooling: This refers to the expenses related to the tools and machinery needed for production. Custom designs may require specialized tooling, which can increase upfront costs.

-

Quality Control (QC): Ensuring that dividers meet specific standards incurs additional costs. Effective QC processes can prevent costly returns and enhance customer satisfaction.

-

Logistics: Transportation costs vary widely based on distance and mode of transport. International shipping, especially for bulky items like room dividers, can add significant costs.

-

Margin: Suppliers will add a profit margin on top of their costs, which can range from 10% to 50%, depending on the market and competition.

How Do Price Influencers Affect the Cost of Room Dividers?

Several factors influence the pricing of floor to ceiling room dividers:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often offer discounts for bulk purchases. Understanding the MOQ can help buyers negotiate better rates.

-

Specifications and Customization: Custom features or specific dimensions can lead to increased costs. Buyers should clarify their needs upfront to avoid unexpected charges.

-

Material Quality and Certifications: Higher-quality materials or those that meet specific certifications (like fire safety or environmental standards) can command higher prices.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established manufacturers may charge more due to their track record of quality and service.

-

Incoterms: Understanding shipping terms is crucial for international transactions. Different Incoterms (like FOB, CIF) can significantly affect the total landed cost of products.

What Are the Best Buyer Tips for Negotiating Costs on Room Dividers?

To maximize cost-efficiency in sourcing floor to ceiling room dividers, consider the following strategies:

-

Negotiate Effectively: Leverage your purchasing power by negotiating terms with suppliers. Requesting quotes from multiple suppliers can create competitive pricing scenarios.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider long-term factors such as maintenance costs, durability, and potential energy savings, especially for acoustic or insulated models.

-

Understand Regional Pricing Nuances: Pricing can vary significantly based on geography. For instance, costs in Germany may differ from those in Nigeria due to local market conditions and logistics. Awareness of these differences can aid in better budgeting.

-

Stay Informed About Market Trends: Keeping abreast of material costs, labor market shifts, and global supply chain issues can provide leverage during negotiations.

-

Consider Sustainability: Eco-friendly materials and manufacturing processes may come at a premium but can enhance brand value and appeal to environmentally-conscious clients.

Disclaimer on Pricing

Prices for floor to ceiling room dividers can fluctuate based on a multitude of factors, including market demand, material availability, and currency exchange rates. Buyers should always seek updated quotes and conduct thorough market research to ensure they secure the best deal for their specific needs.

Illustrative image related to floor to ceiling room divider

Alternatives Analysis: Comparing floor to ceiling room divider With Other Solutions

Exploring Alternatives to Floor to Ceiling Room Dividers

In the quest for optimizing space and enhancing functionality in commercial environments, B2B buyers often consider various solutions to achieve effective room division. While floor to ceiling room dividers provide a robust method for creating privacy and defining spaces, alternative solutions exist that may better suit specific needs based on performance, cost, and ease of implementation. This analysis compares floor to ceiling room dividers with two viable alternatives: portable partitions and hanging fabric dividers.

| Comparison Aspect | Floor To Ceiling Room Divider | Portable Partitions | Hanging Fabric Dividers |

|---|---|---|---|

| Performance | Excellent sound and visual barrier; customizable | Good for temporary setups; less soundproof | Moderate sound dampening; versatile |

| Cost | Higher initial investment; durable | Moderate cost; budget-friendly | Generally low cost; economical |

| Ease of Implementation | Requires installation; may need professional help | Easy to set up and move around | Simple to install; minimal tools needed |

| Maintenance | Low maintenance; durable materials | Moderate; depends on material | Low; fabric can be washed or replaced |

| Best Use Case | Permanent or semi-permanent spaces like offices and clinics | Events, trade shows, or temporary setups | Flexible environments like studios or shared offices |

What Are the Advantages and Disadvantages of Portable Partitions?

Portable partitions are ideal for businesses that require flexibility in their space layout. These dividers can be easily moved and reconfigured as needed, making them perfect for trade shows, conferences, or temporary office settings. They typically have a lower upfront cost compared to floor to ceiling room dividers, which is attractive for budget-conscious buyers. However, they may not provide the same level of sound insulation or visual privacy, making them less suitable for environments where these factors are critical.

How Do Hanging Fabric Dividers Offer Flexibility?

Hanging fabric dividers are another alternative that offers unique benefits, particularly in terms of aesthetics and versatility. They can be suspended from ceilings, creating a lightweight, airy separation that allows for light and airflow. This solution is often the most economical option, appealing to businesses looking for cost-effective space solutions. However, they generally provide only moderate sound dampening and may not be suitable for professional environments requiring significant privacy or noise control.

Making the Right Choice for Your Space

When choosing between floor to ceiling room dividers and alternative solutions, B2B buyers should consider their specific requirements, including the intended use of the space, budget constraints, and the need for sound insulation or visual privacy. For permanent installations where durability and performance are paramount, floor to ceiling dividers are likely the best option. Conversely, if flexibility and cost-effectiveness are the primary concerns, portable partitions or hanging fabric dividers may be more appropriate.

Ultimately, the decision should align with the business’s operational needs and the environment it seeks to create. By carefully evaluating these alternatives, buyers can make informed choices that enhance functionality and optimize their space.

Essential Technical Properties and Trade Terminology for floor to ceiling room divider

What Are the Essential Technical Properties of Floor to Ceiling Room Dividers?

When selecting floor to ceiling room dividers, understanding the technical specifications is crucial for making informed purchasing decisions. Here are some key properties that B2B buyers should consider:

1. Material Grade

The material grade indicates the quality and durability of the room divider. Common materials include solid wood, engineered wood, metal, glass, and various plastics. Each material has its own strengths; for example, metal offers robustness, while glass provides a sleek aesthetic. Choosing the right material is essential for ensuring longevity and suitability for different environments, such as offices, hospitals, or educational settings.

2. Acoustic Performance

Acoustic performance measures a room divider’s ability to reduce sound transmission between spaces. This property is particularly important in environments where noise control is essential, like offices or conference rooms. Manufacturers often provide an acoustic rating, which can guide buyers in selecting products that meet specific sound absorption needs, enhancing privacy and productivity.

3. Tolerance

Tolerance refers to the permissible variation in dimensions of the room divider. It is critical for ensuring a proper fit within a designated space. High tolerance levels are essential for custom installations, as even slight discrepancies can affect aesthetics and functionality. Understanding tolerance specifications helps B2B buyers ensure compatibility with existing structures or designs.

Illustrative image related to floor to ceiling room divider

4. Load-Bearing Capacity

The load-bearing capacity indicates how much weight a room divider can support without compromising structural integrity. This is particularly relevant for ceiling-mounted options or those that may support additional features like shelving. Ensuring adequate load-bearing capacity is crucial for safety and durability, especially in high-traffic commercial environments.

5. Finish and Aesthetics

The finish of a room divider affects both its appearance and its resistance to wear and tear. Options range from natural wood finishes to painted or laminated surfaces. Aesthetic considerations are vital for B2B buyers who aim to create specific atmospheres in commercial spaces, influencing customer perceptions and employee satisfaction.

6. Installation Method

Understanding the installation method—whether wall-mounted, ceiling-mounted, or freestanding—is essential for planning and execution. Different methods may require varying levels of expertise and tools, impacting project timelines and costs. Knowing the installation requirements helps buyers prepare adequately for deployment and reduces the risk of delays.

Which Trade Terminology Should B2B Buyers Know When Purchasing Room Dividers?

Familiarizing yourself with industry-specific terminology can streamline the purchasing process and enhance communication with suppliers. Here are some common terms associated with floor to ceiling room dividers:

Illustrative image related to floor to ceiling room divider

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of room dividers, working with OEMs can provide access to high-quality materials and innovative designs that meet specific industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for budget planning and inventory management, as some suppliers may require large minimum orders, impacting the overall cost-effectiveness for small to medium-sized businesses.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. B2B buyers use RFQs to compare offers from different manufacturers, ensuring they secure the best deal for their required room dividers.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects such as shipping costs, insurance, and risk of loss. Familiarity with Incoterms is essential for B2B buyers engaged in global procurement, as they clarify obligations and help avoid disputes.

Illustrative image related to floor to ceiling room divider

5. Customization

Customization refers to the ability to modify a product according to specific requirements, such as size, color, or features. This is particularly relevant in the room divider market, where businesses often seek tailored solutions to fit unique spaces and design preferences.

By understanding these essential properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and project goals.

Navigating Market Dynamics and Sourcing Trends in the floor to ceiling room divider Sector

What are the Current Market Dynamics and Key Trends in the Floor to Ceiling Room Divider Sector?

The global market for floor to ceiling room dividers is witnessing robust growth, driven by several key factors. Increased urbanization and the rising demand for flexible workspace solutions are reshaping how businesses and commercial spaces utilize their environments. In regions like Africa and South America, where space optimization is critical due to high population densities, the demand for adaptable room dividers is especially pronounced. Similarly, in Europe and the Middle East, there is a growing trend towards multifunctional spaces that can quickly transition between uses, such as from open offices to private meeting areas.

Emerging B2B technologies, such as augmented reality (AR) and virtual reality (VR), are also impacting the sourcing process. These technologies allow buyers to visualize room dividers in their intended spaces before making purchasing decisions, enhancing customer engagement and satisfaction. Additionally, automated supply chain solutions are streamlining sourcing, making it easier for international buyers to access diverse product offerings efficiently.

Another notable trend is the customization of room dividers to meet specific client needs. Modular and customizable designs are becoming increasingly popular, allowing companies to tailor solutions that reflect their brand identity and operational requirements. As competition intensifies, suppliers who offer innovative, flexible solutions will likely gain a significant advantage in the market.

How Does Sustainability and Ethical Sourcing Impact the Floor to Ceiling Room Divider Sector?

Sustainability is a critical consideration for international B2B buyers in the floor to ceiling room divider market. As environmental concerns rise, companies are increasingly scrutinizing the materials and manufacturing processes used in their sourcing. Ethical supply chains that prioritize eco-friendly materials and practices are becoming essential for maintaining brand integrity and meeting consumer expectations.

Buyers are encouraged to seek out suppliers who offer sustainable materials, such as reclaimed wood, recycled metals, and low-VOC (volatile organic compounds) finishes. Certifications like FSC (Forest Stewardship Council) and Cradle to Cradle not only enhance the environmental credentials of products but also serve as a mark of quality and responsibility. Companies that invest in ‘green’ certifications and sustainable practices can differentiate themselves in a competitive market while appealing to a growing segment of environmentally-conscious consumers.

Furthermore, the integration of sustainability into the design of room dividers—such as using modular and recyclable components—can reduce waste and lower the carbon footprint associated with production and transportation. As regulations tighten globally, prioritizing sustainability in sourcing decisions will not only align with corporate social responsibility goals but also mitigate risks associated with environmental compliance.

What is the Evolution and Historical Context of the Floor to Ceiling Room Divider Market?

The evolution of floor to ceiling room dividers can be traced back to the early 20th century when the need for flexible space management began to emerge in commercial settings. Initially, these dividers were primarily made from heavy materials like wood and glass, limiting their versatility and ease of installation. However, advancements in materials science led to the development of lighter, more versatile options such as aluminum and fabric, which allowed for the creation of more innovative designs.

Over the decades, the demand for room dividers has expanded beyond traditional office settings to include educational institutions, healthcare facilities, and residential spaces. The rise of open-plan offices in the late 20th century catalyzed the need for solutions that could provide privacy without sacrificing the collaborative spirit of these environments. Today, the market is characterized by a blend of functionality, aesthetics, and sustainability, reflecting broader trends in design and user experience.

As businesses continue to adapt to changing work environments, the floor to ceiling room divider sector is poised for further innovation, with a focus on smart technology integration and sustainable practices that cater to the evolving needs of global markets.

Frequently Asked Questions (FAQs) for B2B Buyers of floor to ceiling room divider

1. How can I determine the right size for a floor to ceiling room divider in my space?

To determine the appropriate size for a floor to ceiling room divider, start by measuring the height and width of the area you wish to divide. Consider the function of the divider—whether it’s for privacy, noise reduction, or aesthetic appeal. Additionally, assess the layout and flow of the space to ensure the divider complements existing furnishings. Most suppliers offer customizable options, allowing you to tailor the dimensions to your specific needs. Always consult with your supplier to discuss potential limitations or recommendations based on your measurements.

Illustrative image related to floor to ceiling room divider

2. What materials are commonly used for floor to ceiling room dividers, and which is best for my needs?

Common materials for floor to ceiling room dividers include wood, glass, metal, and fabric. Wood provides warmth and durability, while glass offers a modern look and maintains light flow. Metal dividers are sturdy and often used in industrial settings, whereas fabric options can enhance acoustic properties and offer flexibility. The best material depends on your intended use, such as privacy requirements, aesthetic preferences, and maintenance considerations. Discuss your specific needs with suppliers to identify the most suitable option for your project.

3. What customization options are available for floor to ceiling room dividers?

Many manufacturers offer extensive customization options for floor to ceiling room dividers. You can choose from various materials, colors, sizes, and configurations to match your design vision. Additionally, some suppliers allow you to integrate features like acoustic panels or movable sections. When discussing customization, communicate your specific requirements and design aspirations to ensure the final product aligns with your expectations. Always request samples or prototypes to evaluate material quality and aesthetics before finalizing your order.

4. How do I verify the credibility of a supplier for room dividers?

To verify a supplier’s credibility, start by researching their reputation in the industry. Look for reviews, testimonials, and case studies from previous clients, particularly those in your region. Additionally, check for relevant certifications, such as ISO standards, that indicate quality assurance processes. Engaging in direct communication with the supplier can also provide insights into their customer service and responsiveness. Consider requesting references and visiting their facilities if possible to assess their production capabilities and operational standards.

5. What are typical minimum order quantities (MOQs) for floor to ceiling room dividers?

Minimum order quantities (MOQs) for floor to ceiling room dividers can vary significantly based on the supplier and the complexity of the customization. Generally, MOQs can range from a few units for standard models to larger quantities for customized designs. It’s essential to discuss your project requirements with the supplier early in the negotiation process to understand their MOQ policies. If your order falls below their MOQ, inquire about potential options, such as joining with other buyers to meet the requirement.

6. What payment terms should I expect when sourcing room dividers internationally?

Payment terms can vary widely among suppliers, but common practices include a deposit upfront (often 30% to 50%) with the balance due prior to shipment. Some suppliers may offer net terms, allowing you to pay after receiving the goods. When dealing with international suppliers, consider using secure payment methods such as letters of credit or escrow services to protect your transaction. Always clarify payment terms in your contract to avoid misunderstandings and ensure that you are comfortable with the agreed-upon conditions.

7. How can I ensure quality assurance for my floor to ceiling room divider order?

To ensure quality assurance for your order, begin by discussing the supplier’s quality control processes. Request information on their testing methods and any certifications they hold. It’s also advisable to establish clear specifications for your order, including material quality, dimensions, and finish. Consider scheduling a factory inspection or requesting third-party quality checks before shipment. Additionally, inquire about the supplier’s return policy and warranty terms to safeguard your investment in case of defects or discrepancies.

8. What logistics considerations should I keep in mind when importing room dividers?

When importing floor to ceiling room dividers, several logistics considerations are crucial. First, verify shipping options and lead times with your supplier to ensure timely delivery. Assess import duties and taxes applicable in your country, as these can impact overall costs. Additionally, choose a reliable freight forwarder who can handle customs clearance and transportation. Lastly, ensure that the packaging is robust to prevent damage during transit and consider insurance options for high-value items to mitigate risks.

Illustrative image related to floor to ceiling room divider

Top 2 Floor To Ceiling Room Divider Manufacturers & Suppliers List

1. Godear – Adjustable Sliding Panels

Domain: godear.com

Registered: 2016 (9 years)

Introduction: {“product_name”:”Adjustable Sliding Panels | Semi-Sheer (Dense Weave) | Summer”,”price”:”$329.99″,”size”:”45.8\”-86\” W x 96\” H”,”fabric_composition”:”50% Paper + 50% Poly”,”privacy_level”:”1 (least privacy)”,”dimensions”:”Includes 4 panels, each measuring 23\” wide and 96\” tall”,”adjustable_track_width”:”45.8” to 86” wide”,”depth”:”2.56””,”mounting_requirements”:”Inside/Ceiling Mount: Minimum d…

2. Pinterest – Floor to Ceiling Room Divider

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Floor to Ceiling Mounted Room Divider

Strategic Sourcing Conclusion and Outlook for floor to ceiling room divider

In conclusion, the strategic sourcing of floor-to-ceiling room dividers presents a pivotal opportunity for businesses aiming to optimize space while enhancing functionality and aesthetics. By understanding the diverse materials and configurations available—such as wall-mounted, ceiling-mounted, and freestanding options—buyers can tailor solutions to their specific needs, whether in commercial, educational, or healthcare settings. The growing emphasis on flexible workspaces, particularly in emerging markets across Africa and South America, highlights the increasing demand for these versatile dividers.

Investing in high-quality room dividers not only elevates the visual appeal of spaces but also significantly improves acoustic performance and privacy. This is particularly important in high-traffic environments where distraction reduction is crucial for productivity.

As international B2B buyers, particularly from regions like Nigeria, Germany, and the Middle East, continue to seek innovative solutions, now is the time to explore partnerships with reputable suppliers. By strategically sourcing these products, you can enhance your offerings and drive value for your clients. Engage with manufacturers who provide customization options and quick shipping to ensure that your projects meet the dynamic needs of your customers. Embrace this opportunity to lead in creating adaptive environments that promote efficiency and collaboration.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.